Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce saltiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of high-salt diluted and low-temperature fragrant soy sauce

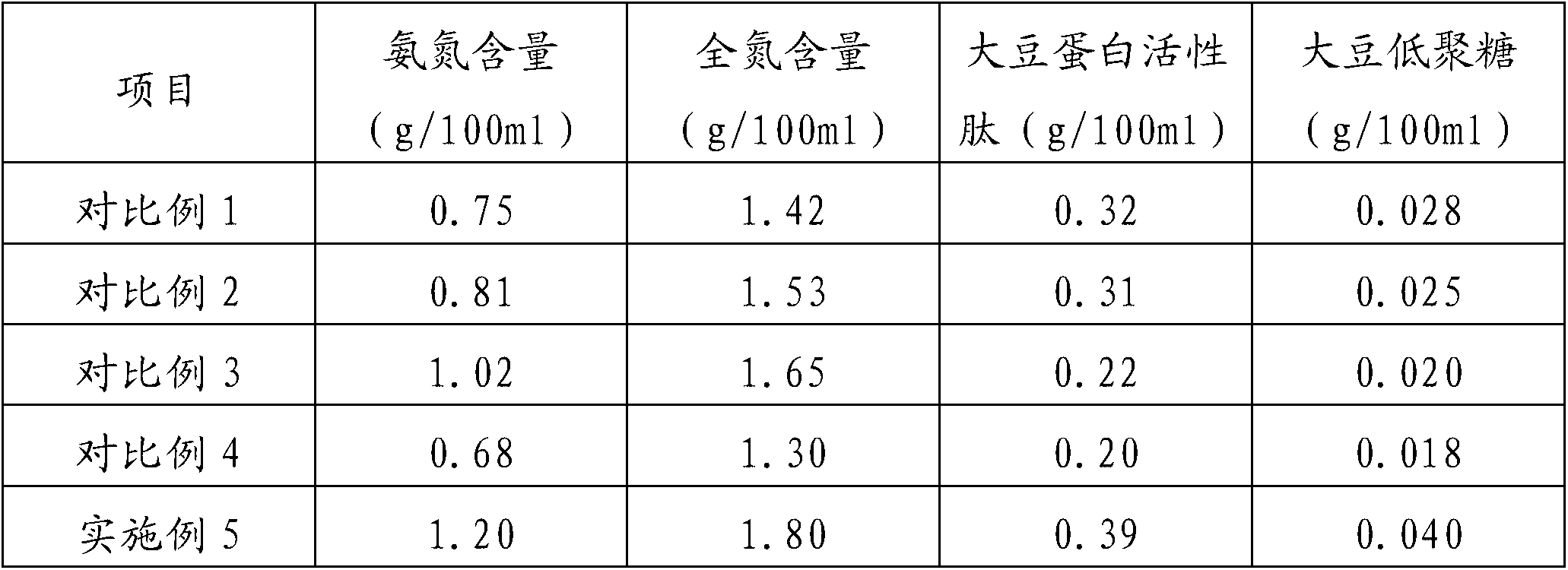

The invention discloses a production method of a high-salt diluted and low-temperature fragrant soy sauce, which comprises the following steps of: (1) curing raw materials including wheat and defatted soybeans, and then uniformly mixing the wheat and the defatted soybeans; (2) inoculating aspergillus oryzae strains to the obtained raw material mixture so as to obtain a yeast; (3) cultivating the yeast for 44-48 hours at a temperature of 25-30 DEG C so as to obtain a mature yeast; (4) adding 2.0-2.5 weight times of saline water into the mature yeast so as to obtain a raw soy sauce mash; (5) moving the raw soy sauce mash to the inside of an airtight fermentation tank for fermenting: firstly fermenting for 23-27 days at a temperature of 13-17 DEG C, then continuing to ferment at a temperature of 28-32 DEG C, and on the 28-32nd days, adding mixed fermentation strains into the fermentation tank and continuing to ferment; in the process of fermentation, stirring by using a compressed air flow; and fermenting for more than six months so as to obtain a mature soy sauce mash; and (6) squeezing and filtering the mature soy sauce mash so as to obtain the low-temperature fragrant soy sauce. According to the invention, the conversion rate of proteins in raw materials is high, and the contents of ammonia nitrogen, total nitrogen, soybean peptides and soybean oligosaccharides in the prepared soy sauce are high.

Owner:好太太食品有限公司

Production of biochemical fish meal from fish-meal waste water

The invention is concerned with a kind of method to produce biochemical fish powder using waste water of fish powder. Filtrate and callback the solid stuff in the waste water of fish powder, and add separating assistant agent in the oil-water to separate and callback the fish oil. After the separation, decompress and concentrate the water solution with low temperature and add preserative agent to keep fresh for using. Dispose the waste water through microwave cracking into cracked solution, add compound proteinase to crack the protein of the cracked solution, adjust the pH value of enzyme hydrolyze solution and add biology gene with some components, such as microzyme to counteract the ferment at feasible temperature, adjust the flowing state of material to counteract the bitterness, salted and fishy smell of solution. Filtrate the viscous stuff such as mucopolysaccharides with ceramic filter having different apertures, and send the concentrated filtrate into the desiccation tower in vacuum to produce the biochemical fish powder by spraying and drying. This invention reduces the produce cost and enhances the quality and digest rate with advanced and feasible process.

Owner:威海市桢昊生物技术有限公司

Konjak dietary fiber moon cake

ActiveCN102308864AReduce tasteReduce appearanceDough treatmentBakery productsMonosodium glutamateDietary fiber

A konjak dietary fiber moon cake is made of flour, ham, white sugar, xylitol, konjac gum, edible soda ash, maltose, sauce, monosodium glutamate, cooked Dahe black pig lard, Fuyuan trampled pickled vegetable, pure water, sesame, ginger powder and cooking wine, and is characterized in that: in percentage by weight, the components are 42 to 45 percent of flour, 25 to 28 percent of cooked Dahe black pig lard, 1.6 to 2.0 percent of white sugar, 1.6 to 2.0 percent of xylitol, 1.6 to 2.0 percent of konjac gum, 0.15 to 0.22 percent of edible soda ash, 1.0 to 1.5 percent of maltose, 0.8 to 1.2 percentof sauce, 0.5 to 0.8 percent of monosodium glutamate, 12 to 14 percent of cooked Dahe black pig lard, 4.8 to 5.8 percent of Fuyuan trampled pickled vegetable, 0.1 to 0.2 percent of edible salt, 0.2 to 0.5 percent of ginger powder, 0.3 to 0.5 percent of sesame and 0.8 to 1.20 percent of cooking wine for preparing the konjak dietary fiber moon cake. The components are then separately processed, andare respectively made into filling material and wrapper material, the wrapper material is divided into appropriate small pieces for cakes, each small piece is pressed to form a sheet, the filling is wrapped in the sheets, and after baking, the moon cakes are produced.

Owner:云南富源金田原农产品开发有限责任公司

Production of ham

InactiveCN1406519AReduce saltinessNot easy to damp, mildew and deteriorationFood preparationNitriteHot peppers

A technology for producing ham includes such steps as examining and pre-treating the pork leg, immersing in the mixture of spirit, sodium chloride, potassium chloride, edible glucose, hot pepper, Caoguo powder and pepper powder, preseriving, drying in air, wrapping by cotton paper, burying in the mixture of dried charcoal and plant ash, fermenting and removing ash. Its advantages are no or a little nitrate, good smell, short fermenting period, and high percentage of qualified products (99%).

Owner:LIJIANG YUYUAN FOOD

Taste-Improving Agent

ActiveUS20140328991A1Suppress unpleasant tasteReduce saltinessLactobacillusLeuconostocLactic acid bacteriumYeast cell extract

Provided is a taste-improving agent that suppresses the unpleasant taste of potassium, such as harshness, irritativeness, and bitterness without reducing the salty taste of a potassium-containing food or drink. The taste-improving agent for a potassium-containing food or drink comprises a lactic acid-fermented yeast extract that is obtainable by fermenting a yeast extract with a lactic acid bacterium and contains 7.5 (w / w) % or more of lactic acid relative to the solid content of the yeast extract.

