Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Automate flipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

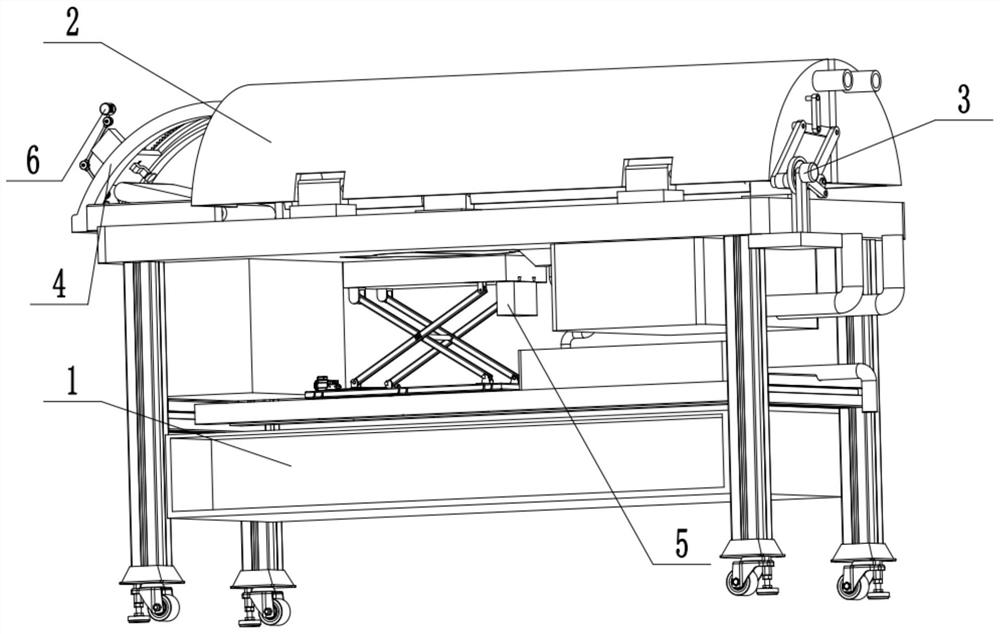

Board overturning device

The invention relates to the field of board processing, in particular to a board overturning device. The board overturning device comprises a first conveying belt, a overturning mechanism and a secondconveying belt, wherein the first conveying belt and the second conveying belt are sequentially arranged in the board processing direction in a spaced mode, the overturning mechanism is located between the output end of the first conveying belt and the input end of the second conveying belt, a first material moving device conveying boards on the first conveying belt to the overturning mechanism is arranged at the bottom of the first conveying belt, a second material moving device for transferring the boards on the overturning mechanism to the second conveying belt is arranged at the top of the second conveying belt, and overturning assemblies matched with the first conveying belt and the second conveying belt and driving parts for driving the overturning assemblies to rotate are arrangedon the overturning mechanism. The board overturning device receives boards through a material receiving board, drives second chain wheels, chains and first chain wheels through a second motor to makerollers rotate so as to rotate the boards through 180 degrees, manual board overturning is avoided, and automatic overturning is implemented.

Owner:何健民

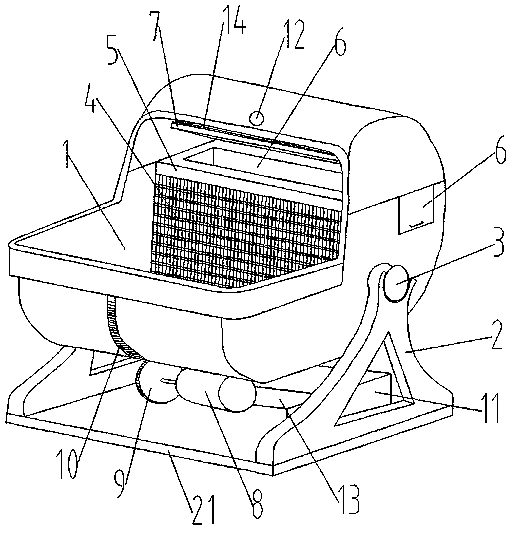

Cat litter box with automatic filtering function

InactiveCN109287495AFilter in timeThere will be no problems such as odorAnimal housingEngineeringAutomatic filtering

The invention discloses a cat litter box with an automatic filtering function. The box includes a baseplate, two triangular brackets are symmetrically arranged at the upper portion of the baseplate and movably connected with a main cat litter box body, and a driving device used for driving the main cat litter box body to turn over is arranged below the main cat litter box body. Cat litter can be automatically filtered in the cat litter box in time, the problems of stink and the like cannot occur, and the cat litter box is novel in design and practical in function. When a cat owner cleans awaycat feces, convenience is provided for picking up the cat feces.

Owner:丁翠芳

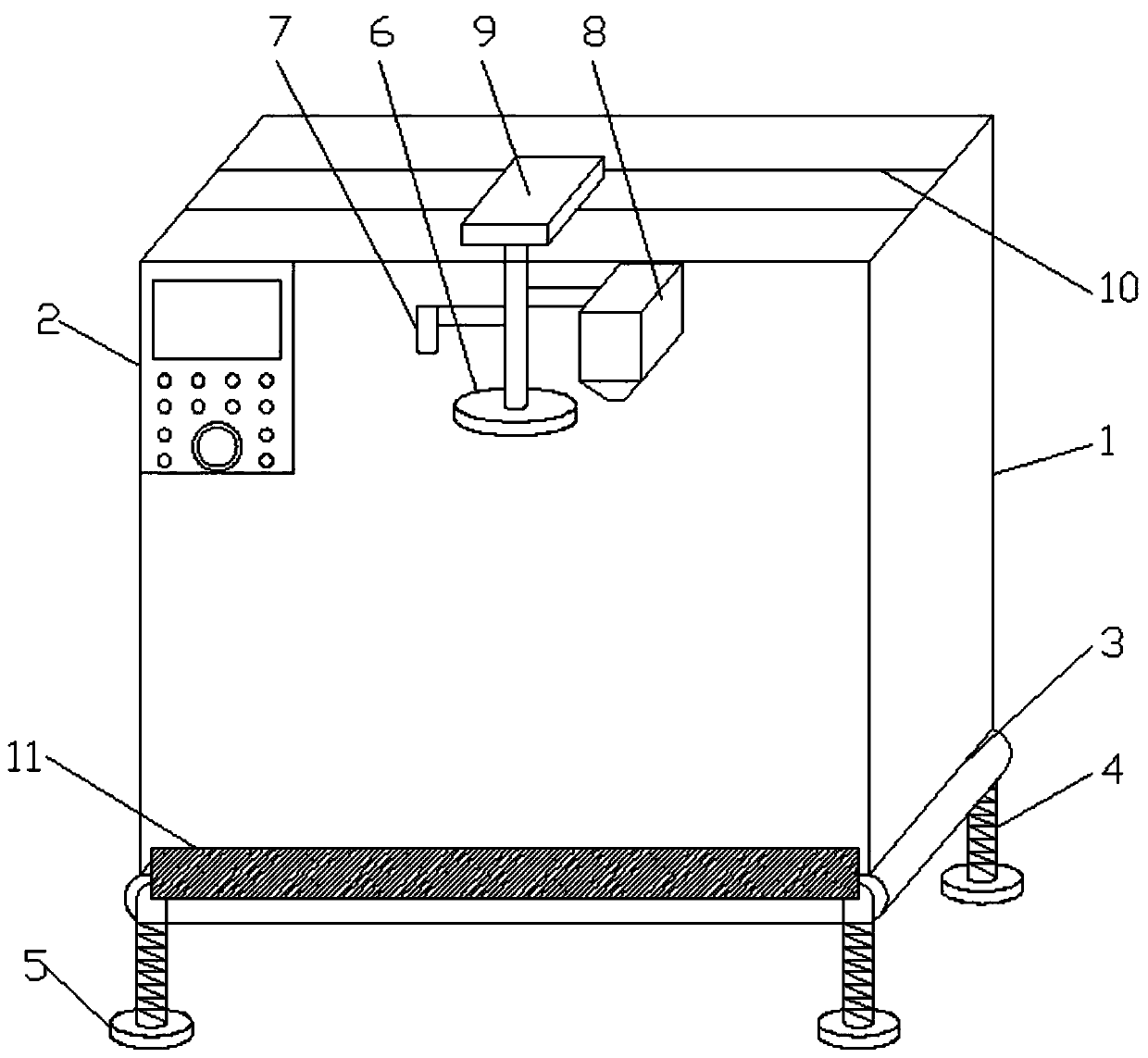

Large-scale solid wood furniture surface grinding full-automatic robot

ActiveCN108908010AActive connectionImprove the effect of intelligenceAutomatic grinding controlGrinding machinesSolid woodPulp and paper industry

The invention discloses a large-scale solid wood furniture surface grinding full-automatic robot. The robot structurally comprises a solid wood furniture grinding machine body, a control panel, a conveying device, supporting legs, rubber fixing pads, a grinding wheel, a monitoring device and a dust removing device. The left side of the front portion of the solid wood furniture grinding machine body is provided with the control panel, and the bottom of a first cylinder is connected with the grinding wheel via a pneumatic rod. The monitoring device is connected to the left portion of the gas pressure rod, and the dust removing device is connected to the right portion of the pneumatic rod. A second cylinder is disposed on both sides of a sliding device respectively, a second pneumatic rod isdisposed at the bottom of each second cylinder, and a suction cup is disposed at the bottom of each second pneumatic rod. The bottom of the solid wood furniture grinding machine body is provided withthe conveying device, the support legs are distributed at the bottom of the conveying device, and the rubber fixing pads are arranged at the bottoms of the support legs. The large-scale solid wood furniture surface grinding full-automatic robot has high automation performance, improves grinding efficiency, and achieves automatic turning.

