Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce patching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

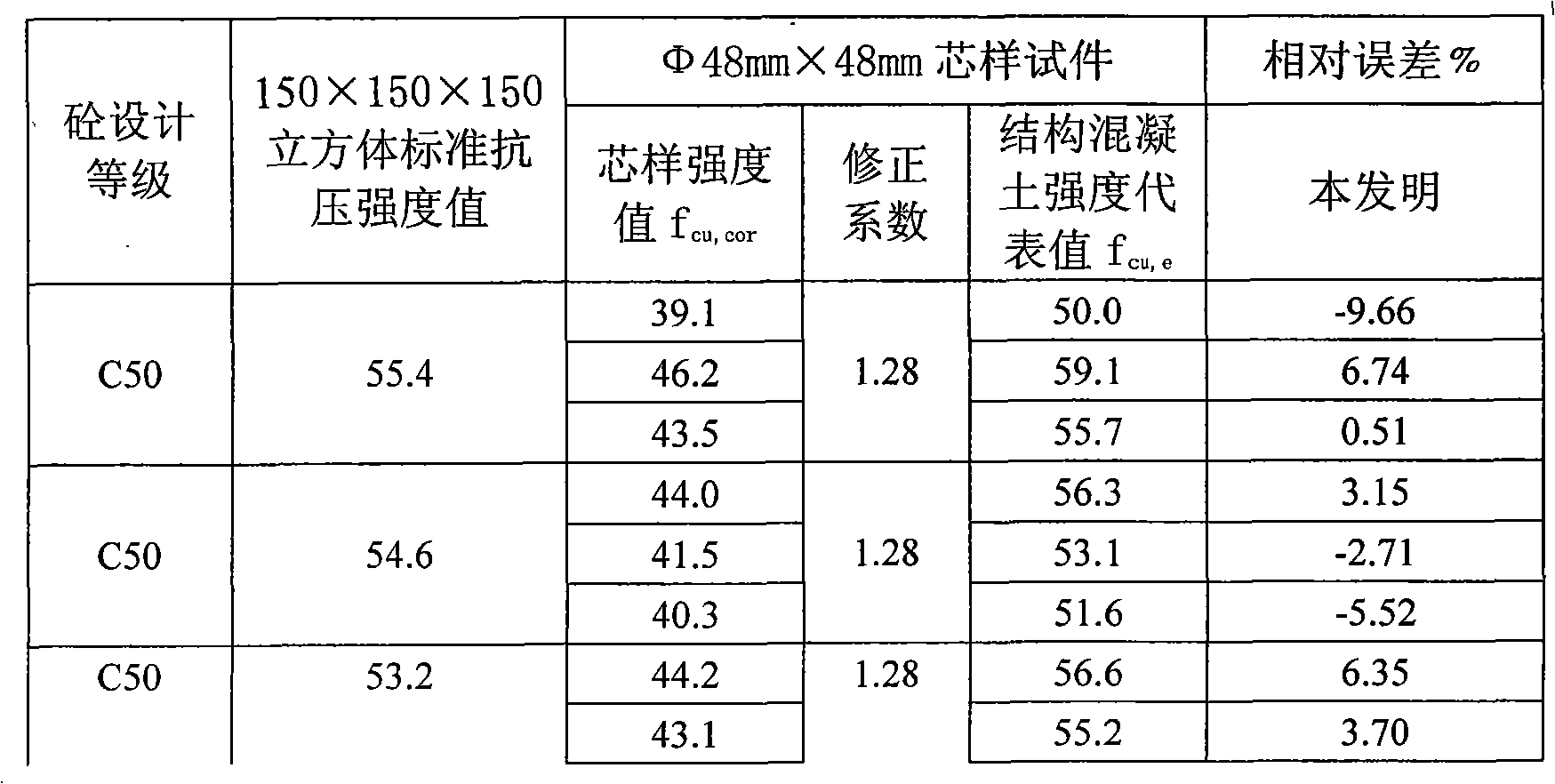

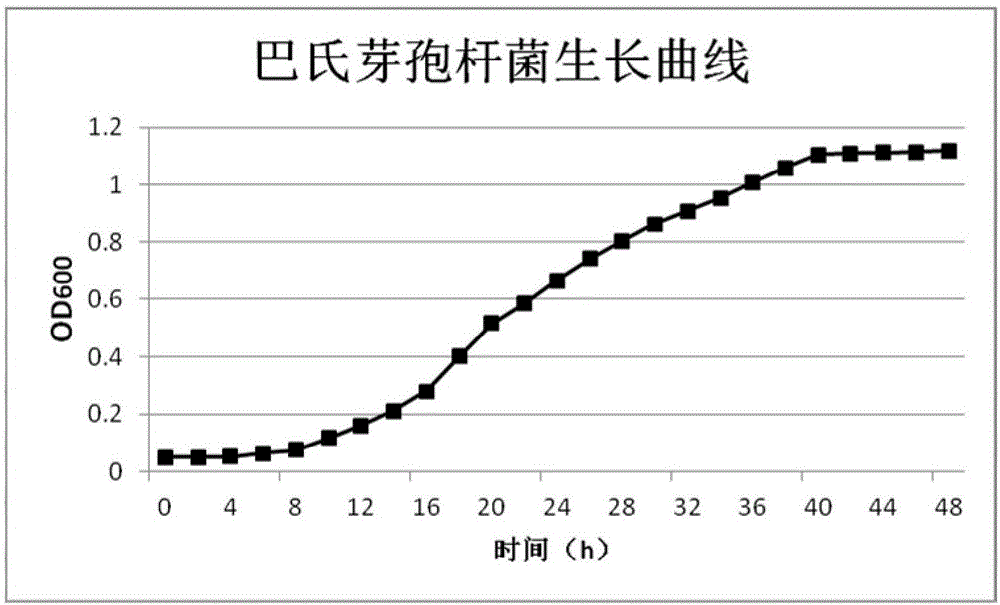

Method for estimating concrete strength of thin-walled structure by using small core sample strength

InactiveCN101551380ASmall intensity errorHigh precisionWithdrawing sample devicesMaterial strength using tensile/compressive forcesMaterials testingUltimate tensile strength

The invention discloses a method for estimating the concrete strength of the thin-walled structure by using the small core sample strength, which belongs to the concrete strength detection of construction projects. The main technical proposal is as follows: a core sample with the diameter of 48mm is drilled from the concrete entity of the thin-walled structure through the cutting and polishing, the compressive strength test is conducted by using an universal material testing machine to obtain a concrete compressive strength value of the small core sample, and the concrete strength of the thin-walled structure is deduced by a correction factor formula. The invention has the advantages of small error and high accuracy, can be applied to the quality control in the construction projects under construction, and the assessment and identification of justice in the existing building and the construction after the disaster.

Owner:XUZHOU INST OF ARCHITECTURAL TECH

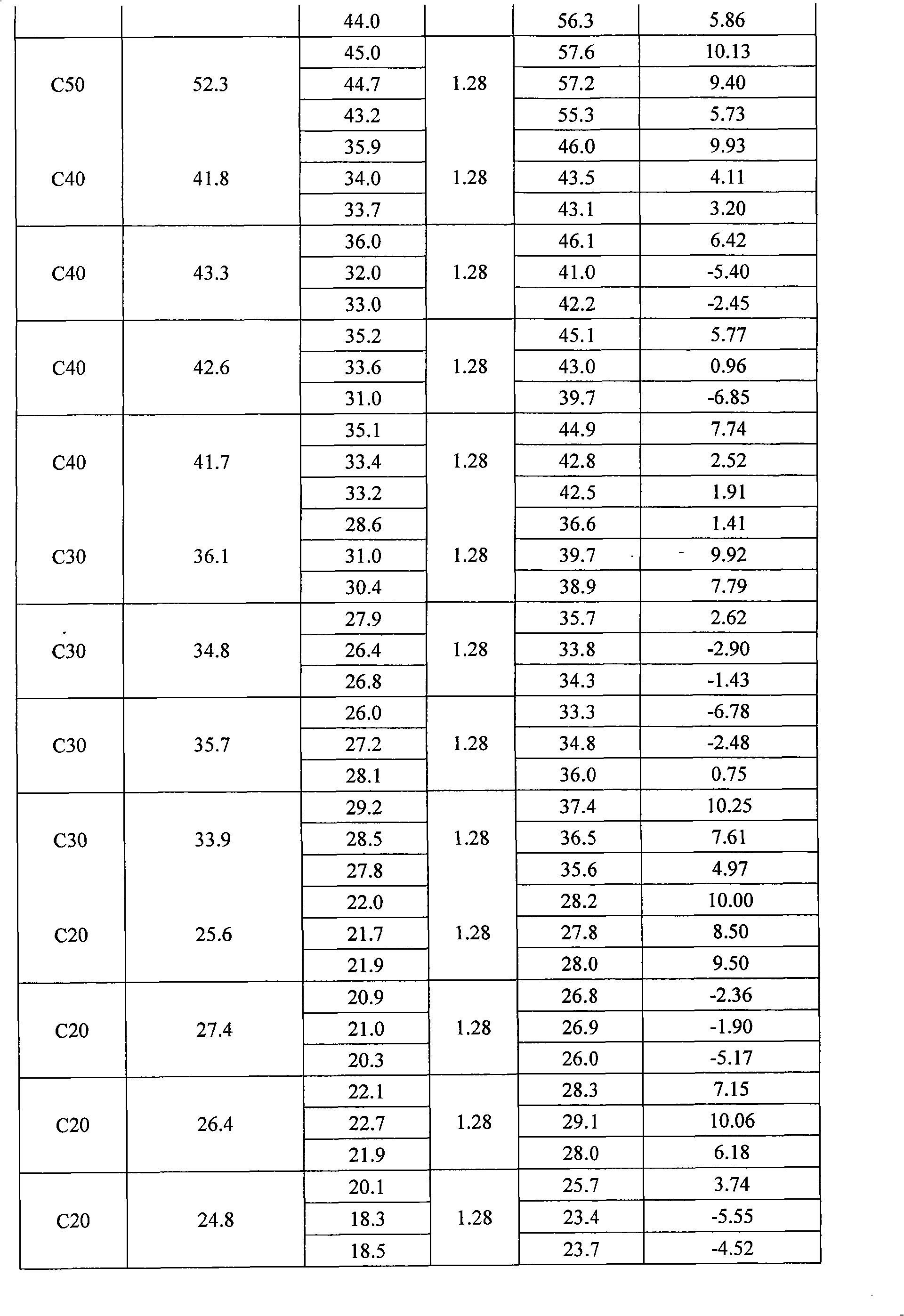

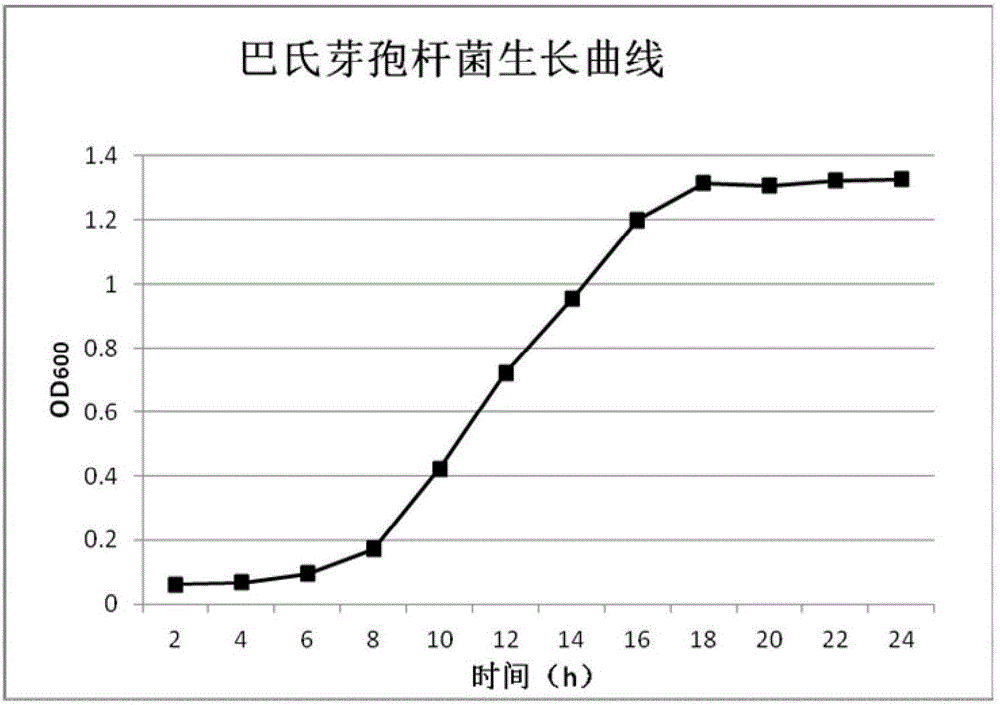

Culture solution for accelerating rapid growth of microorganisms and using method thereof

ActiveCN106085944AIncrease pHPromote growth and reproductionBacteriaMicroorganism based processesMicroorganismRepair time

