System and method for providing egr to engine

A technology of engine and engine load, applied in the direction of engine components, combustion engine, engine control, etc., to achieve the effect of reducing the possibility, reducing the tendency of knocking, and reducing the generation of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

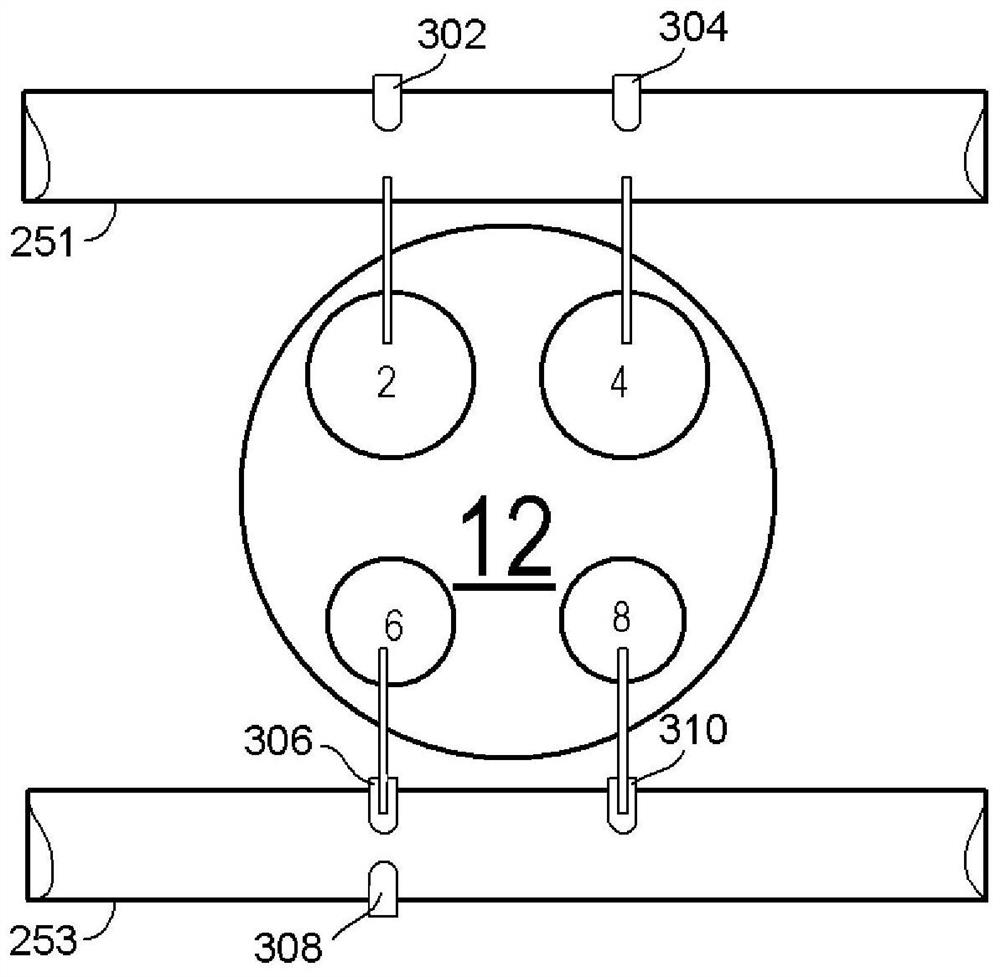

[0013] The following description relates to systems and methods for providing EGR to an engine. In one example, the engine may include

[0014] In the following description, the poppet valve is operable or activated to indicate that it is