Owner:宁国市长远知识产权代理有限公司

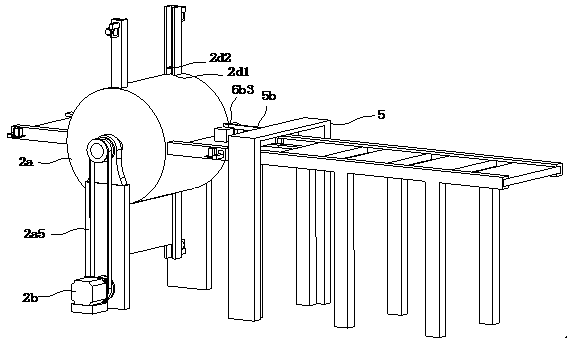

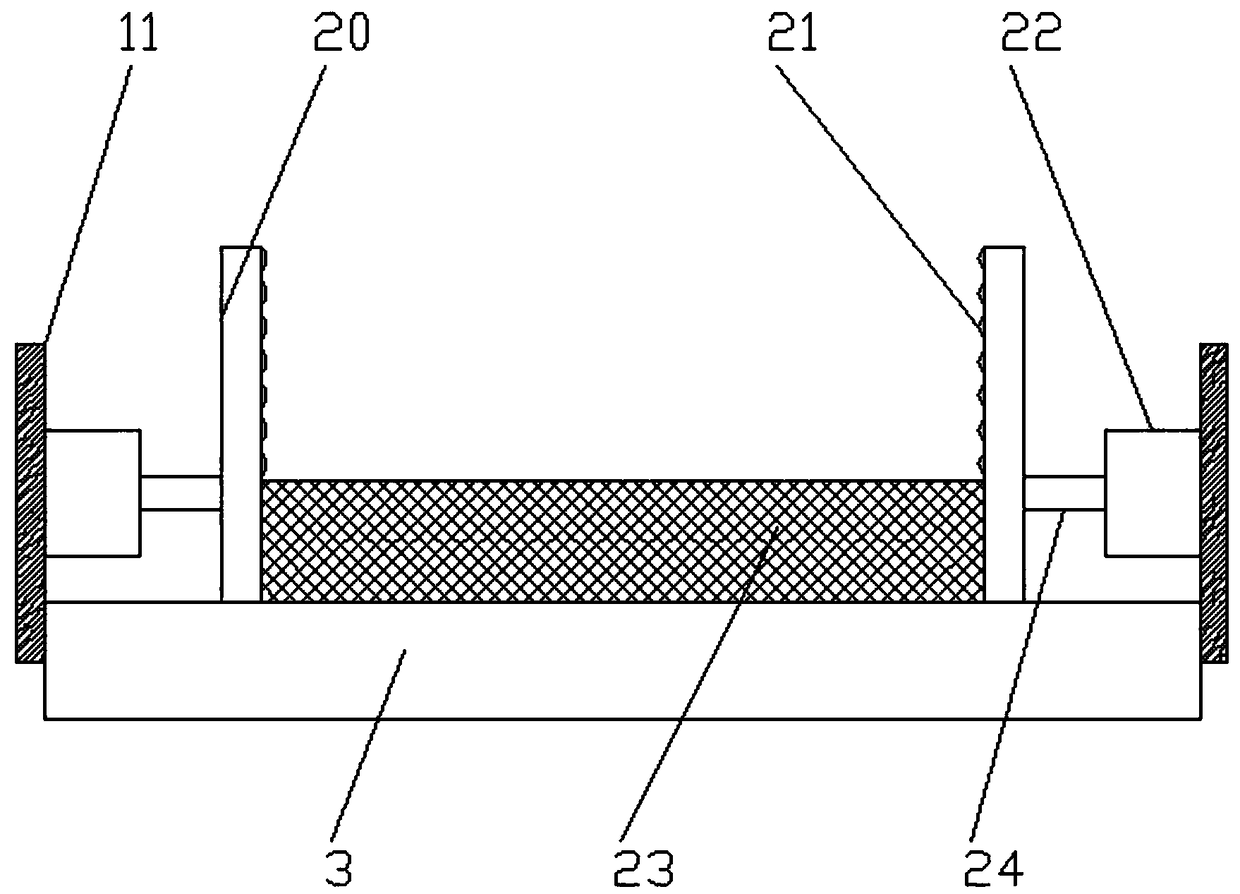

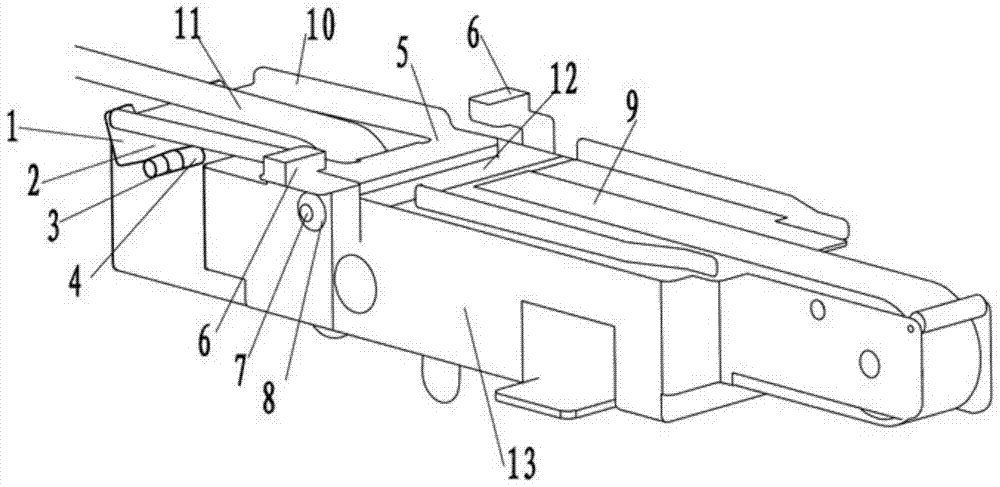

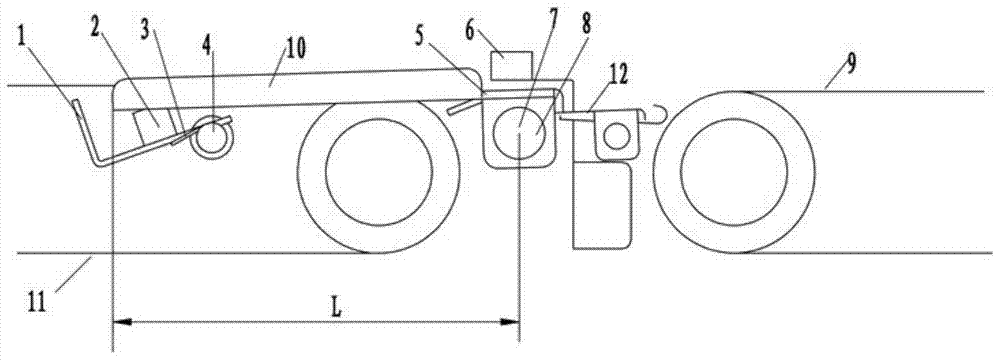

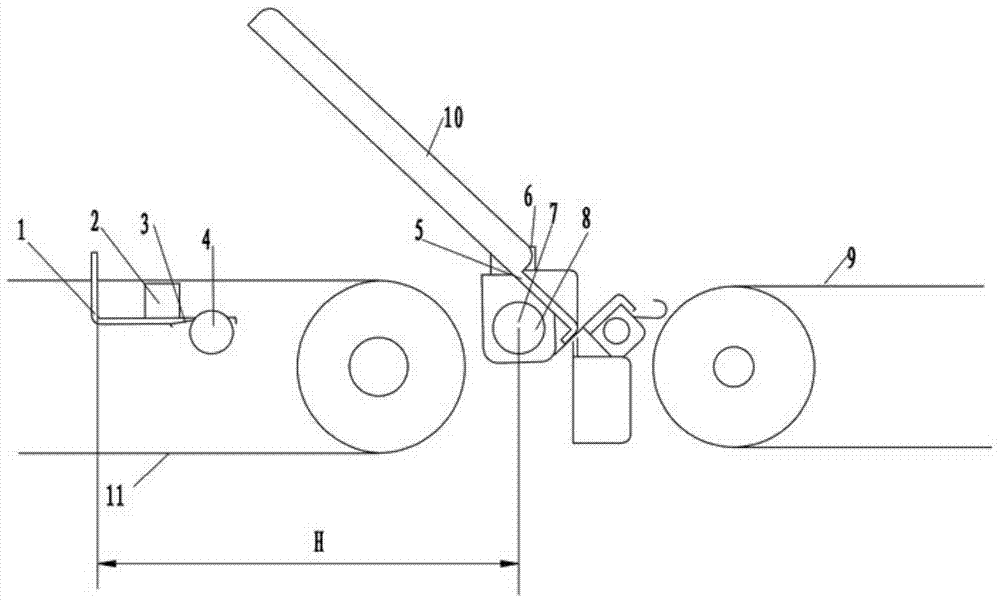

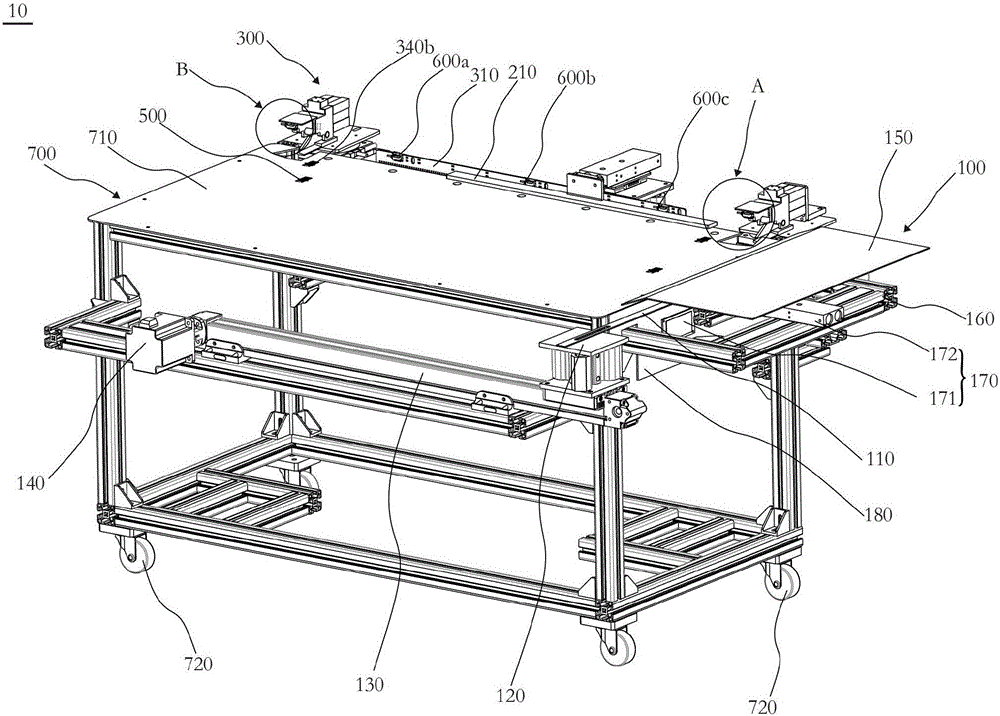

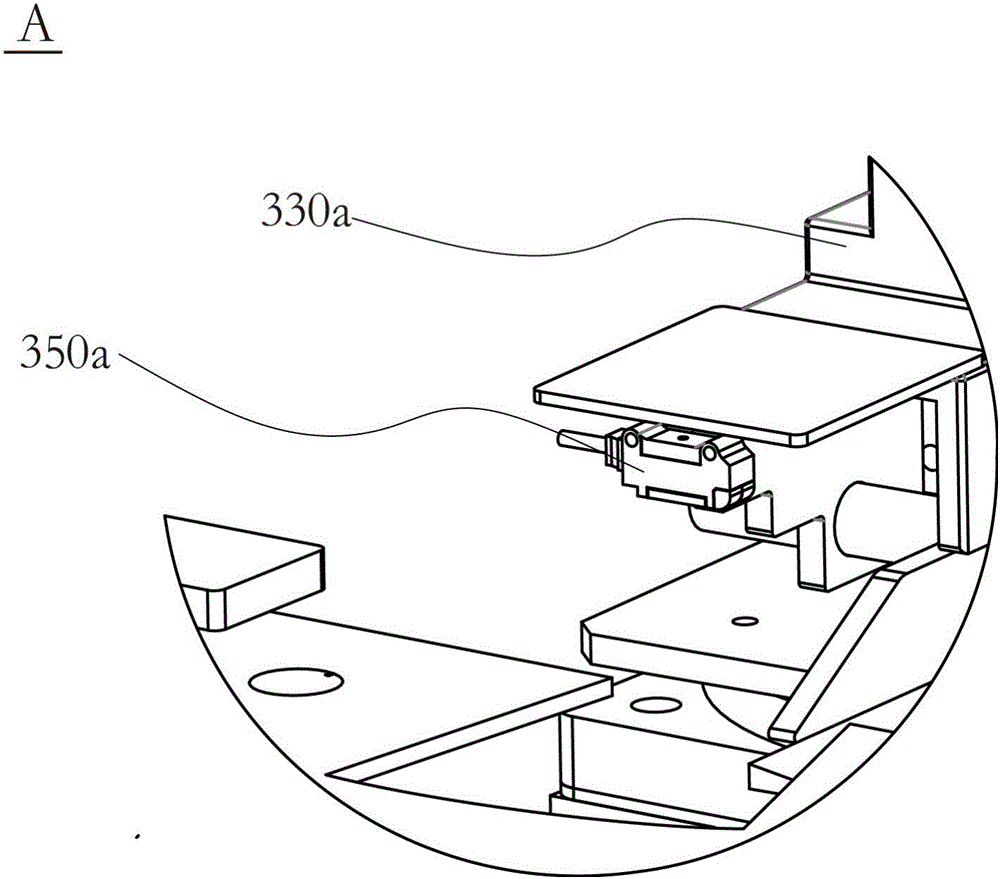

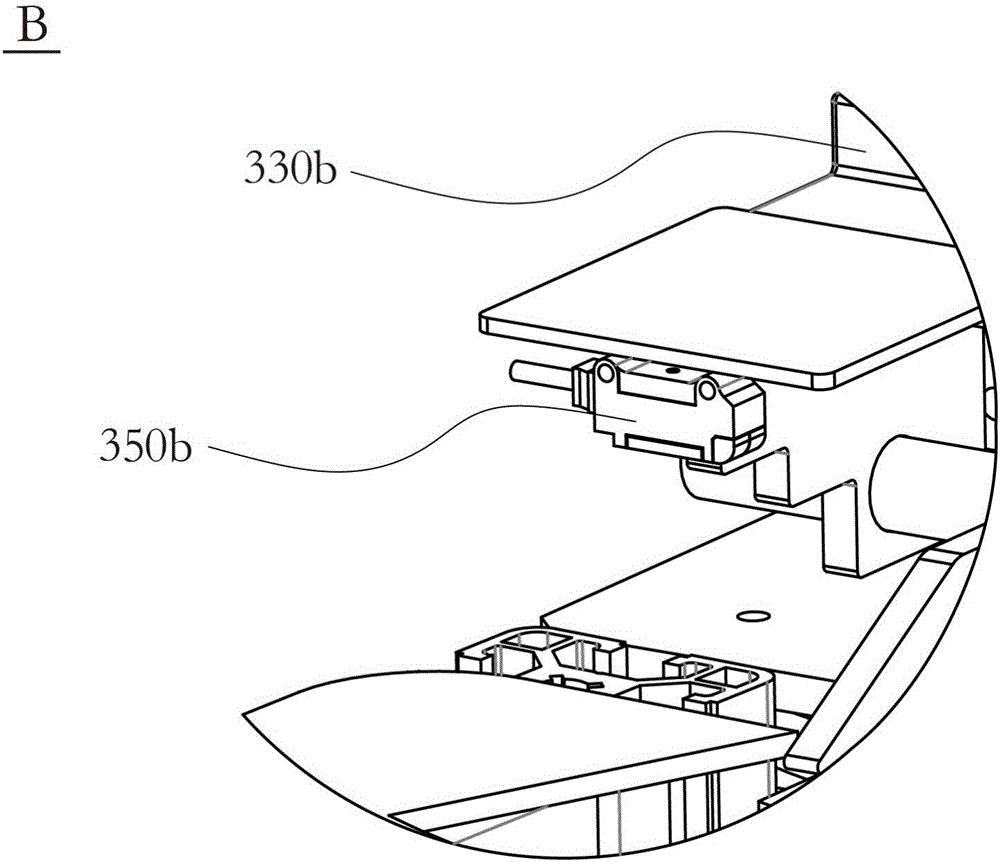

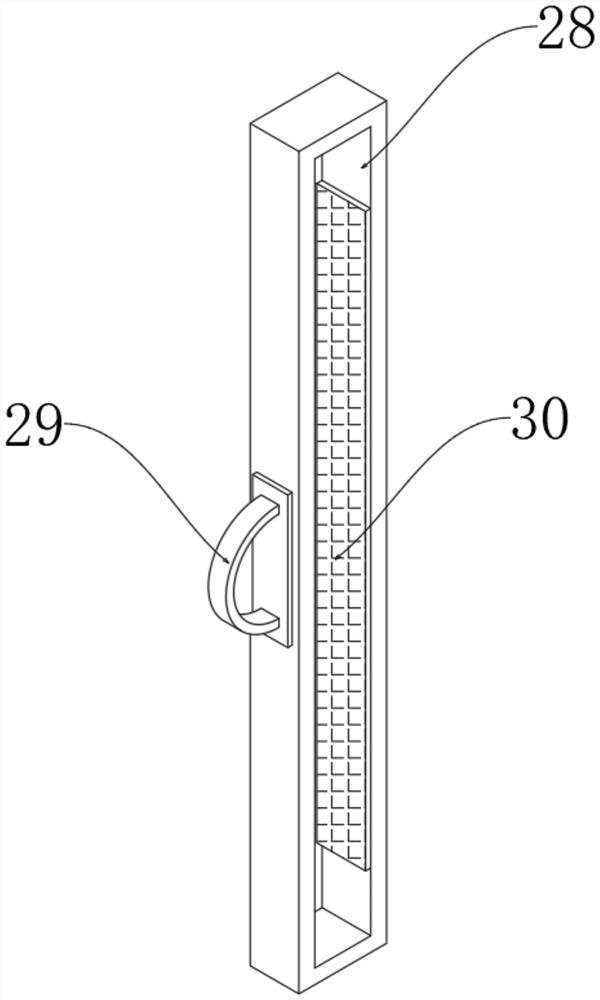

Automatic fabric cut-part turnover system and automatic fabric cut-part turnover system method

ActiveCN105361311AEasy flipEasy to moveSevering textilesClothes making applicancesEngineeringMechanical engineering

The invention discloses an automatic fabric cut-part turnover system and an automatic fabric cut-part turnover system method. The automatic fabric cut-part turnover system comprises a workbench and a turnover device. The desktop of the workbench is provided with a cut-part passage; the turnover device comprises detection parts, a retainer, a press plate, a press plate drive element, a driving lever, a driving lever holder and a driving lever drive element. The detection parts are connected to the workbench; the retainer disposed under the desktop of the workbench is fixed to the workbench; the press plate disposed under the desktop of the workbench is connected to the workbench movably; the retainer and the press plate are respectively arranged on two sides of the passage along a straight direction; the press plate drive element is arranged on the workbench and connected to the press plate; the driving lever is fixed to the driving lever holder which is slidably connected to the workbench; and the driving lever drive element is arranged on the workbench and connected to the driving rod holder to drive the same. The automatic fabric cut-part turnover system is capable of turning and feeding cut-parts automatically.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Battery pack turning device

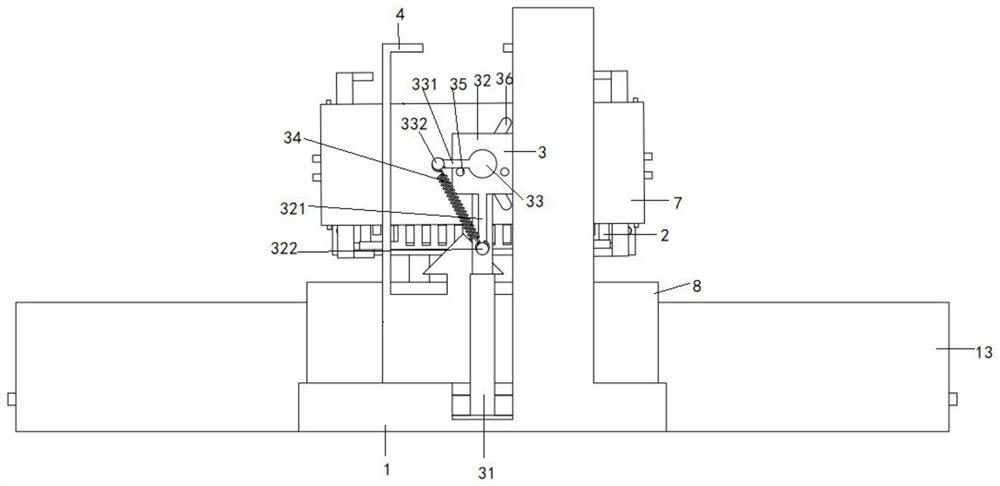

The invention relates to the technical field of battery production and assembly equipment, in particular to a battery pack turning device. The battery pack turning device includes a conveyor belt, a turning device arranged on one side of the conveyor belt and a PLC control system for controlling the turning device. The turning device includes a rack, a rotating mechanism installed on the rack, a clamping mechanism arranged at the front end portion of the rotating mechanism and a lifting mechanism connected to the rotating mechanism and the clamping mechanism, and the lifting mechanism can drive the rotating mechanism and the clamping mechanism to move up and down. The lifting mechanism drives the entire rotating mechanism and clamping mechanism to move up and down, the clamping mechanism clamps a battery pack, the rotating mechanism overturns the battery pack, and the conveyor belt transports the battery pack to a next station, and the PLC control system is used for controlling the entire process. The device realizes automatic turning, is high in precision and good in reliability, greatly saves manpower, improves the production efficiency, is especially suitable for overturning ofheavy-duty and large-volume battery packs and can work in coordination with the upstream and downstream of a production line.

Owner:江苏洛柳精密科技有限公司

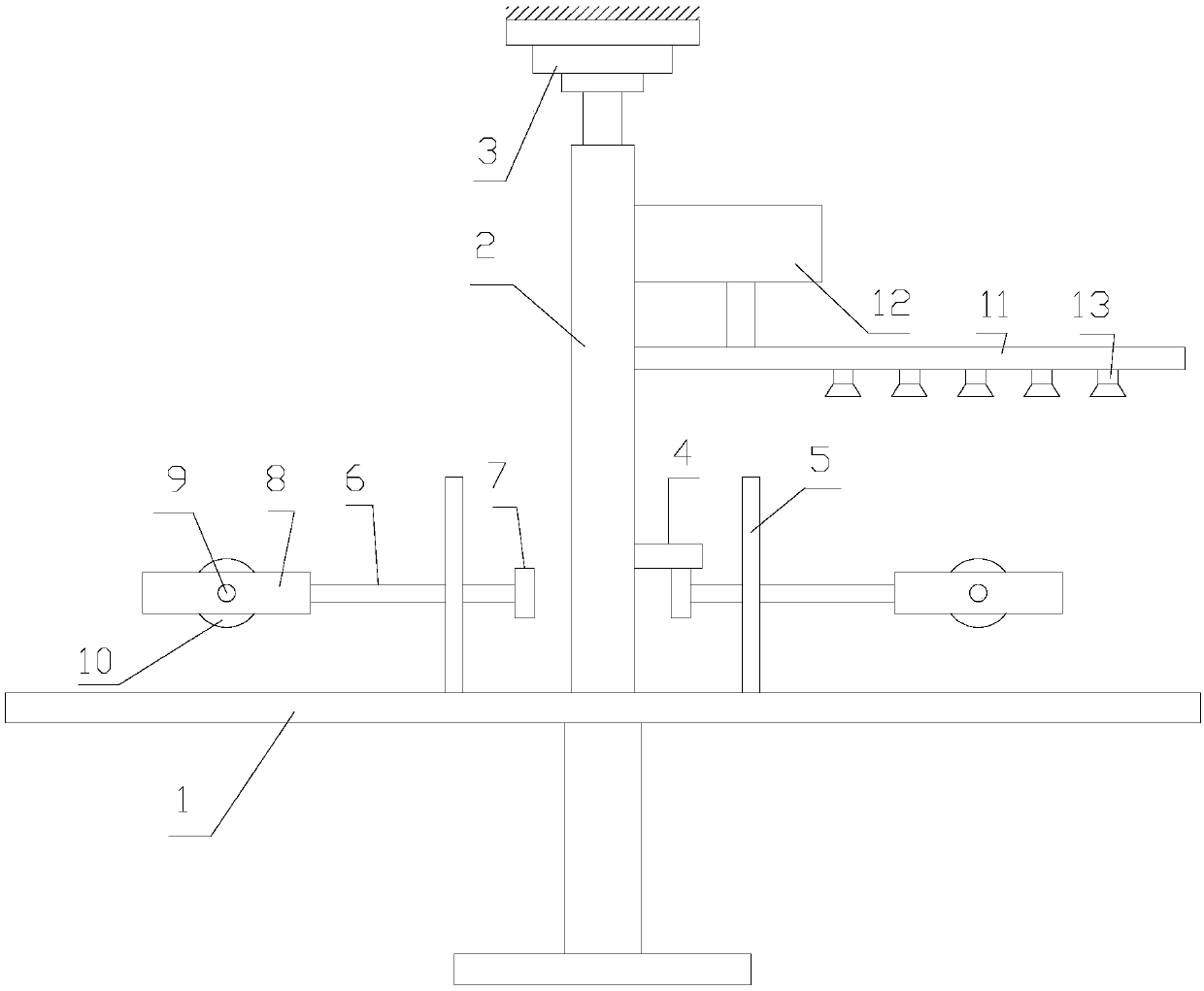

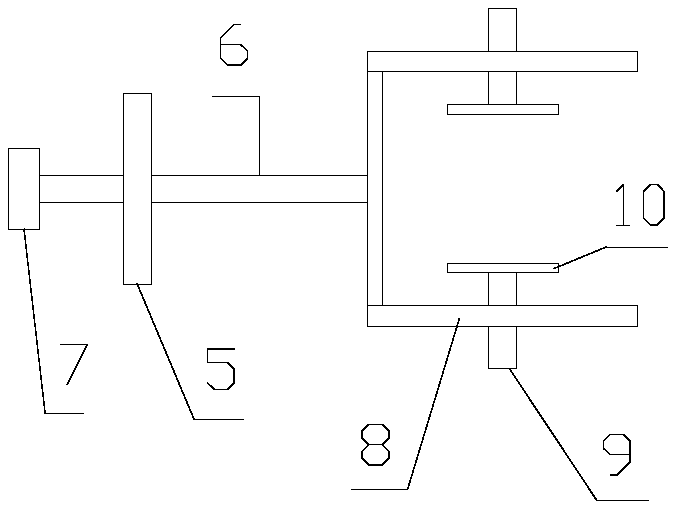

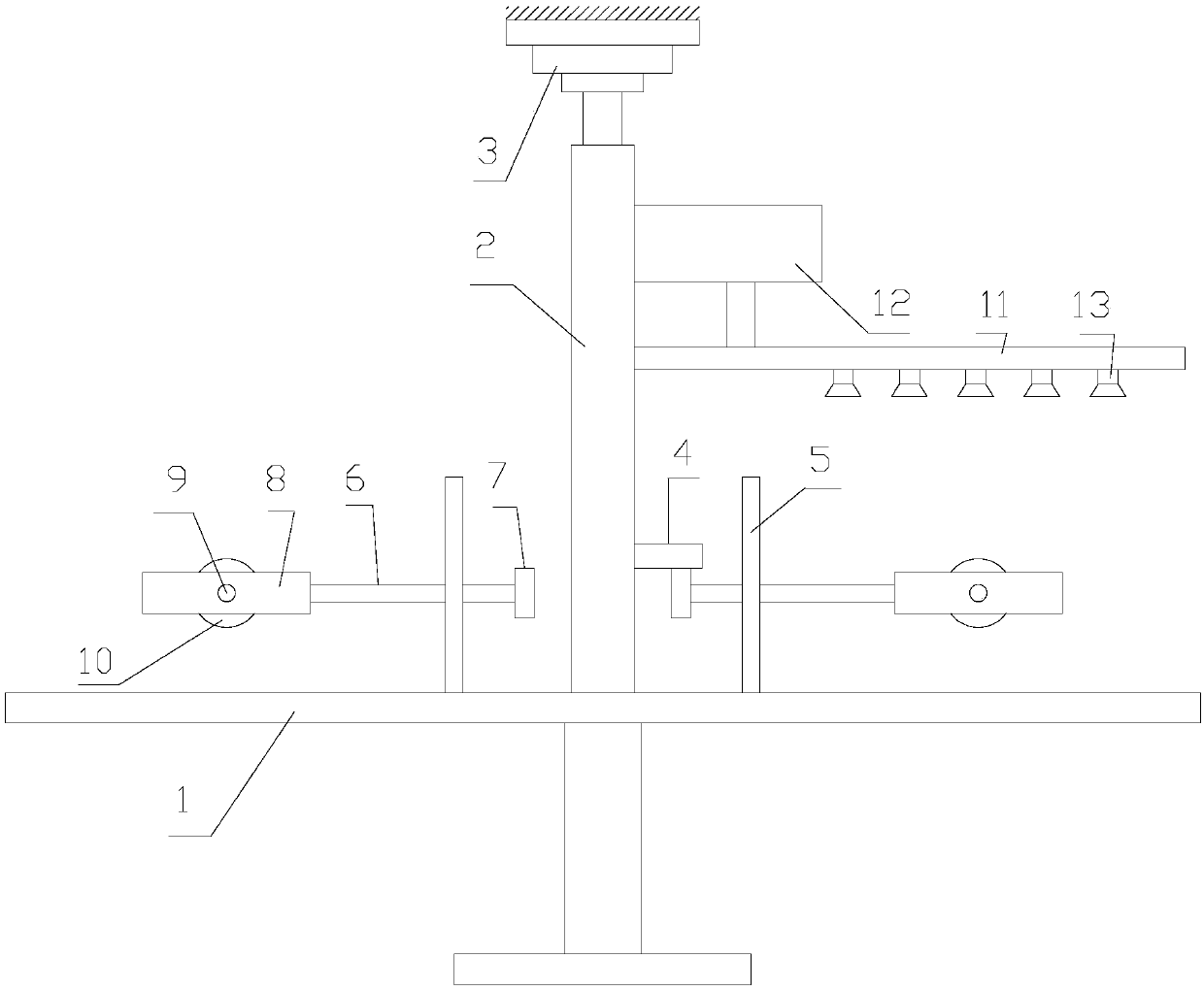

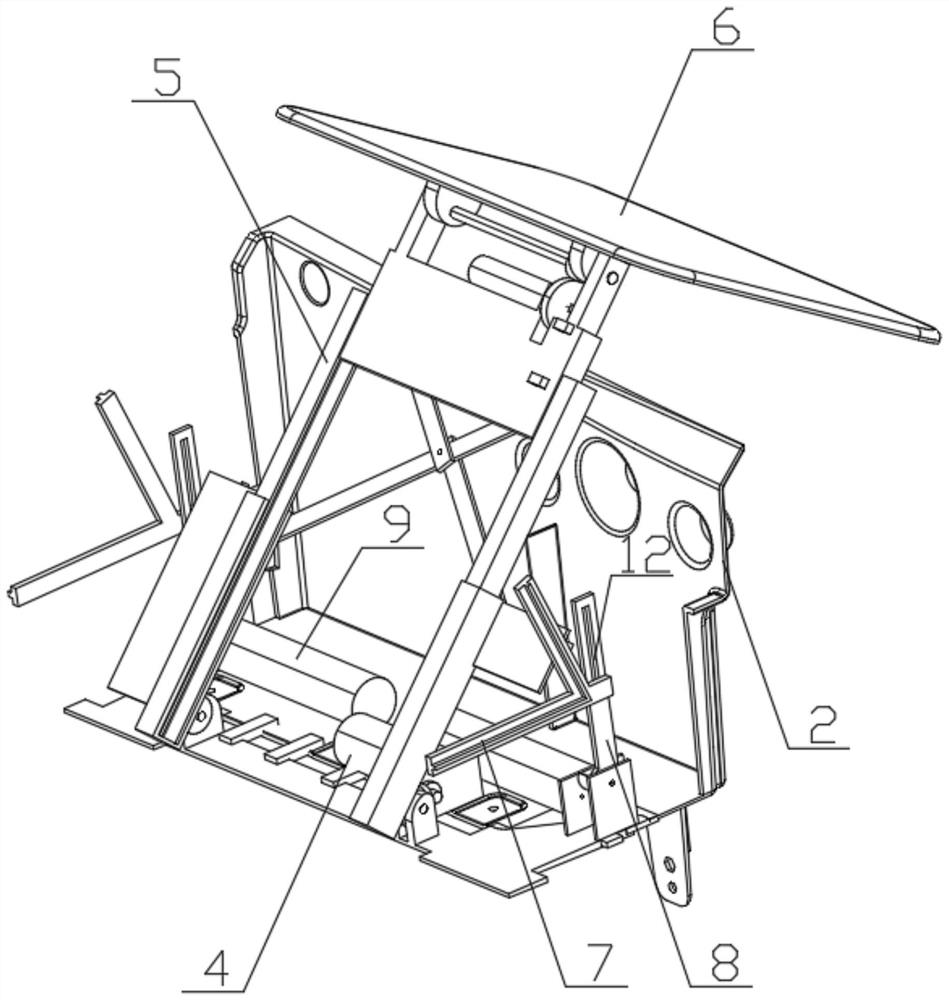

Chassis online overturning equipment

The invention discloses chassis online overturning equipment. A bracket (2) is connected with a base (1) through a rotation shaft (11) and can move relative to the base (1) around the rotation shaft (11); a walking motor (8) installed on the base (1) moves to drive a gear rack mechanism (9) connected to the walking motor (8), to drive the whole equipment to walk in a foundation; a rotary motor (6) installed on the base (1) moves to drive a transmission chain (7) fixed to an overturn circle (3) to move, to drive the whole overturn circle to rotate; a retraction oil cylinder (5) connected with the base (1) and the bracket (2) performs telescopic movements to drive the bracket (2) and the overturn circle (3) to move together around the rotation shaft (11), and thus retraction movements of the bracket and the overturn circle are realized. According to the invention, a chassis can be overturned without being offline, bumping and distortion caused by deformation of the chassis can be reduced, lean production is promoted, and quality of products is also improved.

Owner:XUZHOU HEAVY MASCH CO LTD

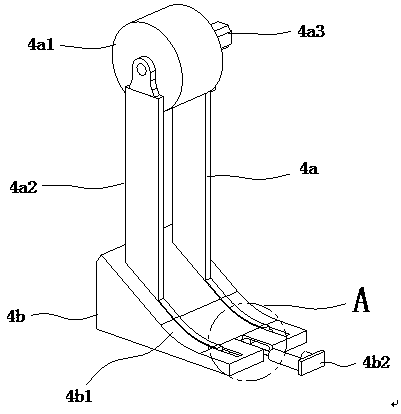

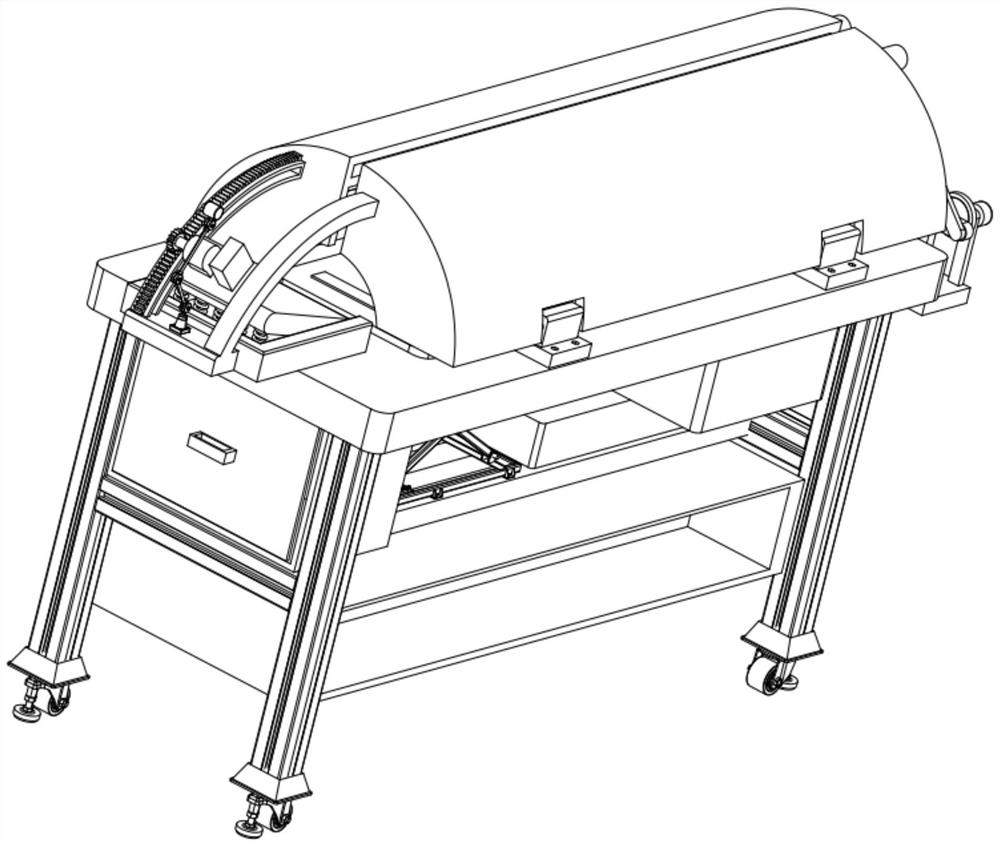

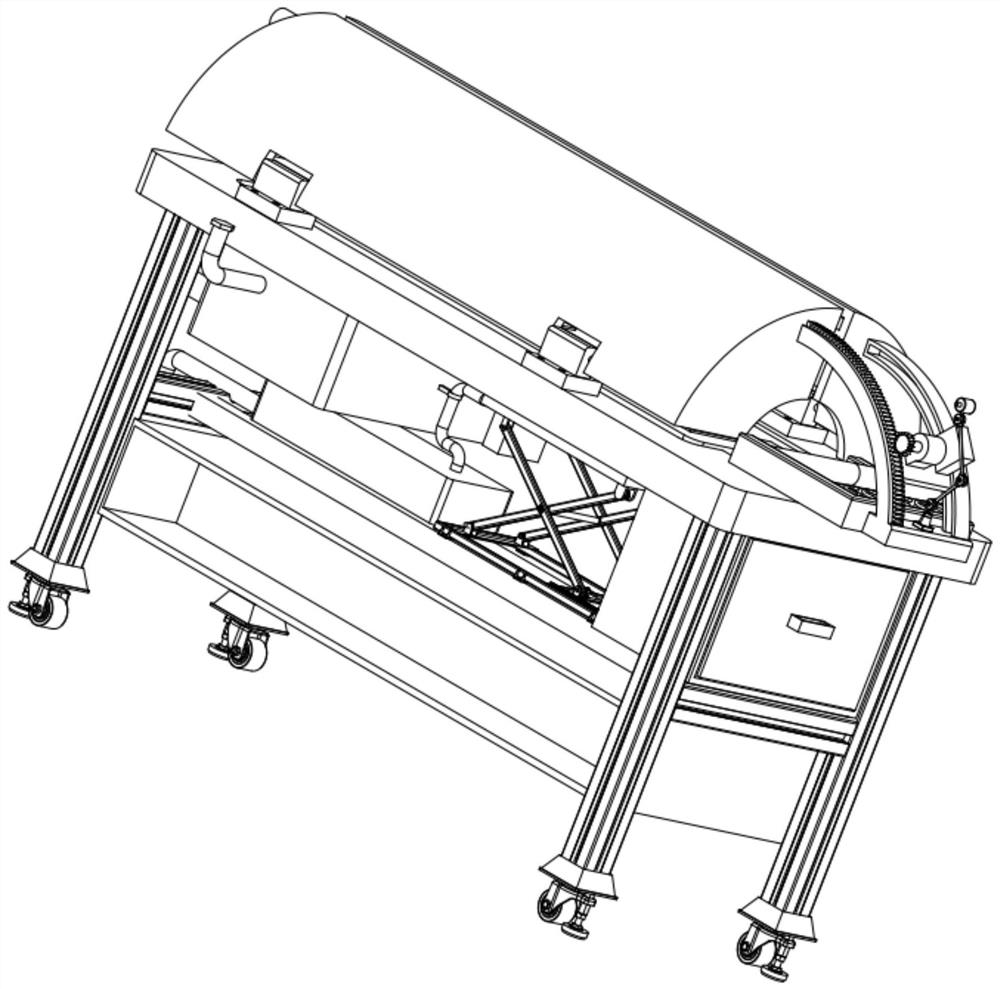

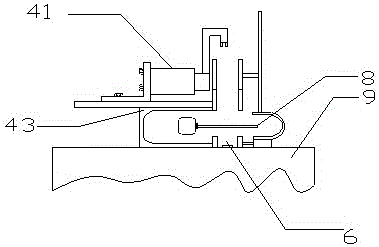

Overturning device of hosiery knitter

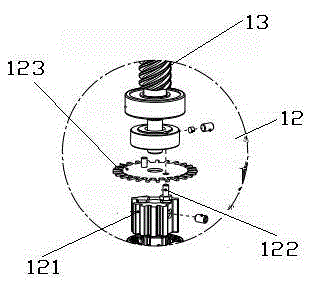

ActiveCN104894738AAutomate flippingIncrease productivityMechanical cleaningPressure cleaningBarrel ShapedEngineering

The invention discloses an overturning device of a hosiery knitter. The device comprises a driving mechanism, an overturning mechanism and an inclining mechanism. When in overturning, the inclining device acts to incline the overturning mechanism; the inclined overturning mechanism can absorb a barrel shaped knitting matter to be overturned into a fixing joint part of the overturning mechanism; then the inclining mechanism is returned to the original position; an overturning tube in the overturning mechanism upwards moves to overturn the barrel shaped knitting matter; thus the overturning is done, the sewing or knitting can be performed. With the adoption of the device, automatic overturning is achieved; the production efficiency can be greatly increased; the labor cost can be saved.

