Novel umami oligopeptide as well as preparation method and application thereof

An umami-flavored oligopeptide and oligopeptide technology, applied in biochemical equipment and methods, microorganism-based methods, peptides, etc., can solve the problems of insufficient flavor of umami-flavored peptides, inability to meet extensive needs in the field of food processing, and high production costs , to achieve the effect of improving taste application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1 Application of halophilic Tetradendococcus SNTH-1 in the production of umami peptides by fermentation

[0063] 1. Strain activation:

[0064] Take 1 portion of the preserved Tetragenococcus shalophilus SNTH-1 strain from the -80°C ultra-low temperature refrigerator, and inoculate it in 50 mL of MRS with 1% (v / v) inoculation amount after melting the ice medium, adjust the pH value to 8.3, and shake the flask for 40 hours at 37°C. When the strain grows to the end of the logarithmic growth phase, take 0.5mL of fermentation broth and repeatedly inoculate it in 50mL of MRS medium to obtain activated Halotetradendococcus SNTH-1 strain;

[0065] 2. Seed solution culture:

[0066] Inoculate the above-mentioned activated bacterial liquid into a 5L fermenter with 3L of enriched medium, at a temperature of 37°C, a rotation speed of 200rpm, an air flow ratio of 1:0.5, and a tank pressure of 0.1kg / cm 2 Cultivate 24h under the condition of obtaining seed liquid;

[0067...