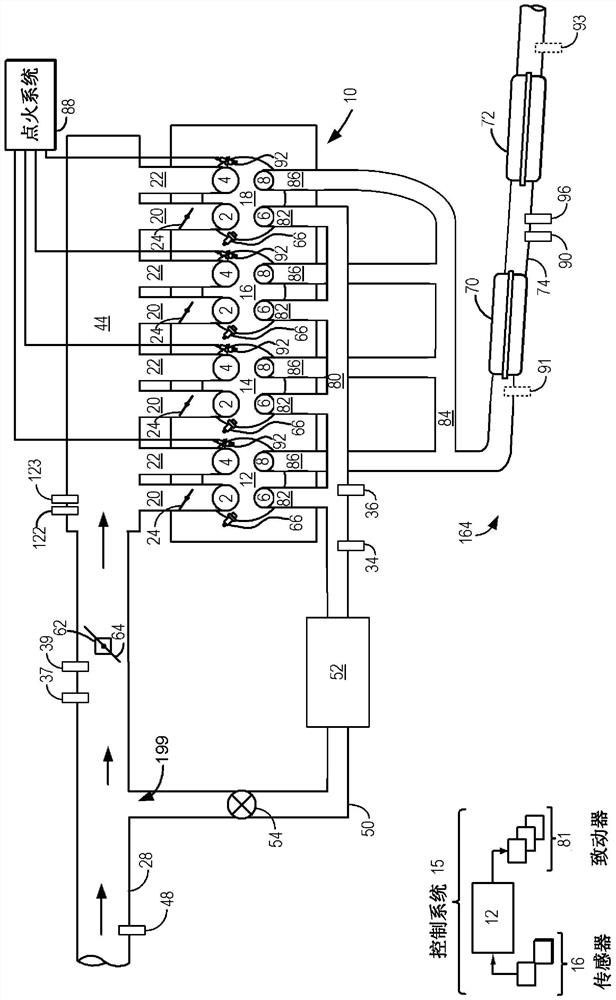

[0015] FIG. 1 shows a schematic diagram of a multi-cylinder internal combustion engine 10 that may be included in a propulsion system of an automobile. launch

[0017] One or more of the intake passages may include a charge motion control valve (CMCV). As shown in Figure 1, the

[0018] A high pressure dual stage fuel system, such as the fuel system shown in FIG. 2, may be used to generate fuel at injector 66

[0019] Each exhaust runner may selectively communicate with a cylinder with which each exhaust runner is in fluid communication via an exhaust valve

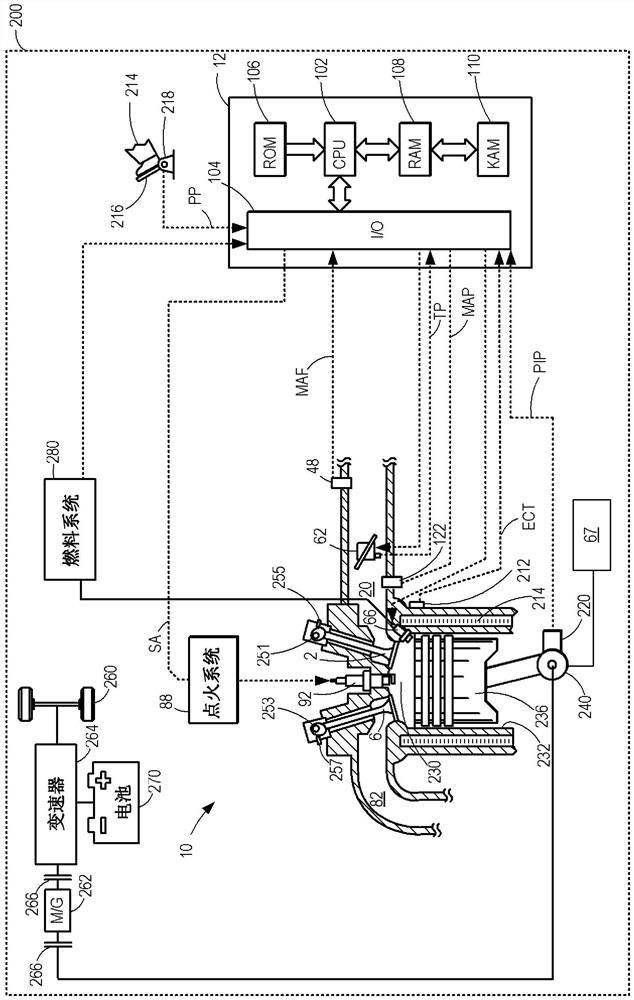

[0027] In some examples, the engine 10 may be coupled to an electric motor / battery system in a hybrid vehicle (FIG. 2

[0030] Referring now to FIG. 2, which depicts a portion of a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com