Owner:ZHEJIANG YEXIAO KNITTING MACHINERY

Refrigerator standing device

PendingCN106144531AAvoid damage to the refrigeratorSimple structureConveyor partsEngineeringMechanical engineering

The invention relates to a refrigerator standing device comprising an input rail, an auxiliary table top, an overturning platform, a refrigerator standing appliance and an output rail. The auxiliary table top is arranged at the tail end of the input rail. The output rail is arranged on the side edge of the auxiliary table top. The output rail and the input rail are parallel. The overturning platform is located between the auxiliary table top and the output rail. The refrigerator standing appliance is installed on the overturning platform and comprises a motor, a rotating roller, rotating arms, clamping plates, clamping air cylinders, telescopic rods and clamping blocks. The refrigerator standing device is simple in structure and convenient and rapid to operate, achieves automatic overturning, saves the manpower resource, improves the work efficiency and effectively avoids the phenomenon that because of manual operation, a refrigerator is damaged.

Owner:ANHUI HONGSHI AUTOMATION EQUIP CO LTD

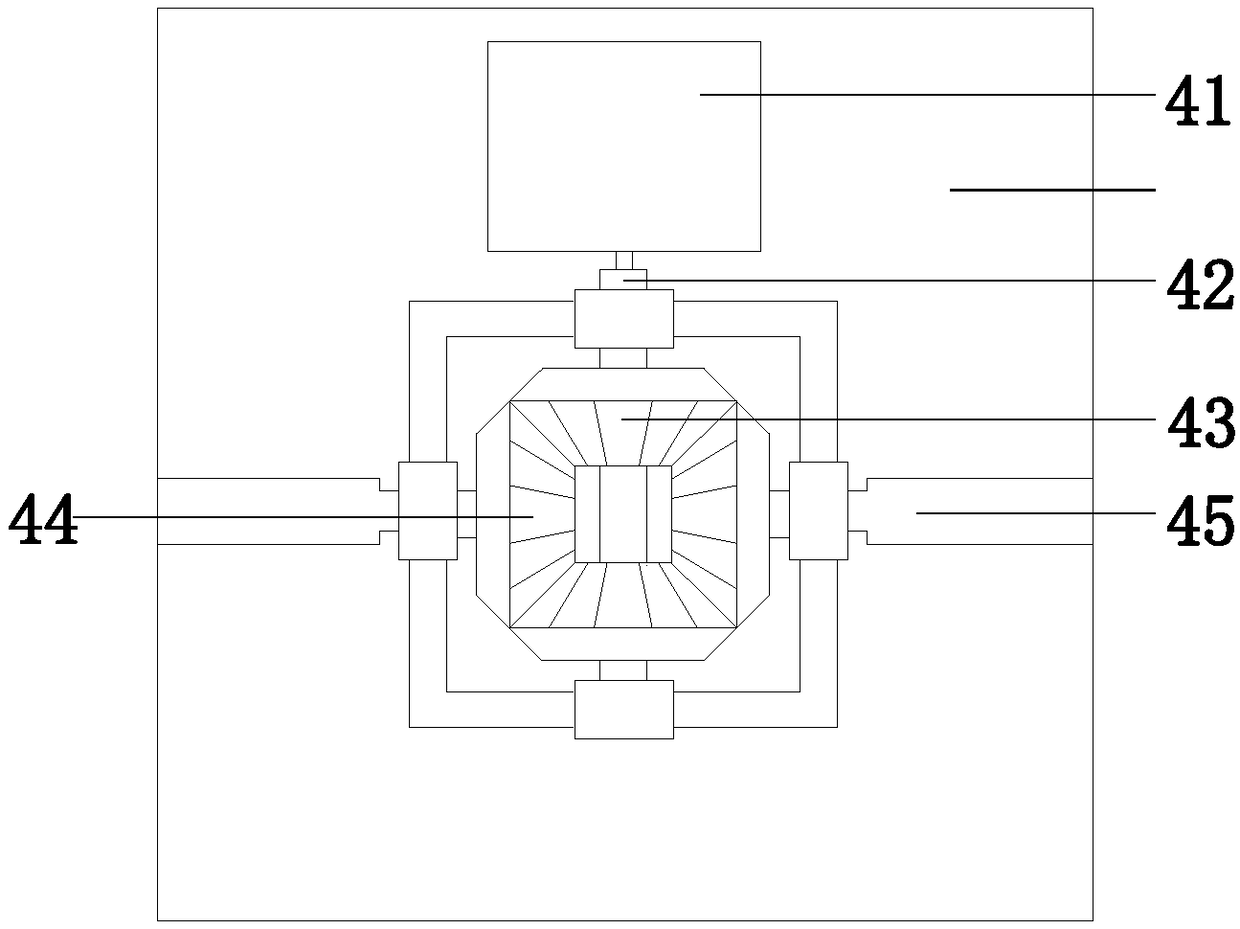

Paralyzed patient nursing sickbed

InactiveCN112842752ARealize processingAutomate flippingRespiratory masksNursing bedsNursing techniquesWater storage tank

The invention provides a paralyzed patient nursing sickbed, and belongs to the technical field of medical nursing. The nursing sickbed comprises a bed body supporting mechanism, a bed cover mechanism, a turnover mechanism, a headrest mechanism and an excrement and urine collecting mechanism, wherein the bed body supporting mechanism comprises a support, a bed board, a water storage tank and a water outlet; the lower end face of the bed board is fixedly connected with the upper end face of the support; the water storage tank is fixedly installed on the lower end face of the support. A water outlet is formed in the water storage tank; the bed cover mechanism comprises a support, an arc-shaped cover and a water inlet pipe and is used for flushing the patient and preserving heat when the patient lies on the bed board and is not covered with a quilt; the turnover mechanism comprises a turnover frame and a turnover mechanism, wherein the overturning frame is rotationally connected with the outer side of the arc-shaped cover, and automatic overturning of the arc-shaped cover is achieved through rotation of the overturning frame; the headrest mechanism is convenient for the patient to inhale oxygen; the excrement and urine collecting mechanism comprises a bottom frame; the bottom frame is fixedly installed on the baffle of the support. The washing mechanism is convenient for the patient to wash.

Owner:胡忠胜

Gathering perfect binding linking line

ActiveCN105711284AImprove glue binding efficiencyReduce labor intensityBook making processesSheet bindingEngineeringHot melt

The invention relates to a gathering perfect binding linking line. The gathering perfect binding linking line is characterized in that the gathering perfect binding linking line comprises a gathering machine, a torsion conveying system, a delivering system, an overturning system and an input system; and the gathering machine, the torsion conveying system, the delivering mechanism, the overturning system and the input system are sequentially arranged according to technological processes. The automatic overturning system of the gathering perfect binding linking line is used for replacing an original manner of manually overturning paper, so that automation is achieved, the perfect binding efficiency of the paper is improved, and the labor intensity of workers is lowered. The input system is adopted for replacing a manner of manually inputting book blocks, the labor intensity of the workers is lowered, and automation is achieved; and in addition, a hot melt glue technology is used for replacing a cold glue technology and a manual binding technology, the perfect binding effect is firmer, pages are not liable to fall, and gathering perfect binding automation of octavos and large octavos (450 mm*315 mm) is achieved.

Owner:NANTONG SANJING MACHINERY

Zipper and button automatic processing device and automatic processing technology for textile garment

The invention relates to a zipper and button automatic processing device and automatic processing technology for textile garment. The zipper and button automatic processing device comprises a bottom plate, a cutting device and a turning device; the cutting device is mounted on the right side of an upper end surface of the bottom plate, and the turning device is mounted on the left side of the upper end surface of the bottom plate; the turning device includes a swinging mechanism; the swinging mechanism is mounted on the left side of the upper end surface of the bottom plate; a swinging plate is mounted on a right end of the swinging mechanism; the swinging plate is circular; and turning mechanisms are mounted on the swinging plate, and the number of the turning mechanisms is 3. The zipperand button automatic processing device and automatic processing technology can solve the problems that when zippers and buttons of the waste and old textile garment are removed mechanically, clothes cannot be firmly fixed, and automatic turning of the clothes cannot be realized; and the efficiency is low and the number of the labors is large, removal is not thorough, and the input cost is high during manual removal can be solved. The zipper and button automatic processing device and automatic processing technology can realize automatic turning and removal of the zippers and buttons of the waste and old textile garment, and have the advantages of firm fixation, automatic turning, high working efficiency, thorough removal, low input cost, and time and labor saving.

Owner:桐庐裕泰拉链有限公司

Ceramic tile overturning equipment

InactiveCN109335579AAutomate flippingNo manual operationConveyorsDischarging arrangementEngineeringMechanical engineering

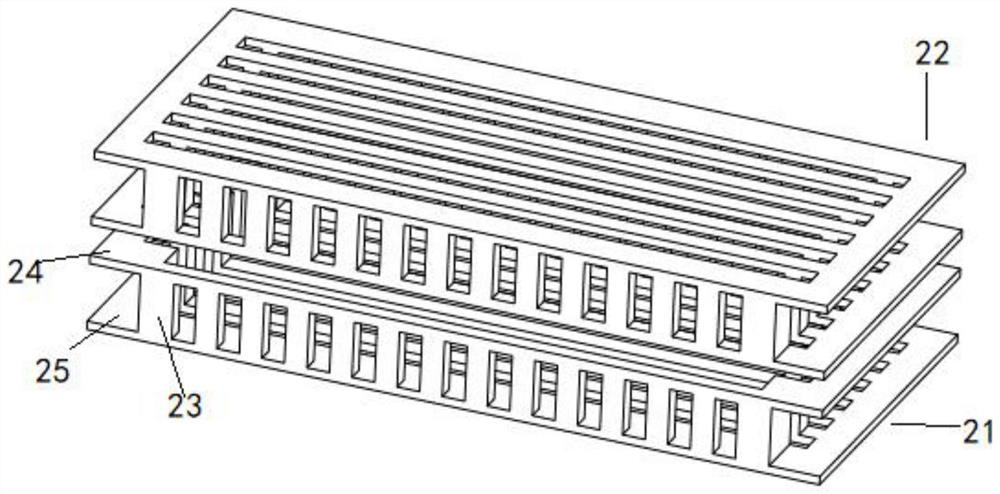

The invention discloses ceramic tile overturning equipment, which comprises a clamping part and support feet. The support feet are mounted on the two sides of the clamping part through rotating shafts, and the clamping part is a pair of rolling layers which is driven by an air cylinder and can get close to or away from each other; the rolling layers comprise mounting fences and rotating rods, wherein the rotating rods are used for rotationally transporting ceramic tiles; and the multiple rotating rods are mounted between the two mounting fences. According to the ceramic tile overturning equipment, automatic operation of ceramic tile overturning is achieved, manual operation is not needed, and thus the labor cost is reduced.

Owner:江门市博业陶瓷有限公司

Glass cup turnover device for glass cup production line

InactiveCN109850561AAutomate flippingImprove turnover efficiencyConveyor partsProduction lineEngineering

The invention discloses a glass cup turnover device for a glass cup production line. The glass cup turnover device comprises a first rotary air cylinder, a connecting sleeve, a turnover rod, a supporting plate, a second rotary air cylinder, a third rotary air cylinder, first connecting rods, second connecting rods and frame rods; the connecting sleeve is fixedly connected to a rotary shaft of thefirst rotary air cylinder, a first flange plate is arranged at the end of the connecting sleeve, a second flange plate is arranged at one end of the turnover rod, and the second flange plate is fixedly connected to the first flange plate; and the supporting plate is fixedly connected to the other end of the turnover rod, the second rotary air cylinder is fixedly connected to the supporting plate,the third rotary cylinder is fixedly connected to the supporting plate, a hinging seat is arranged at each of the two corners of the supporting plate, and a first cylindrical hole and a second cylindrical hole are symmetrically formed in each frame rod. Automatic turnover of glass cups on the production line is realized, the turnover efficiency is high, and workers are liberated from a high-temperature workshop.

