Battery automatic loading and unloading device

An automatic loading and unloading and battery technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of complex structure, poor reliability, high failure rate, etc., to improve the efficiency of blanking, improve reliability, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The battery automatic loading and unloading device of the present invention will be described in detail below with reference to the accompanying drawings.

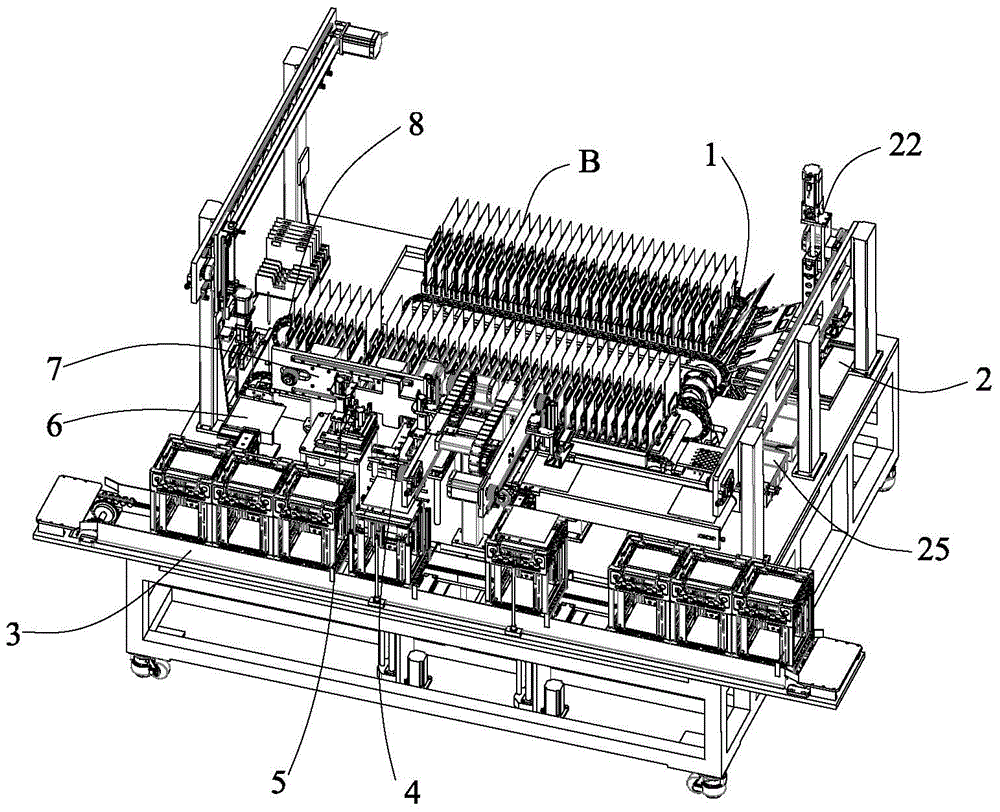

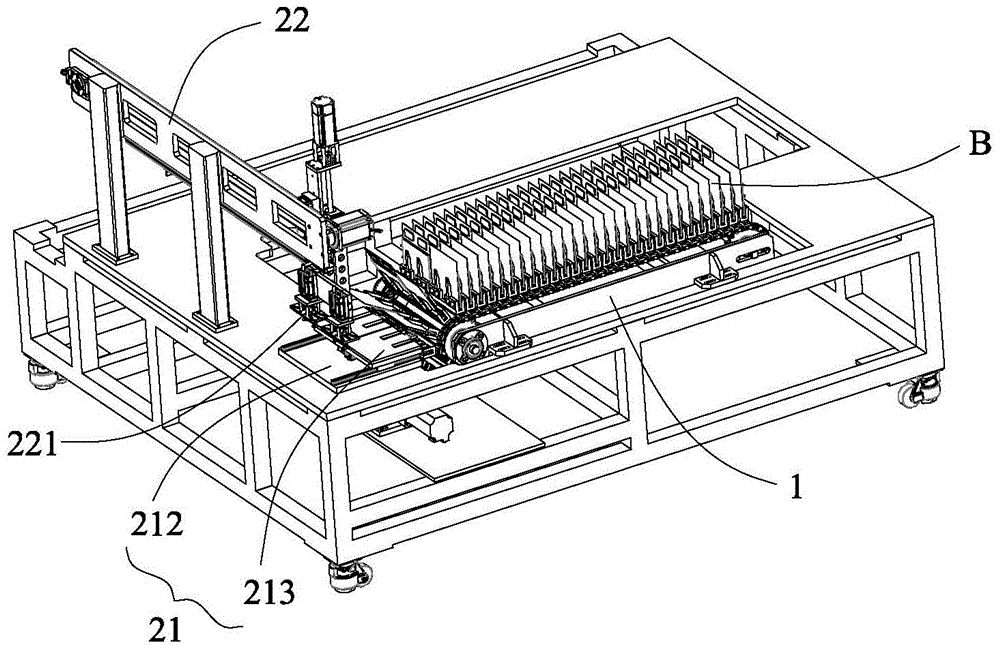

[0027] refer to Figure 1 to Figure 4 , according to the battery automatic loading and unloading device of the present invention comprises: unloading car 1, after collecting