Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce bumps and scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

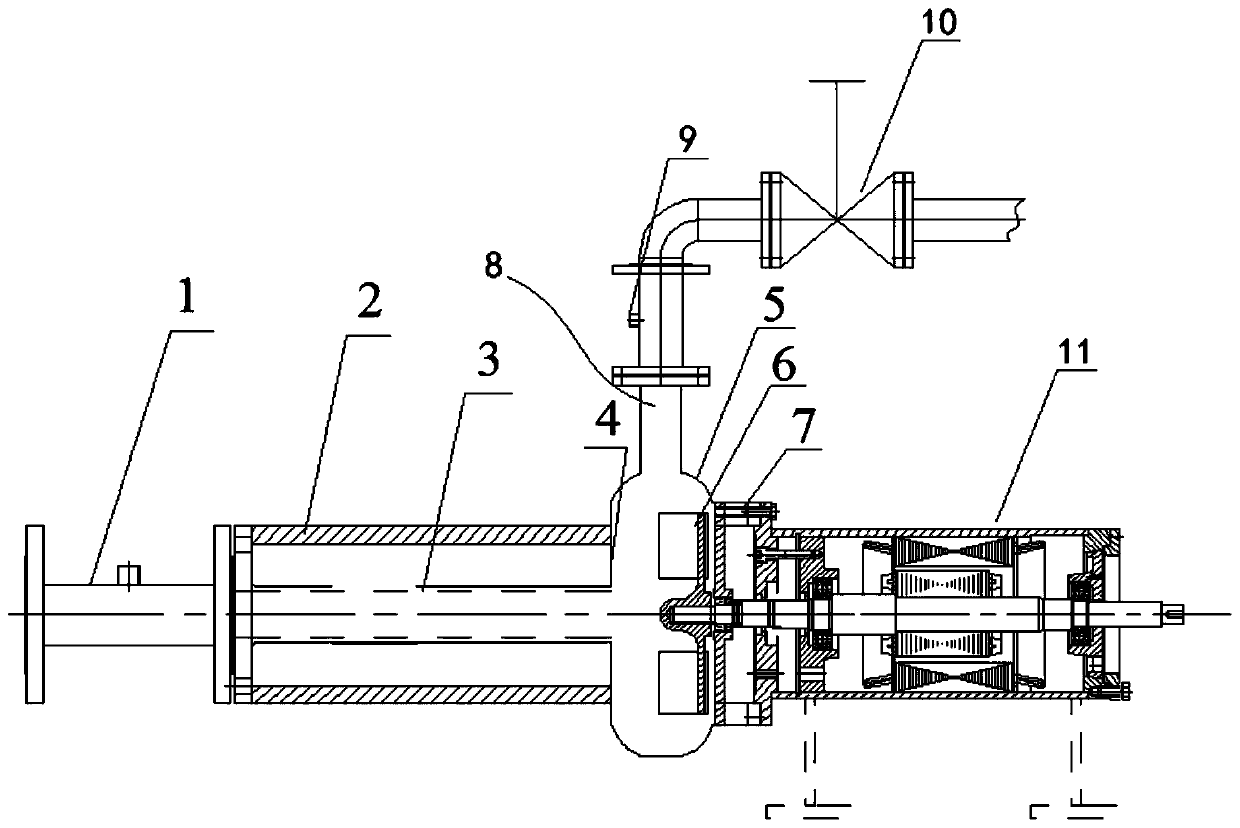

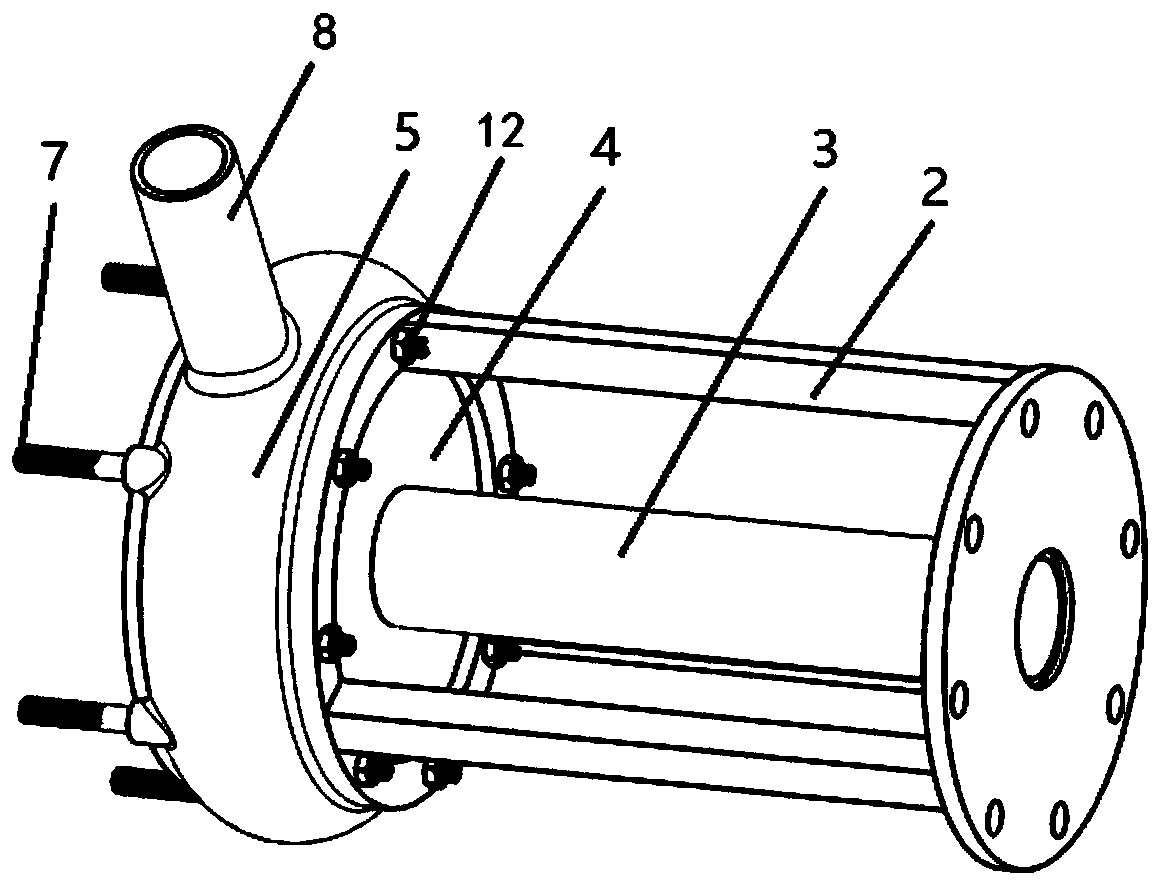

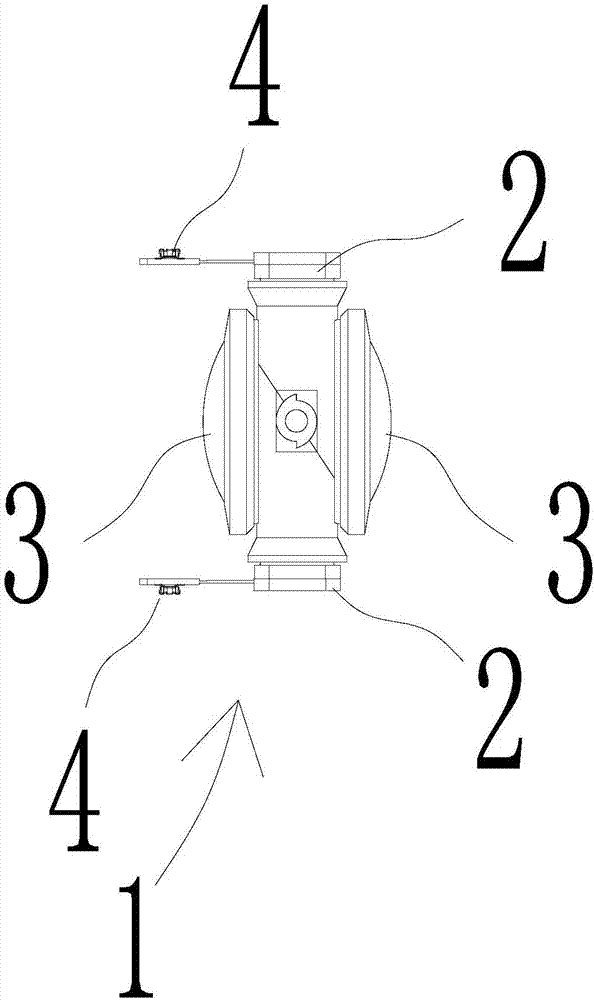

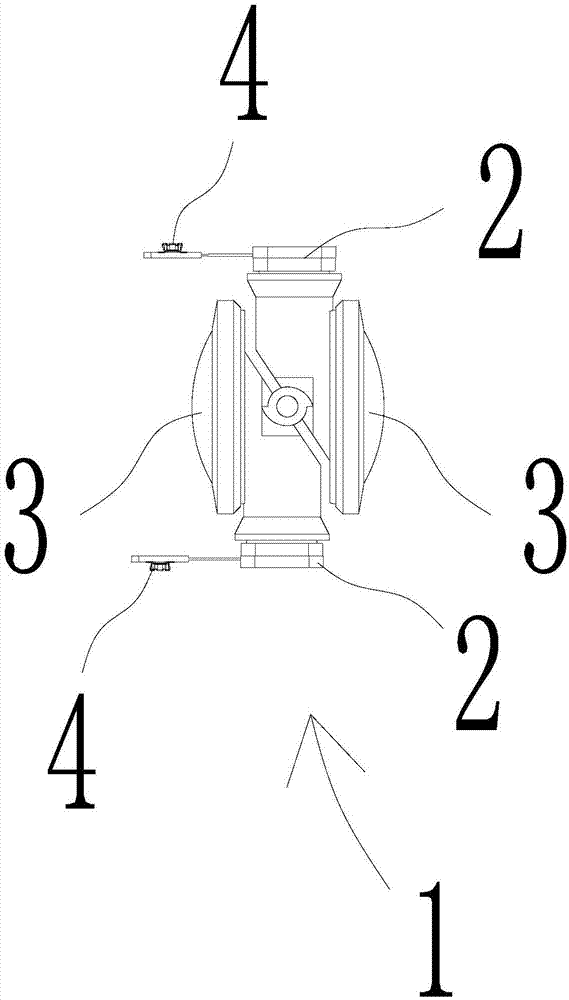

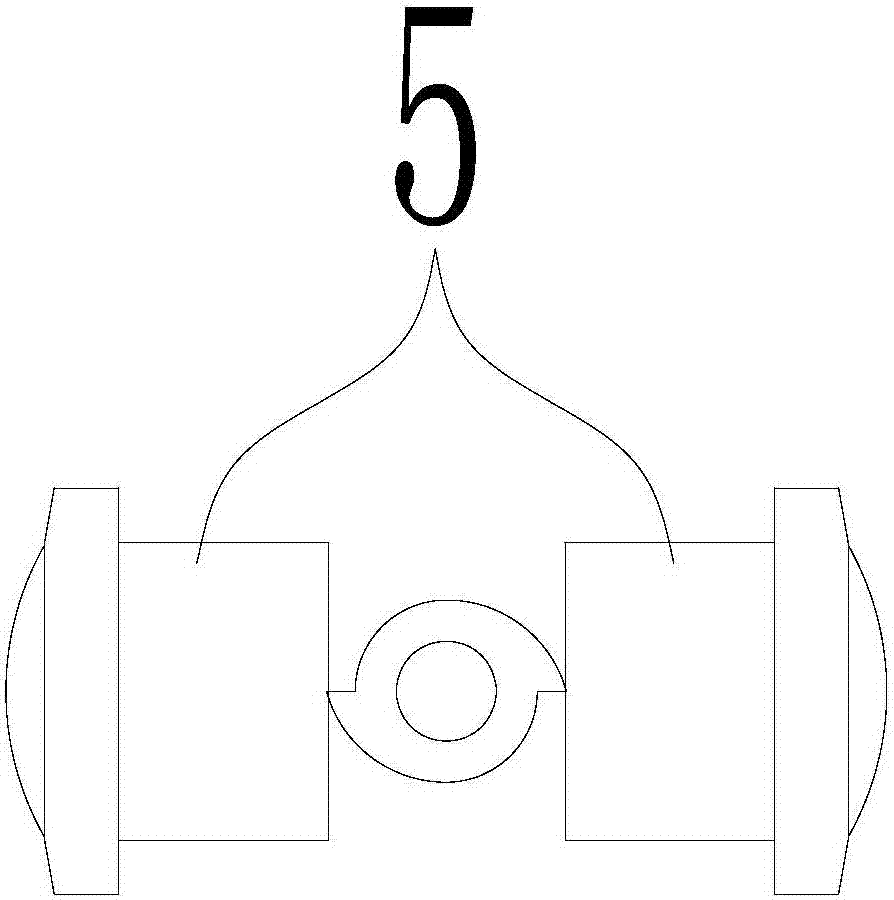

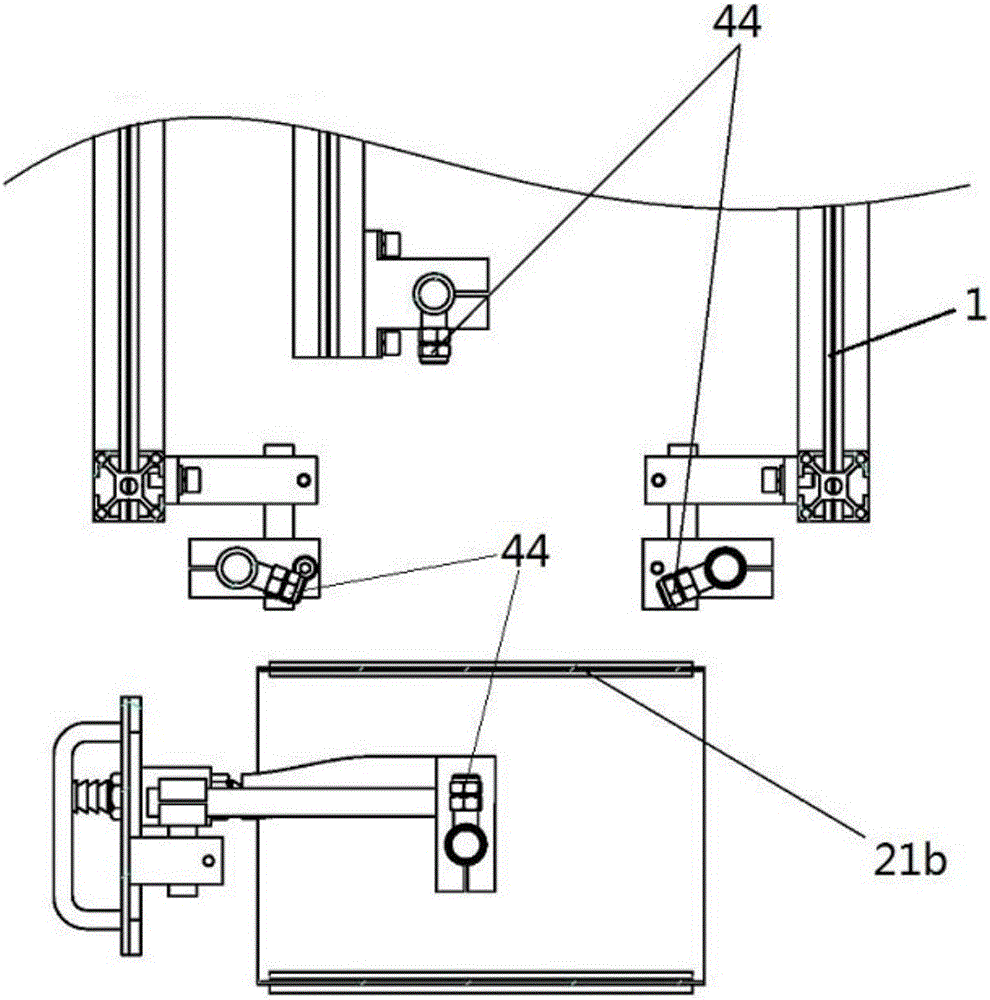

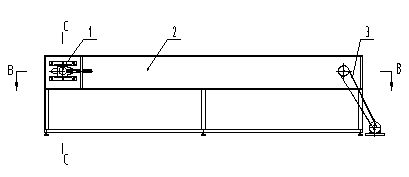

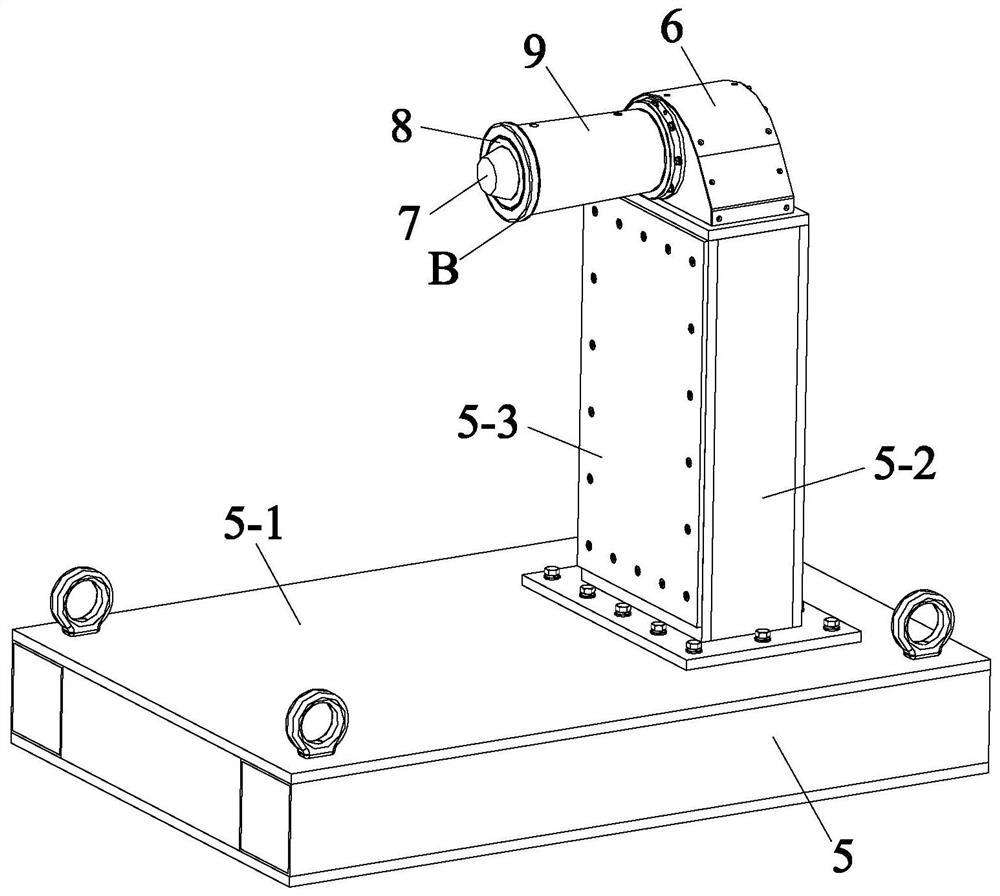

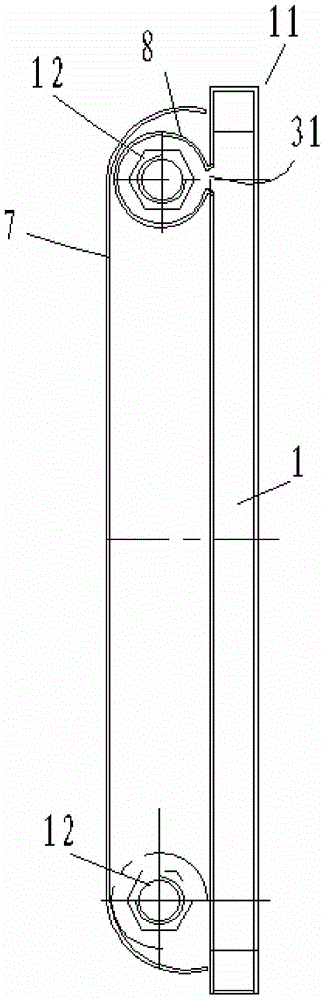

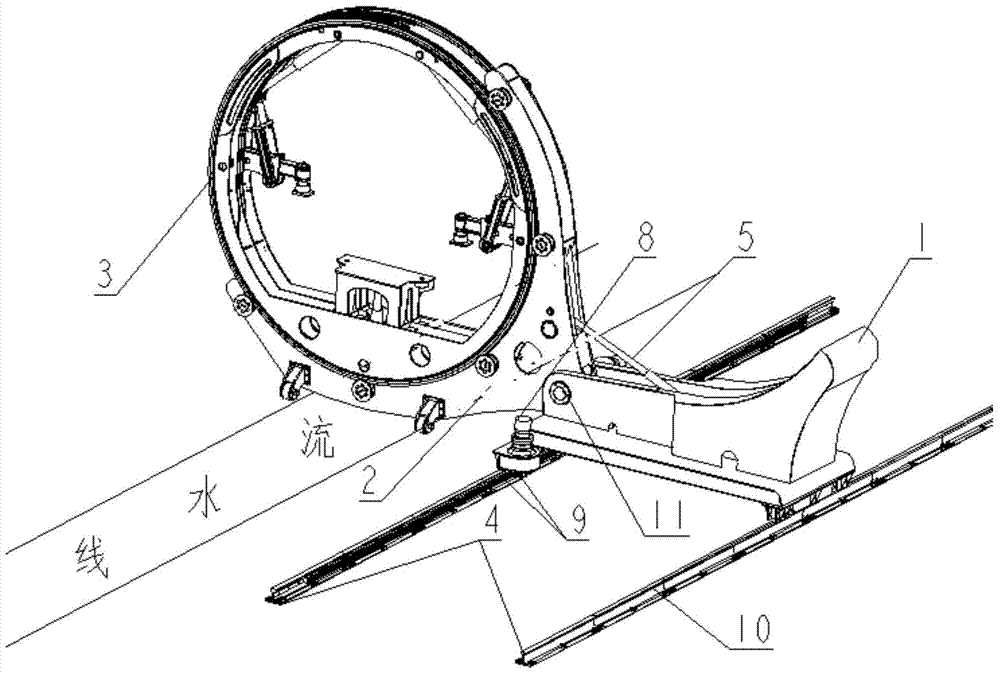

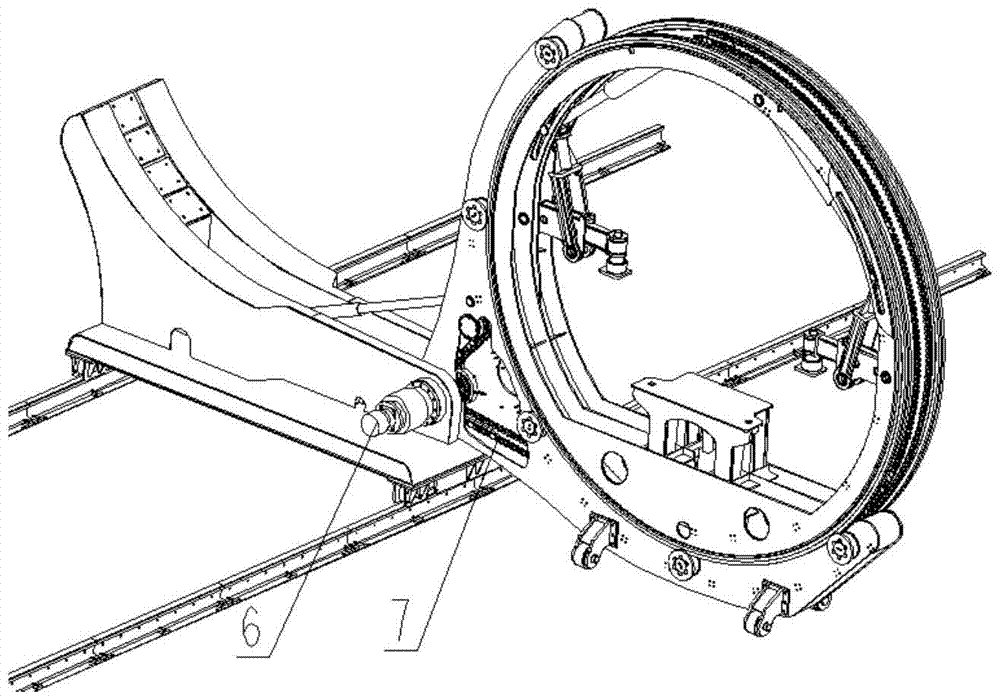

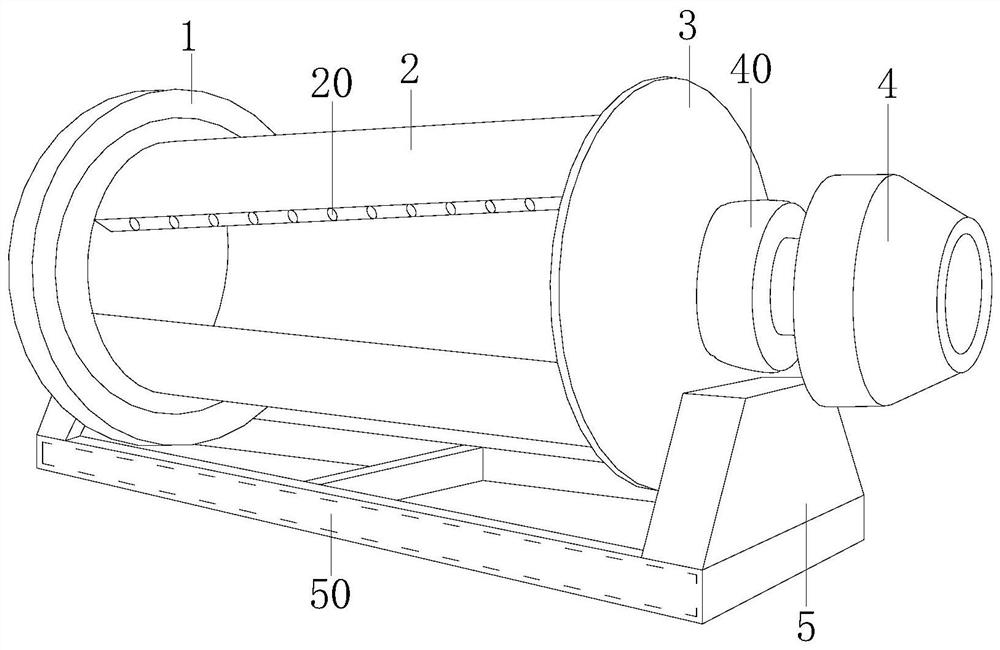

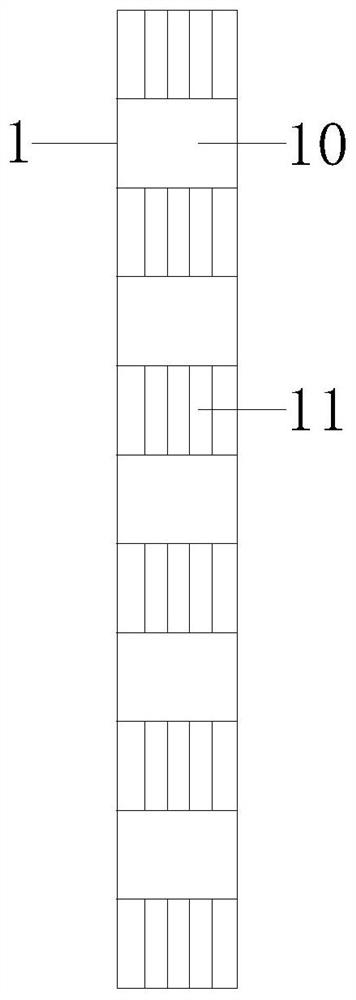

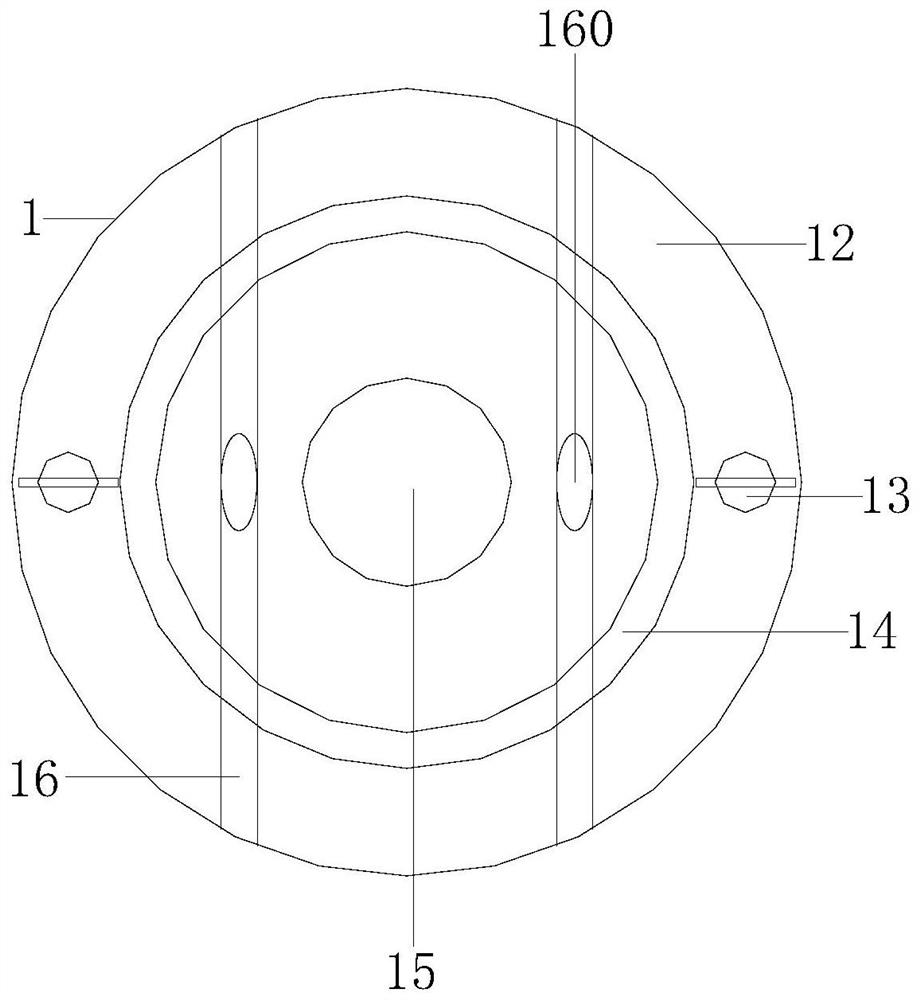

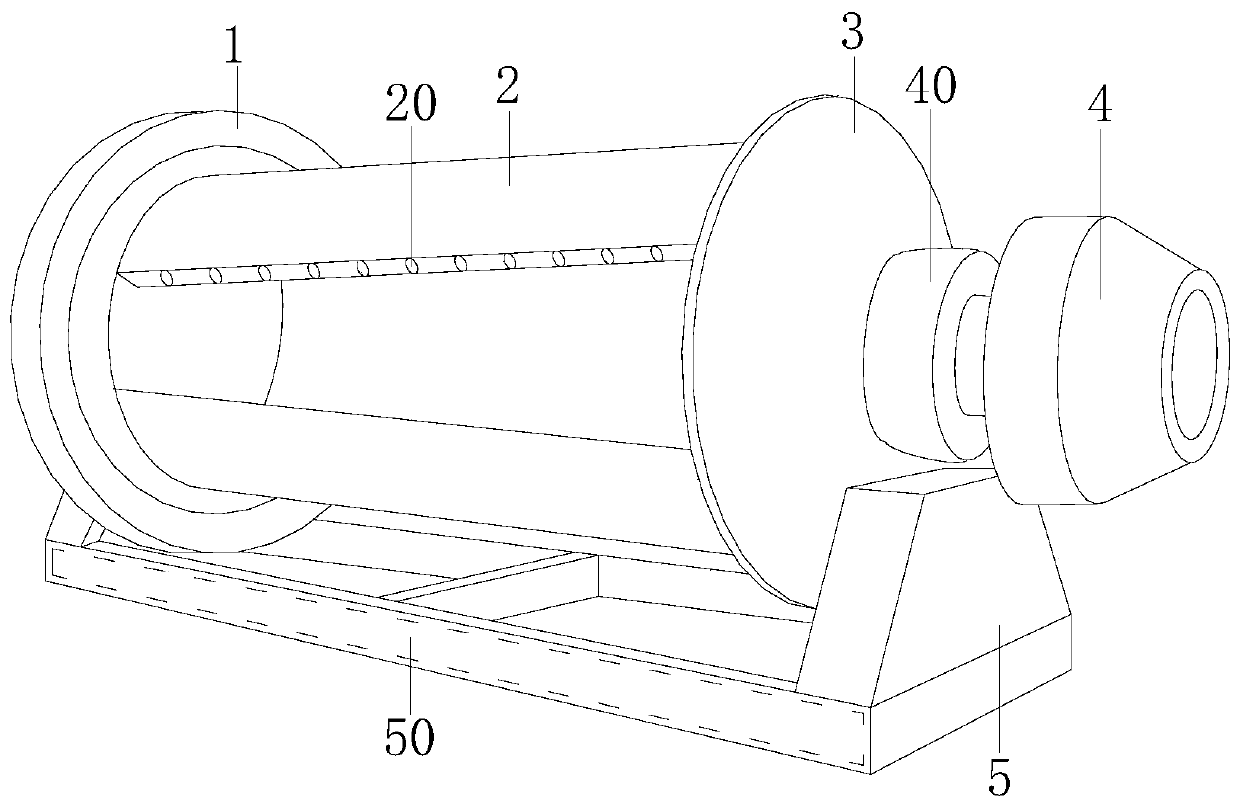

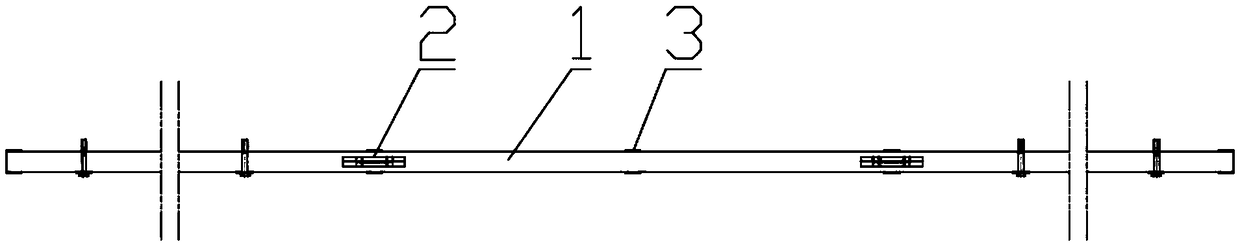

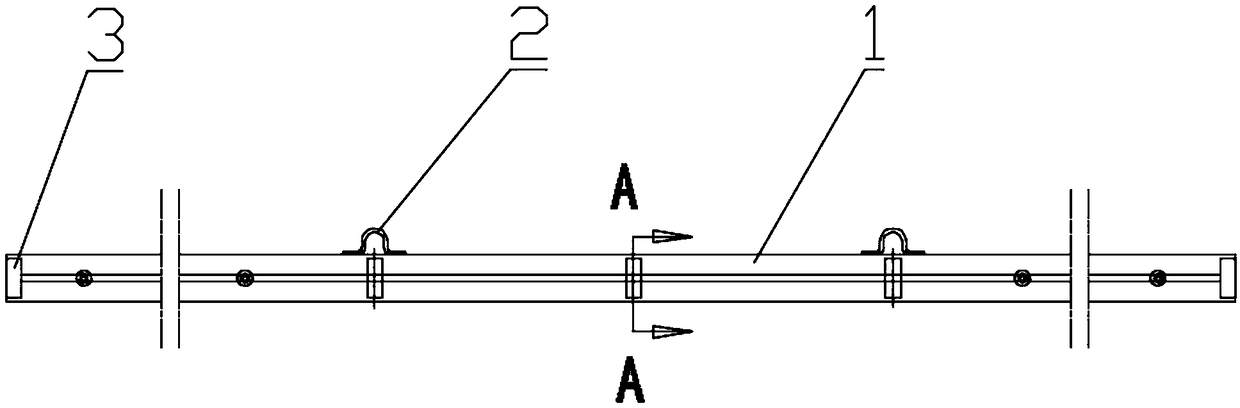

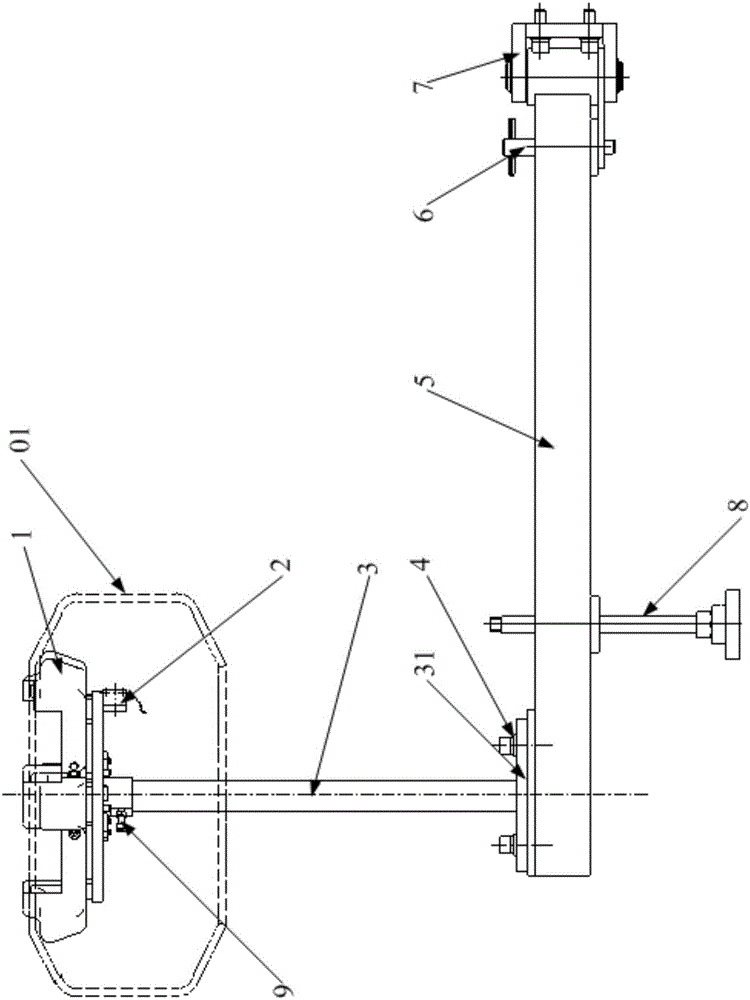

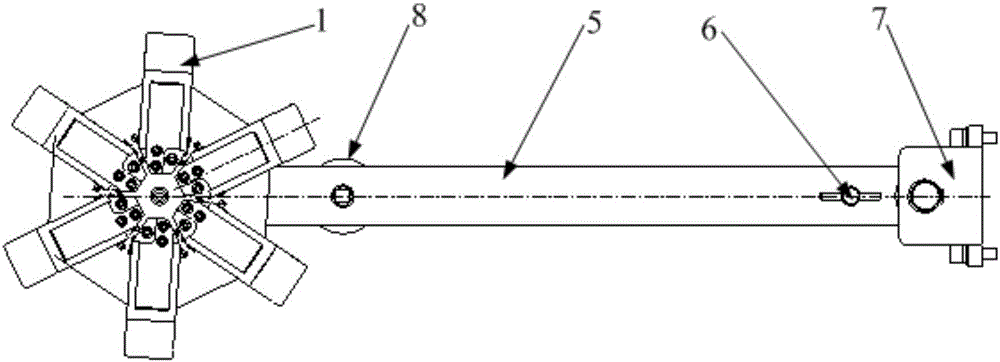

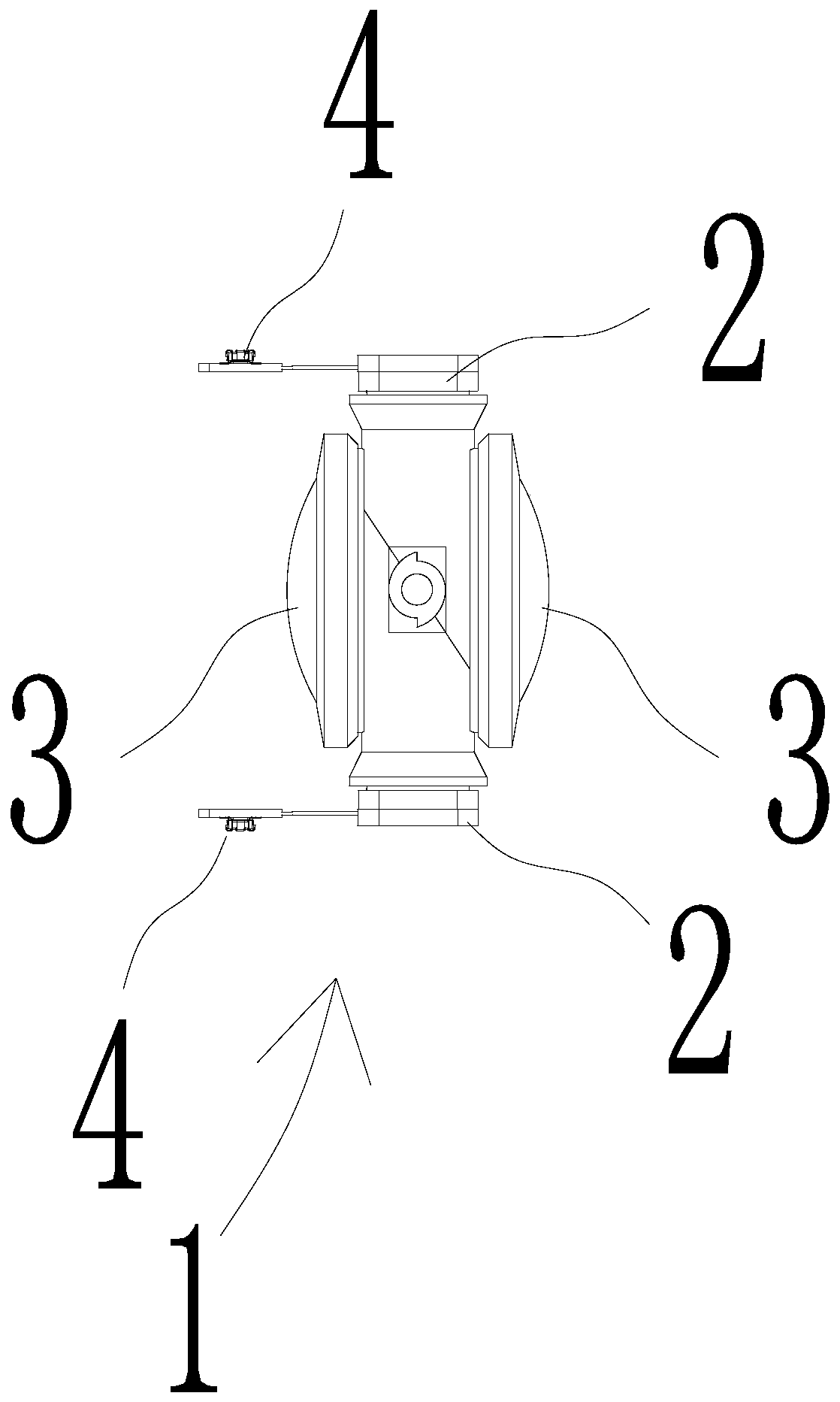

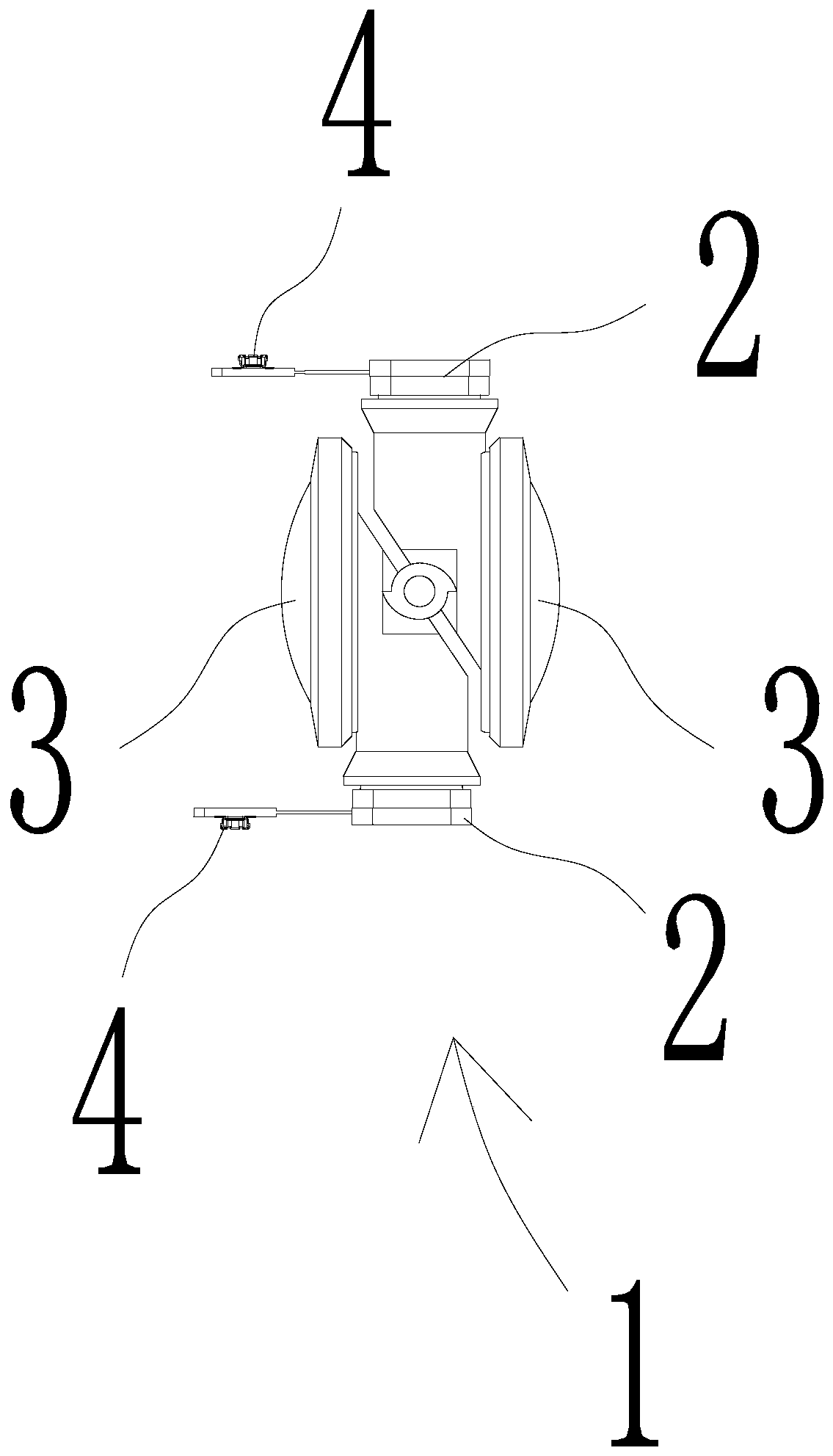

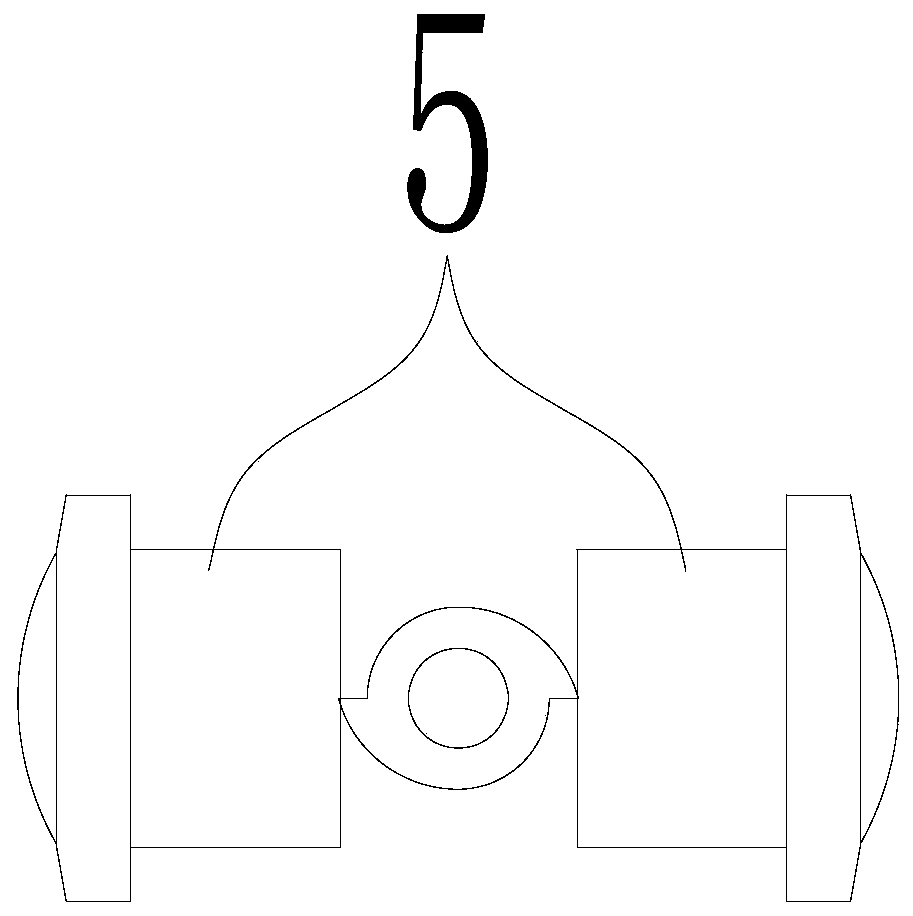

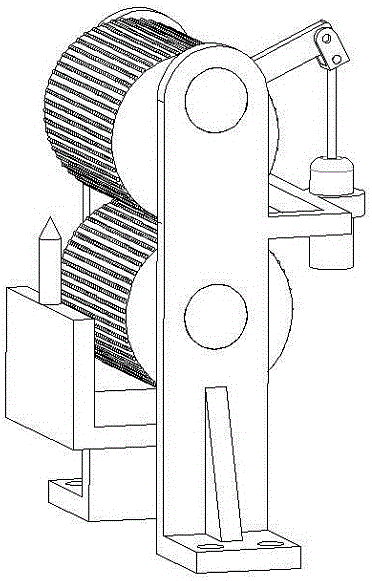

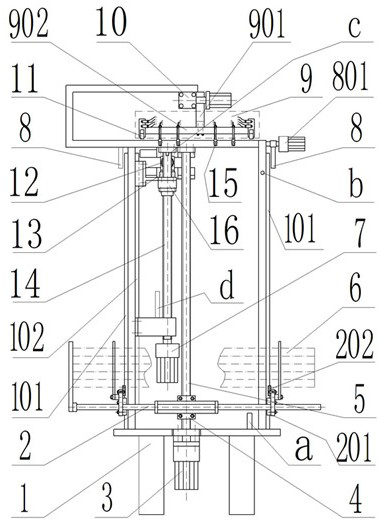

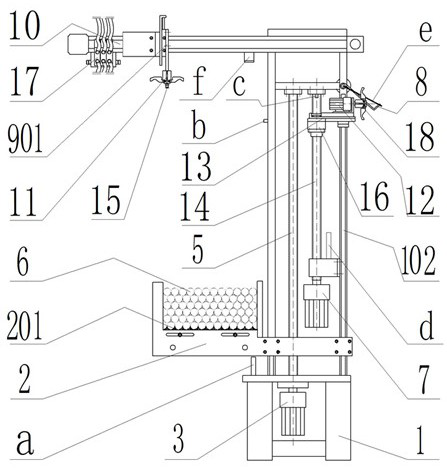

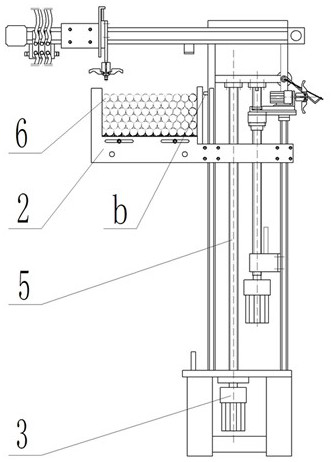

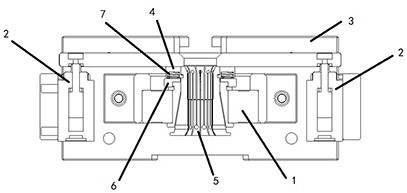

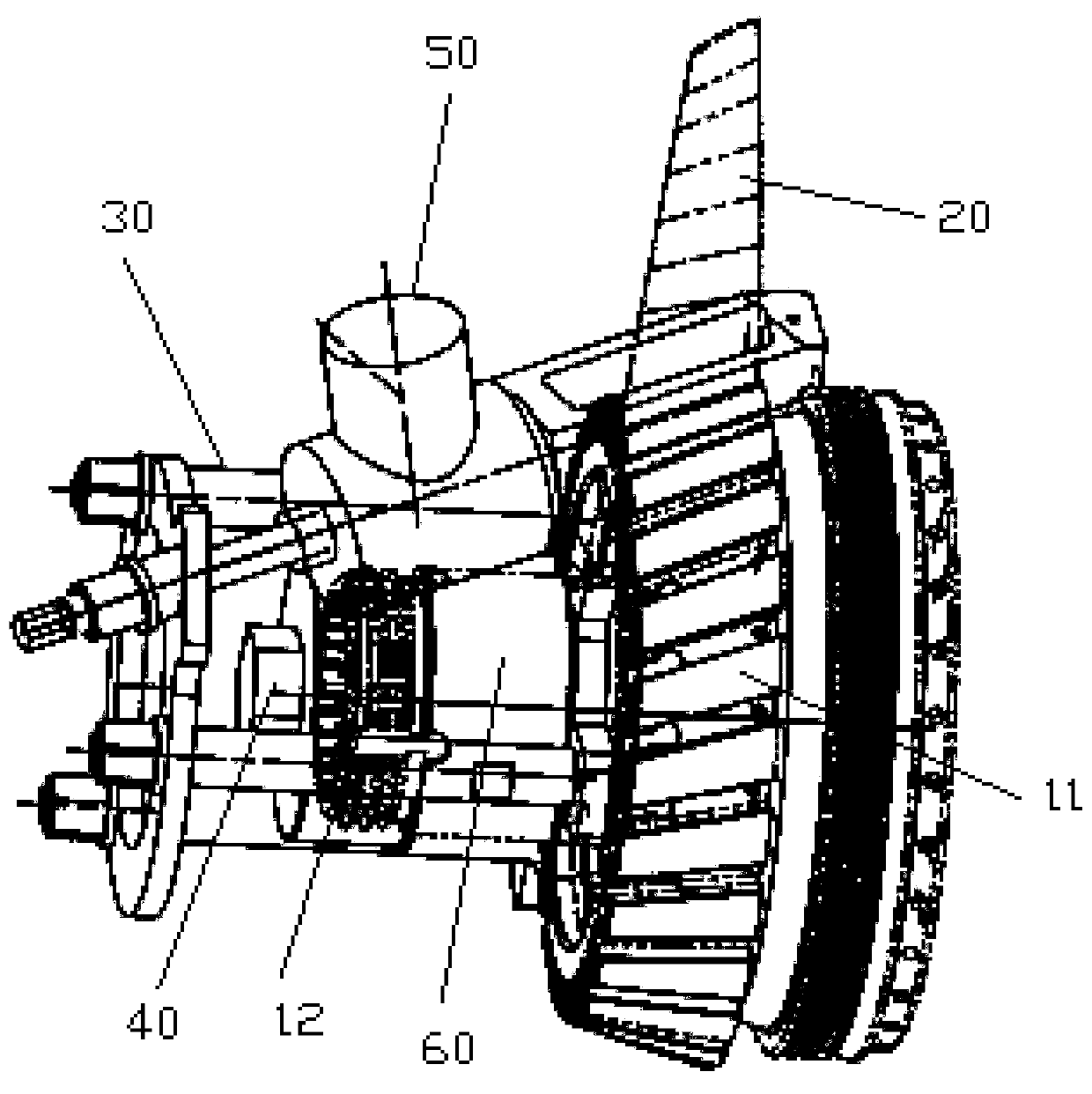

Chassis online overturning equipment

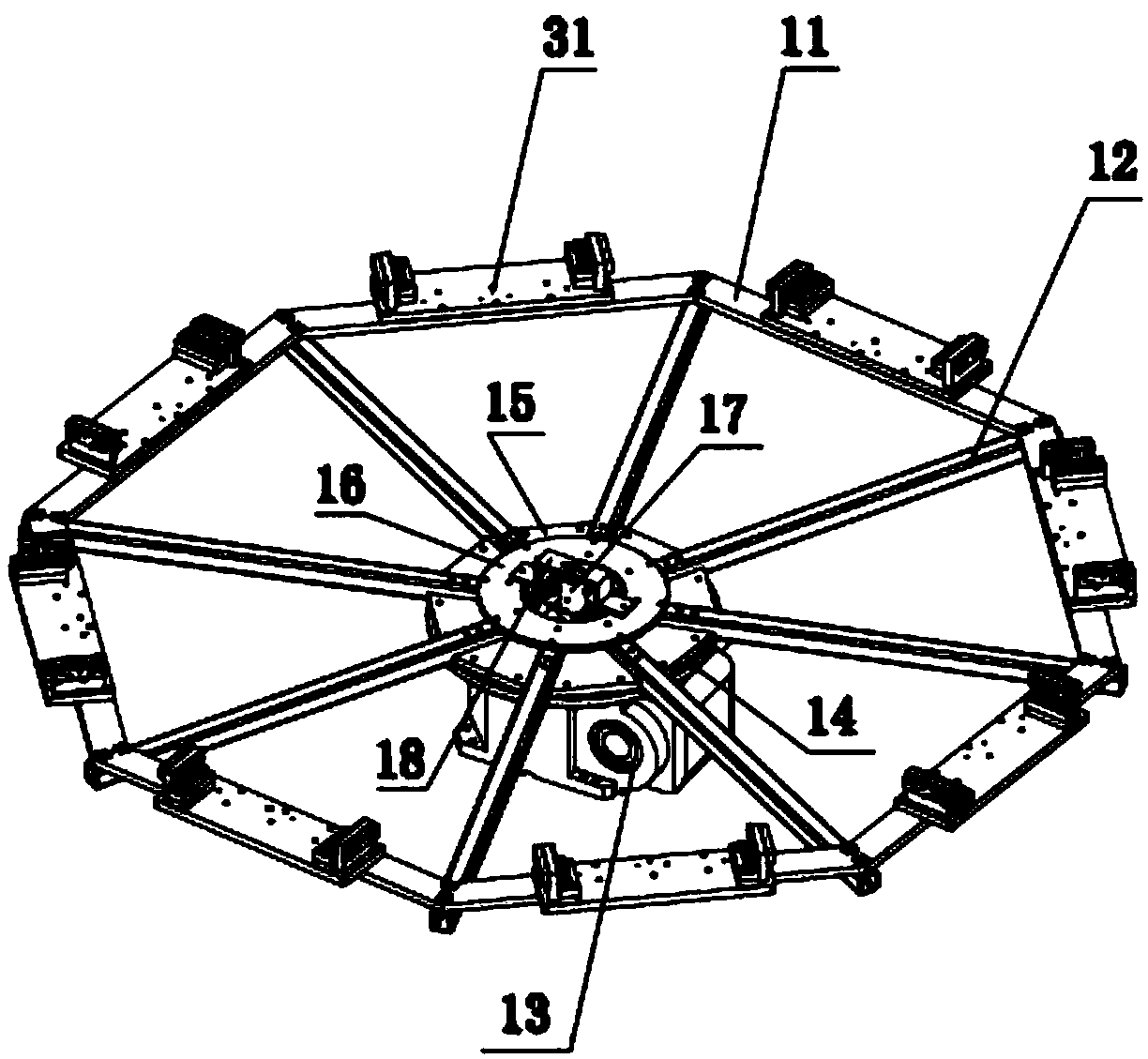