Owner:KIKKOMAN CORP

Production technology of salted duck eggs

The invention discloses a production technology of salted duck eggs. The technology comprises the following steps of firstly detecting the moisture content and the fresh degree of fresh duck eggs in each batch, and then performing classification, light inspection and tapping selection so as to obtain 5 kinds of duck eggs of different weight classes, namely top-class duck eggs, first-class duck eggs, second-class duck eggs, third-class duck eggs and fourth-class duck eggs; and separately pickling the 5 kinds of duck eggs of different weight classes in different rooms according to different weight classes, wherein the consumption quantity of salt for pickling the duck eggs of the lowest weight class is 1.2-2.0g for each duck egg, the difference between the consumption quantity of the salt for pickling the duck eggs of the lower weight class and the consumption quantity of the salt for pickling the duck eggs of the adjacent weight class is 0.1-0.5g, and the pickling time is 60 days or above. The prepared salted duck eggs are moderate in saline taste and not high in salt content; salted duck egg cores can generate sandy particles, can be bright and generate oil, and are good in mouth feel.

Owner:SICHUAN FUTAI FOOD CO LTD

Preparation method and application of craft soy sauce

ActiveCN112956677AIncrease umamiReduced saltinessClimate change adaptationFood ingredient as taste affecting agentFood biotechnologyEngineering

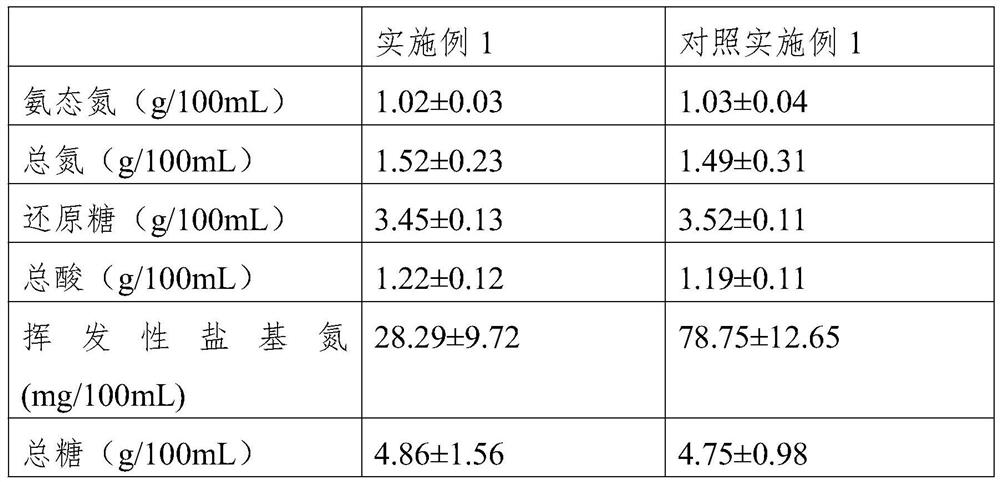

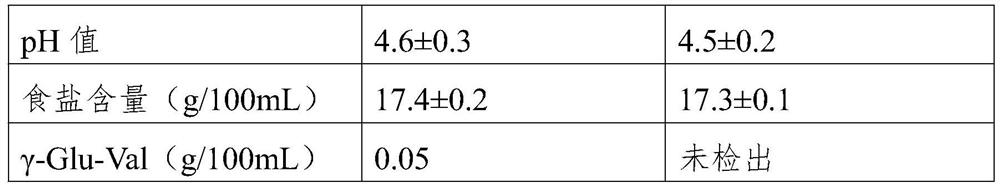

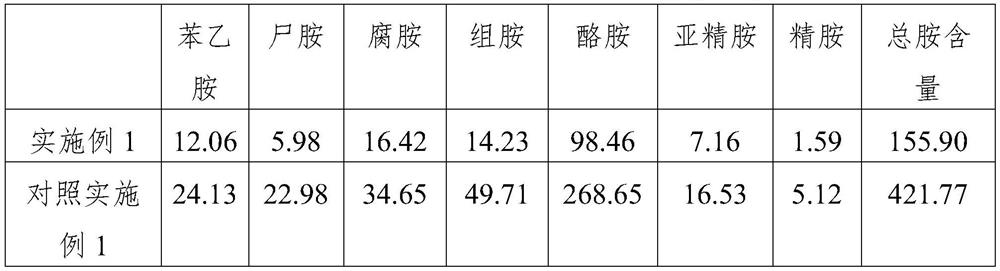

The invention discloses a preparation method and application of a craft soy sauce, and particularly relates to the technical field of food biotechnology. The preparation method comprises the following steps: 1, soybeans or soybean meal is cooked and then evenly mixed with wheat flour to obtain a mixture, the mixture is cooled to the normal temperature, then the cooled mixture is inoculated with koji essence for koji making to obtain the yeast for making hard liquor; and (2) the yeast obtained in the step (1) is uniformly mixed with saline water, fermenting in a fermentation container by adopting a high-salt liquid-state soy sauce brewing method, performing negative pressure treatment in the fermentation process, sterilizing, deactivating enzyme, squeezing, filtering and taking filtrate after the fermentation is finished, thereby the craft soy sauce is obtained. According to the invention, the negative pressure is formed in the fermentation process, so that the content of volatile basic nitrogen in the soy sauce can be effectively reduced, the palatable taste of the prepared soy sauce is obviously improved, the salty taste is obviously reduced, and the overall flavor is obviously improved.

Owner:珠海佳霖食品有限公司

Compound seasoning with reduced salt and enriched flavor and preparation method thereof

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Production method of creamy fermented bean curd

InactiveCN106417665ALow viscosityIncrease the fragranceCheese manufactureFood sciencePectinaseHydrolysate

The invention provides a production method of creamy fermented bean curd, comprising: mixing well soybean flour and water to obtain fermentation material; adding pectinase and cellulase to the fermentation material, enzymatically hydrolyzing at 40-55 DEG C for 2-4 h, and sterilizing to obtain primary hydrolysate; adding Bacillus subtilis and Micrococcus luteus to the primary hydrolysate, enzymatically hydrolyzing at 35-45 DEG C for 8-18 h, and sterilizing to obtain secondary hydrolysate; adding rice saccharified liquid, soy sauce aroma enhancing yeast and lactic acid bacteria to the secondary hydrolysate, performing aroma-enhancing enzymatic hydrolysis at 40-55 DEG C for 20-30 h, and sterilizing to obtain mixed fermentation broth; flavoring and thickening the mixed fermentation broth to obtain the creamy fermented bean curd. The creamy fermented bean curd has little edible salt and good flavor, is significantly lower in salinity than common fermented bean curd, is better in health and safety, takes short time to produce, and has higher industrial production value.