Owner:芜湖中义玻璃有限公司

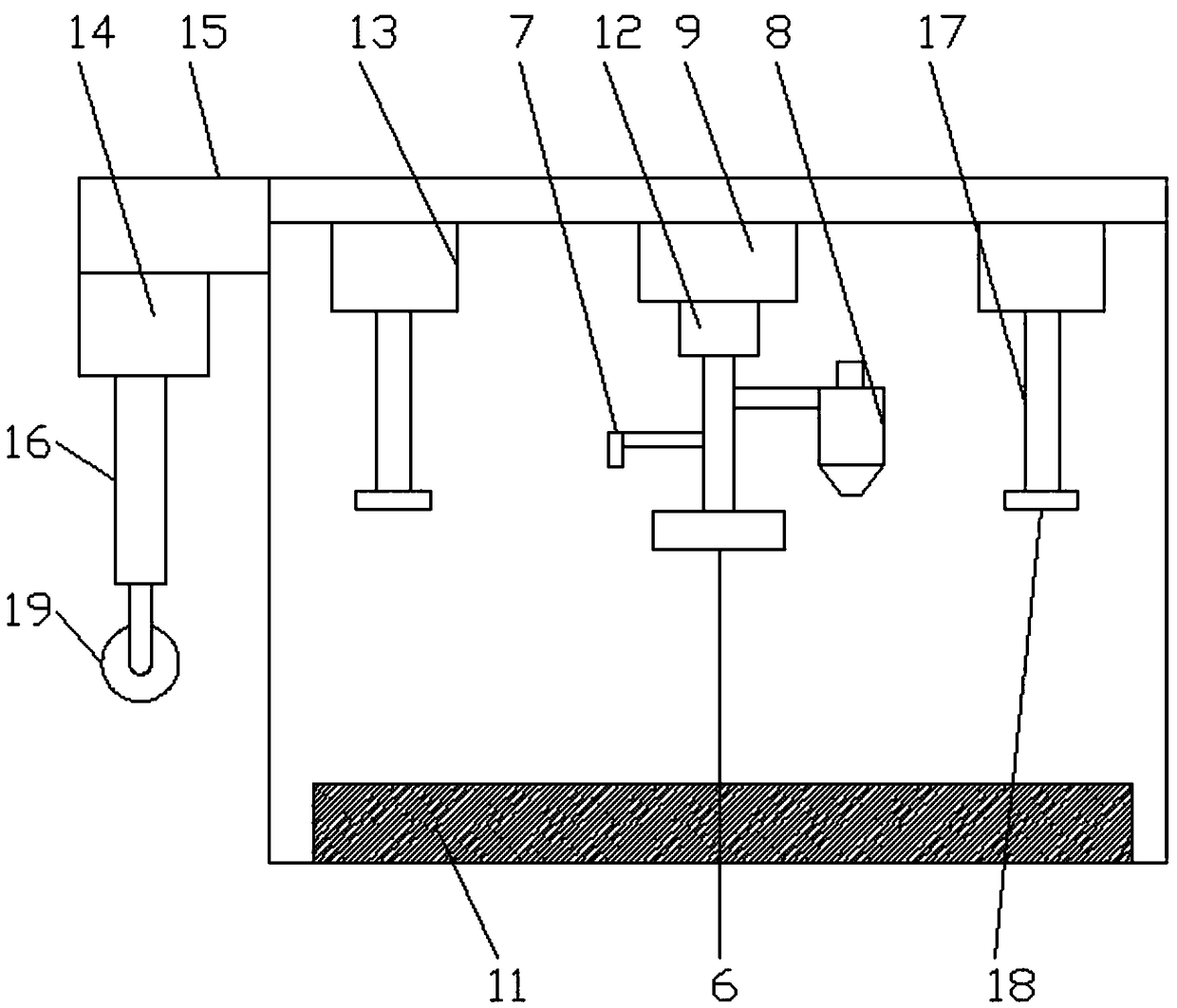

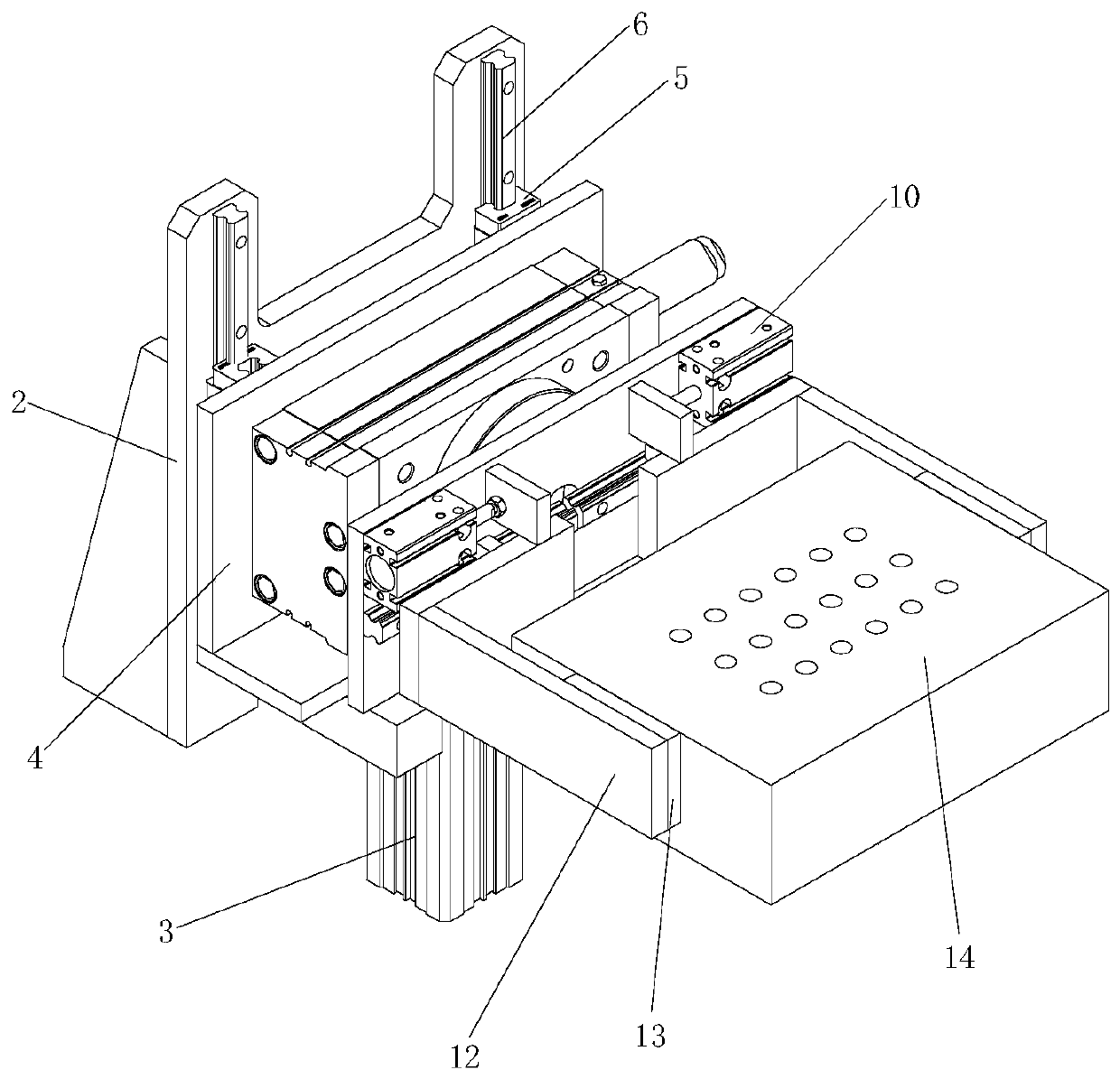

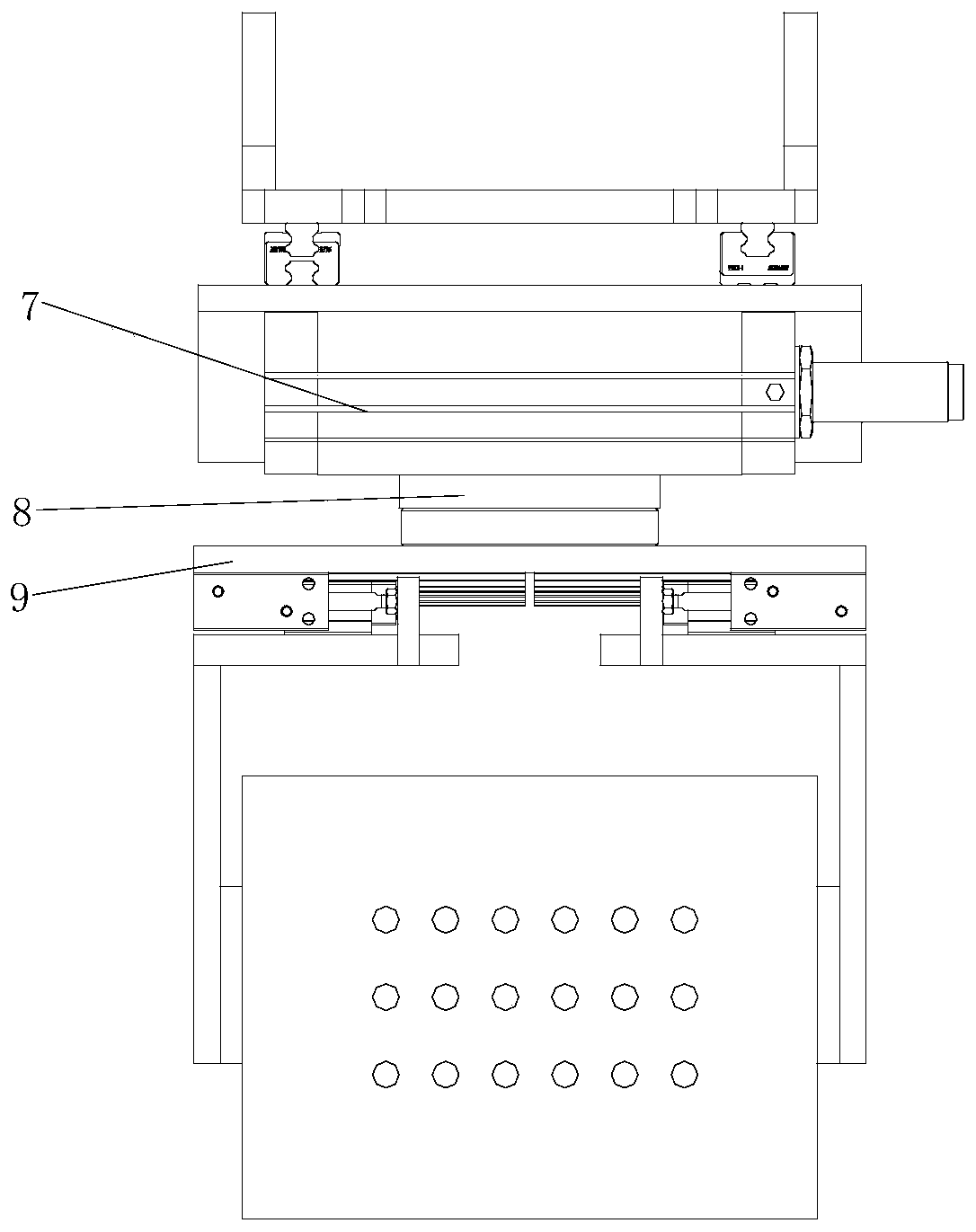

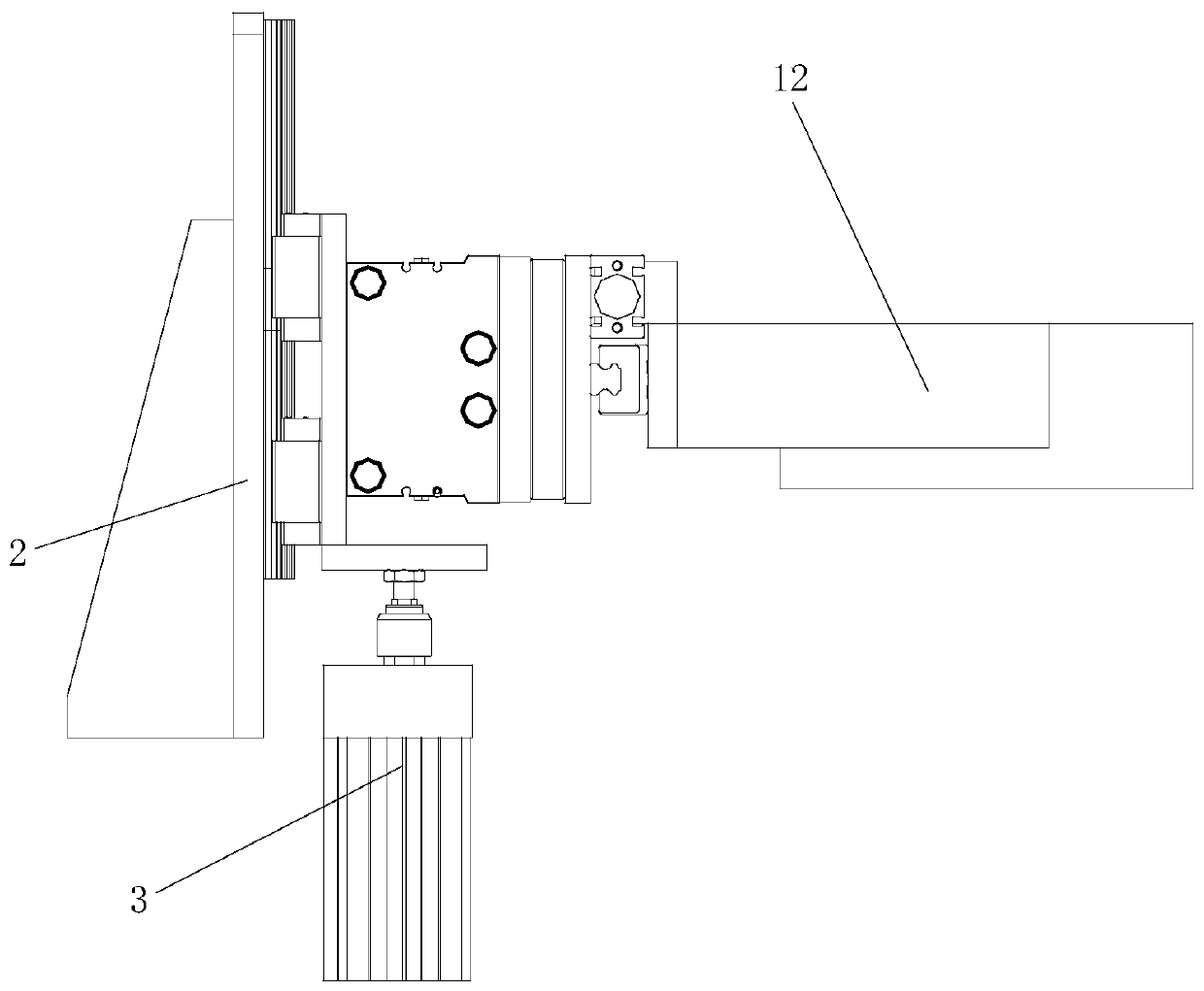

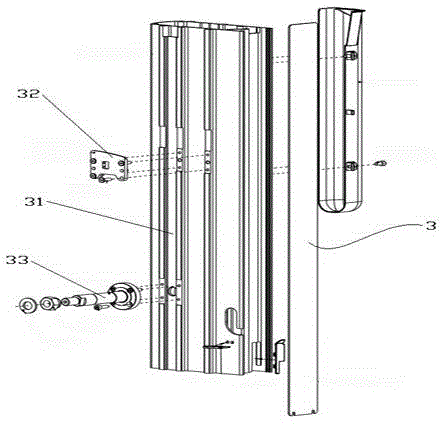

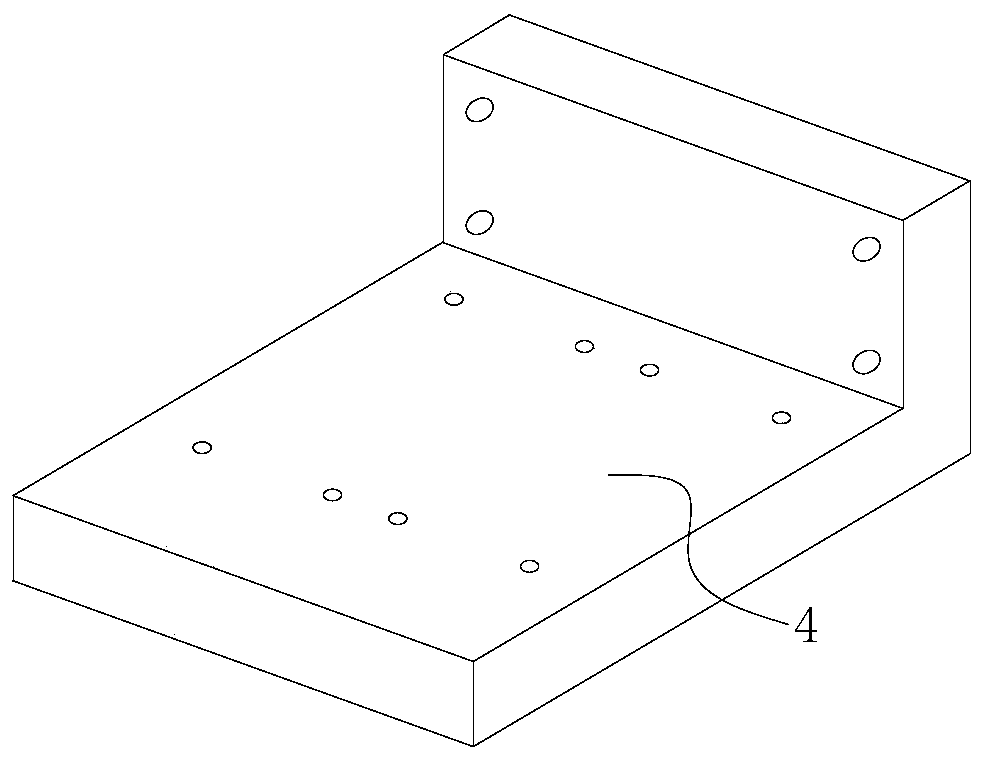

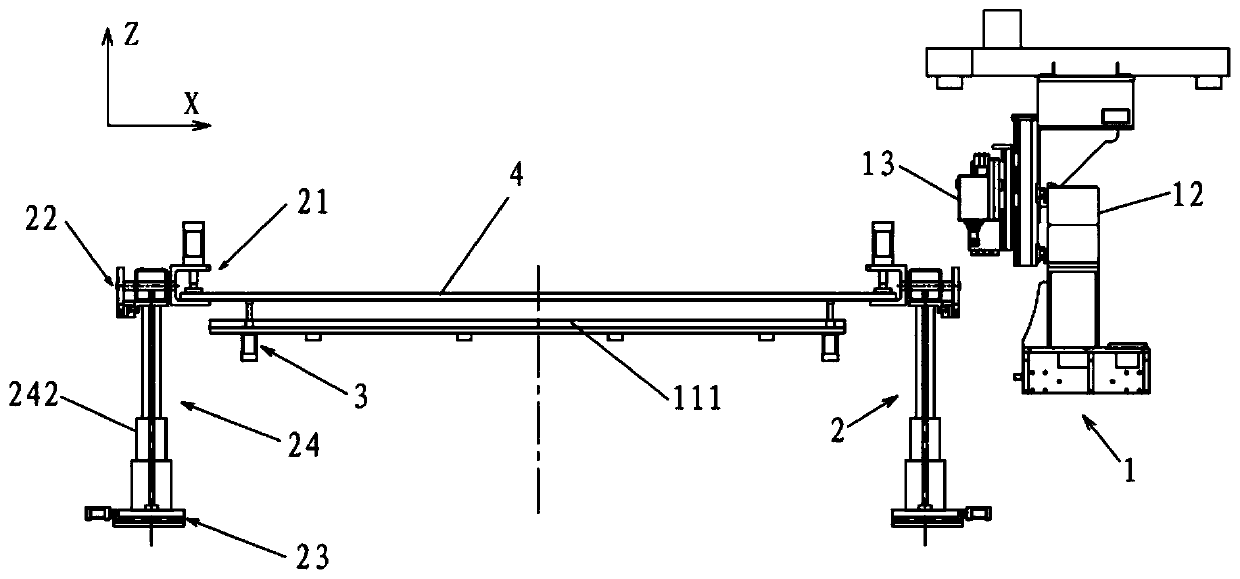

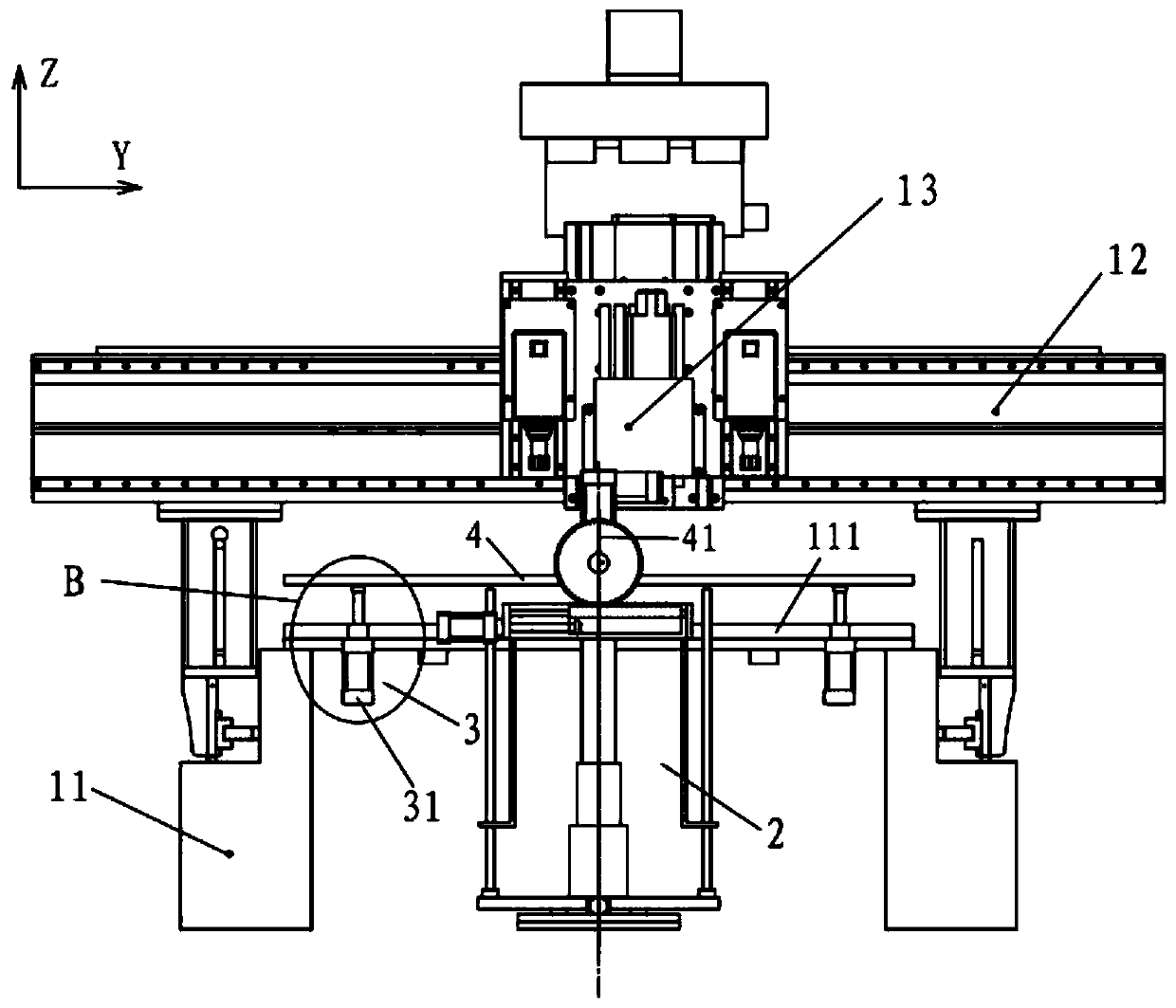

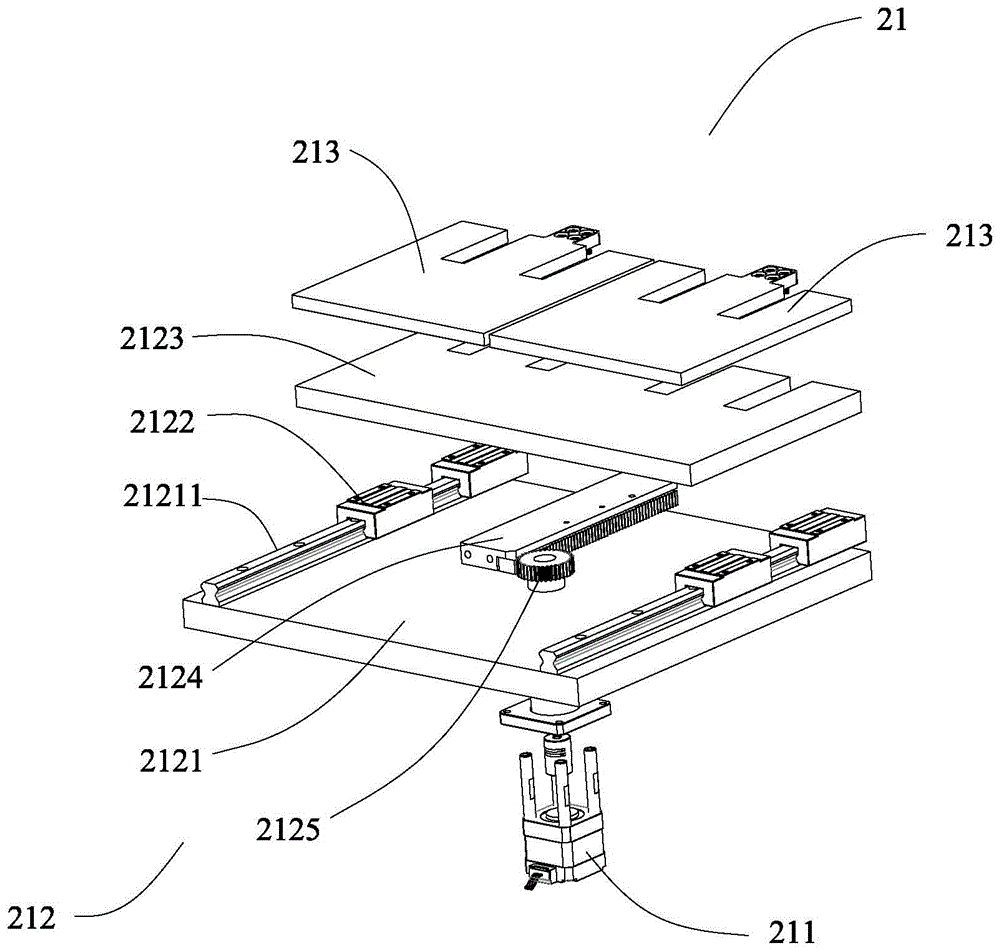

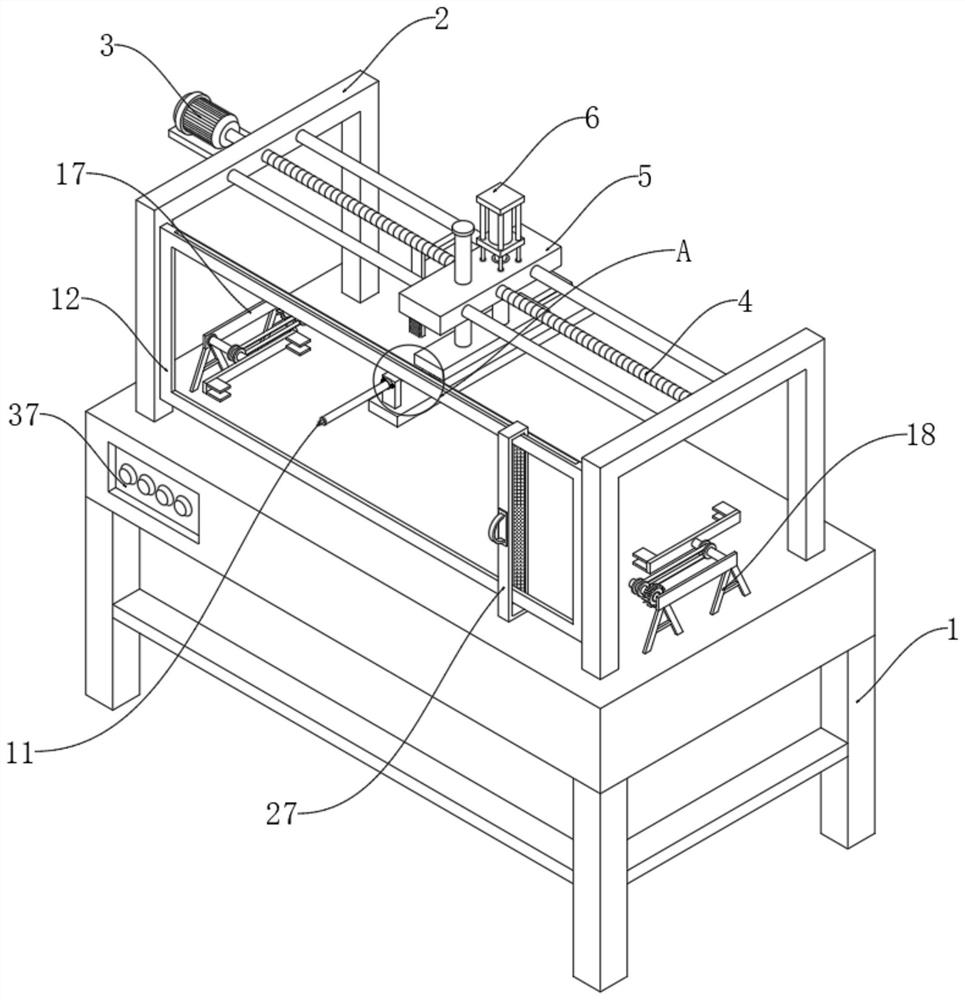

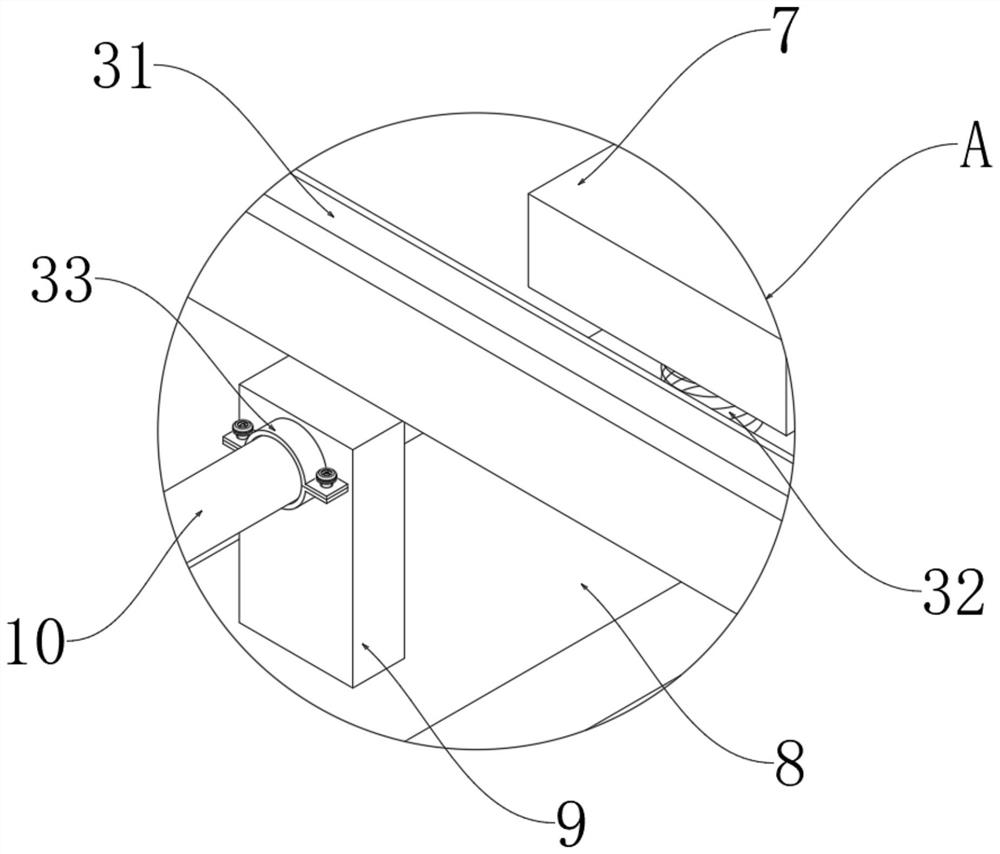

Processing center having automatic overturning function

PendingCN109877918ASimple and fast operationOptimize layoutProfiling/shaping machinesEngineeringMachine tool