The invention discloses chassis online overturning equipment. A bracket (2) is connected with a base (1) through a rotation shaft (11) and can move relative to the base (1) around the rotation shaft (11); a walking motor (8) installed on the base (1) moves to drive a gear rack mechanism (9) connected to the walking motor (8), to drive the whole equipment to walk in a foundation; a rotary motor (6) installed on the base (1) moves to drive a transmission chain (7) fixed to an overturn circle (3) to move, to drive the whole overturn circle to rotate; a retraction oil cylinder (5) connected with the base (1) and the bracket (2) performs telescopic movements to drive the bracket (2) and the overturn circle (3) to move together around the rotation shaft (11), and thus retraction movements of the bracket and the overturn circle are realized. According to the invention, a chassis can be overturned without being offline, bumping and distortion caused by deformation of the chassis can be reduced, lean production is promoted, and quality of products is also improved.

Owner:XUZHOU HEAVY MASCH CO LTD

Cyclone pump cavitation test device

PendingCN109724891AGuaranteed reliabilityReduce scratches and bumpsInvestigating abrasion/wear resistanceCycloneCavitation

The invention provides a cyclone pump cavitation test device, which comprises a cyclone pump and a reinforcing bracket, wherein the cyclone pump comprises a pump casing, a rear cover plate, an inlet pipe and an outlet pipe; the pump casing comprises a side wall and an end wall, the side wall and the end wall