Owner:安顺市平坝区万佳农产品开发有限公司

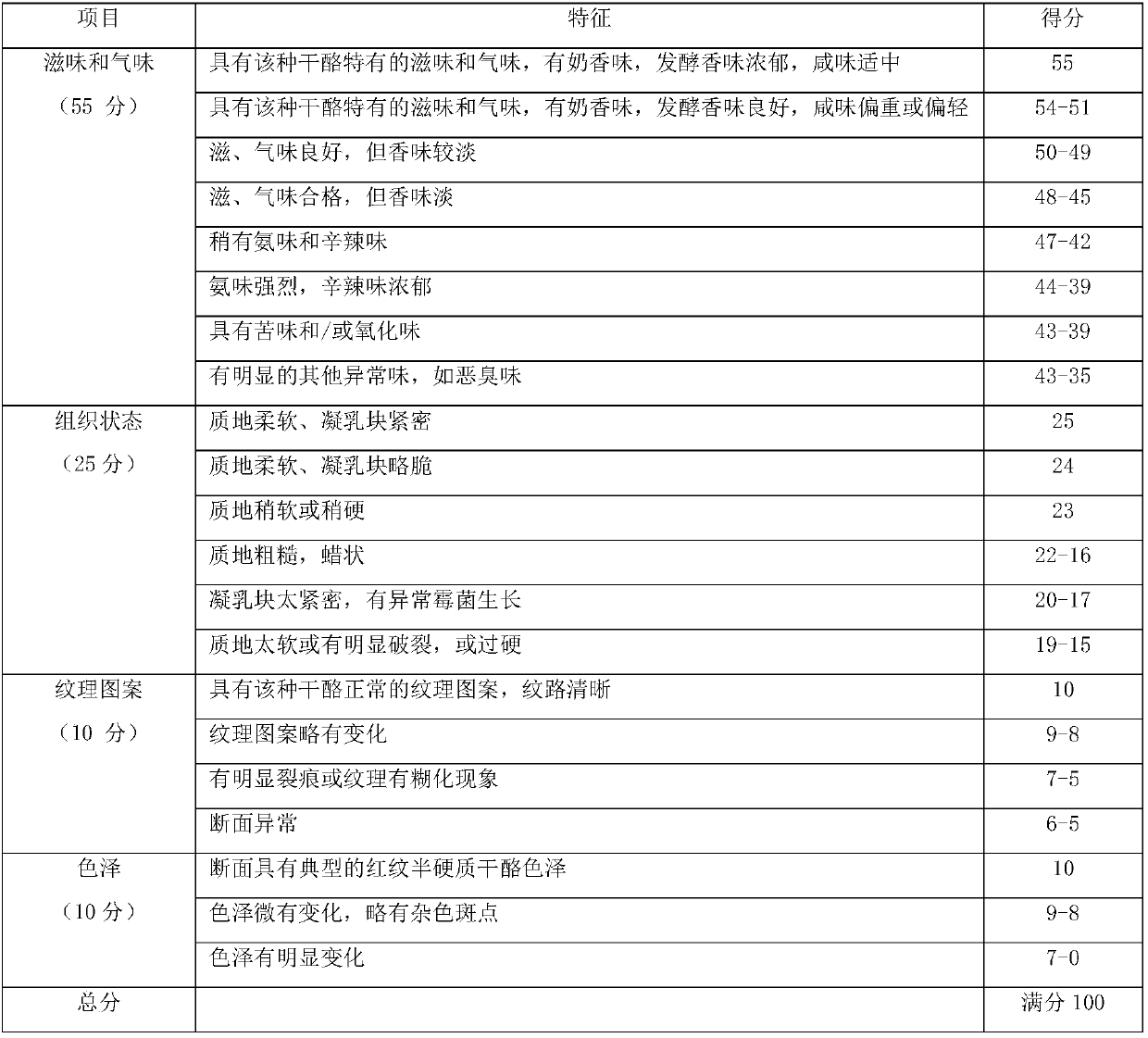

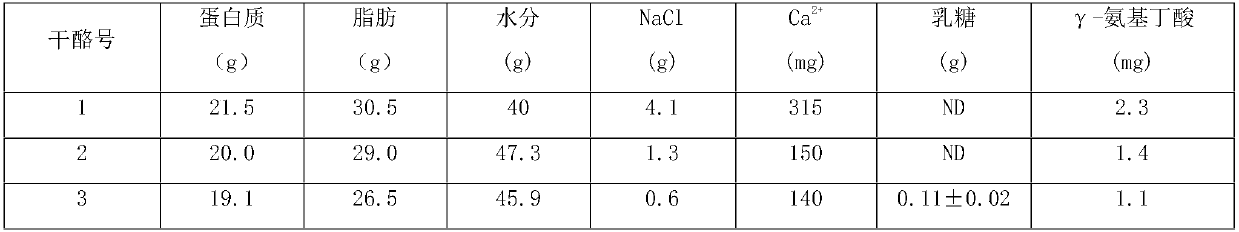

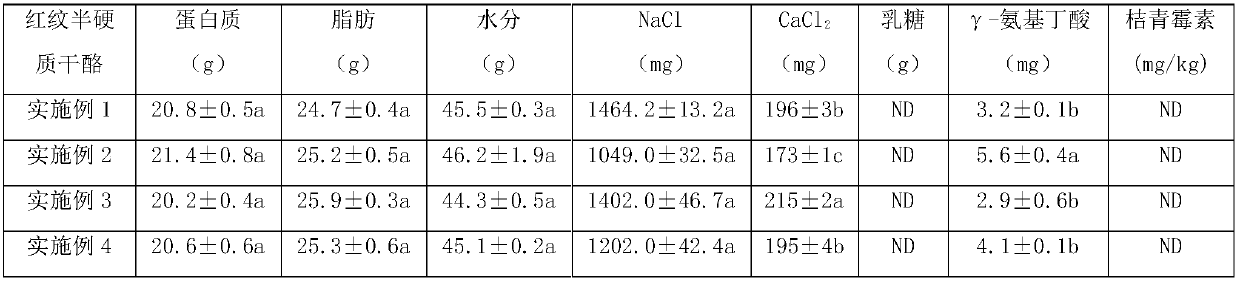

Red-texture and semi-hard cheese and preparation method thereof

ActiveCN107801785AMeet the demands of reducing salt and fatSoft sticky textureStrepto/lacto-coccusCheese manufactureFlavorBiotechnology

The present invention provides red-texture and semi-hard cheese. The cheese is monascus intra-ripening-accelerated natural mold cheese. Every kilogram of the cheese contains 202-214 g of proteins, 247-259 g of fats, 12-15 g of NaCl, 1,730-2,150 mg of Ca<2+> and 29-56 mg of gamma-aminobutyric acid. The monascus is used as a secondary fermentation agent instead of traditional mold species of penicillium roqueforti to be added into the cheese to develop a new cheese variety with Chinese characteristics. The cheese is characterized in that: after cutting open the cheese, internal sections presenta marble-like texture, color of the texture is striking bright red, and a visual appearance of the product itself is enhanced. Due to the use of the monascus for intra-ripening-accelerating of the cheese, the prepared red-texture and semi-hard cheese has a monascus fermented aroma, is crisp in texture, obviously weakened in spicy and pungent flavor, prominent in milk fragrance, and good in taste,and the produced gamma-aminobutyric acid in the ripening-accelerating process of the cheese by the monascus has beneficial effects on human body and further enhances nutritional value and health-careefficacies of the cheese.

Owner:BRIGHT DAIRY & FOOD

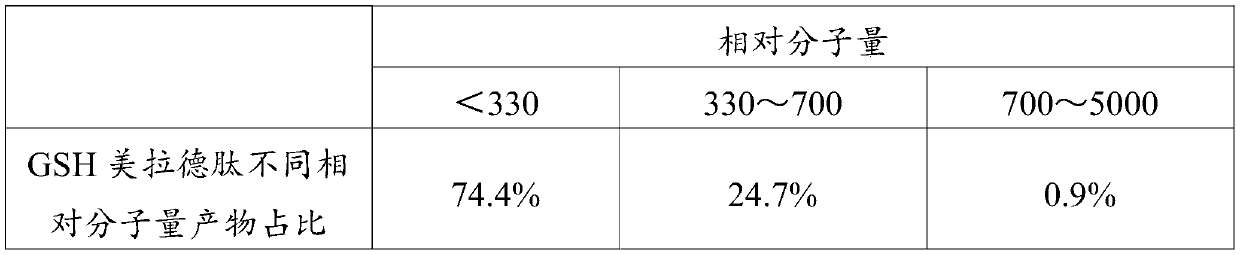

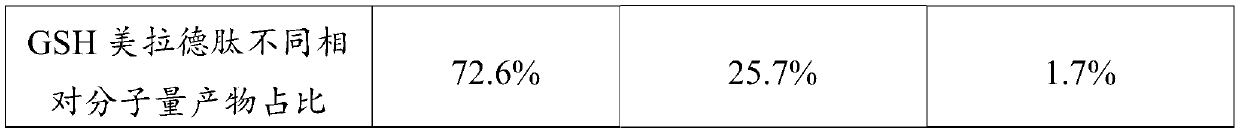

GSH Maillard peptide flavoring agent for reducing salinity of seasonings and preparation method of flavoring agent

ActiveCN110063482AReduce saltinessAdd flavorClimate change adaptationFood ingredient as taste affecting agentOysterEconomic benefits

The invention discloses a preparation method of a GSH Maillard peptide flavoring agent for reducing the salinity of seasonings. The preparation method comprises the following steps that 1, water is added into glutathione and reducing monosaccharide, and the materials are stirred until the glutathione and the reducing monosaccharide are completely dissolved; 2, the solution obtained in step 1 reacts at 100-120 DEG C and is stirred; 3, the solution obtained after the reaction in step 2 is cooled to 25 DEG C or below; 4, the solution cooled in step 3 is centrifuged, clean liquor is obtained, andthe GSH Maillard peptide flavoring agent is obtained, wherein the GSH Maillard peptide flavoring agent comprises, by weight, 5-10 parts of the glutathione, 15-30 parts of the reducing monosaccharide and 90-120 parts of water. The GSH Maillard peptide flavoring agent prepared through the method has the function of reducing the salinity, has a remarkably the saline taste when used in soybean sauce,oyster sauce, soybean paste and other high-salinity food or seasonings, improves the overall flavor of the seasonings, and is remarkable in economic benefit.