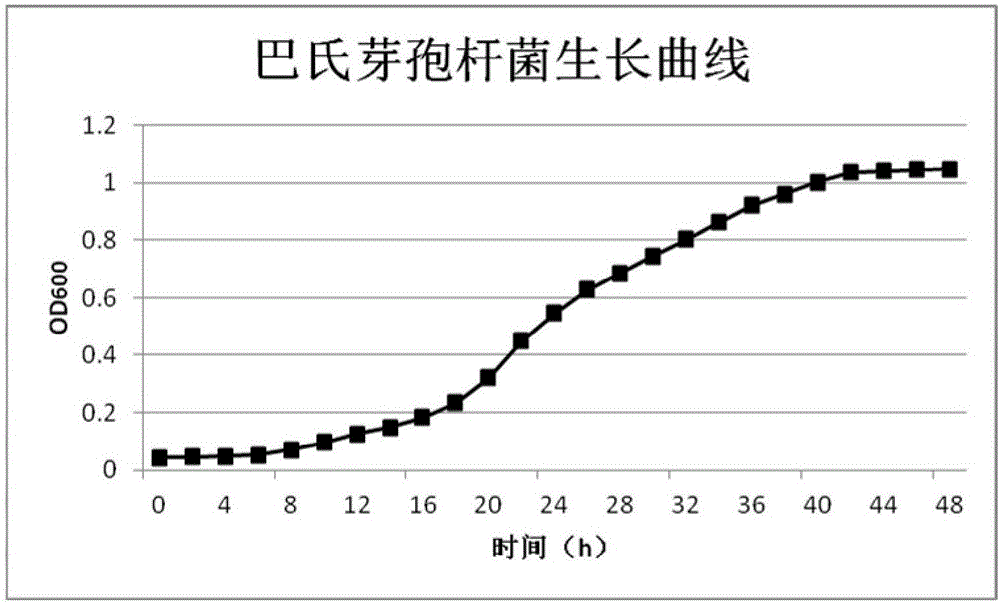

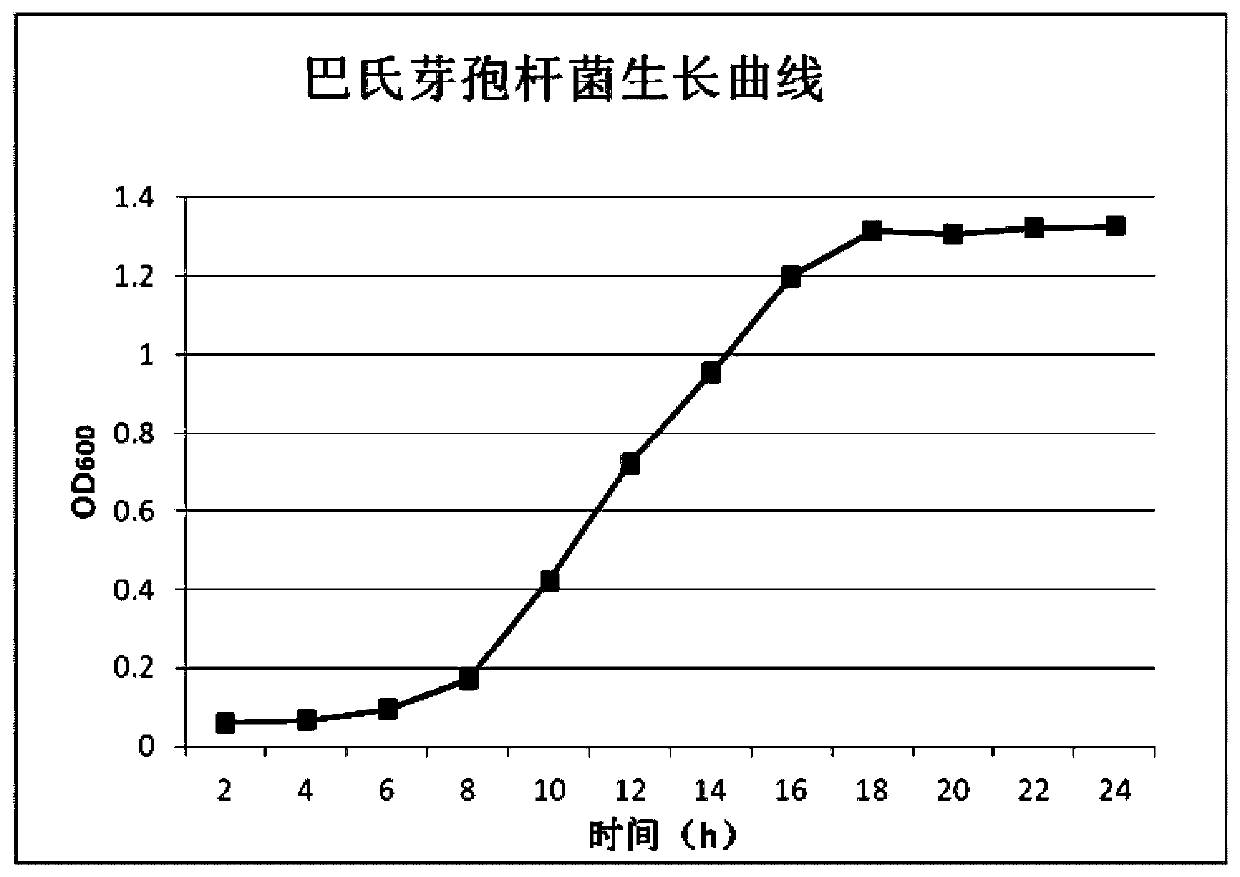

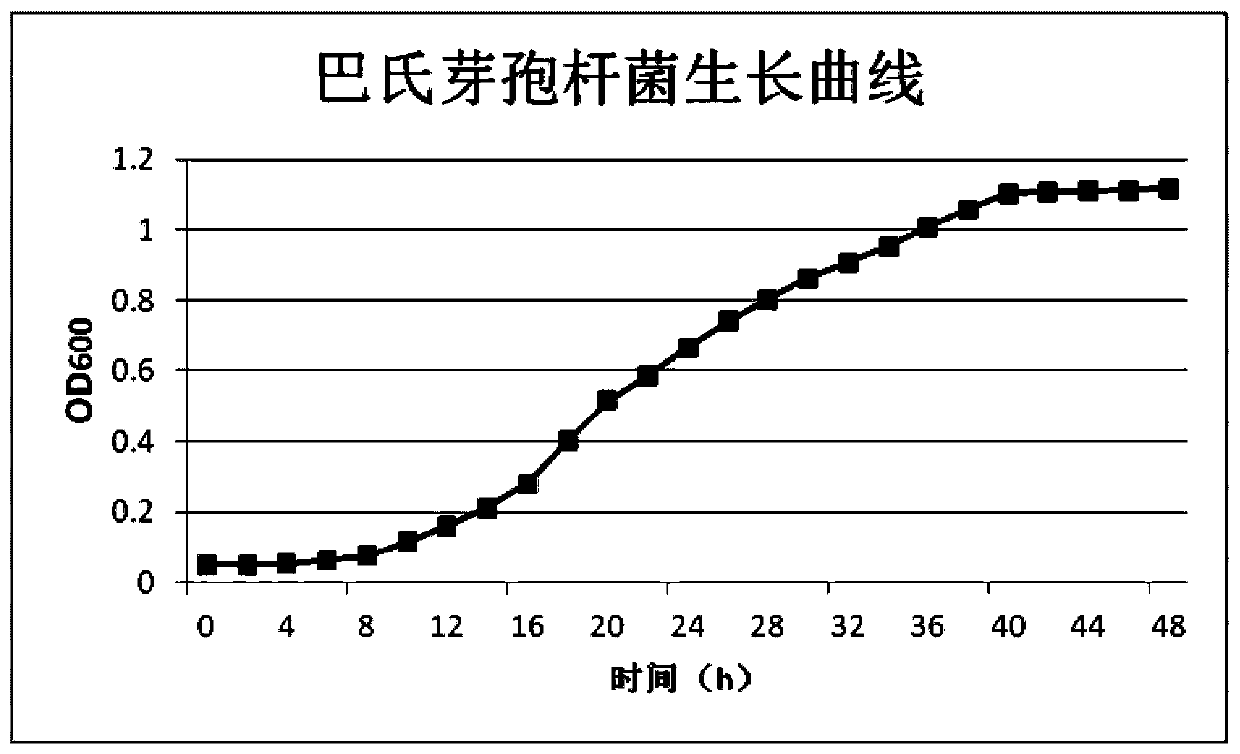

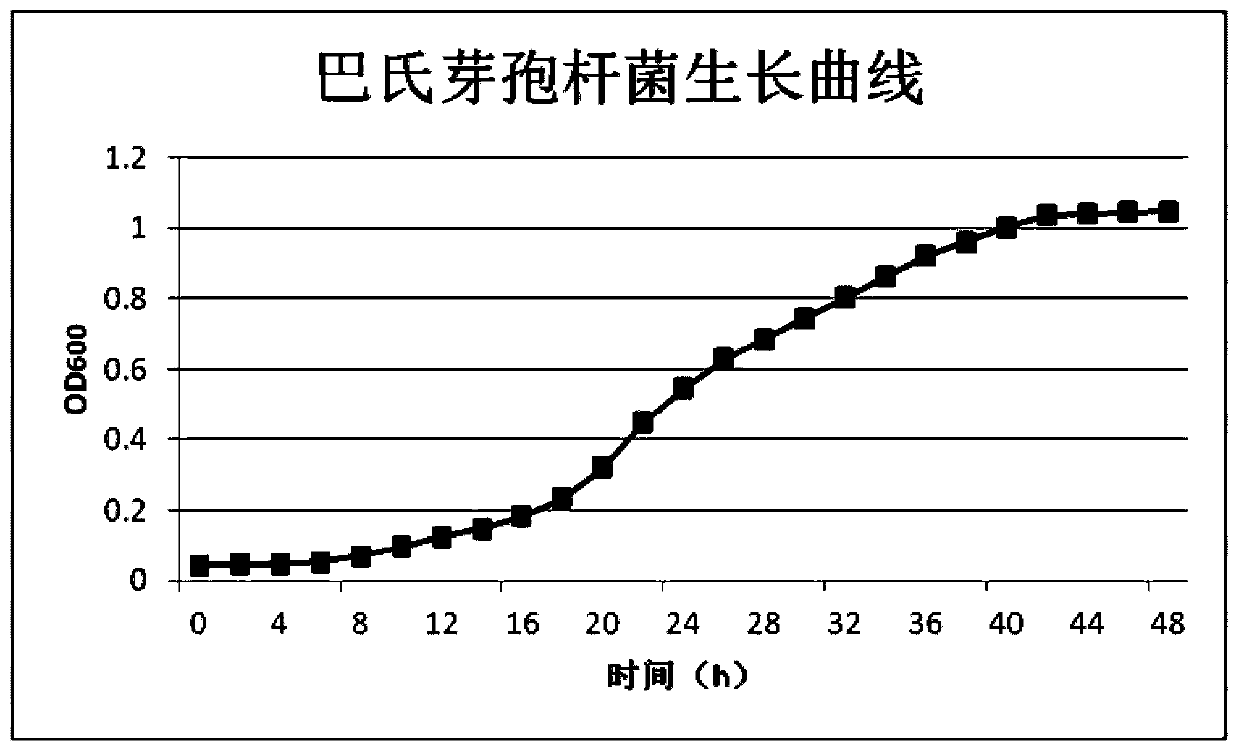

The invention discloses a culture solution for accelerating rapid growth of microorganisms and a using method thereof. Bacillus pasteurii is inoculated into a culture medium containing various nutrient substances, constant temperature shaking culture is performed at 25-30 DEG C, the initial PH value is controlled to be about 6, culture is performed for 12-24 h, part of bacteria solution is taken out every two days in the culture process, a spectrophotometer is utilized to measure the absorbance OD600, a strain growth curve is obtained, strains enter into a stable stage in about 18 h according to observation, and compared with research by predecessors, the strain growth speed is obviously accelerated. The culture solution for accelerating rapid growth of the microorganisms and the using method have the advantages that substances in the culture solution can be fully utilized, and the culture solution is simple in process, high in efficiency, short in used time, clean in environment and low in cost; the efficiency of microbial induction of calcium carbonate is further improved, and the concrete crack repair time can be shortened.

Owner:SOUTHEAST UNIV

Sheet for repairing and reinforcing concrete structure and repairing and reinforcing method thereof

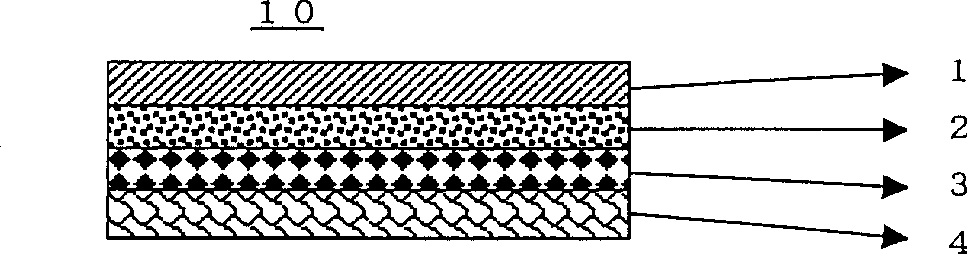

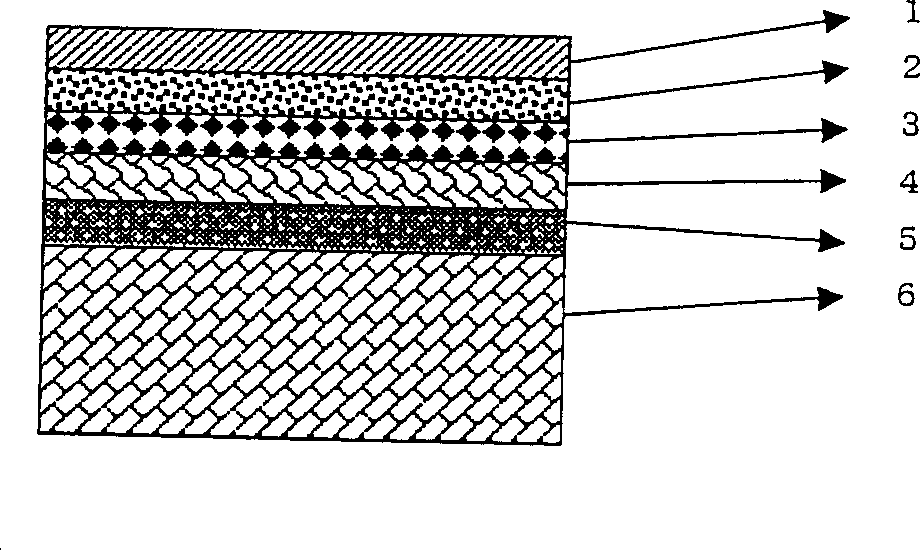

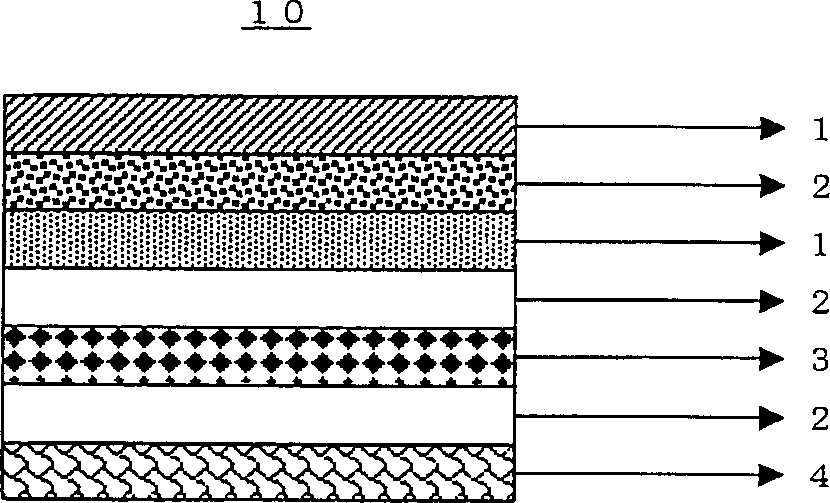

InactiveCN1362567AReduce patchingLighten up workSynthetic resin layered productsBuilding repairsReinforced concreteAdhesive

A sheet for repairing and reinforcing a concrete structure is provided as a lamination having a protective layer and a sticking layer. A method of repairing and reinforcing a concrete structure by sticking the sheet to the surface of the structure is also provided. The invention is able to facilitate the operation of applying an adhesive and paint at a construction site and facilitate construction work.

Owner:SHO BOND CONSTRUCTION CO LTD +1

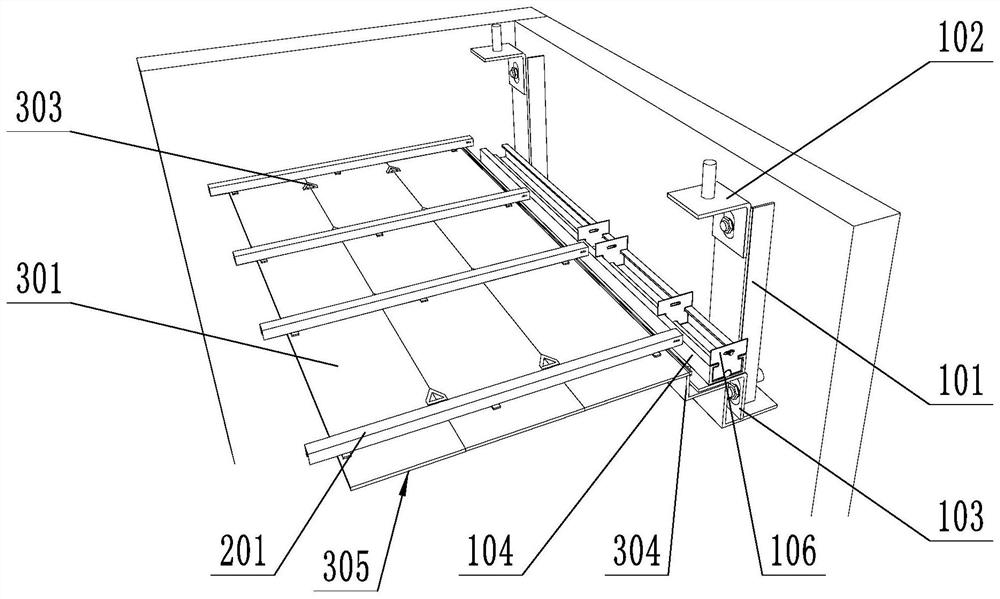

Suspended ceiling structure without suspension rod

The invention discloses a suspended ceiling structure without a suspension rod. The suspended ceiling structure comprises a suspended ceiling supporting structure and a veneer, wherein the suspended ceiling supporting structure is fixed with a wall surface; the veneer is fixed on the suspended ceiling supporting structure and comprises vertical rods, upper corner braces, horizontal supports, keelsand sliding plates, wherein the sliding plates are in sliding connection with the horizontal supports; the vertical rods are vertically fixedly arranged on the upper corner braces; the horizontal supports are fixed with the vertical rods; the two ends of each keel are fixed with the sliding plates; and the veneer is fixed on the keels. The suspended ceiling structure without the suspension rod has the advantages of a simple structure, good adjustability, convenience for installation and the like.

Owner:ZHEJIANG YASHA DECORATION

Multielement high-strength wear-resistant composite paint and preparation method thereof

InactiveCN104628403AImprove high temperature resistanceImprove stabilityWear resistantBound property

The invention relates to a refractory material and a preparation method thereof, particularly a multielement high-strength wear-resistant composite paint and a preparation method thereof. The multielement high-strength wear-resistant composite paint is composed of a main material and an auxiliary material, wherein the main material is composed of fused alumina zirconia fine powder, kyanite, pure calcium aluminate cement, aluminium titanate, magnesium zircon sand, silicon micropowder, aluminum oxide micropowder, sodium tripolyphosphate, calcium chromate and gahnite; and the auxiliary material is composed of phosphoric acid, aluminum hydroxide for inks, aluminum chloride, boron-iron-molybdenum alloy, borax and agglutinant. The multielement high-strength wear-resistant composite paint provided by the invention has the advantages of high compressive strength, higher hardness, high Mohs hardness, high density, favorable wear resistance, favorable erosion resistance, favorable scour resistance, high thermal shock stability and high binding property. When being used for a circulating fluid bed boiler, the multielement high-strength wear-resistant composite paint prolongs the service life of the paint coat, reduces the repair frequency and lowers the maintenance cost.

Owner:YIXING GUOQIANG FURNACE IND

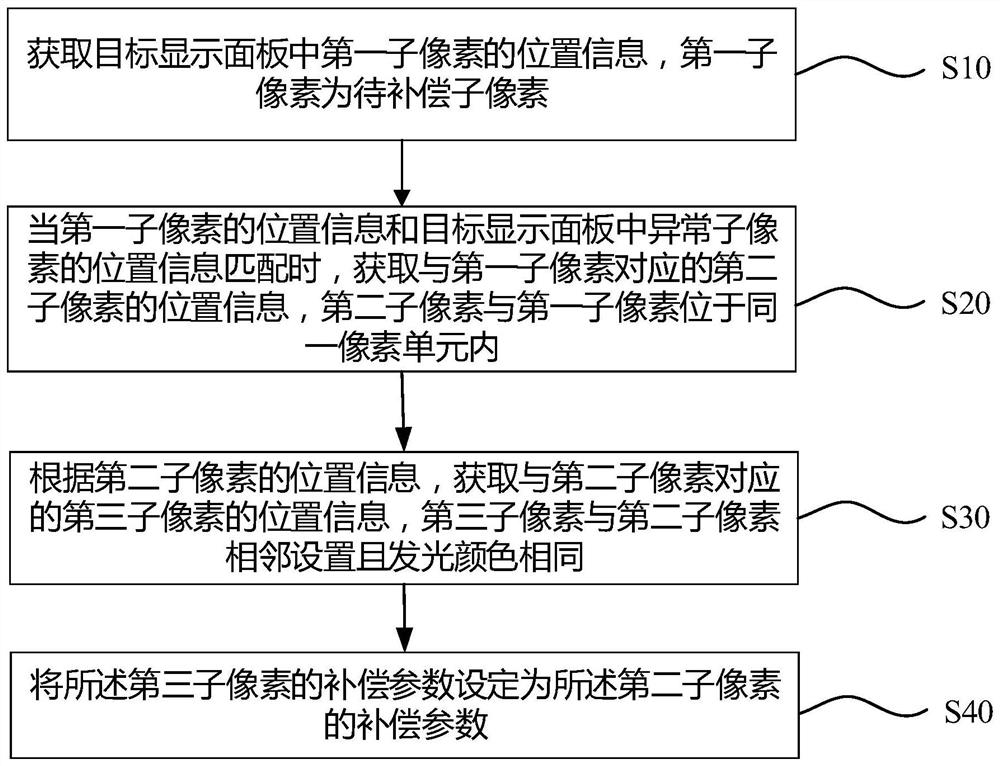

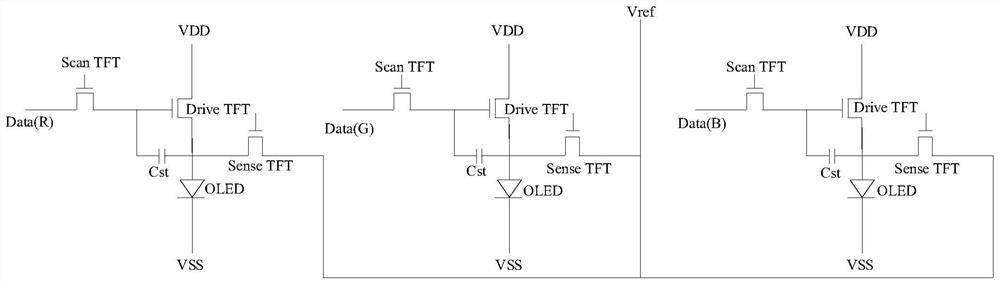

Compensation method and compensation device for display panel

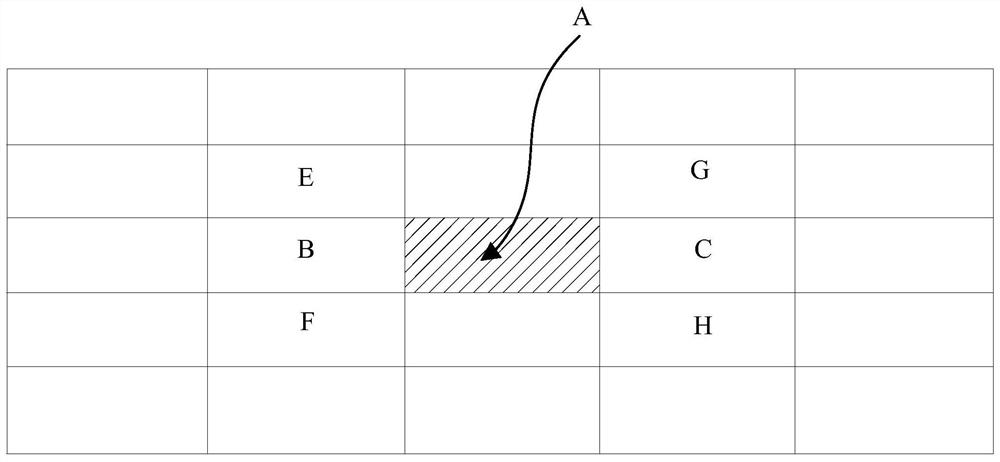

PendingCN114038428AAvoid yield lossOptimize the process flowStatic indicating devicesDark spotEngineering

The embodiment of the invention provides a compensation method and a compensation device for a display panel. The compensation method comprises the following steps: firstly, acquiring position information of a first sub-pixel; when the position information of the first sub-pixel is matched with the position information of the abnormal sub-pixel, obtaining the position information of a second sub-pixel, and the second sub-pixel and the first sub-pixel are located in the same pixel unit; then, according to the position information of the second sub-pixel, obtaining the position information of a third sub-pixel, and the third sub-pixel and the second sub-pixel are adjacently arranged and have the same light emitting color; and finally, setting the compensation parameter of the third sub-pixel as the compensation parameter of the second sub-pixel. According to the compensation method, whether display of the first sub-pixel is abnormal is determined firstly, then the compensation parameter of the third sub-pixel is set as the compensation parameter of the second sub-pixel, and therefore the situation that the second sub-pixel is compensated to be a bright spot or a dark spot due to the fact that the first sub-pixel has defects is avoided, the display module manufacturing process flow is optimized, and the repair and compensation capacity of the display module is reduced.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD +1

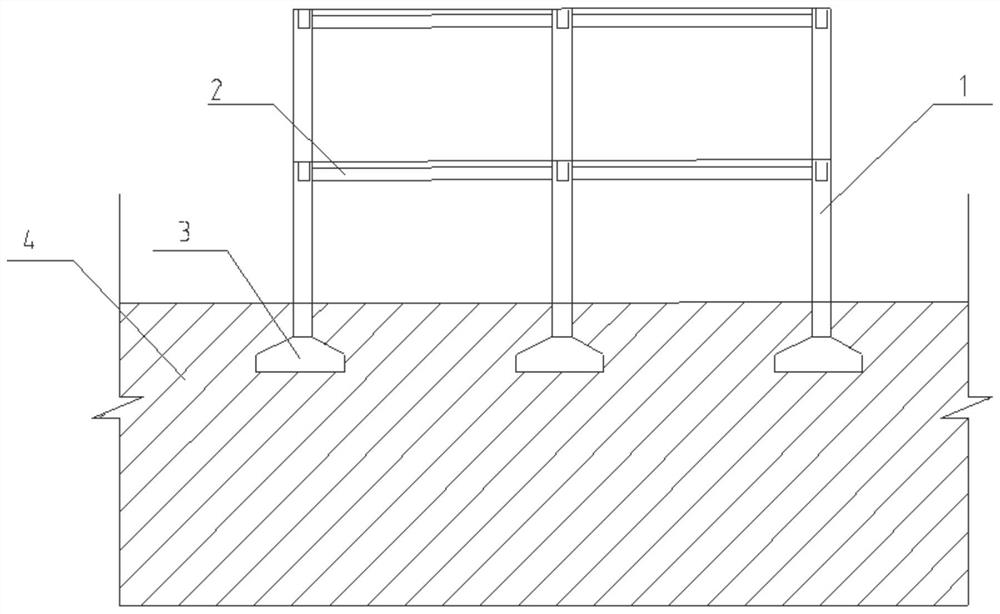

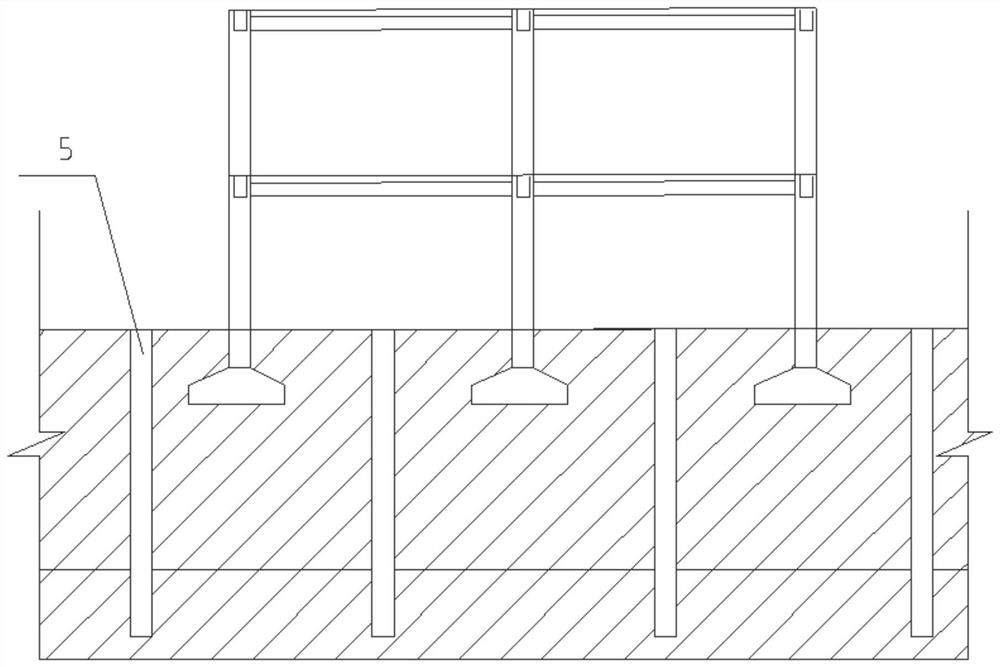

External enclosure construction method of fabricated concrete structure

InactiveCN108590332AReduce patchingAvoid drillingFencingBuilding material handlingFalseworkFloor slab

The invention relates to a building construction method, in particular to an external enclosure construction method of a fabricated concrete structure. The construction method comprises the followingsteps that when a prefabricated wall is manufactured, an embedded sleeve for an external enclosure railing to insert is pre-embedded in the prefabricated wall; during site construction, the prefabricated wall is installed and then the external enclosure railing is inserted into the embedded sleeve; and after a prefabricated floor is installed, when post-poured concrete is poured, the external enclosure railing is removed and the embedded sleeve is sealed with the post-poured concrete. According to the external enclosure construction method of the fabricated concrete structure, the situation that a scaffold is erected outside the wall to install an enclosure is effectively avoided, at the same time, drilling on the prefabricated wall is avoided, late wall repair is reduced, labor is saved greatly and the construction period is shortened greatly.