are connected to form a pump chamber, the inlet pipe is connected to the end wall, the rear cover plate is connected to one end of the side wall away from the end wall, the outlet pipe is disposed on the side wall, and the inlet pipe and the outlet pipe are respectively connected to the pump chamber; the reinforcing bracket is sleeved on the outer side of the inlet pipe and is connected to the front end of the pump casing, one end of the inlet pipe away from the pump casing is supported on the reinforcing bracket having a hollowed area for observation; at least part of the end wall is a first visual area, and at least part of the inlet pipe is a second visual area. The device provided by the invention adopts the preparation of the organic glass at least part of the end wall of the inlet pipe and the pump casing to ensure the visualization of the test device, the other part adopts the cast iron to ensure the hardness and wear resistance, and the outer periphery of the inlet pipe is provided with the reinforcing bracket to ensure the overall stability.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH +1

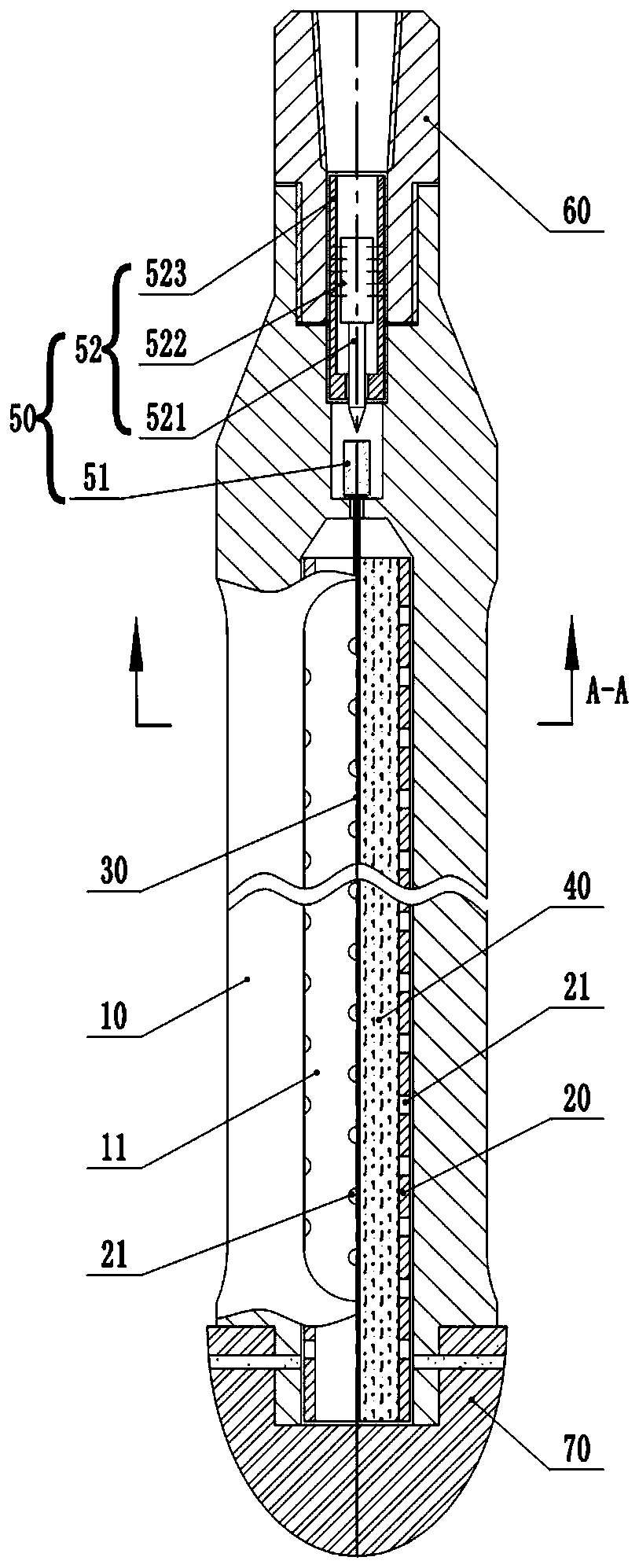

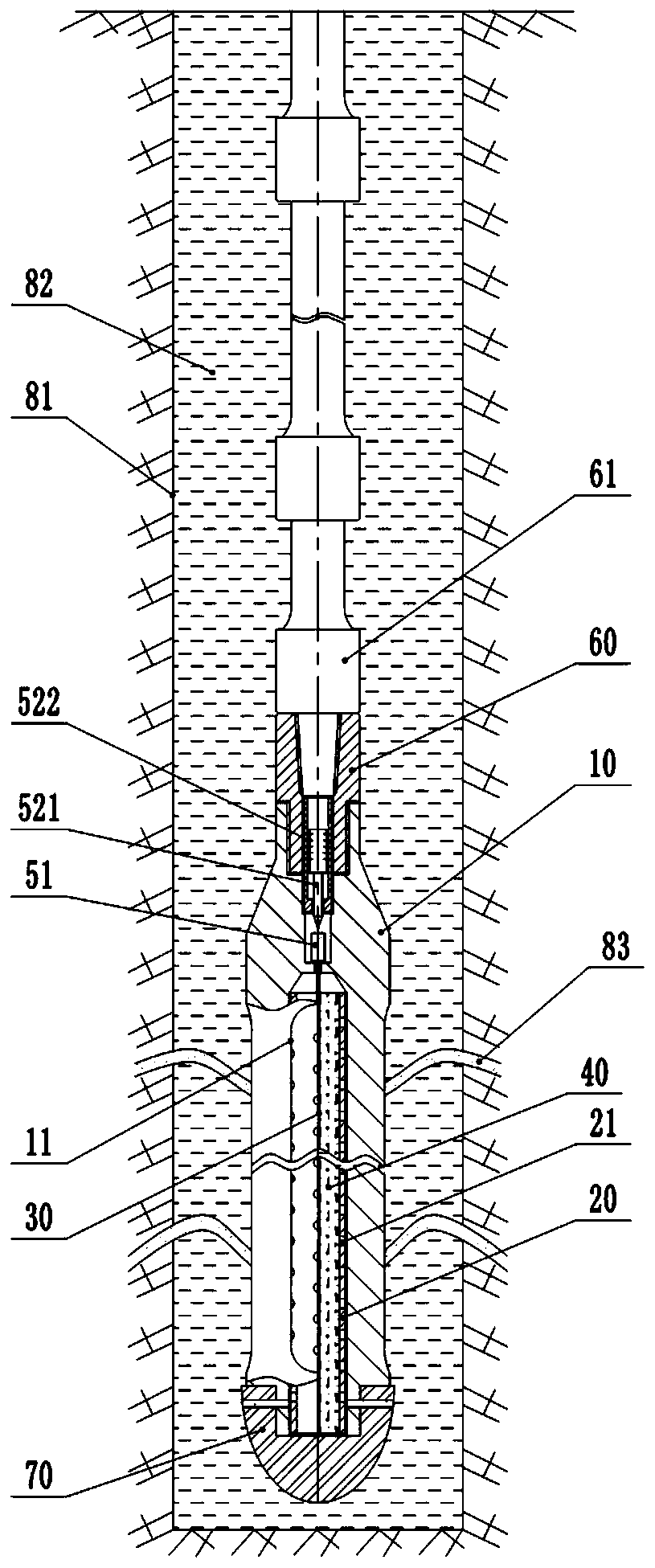

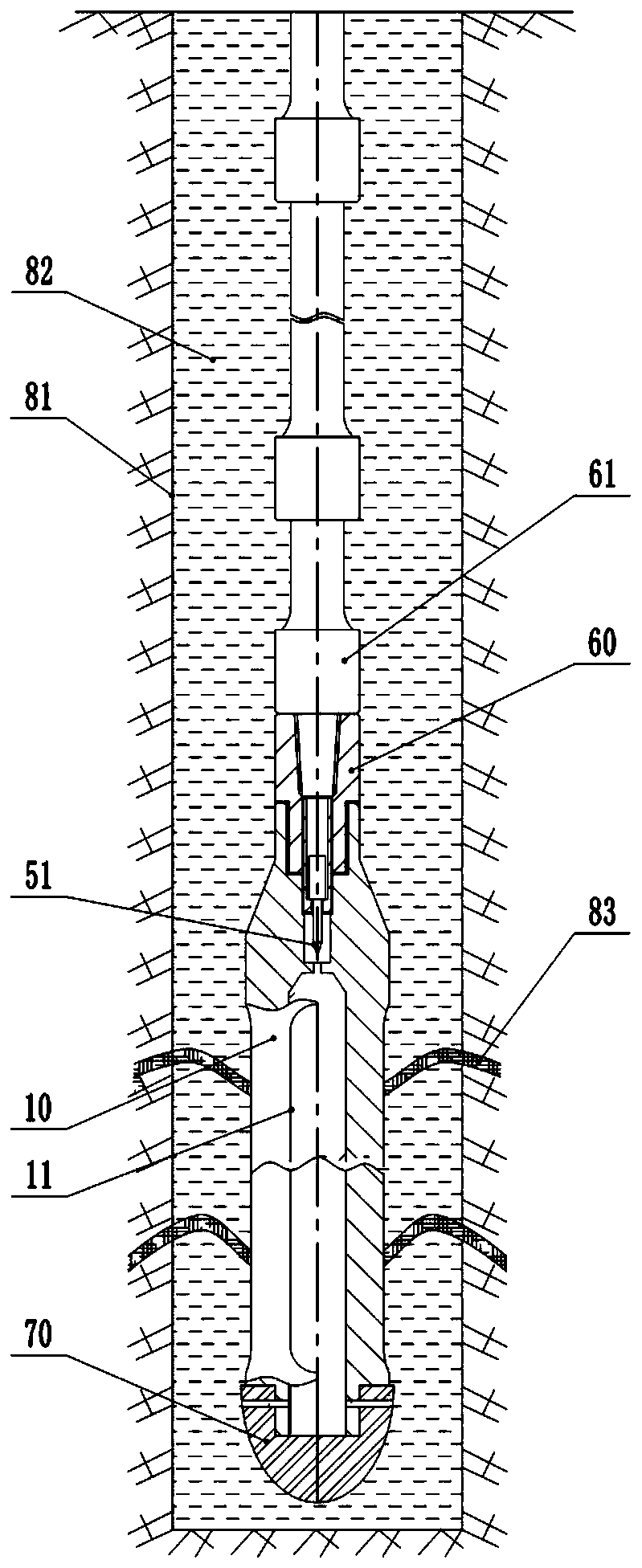

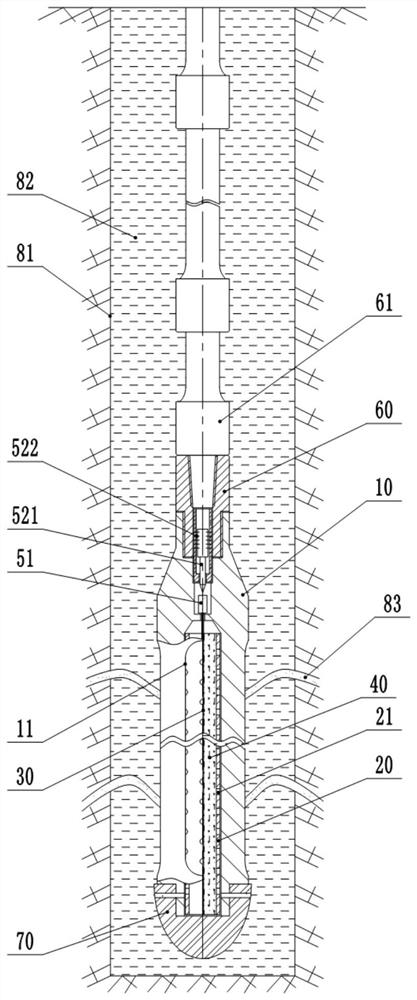

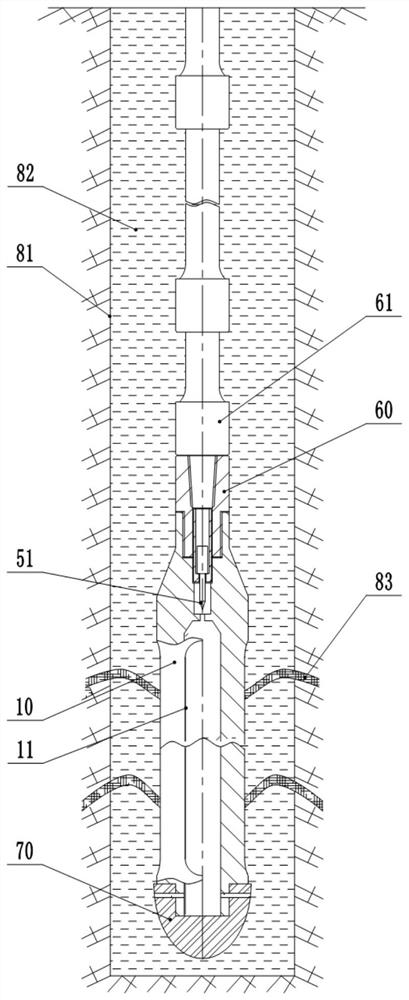

Underground leakage stopping device

ActiveCN110185412AReduce bumps and scratchesSimplify operation stepsSealing/packingStops deviceEngineering