Owner:FOSHAN HAITIAN GAOMING FLAVORING & FOOD +2

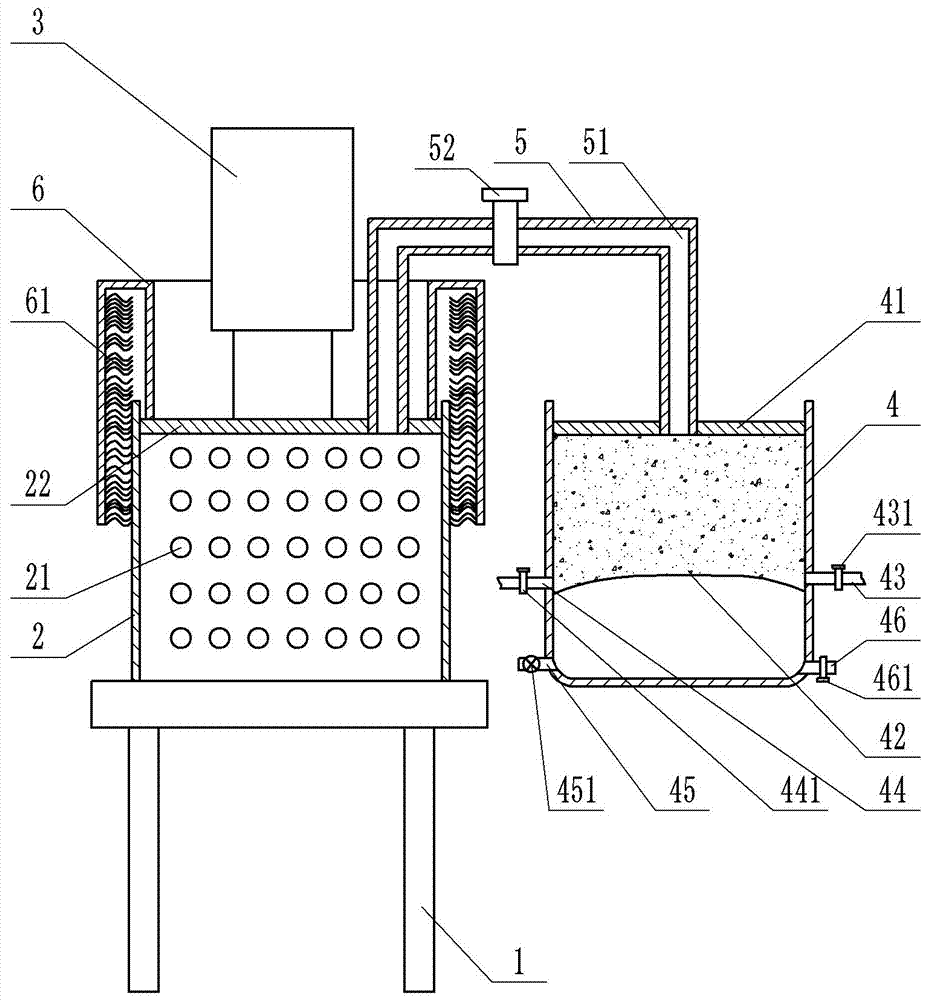

Pickled vegetable pressing and desalting device

InactiveCN106962852AReduce labor intensityIncrease productivityFood scienceHydraulic cylinderBristle

The invention belongs to the technical field of pickled food or food materials, and particularly discloses a pickled vegetable pressing and desalting device. The pickled vegetable pressing and desalting device comprises a worktable, a pressing block, a pressing barrel, a hydraulic cylinder, a water inlet tube, a water outlet tube and a water storage tank, wherein the pressing barrel is fixed on the worktable; the pressing block is slidably connected to the inside of the pressing barrel; the water inlet tube and the water outlet tube respectively communicate with the water storage tank; a one-way valve which only can be opened towards one side of the water storage tank is arranged on the water inlet tube; a first valve is arranged on the water outlet tube; the inside of the water storage tank is slidably connected with a piston; the piston is provided with a linkage rod which is connected with the pressing block; a channel which communicates with the water storage tank and the pressing barrel is formed in the linkage rod; a second valve is arranged on the linkage rod; an annular brushing barrel is arranged on the upper surface of the pressing block; and bristles which are extruded by the outer wall of the pressing barrel are arranged on the inner wall of the brushing barrel. Pickled vegetables are pressed and desalted by the device, a water outlet hole can be prevented from being blocked, the trouble of cleaning is avoided, the pickled vegetables can be cleaned in a pressing process, and therefore, salinity of the pickled vegetables is reduced effectively.

Owner:CHONGQING ZHOUYI FOOD CO LTD

Pickling method of multi-flavor marinated eggs

The invention relates to a food processing method, in particular to a pickling method of multi-flavor marinated eggs, which comprises the following steps: firstly, placing fresh eggs into a pickling salt solution after pretreatment; then, placing the pickling salt solution with the fresh eggs into a sealed container; introducing pulse pressure to the inside of the container at the normal temperature, wherein one pulse period of the pulse pressure is between 5 and 20 minutes, the ratio of the high pressure maintaining time to the low pressure maintaining time of the pulse pressure is 1 / 2, the time for raising the low pressure to the high pressure in one pulse period is 35 to 50 seconds, and the time for relieving the high pressure to the low pressure is 5 to 30 min; carrying out sampling verification on the picked marinated eggs; carrying out post maturation treatment; and steaming or boiling the marinated eggs after the post maturation to obtain finished products. The marinated eggs prepared by the invention have the advantages that the salinity of egg white and egg yolk are moderate, the appearance of the egg cases is good, the mouth feeling of the marinated eggs is good, in addition, the processing time of the finished eggs is short, and the storage period is long.

Owner:CHINA AGRI UNIV

Process for processing Huangshan rock partridge and umbilicaria esculenta soup

InactiveCN103932167ALow in fatReduce saltinessFood ingredient as flavour affecting agentFood preparationReady to eatUmbilicaria esculenta

The invention discloses a process for processing Huangshan rock partridge and umbilicaria esculenta soup. The process comprises the following steps: 1, cleaning and slicing rock partridge and then adding cooking wine, shredded ginger and salt to pickle the sliced rock partridge; 2, frying the rock partridge processed in the step 1 until muscles tighten and the color is golden; 3, soaking for rehydrating dry umbilicaria esculenta; 4, baking ham slices till oil is made off the ham slices; 5, adding ginger slices and green onion sections after mixing the rock partridge processed in the step 2 with the ham processed in the step 4, and stewing in water; 6, adding the umbilicaria esculenta processed in the step 3, chicken powder, fish sauce and white pepper before the product obtained in the step 5 is taken out of a pot; and 7, cooling the product processed in the step 6, sealing the product in a thick aluminum foil bag, and carrying out radiation sterilization by 60Co. By the process for processing the Huangshan rock partridge and umbilicaria esculenta soup disclosed by the invention, the defects that existing Huangshan rock partridge and umbilicaria esculenta soup has certain fishy smell, and is high in content of grease and salt are overcome, and the Huangshan rock partridge and umbilicaria esculenta soup can be stored for 3-6 months, and has the advantage of being ready to eat after being unpacked.

Owner:INST AGRO PROD PROCESSING ANHUI ACADEMY AGRI SCI

Preparation method of hams

The invention discloses a preparation method of hams. The preparation method comprises the following steps of selecting ham materials; performing trimming and shaping; performing pickling; performingwashing with water and performing desalting; performing hanging and performing smoking; performing complete fermenting, wherein ground black salt and cloves are adopted as pickling materials, sesame oil is applied in the preparation process, and soaking with green tea water is performed, wherein a mixture of tartary buckwheat straws, pine branches, mulberries, pear trees and orange peel is adoptedas smoking materials. According to the hams obtained by the preparation method disclosed by the invention, no preservatives and additives are added; and the hams are pink in meat color, is tender inmeat quality, is mellow in taste, is rich in nutrition and is low in saltiness, has unique smoking flavor and delicate fragrance of tartary buckwheat, and is rich in various amino acids, trace elements and vitamins, is diverse in eating methods, and is green and healthy.

