Preparation method and application of high-quality food-grade plant-derived compound amino acid

A compound amino acid, food-grade technology, applied in the field of plant protein, can solve the problems of reproductive system damage, many impurities, low amino acid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

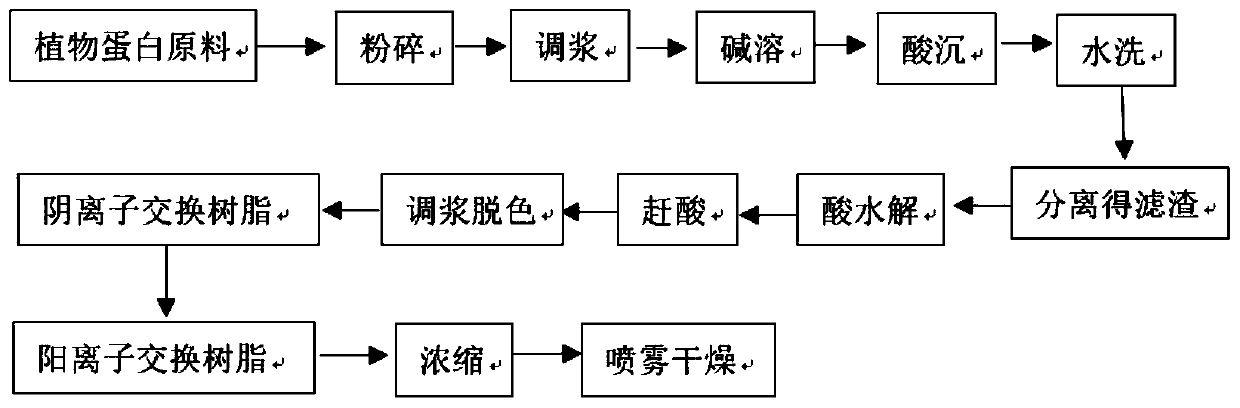

Method used

Image

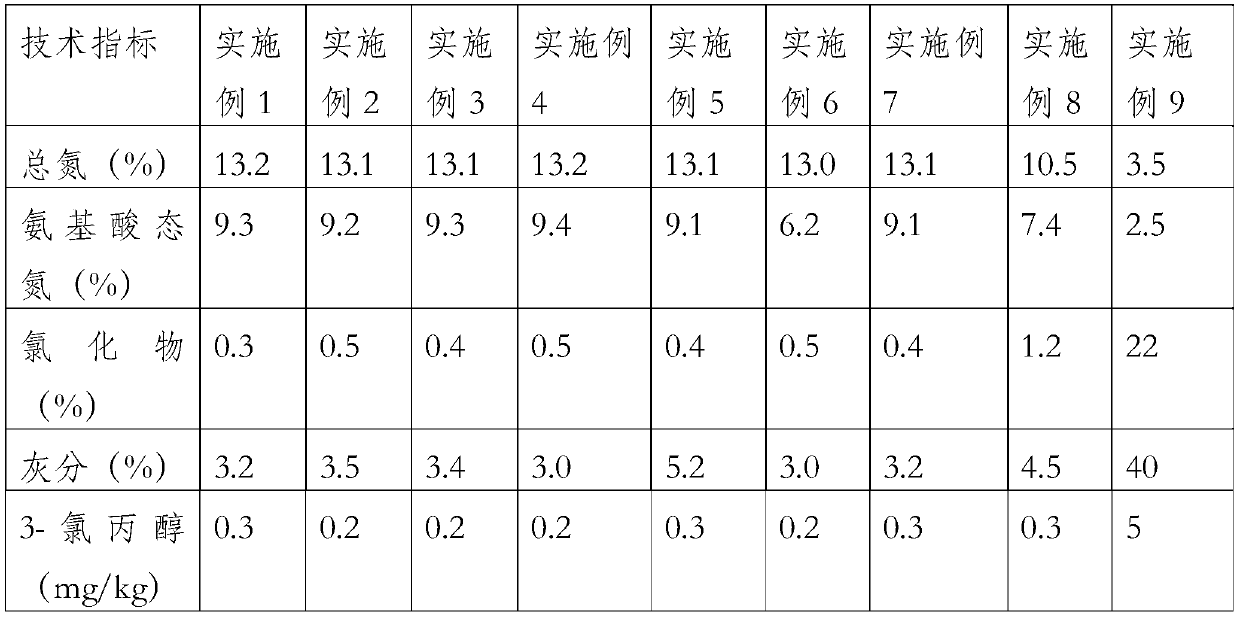

Examples

Embodiment 1

[0027] Weigh 1kg of soybean meal and grind it to 120 mesh;

[0028] Mix with water to 10L;

[0029] Use sodium hydroxide to adjust the pH to 9, stir at 50°C and 150 rpm / min for 20 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filtrate;

[0030] Adjust the pH of the filtrate to 4.5 with hydrochloric acid, stir at 45°C and 150 rpm / min for 20 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filter residue;

[0031] Slurry the filter residue to 20%, stir at 150 rpm / min at room temperature for 10 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filter residue;

[0032] Take this part of the filter residue, add 4kg of hydrochloric acid, put it into a normal pressure reactor after slurry adjustment, adjust the temperature of the reactor to 108°C, and the rotation speed to 150rpm / min, react for 20 hours, and condense and reflux during the hydrolysis process;

[0033] After the reaction is completed, the hydrolyzed ...

Embodiment 2

[0040] Weigh 1kg of cornmeal and grind it to 120 mesh;

[0041] Mix with water to 10L;

[0042] Use sodium hydroxide to adjust the pH to 9, stir at 50°C and 150 rpm / min for 20 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filtrate;

[0043] Adjust the pH of the filtrate to 4.5 with hydrochloric acid, stir at 45°C and 150 rpm / min for 20 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filter residue;

[0044] Slurry the filter residue to 20%, stir at 150 rpm / min at room temperature for 10 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filter residue;

[0045] Take this part of the filter residue, add 4kg of hydrochloric acid, put it into a normal pressure reactor after slurry adjustment, adjust the temperature of the reactor to 108°C, and the rotation speed to 150rpm / min, react for 20 hours, and condense and reflux during the hydrolysis process;

[0046] After the reaction is completed, the hydrolyzed soluti...

Embodiment 3

[0053] Weigh 1kg of peanut meal and grind it to 120 mesh;

[0054] Mix with water to 10L;

[0055] Use sodium hydroxide to adjust the pH to 9, stir at 50°C and 150 rpm / min for 20 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filtrate;

[0056] Adjust the pH of the filtrate to 4.5 with hydrochloric acid, stir at 45°C and 150 rpm / min for 20 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filter residue;

[0057] Slurry the filter residue to 20%, stir at 150 rpm / min at room temperature for 10 minutes, and centrifuge at 4000 rpm / min for 10 minutes to separate the filter residue;

[0058] Take this part of the filter residue, add 4kg of hydrochloric acid, put it into a normal pressure reactor after slurry adjustment, adjust the temperature of the reactor to 108°C, and the rotation speed to 150rpm / min, react for 20 hours, and condense and reflux during the hydrolysis process;

[0059] After the reaction is completed, the hydrolyzed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com