The invention provides an underground leakage stopping device which comprises at least one hood barrel, at least one material storage pipe filled with a leakage stopping material, and a detonating fuse and a detonating mechanism for detonating the detonating fuse, wherein at least one channel communicating to the inner and outer sides of the hood barrel is arranged on the outer wall of the hood barrel; the material storage pipe is arranged in the at least one hood barrel; the detonating mechanism is mounted at the upper end of the hood barrel, the upper end of the detonating fuse is connectedto the detonating mechanism, and the lower end of the detonating fuse is arranged in the material storage pipe; when the detonating fuse explodes, the material storage pipe can be exploded and the leakage stopping material in the material storage pipe is driven to be spray out of the hood barrel through the channel. The underground leakage stopping device solves the technical problem that a leakage treatment method in the prior art is relatively poor in effect and is hard to take effect at one time.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

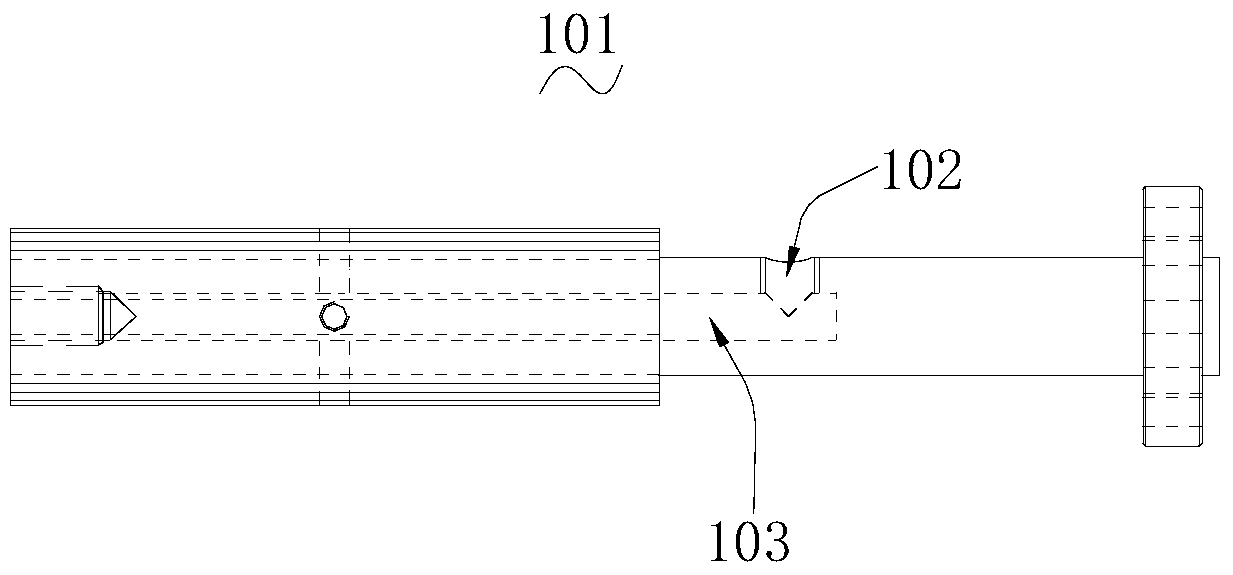

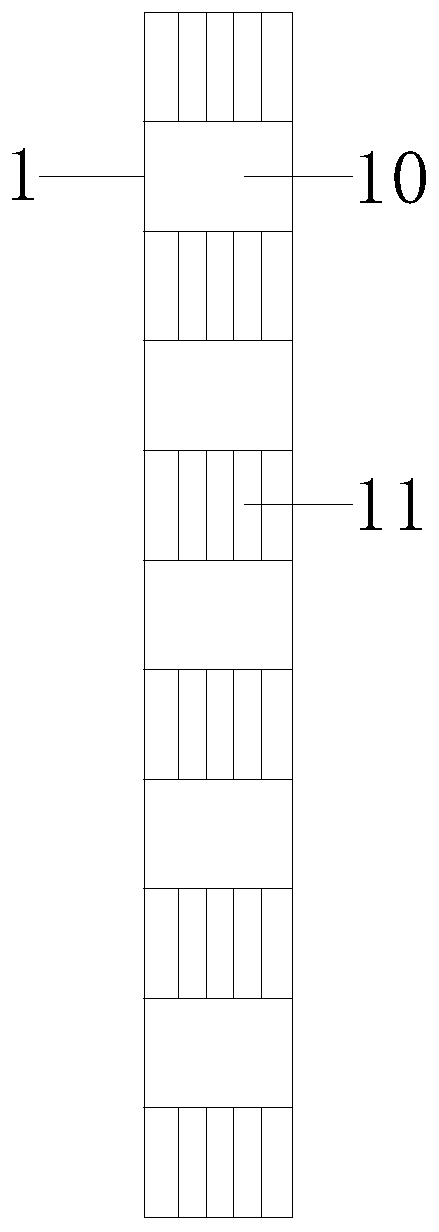

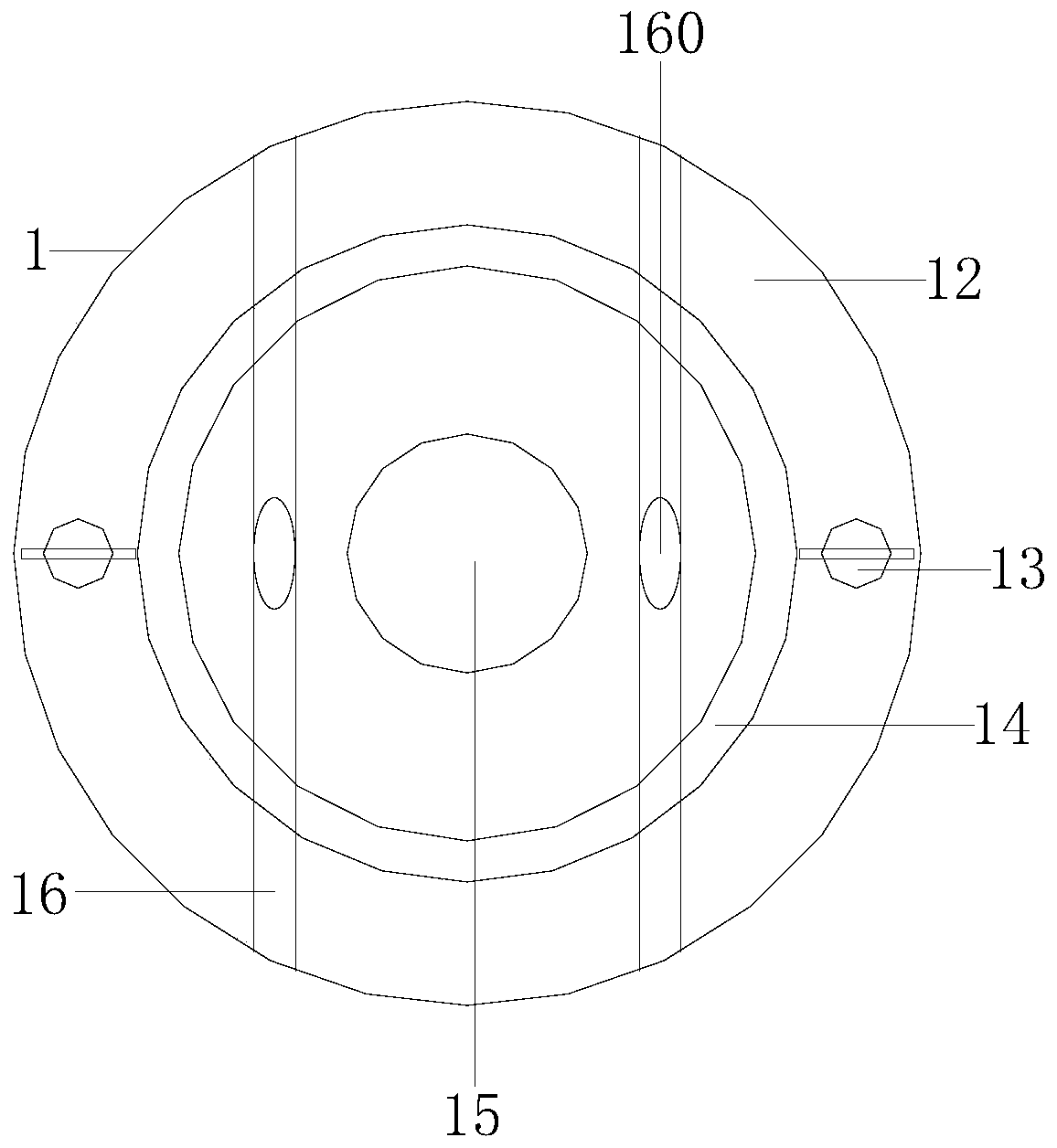

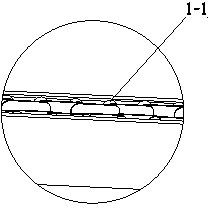

Thickness-adjustable panoramic lens

The present invention discloses a thickness-adjustable panoramic lens. The thickness-adjustable panoramic lens comprises a panoramic lens body which is used for 360-degree stereo image pickup and is provided with imaging systems; each of the imaging systems comprises an image pickup lens and an imaging sensor for taking an image formed by the image pickup lens; the two imaging systems are installed in a mirror image manner through an involute cam structure so as to be matched with each other to form the panoramic lens body; and the panoramic lens body can be adjusted to extent outwards or contract inwards along the center of the panoramic lens body through the two imaging systems. The thickness-adjustable panoramic lens comprises the panoramic lens body; the panoramic lens body is arranged within a hand-held mobile device; the panoramic lens body is set to extend out from the hand-held mobile device through the imaging systems; and when the panoramic lens body is set to contract into the hand-held mobile device, the panoramic lens body is recessed into or flush with the hand-held mobile device. The thickness-adjustable panoramic lens of the invention can be adjusted according to the actual requirements of the mobile device and can contract into the device when not being used.

Owner:中山市怡山光学有限公司

Manufacturing technology method of automobile motor fan housing

InactiveCN103802292AHeating temperature increasesReduce blushingManufacturing technologyInjection moulding

The invention discloses a manufacturing technology method of an automobile motor fan housing. The manufacturing technology method of the automobile motor fan housing comprises the following steps: drying materials, injection molding and putting products in order. The injection molding technological condition is adjusted, the drying time is prolonged, and paper baffles are formed among the formed products, so that the problems of whitening, damage caused by hitting and scratching and the like of the fan housing are prevented effectively, the quality of the automobile motor fan housing is improved, and the reject ratio of automobile motor fan housings is reduced.

Owner:HUIZHOU DONGFENG YIJIN IND

Automatic release appliance for optical lens

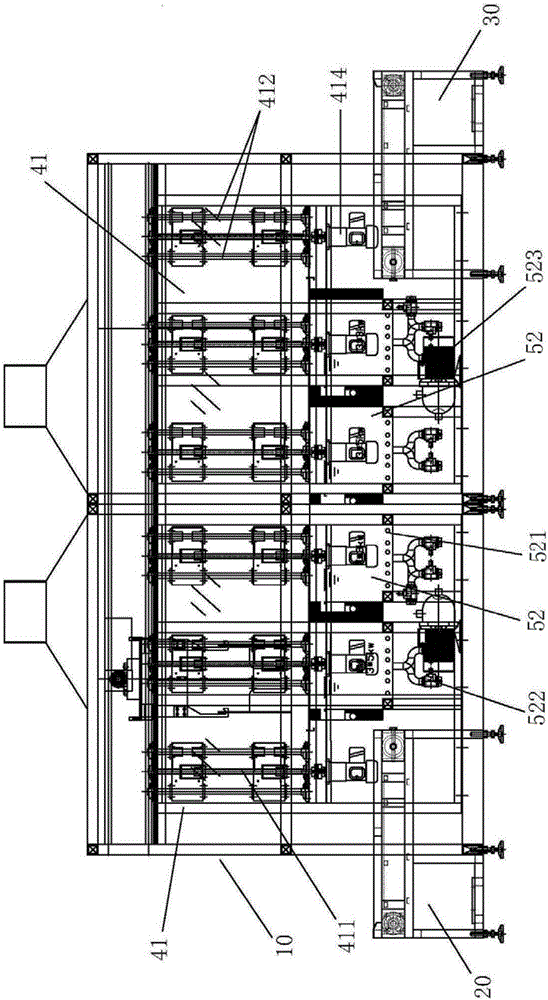

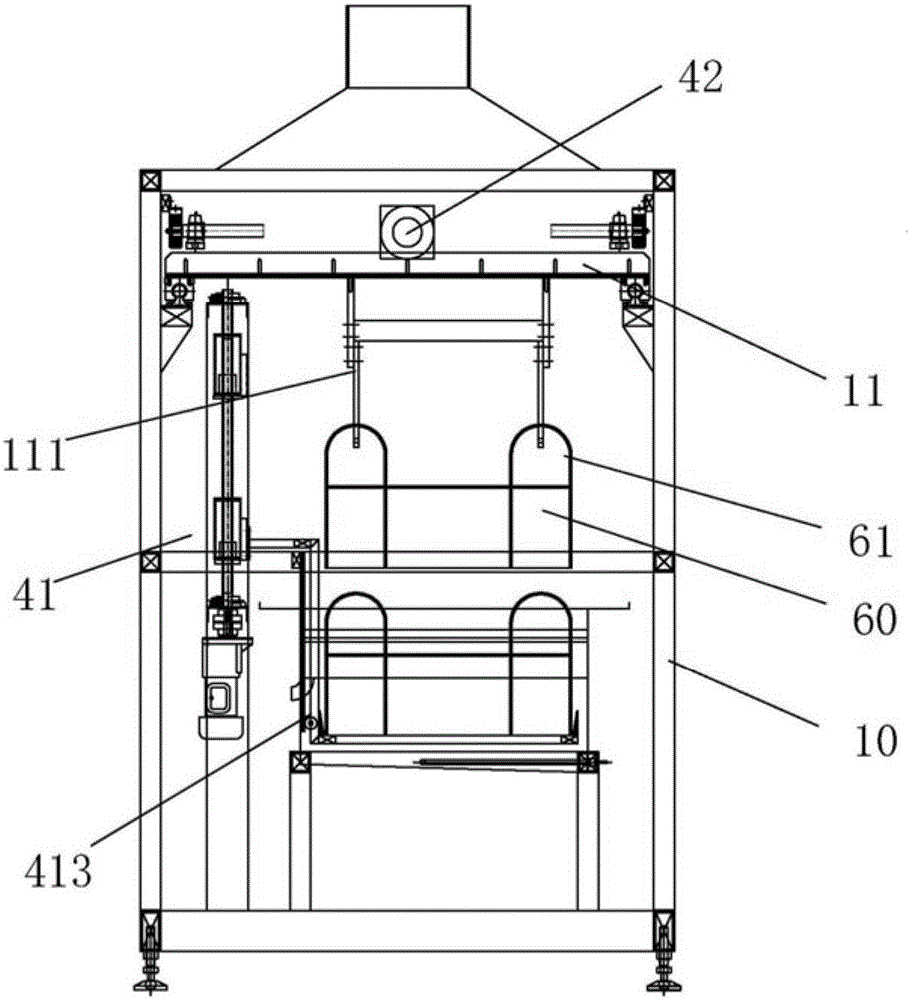

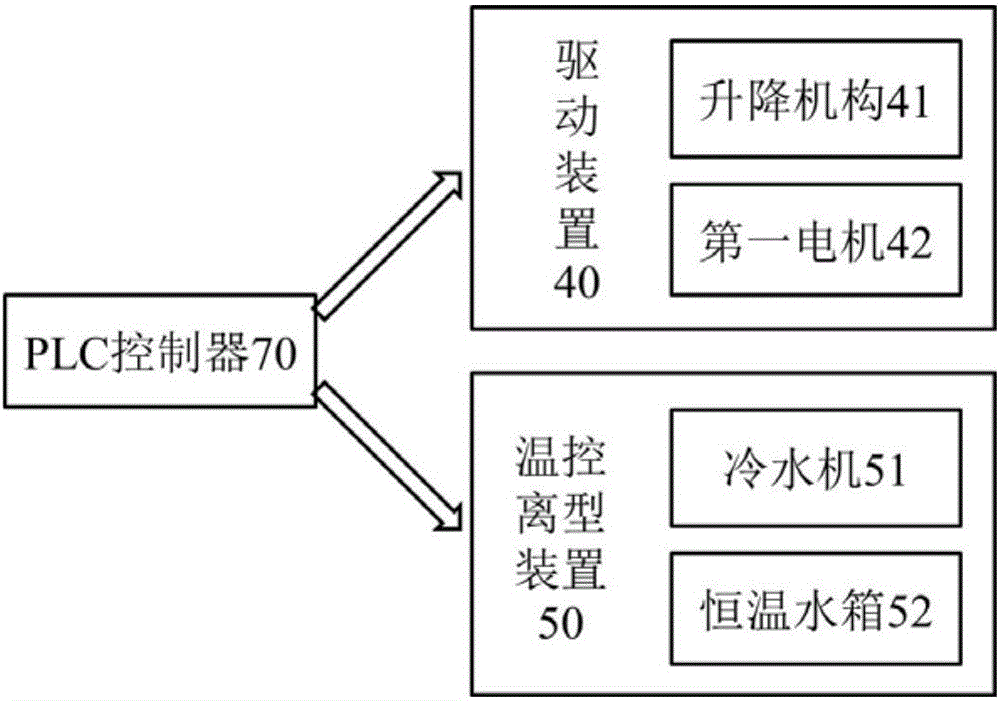

ActiveCN106477856AAccurate temperatureReduce lossGlass pressing apparatusTemperature controlControlled release

The application aims at providing an automatic release appliance for an optical lens. The automatic release appliance for the optical lens comprises a frame, a charging platform and a discharging platform, wherein the charging platform and the discharging platform are arranged on two sides of the frame respectively; the automatic release appliance for the optical lens also comprises a temperature-controlled release device; the temperature-controlled release device comprises a water cooler and a constant-temperature water tank which is arranged at the bottom of the frame; the water cooler is mounted outside the frame; a circulating water pump used for circulating cold and hot water is arranged between the water cooler and the constant-temperature water tank. Compared with the prior art, the automatic release appliance for the optical lens has the advantages that the temperatures of a heat source and cold water can be controlled precisely and in time, the release rate of the optical lens is high, the loss of a mold is low, a water source is wasted little, the structure is compact, the floor area is less, and the like.