Owner:泸水市天运农业有限公司

Caulerpa lentillifera and tremella fuciformis soup and preparing method thereof

InactiveCN106235302AReduce fishy smell and saltinessImprove tasteFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentDesalinationSuaeda glauca

The invention provides a caulerpa lentillifera and tremella fuciformis soup and a preparing method thereof, and relates to the technical field of healthcare drink preparing methods. The caulerpa lentillifera and tremella fuciformis soup is prepared through the seven steps of acid-base synthesis, desalination, dispersion, dry tremella fuciformis treatment, expansion, mixed preparation and filling with 95% of caulerpa lentillifera and 5% of dry tremella fuciformis as raw materials. Acid-base neutralization is carried out on fishy smell ingredients on the surface of caulerpa lentillifera with lime earth obtained by firing air-dried suaeda glauca, then desalination is carried out to reduce the salinity of caulerpa lentillifera, then caulerpa lentillifera is dispersed and stewed together with expanded tremella fuciformis, and the caulerpa lentillifera and tremella fuciformis soup is obtained; the fishy smell and salinity of caulerpa lentillifera are reduced, and the taste of the caulerpa lentillifera and tremella fuciformis soup is improved; moreover, the caulerpa lentillifera and tremella fuciformis soup is more smoother when eaten, and is delicious and unique in taste and high in nutritive value.

Owner:NINGDE JIAOCHENG DISTRICT DAWANG AQUATIC TRADE

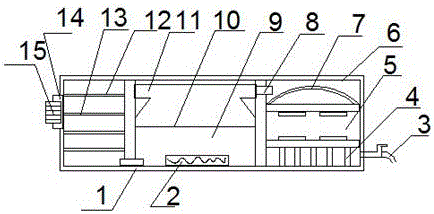

Seawater purifying device

InactiveCN105858992AReduce saltinessImprove securityWater/sewage treatment by irradiationSeawater treatmentSeawaterNanofiltration

The invention discloses a seawater purifying device. The seawater purifying device comprises a seawater purifying device body, and a primary purifying bin, a secondary purifying bin and a final purifying bin are sequentially arranged in the seawater purifying device body from left to right; a micrometer filter screen is arranged in the primary purifying bin; a heater is arranged in the secondary purifying bin, and a water vapor collecting pipeline is arranged above the heater; a reverse osmosis membrane is arranged above the final purifying bin; an ultraviolet disinfection chamber is arranged under the reverse osmosis membrane; and a nanofiltration chamber is arranged under the ultraviolet disinfection chamber. The seawater purifying device has the advantages of simple structure, convenient use, simple operation, simple manufacturing, good purifying effect due to adoption of three-layer purifying bin purification, filter-out of microbes and bacteria in seawater, reduction of the salinity of the seawater, and improvement of the use safety of the seawater.

Owner:HEFEI JIUYUAN ENVIRONMENT TECH CO LTD

Deep processing and making technology of flavored cured meat

InactiveCN106722228AReduce saltinessImprove palatabilityFood ingredient as mouthfeel improving agentMoistureLysimachia sikokiana

The invention discloses a deep processing and making technology of flavored cured meat in the field of food processing. The deep processing and making technology comprises the following steps of thoroughly cleaning cured meat, enabling moisture on the surface of the cleaned cured meat to be drained in a sucking manner, and cutting the dried cured meat into diced cured meat; preparing seasoning including the raw materials of dictyophora indusiata, cordyceps militaris, lysimachia sikokiana, amomum cardamomum, haws, cablin patchouli herbs, lysimachia foenum-graecum hance, rhizoma kaempferiae, cumin seeds, fructus piperis, caraway seeds and Chinese prickly ash, grinding all the raw materials into powder, and performing mixing; putting the seasoning into a hot pot of 70-80 DEG C, adding table salt and crystal sugar powder, and performing stir-frying for 30-40min; then controlling the temperature of the seasoning to be within the range of 60-70 DEG C, putting the diced cured meat into the hot pot, and enabling the diced cured meat to be buried with the seasoning; and covering the pot with a pot cover, performing braising for 7-8h, picking out the braised diced cured meat from the seasoning, performing cooling, and then performing vacuum packaging. The cured meat deeply processed and made by the technology disclosed by the invention is fragrant in odor, and after the cured meat deeply processed and made by the technology is eaten, fragrance is kept in mouths for a long term; and the cured meat is chopped into the diced cured meat, processing and cooking are performed, then vacuum packaging is performed, and no other additives are added, so that the flavored cured meat can be preserved for a long term, is convenient to carry and can be eaten after being unpackaged.

Owner:遵义市俊丰食品有限责任公司

Method for preparing instant cured dishes

The invention discloses a method for preparing instant cured dishes. The method for preparing the instant cured dishes comprises the steps that preserved meat is washed and stripped and sliced, and the preserved meat is boiled in water for 1-5 minutes, removed and drained and sliced or diced or cut into strips for standby application; dried turnips, preserved vegetables and dried long beans are cleaned and drained, the dried long beans and the dried turnips are cut into segments, and the preserved vegetables are chopped; the treated dried long beans, preserved vegetables, dried turnips and preserved meat are mixed evenly, and the mixture is cooked with steam until raw materials are soft to obtain main materials; and white peppers are cut into segments, red peppers, garlic and chives are chopped, cooking oil is poured into a pan and heated, the white pepper segments, the red peppers and minced garlic are added and fried, the main materials are added and fried in a stirring mode for certain time, soy sauce, salt, spices powder, the chives, food additives are added in sequence, the mixture is fried evenly in a stirring mode, cooled, canned and sterilized to obtain the finished product. The preserved meat is mixed with the dried turnips, the preserved vegetables and the dried long beans, so that the flavors of the raw materials are fused, and the resulting dishes are has lipidol and is delicious, rich in taste, reasonable in nutrition and non-greasy in using.