Owner:CHINA 22MCC GROUP CORP

Construction method of ultrahigh and ultra-strong RC chimney trapezoidal template fastening digital assembling mould

InactiveCN106939696AImprove satisfactionEliminate potential safety hazardsForms/shuttering/falseworksBuilding support scaffoldsSocial benefitsArchitectural engineering

The invention discloses a construction method of an ultrahigh and ultra-strong RC chimney trapezoidal template fastening digital assembling mould. The construction method comprises the following steps: (1) installation and construction of a scaffolding, a derrick, an inner double-deck platform and a lifting system; (2) production and installation of the trapezoidal template; and (3) dismantling construction of an inner frame. The construction method is simple and rapid in construction and convenient to control quality. The technologies of digital assembling of fastening section mould and the like are adopted in construction, labor force is saved, building time is shortened, quality is improved, and late repairing cost and back repairing cost are reduced. Belt-type mold locking is arranged on the outer side of a chimney, security risks of supporting an outer mould in construction is eliminated, labor intensity is reduced, construction schedule is speeded, and building time is shortened. Construction direct cost is saved by a total of 253,000 yuan, and economic benefits are significant. The key technology of the construction method is mature and reliable, the flatness of a structure is improved, the appearance quality is improved, and the reliability of the structure is ensured; and construction is environmentally friendly and clean, the customer satisfaction is good, and good social benefits are achieved.

Owner:贾茂来

Method for rapidly repairing defect on outer surface of automobile through weathered stone

InactiveCN105598011AShort curing timeReduce patchingPretreated surfacesCoatingsRepair timeGranularity

The invention discloses a method for rapidly repairing the defect on the outer surface of an automobile through weathered stone. The method includes the steps of removing a putty layer and a spray-coated layer, within the range of 1-2 cm, around the defect on the outer surface of the automobile, removing dust and particles in the defect through a piece of scrubbing cloth wetted by cleaning fluid so that the defect can be kept clean, leaving a small amount of cleaning fluid in the defect, drying the cleaning fluid left in the defect through a spray gun, mixing weathered stone powder which is formed through high-temperature calcination and ball grinding and has the granularity of 200-250 mesh with glue to form thick colloid, putting the thick colloid in an extruder, evenly filling the defect with the thick colloid through the extruder, sealing the colloid through a transparent adhesive, and repeatedly conducting scrubbing till the surface is smooth. Due to the fact that the curing time is short, all repair procedures can be balanced, the whole repair time is greatly shortened, putty powder repair is reduced, labor hours and expenses are reduced, the work efficiency is improved, repair expenses are reduced and can be reduced by 50% or above, and the repair time is shortened to be within one day.

Owner:黄晖 +4

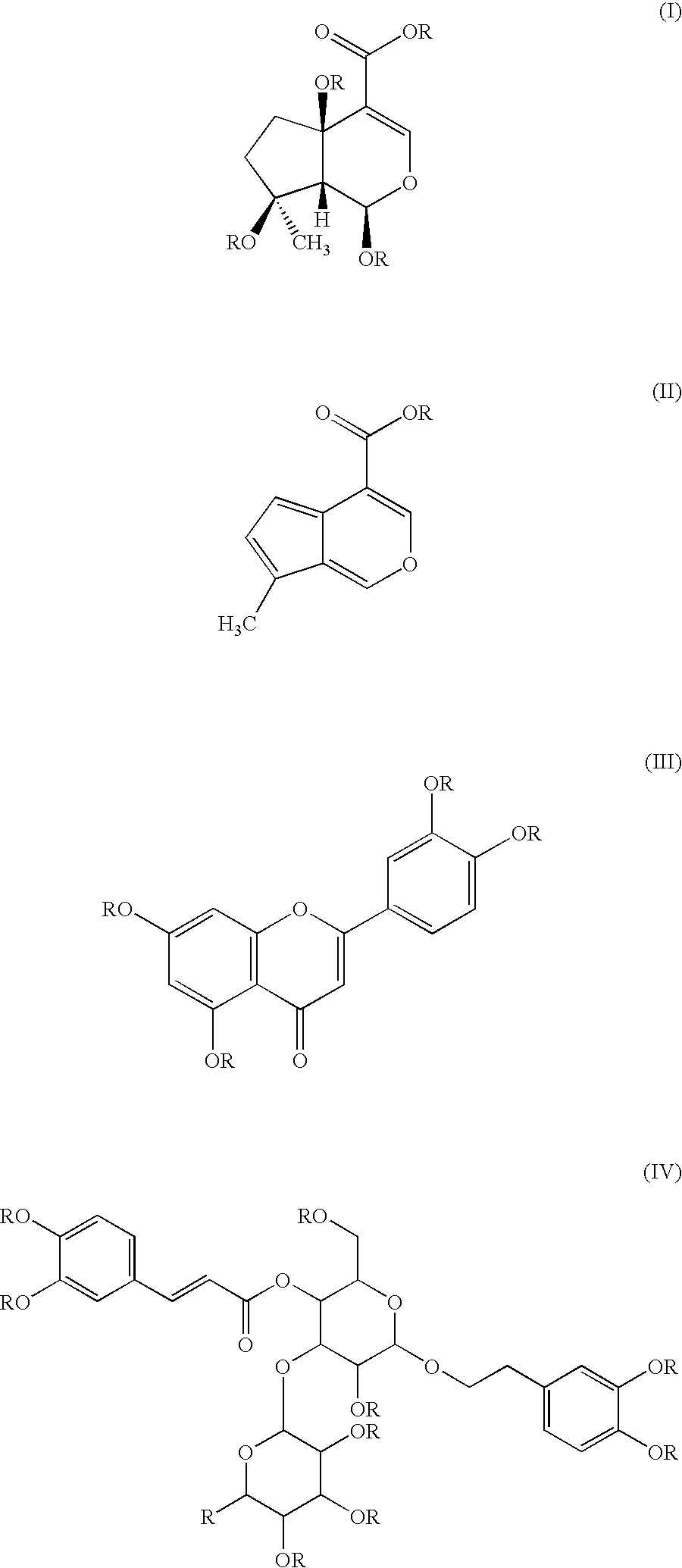

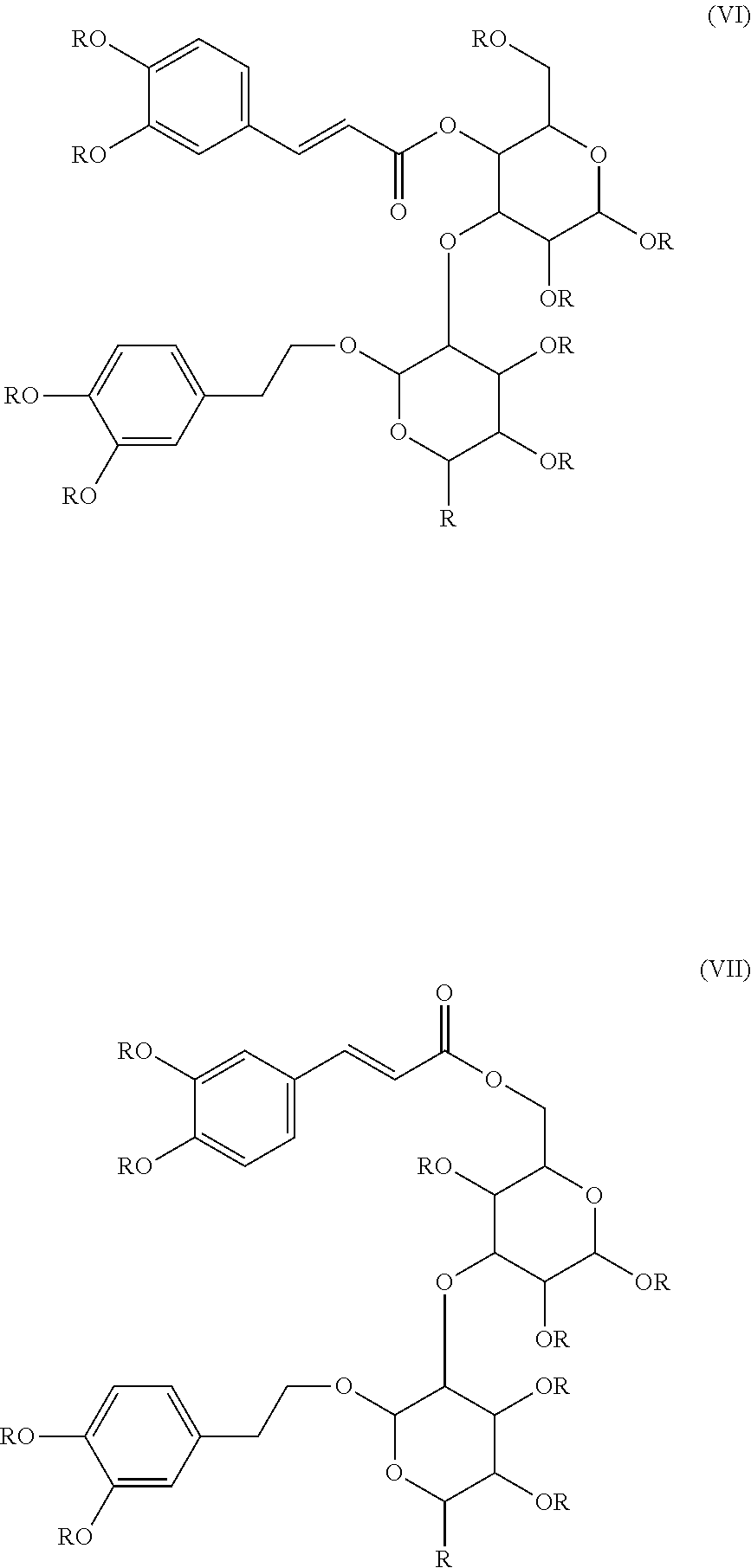

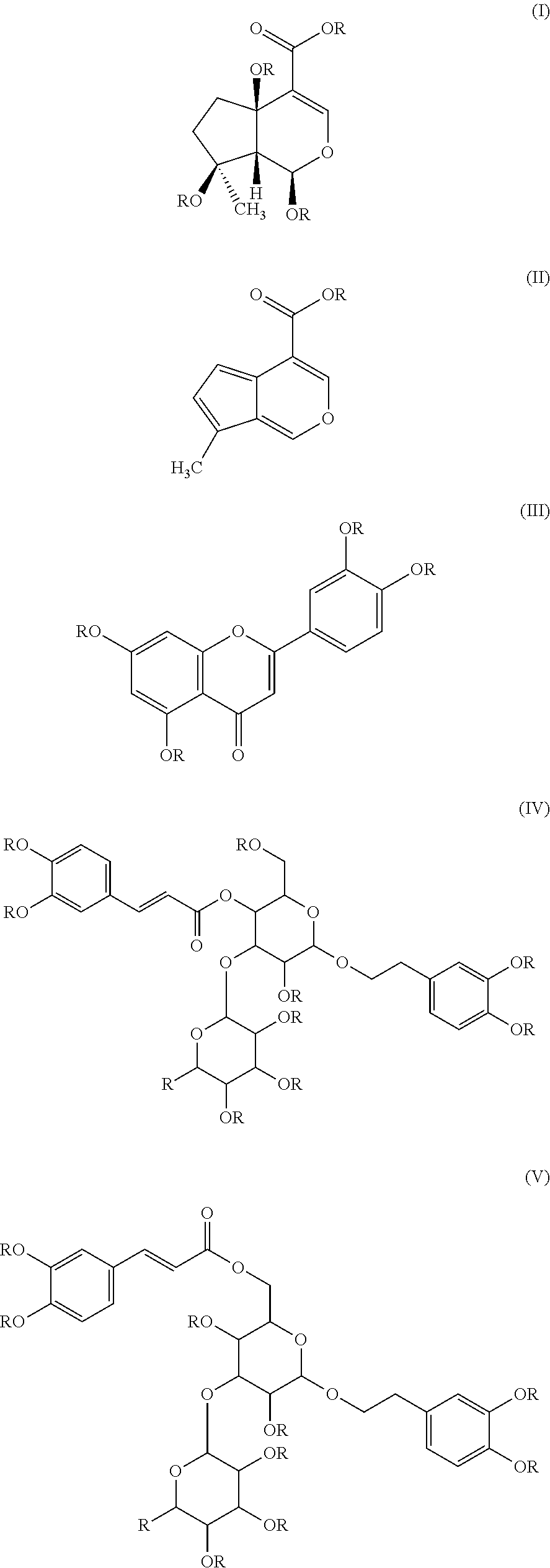

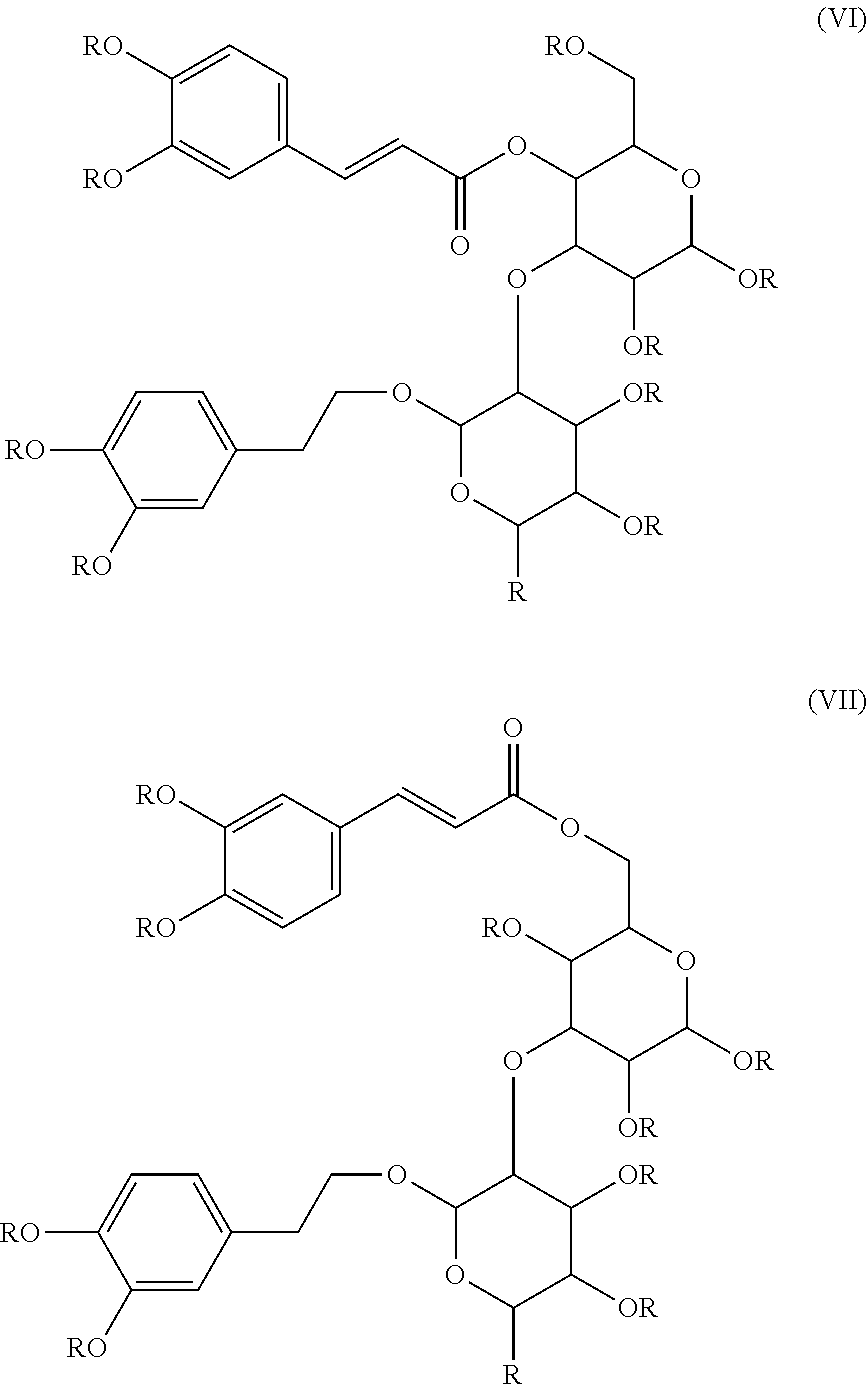

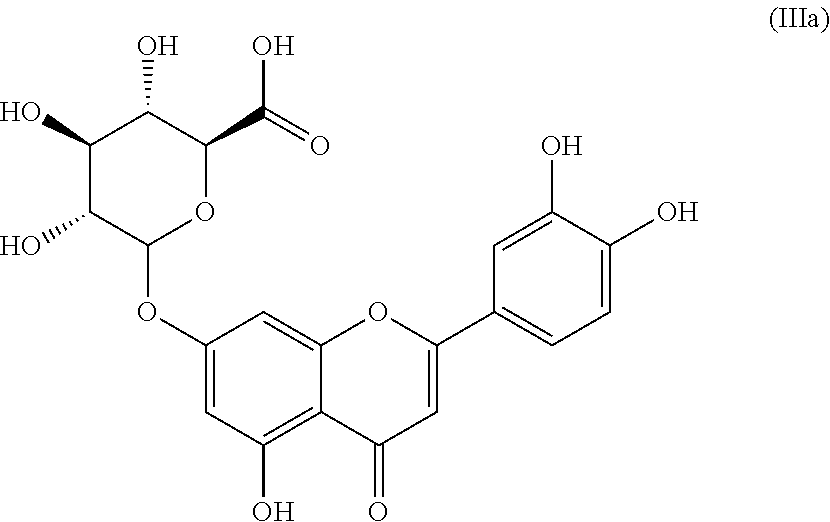

Pharmaceutical composition on the basis of stachytarpheta sp., a process for obtaining the same and its use for treating vitiligo

InactiveUS20100028400A1Easily found in natureHigh feasibilityPowder deliveryBiocideEmulsionNanoparticle

This invention generally refers to the process to obtain a compound and a standard pharmaceutical product from one or more parts of plant of the Stachytarpheta (Verhenaceae family) species, as well as roots, stems, barks, and leaves of plants in the form of extracts or enriched fractions, or pure isolated compounds or compounds obtained from synthesis, used alone or mixed with other natural or synthetic products, in different ratios, in order to integrate pharmaceutical compositions to be used by appropriate routes (topic or oral), particularly in the form of tablets, capsules, dyes, emulsions, W / O and O / W (creams and gels), liposomes, microcapsules, nanoparticles, aerosols, ointments, and the like, as well as formulations for slow-release implants, used to treat vitiligo.

Owner:ACHE LAB FARM

New rubber riding wheel and fabricating process thereof

ActiveCN101586594ASolve \"oversulfur\", poor surface compactnessSolve problems such as \"flow traces\"Shaft and bearingsParaffin waxRubber material

The invention relates to a new rubber riding wheel and fabricating process thereof. The fabricating process of the invention comprises steps of: 1) first mixing, masticating and thinning natural rubber NR and synthetic rubber SBR on an open mill, controlling plasticity of rubber at 0.44 to 0.45; 2) casting the rubber to a mixer, injecting for 3min to 5min, adding accelerator, octadecoic acid, zinc oxide, antiager, coumarone resin and tert-butyl phenolic resin in sequence, injecting for 4min to 6min, adding carbon black, machine oil and paraffin, after pressurizing load, adding sulfur within 60s to mix, discharging immediately and making pieces, cooling after turning evenly on a flat-bed machine, controlling mixing plasticity of rubber at 0.4 to 0.5; 3) casting mixed rubber material to the open mill to warm, then coiling or making pieces, supplying the same to a squeezer to squeeze, distributing pieces and weighing the rubber material according to product requirements for spare use; 4) packing weighed rubber material to a die cavity to enter a flat vulcanizing machine; pressurizing to vulcanize by using low temperature in grads gradually; 5) completing vulcanization.