Owner:上海银杉工业品销售有限公司

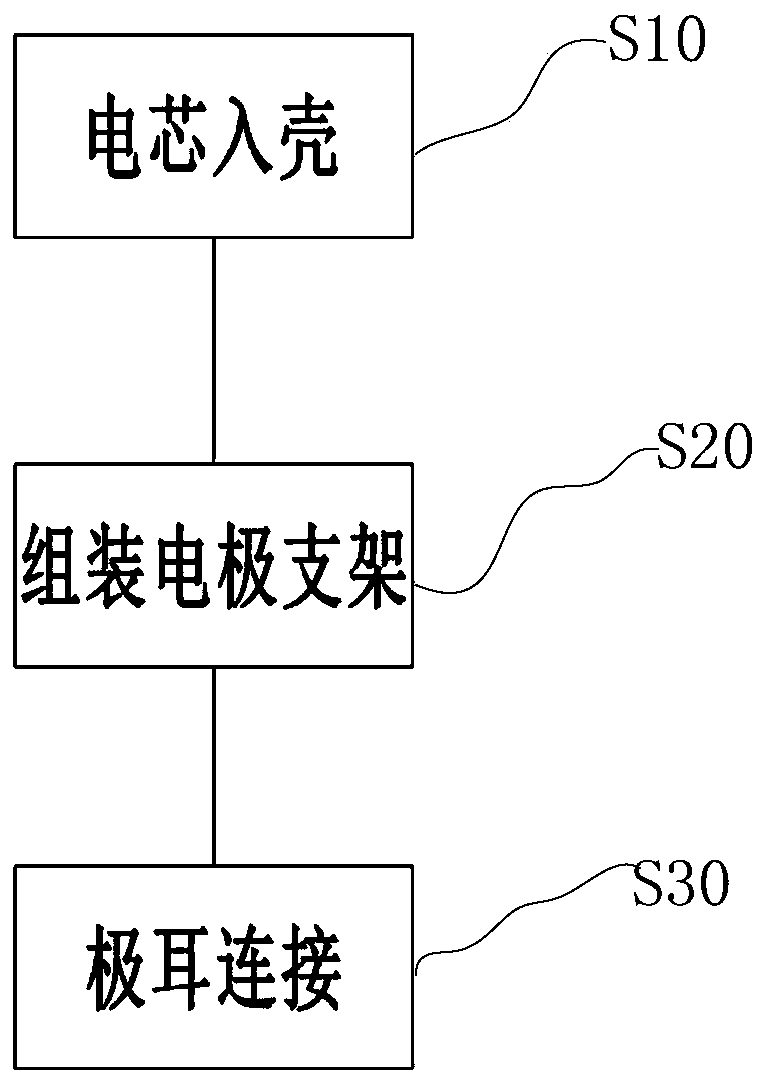

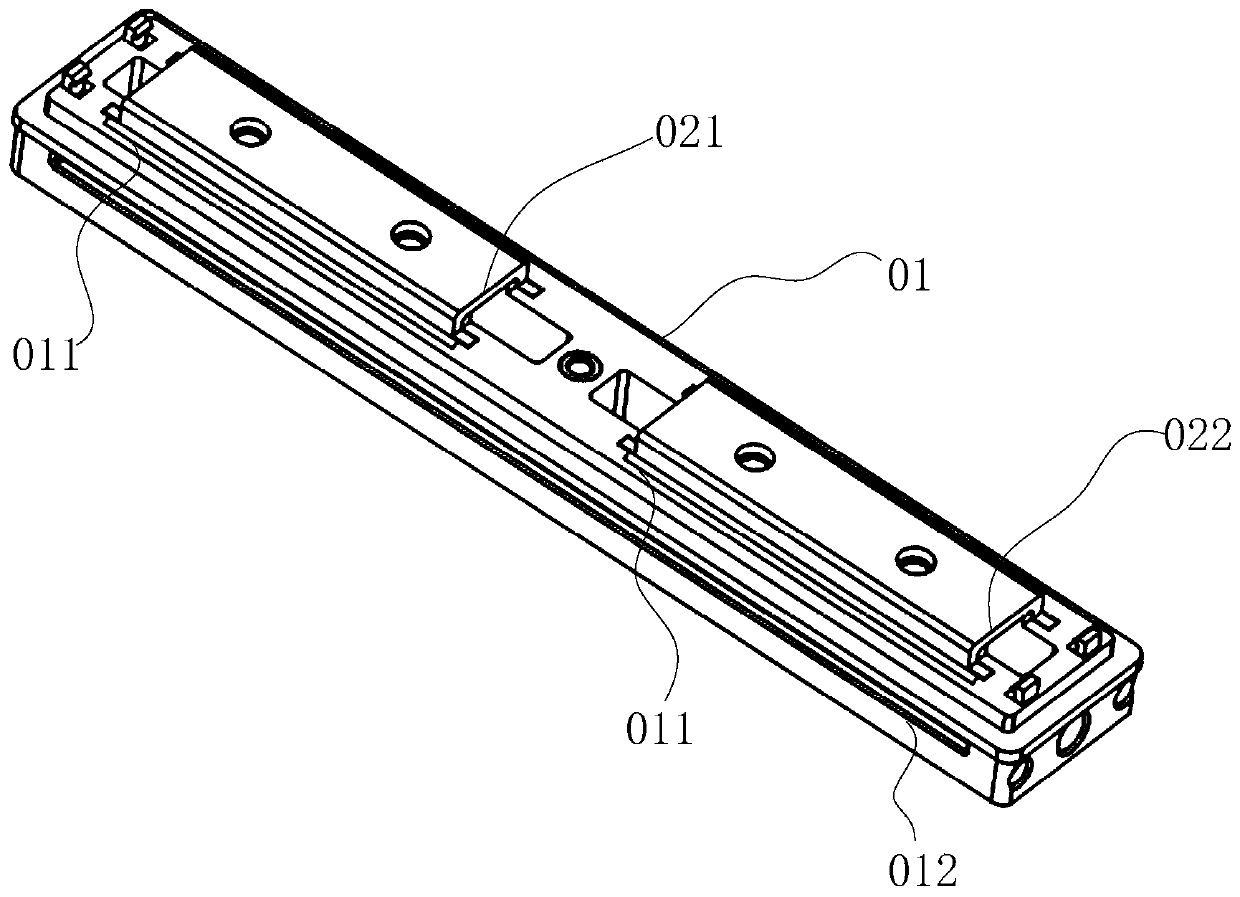

Battery module assembling method

InactiveCN109728337AGuarantee product qualityReduce bumps and scratchesFinal product manufactureSecondary cells manufactureElectrical batteryEngineering

The invention provides a battery module assembling method, and relates to the technical field of soft packing batteries. The provided battery module assembling method comprises the steps that S10) battery electrical cores are sent into a battery casing via an opening of the battery casing, and positive and negative tabs of the battery electrical cores all extend out of the opening of the battery casing; S20) an electrode support is fixed in the opening of the battery casing, and the positive and negative tabs of the battery electrical cores penetrate tab through grooves in the electrode support respectively; and S30) the part, extending out of the tab through groove, of each positive tab of the battery electrical core is fixed to a positive electrode of the electrode support, and the part,extending out of the tab through groove, of each negative tab of the battery electrical core is fixed to a negative electrode of the electrode support. Via the provided battery module assembling method, the technical problem that a battery assembly in the prior art is high in the assembling difficulty and low in efficiency is solved.

Owner:BEIJING NAT BATTERY TECH

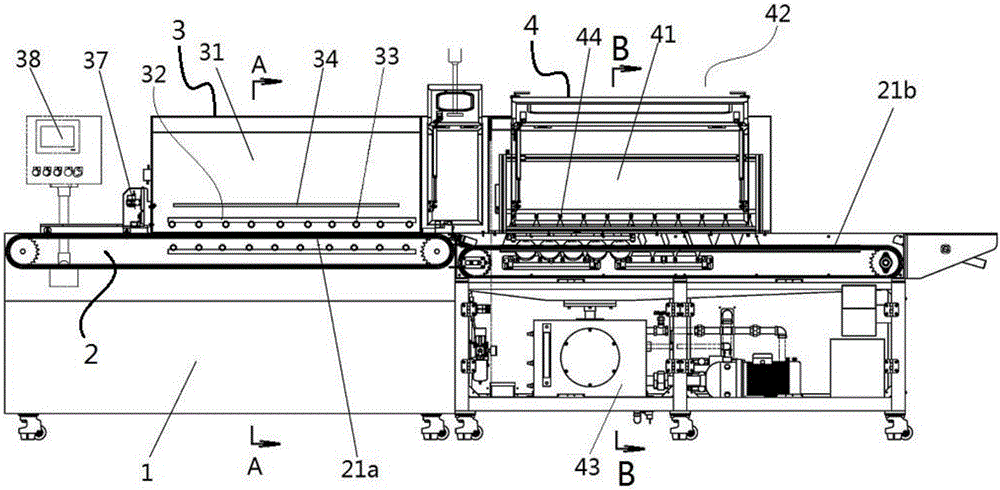

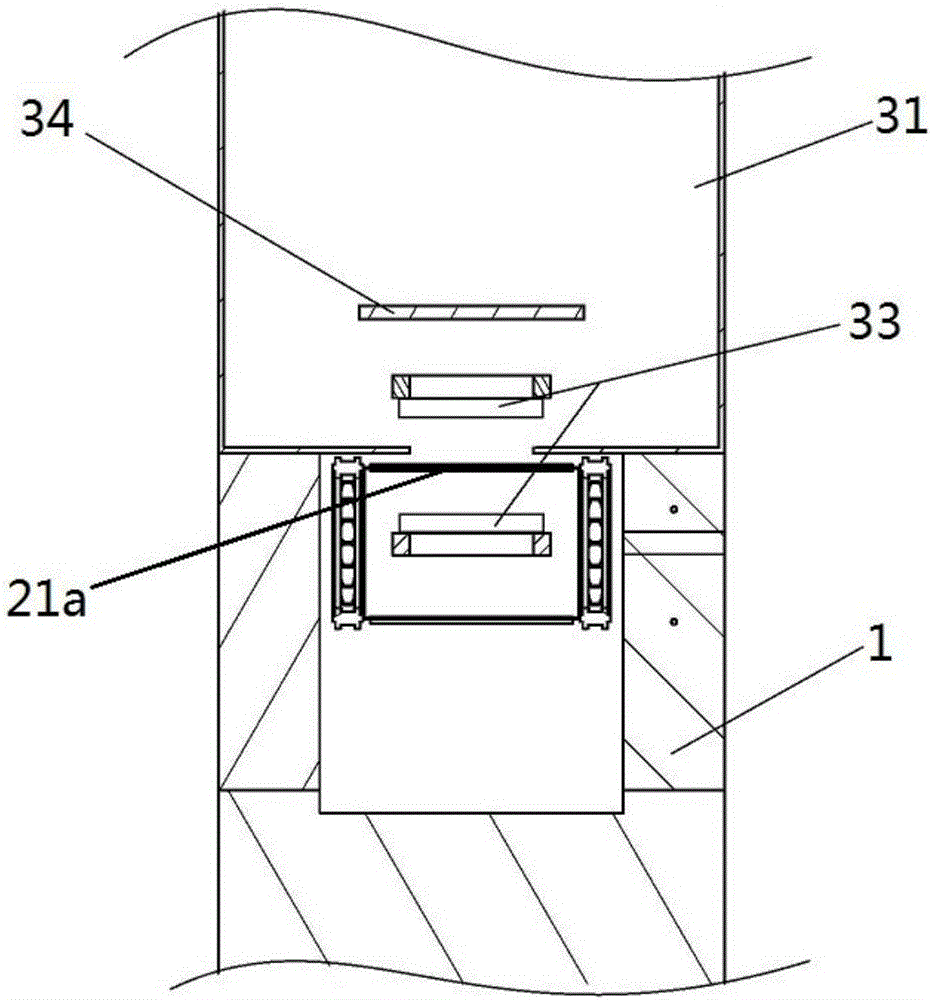

Automatic die opening device used for optical lenses

The invention discloses an automatic mold opening device for optical lenses, which includes a frame, a conveying unit, a heating unit, a cooling unit, and a controller. The conveying unit includes a conveyor belt horizontally arranged on the frame. The heating unit includes an oven for heating, the cooling unit includes a cooling box for cooling, the conveyor belt passes through the oven and the cooling box in turn, the delivery unit, the heating unit, and the cooling unit are connected to the controller. The conveying unit is controlled by the controller to transport the template and the lens taken out of the curing furnace to the heating unit for heating, and then to the cooling unit for cooling. After the lens and the mold are alternately cooled and heated, the deformation of the lens and the mold are separated after cooling. , to achieve automatic mold opening, without manual mold opening, improve production efficiency, automatic mold opening, reduce bumps and scratches on the lens, and improve the pass rate of products.

Owner:SHANGHAI MAIWAN IND AUTOMATION CO LTD

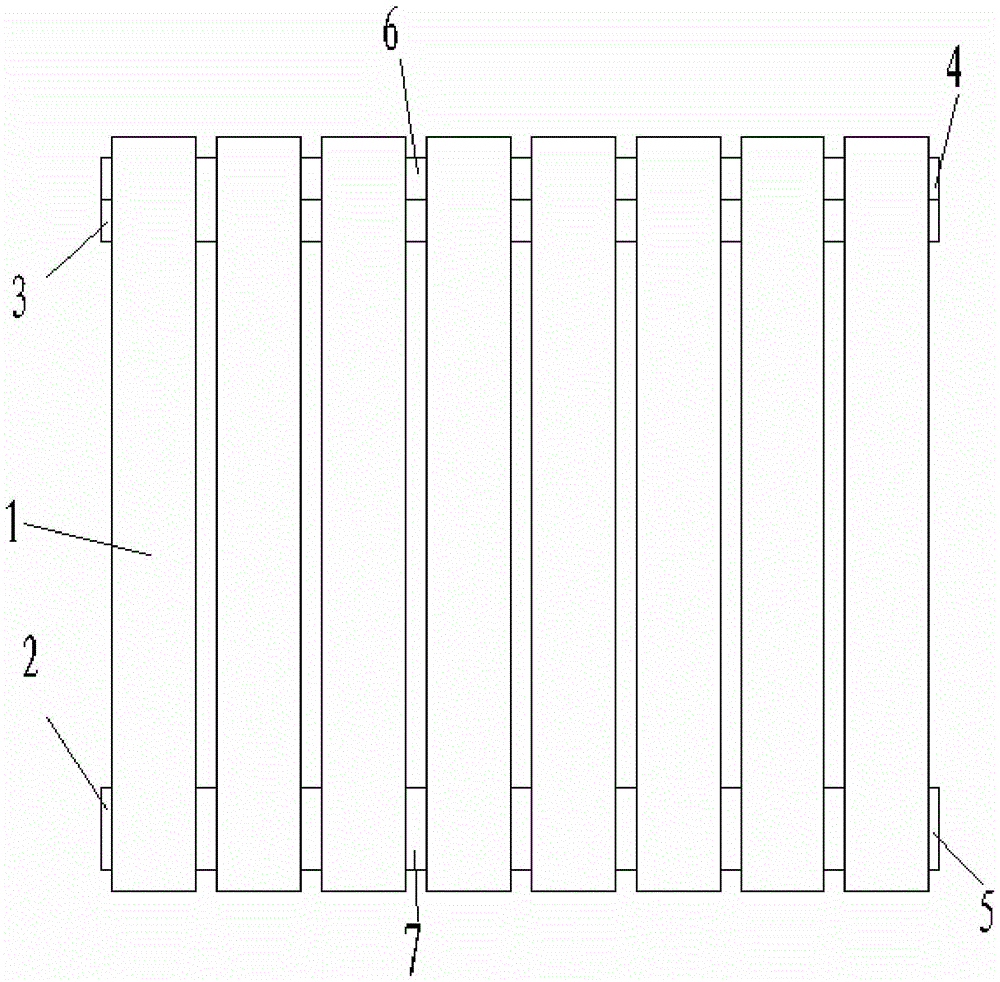

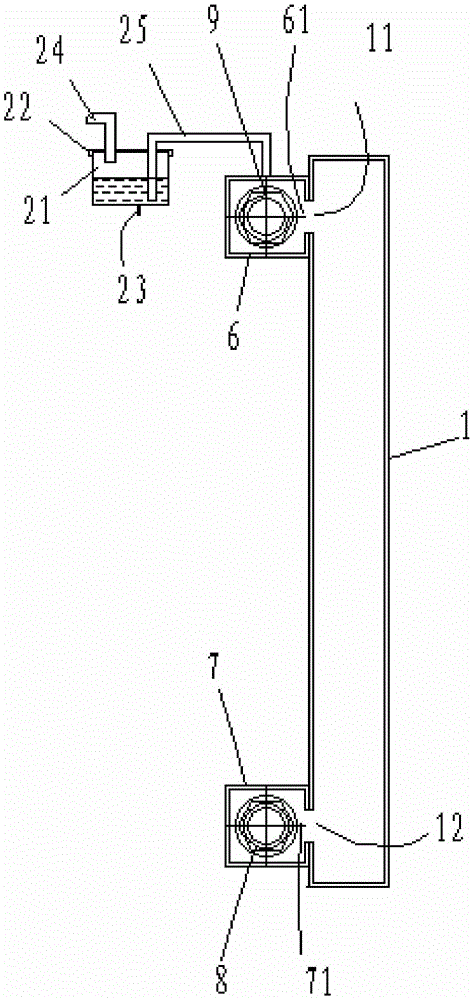

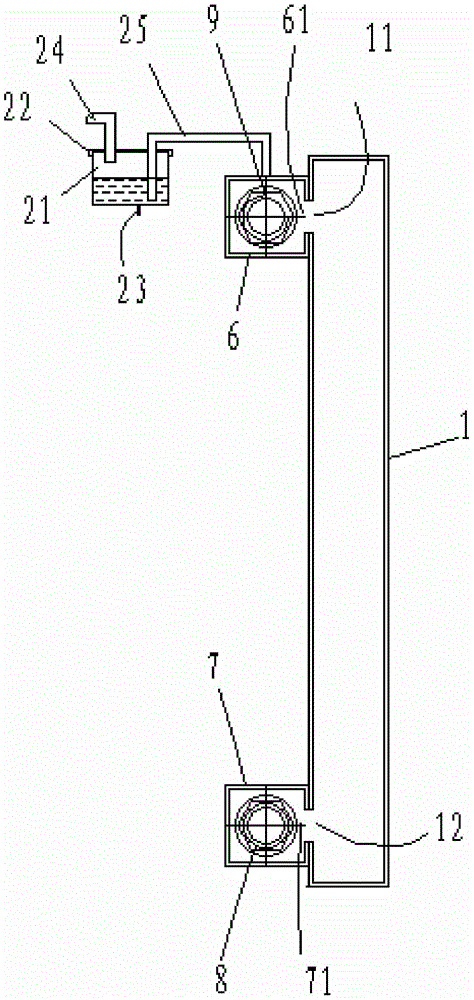

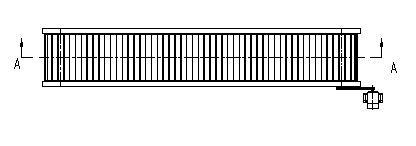

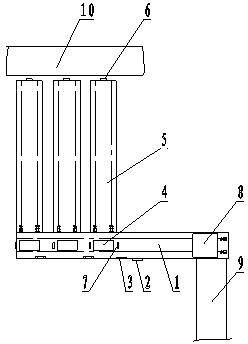

Radiator for heating with large cooling area

ActiveCN105021059BReduce occupancyImprove the effective use of areaStationary conduit assembliesHeat exchanger casingsWater flowEngineering

The invention discloses a heating radiator with a large heat dissipation area, which comprises an upper water tank, a lower water tank, and a cooling fin. The upper water tank is provided with a water inlet and a water outlet; A sealed cavity with an upper connection port and a lower connection port at the lower part, the upper connection port and the lower connection port are arranged on the same side of the sealed cavity body, the two ends of the upper water tank and the two ends of the lower water tank are respectively provided with internal threads, and the upper part The outer section of the water tank and the lower water tank perpendicular to the water flow direction is rectangular, and the outer section of the cooling fin perpendicular to the water flow direction is rectangular. The present invention adopts the detachable connection of the water inlet and the water outlet, and selects the water inlet, the water outlet and the water inlet and outlet paths according to the installation requirements, and has a compact structure, is suitable for use in a narrow installation space, reduces space occupation, and increases the effective use area of the space. The heat dissipation area is large, the heat radiation source is increased, the heat dissipation efficiency is accelerated, the heat utilization rate is improved, and the effectiveness of the radiator is fully exerted.

Owner:JINAN QUANZHONGXIN BUILDING MATERIAL

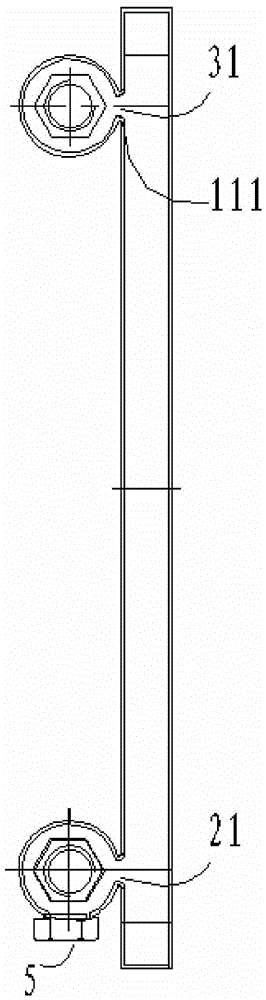

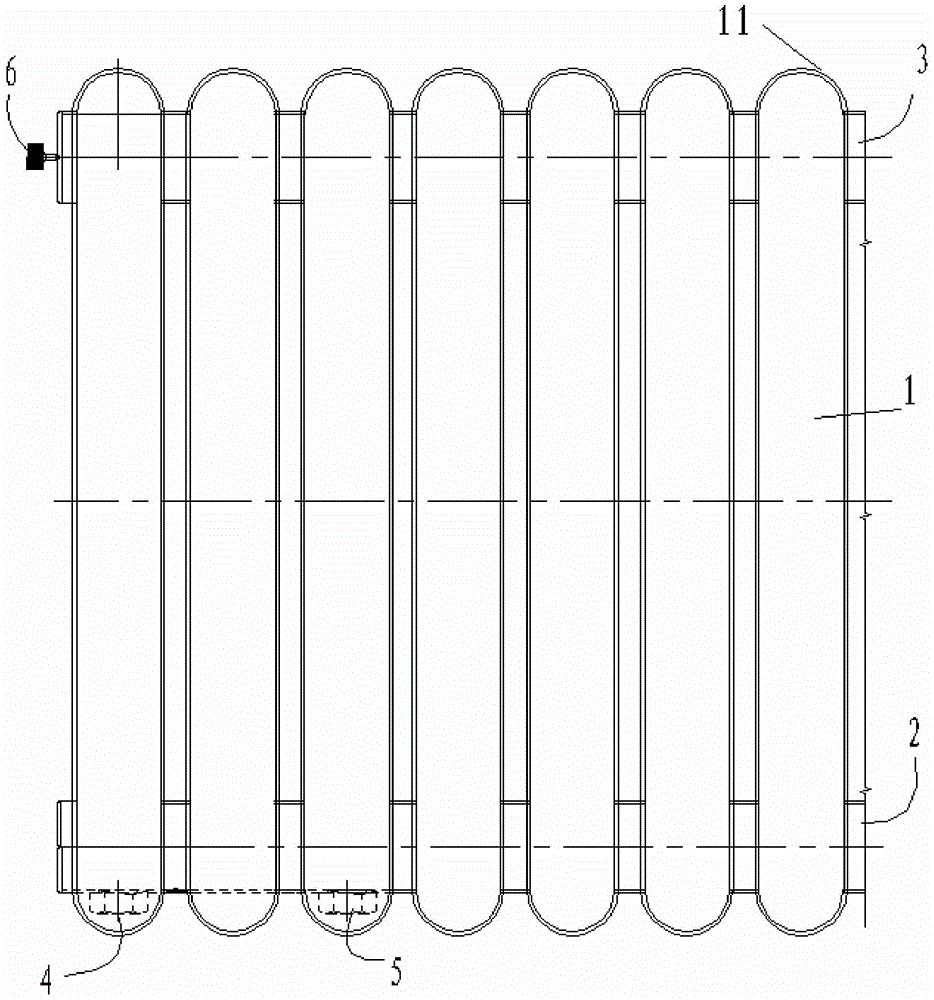

Heating radiator with large radiation area

ActiveCN105021059AReduce occupancyImprove the effective use of areaStationary conduit assembliesHeat exchanger casingsWater flowEngineering

The invention discloses a heating radiator with a large radiation area. The heating radiator comprises an upper water tank, a lower water tank and cooling fins. The upper water tank is provided with a water inlet and a water outlet. The lower water tank is provided with a water inlet and a water outlet. Each cooling fin is a sealing cavity which comprises an upper connector arranged on the upper portion and a lower connector arranged on the lower portion, wherein the upper connector and the lower connector are arranged on the same side of the sealing cavity. The two ends of the upper water tank are provided with internal threads respectively. The two ends of the lower water tank are provided with internal threads respectively. The outline section of the upper water tank and the outline section of the lower water tank are rectangular in the direction perpendicular to water flow. The outline sections of the cooling fins are rectangular in the direction perpendicular to the water flow. The water inlets and the water outlets which are detachably connected are adopted, the water inlets, the water outlets and water inlet and outlet paths are selected according to installation needs, the structure is compact, and the heating radiator is suitable for being used in a narrow installation space. Occupied space is reduced, and the effective utilization area of the space is increased; the cooling area is large, thermal radiation sources are increased, radiating efficiency is improved, the heat utilization rate is improved, and the efficiency of the radiator is given to full play.