Owner:湖南俏小楚科技有限公司

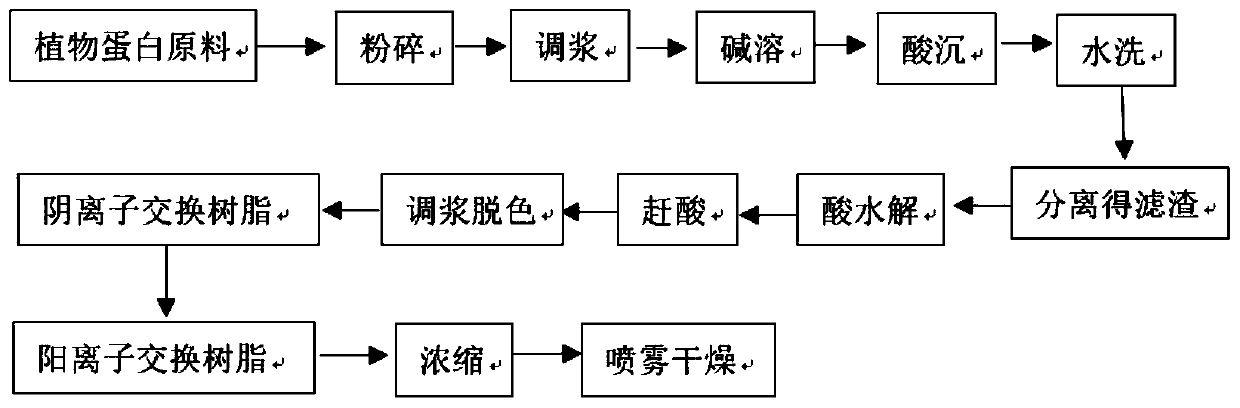

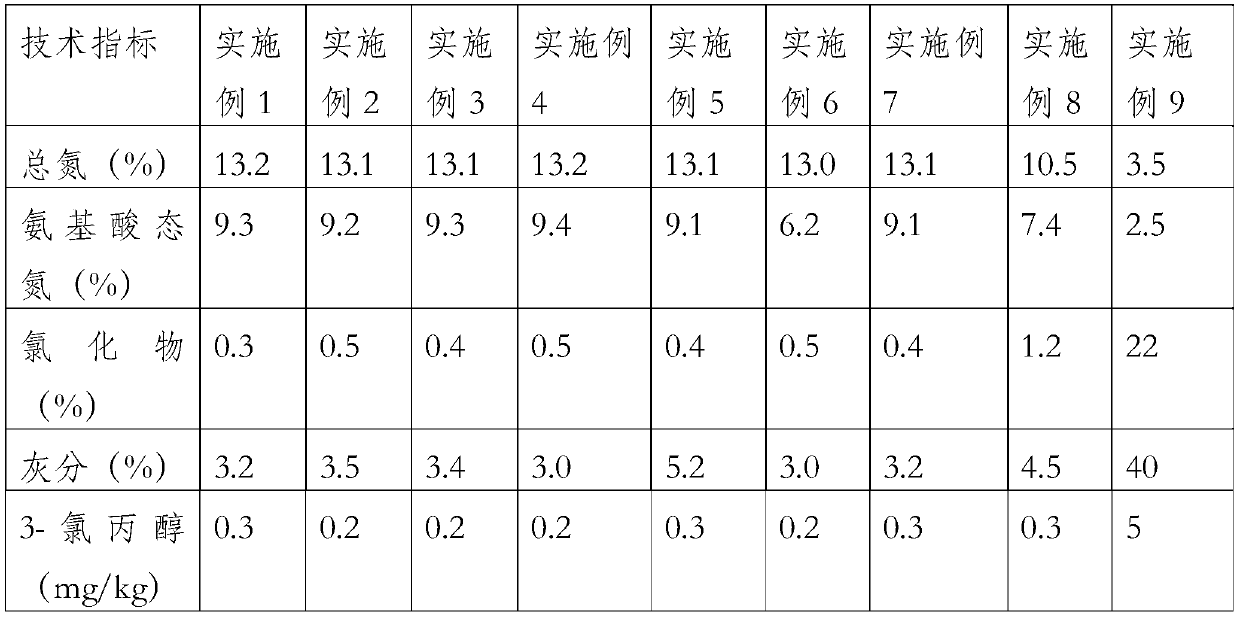

Preparation method and application of high-quality food-grade plant-derived compound amino acid

PendingCN111374295AAchieve recyclingIn line with the development trendAcidic food ingredientsBiotechnologyFood grade

The invention discloses a preparation method and application of high-quality food-grade plant-derived compound amino acid. The preparation method comprises the following steps: pretreating vegetable proteins, followed by impurity-removing and purifying; mixing the pretreated vegetable proteins with hydrochloric acid and carrying out acid hydrolysis; removing the hydrochloric acid (80% or above) from hydrolysate liquid by a hydrogen chloride recovery device to realize cyclic utilization of the hydrochloric acid; decolorizing acid-removed liquid to obtain decolorized liquid, and removing anionsand cations by using anion-exchange resins and cation-exchange resins; and subjecting effluent liquid to concentrating and spray drying to obtain the high-quality food-grade plant-derived compound amino acid. The invention has the advantages of simple preparation process, low energy consumption, low product salt content, short production cycle and high product quality. Compared with the traditional acid-hydrolyzed vegetable protein products, the salt content and the chloropropanol content of the high-quality food-grade plant-derived compound amino acid are greatly reduced, and the high-qualityfood-grade plant-derived compound amino acid is in line with the development trend of low-salt health food.

Owner:无锡秋可生物科技有限公司

A kind of processing method of low-salt ham

The invention relates to a processing method of low-salt ham, which belongs to the technical field of food processing. The method comprises the following steps of a. freezing fresh pork leg at minus 32 DEG C to minus 28 DEG C; b. thawing the pork leg at the normal temperature; c. adding 65g to 75g of salt into 1kg of fresh pork leg and then salting the pork leg, storing the salted pork leg for 30 to 40 days, and then immersing the pork leg in 1% salty water for 24h to 96h; d. desalting, namely washing the salted pork leg; e. directly carrying out air drying on the pork leg under the sunlight until the surface of the pork leg is dry; and f. fermenting the pork leg for more than or equal to 5 months under the condition that the temperature is 20 to 26 DEG C and the humidity is 40 to 60 percent. The processing method has the beneficial effects that the processed ham is less in salt content, unique in flavor and good in taste.

Owner:HUIZE TIANWEI HAM

Melting prevention method of vacuum-packaged salted pork in jelly

The invention discloses a melting prevention method of vacuum-packaged salted pork in jelly. The method comprises the following steps: adding 0.65-2.0 parts by weight of TG enzyme to 75-150 parts by weight of a marinating soup before die-filling and molding, reacting at 35-65DEG C for 15-45min, carrying out water bath sterilization on a product obtained after molding at 65-90DEG C for 20-90min, and cooling the sterilized product in 0-10DEG C cold water for 30-60min. The total quantity of bacteria in the salted pork in jelly when the salted pork in jelly is stored for 30d reduces by two orders of magnitude; and the method has the advantages of increase of the elasticity and the chewiness of the salted pork in jelly, improvement of the slicing property of the salted pork in jelly, no influences on the flavor of the salted pork in jelly, and reduction of the saline taste.

Owner:NANJING YURUN FOOD

Aroma enhanced egg and making method thereof

The invention discloses aroma enhanced eggs and a making method thereof. According to the making method, eggs are soaked into an aroma enhancing liquid with a white spirit, aroma substances in condiments and a small amount of salt are rapidly fed into the eggs along with the intensive permeability of the white spirit, then the eggs have fragrance and salty taste, and oil in yolk can be extruded out by the white spirit; the eggs are further taken out, wrapped by mud and exposed to blazing sunshine, then the aroma substances can be rapidly fed into the eggs, particularly into the egg white, through blazing sunshine exposure, and the fragrance of the egg white can be further enhanced; the eggs are further pickled after the wrapping mud is removed, the eggs are pickled under the action of salt, then the decomposition and change speed of contents of the eggs can be retarded, and functions of aroma enhancement and deterioration prevention can be achieved. The aroma enhanced eggs made by using the method have meticulous and dense yolk with rich oil, have egg white which is not too salty, have rich fragrance as a whole, are moderate in salt degree, are easy to take, and are well loved by customers.

