Test bench template support device and installation method for wind power blade inspection

A wind power blade and formwork support technology, which is applied in the direction of measuring devices, mechanical parts testing, formwork/formwork/work frame, etc., can solve the problem of increasing the installation of formwork systems, difficulty in reinforcement, unachievable bolt reinforcement, and collision conflicts between component positions and other problems, to achieve a good molding effect, reduce the repair of the next process, and ensure the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

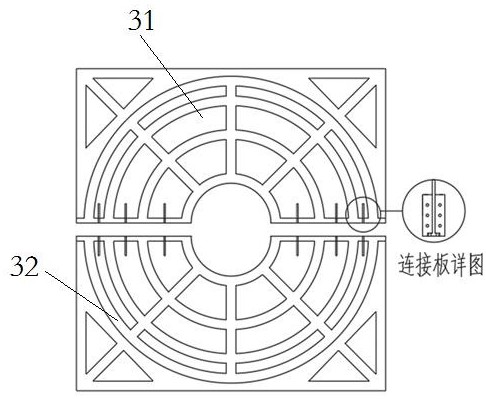

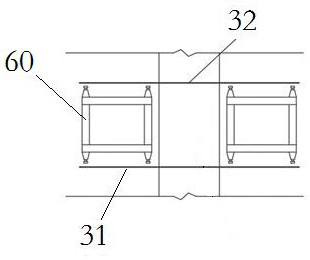

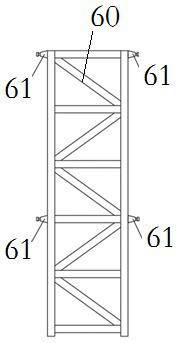

[0056] Example: The front panel is 6m in diameter, the middle opening diameter is 1.45m, the thickness is 250mm steel plate, and its own weight is about 52.1t. 8 horizontal jacks are installed to adjust the verticality of the panel. The most unfavorable working conditions should be considered in the calculation. The load is calculated by the lower half of the frame. In this embodiment, the deformation calculation results show that the maximum displacement is 0.59mm; the maximum stress of the truss assembly is 41.40Mpa; the maximum stress of the front panel is 43.54Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com