Owner:JINAN QUANZHONGXIN BUILDING MATERIAL

Welding production line for evaporator assembly

The invention discloses a welding production line for an evaporator assembly, which comprises a support assembly, a tensioning mechanism, a power driving device, a sprocket wheel transmission support device and a support plate. The sprocket wheel transmission support device is arranged inside the support assembly and is composed of a plurality of groups of sprocket wheel transmission mechanisms parallelly arranged on a set of sprocket wheel shaft. One end of the sprocket wheel shaft is connected with the power driving device. The support plate is transversely and fixedly connected with the outer sides of a plurality of groups of parallelly arranged chains and is manufactured by compounding metal material and non-metal abrasion resistant material. When the welding production line is in use, all components are placed on the support plate, the conveying translation of the evaporator assembly from a prior work station to a next work station is realized through the sprocket wheel transmission support device, and therefore, the labor intensity of workers is greatly reduced, the labor efficiency is greatly increased, and on the other hand, the limping and the scratching on the surface of a component are also reduced.

Owner:JIANGSU YAGUANG METAL PROD

A parking guidance device

The invention discloses a parking space guiding device, which comprises a garage frame fixed on the ground, a lifting chamber with an opening facing forward is fixed in the garage frame, a vehicle frame is slid in the lifting cavity, and the vehicle There is a car cavity with an opening facing forward fixedly in the frame. The device of the present invention is simple in structure and easy to use. The device is provided with front and rear wheel restricting parts. By restricting the front and rear wheels at the same time, the three-dimensional garage will Even if the handbrake is slightly pulled by the driver, the car will not move and cause a collision, and this device is equipped with anti-scratch parts. When the front of the car or the body hits, the anti-scratch parts are equipped with a buffer mechanism and a sponge pad to absorb the car. The kinetic energy gives the driver sufficient time to stop the vehicle, reducing or even eliminating the occurrence of collisions and scratches.

Owner:英都科技(广州)有限公司

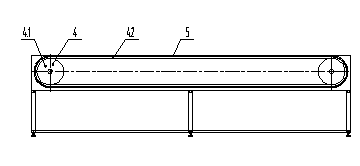

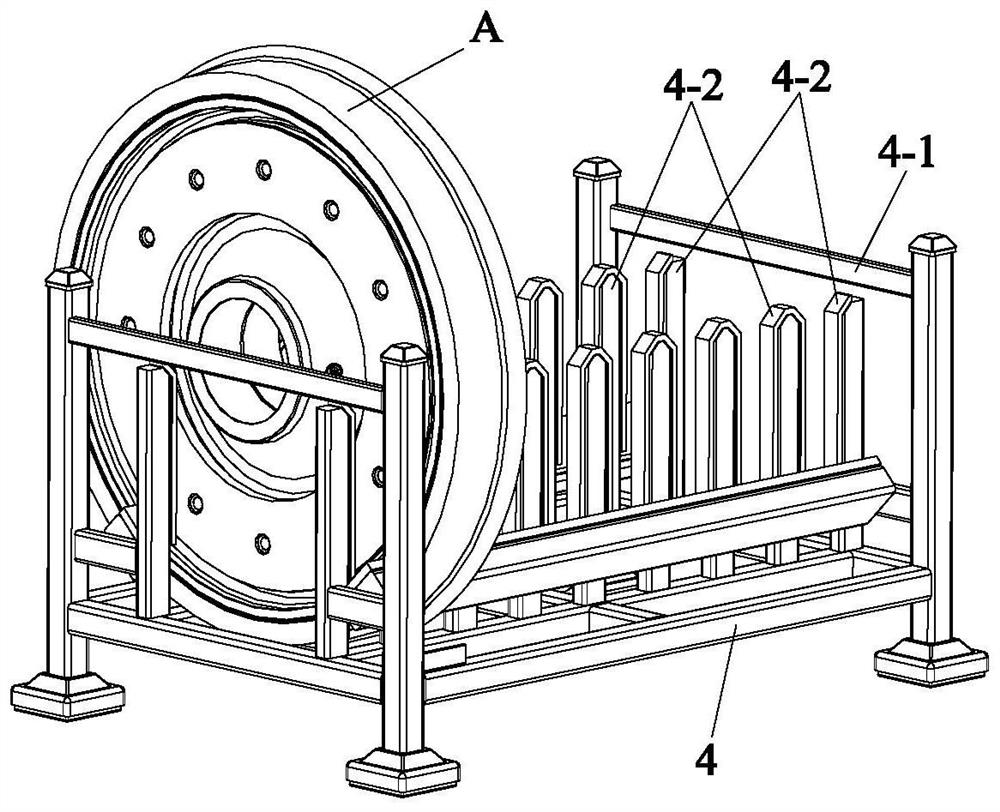

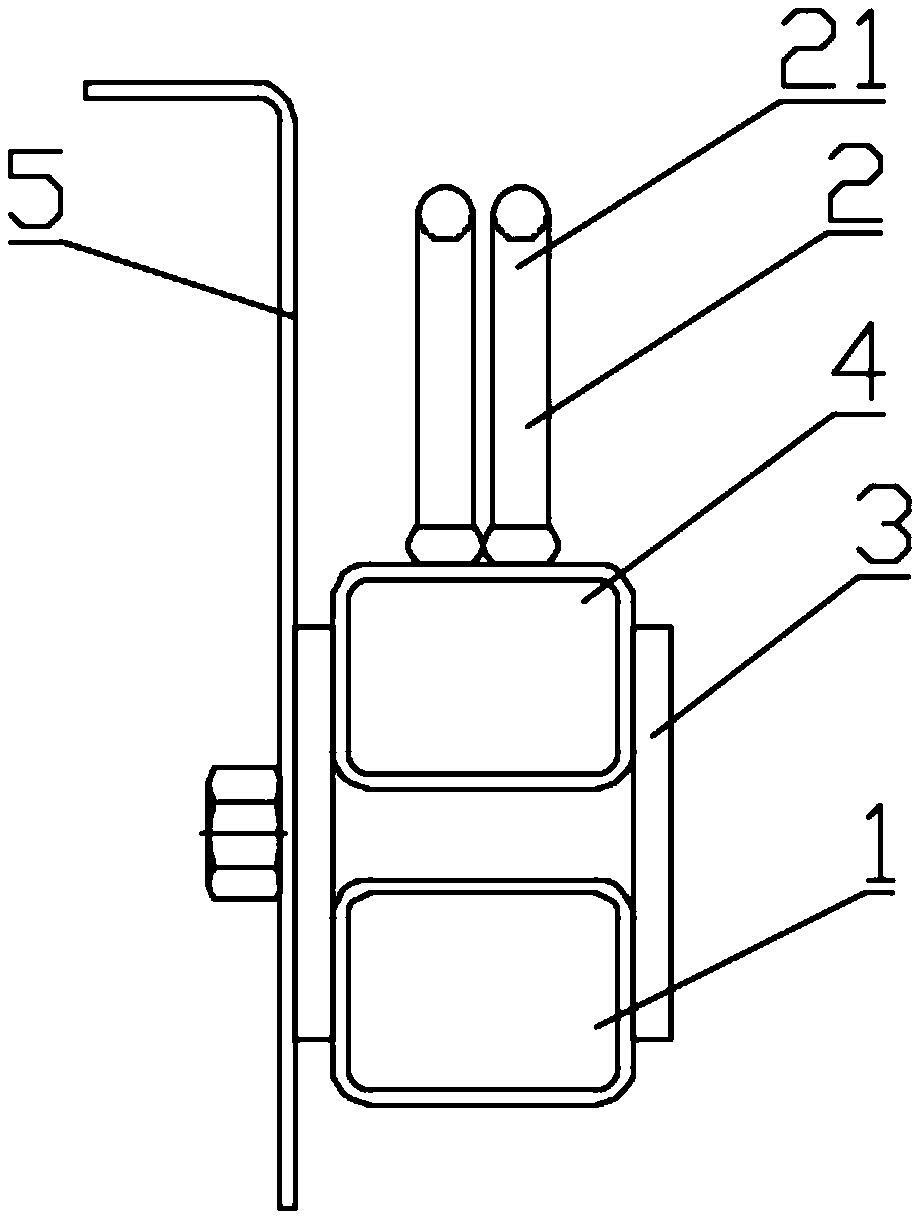

Pre-assembling device for wheel-mounted brake disc of motor train unit

PendingCN113843732AEasy to operateAvoid occlusion interference problemsWork holdersNylon materialBrake

A pre-assembling device for a wheel-mounted brake disc of a motor train unit is characterized in that the pre-assembling device comprises a support platform, a bearing mechanism and a mandrel mechanism, the support platform comprises a horizontal base, a vertical support and an anti-collision base plate, and the mandrel mechanism comprises a center shaft, an inner sleeve and an outer sleeve. Operation convenience is provided for mounting other wheel accessories on the front end face of a hub and mounting a plurality of bolts on the wheel-mounted brake disc, and the problem that an existing storage rack shields and interferes with a wheel mechanism A in the mounting process is solved. By means of the cone angle parameter design of the sleeve with the cone outer side wall, the wheel mechanism A can slide to the end where an annular baffle is located through the self weight, so that the wheel mechanism A is prevented from slipping off the sleeve, and the slipping risk of the wheel mechanism A is further reduced through a disengaging stop ring located at the front end of the mandrel mechanism B. The anti-collision base plate and the outer sleeve are both made of nylon materials, and collision and scratching of the wheel mechanism A in the assembling process are effectively reduced.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Downhole plugging device

ActiveCN110185412BPlay a protective effectReduce bumps and scratchesSealing/packingEngineeringStructural engineering

The invention provides an underground leakage stopping device which comprises at least one hood barrel, at least one material storage pipe filled with a leakage stopping material, and a detonating fuse and a detonating mechanism for detonating the detonating fuse, wherein at least one channel communicating to the inner and outer sides of the hood barrel is arranged on the outer wall of the hood barrel; the material storage pipe is arranged in the at least one hood barrel; the detonating mechanism is mounted at the upper end of the hood barrel, the upper end of the detonating fuse is connectedto the detonating mechanism, and the lower end of the detonating fuse is arranged in the material storage pipe; when the detonating fuse explodes, the material storage pipe can be exploded and the leakage stopping material in the material storage pipe is driven to be spray out of the hood barrel through the channel. The underground leakage stopping device solves the technical problem that a leakage treatment method in the prior art is relatively poor in effect and is hard to take effect at one time.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Radiators for efficient heating

ActiveCN104990428BReduce occupancyImprove the effective use of areaStationary conduit assembliesEngineeringThin sheet

The invention discloses a radiator for efficient heating. The radiator comprises an upper water tank, a lower water tank and a radiating pipe; the upper water tank is connected with the lower water tank through the radiating pipe and is connected with an opening at the upper portion of the radiating pipe through a horizontal water inlet, and the lower water tank is connected with an opening at the lower portion of the radiating pipe through a horizontal water outlet; heat reflection plates are vertically arranged on the outer side of the upper water tank and the outer side of the lower water tank, and the outer surface of the upper water tank and the outer surface of the lower water tank are of cylinder structures; a thin-sheet annular fixing clamp with an opening on one side is arranged on the outer surface of each cylinder, inwards-protruding arc-shaped clamping jaws are arranged at the two ends of the opening of each fixing clamp, and fixing clamping grooves are arranged on radiating sheets at the horizontal water inlet and the horizontal water outlet; and the clamping jaws of the fixing clamps are matched with the clamping grooves, and the two clamping jaws are clamped at the positions, close to the radiating pipe, of the inner sides of the clamping grooves. The radiator for efficient heating is compact in structure, conversion of the water in-and-out directions is conveniently achieved, the radiator can be reasonably installed and fixed within narrow space, occupation of the space is reduced, the heat radiating range is long, and the radiating efficiency is high.

Owner:JINAN QUANZHONGXIN BUILDING MATERIAL

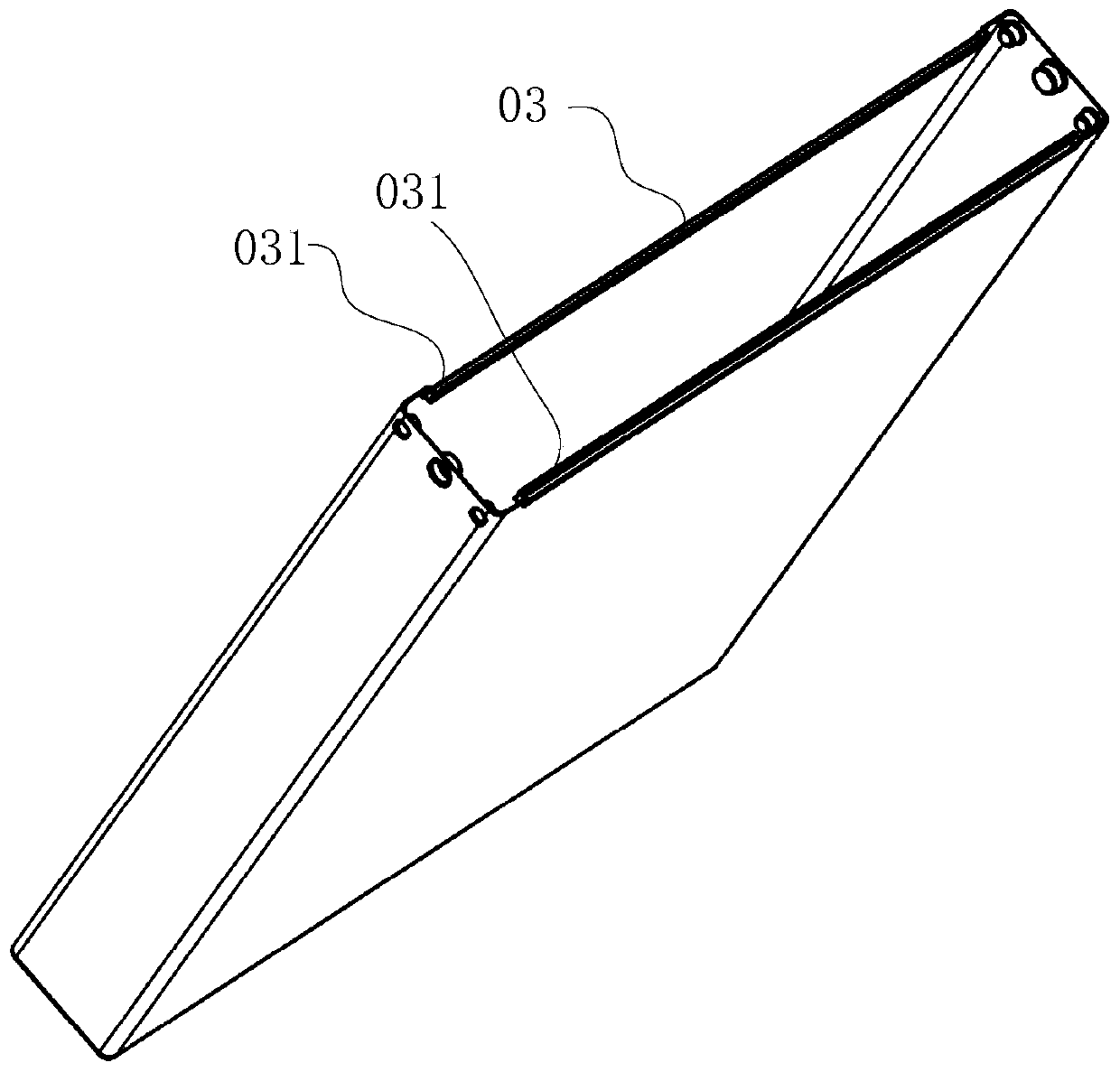

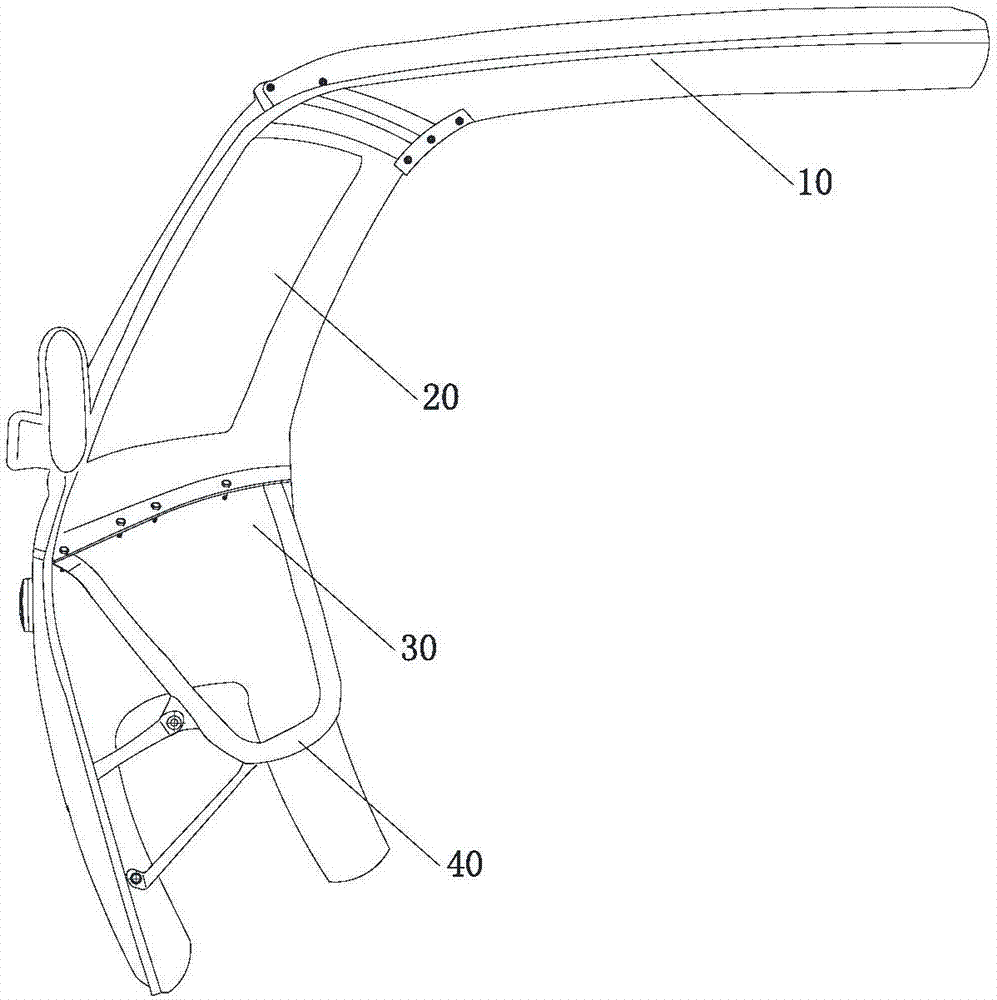

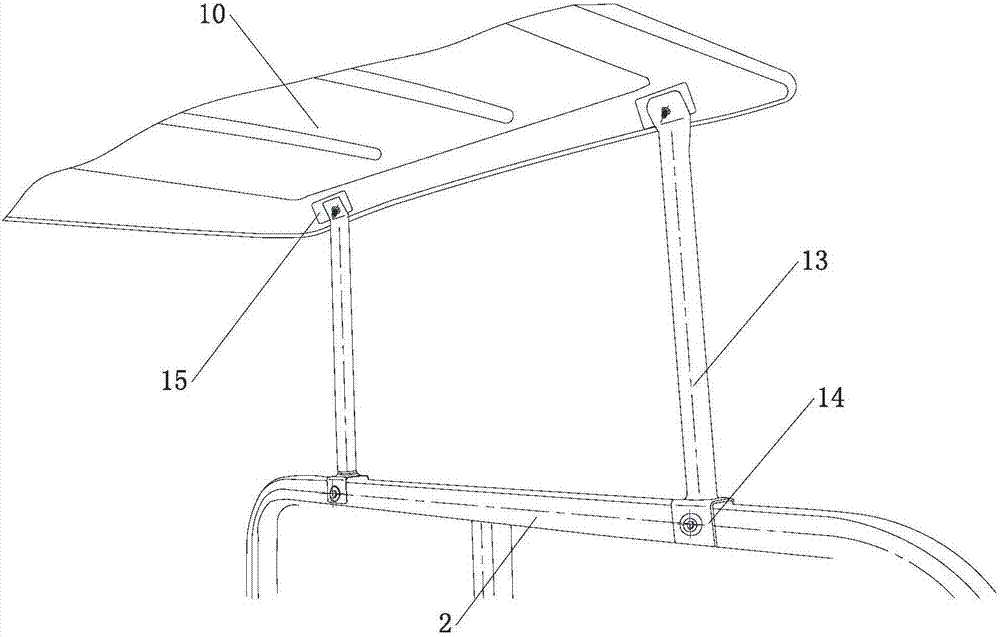

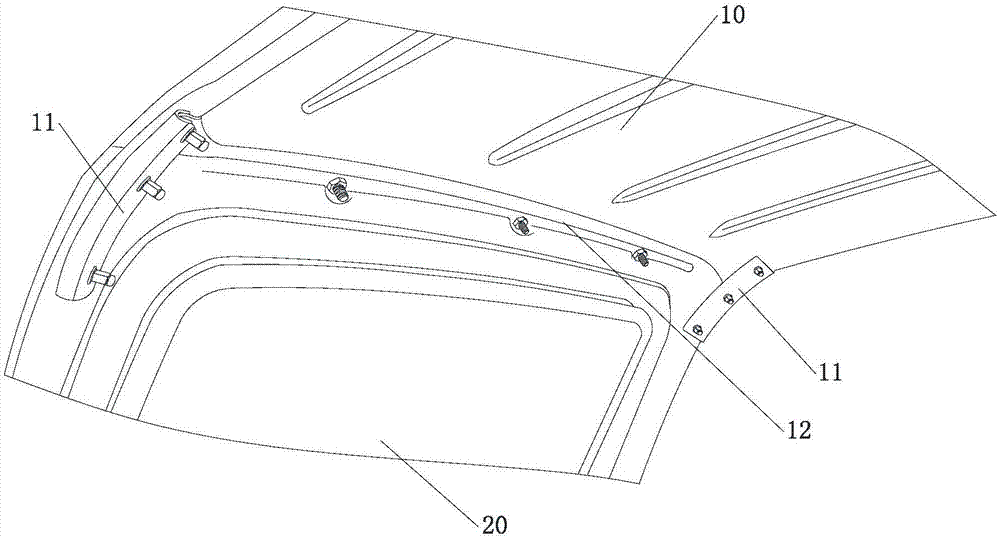

Split type head tent structure of tricycle and tricycle with structure

The invention discloses a split type head tent structure of a tricycle and the tricycle with the structure. The structure comprises a head tent upper top cover, a head tent front windshield, a head tent lower windshield and a head tent lower windshield supporting rod, wherein the edge of the front portion of the head tent upper top cover is in lap joint with the edge of the upper portion of the head tent front windshield and is fixedly connected through a locking part, and arc-shaped edge-covered connecting blocks are arranged at two ends of the connecting position of the head tent front windshield and are fixedly connected with the head tent upper top cover or / and the head tent front windshield. A turnup is inwards arranged at the lower portion of the head tent front windshield and the upper portion of the head tent lower windshield respectively, the head tent front windshield and the head tent lower windshield are locked and fixedly connected through the turnups, the head tent lower windshield supporting rod is of a U-shaped structure, and two free ends of the supporting rod are in flat shapes and are fixedly connected to the turnup of the head tent front windshield or the head tent lower windshield. A connecting rod is arranged on the head tent lower windshield supporting rod, and the other end of the connecting rod is fixedly connected to the head tent lower windshield. The tricycle adopts the split type head tent structure, the cost in the production, transfer and assembly process is reduced, the space occupied for package and transfer is small, the bumping and scratching situations in the packaging and transfer process are also decreased, and the service life is long.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

A chassis on-line flipping device

The invention discloses an on-line flipping device for a chassis. A bracket (2) is connected to a base (1) through a rotating shaft (11), and can rotate relative to the base (1) around the rotating shaft (11); it is installed on the base (1). The traveling motor (8) on the pedestal rotates and drives the rack and pinion mechanism (9) connected with the traveling motor (8) to drive the entire equipment to walk in the foundation; the rotary motor (6) installed on the base (1) rotates and drives The transmission chain (7) fixed on the turning ring (3) rotates to drive the entire turning ring to rotate; The turning ring (3) rotates around the rotating shaft (11) together to realize the retracting movement of the bracket and the turning ring; the present invention can realize turning over without the need of offline of the chassis, and can reduce the bumping of the chassis and the damage caused by twisting. Deformation, promote lean production while improving product quality.