and processing multiple rows of batteries B, the direction of tabs B1 of at least two rows of batteries B in the multiple rows of batteries B is opposite; and a blanking mechanism 2. Remove the battery B in the unloading car 1.

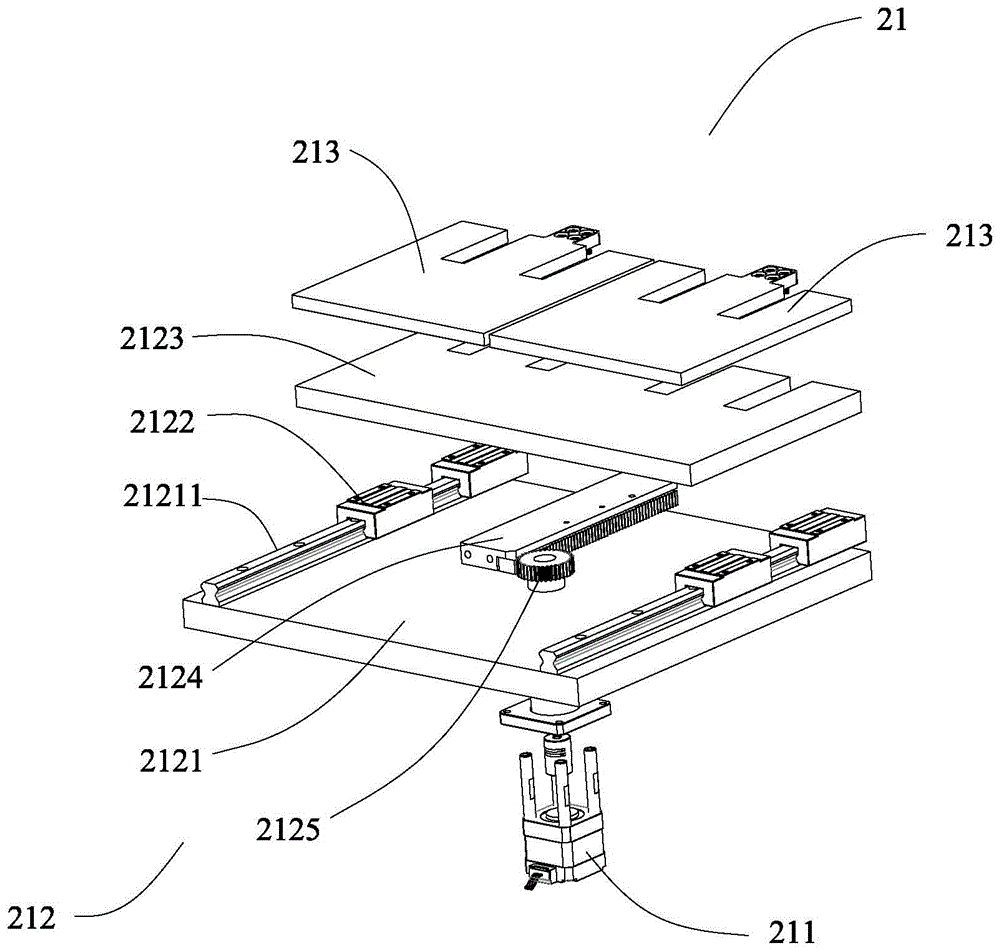

[0028] Wherein, the blanking mechanism 2 includes: a discharging mechanism 21, which takes out at least two batteries B with opposite directions of the tabs B1 from the blanking car 1; a retrieving manipulator 22, which moves the battery B taken out by the discharging mechanism 21; a conveyor belt 24, Receiving a part of batteries B among all the batteries B moved by the retrieving manipulator 22; , so that the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com