Owner:山东陈氏特产食品有限公司

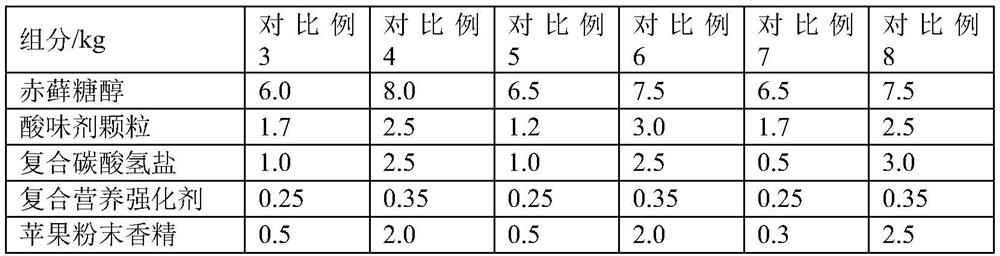

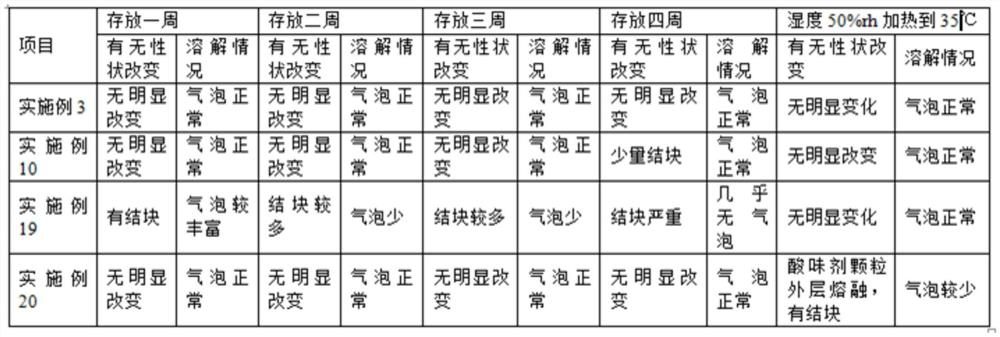

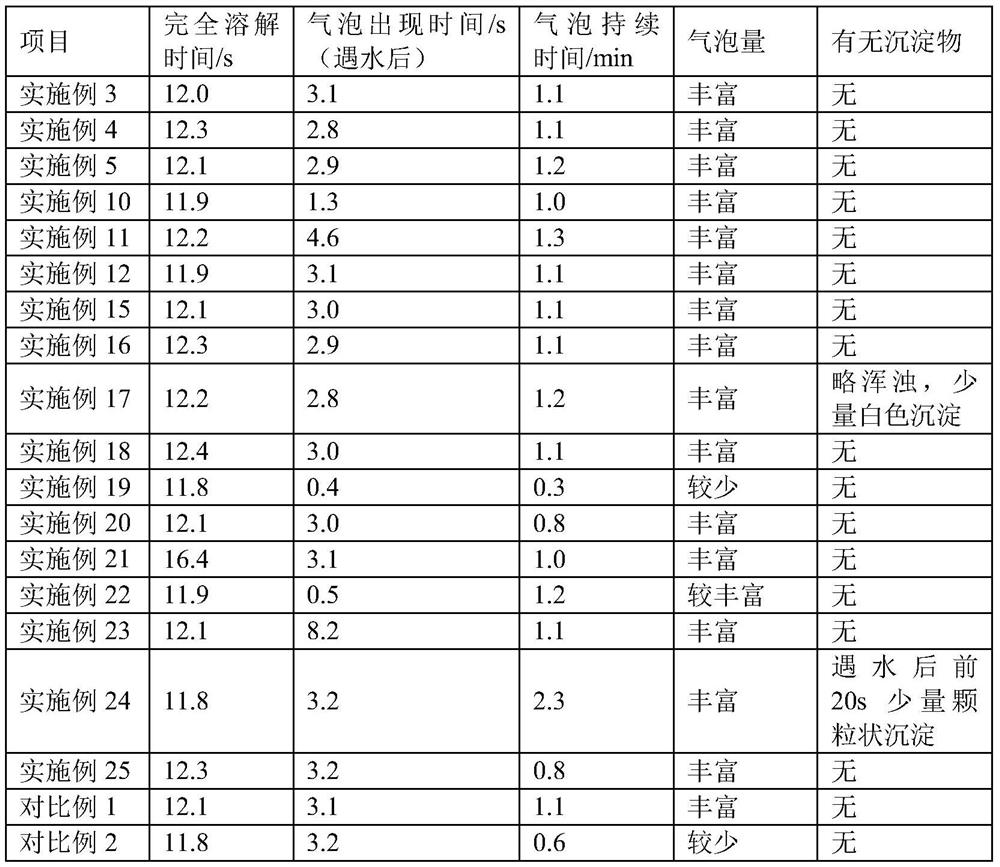

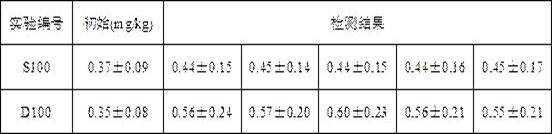

Bottled nutritional soda solid beverage and processing technology thereof

PendingCN113040309ALess saltyBalances Flavors and TexturesInorganic compound food ingredientsFood ingredient as encapsulating agentHydroxypropylmethyl celluloseBicarbonate

The invention relates to the field of beverages, and particularly discloses a bottled nutritional soda solid beverage and a processing technology thereof. The bottled nutritional soda solid beverage comprises the following components in parts by weight: 65-75 parts of a sweetening agent, 17-25 parts of acidulant particles, 10-25 parts of composite bicarbonate, 2.5-3.5 parts of a composite nutrition enhancer and 5-20 parts of edible powder essence. The preparation method of the bottled nutritional soda solid beverage comprises the following steps: uniformly mixing the acidulant particles, the sweetening agent, the composite bicarbonate, the composite nutrition enhancer, the edible powder essence and the acidulant particles to prepare a solid beverage, filling the solid beverage into a beverage bottle, filling inert gas into the beverage bottle, and finally packaging the beverage bottle. The compound bicarbonate is used for replacing pure baking soda as a carbon dioxide supply source, so that the mouth feel and the taste can be balanced. The hydroxypropyl methyl cellulose solution forms a coating with a proper thickness outside the anhydrous citric acid, so that bubbles can last for a long time.

Owner:烟台金利昌食品有限公司

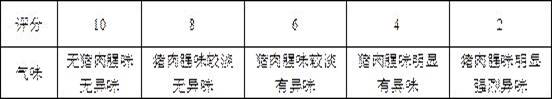

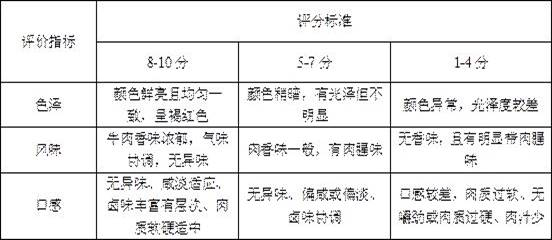

Large-particle beef sauce and preparation method thereof

PendingCN113632931AStrong fragranceReduce saltinessClimate change adaptationFood scienceFood additivePreservative

The invention provides a large-particle beef sauce. The large-particle beef sauce is prepared from the following raw materials in parts by mass: 4500 to 5500 parts of beef, 1700 to 3300 parts of edible oil, 1350 to 1650 parts of sauce, 1800 to 2200 parts of chili, 450 to 550 parts of garlic, 225 to 275 parts of ginger, 225 to 275 parts of onion, 45 to 55 parts of white sugar and 45 to 55 parts of Baijiu. The method comprises the following steps: pretreating beef to remove blood stains; carrying out high and low pressure alternate marinating on the pretreated beef, the marinating temperature is 2-5 DEG C, and the marinating pressure is controlled to be 0.7-1.3 atm; chopping the ginger, the garlic, the onion and the chili; performing dicing treatment on the marinated beef; heating the edible oil to 140-150 DEG C, pouring the ginger, the garlic and the onion, decocting with a medium fire until the mixture is dehydrated into golden yellow, pouring the chili and the white sugar, decocting together, after the edible oil is decocted to be dark red, adjusting with a small fire, pouring the sauce and the Baijiu, decocting with a small fire for 20-30 minutes, then pouring the marinated beef, and continuously decocting for 20-30 minutes until the mixture is cooked; and cooling and drying the prepared beef sauce, filling, sealing and storing. Preservatives, essence and food additives are not added, so that the taste of the large-particle beef sauce is improved, and the quality of the beef sauce is improved.

Owner:淳安县威酱坊食品有限公司

A kind of Huangshan double stone pot processing technology

InactiveCN103932167BFull of flavorReduce the degree of thermal decompositionFood ingredient as flavour affecting agentReady to eatUmbilicaria esculenta

The invention discloses a process for processing Huangshan rock partridge and umbilicaria esculenta soup. The process comprises the following steps: 1, cleaning and slicing rock partridge and then adding cooking wine, shredded ginger and salt to pickle the sliced rock partridge; 2, frying the rock partridge processed in the step 1 until muscles tighten and the color is golden; 3, soaking for rehydrating dry umbilicaria esculenta; 4, baking ham slices till oil is made off the ham slices; 5, adding ginger slices and green onion sections after mixing the rock partridge processed in the step 2 with the ham processed in the step 4, and stewing in water; 6, adding the umbilicaria esculenta processed in the step 3, chicken powder, fish sauce and white pepper before the product obtained in the step 5 is taken out of a pot; and 7, cooling the product processed in the step 6, sealing the product in a thick aluminum foil bag, and carrying out radiation sterilization by 60Co. By the process for processing the Huangshan rock partridge and umbilicaria esculenta soup disclosed by the invention, the defects that existing Huangshan rock partridge and umbilicaria esculenta soup has certain fishy smell, and is high in content of grease and salt are overcome, and the Huangshan rock partridge and umbilicaria esculenta soup can be stored for 3-6 months, and has the advantage of being ready to eat after being unpacked.

Owner:INST AGRO PROD PROCESSING ANHUI ACADEMY AGRI SCI

Salty-reducing additive for tobaccos, and preparation method and application of salty-reducing additive

ActiveCN102960856BComfortable aftertasteSimple preparation processTobacco preparationTobacco treatmentBiotechnologySodium acetate

The invention relates to a salt-reducing additive for cigarettes, a preparation method and application thereof. The preparation method of the salt-reducing additive for tobacco is as follows: firstly preparing extracts of licorice root and stevia rebaudiana, the filtrate obtained after the extracts are separated by membrane and macroporous resin, and concentrated under reduced pressure to make extract. Then add an appropriate amount of sodium acetate aqueous solution to form a cigarette salty taste inhibitor. The salty taste inhibitor is dissolved in a certain concentration of ethanol and propylene glycol solution, evenly sprayed on shredded tobacco, shredded stems or tobacco sheets of cigarettes and rolled into cigarettes. Its dosage is 0.01-0.5% of the weight of shredded tobacco, shredded stems or tobacco flakes. This kind of salty taste inhibitor can significantly reduce the salty taste of the mouth caused by smoking some cigarettes, and can coordinate the smoke aroma, improve the sweetness of the mouth, make the smoke delicate and soft, and reduce the irritation of the cigarette smoke on the mouth. Improving the oral sensory quality of cigarette smoking.