Owner:JIHUA 3517 RUBBER PROD

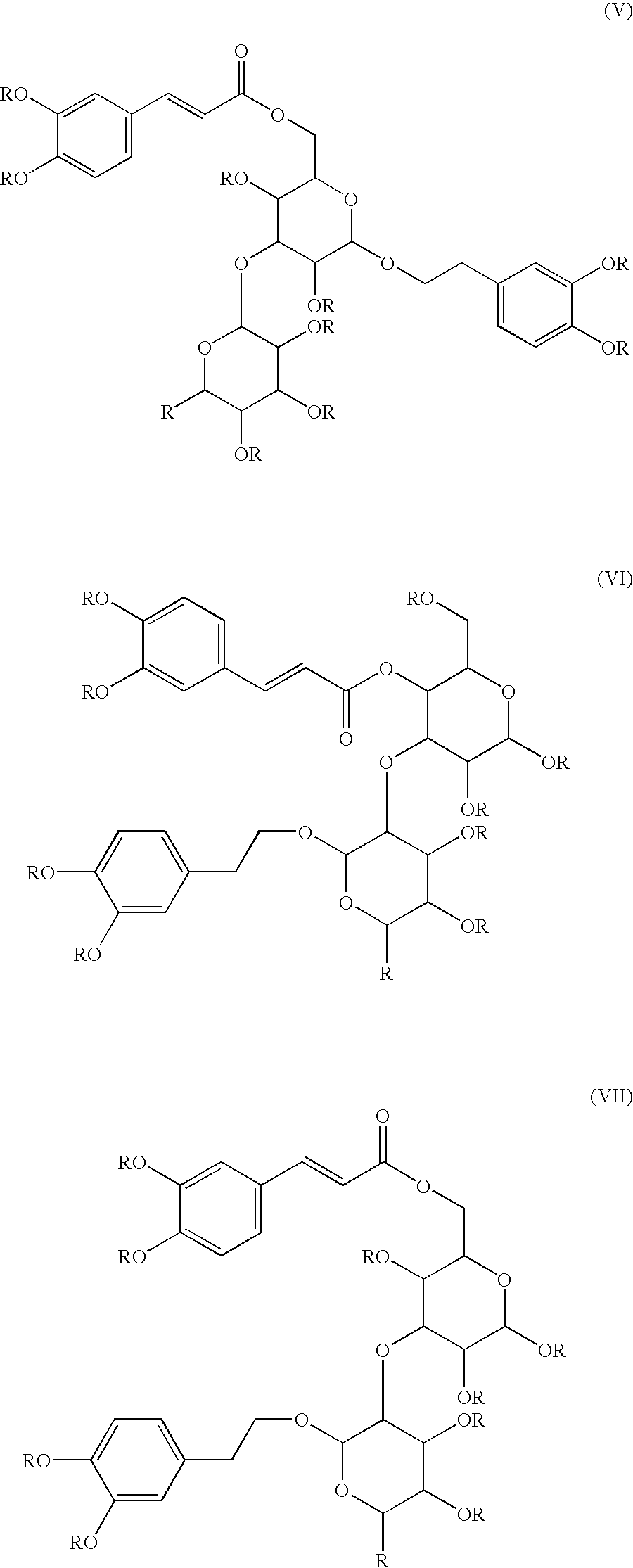

Superior-performance blast furnace connector material

InactiveCN106747514AExcellent physical and chemical propertiesImprove corrosion resistanceAntioxidantFire resistance

The invention discloses a superior-performance blast furnace connector material. The superior-performance blast furnace connector material is prepared by combining, by weight, 20-50 parts of brown corundum powder, 10-15 parts of silicon carbide, 5-10 parts of reactive alumina fine powder, 1-4 parts of silica powder, 1-3 parts of graphite, 2-5 parts of nanometer carbon powder, 15-30 parts of kaolin, 1-5 parts of calcium aluminate cement, 1-3 parts of a water reducer and 1-3 parts of an antioxidant with extra added 5-8 parts of a no-water and high-temperature binding agent. By the arrangement that brown corundum is added to the connector material in ingredient, the brown corundum has the advantages of good crystallization, strong liquidity, low linear expansion coefficient, corrosion resistance and no crack, and good physical and chemical properties and corrosion resistance and safety performance of the connector material are achieved; the kaolin added to the connector material has good plasticity and fire resistance, so that plasticity of the connector material is enhanced.

Owner:XINCHANG JINYU DECORATION CO LTD

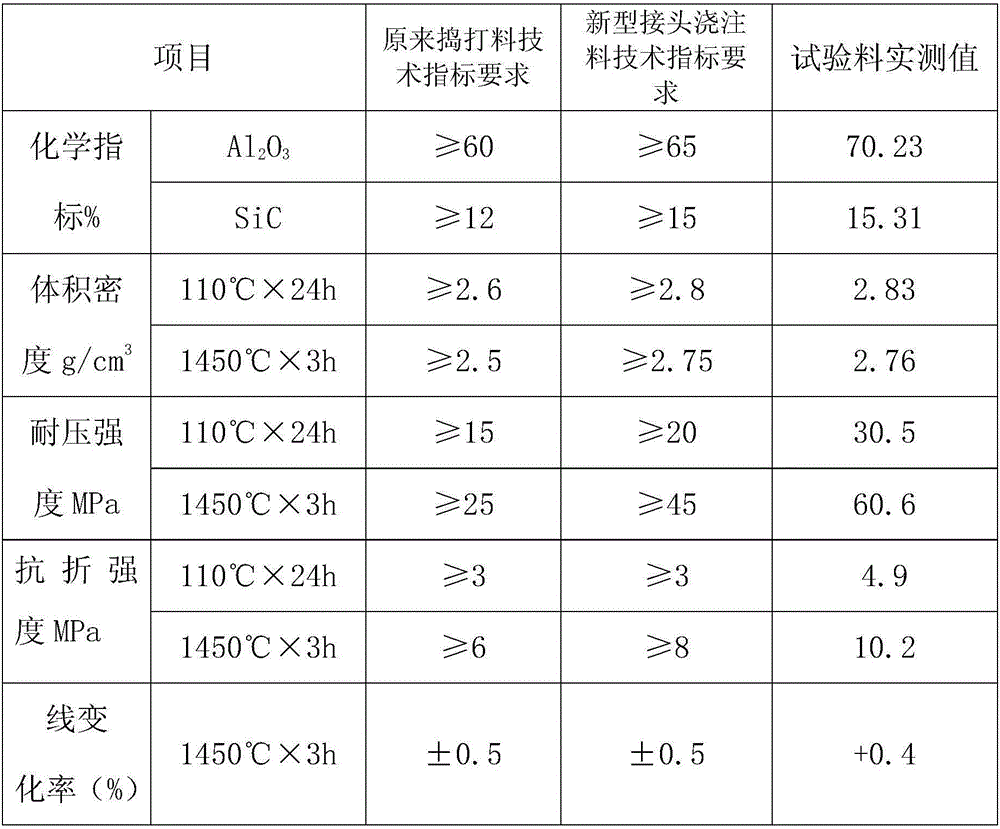

Elevator shaft tool type operation steel platform and manufacturing method thereof

InactiveCN105544955AThe principle is simpleImprove securityScaffold accessoriesBuilding support scaffoldsSheet steelEngineering

The invention discloses an elevator shaft tool type operation steel platform and a manufacturing method thereof; the method uses a riffled plate and reinforced section bars arranged on the bottom of the riffled plate to form a work table of the platform; the bottom of the riffled plate is provided with at least two sets of right angle tripods used for supporting the riffled plate; one vertical edge of the right angle tripod is tightly attached to the bottom of the riffled plate, and the bottom of the other vertical edge is provided with a clamp with a L-shape section; in usage, the clamp is clamped in an elevator shaft well opening, and one side, corresponding to the clamp, of the elevator shaft tool type operation steel platform is tightly attached to a shearing force wall in the elevator shaft, thus completing the installation of the elevator shaft tool type operation steel platform; the elevator shaft tool type operation steel platform is simple in principle and operation, high in safety, can reduce steel pipe erection and dismounting material and labor invest, can reduce later maintenance in the elevator shaft well, can reduce safety problems caused by steel pipe erection, and thus fast and conveniently providing the elevator shaft inner operation platform.

Owner:CCFED THE FIRST CONSTR & ENG

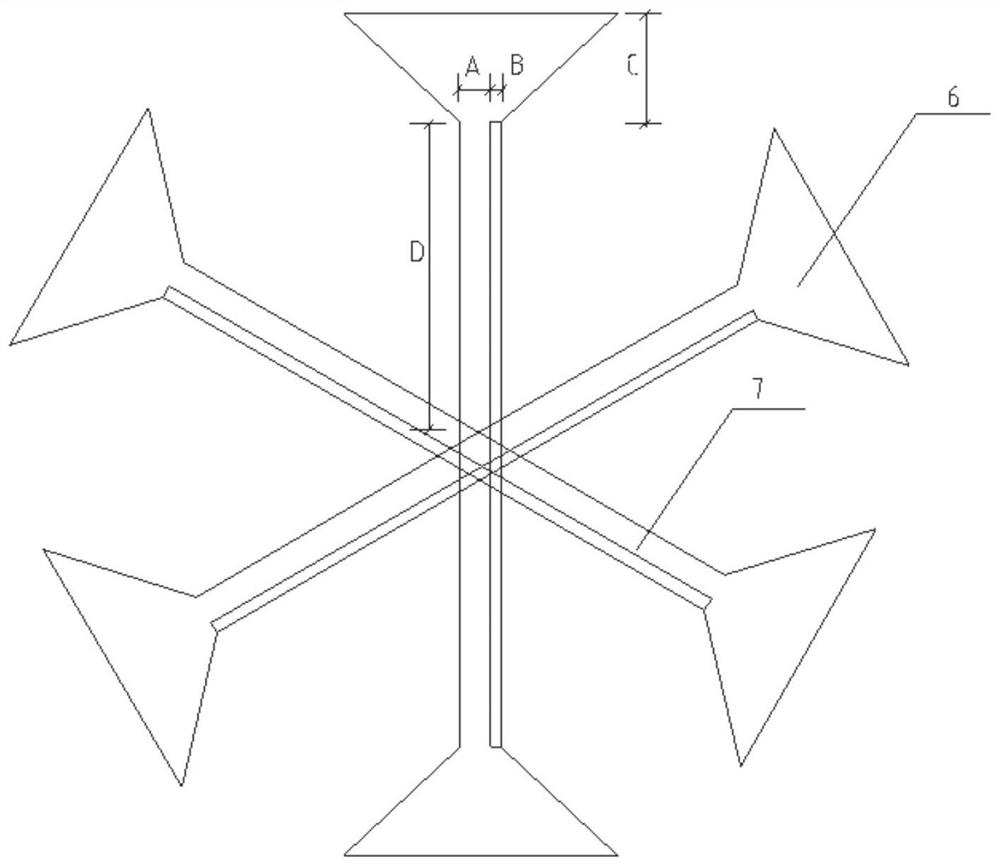

Process for installing and positioning double-rudder sleeve and tail casting in segmented construction stage

PendingCN113148058AAvoid damageReduce patchingWaterborne vesselsStructural engineeringMechanical engineering

The invention discloses a process for installing and positioning a double-rudder sleeve and a tail casting in a segmented construction stage, which aims to provide theoretical support for the scheme on the premise that the overall precision level of the existing ship construction is greatly improved, the tail end surface of the FR8 assembly tail casting is not processed, namely, the tail end surface is fixed, and a small amount of deviation of the center line of a tail shaft can be adjusted by epoxy. According to the scheme, the purpose of segmented division is that the rudder sleeve is installed in place in the segmented construction stage, the rudder sleeve does not need to be hoisted in the later carrying stage, and the trouble of high-altitude operation is avoided; the distance between the tail end face and the central rib positions of the two rudderstocks is determined in the segmented construction stage, and all other works in the later stage do not affect the size, so that the time for positioning and secondary precise control in the later carrying stage is shortened, the corresponding high-altitude operation is reduced, and the construction safety is improved; paint damage and repair are reduced, multiple positions in the tail area are narrow in the position space and difficult in construction, and construction safety is greatly improved.

Owner:江苏扬子三井造船有限公司

A culture solution for promoting rapid growth of microorganisms and its application method

ActiveCN106085944BFast growthReduce patchingBacteriaMicroorganism based processesMicroorganismRepair time

The invention discloses a culture solution for accelerating rapid growth of microorganisms and a using method thereof. Bacillus pasteurii is inoculated into a culture medium containing various nutrient substances, constant temperature shaking culture is performed at 25-30 DEG C, the initial PH value is controlled to be about 6, culture is performed for 12-24 h, part of bacteria solution is taken out every two days in the culture process, a spectrophotometer is utilized to measure the absorbance OD600, a strain growth curve is obtained, strains enter into a stable stage in about 18 h according to observation, and compared with research by predecessors, the strain growth speed is obviously accelerated. The culture solution for accelerating rapid growth of the microorganisms and the using method have the advantages that substances in the culture solution can be fully utilized, and the culture solution is simple in process, high in efficiency, short in used time, clean in environment and low in cost; the efficiency of microbial induction of calcium carbonate is further improved, and the concrete crack repair time can be shortened.