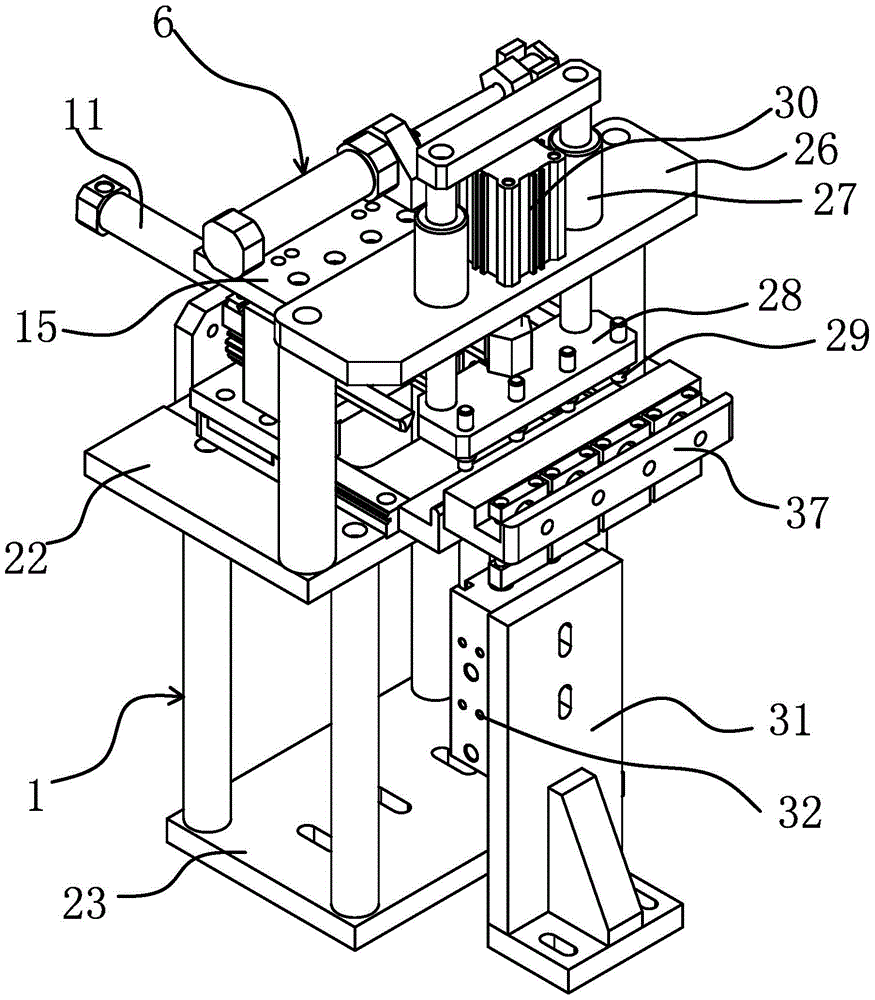

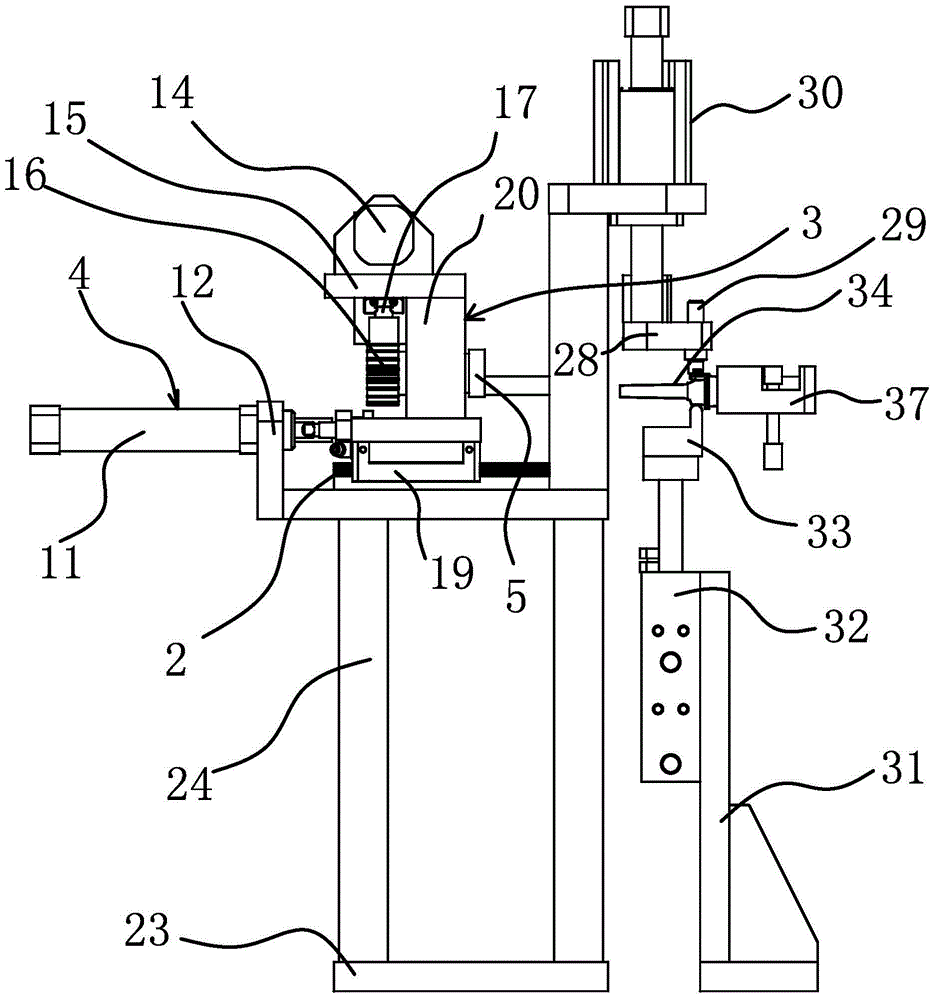

The invention discloses a processing center having an automatic overturning function. The processing center comprises a machine tool, an overturning device and a jacking device, wherein the machine tool comprises a machine frame; an operation table for allowing sheet materials to be placed is arranged on the machine frame; the overturning device is arranged below the middle part of the operation table in an X direction, and comprises a clamping mechanism, a rotating mechanism and a rising and falling mechanism; the rising and falling mechanism comprises a rising and falling platform of which the height can be adjusted; the clamping mechanism is connected with the rising and falling platform, and rises and falls along with rising and falling of the rising and falling platform; and the clamping mechanism comprises a clamping plate and a clamping block for clamping the sheet materials, and is used for overturning the sheet materials under the driving of the rotating mechanism, so that theoverturning operation of the sheet materials is performed above the operation table, and space is saved; and furthermore, the jacking device and a translating mechanism are also arranged, so that full-automatic sheet material overturning is realized, and the production efficiency is improved.

Owner:文静

Hosiery machine turning device

ActiveCN104894738BAutomate flippingIncrease productivityMechanical cleaningPressure cleaningBarrel ShapedEngineering

The invention discloses an overturning device of a hosiery knitter. The device comprises a driving mechanism, an overturning mechanism and an inclining mechanism. When in overturning, the inclining device acts to incline the overturning mechanism; the inclined overturning mechanism can absorb a barrel shaped knitting matter to be overturned into a fixing joint part of the overturning mechanism; then the inclining mechanism is returned to the original position; an overturning tube in the overturning mechanism upwards moves to overturn the barrel shaped knitting matter; thus the overturning is done, the sewing or knitting can be performed. With the adoption of the device, automatic overturning is achieved; the production efficiency can be greatly increased; the labor cost can be saved.

Owner:ZHEJIANG YEXIAO KNITTING MACHINERY

Manufacturing process of comprehensively-glazed ceramic

ActiveCN112339088AFull GlazingNo manual deliveryAuxillary shaping apparatusGlazeMechanical engineering

The invention discloses a manufacturing process of comprehensively-glazed ceramic. The ceramic is comprehensively glazed through an overturning type comprehensive glazing device in the ceramic manufacturing process. The overturning type comprehensive glazing device comprises a limiting and fixing base plate and a bearing frame assembly for containing the ceramic. A lifting and overturning mechanism and a positioning assembly used in cooperation with the lifting and overturning mechanism are installed on one side of the surface of the limiting and fixing base plate, and an adjusting and fixingglazing mechanism is installed on the lifting and overturning mechanism. By means of the overturning type comprehensive glazing device, the ceramic can be overturned after being glazed by dipping, then glaze in the ceramic with grooves is poured out in the overturning process; and then glazing by dipping is conducted, and therefore a contact part of the ceramic can also be dipped with the glaze.

Owner:广东顺辉新型材料科技有限公司

A turning device for the cover of the plastic needle blue cover in the infusion set assembly machine

The invention provides a turnover device of a cover body of a needle molding flange cover in an infusion apparatus assembling machine, and belongs to the technical field of the infusion apparatus assembling machine. The turnover device solves the technical problem that in the prior art, a counter of the flange cover cannot be automatically closed so that the efficiency can be low. The turnover device comprises a rack, a first guide rail arranged in the horizontal direction is fixed to the rack, and a sliding base is connected to the first guide rail in a sliding manner; a first driving source for driving the sliding base to move along the first guide rail is arranged on the rack, a rotating shaft with the axis arranged in the horizontal direction is inserted into the sliding base in a connected manner, and a rotating shaft can rotate around the axis relative to the sliding base; and a second driving source for driving the rotating shaft to rotate is fixed to the sliding base, and a pulling rod arranged in the horizontal direction is fixedly connected to the front end of the rotating shaft and located at the eccentric position of the rotating shaft. According to the turnover device, the first driving source and the second driving source are linked, so that the pulling rod abuts against the cover body of the flange cover and overturns the cover body to enable the cover body to cover the flange cover, the cover body of the flange cover for needle molding can be automatically overturned and closed accordingly, and the assembly efficiency and the sanitation grade are improved.

Owner:浙江东美智能设备有限公司

A banknote handle turning unit

Owner:CITIC TIANJIN OUTSOURCING SERVICES

A fully automatic robot for surface grinding of large solid wood furniture

ActiveCN108908010BActive connectionImprove the effect of intelligenceAutomatic grinding controlGrinding machinesSolid woodDust control

The invention discloses a large-scale solid wood furniture surface grinding full-automatic robot. The robot structurally comprises a solid wood furniture grinding machine body, a control panel, a conveying device, supporting legs, rubber fixing pads, a grinding wheel, a monitoring device and a dust removing device. The left side of the front portion of the solid wood furniture grinding machine body is provided with the control panel, and the bottom of a first cylinder is connected with the grinding wheel via a pneumatic rod. The monitoring device is connected to the left portion of the gas pressure rod, and the dust removing device is connected to the right portion of the pneumatic rod. A second cylinder is disposed on both sides of a sliding device respectively, a second pneumatic rod isdisposed at the bottom of each second cylinder, and a suction cup is disposed at the bottom of each second pneumatic rod. The bottom of the solid wood furniture grinding machine body is provided withthe conveying device, the support legs are distributed at the bottom of the conveying device, and the rubber fixing pads are arranged at the bottoms of the support legs. The large-scale solid wood furniture surface grinding full-automatic robot has high automation performance, improves grinding efficiency, and achieves automatic turning.

Owner:宁国市长远知识产权代理有限公司

Automatic flip fabric cutting system and its automatic flip fabric cutting method

ActiveCN105361311BEasy flipEasy to moveSevering textilesClothes making applicancesEngineeringMechanical engineering

The invention discloses an automatic fabric cut-part turnover system and an automatic fabric cut-part turnover system method. The automatic fabric cut-part turnover system comprises a workbench and a turnover device. The desktop of the workbench is provided with a cut-part passage; the turnover device comprises detection parts, a retainer, a press plate, a press plate drive element, a driving lever, a driving lever holder and a driving lever drive element. The detection parts are connected to the workbench; the retainer disposed under the desktop of the workbench is fixed to the workbench; the press plate disposed under the desktop of the workbench is connected to the workbench movably; the retainer and the press plate are respectively arranged on two sides of the passage along a straight direction; the press plate drive element is arranged on the workbench and connected to the press plate; the driving lever is fixed to the driving lever holder which is slidably connected to the workbench; and the driving lever drive element is arranged on the workbench and connected to the driving rod holder to drive the same. The automatic fabric cut-part turnover system is capable of turning and feeding cut-parts automatically.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

