Ceramic tile overturning equipment

A technology for turning over equipment and tiles, which is applied in the direction of ceramic forming machines, conveyor control devices, unloading devices, etc., which can solve the problems of low turning efficiency and inconvenient operation of manually turning tiles, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

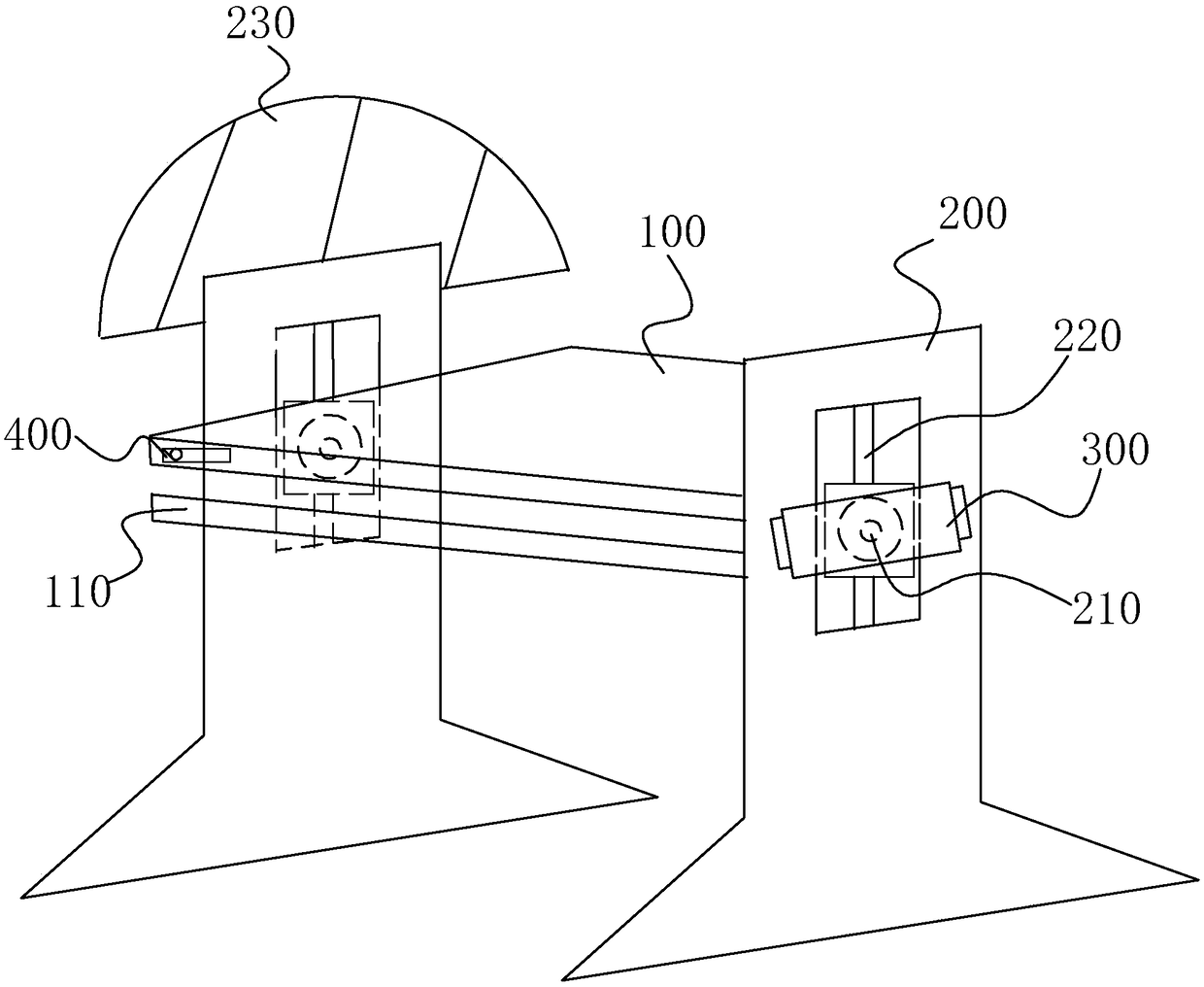

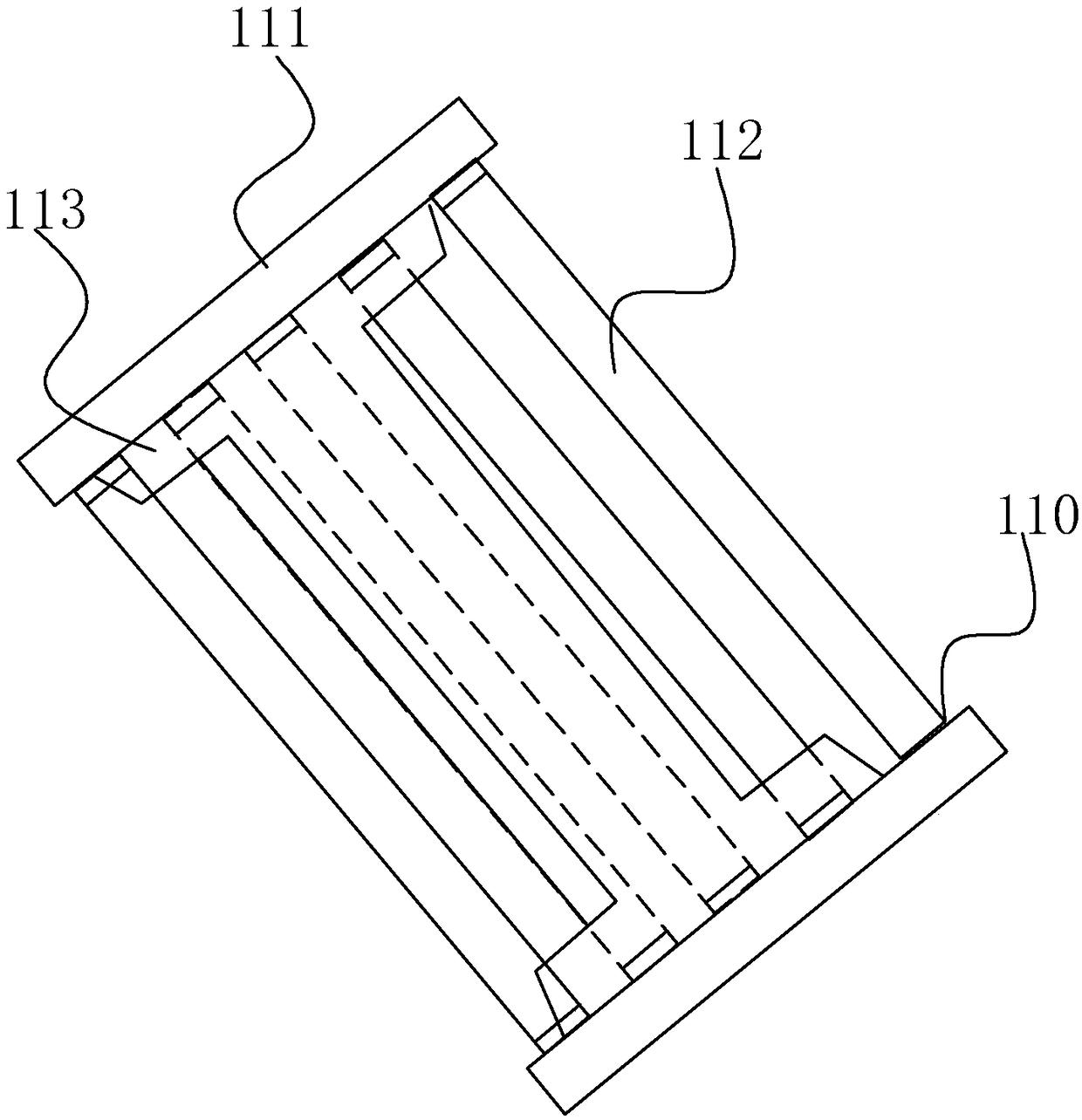

[0016] refer to figure 1 and figure 2 , the embodiment of the present invention provides a tile flipping device, including a clamping part 100 and a support foot 200, the support foot 200 is installed on both sides of the clamping part 100 through a rotating shaft 210; the clamping part 100 is a For the rolling layers 110 driven by air cylinders that can approach or move away from each other; the rolling layers 110 include installation rails 111 and rotating rods 112 for rotating and transporting tiles, and multiple rotating rods 112 are installed between the two installation rails 111 .

[0017] Further, the front and rear ends of the rolling layer 110 are provided with infrared sensors for detecting the passage of tiles. The rotating shaft 210 is connected with a rotating motor 300, and the plurality of rotating rods 112 are driven by the rotating motor through meshing gears. A tile flipping device further includes a controller which is respectively connected to the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com