Owner:SOUTHEAST UNIV

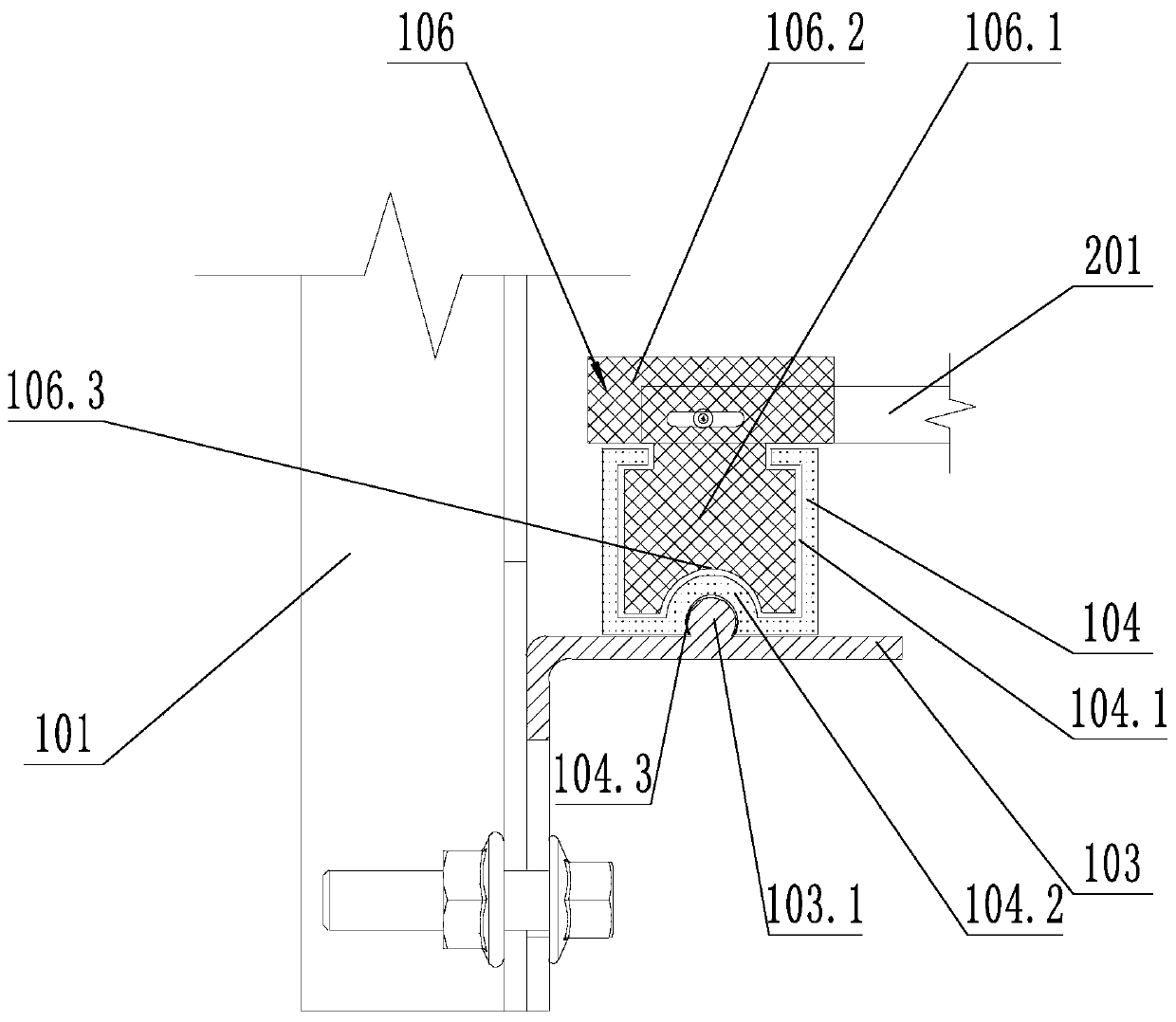

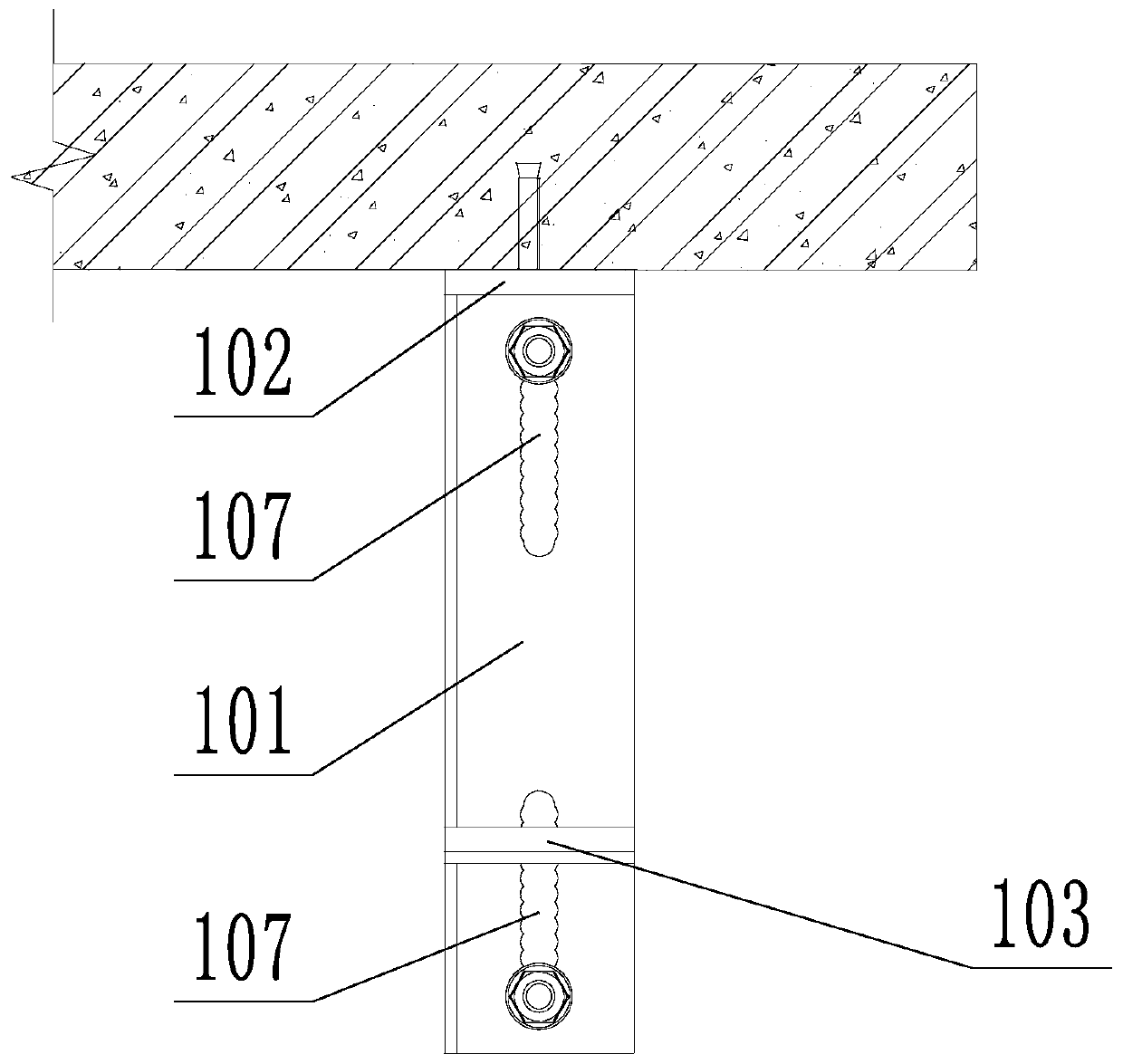

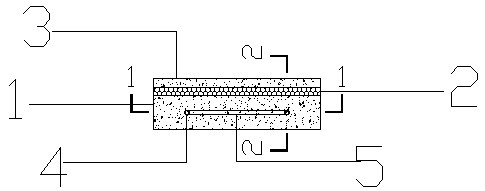

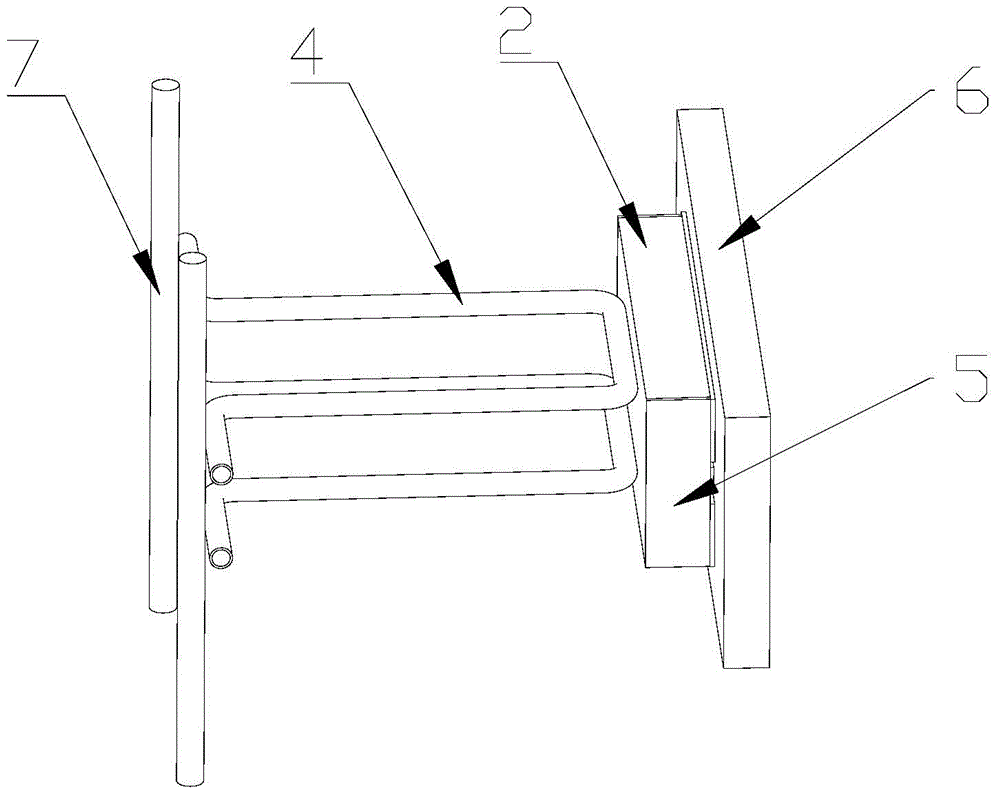

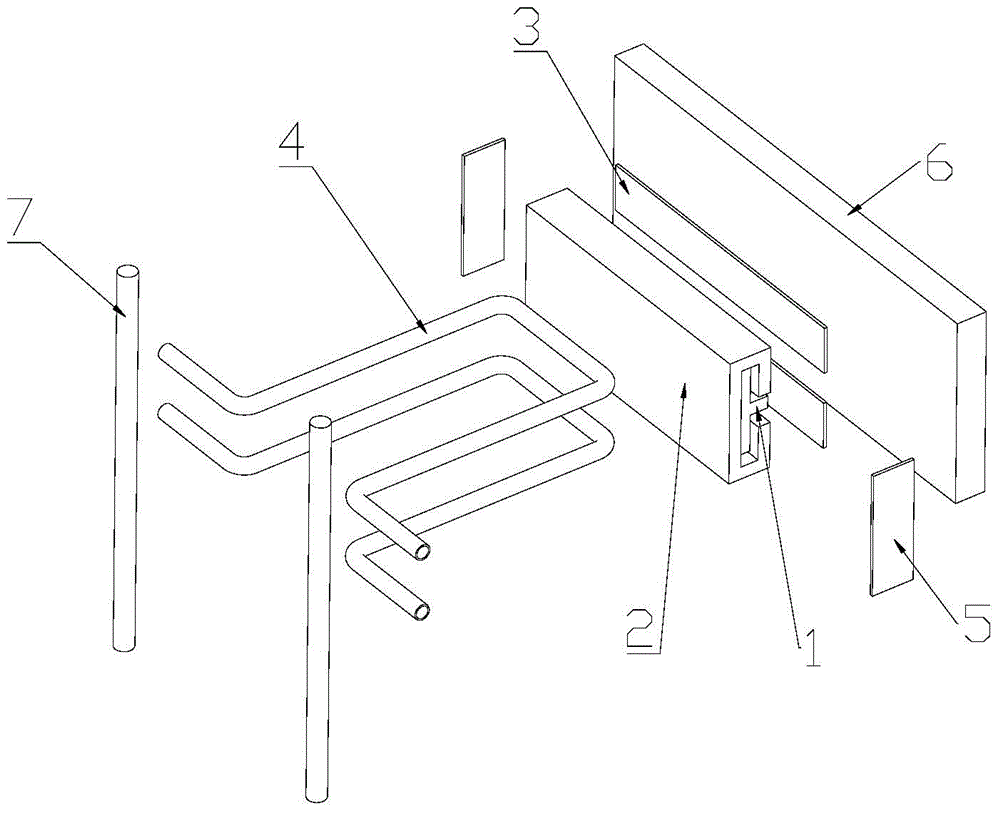

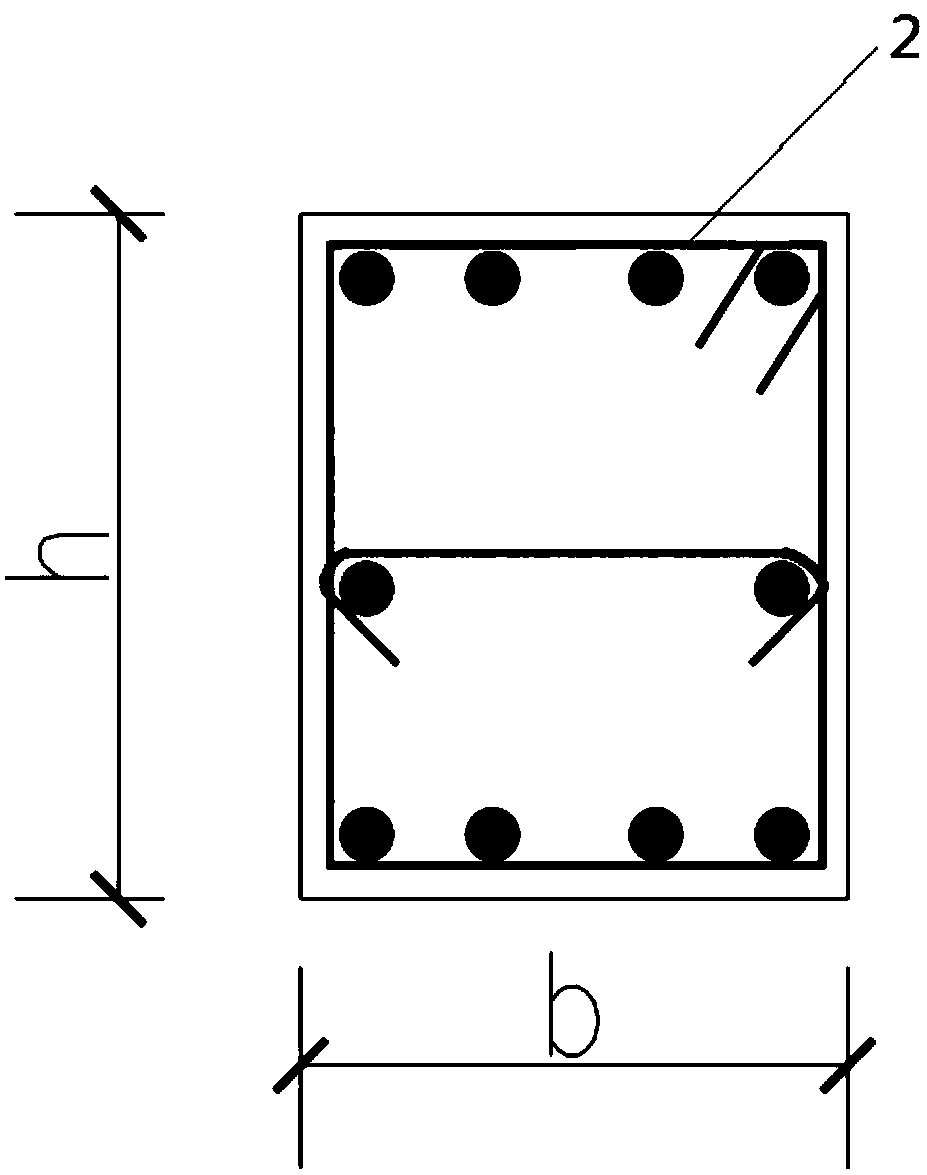

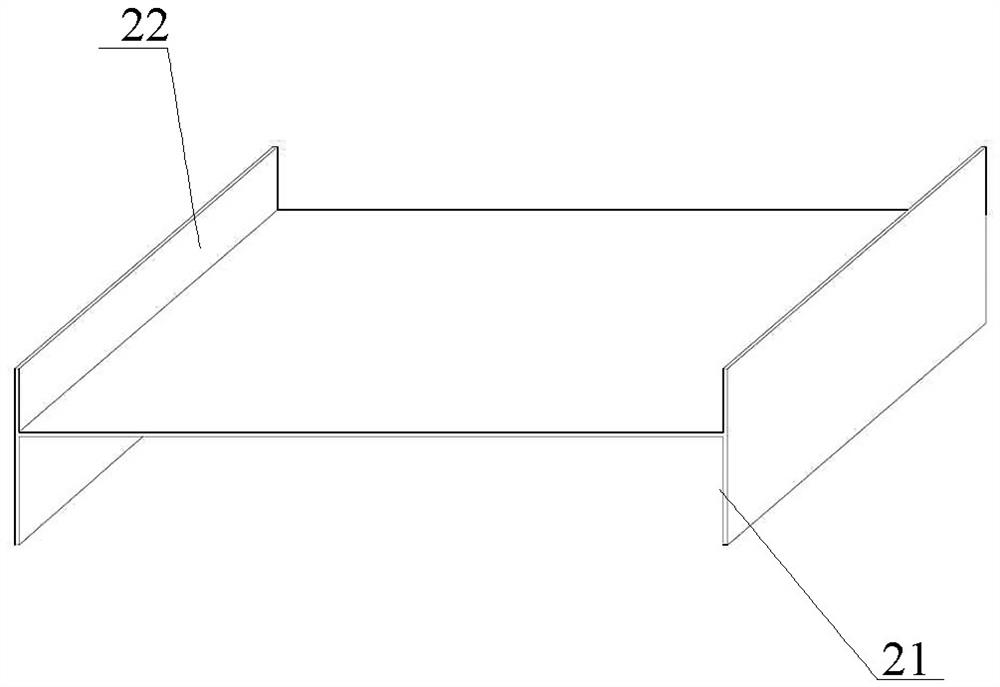

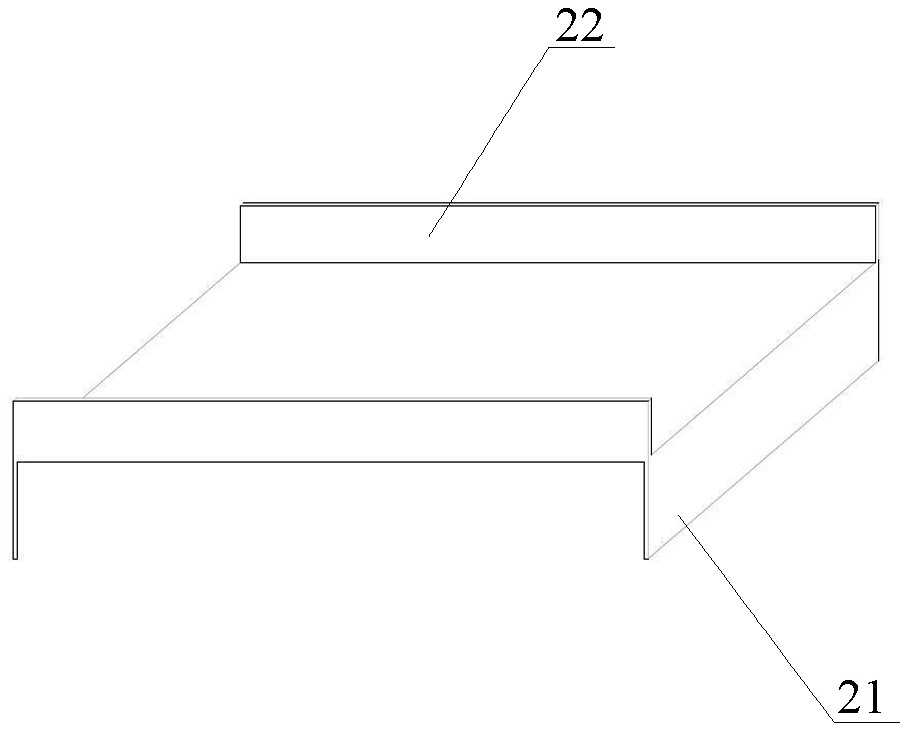

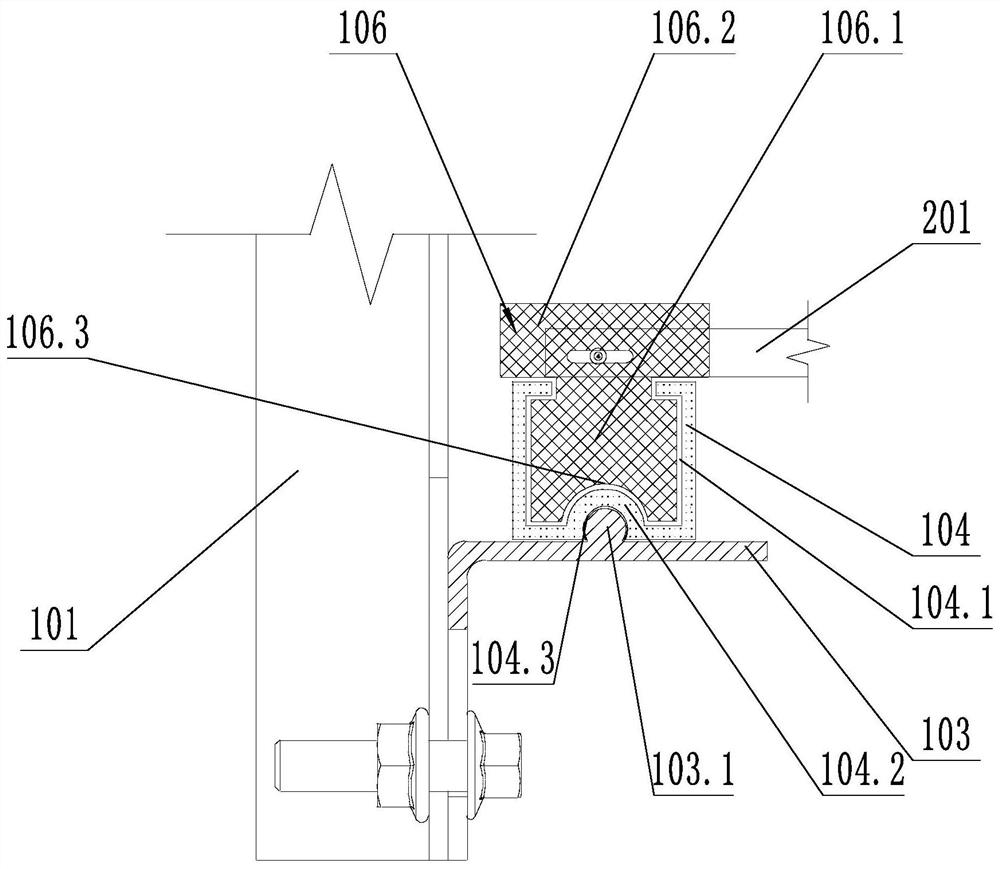

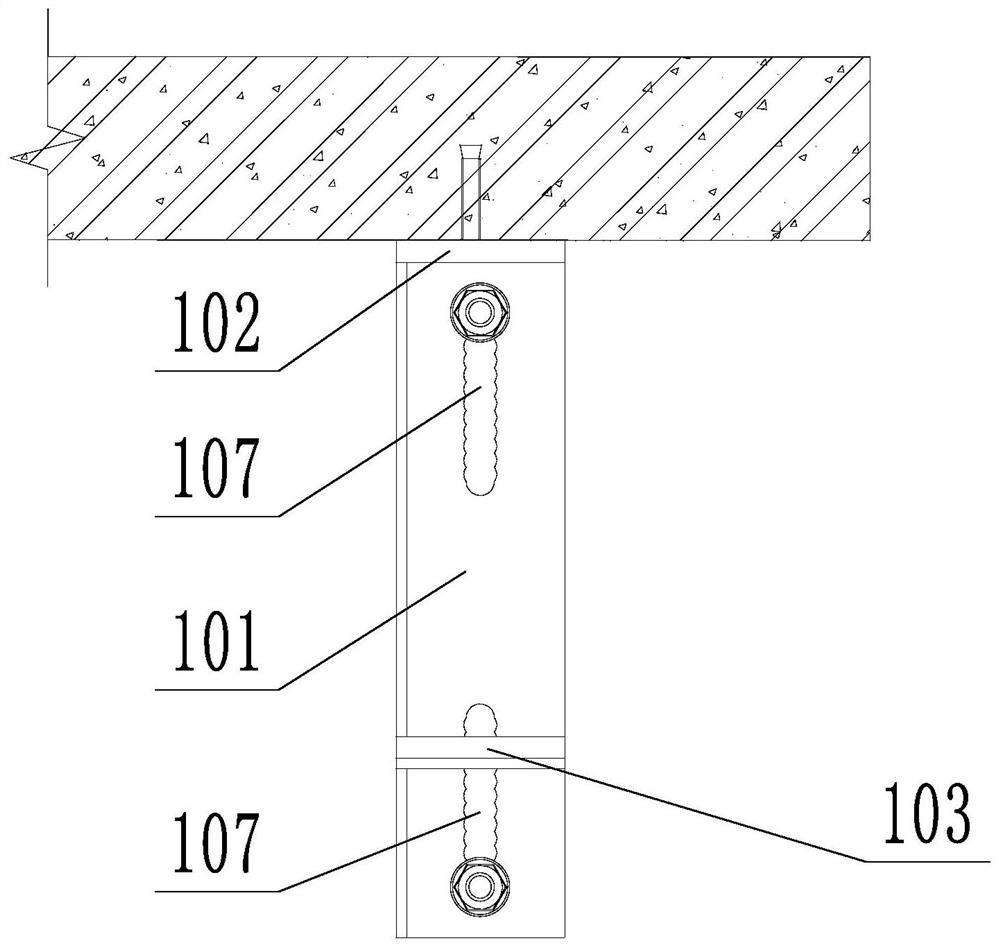

Sliding connection device for construction column and steel column

The invention discloses a sliding connection device for a construction column and a steel column. The sliding connection device comprises a sliding track, a sliding groove, tail end hooked reinforcing bars, sealing plates and rubber pads. The sliding track is of a T-shaped structure. One end of the sliding track is welded to the steel column. The sliding groove is matched with the sliding track. The thickness of the sliding groove is 8 mm. A gap between the inner wall of the sliding groove and the sliding track ranges from 4 mm to 8 mm. Impact on the sliding groove and the steel column is buffered through the rubber pads. The two ends of the sliding groove are sealed through the sealing plates. Concrete is prevented from entering the sliding groove. Each tail end hooked reinforcing bar is a U-shaped reinforcing bar with the two ends bent by 90 degrees. The number of the tail end hooked reinforcing bars is two. The tail end hooked reinforcing bars are welded to the sliding groove. The tail ends of the tail end hooked reinforcing bars are welded to main reinforcement of the construction column. The construction column and the steel column can form a whole and are relatively independent from each other, the situation that the construction column and the steel column are damaged under different deformation conditions is avoided, pouring construction is carried out on the construction column, and the sliding connection device is safe and reliable.