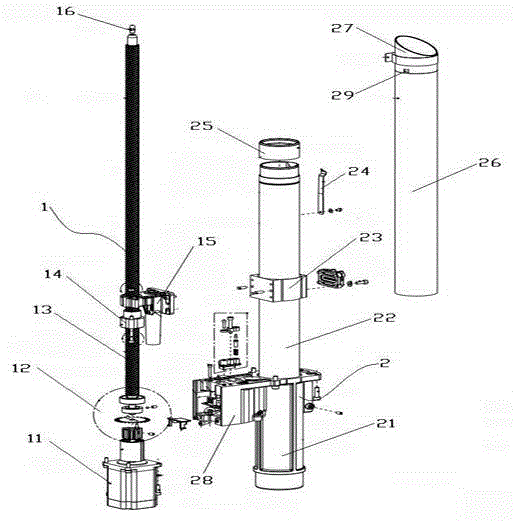

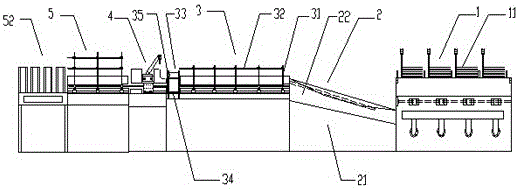

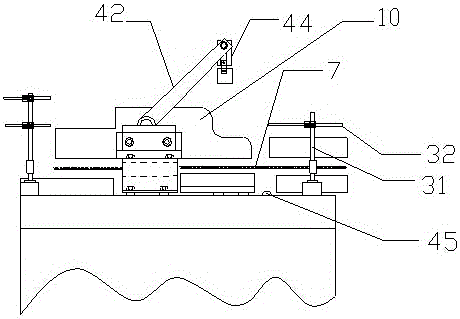

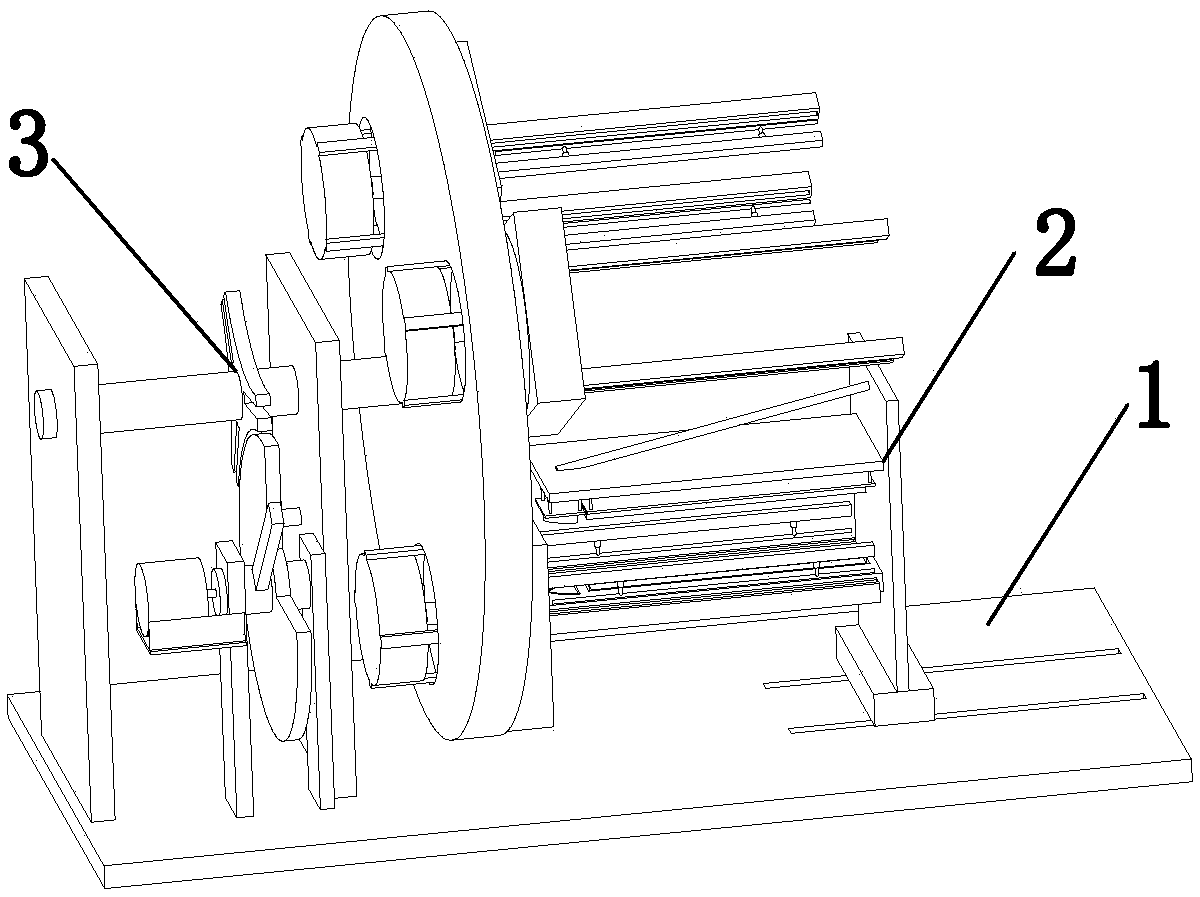

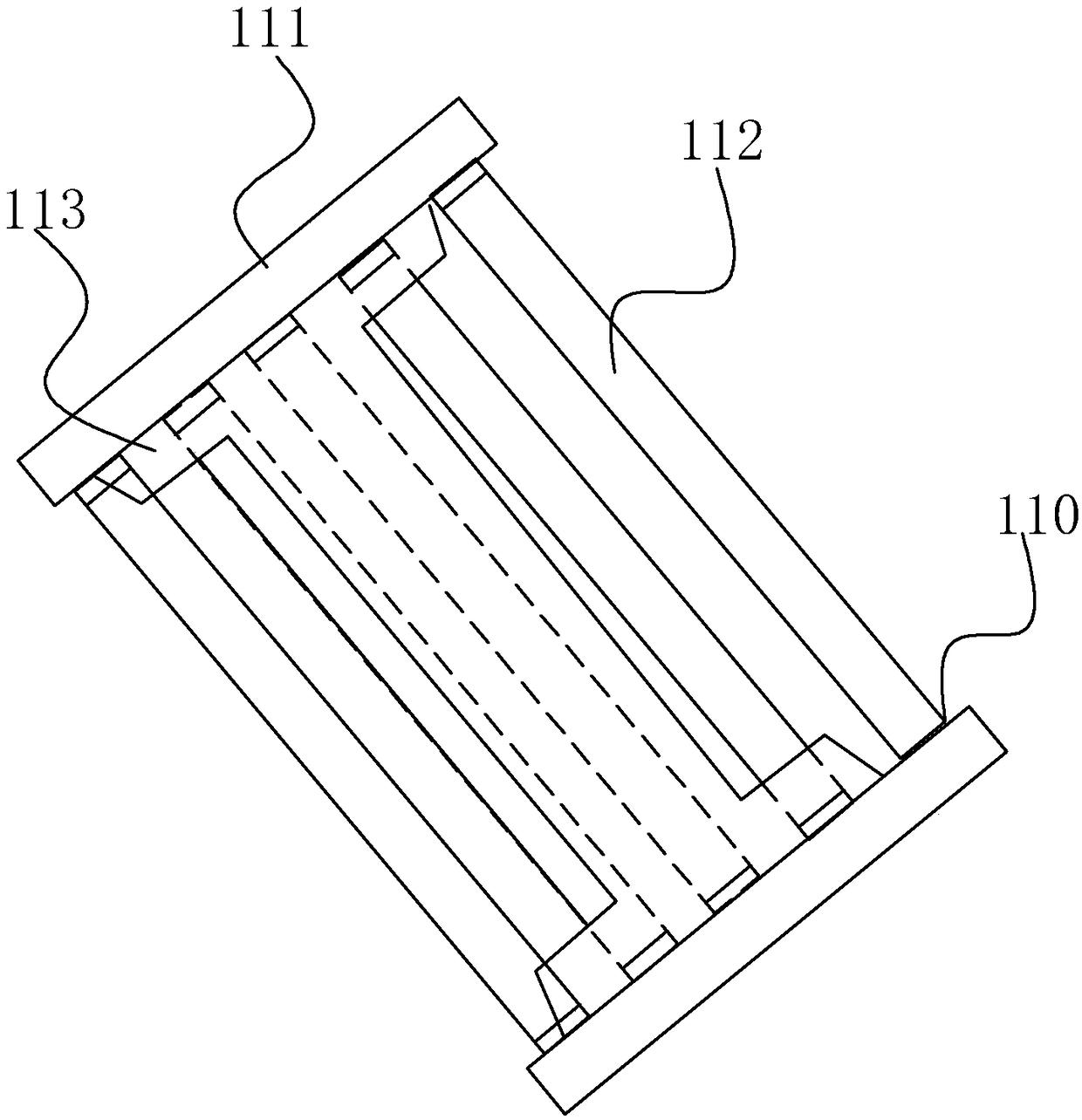

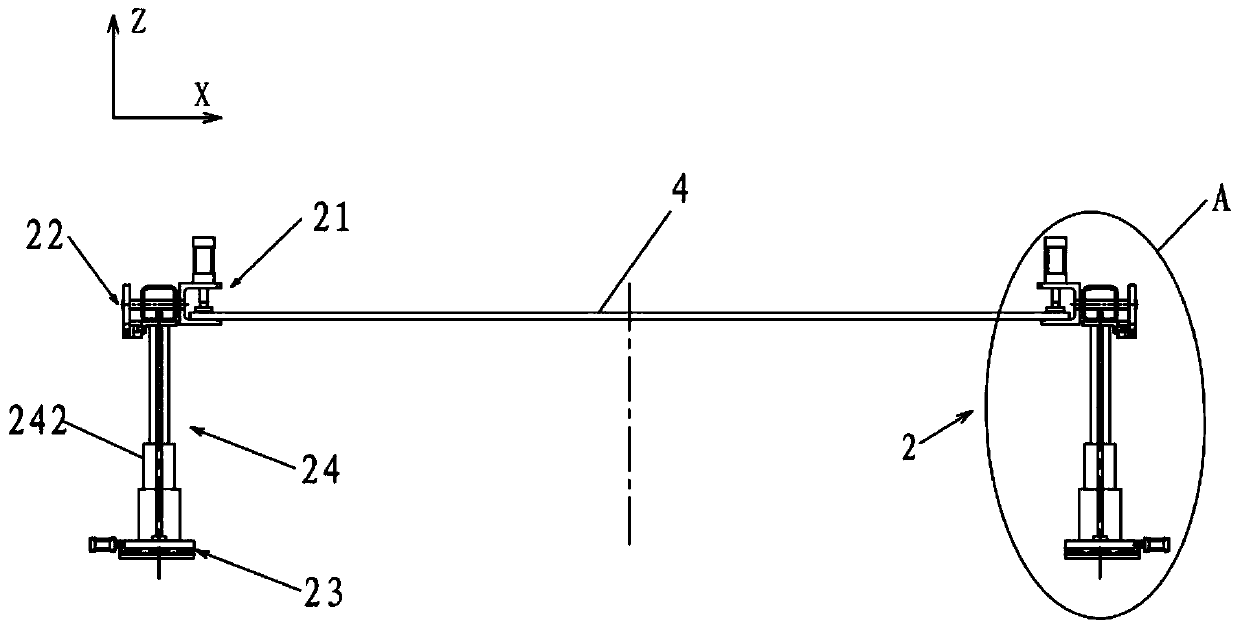

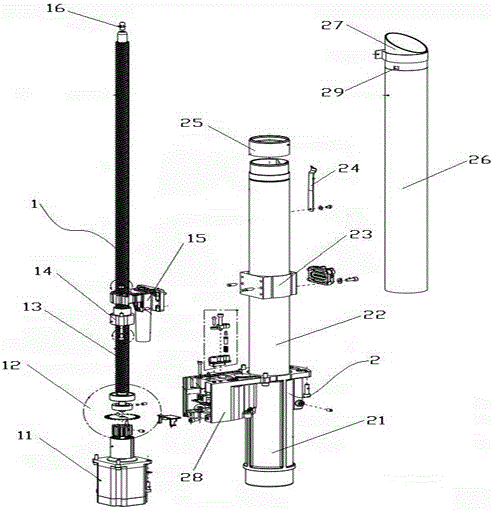

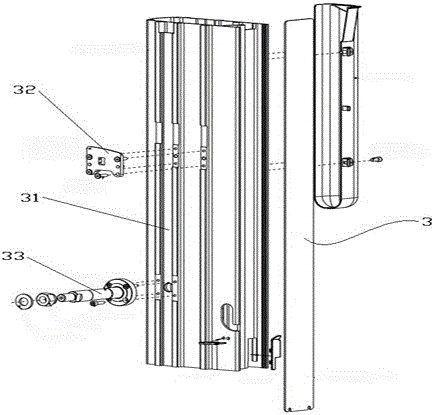

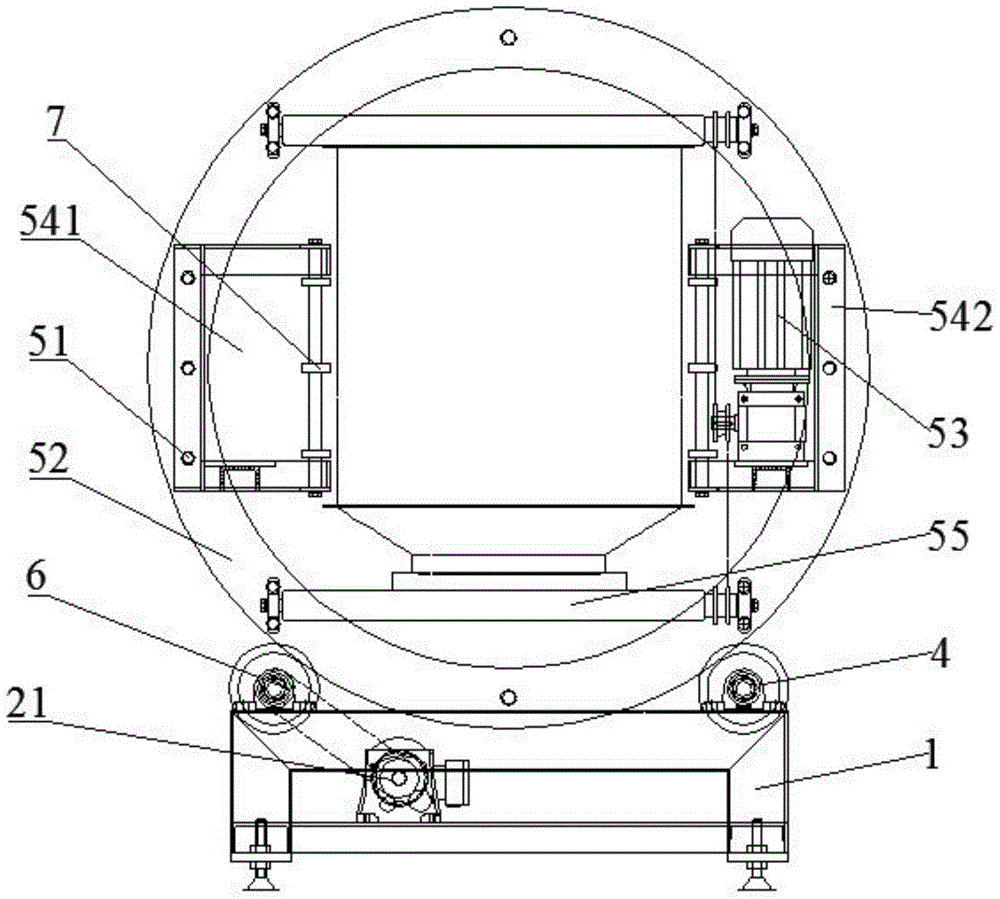

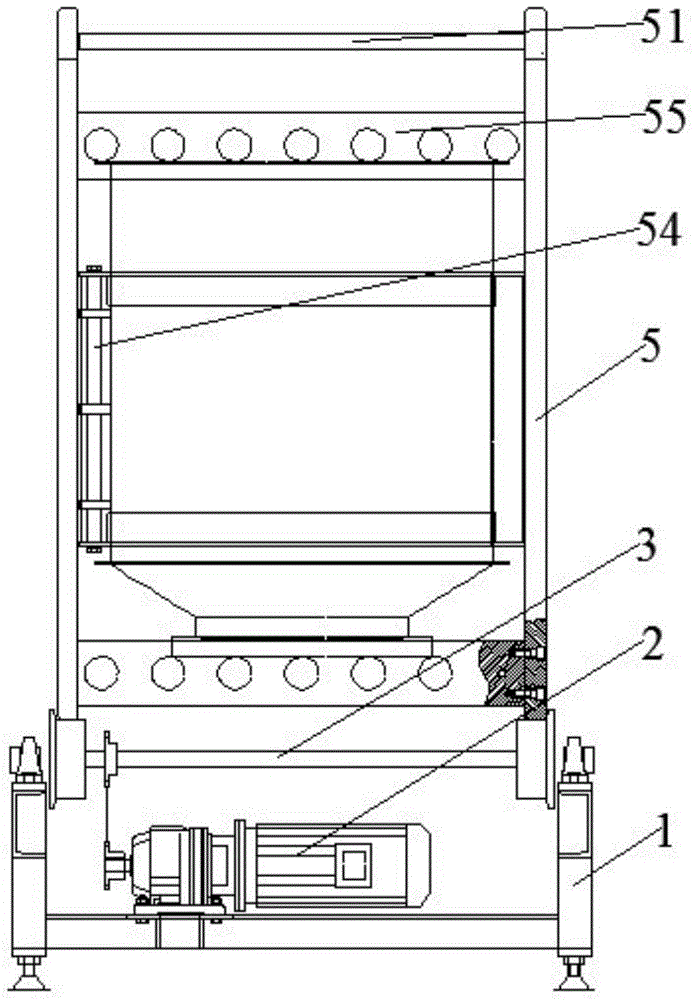

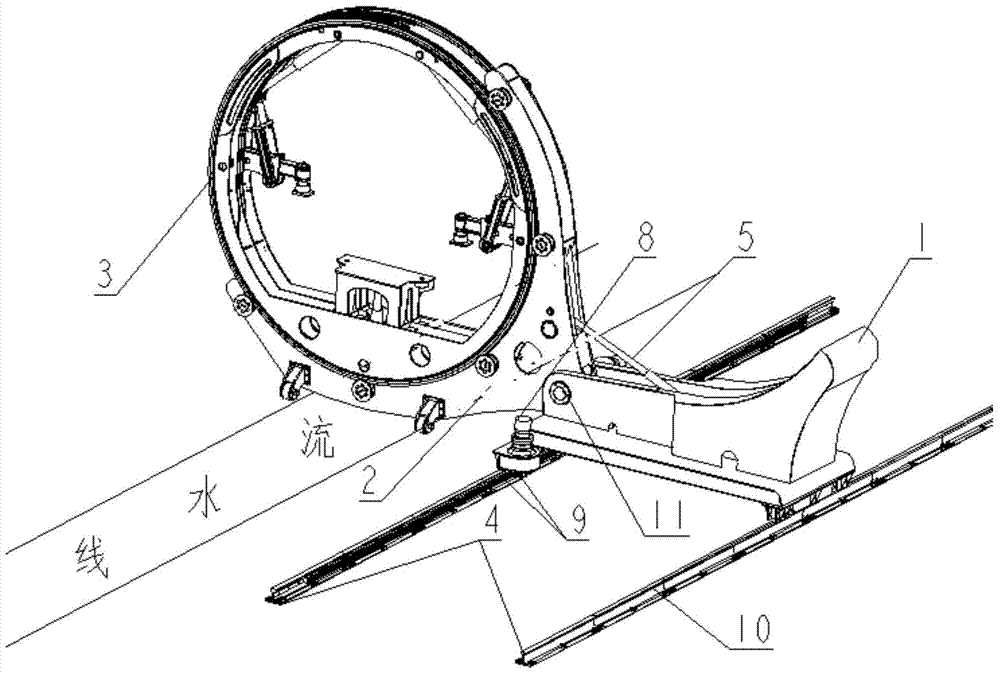

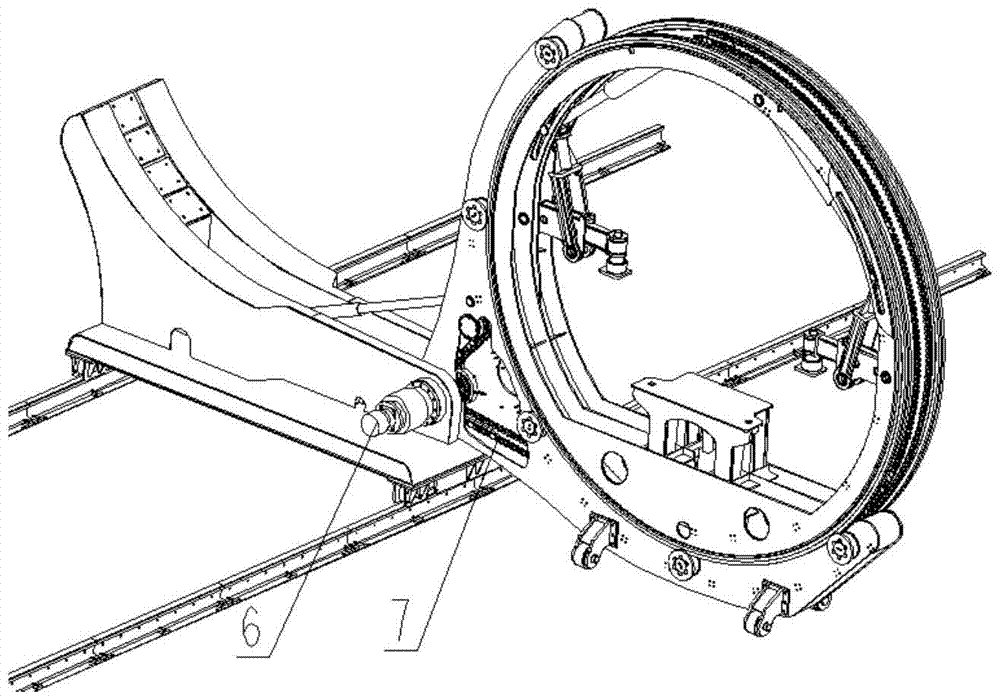

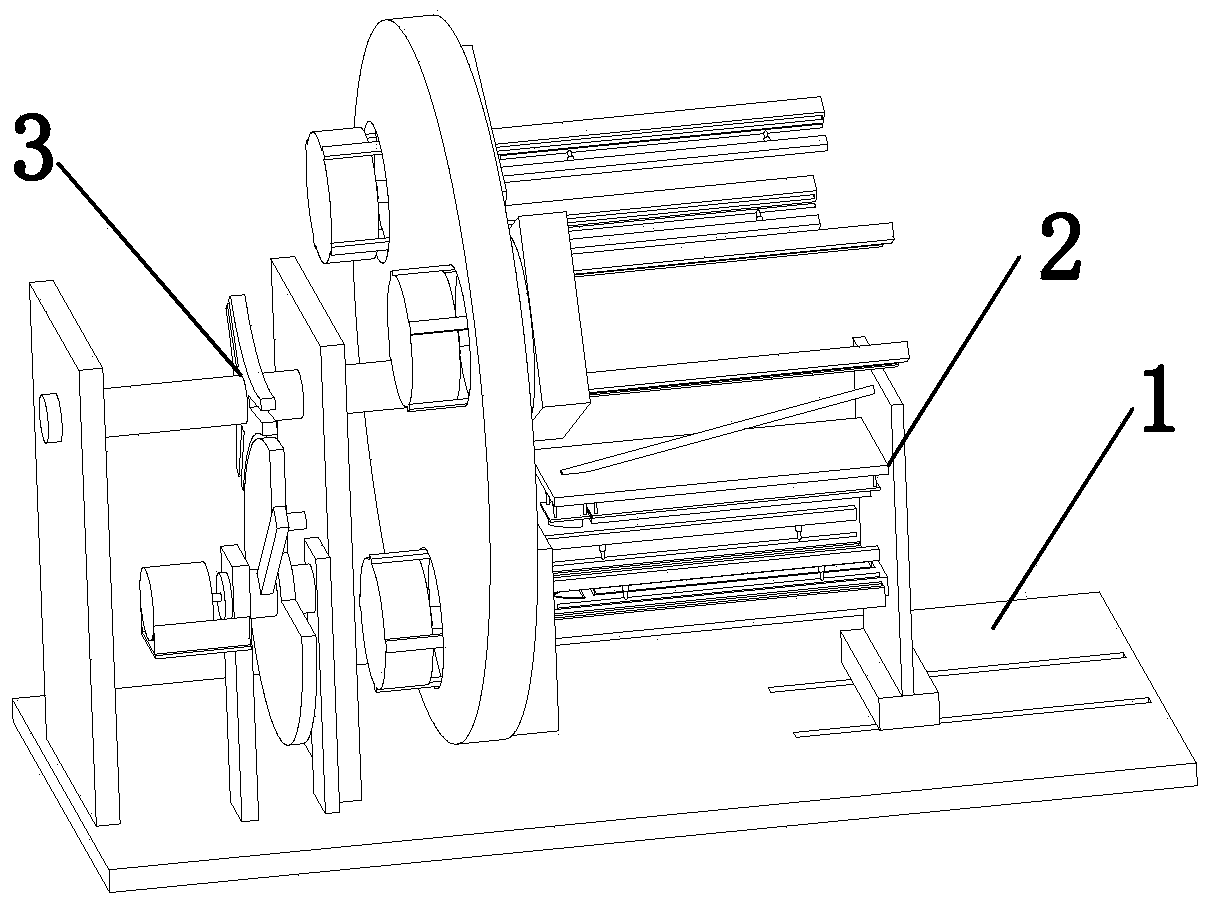

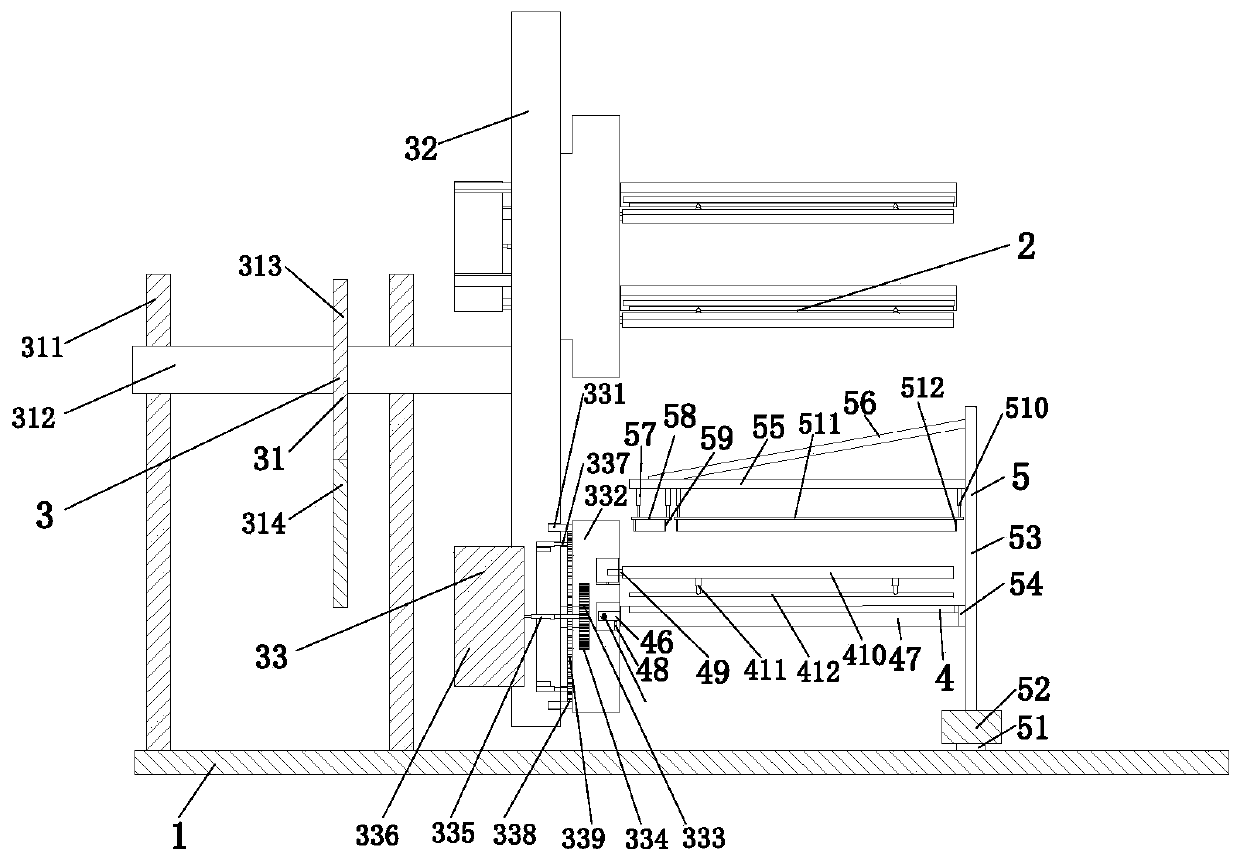

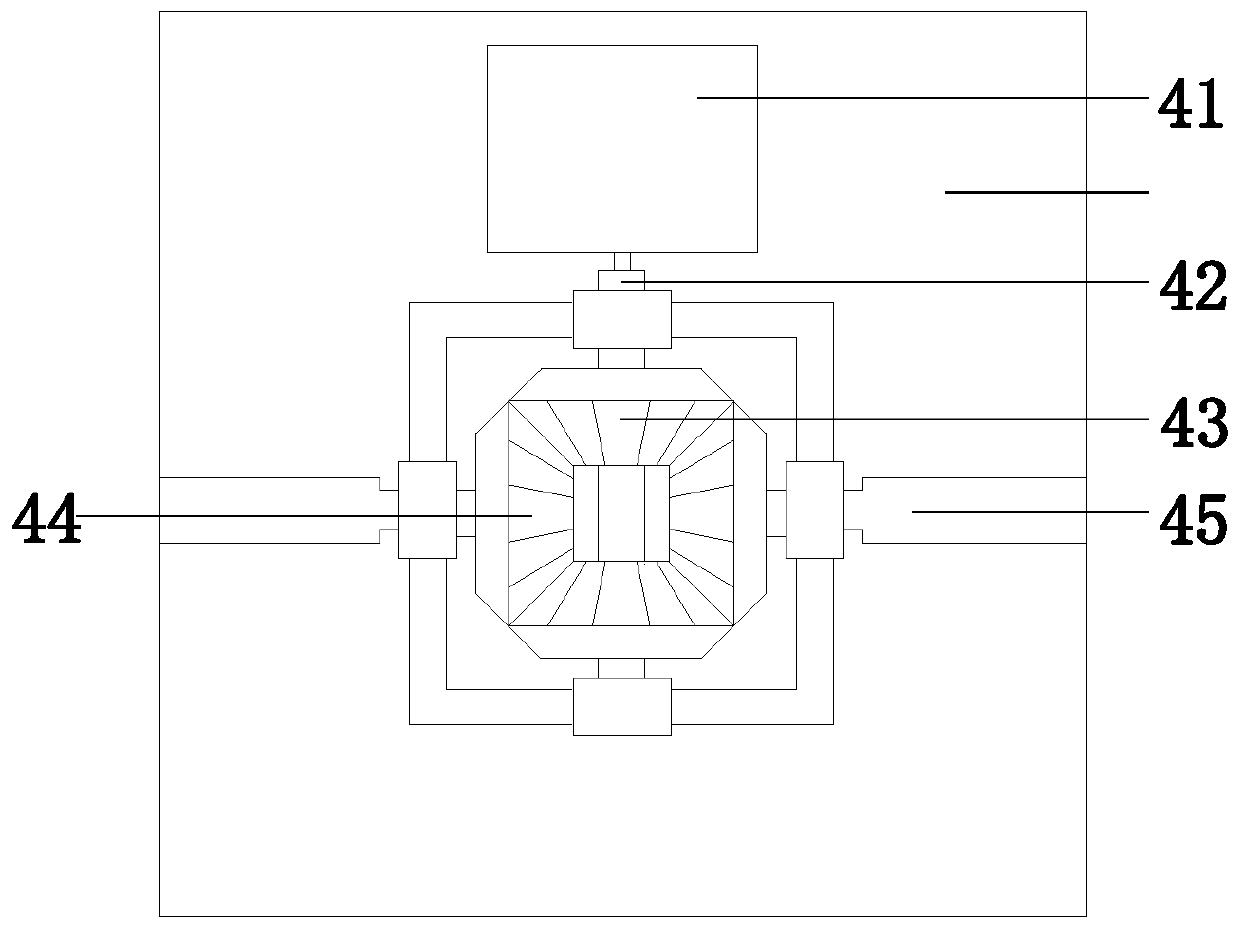

Double roller table turning machine for the spinning process of filter absorber

ActiveCN104646476BAutomate flippingReduce labor intensityMetal-working feeding devicesPositioning devicesElectric machineEngineering