Embodiment 2

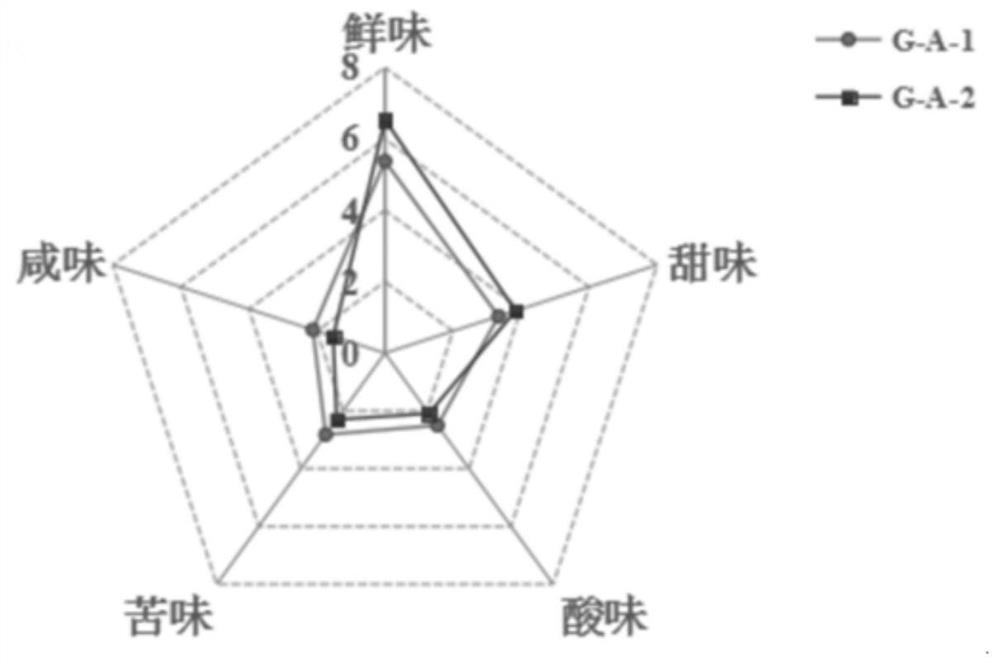

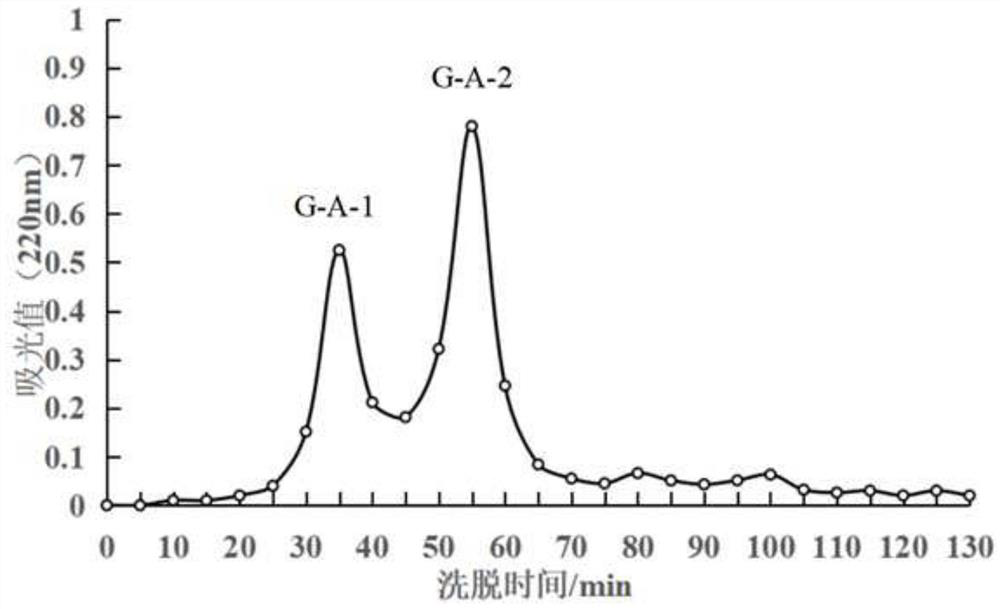

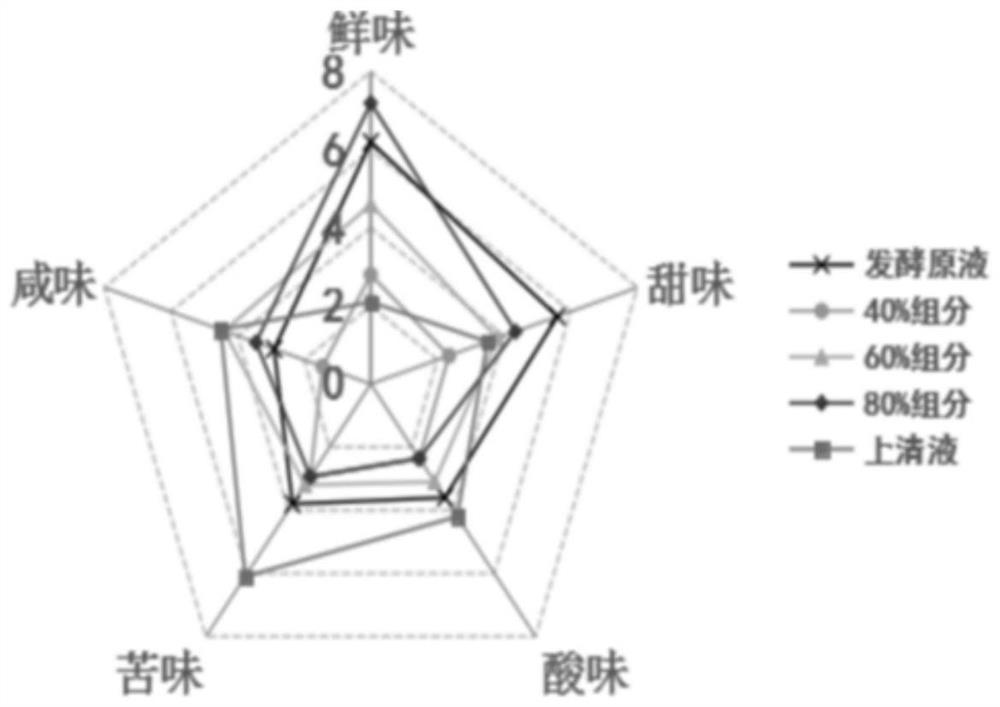

[0080] Example 2 Extraction and Purification of Umami Peptides Produced by Tetradynococcus halophilus SNTH-1

[0081] 1. Ethanol classification:

[0082] (1) Get the fermented liquid of halophilic Tetradendococcus SNTH-1 described in 200mL embodiment 1, concentrate to 100mL, then add 67mL edible grade dehydrated alcohol to the fermented liquid after the concentration then stir at room temperature for 30min and centrifuge (8000g, 30min ), to obtain precipitate E1 and supernatant 1;

[0083] (2) Freeze-dry the precipitate E1 to obtain the fraction extracted with 40% ethanol; mix the supernatant 1 with 80mL ethanol to make a solution with a final ethanol concentration of 60%, stir at room temperature for 30min and centrifuge (8000g, 15min) , to obtain precipitate E2 and supernatant 2;

[0084] (3) Get the precipitate E2 to freeze-dry to obtain the component extracted by 60% ethanol; add 200mL ethanol to the supernatant 2 and mix to form a solution with a final ethanol concentra...

Embodiment 3

[0112] Example 3 Identification, Synthesis and Evaluation of Umami Peptides Produced by Halo-tetradendococcus SNTH-1

[0113] 1. UPLC-ESI-MS / MS sequence analysis and identification:

[0114] The umami component G-A-2-II separated by RP-HPLC in Example 2 was used for amino acid sequence analysis.

[0115] The specific method is as follows:

[0116] The A solution used in the liquid phase is 0.1% formic acid aqueous solution, and the B solution is 0.1% formic acid acetonitrile aqueous solution (acetonitrile is 84%). A liquid chromatography column (0.15mm*150mm, RP-C18, Column Technology Inc.) was equilibrated with 95% liquid A, and the sample was loaded onto Zorbax 300SB-C18 peptide traps (Agilent Technologies, Wilmington, DE ), and separated by liquid chromatography column, the relevant liquid phase gradient is set as follows: 0-50min, B liquid linear gradient from 4%-50%; 50-54min, B liquid linear gradient from 50%-100%; 54-60min , Liquid B was maintained at 100%. The prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com