Owner:HEFEI CONSTR ENG GRP

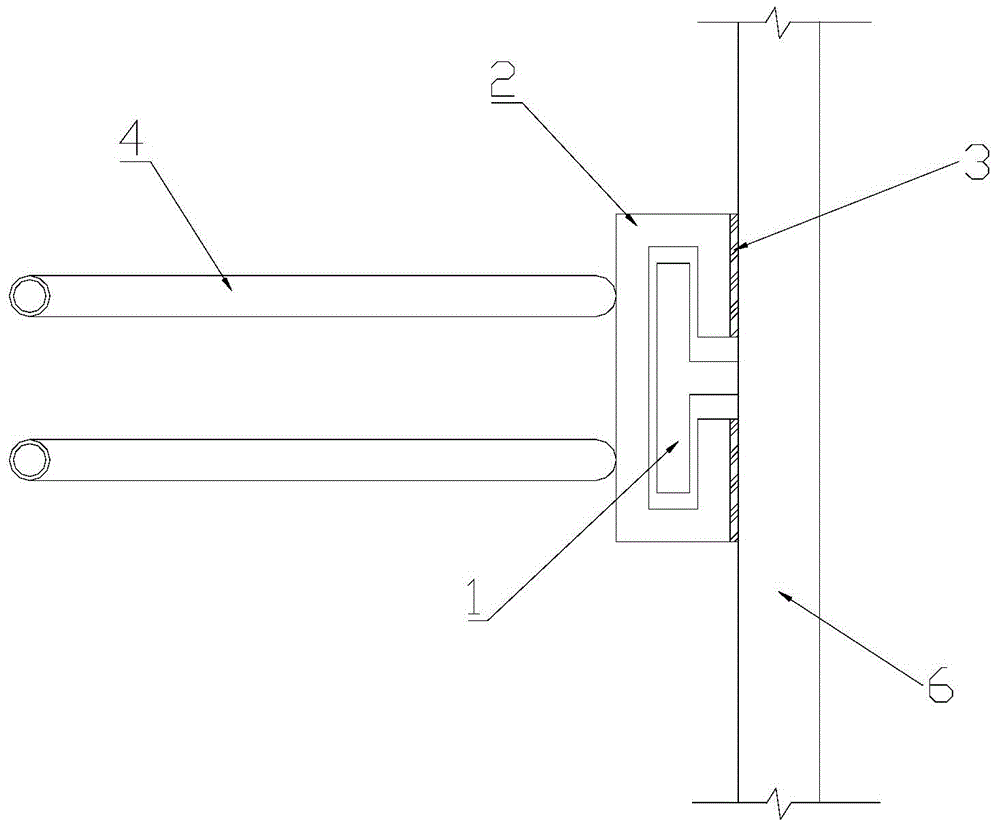

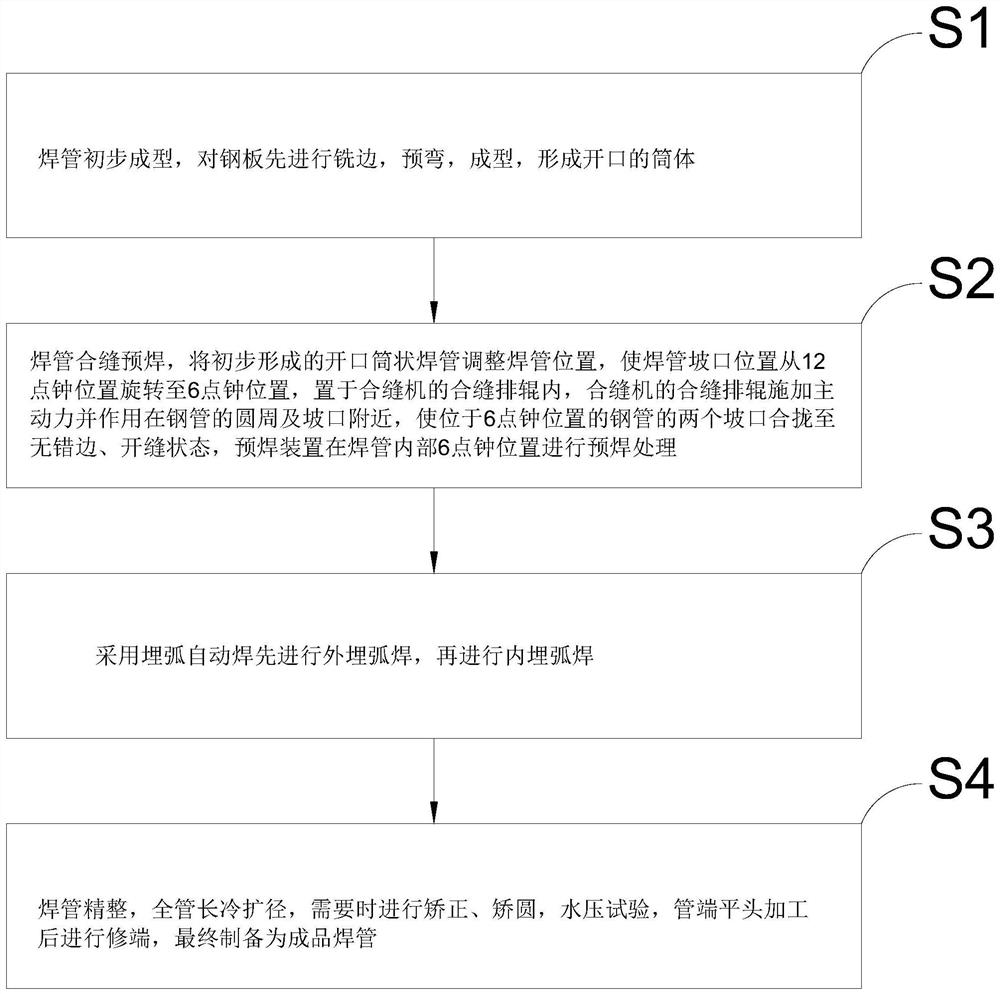

Method for manufacturing longitudinal submerged arc welded pipe

The invention provides a method for manufacturing a longitudinal submerged arc welded pipe, which comprises the following steps of: adjusting the position of a welded pipe during pre-welding, rotating the groove position of the welded pipe from 12 o'clock position to 6 o'clock position, correspondingly rotating nine groups of row rollers of a joint closing machine by 180 degrees, rotating a 9 # roller from 12 o'clock position to 6 o'clock position, and rotating a 9 # roller from 12 o'clock position to 6 o'clock position by 180 degrees; a joint closing row roller of the joint closing machine applies main power and acts on the circumference of the steel pipe and the vicinity of a groove, and pre-welding treatment is carried out. The pre-welding device is changed from the 12 o'clock position outside the welded pipe to the 6 o'clock position inside the welded pipe. Therefore, the problems that in the prior art, the welded pipe is tracked and then pre-welded after coming out of the row roller of the sewing machine, the welded pipe is pre-welded after being slotted to different degrees, misalignment and weld beading are prone to being generated, and tracking of an inner welding cutter wheel is affected by the weld beading are solved. In addition, the submerged-arc welding of the welded pipe adopts a manner that outer submerged-arc welding is firstly carried out and then inner submerged-arc welding is carried out by submerged-arc automatic welding, so that the inner welding quality is improved, the repair of an inner welding seam is reduced, the qualification rate is greatly improved, and the repair cost is also reduced.

Owner:HUNAN SHENGLI XIANGGANG STEEL PIPE CO LTD

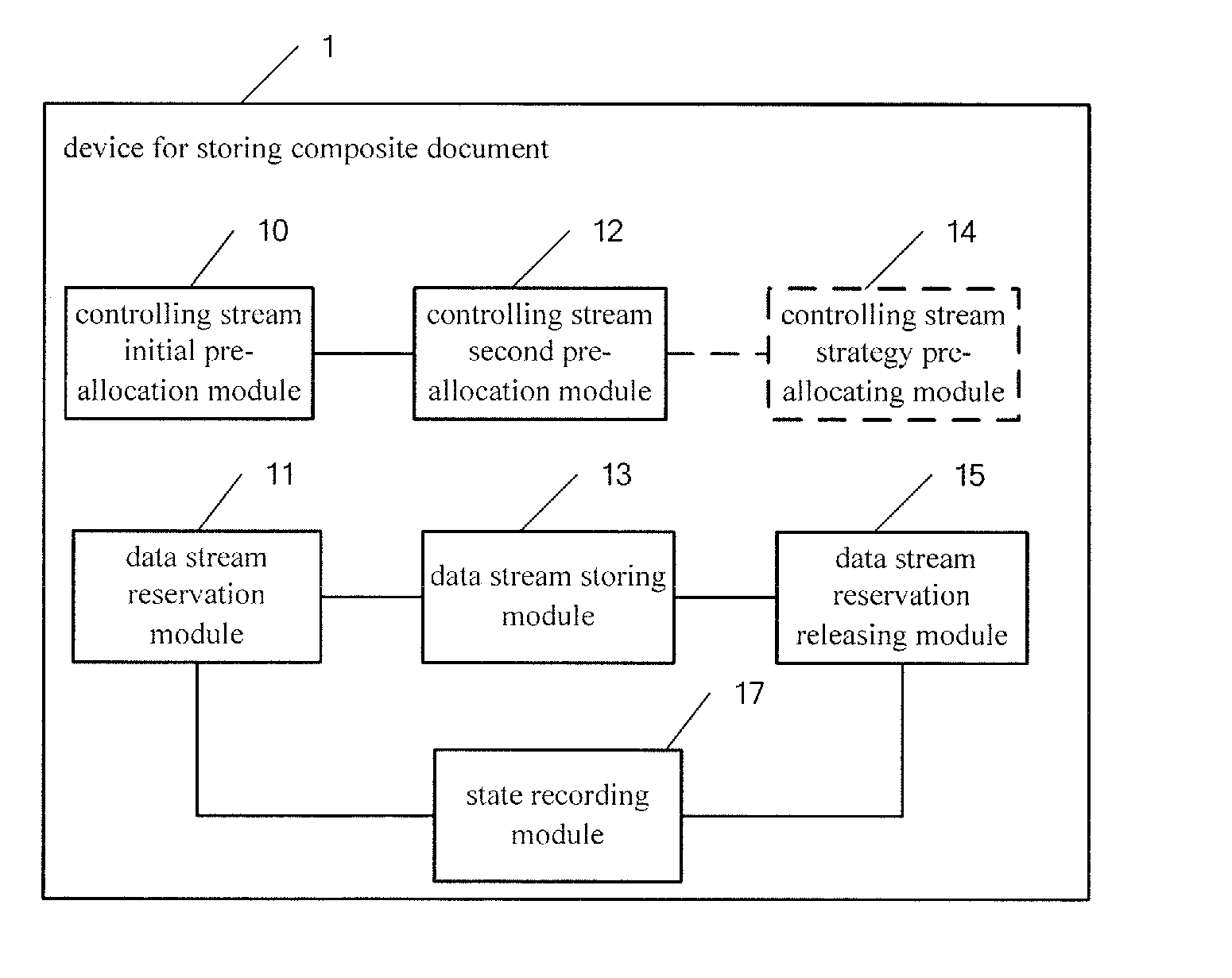

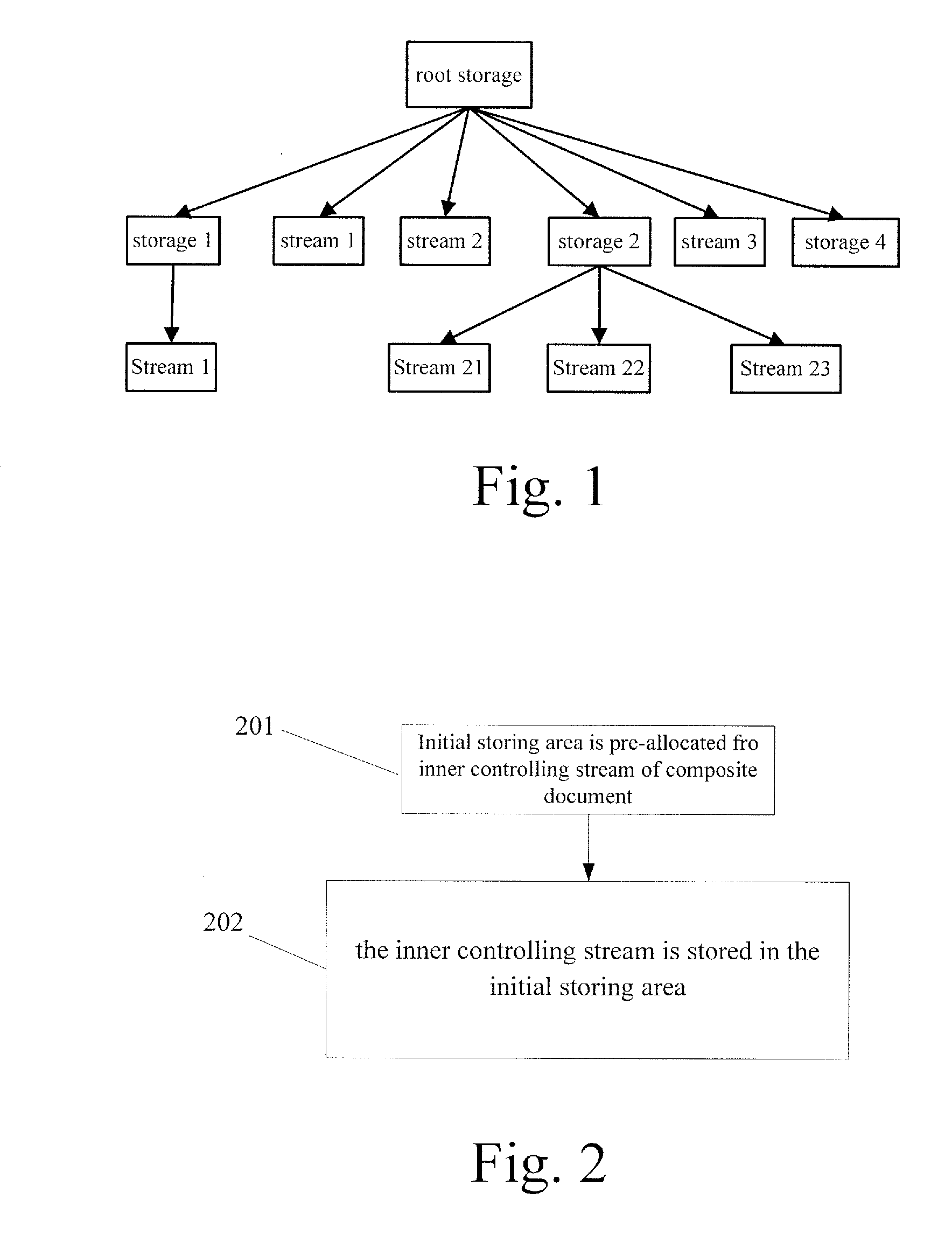

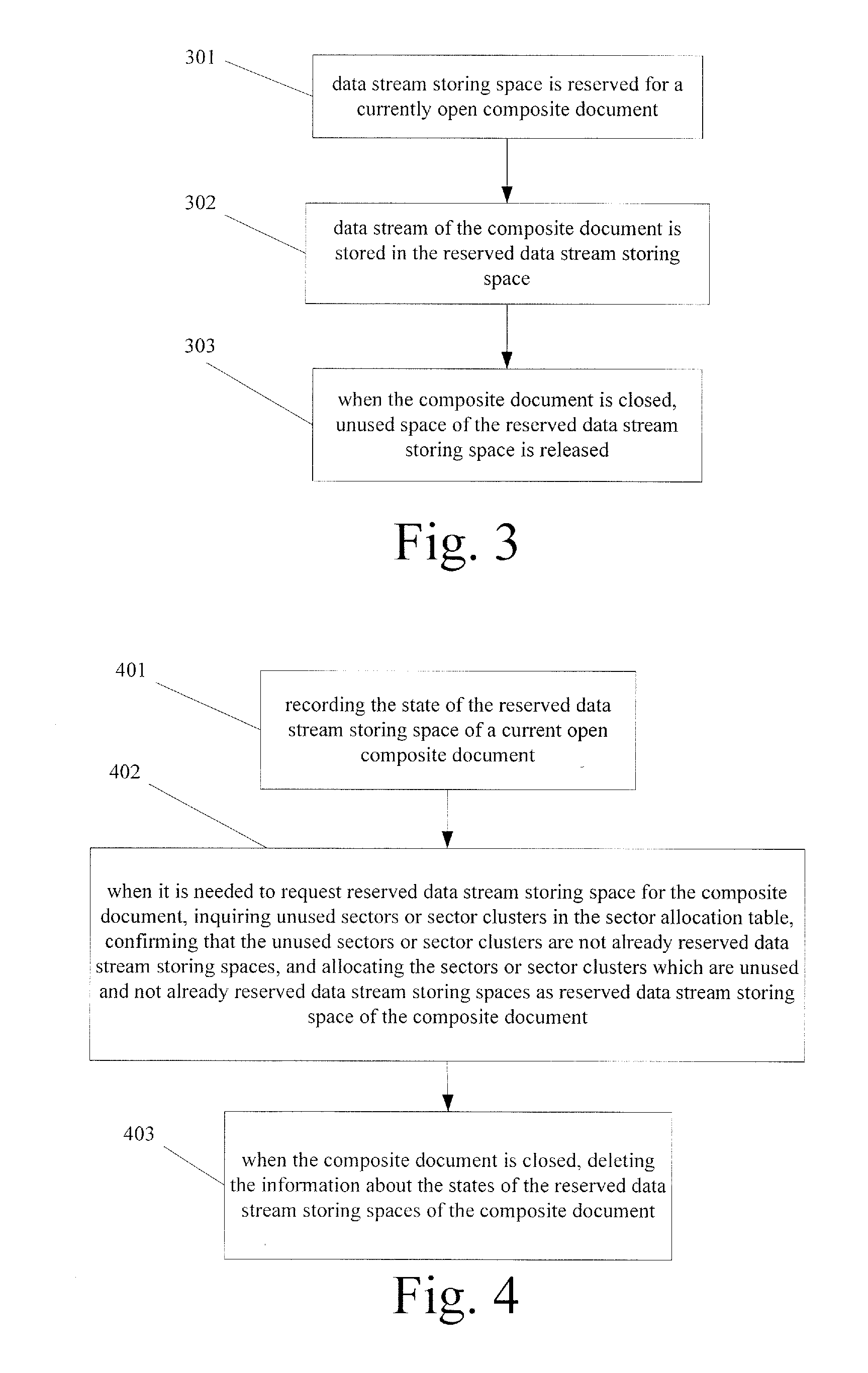

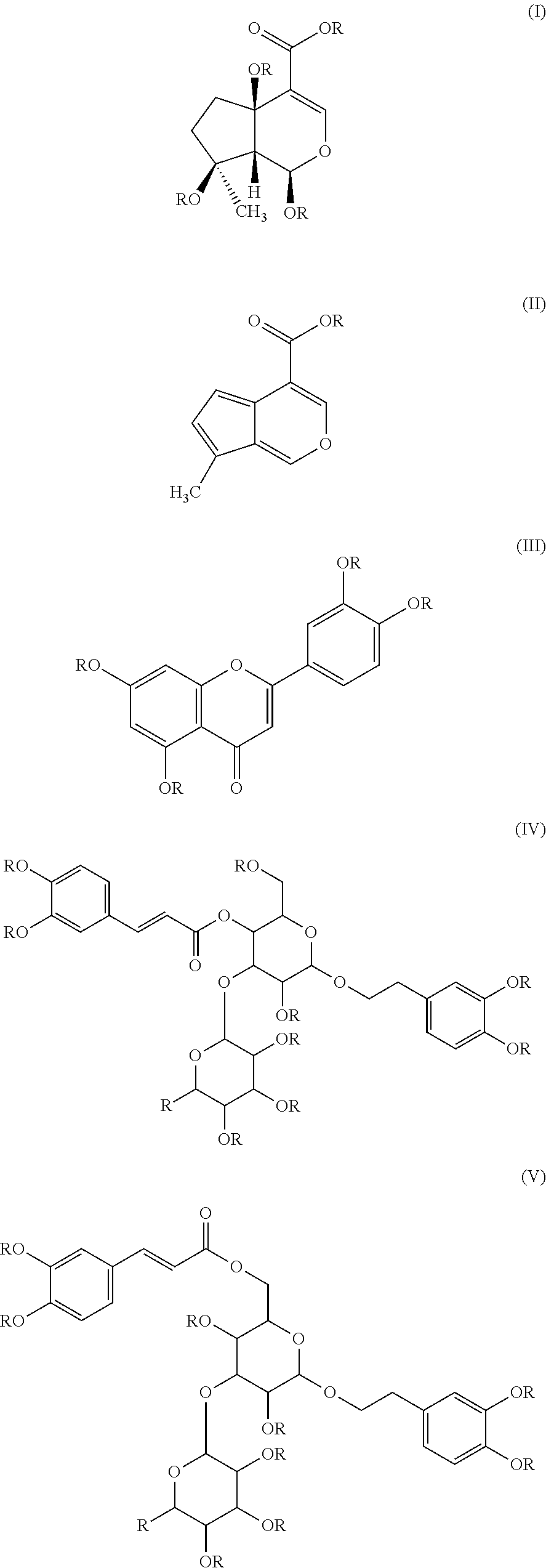

Method and device for storing and reading/writing composite document

ActiveUS20120272034A1Improve reading and writing efficiencyIncrease probabilityMemory adressing/allocation/relocationSpecial data processing applicationsData streamOperating system

A method and device for storing and reading / writing composite document are disclosed. The method includes: an initial storing area is pre-allocated for an inner controlling stream of the composite document and the initial storing area is continuous sectors or sector clusters; the inner controlling stream is stored in the initial storing area. The patches of a user data stream and the inner controlling stream in the composite document are reduced using the method or device. Correspondingly, pre-allocating storing area makes the probability of continuously storing the user data stream and the inner controlling stream in the composite document increased. The I / O can be optimized by introducing a strategy of reading cache and writing in a batch size, which can improve the efficiency of reading and writing.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Pharmaceutical composition on the basis of stachytarpheta sp., a process for obtaining the same and its use for treating vitiligo

ActiveUS20180071356A1Increasing catecholamineReduce patchingOrganic active ingredientsImmunological disordersEmulsionNanoparticle

This invention generally refers to the process to obtain a compound and a standard pharmaceutical product from one or more parts of plants of the Stachytarpheta (Verbenaceae family) species, as well as roots, stems, barks, and leaves of plants in the form of extracts or enriched fractions, or pure isolated compounds or compounds obtained from synthesis, used alone or mixed with other natural or synthetic products, in different ratios, in order to integrate pharmaceutical compositions to be used by appropriate routes (topic or oral), particularly in the form of tablets, capsules, dyes, emulsions, W / O and 0 / W (creams and gels), liposomes, microcapsules, nanoparticles, aerosols, ointments, and the like, as well as formulations for slow-release implants, used to treat vitiligo.