Owner:XUZHOU HEAVY MASCH CO LTD

A lifting and translation equipment based on circular pipe transfer noise reduction transmission

The invention discloses a lifting translation device based on circular pipe transfer noise reduction transmission, the structure of which comprises a left gear lifting plate, a pipe cover, a right gear lifting plate, a pendant block, a bottom bracket, a pipe cover and a left gear lifting plate 1. The lifting plate of the right gear is installed and connected, the lifting plate of the right gear is connected with the shaft of the falling block, the lifting plate of the left gear, the lifting plate of the left gear and the lifting plate of the right gear of the present invention drive the pipe cover to move on the bottom bracket to move the round pipe Put it in the tube cover, and then move the mobile device through the bottom bracket to realize the transfer of the round tube. The transfer of the round tube is done by the equipment instead of manual, which greatly improves the safety during the transfer. The screw teeth are moved in the way of meshing with the bottom bracket , the stability is improved, and the movement is assisted by the moving key, so that when the round pipe is transferred to the pipe cover, the collision and scratch are minimized, and the track lock is used to further strengthen the pipe cover when moving, and the pad wheel structure is flexible The round tube can be moved efficiently, effectively reducing noise and keeping the round tube intact.

Owner:苏州绿萃筑信息科技有限公司

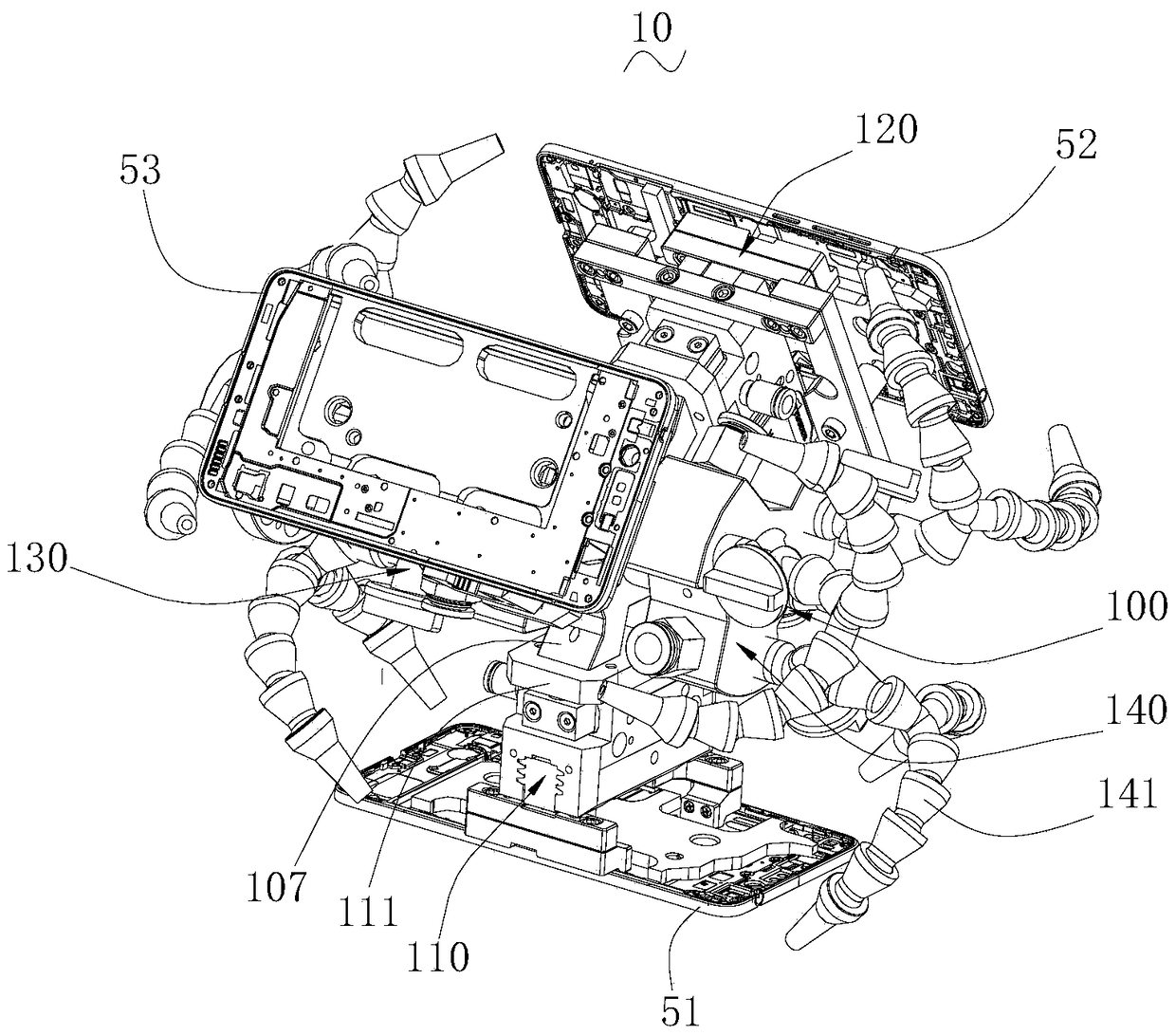

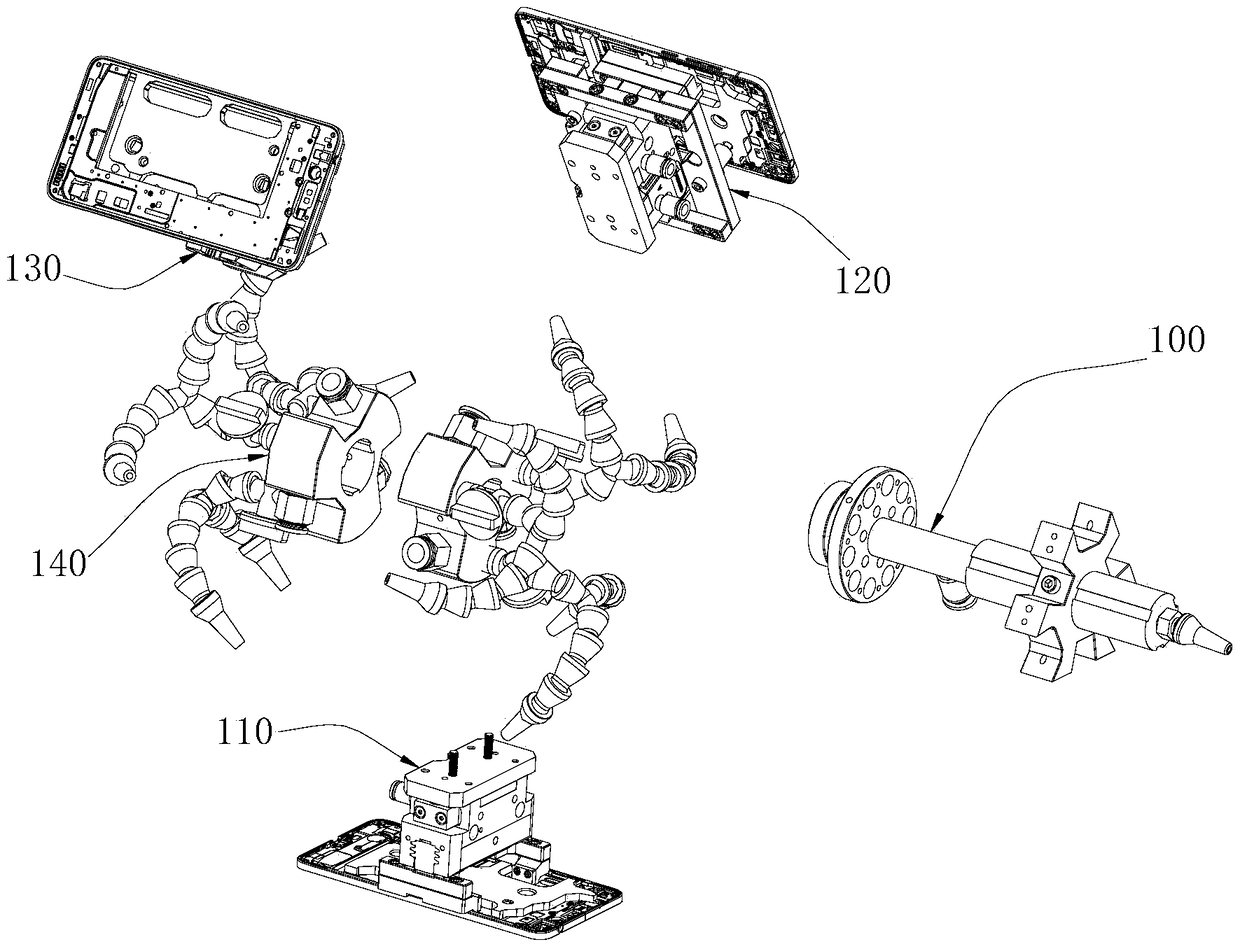

Intelligent robotic hand

ActiveCN105364621BIncrease productivityReduce manufacturing costMetal working apparatusMaintainance and safety accessoriesEngineeringInjection air

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD +1

Lifting and translation device based on circular tube transferring noise-reduction transmission

The invention discloses a lifting and translation device based on circular tube transferring noise-reduction transmission. The lifting and translation device structurally comprises a left gear liftingdisc, a tube shield, a right gear lifting disc, a falling block and a bottom support. The tube shield is assembled and connected with the left gear lifting disc and the right gear lifting disc. The right gear lifting disc is in shaft connection with the falling block. The left gear lifting disc and the right gear lifting disc drive the tube shield to move on the bottom support so that a circulartube can be stored into the tube shield, then, movable equipment is moved by the bottom support so that the circular tube can be transferred, the equipment is used for replacing manual work to transfer the circular tube, the safety during transferring is greatly improved, screw teeth are moved in the mode of being meshed with the portion at the bottom support, and the stability is improved. Due toauxiliary motion of a movable key, when the circular tube is transferred to the position of the tube shield, collision and scraping are greatly lowered, motion of the tube shield is further reinforced through a track lock, due to the structure of a cushion wheel, the circular tube is flexibly moved, noise is effectively lowered, and the circular tube is kept intact.

Owner:苏州绿萃筑信息科技有限公司

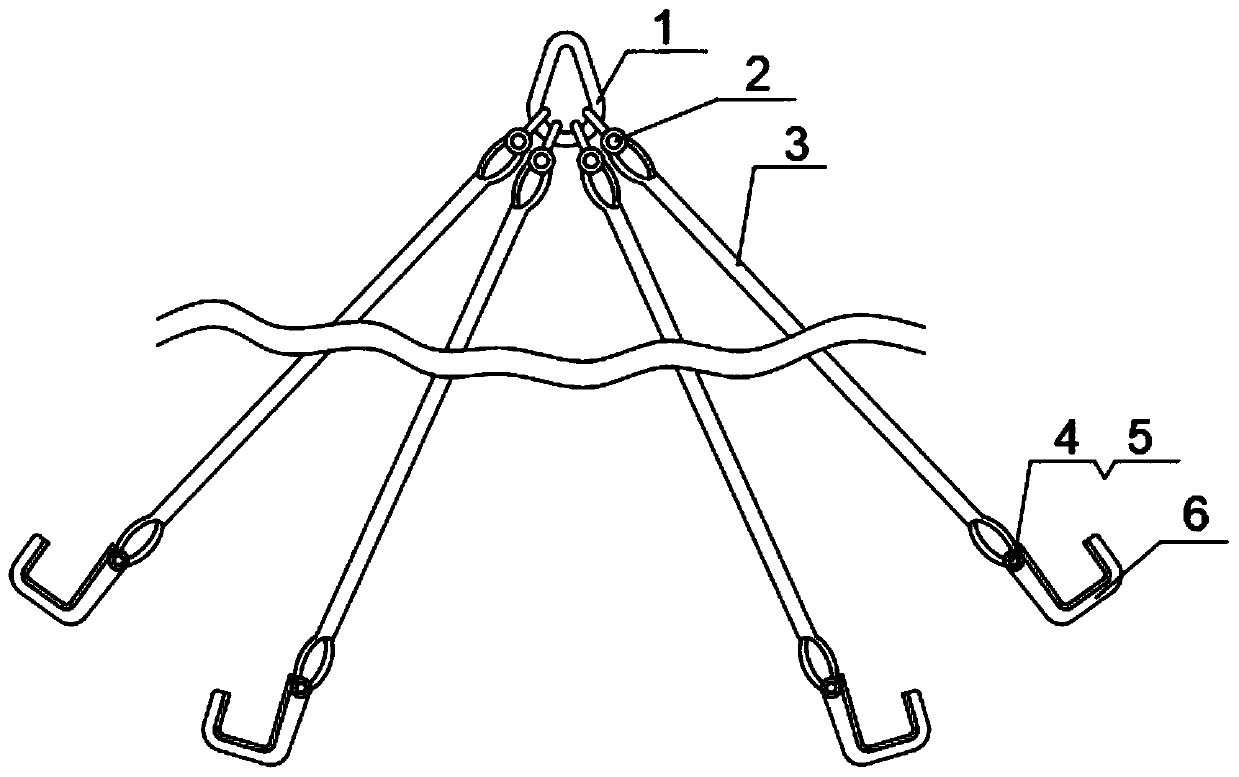

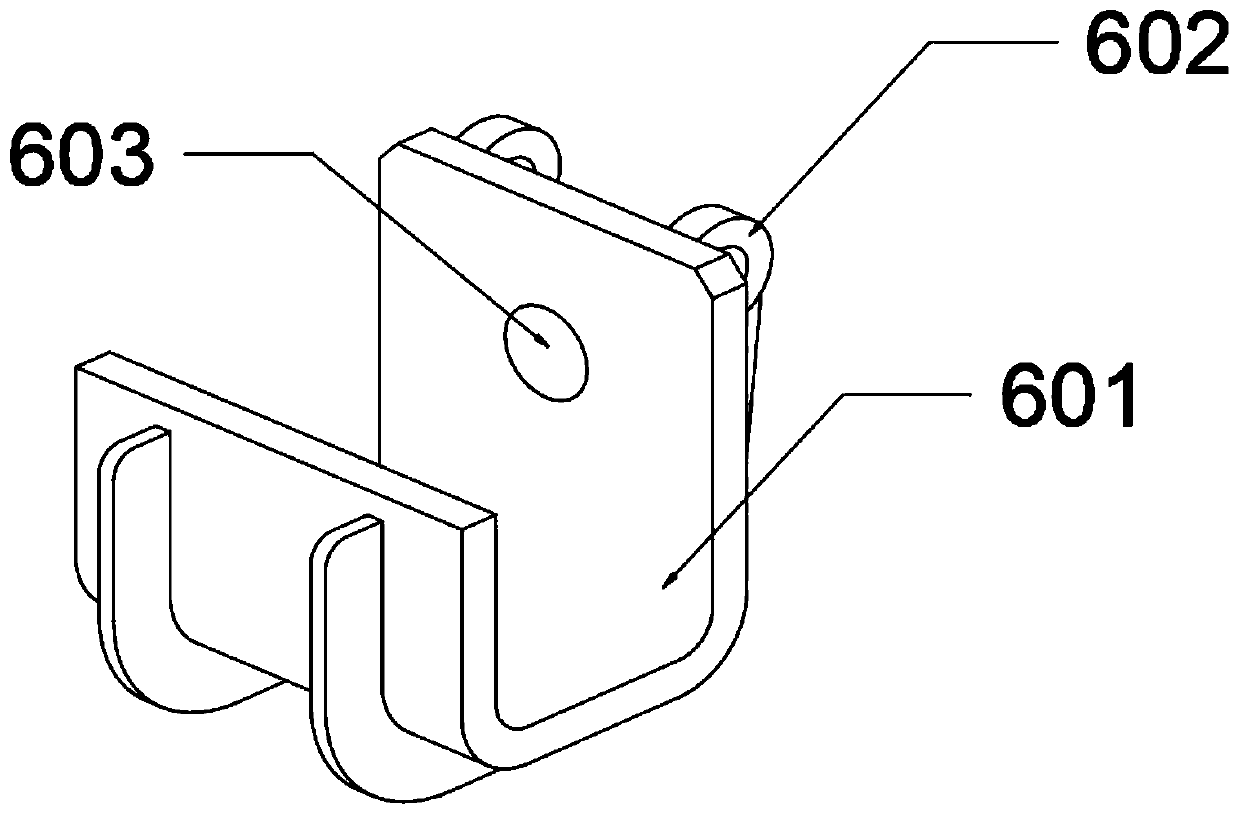

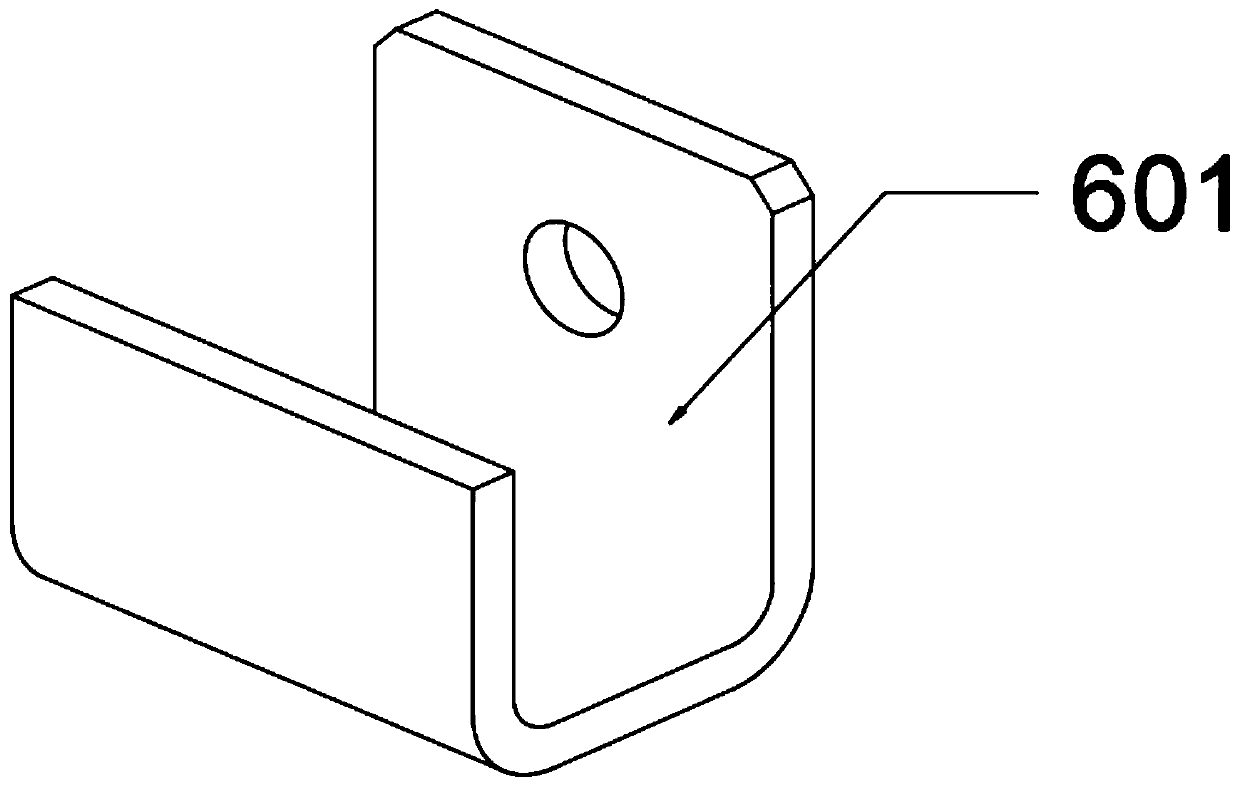

Special lifting appliance of large volume van vehicle carriage assembly

The invention provides a special lifting appliance of a large volume van vehicle carriage assembly, which comprises a pear-shaped lifting ring, D-shaped shackles, flat lifting belts with two end buckles, pin shafts, cotter pins, lifting hook assemblies, a supporting plate, a rear plate, and a magnetic bar; the D-shaped shackles can be fixedly arranged at the outer end of the pear-shaped lifting ring through a buckle structure correspondingly, and the flat lifting belts with the two end buckles are fixedly fixed to the bottoms of the D-shaped shackles through lock catches; the pin shafts are fixedly arranged at the bottoms of the flat lifting belts with the two end buckles through lock catches, and the lifting hook assemblies are movably arranged at the outer ends of the pin shafts throughthe cotter pins matched with spacers; arrangement of the supporting plate and the rear plate provides convenience for the assembly, the supporting plate and the rear plate form a whole by welding, overall stiffness and load capacity are substantially provided, structural safety of the lifting appliance is improved, lifting hooks and the lifting ring are connected together through the lifting belts, a profile modeling lifting hook structure is fully used, it is convenient to hang and fix a carriage, operation is simple, and the working efficiency is greatly improved.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Reinforcing lifting appliance for van vehicle top plate welding assembly oil paint line passing

InactiveCN109179189AGuaranteed stiffnessIncrease stiffnessLoad-engaging elementsManufacturing technologySheet steel

The invention discloses a reinforcing lifting appliance for van vehicle top plate welding assembly oil paint line passing and relates to the technical field of automobile production and manufacture. The reinforcing lifting appliance comprises a fixing beam assembly. The fixing beam assembly is formed in a manner that two rectangular pipes are welded through steel plates, and a gap is reserved between the two rectangular pipes so that bolts can pass through. The upper end of the fixing beam assembly is provided with a lifting hook. According to the reinforcing lifting appliance, the integral rigidity of a top plate assembly is reinforced, the lifting problem is solved, and meanwhile the safety in the lifting process is improved.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

Tyre storage device and tyre vulcanizer

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG

Automobile seat transporting and conveying system

InactiveCN102718038BGuaranteed StrengthSolve the problem of high labor intensity in long-distance transportationControl devices for conveyorsChutesProduction lineCar seat

The invention provides an automobile seat transporting and conveying system which is used for packaging, transporting, storing and delivering after a seat product line is finished. The automobile seat transporting and conveying system comprises a conveying rail, a steering mechanism, a storing and delivering cargo rail, a seat tray and a PLC (Programmable Logic Controller) control system, wherein the front end of the conveying rail is connected with a seat production line; the tail end of the storing and delivering cargo rail is connected with a physical distribution channel; the quantity of the steering mechanism and the storing and delivering cargo rail is matched with the type of the seat; the steering mechanism is arranged at the combined part of the conveying rail and the storing and delivering cargo rail; the seat tray can slide on the conveying rail and can enter the storing and delivering cargo rail through the steering mechanism; and a seat product is placed above the seat tray. The automobile seat transporting and conveying system has the advantages of stable performance, strong practical applicability and low manufacturing cost, solves the problem that the labor intensity is great as the seat product is remotely transported after the production line is finished, and avoids secondary transportation and package work of the seat; and therefore, the collision scratches and bottom corner deformation in a transportation and turnover process of the seat are reduced, and the quality of the seat product is effectively guaranteed.