Owner:HONGTA TOBACCO GRP

Taste-improving agent

ActiveUS9795161B2Suppress unpleasant tasteReduce saltinessLactobacillusLeuconostocLactic acid bacteriumSalty taste

Owner:KIKKOMAN CORP

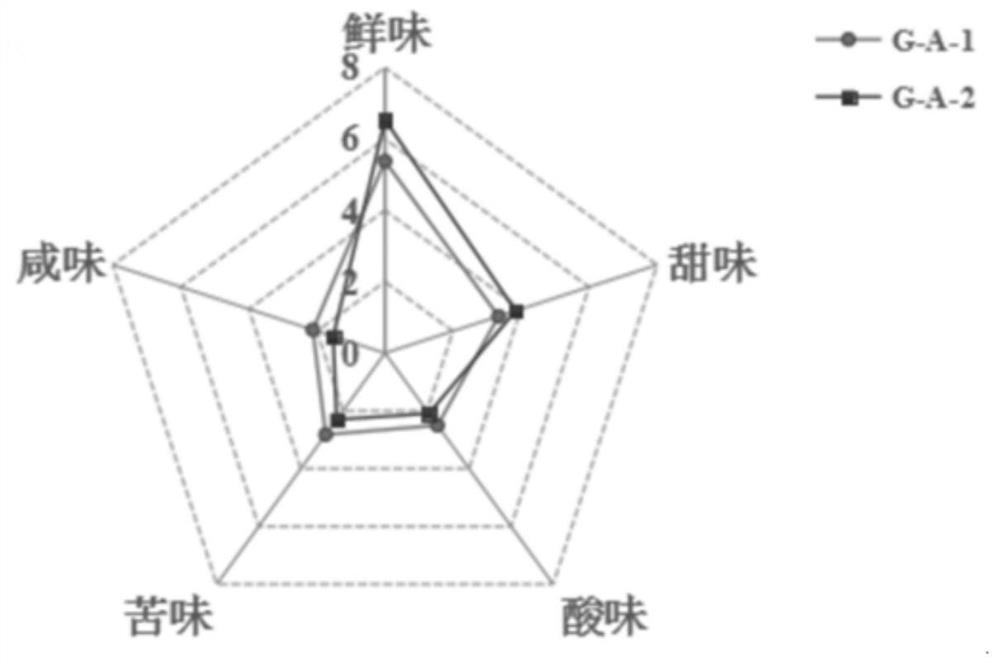

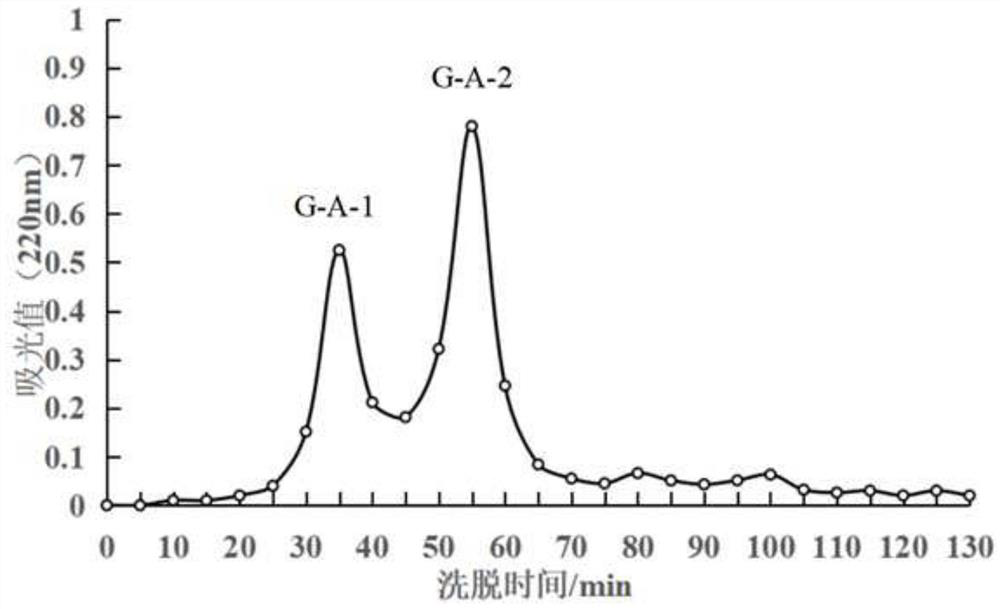

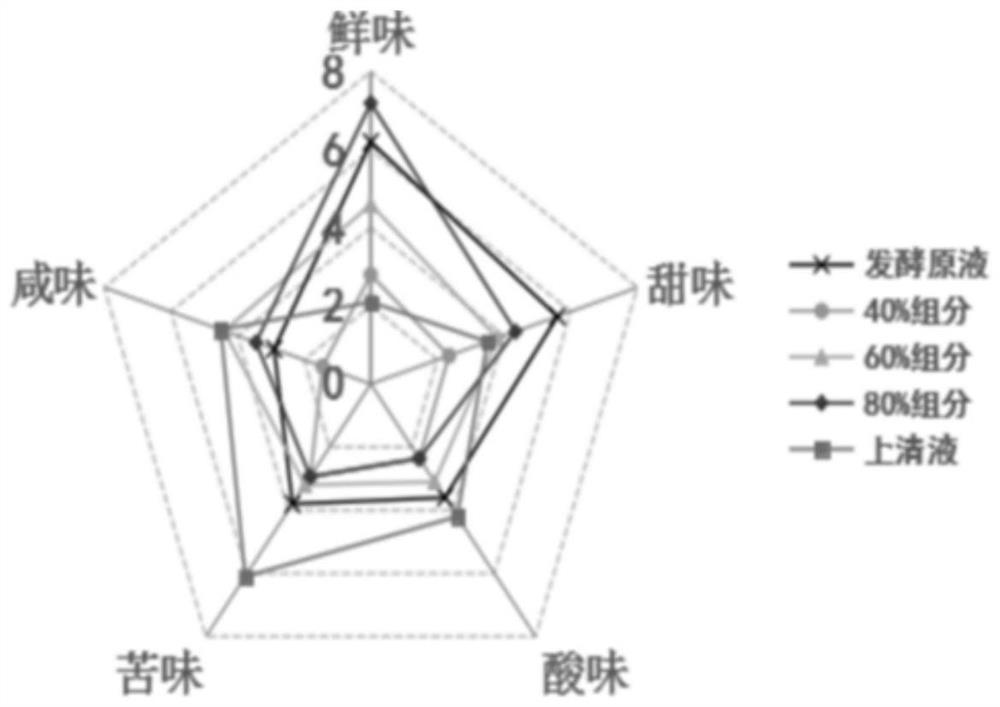

Novel umami oligopeptide as well as preparation method and application thereof

PendingCN114181278AImprove taste appGood umami effectBacteriaMicroorganism based processesFood biotechnologyFermentation broth

The invention relates to the technical field of functional microorganism screening and food biology, and particularly provides novel delicate flavor oligopeptide as well as a preparation method and application thereof. The umami oligopeptide is separated and extracted from fermentation liquor of tetrastreptococcus halophilus, has strong umami and strong taste extension feeling, has an umami enhancing effect, and can be widely applied to the fields of foods and seasonings.

Owner:SHENYANG AGRI UNIV

Method for preparing fragrance tea health salted egg

The preparation process of health salted tea egg includes the following steps: 1. sorting fresh duck egg with complete shell and washing; 2. boiling seasonings in water to prepare soaking liquid; 3. soaking egg in the soaking liquid and adding certain amount of black tea fungus liquid and salt; 4. sealing for 15-20 days in summer or 45-50 in winter; and 5. taking out egg, air drying and packing. Thus prepared salted egg is delicious and less salty, and possesses several health functions.

Owner:马振志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com