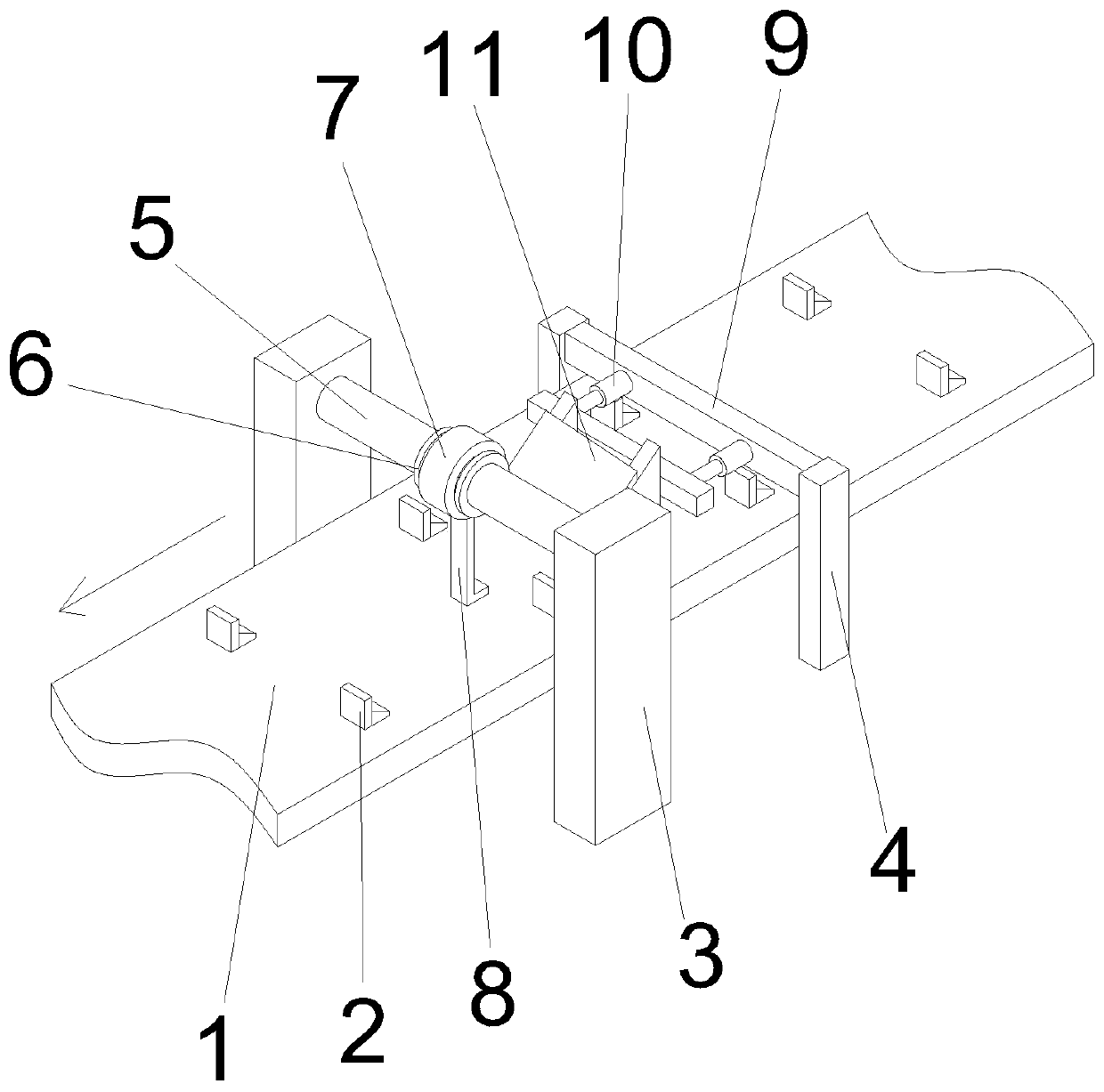

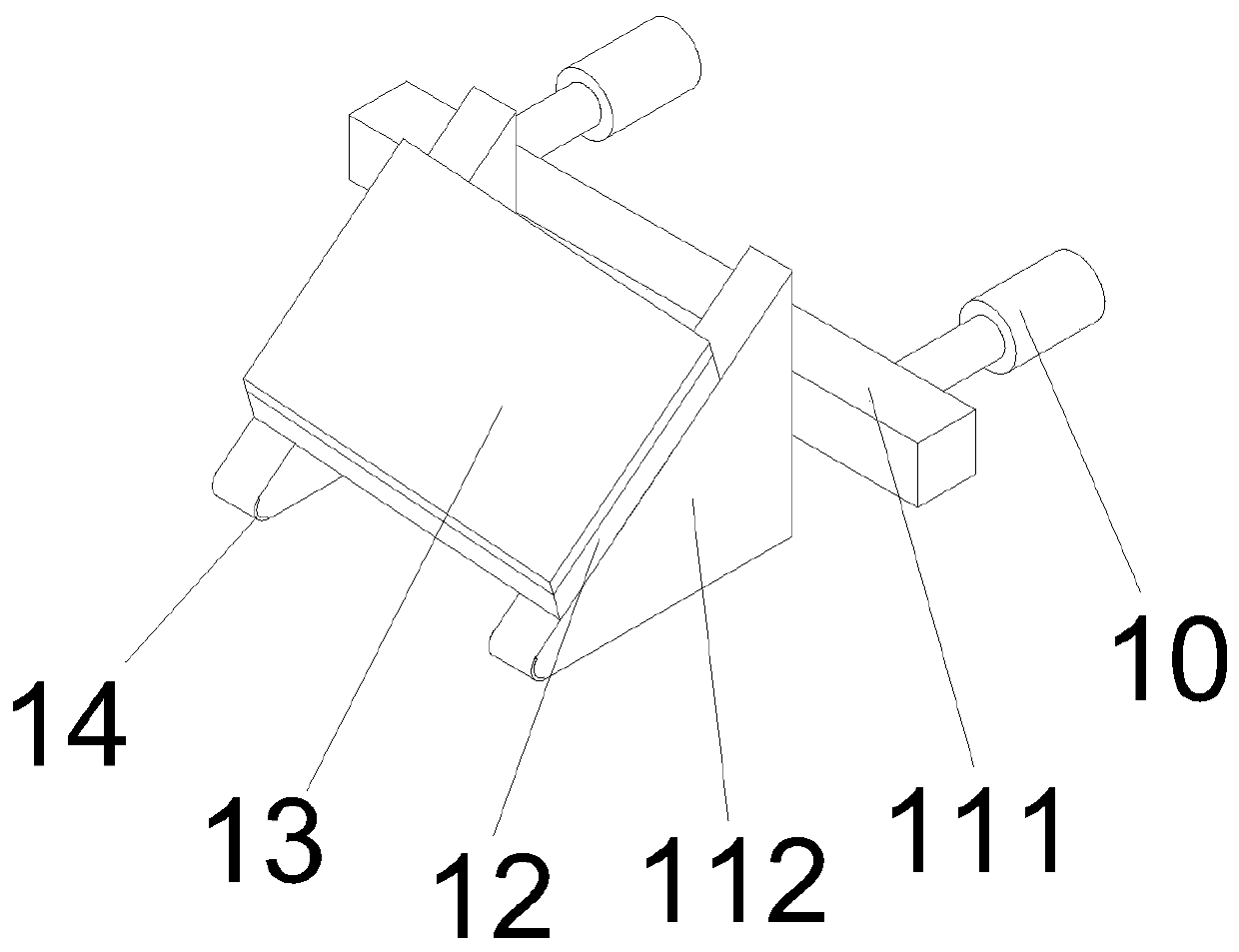

The invention relates to a turnover machine and discloses a double-roller way turnover machine in a filter absorber spinning process. The double-roller way turnover machine comprises a base (1), wherein a rotary motor (2) and two groups of support mechanisms (3) are arranged on the base (1), the support mechanisms (3) comprise rotary rollers (4) which are driven by the rotary motor (2), a rotary body (5) is supported on the two groups of support mechanisms (3), the rotary body (5) comprises two rotary disks (52) which are connected through a plurality of connecting rods (51), and the rotary rollers (4) are tangent with the outer edges of the rotary disks (52); a roller way motor (53), two fixtures (54) which are used for clamping a filter absorber and two roller ways (55) which are driven by the roller motor (53) are arranged in the rotary body (5).According to the double-roller way turnover machine, automatic turnover of the filter absorber in the spinning process can be realized, the labor intensity is effectively reduced, the auxiliary time of production is saved, and the production efficiency and labor beats are improved.

Owner:ZHEJIANG SANYI TECH CO LTD

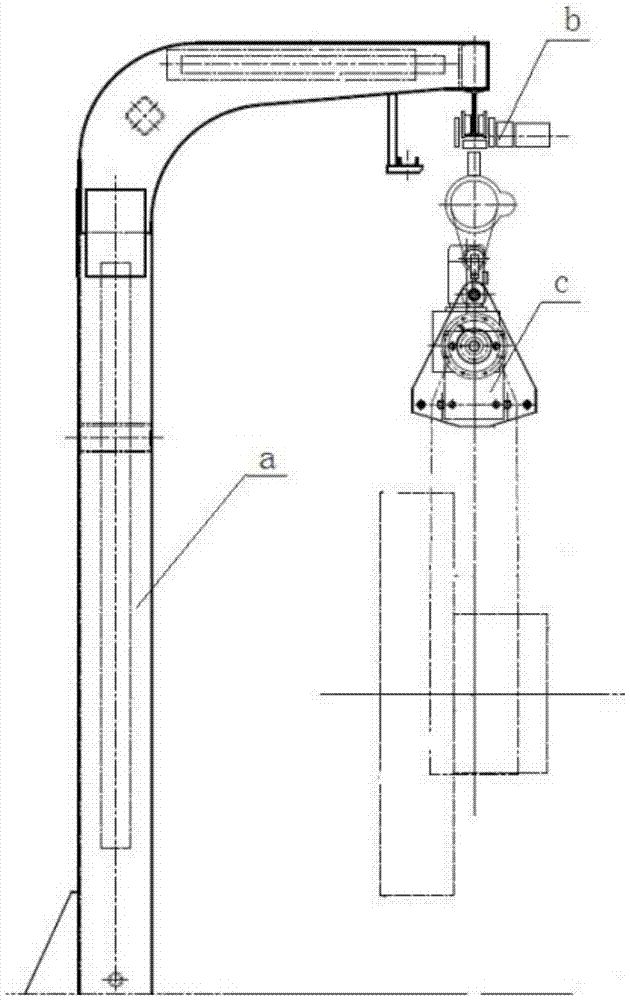

A chassis on-line flipping device

The invention discloses an on-line flipping device for a chassis. A bracket (2) is connected to a base (1) through a rotating shaft (11), and can rotate relative to the base (1) around the rotating shaft (11); it is installed on the base (1). The traveling motor (8) on the pedestal rotates and drives the rack and pinion mechanism (9) connected with the traveling motor (8) to drive the entire equipment to walk in the foundation; the rotary motor (6) installed on the base (1) rotates and drives The transmission chain (7) fixed on the turning ring (3) rotates to drive the entire turning ring to rotate; The turning ring (3) rotates around the rotating shaft (11) together to realize the retracting movement of the bracket and the turning ring; the present invention can realize turning over without the need of offline of the chassis, and can reduce the bumping of the chassis and the damage caused by twisting. Deformation, promote lean production while improving product quality.

Owner:XUZHOU HEAVY MASCH CO LTD

Rotor overturning device

InactiveCN108705483AAutomate flippingNo manual operation requiredWork holdersMetal-working hand toolsEngineeringVertical axis

The invention discloses a rotor overturning device. The rotor overturning device comprises a base, a supporting frame, a first air cylinder, a lifting block, a rotation base and a clamping mechanism.The supporting frame is vertically arranged on the base, and the first air cylinder is arranged on the supporting frame. A telescopic rod is detachably connected to the lifting block. The supporting frame is provided with a first sliding groove in the vertical direction, wherein the first sliding groove is matched with the lifting block, and the first sliding groove extends to the other end from one end of the supporting frame. Accordingly, when the telescopic rod of the first air cylinder stretches and contracts in the vertical direction, the lifting block can be driven to slide in the vertical direction. The rotation base is movably connected to the lifting block through a rotation mechanism. The clamping mechanism is fixedly connected to the rotation base, the clamping mechanism is provided with a clamping port matched with a rotor, and accordingly when the rotation base rotates along the vertical axis of the lifting block, the rotor clamped on the clamping mechanism can rotate along the vertical axis of the lifting block. The rotor overturning device can achieve automatic rotor overturning, manual operation is not needed, and therefore operators cannot be hurt.

Owner:安徽安元智能科技有限公司

Solar photovoltaic panel turnover device

InactiveCN110867499AFlipAvoid damageFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses a solar photovoltaic panel turnover device, which comprises a conveying belt. The surfaces of the two sides of the conveying belt are fixedly connected with clamping bases at equal intervals. A first support and a second support are arranged on the two sides of the conveying belt correspondingly. The first support is located above the conveying belt and fixedly connected with a round rod, the outer ring of the middle of the round rod is fixedly connected with a limiting sleeve, the limiting sleeve is movably connected with a rotating cylinder, the lower portion of the rotating cylinder is fixedly connected with an L-shaped hook plate, and a transverse rod is fixedly connected between the second supports and fixedly connected with a top plate mechanism through a hydraulic rod. The photovoltaic panel assembly is supported and fixed through the clamping bases, one end of the photovoltaic panel assembly is hooked and lifted through the L-shaped hook plate, the top plate mechanism is pushed through the hydraulic rod, turnover of the photovoltaic panel assembly and mechanical turnover of the photovoltaic panel are achieved, the efficiency is high, the labor amountis reduced, and automatic turnover can be achieved; and the damage and surface pollution of the photovoltaic panel assembly can be effectively reduced, and the product quality of the photovoltaic panel assembly is improved.

