Elevator shaft tool type operation steel platform and manufacturing method thereof

A manufacturing method and elevator shaft technology, which are applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve problems such as high safety risks of high-altitude operations, difficulty in erecting, and potential safety hazards, and achieve high safety and reduce Safety issues, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

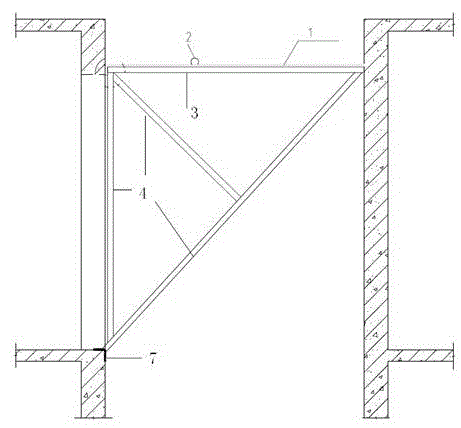

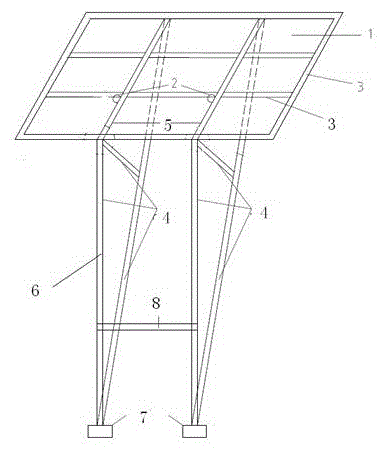

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

[0017] Embodiment of the present invention: a method for manufacturing an elevator shaft tool-type operating steel platform. The method adopts a patterned steel plate and a reinforcing section bar arranged at the bottom of the patterned steel plate to form the working surface of the platform. For the right-angled tripod supporting the patterned steel plate, one vertical side of the right-angled tripod is close to the bottom of the patterned steel plate, and a fixture with an "L" cross-section is set at the bottom of the other vertical side of the right-angled tripod. When using the elevator The well tool-type operating steel platform is placed in the elevator shaft, so that the clamp is stuck at the door opening of the elevator shaft, and the side of the elevator shaft tool-type operating steel platform corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com