Owner:ACHE LAB FARM

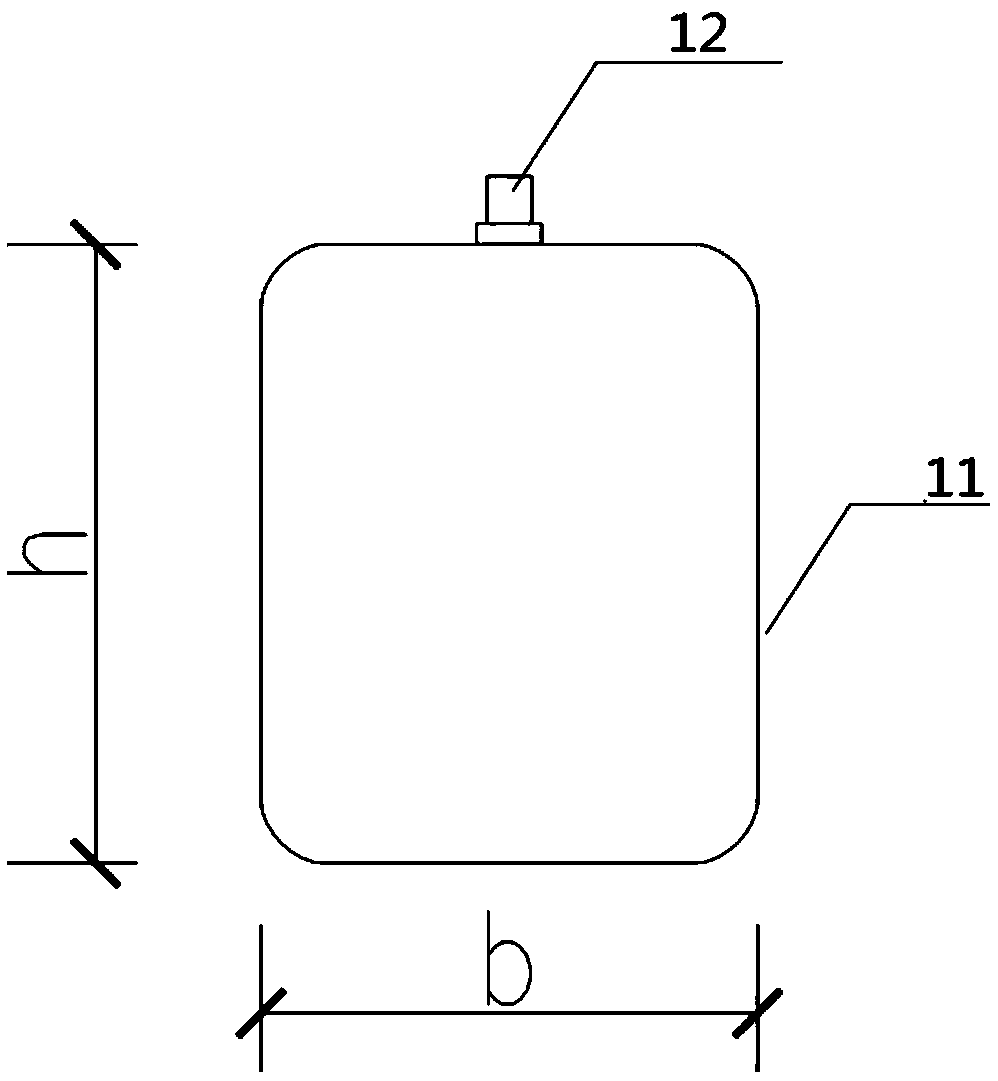

Water closing airbag capable of isolating high and low grade concrete and mounting method of water closing airbag

PendingCN109555309AEffective isolationInhibition of overfillingForms/shuttering/falseworksLower gradeLow graded

The invention provides a water closing airbag capable of isolating high and low grade concrete and a mounting method of the water closing airbag. The water closing airbag can be placed between the to-be-isolated high and low grade concrete, due to the fact that the surface of the inflated water closing airbag has certain softness, a gap between a steel bar and a protective layer can be filled, thehigh and low grade concrete can be effectively isolated, and thus convenience and reliability are achieved. The water closing airbag is easy to operate, field manufacturing is easy, and the field operation difficulty of workers is lowered; the common quality problem of appearance color difference of the high and low grade concrete is solved, repair in the later stage is reduced, and the construction quality is improved; and the phenomenon of super pouring of the high grade concrete is effectively inhibited, and waste of materials is greatly reduced.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

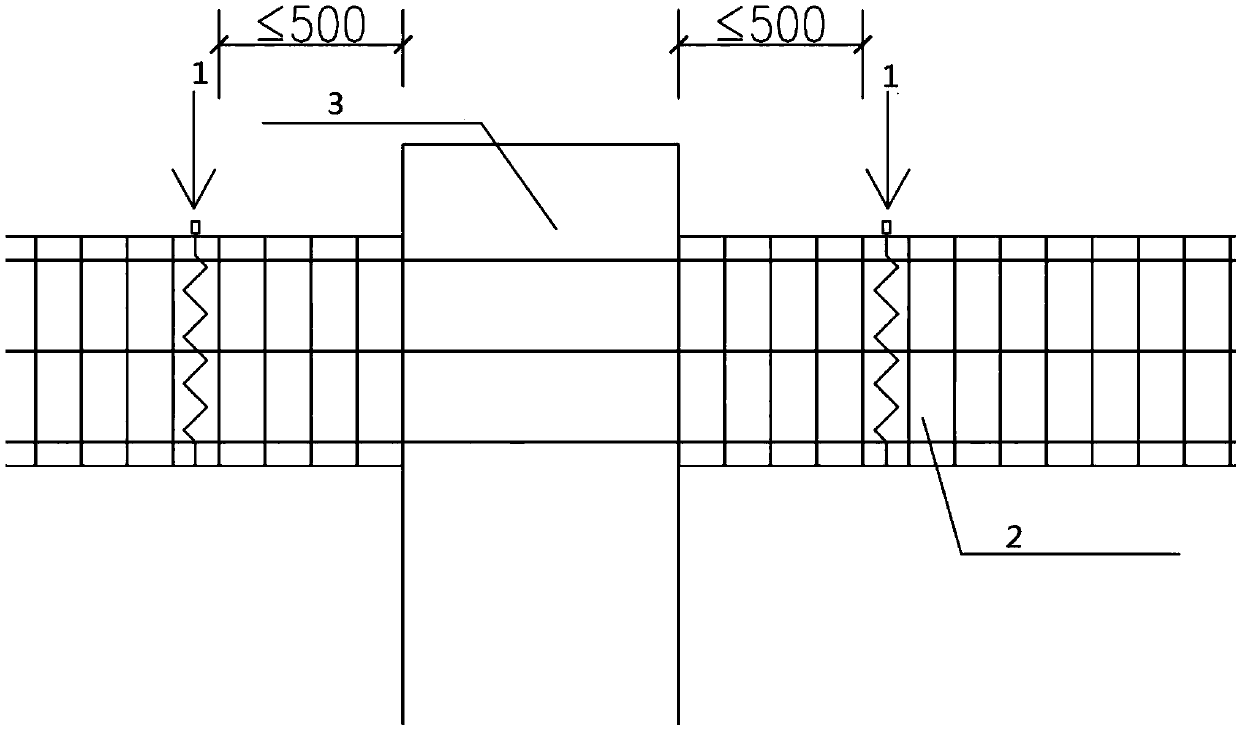

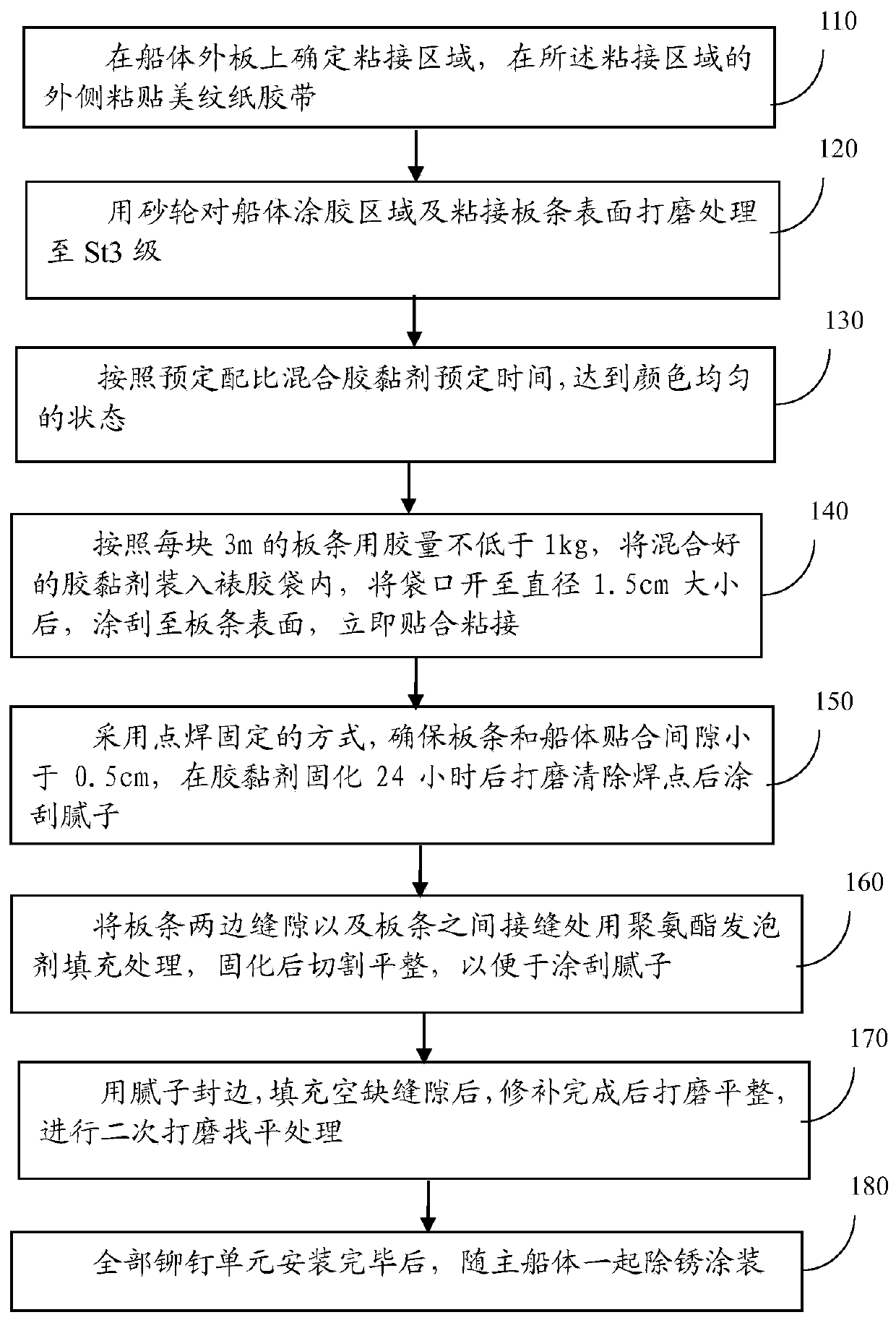

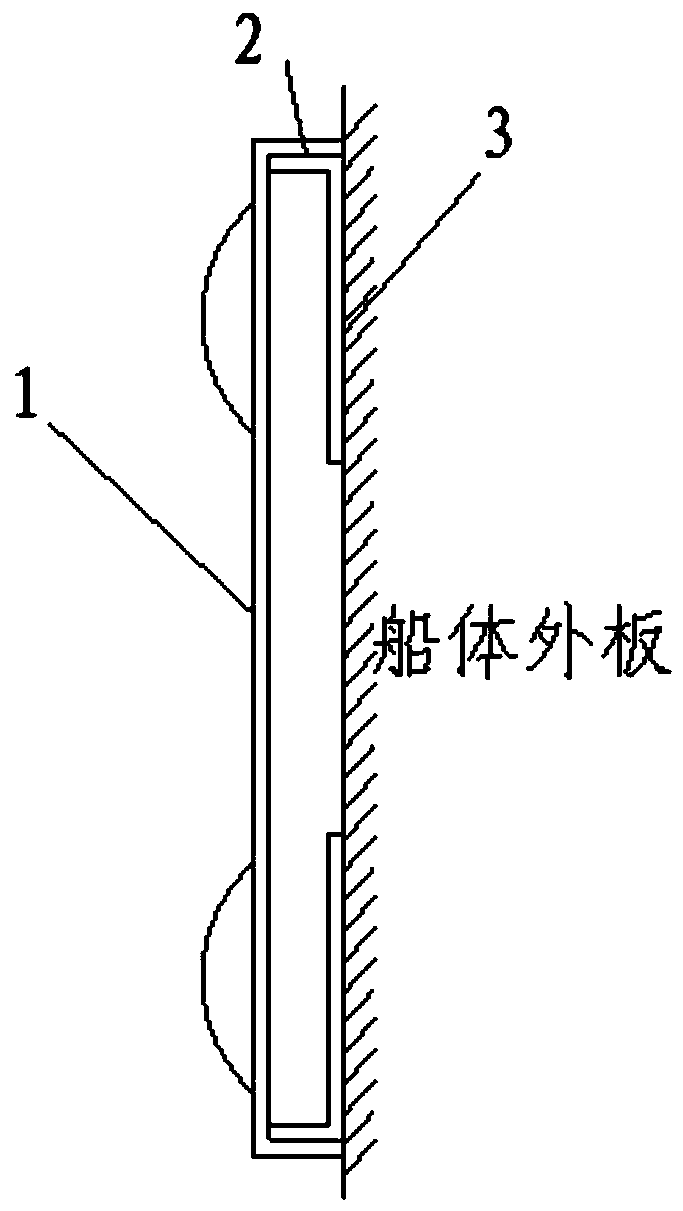

A method of installing antique rivets

ActiveCN108516048BImprove installation accuracyReduce patchingWaterborne vesselsAdhesive beltMasking tape

The invention discloses a method for installing an antique rivet. The method comprises: determining a bonding area on the outer panel of a ship, pasting a masking tape on the outside of the bonding area; Grind the surface of the connecting slats to St3 level; mix the adhesive according to the predetermined ratio for a predetermined time to achieve a uniform color; use no less than 1kg of glue for each 3m slat, and pack the mixed adhesive Put it into a mounting bag, open the mouth of the bag to a diameter of 1.5cm, and then apply and scrape it onto the surface of the slats; fix it by spot welding; fill the gaps on both sides of the slats and the seams between the slats with polyurethane foaming agent ; Seal the edge with putty; After all the rivet units are installed, derust and paint along with the main hull. It achieves the technical effects of no large-area welding of the outer plate of the hull, no damage to the internal coating, high installation accuracy, reduced corrosion of the hull and repair of paint, reduced labor intensity, improved production efficiency, and shortened the construction period.

Owner:WUCHANG SHIPBUILDING IND

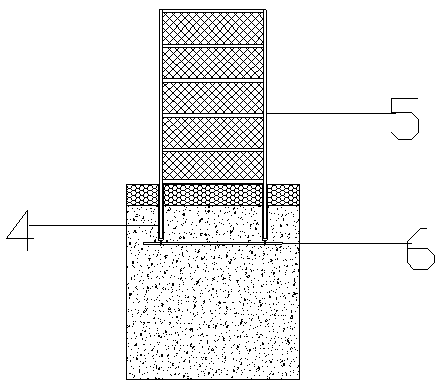

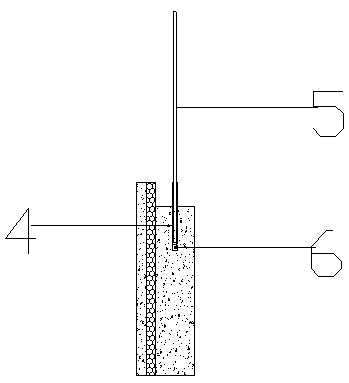

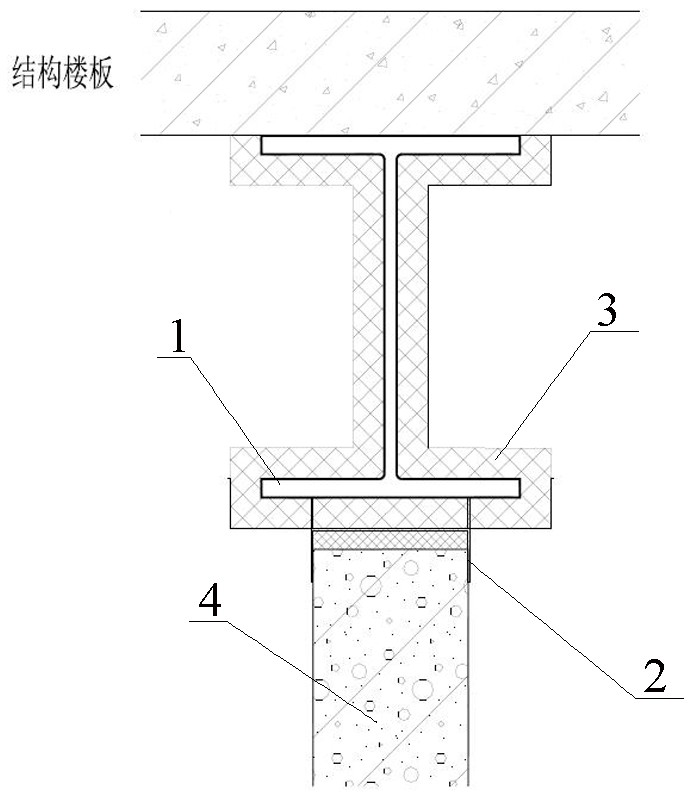

Waterproof method and waterproof structure for pile foundation underpinning underground storey-adding basement

ActiveCN113898015APackage arrivesSolve the leakProtective foundationBasementArchitectural engineering

The invention provides a waterproof method and a waterproof structure for a pile foundation underpinning underground storey-adding basement, and relates to the technical field of underground storey-adding. The pile foundation underpinning underground storey-adding basement aims to solve the problem that the waterproof structure of the basement after underground storey-adding at present is easy to lose efficacy. The waterproof structure is arranged at the bottom of a pile hole in advance, an underpinning pile body is poured under the wrapping action of the waterproof structure, after a foundation pit is excavated, part of the waterproof structure is peeled off to be in lap joint with a waterproof layer in the foundation pit into a whole, the waterproof layer of the basement structure is integrally wrapped, underground water is effectively isolated, and the leakage problem is solved.

Owner:SHANDONG JIANZHU UNIV +2

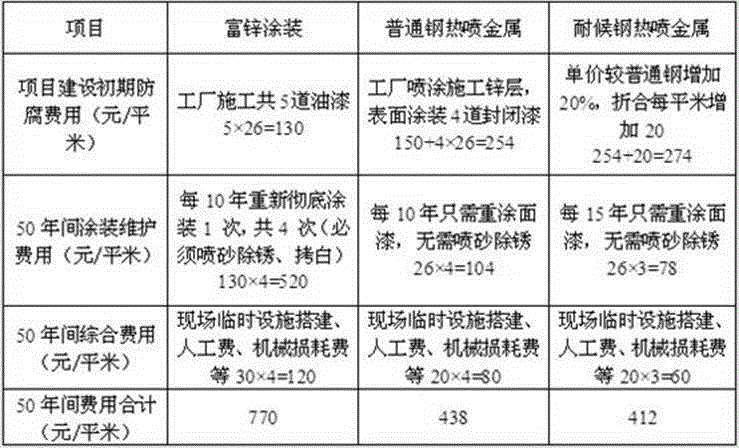

Corrosion protection method for cable tray of cross-sea bridge in high salt-fog region

InactiveCN104104038AReduce patchingReduce repainting timesElectrical apparatusWeather resistanceBrown iron oxide

The invention specifically relates to a corrosion protection method for a cable tray of a cross-sea bridge in a high salt-fog region. The corrosion protection method includes firstly selecting Q355GNH weathering resistant steel to replace normal low alloy steel as a principal material of the tray, wherein the atmospheric corrosion resistant property of the weathering resistant steel is 4 to 8 times that of the ordinary steel, and the coating property of the weathering resistant steel is 2 to 10 times that of the ordinary steel; selecting zinc-aluminium alloy with the volume ratio of 1: 1 as thermal spraying metal and covering epoxy micaceous iron oxide intermediate paint and fluorocarbon finish paint on a metal coating, wherein the epoxy micaceous iron oxide intermediate paint and the fluorocarbon finish paint have excellent performances of corrosion resistance, no maintenance, self cleaning, high adhesiveness, and ultra-long weather resistance; using a Q235 hot-dip galvanized steel grating plate as a grating plate, wherein the Q235 hot-dip galvanized steel grating plate is convenient to install and detach; using A4-70 stainless steel bolts in consideration of the importance of the bolts on a bridge structure and the inadaptation of a corrosion protection system of the principle material to friction that the principle material needs to bear, wherein the stainless steel bolts are good in resistance to salt-fog corrosion. The corrosion protection method is capable of furthest reducing times for repairing or repainting an erosion resistant coating of the cable tray in the high salt-fog region environment, reducing daily maintenance difficulties and investments, and achieving the purpose of minimizing full life cycle costs of the cable tray.

Owner:STATE GRID CORP OF CHINA +3

New rubber riding wheel and fabricating process thereof

ActiveCN101586594BSolve the problem of wear and tearAvoid wastingShaft and bearingsRubber materialVulcanization

Owner:JIHUA 3517 RUBBER PROD

ALC batten construction joint and construction method

The invention provides an ALC batten construction joint and a construction method. The ALC batten construction joint comprises a steel beam and a fixing clamp fixed to the bottom of the steel beam; the steel beam is coated with thick fireproof paint with the thickness ranging from 28mm to 30mm; a glass fiber net is laid in the thick fireproof paint and below the bottom of the beam; the fixing clamp is of an integrally-formed structure and comprises a bottom inverted-U-shaped clamp and at least two welding plates arranged on the top face of the bottom inverted-U-shaped clamp in parallel; the plane where the welding plates are located is perpendicular to or parallel to the plane where the vertical portion of the inverted-U-shaped clamp is located; the welding plates penetrate the thick fireproof paint to be fixed to the bottom face of the steel beam in a spot welding manner; and the height of the welding plates adapts to the thickness of the thick fireproof paint. The ALC batten construction joint has the beneficial effects of being safe, applicable and the like, has very good popularization and practical value and can generate good economic benefits after being widely applied and popularized.