Owner:安徽振兴光伏新能源有限公司

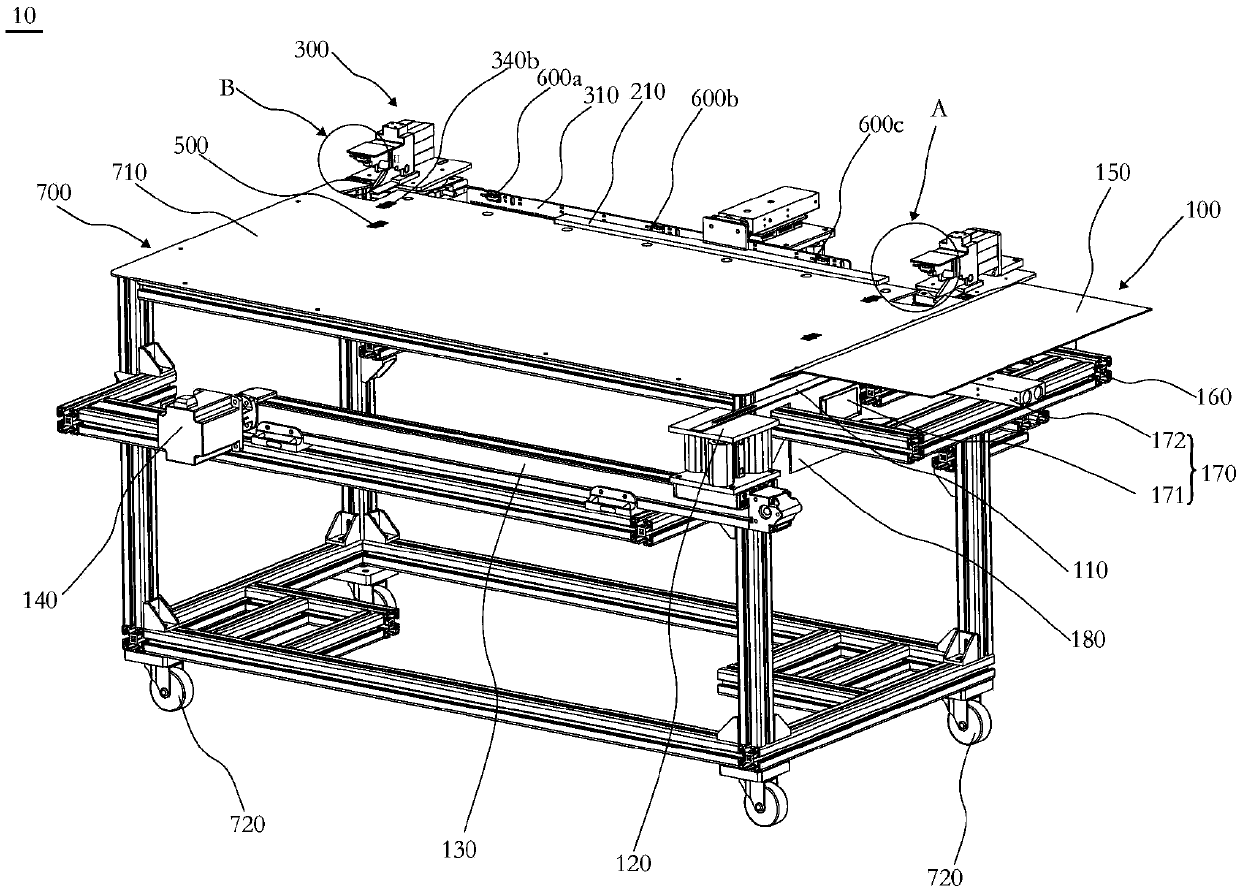

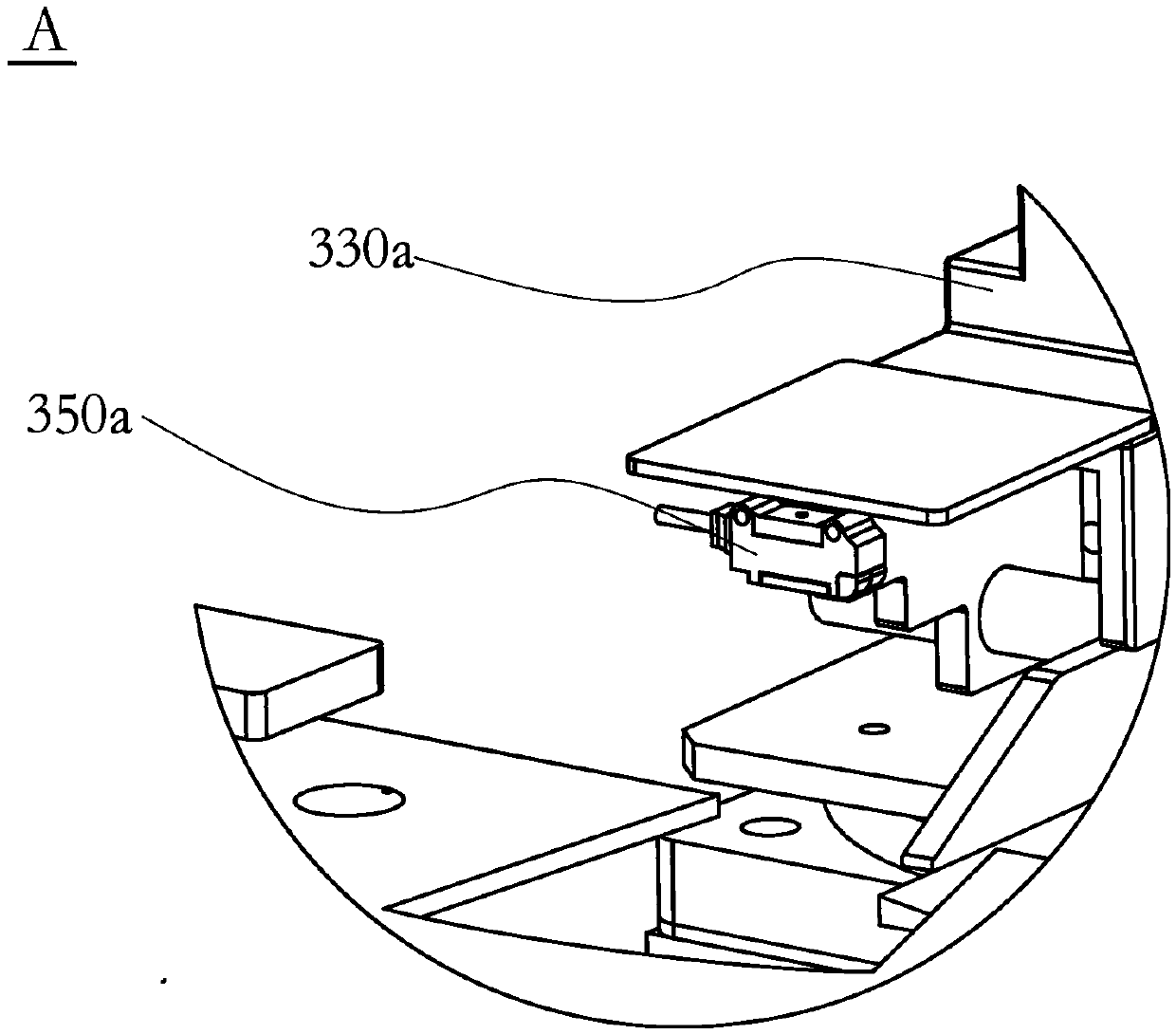

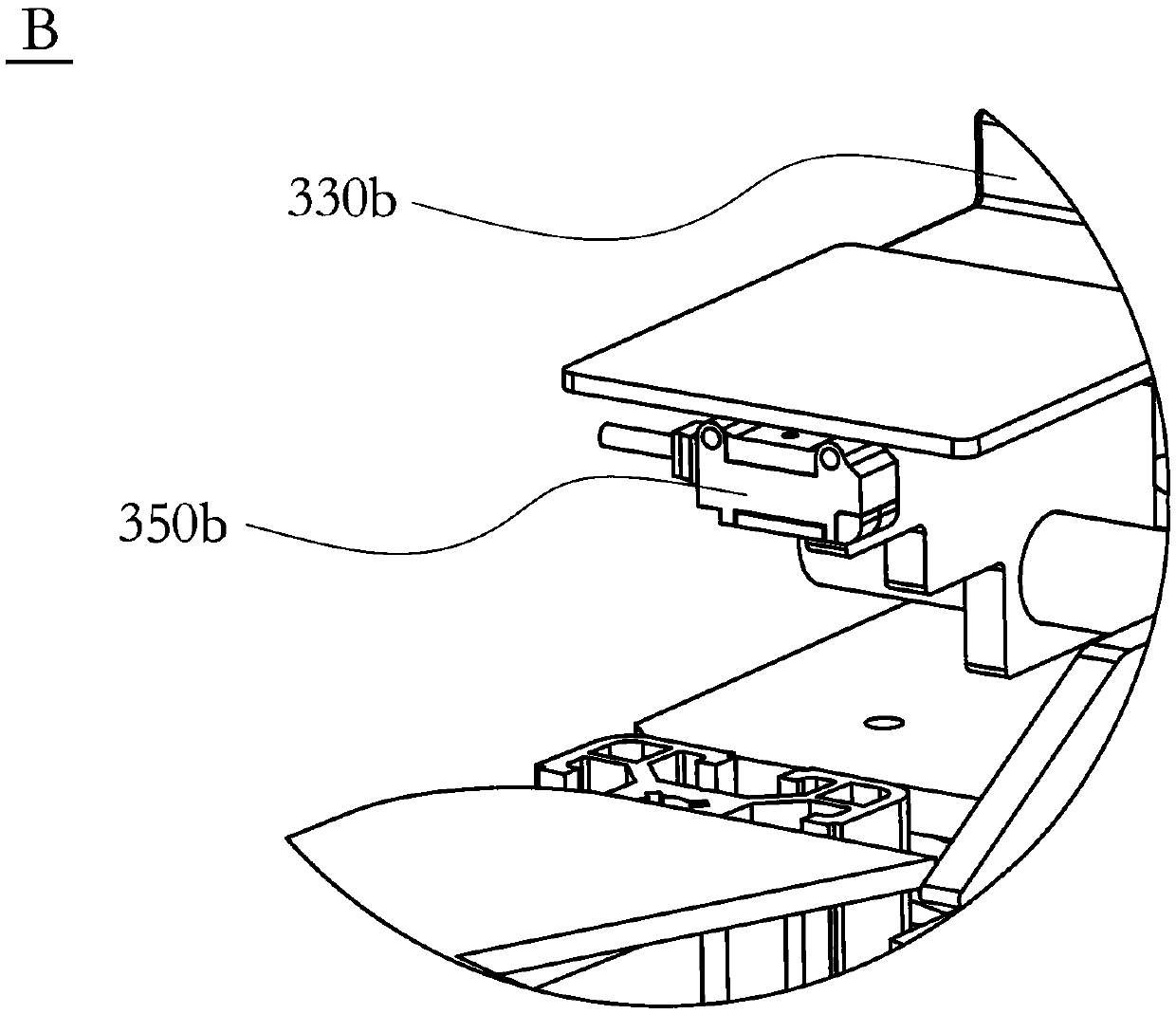

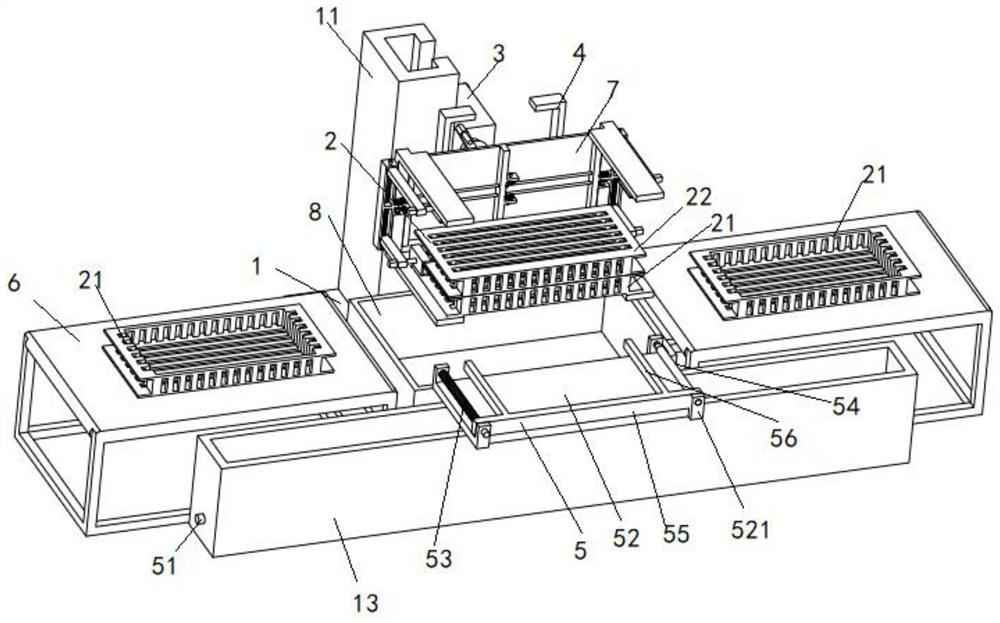

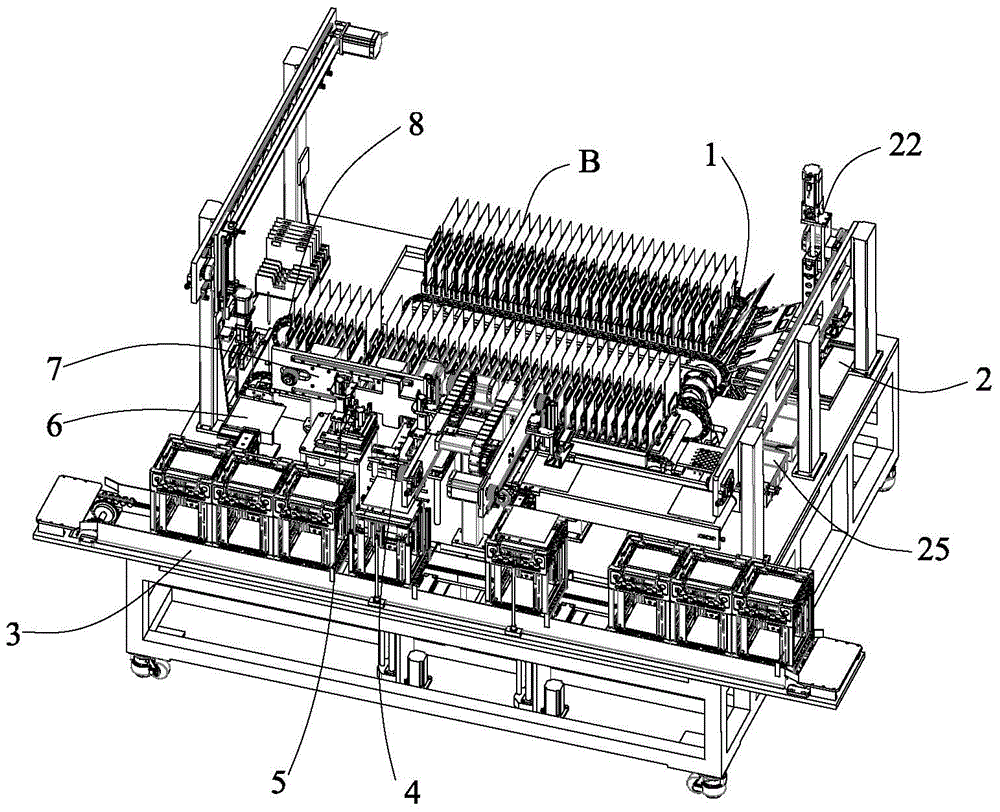

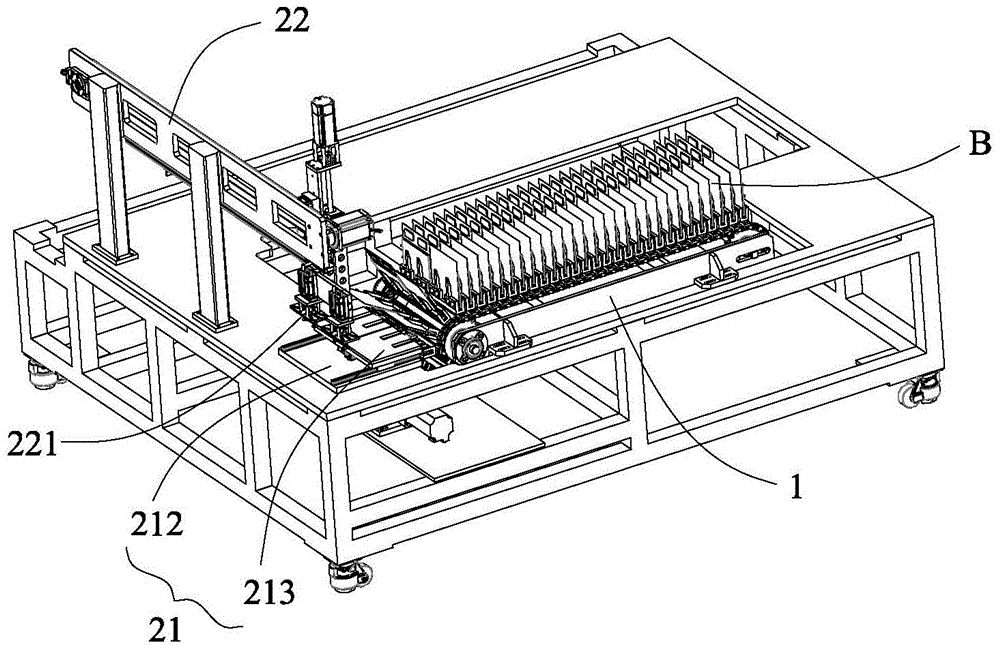

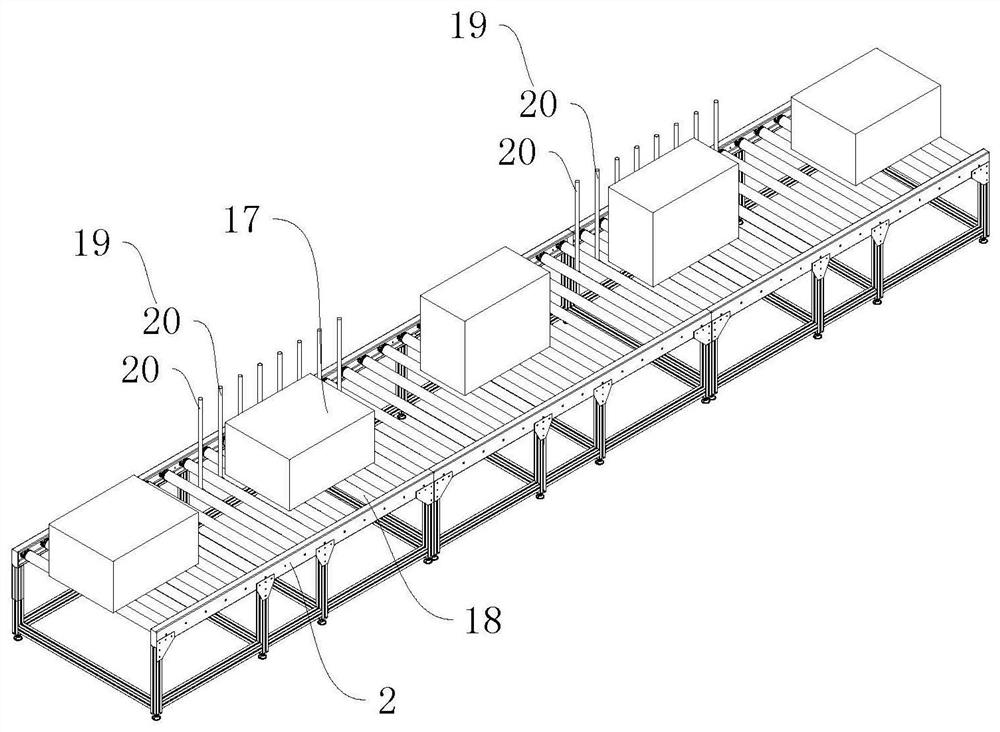

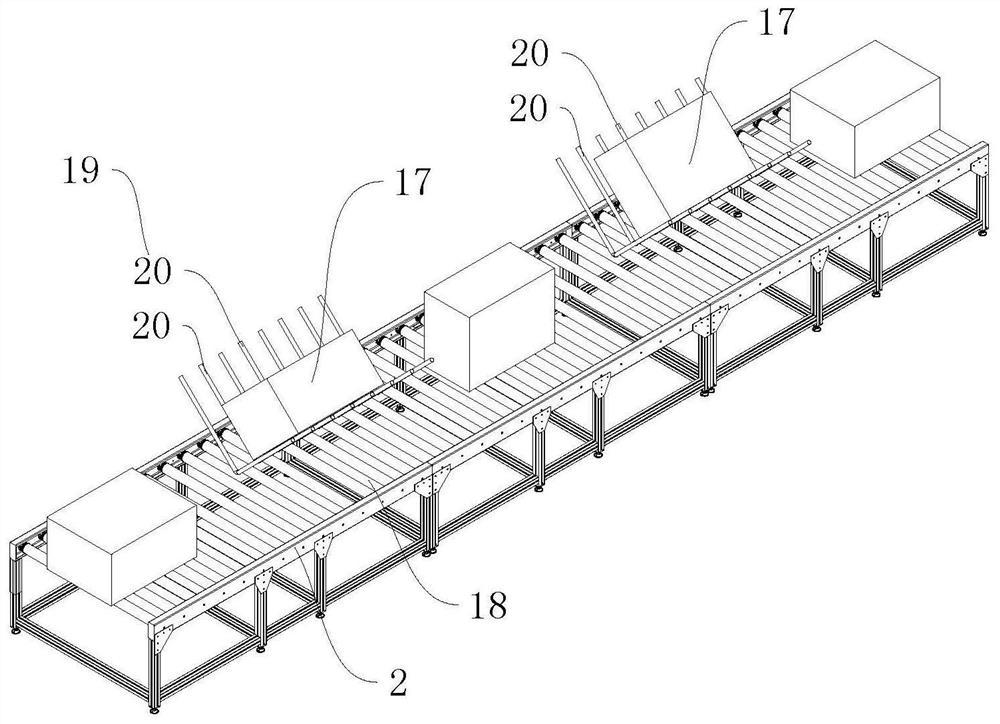

Battery automatic loading and unloading device

ActiveCN105540258BAutomate flippingImprove cutting efficiencyConveyorsConveyor partsEngineeringManipulator

The invention provides an automatic loading and unloading device for batteries. The automatic loading and unloading device for the batteries comprises an unloading trolley and an unloading mechanism, the unloading trolley is used for collecting multiple columns of the processed batteries, the directions of tabs of at least two columns of the batteries are opposite, and the unloading mechanism is used for moving out the batteries in the unloading trolley. The unloading mechanism comprises a discharge mechanism, a taking manipulator, a conveyor belt and an overturning platform; the discharge mechanism takes out at least two batteries with the tabs in the opposite directions from the unloading trolley, the taking manipulator moves the discharge mechanism to take out the batteries, the conveyor belt receives one part of all the batteries moved by the taking manipulator, and the overturning platform receives the other part of all the batteries moved by the taking manipulator and overturns the batteries onto the conveyor belt, so that the directions of the tabs of all the batteries on the conveyor belt are same. Through the overturning platform, automatic overturning of the batteries is achieved, and the unloading efficiency of the batteries is improved; meanwhile, the overturning process of the overturning platform and the discharging process of the discharge mechanism are separated, the structure of the unloading mechanism is simplified, and the overturning reliability of the batteries is improved.

Owner:NINGDE AMPEREX TECH

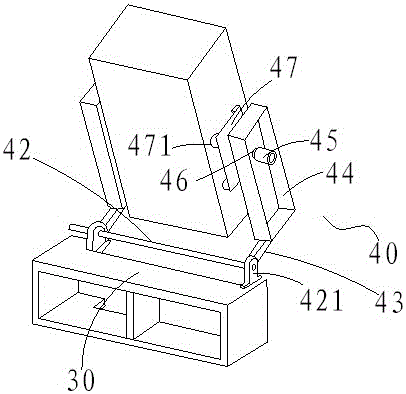

A peripheral painting equipment

ActiveCN107199137BAutomate flippingGood paint effectLiquid spraying apparatusEngineeringEquipment use

The invention discloses circumferential paint spraying equipment used for plate processing. The circumferential paint spraying equipment comprises a supporting table, a supporting shaft, a power mechanism, a paint spraying portion, a rack and multiple clamping portions. The supporting shaft is vertically and rotationally connected with the supporting table. The power mechanism is used for driving the supporting shaft to rotate. The paint spraying portion is connected with the supporting shaft and used for spraying paint to a plate. The rack is connected with the supporting shaft. The multiple clamping portions are distributed on the periphery of the supporting shaft. Each clamping portion comprises a fixing plate, a rotating shaft, a clamping mechanism and a gear, wherein the fixing plate is installed on the supporting table, the rotating shaft is horizontally and rotationally connected with the fixing plate, the clamping mechanism is connected with the rotating shaft and used for clamping the plate, the gear is installed on the rotating shaft and located on the moving path of the rack, and the rack drives the gear to rotate when moving along the moving path and making contact with the gear.

Owner:蚌埠抒阳自动化设备制造有限公司

Flatness detection device for celluloid plate processing

ActiveCN114061419AAutomate flippingReduce human inputMechanical roughness/irregularity measurementsDrive wheelCelluloid

The invention discloses a flatness detection device for celluloid plate processing. The device comprises a processing table, and U-shaped frames are symmetrically and fixedly connected to the surfaces of the two ends of the top of the processing table. Through mutual cooperation of a connecting plate, a first L-shaped rod, a first vertical plate, a first rack plate, a first gear, a driving wheel, a driven wheel and a first fixing mechanism, a strip-shaped plate can drive a celluloid plate to rotate through a positioning clamp until the celluloid plate is turned to a vertical state while a detection plate is reset; and meanwhile, through the mutual cooperation effect of the connecting plate, a second L-shaped rod, a second vertical plate, a second rack plate, a second gear, a driving wheel, a driven wheel and a second fixing mechanism, while the detection plate is reset, the strip-shaped plate can drive the celluloid plate to rotate through a positioning clamp until turnover is completed, therefore, automatic overturning can be achieved, manpower input is saved, and production efficiency is improved.

Owner:九江赛璐珞实业有限公司

A kind of zipper and button automatic processing equipment and automatic processing technology for textile and clothing

The invention relates to a zipper and button automatic processing device and automatic processing technology for textile garment. The zipper and button automatic processing device comprises a bottom plate, a cutting device and a turning device; the cutting device is mounted on the right side of an upper end surface of the bottom plate, and the turning device is mounted on the left side of the upper end surface of the bottom plate; the turning device includes a swinging mechanism; the swinging mechanism is mounted on the left side of the upper end surface of the bottom plate; a swinging plate is mounted on a right end of the swinging mechanism; the swinging plate is circular; and turning mechanisms are mounted on the swinging plate, and the number of the turning mechanisms is 3. The zipperand button automatic processing device and automatic processing technology can solve the problems that when zippers and buttons of the waste and old textile garment are removed mechanically, clothes cannot be firmly fixed, and automatic turning of the clothes cannot be realized; and the efficiency is low and the number of the labors is large, removal is not thorough, and the input cost is high during manual removal can be solved. The zipper and button automatic processing device and automatic processing technology can realize automatic turning and removal of the zippers and buttons of the waste and old textile garment, and have the advantages of firm fixation, automatic turning, high working efficiency, thorough removal, low input cost, and time and labor saving.

Owner:桐庐裕泰拉链有限公司

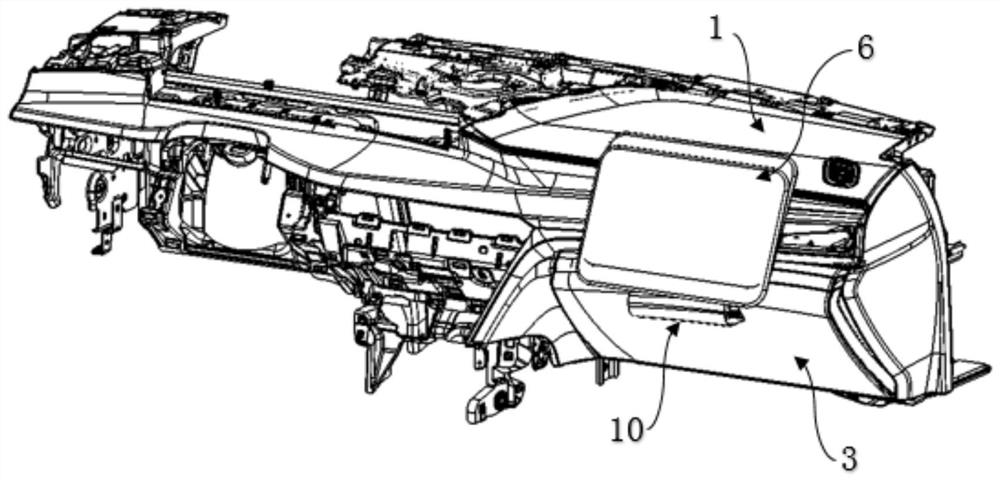

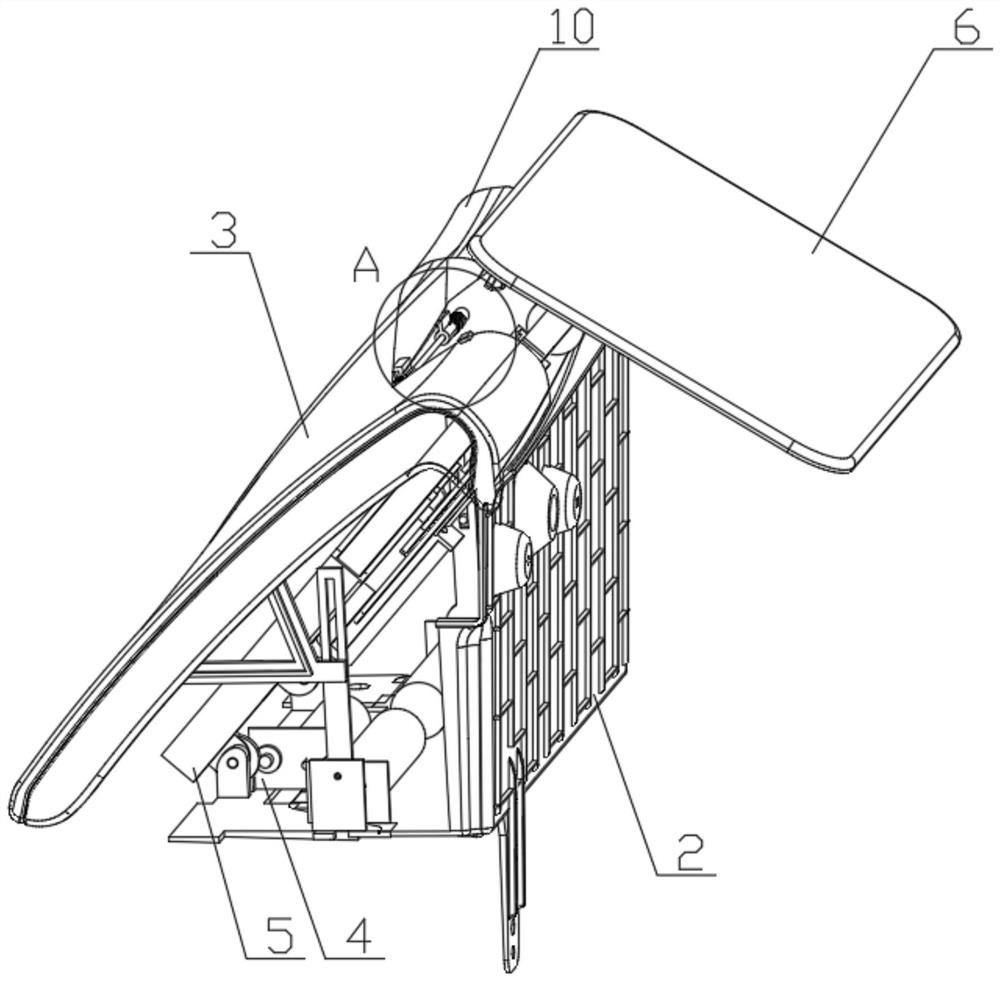

Automobile co-driver automatic rotating screen and using method

Owner:JIANGSU AICRON ELECTRONICS TECH CO LTD

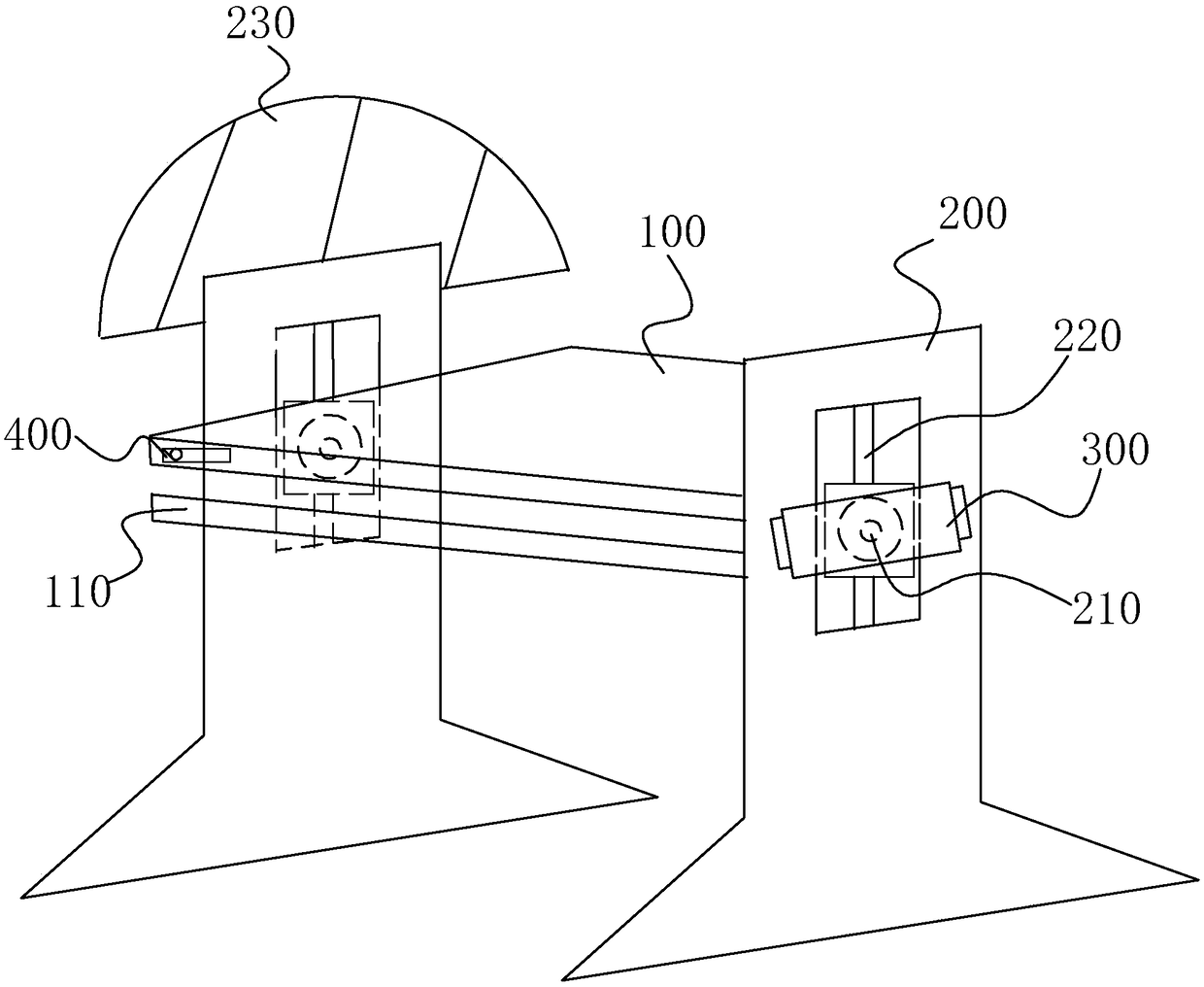

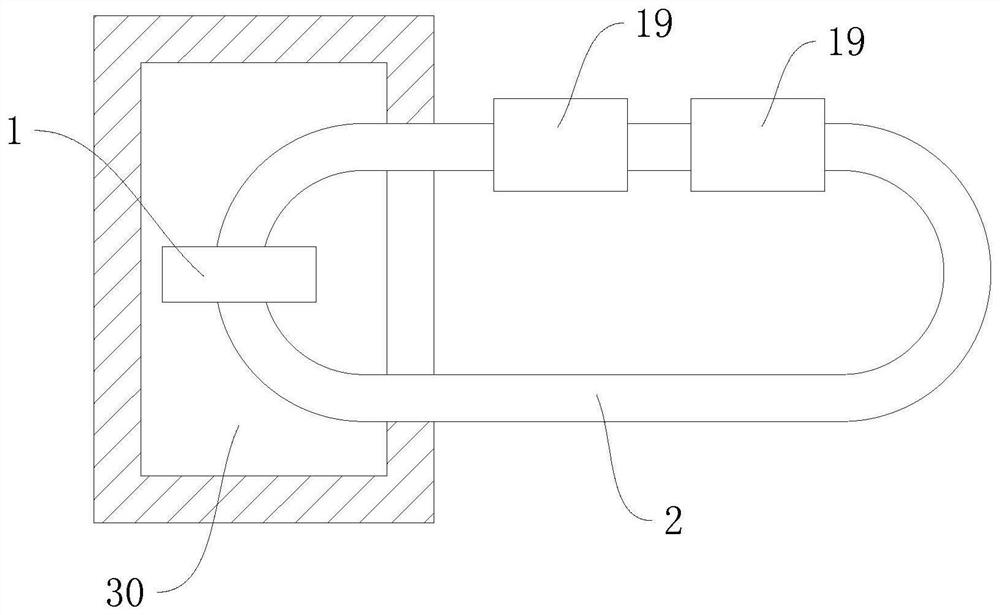

Automatic material overturning device for electron beam irradiation production and turnover treatment system

PendingCN113808776ARealize front and back side irradiation treatmentAutomate flippingConveyor partsIrradiation devicesEngineeringMechanical engineering

The invention discloses an automatic material overturning device for electron beam irradiation production and a turnover treatment system, relates to the technical field of electron beam irradiation equipment, and aims to solve the problem that the processing efficiency is affected as goods need to be turned over manually in the electron beam irradiation treatment process. According to the technical scheme, the automatic material overturning device is characterized by comprising a material overturning assembly arranged on a conveying belt formed by arranging a plurality of feeding rollers, the material overturning assembly comprises a material overturning frame, the material overturning frame comprises a plurality of material overturning rods bent in a right-angle mode, two supporting seats and two connecting rods are arranged on the lower parts of the feeding rollers, the two supporting seats are fixedly installed on the two sides of the lower parts of the feeding rollers, one end of the connecting rod is hinged to the supporting seat, and the other end of the connecting rod is hinged to one side of the material overturning rod; and a hinge joint is fixedly connected to the outer corner of the bending angle of the material overturning rod. The automatic material overturning device further comprises a swing mechanism, wherein the swing mechanism is connected with the hinge joint and used for driving the material overturning rods to swing in a reciprocating mode. The goods to be irradiated can be overturned, and automation of goods overturning is achieved.

Owner:浙江韩情辐照技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com