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

A panoramic lens with adjustable thickness

Owner:中山市怡山光学有限公司

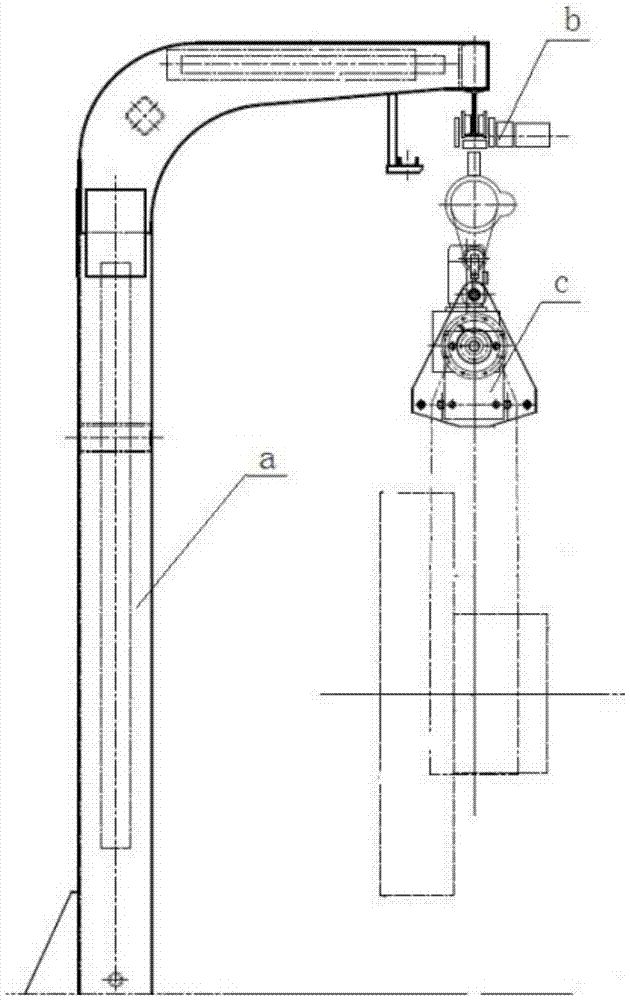

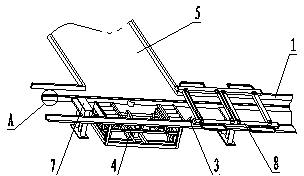

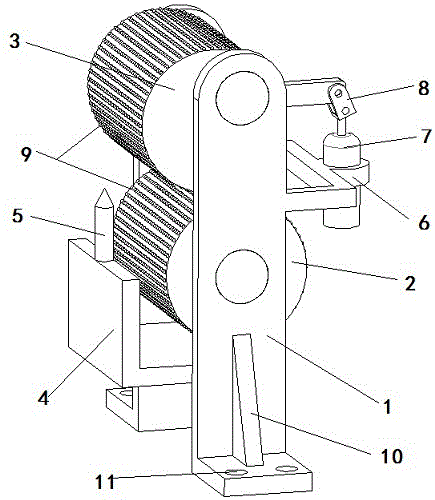

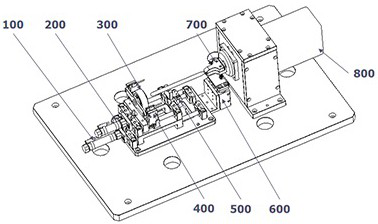

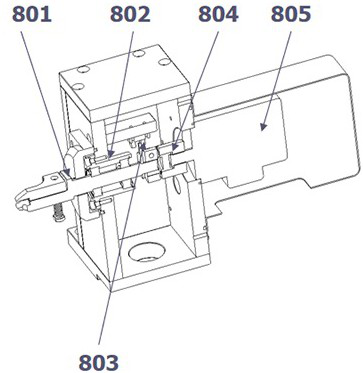

A commercial vehicle roof assembly welding fixture

ActiveCN105033551BReduce bumps and scratchesQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderEngineering

The invention relates to a commercial roof cover assembly welding clamp. The commercial roof cover assembly welding clamp comprises bases, a static roller, an eccentric roller, a baffle, a positioning pin, a holder, a hydraulic cylinder, a connector, contacts, reinforcing ribs and positioning holes, wherein the static roller is arranged between the bases, the eccentric roller is arranged above the static roller and positioned between the bases, the plurality of contacts are uniformly arranged on the surfaces of the static roller and the eccentric roller, the L-shaped baffle is arranged on the left side of the bases, the positioning pin is perpendicularly arranged at the upper end of the baffle, the holder is arranged on the right side of the bases, the hydraulic cylinder is fixed in the middle of the fixer, the upper end of the hydraulic cylinder is hinged to the eccentric roller through the connector, the positioning holes are symmetrically formed in the two ends of the bottom surfaces of the bases, and the reinforcing ribs are arranged between the positioning holes. The commercial welding clamp is simple in structure and convenient to operate, reduces the collision and scratch of the outer surface of the roof cover, ensures the quality of a welded workpiece, reliably clamps, reduces the labor intensity and improves the work efficiency.

Owner:随州常森汽车部件有限公司

Full-automatic intelligent pipe inserting machine

PendingCN113772933AReduce bumps and scratchesReduce hardnessGlass reforming apparatusAutomatic controlBottle

The invention relates to a full-automatic intelligent pipe inserting machine which comprises a rack, a vertical conveying mechanism, a horizontal conveying mechanism, a holding steering pipe inserting mechanism and a control system. The vertical conveying mechanism conveys a bottle-making glass tube to a set height from the lower end of the rack; the horizontal conveying mechanism conveys the bottle-making glass tube to the holding steering pipe inserting mechanism; and the holding steering pipe inserting mechanism inserts the glass tube into a bottle-making machine. Two spiral transmission mechanisms are arranged, so that upward movement and downward tube insertion actions of glass tube transmission are realized respectively; and horizontal movement of glass tube transmission is achieved by arranging a synchronous belt linear sliding table, and intelligent automatic control of moving parts is achieved by arranging a PLC, a photoelectric reflection sensor, a position sensor, a negative pressure sensor and a pneumatic electromagnetic valve. The machine has the advantages of being reasonable in design, simple in structure, good in intelligent automation degree and high in working efficiency.

Owner:JIANHU GUOCHUANG MACHINERY MFG CO LTD

Deflection supporting piece, shaft holding clamp deflection follow-up supporting mechanism and using method of shaft holding clamp deflection follow-up supporting mechanism

ActiveCN114393499AReduce bumps and scratchesIncrease productivityGrinding carriagesPolishing machinesPhysicsGrinding

The invention relates to the technical field of workpiece grinding, in particular to a displacement supporting piece, a shaft holding clamp displacement follow-up supporting mechanism and a using method of the shaft holding clamp displacement follow-up supporting mechanism. The upper displacement air cylinder is arranged above the lower displacement air cylinder; a displacement supporting piece and an upper supporting air cylinder; a lower displacement air cylinder is arranged on the base, an upper jacking air cylinder is arranged at the tail end of the lower displacement air cylinder, a press-fit mechanism is correspondingly arranged above the upper jacking air cylinder, and the press-fit mechanism is installed on a driving assembly. The automatic polishing and grinding machine has the advantages that manual polishing and grinding are replaced by a machine, and the risks that products are scratched and stuck with dirt can be reduced; products can be subjected to segmented displacement polishing, the production efficiency is improved, labor force is reduced, and manual operation is reduced. And due to the design of the displacement supporting piece, automatic feeding can be achieved, and full automation of feeding and grinding is achieved.

Owner:HI P SHANGHAI HOUSING APPLIANCE

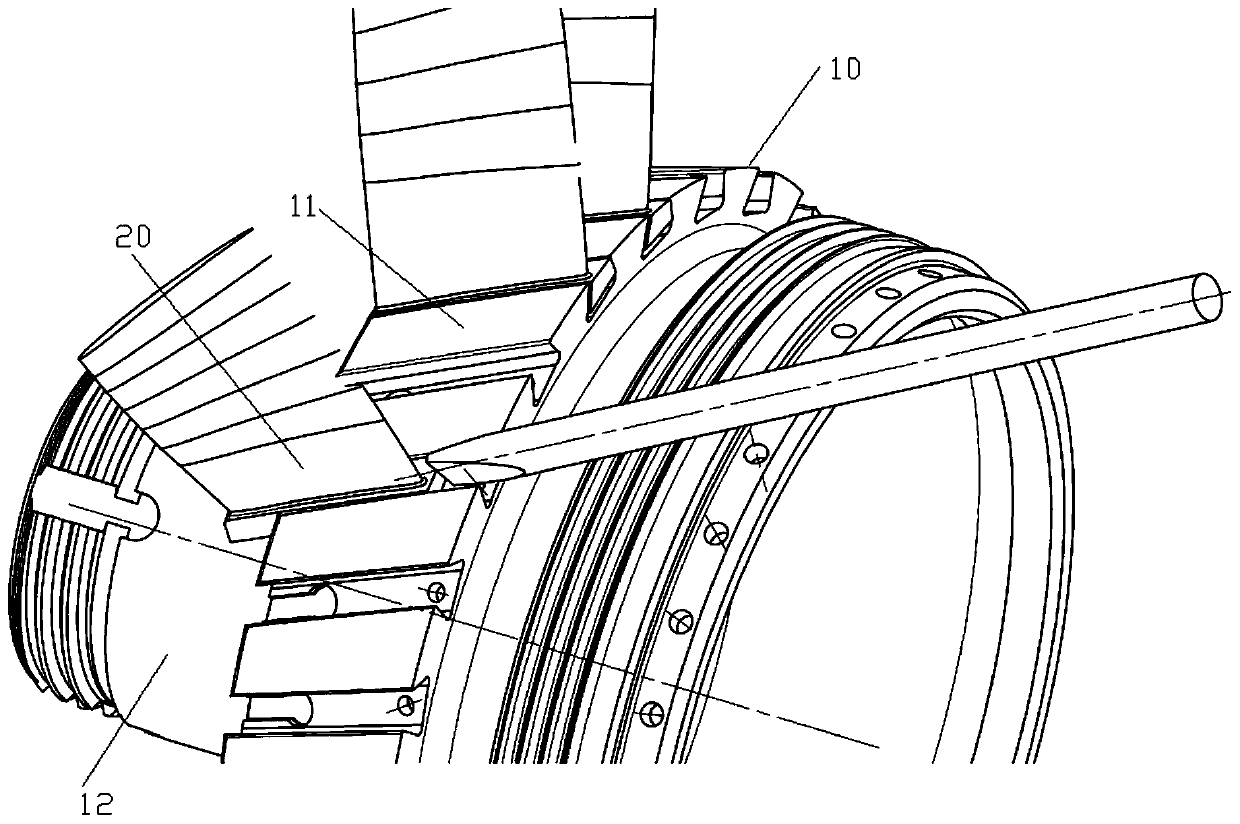

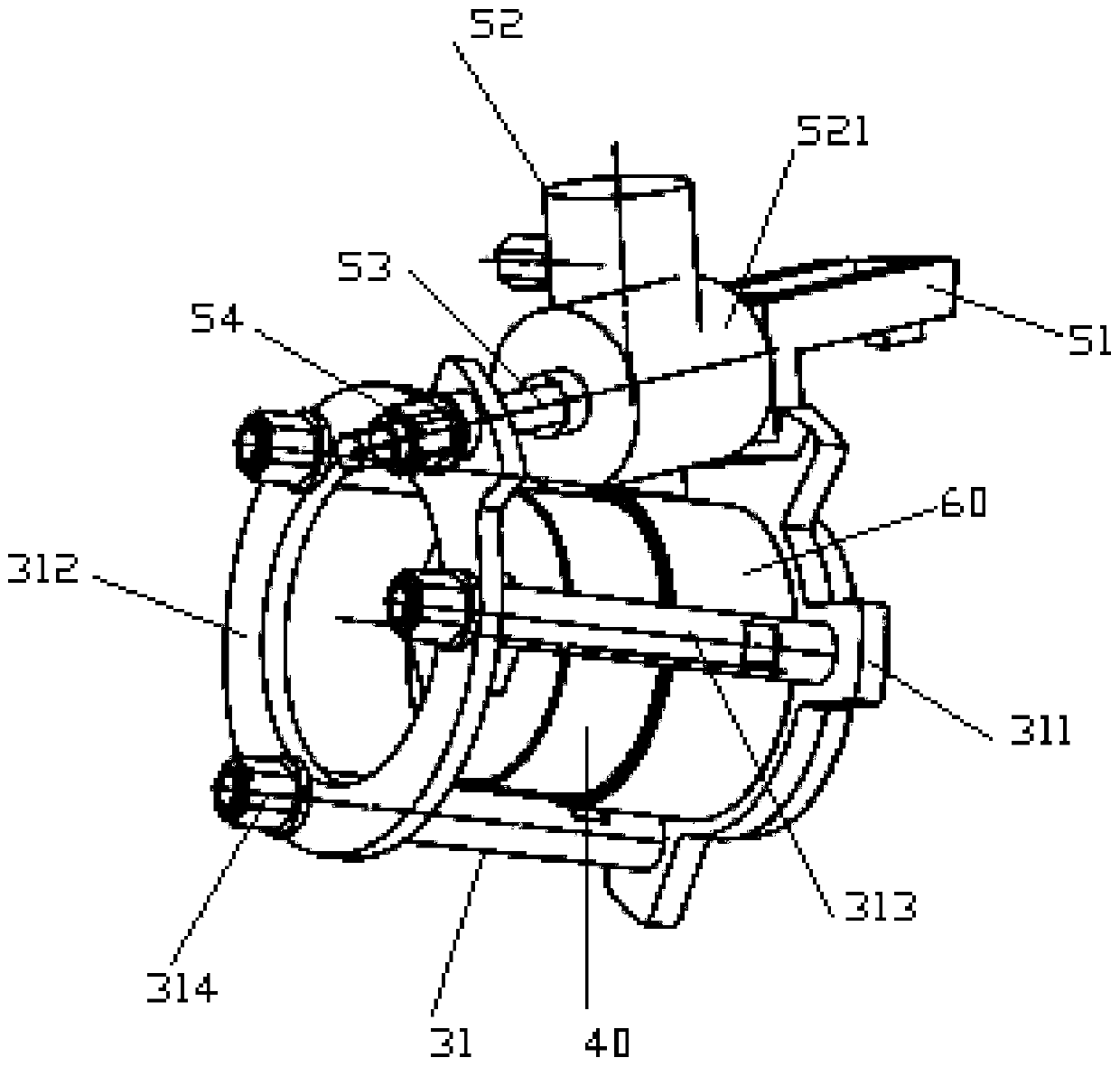

Blade decomposition device

ActiveCN107091803BWon't hurtReduce bumps and scratchesUsing mechanical meansMaterial analysisPull forceDecomposition

The invention discloses a blade-disassembling device, which comprises a device body and a locking part, the device body is used for being mounted on the periphery of a rotor spindle, so that the blade-disassembling device is connected to an air compressor rotor, and the locking part is used for being mounted on the periphery of the rotor spindle to lock the device body and the air compressor rotor. A disassembling and force-measuring component which is used for disassembling a blade from a mortise and measuring the magnitude of disassembling force at the same time is connected to the device body, the disassembling and force-measuring component comprises a claw for holding the tenon of the blade, a force-measuring device which is used for measuring the magnitude of force borne by the tenon is connected to the claw, a pull rod which is used for bearing force is connected to the force-measuring device, the pull rod is slidably inserted in the device body, and a force-applying nut which is used for applying pulling force is connected to the thread of the periphery of the pull rod. The claw, the force-measuring device and the pull rod are sequentially connected along the extension direction of the mortise, so that the pull rod can pull the force-measuring device, the claw and the blade to move along the extension direction of the mortise in a direction away from a mounting disk as rotational force is applied on the nut.

Owner:CHINA HANGFA SOUTH IND CO LTD

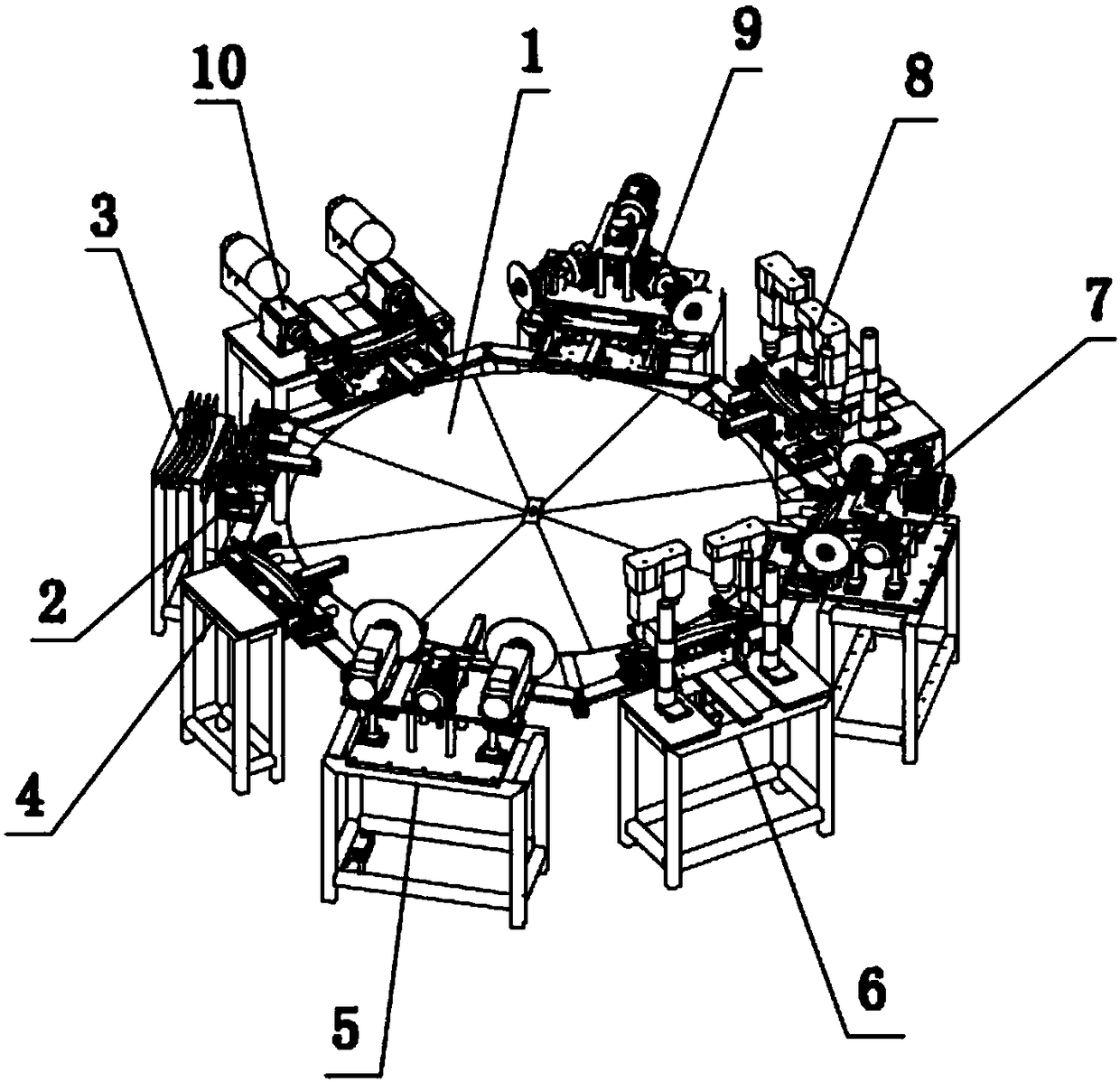

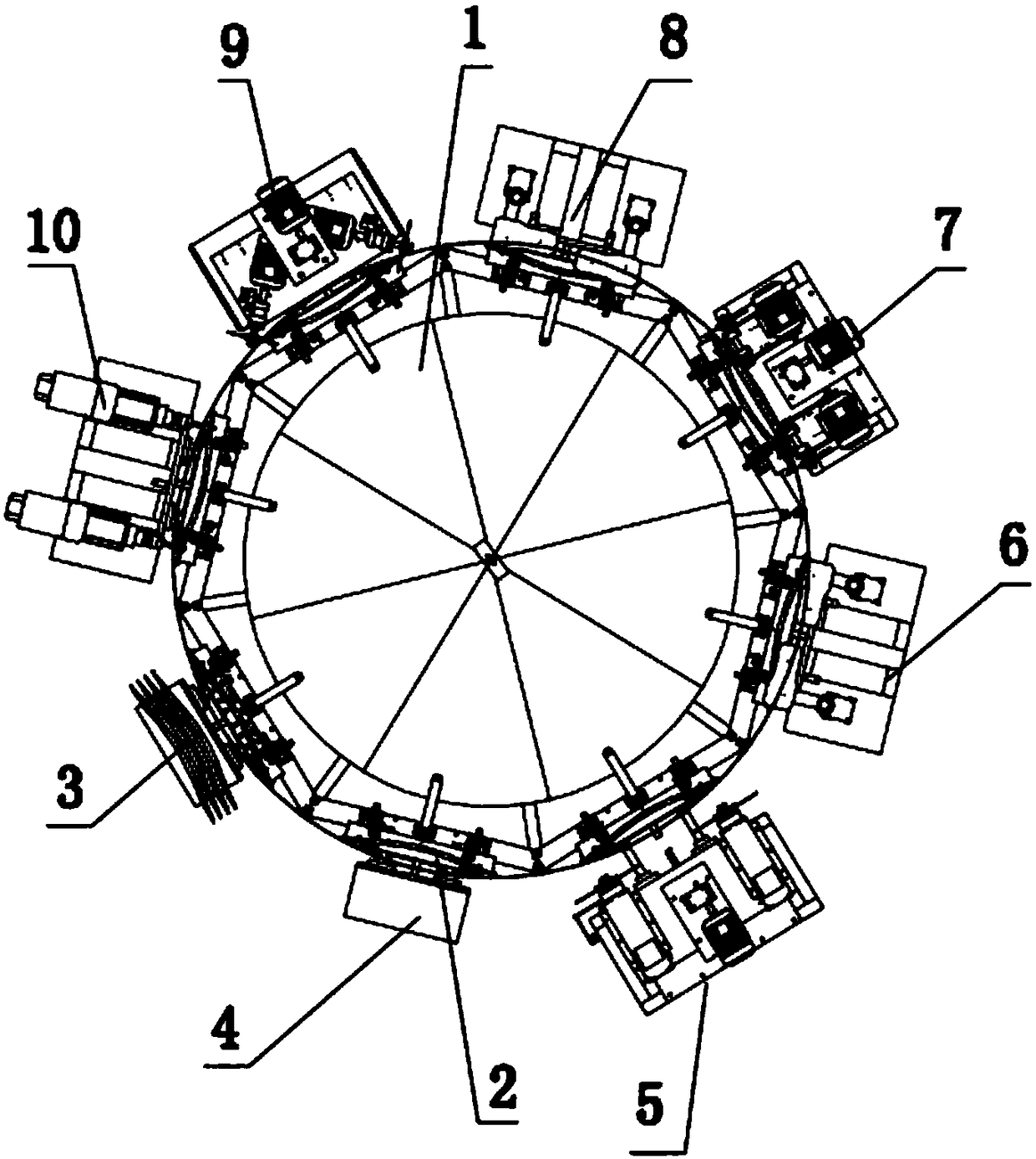

Aluminum alloy workpiece disc type automatic all-in-one machine

ActiveCN106078215BImprove work efficiencyImprove securityOther manufacturing equipments/toolsPositioning apparatusCircular discEngineering

The invention provides a circular disc type automatic all-in-one machine of an aluminum alloy workpiece. The circular disc type automatic all-in-one machine is characterized by comprising a circular disc mechanism, workpiece assemblies, a feeding and discharging station, a reserved station, a large surface drilling device, a side hole drilling device, a fixed length sawing device, a tapping device, a chamfering sawing device and a large hole milling device; the plurality of workpiece assemblies are arranged along the edge of the circular disc mechanism; and the feeding and discharging station, the reserved station, the large surface drilling device, the side hole drilling device, the fixed length sawing device, the tapping device, the chamfering sawing device and the large hole milling device are arranged in front of the workpiece assemblies in sequence around the circular disc mechanism. The circular disc type automatic all-in-one machine is high in working efficiency and good in safety performance; automatic production is realized, and the labor cost is extremely reduced; the circular disc type automatic all-in-one machine is clamped in one step, so that scratches are reduced, and the rate of finished products is improved; the investment is less, and the manufacturing cost is low; and the circular disc type automatic all-in-one machine is simple in structure and easy to maintain.

Owner:ALNAN ALUMINIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com