Owner:BEIJING CONSTR ENG GRP CO LTD

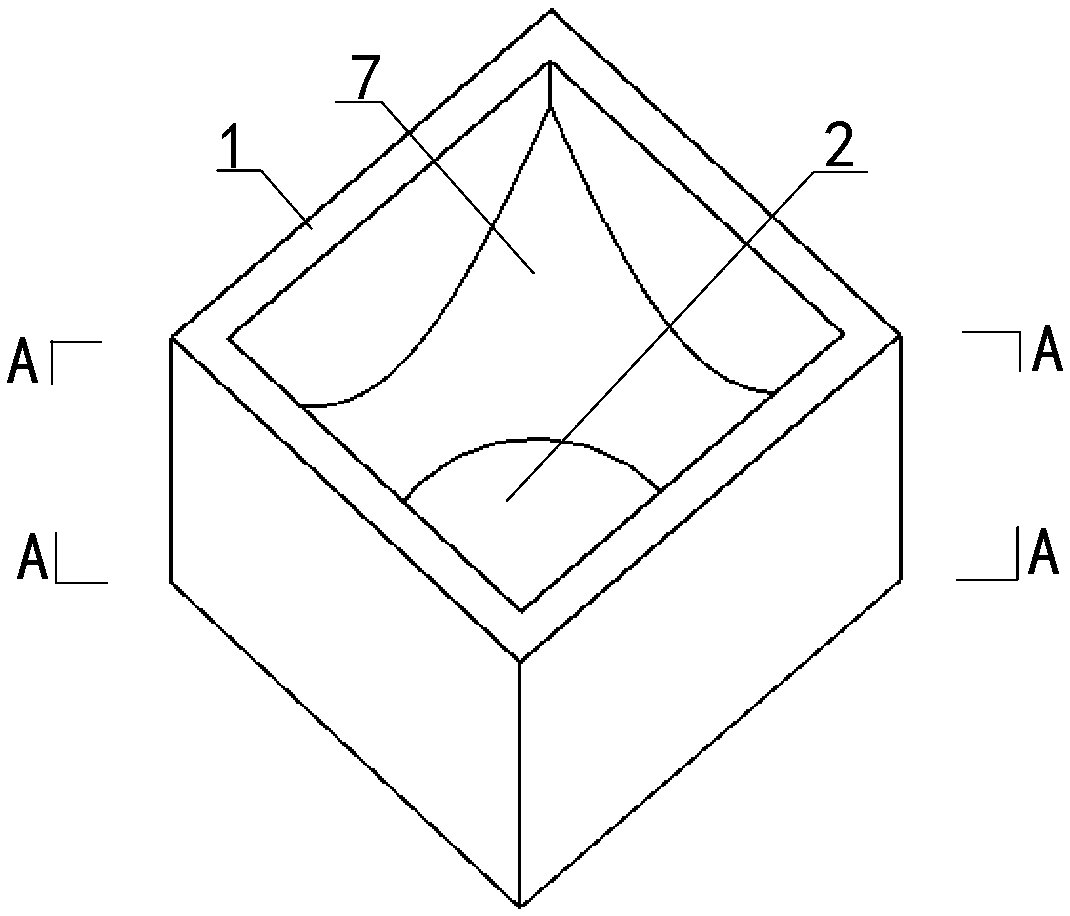

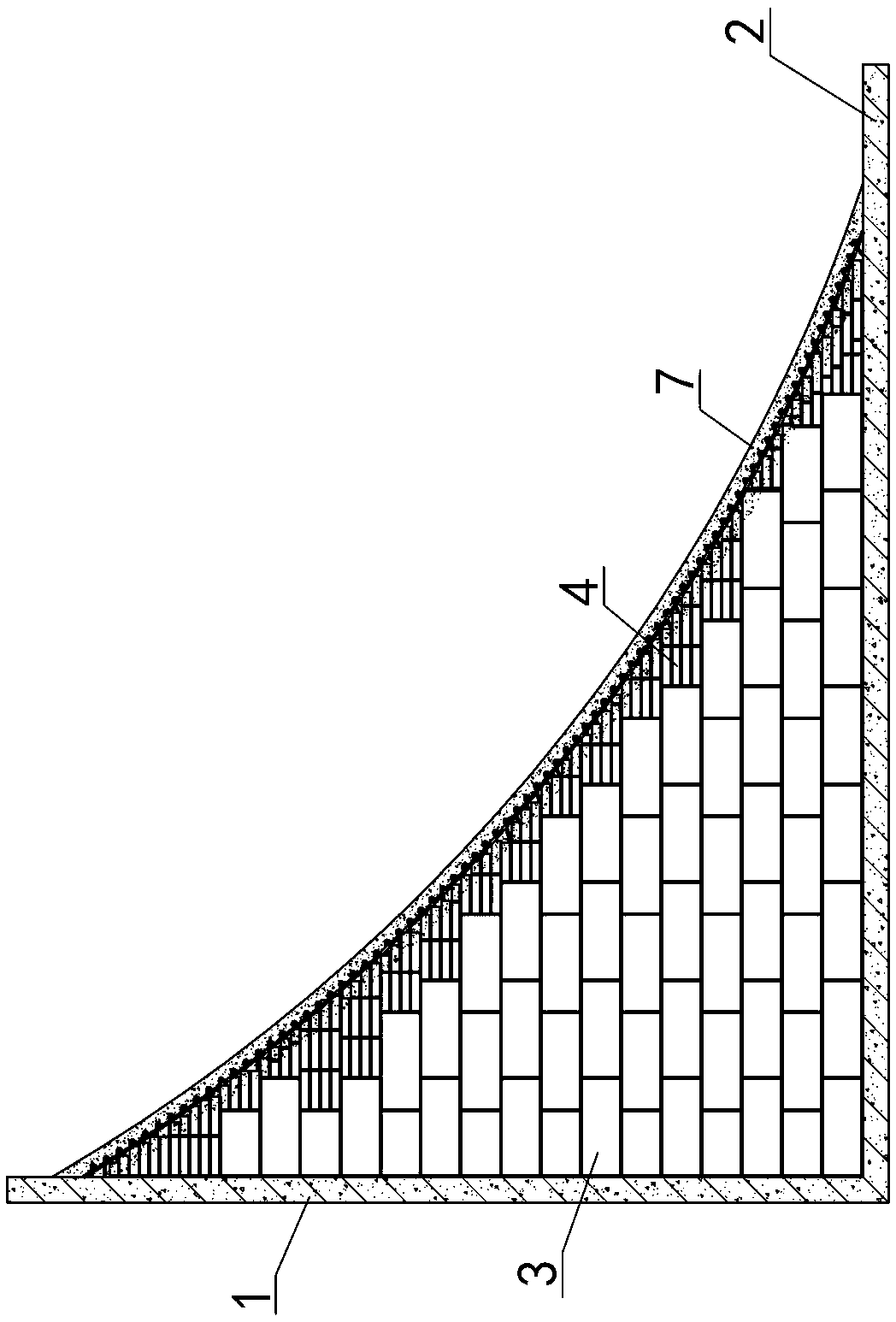

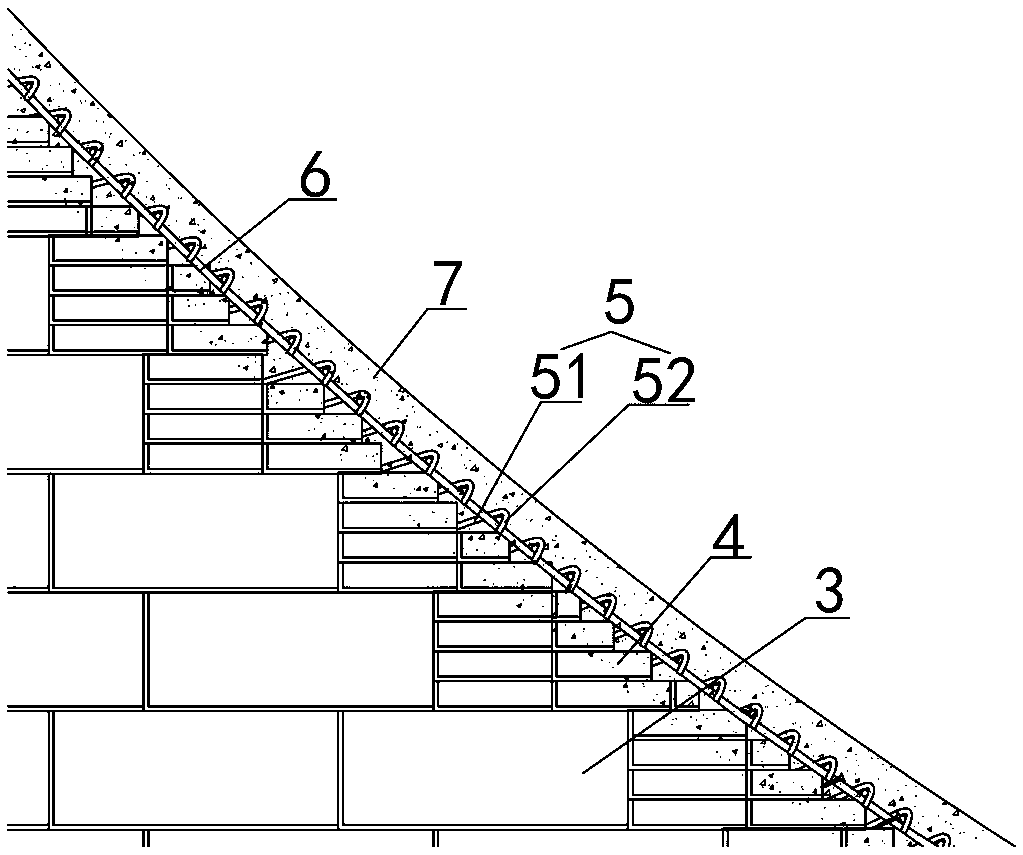

Warehouse bottom heap slopestructure and construction method thereof

PendingCN109441190AReduce patchingSimplify the binding processBulk storage containerClimate change adaptationRebarBlock layer

The invention discloses a warehouse bottom heap slope structure and a construction method thereof. The warehouse bottom heap slope structure structurally comprises a warehouse bottom plate and a warehouse wall plate, the warehouse bottom plate and the warehouse wall plate form an internal corner, the internal corner is built with a heap slope, the heap slope comprises aerated concrete building block layers which are stacked along the bottom end of the warehouse wall plate from bottom to top in the vertical direction and stacked along the outer end of the warehouse bottom plate from exterior tointerior in the axial direction, further comprises brick-filled layers piled on surface blocks, and brick joints of the surface bricks are connected and filled by jointing materials; the heap slope further comprises a steel bar mesh layer, a group of studs is arranged on the steel bar mesh layer in a connected mode, the bottom ends of the studs are inserted into the jointing materials, the top ends of the studs upwards and fixedly connected with a steel bar mesh, and the heap slope further comprises a concrete pavement. According to the warehouse bottom heap slope structure, slope forming issimple and easy to operate, the construction time can be greatly shortened, and the construction period is saved; and meanwhile, stacking of two layers of brick layers can ensure that the size of a masonry material is adjusted in time, the slope forming and construction progress are accelerated, the construction cost is saved, the quality risk is lowered, and durability of the slope in the using process can be ensured during normal use.

Owner:THE THIRD CONSTR OF CHINA CONSTR FIRST GROUP +1

A ceiling structure without suspenders

Owner:ZHEJIANG YASHA DECORATION

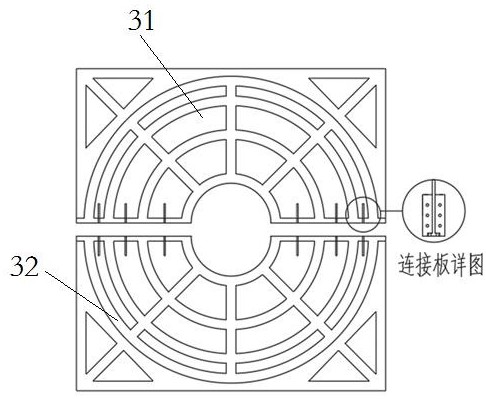

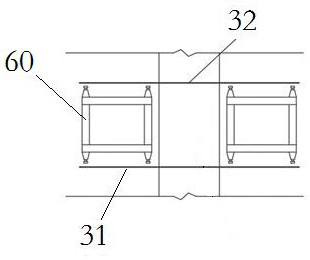

Test bench template support device and installation method for wind power blade inspection

ActiveCN113445733BSpeed upGood formabilityMachine part testingForms/shuttering/falseworksStirrupWind power

The invention provides a test bench formwork support device and an installation method for wind power blade detection, belonging to the field of wind power equipment, including a casing, which is used as a manhole steel pipe; the outer ring of the casing is provided with coaxial multi-turn pre-embedded pipes The embedded pipe is connected with the fixed plate through stirrups to form an integrated structure, and the fixed plate is fixedly connected with the casing; the outer ring of the fixed plate is provided with a frame for reinforcement, and the outer ring and the lower end of the frame are provided with There is a support assembly; the sleeve is disposed horizontally across the support assembly. The structure of the invention has strong bearing capacity, high stability, simple process and strong operability.

Owner:HEBEI CONSTR GRP CO LTD

Pharmaceutical composition on the basis of Stachytarpheta sp., a process for obtaining the same and its use for treating vitiligo

InactiveUS20130287868A1Increasing catecholamineReduce patchingBiocideOrganic active ingredientsEmulsionNanoparticle

This invention generally refers to the process to obtain a compound and a standard pharmaceutical product from one or more parts of plants of the Stachytarpheta (Verbenaceae family) species, as well as roots, stems, barks, and leaves of plants in the form of extracts or enriched fractions, or pure isolated compounds or compounds obtained from synthesis, used alone or mixed with other natural or synthetic products, in different ratios, in order to integrate pharmaceutical compositions to be used by appropriate routes (topic or oral), particularly in the form of tablets, capsules, dyes, emulsions, W / O and O / W (creams and gels), liposomes, microcapsules, nanoparticles, aerosols, ointments, and the like, as well as formulations for slow-release implants, used to treat vitiligo.

Owner:ACHE LAB FARM

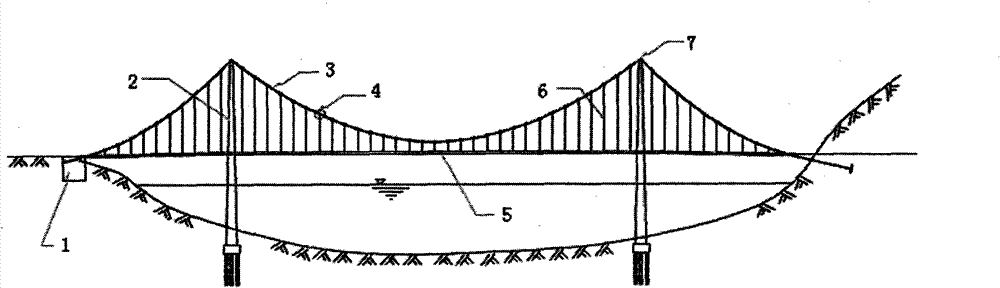

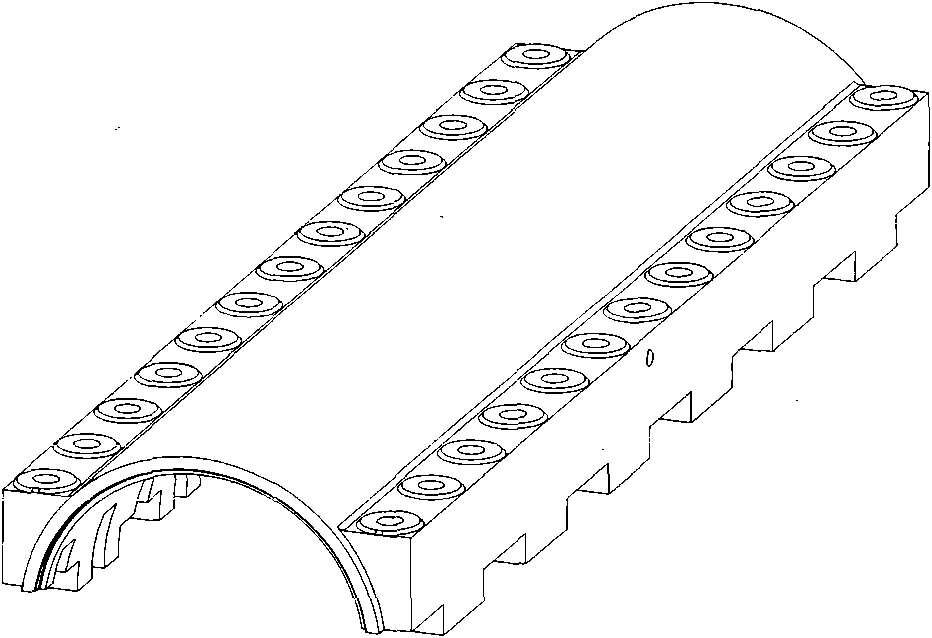

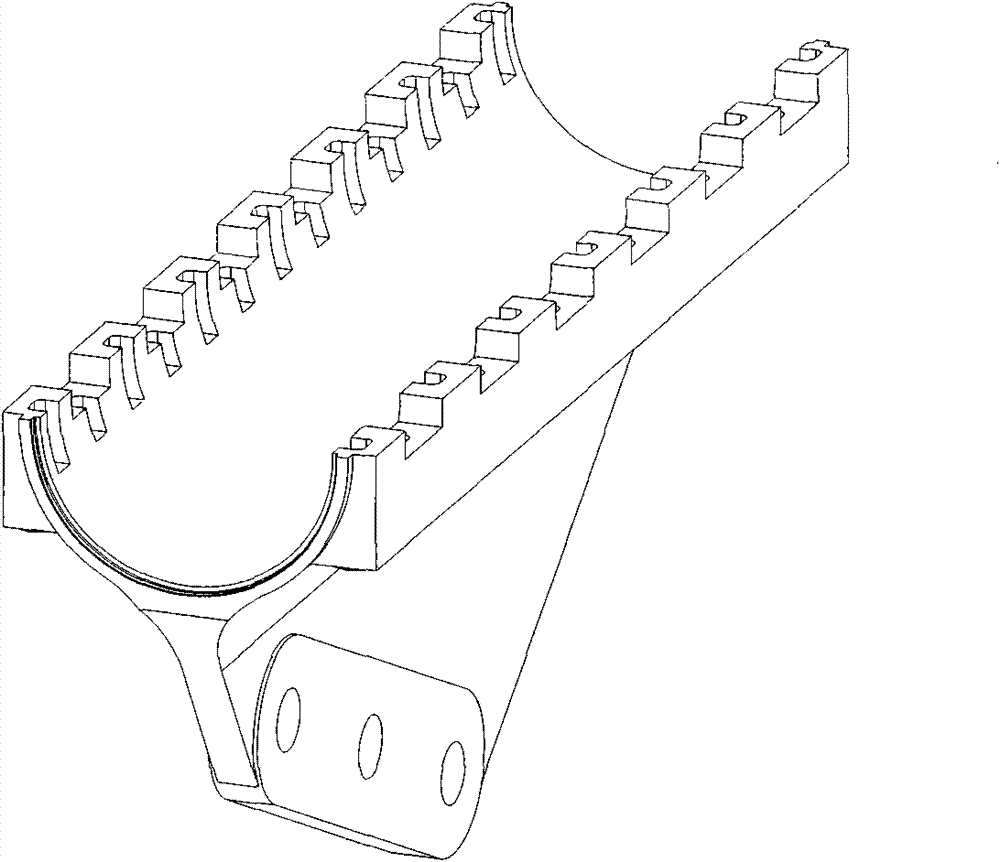

Casting method of pin-jointed cable clamp for lifting lug of suspension bridge

ActiveCN101941052BImprove securityReduce patchingFoundry mouldsFoundry coresStructural engineeringMolten steel

The invention provides a casting method of a pin-jointed cable clamp for a lifting lug of a suspension bridge. The pin-jointed cable clamp for the lifting lug is divided into an upper part and a lower part which are respectively cast by the steps of manufacturing of a manufacturing model, molding, casting and after-treatment. A cable hole of the casting at the upper part is downward, pouring heads are arranged at two ends of the casting at the upper part and are connected with the casting at the upper part through a pouring channel, a riser is arranged on the upper surface of the casting at the upper part, and chilling blocks are arranged at the outer side of a convex plate of a bolt joint and on the surface of the cable hole. A cable hole of the casting at the lower part is upward, pouring heads are arranged at two ends of the casting at the lower part and are connected with the casting at the lower part through a pouring channel, a riser is arranged on the surface of the cable hole,and chilling blocks are arranged at the outer side of a convex plate of a bolt joint, at the connecting part of a lug board and a jacket and on the surface of the lug board. The invention enables thecasting structure to be quickly formed in a shortest time, thereby improving the tensile strength; and simultaneously, because the chilling blocks are firstly cooled, the molten steel is preferably fed, thereby greatly reducing and even eliminating the generation of cracks.

Owner:DEYANG TIANYUAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com