Hosiery machine turning device

A technology of turning device and sock knitting machine, which is applied in knitting, weft knitting, mechanical cleaning, etc. It can solve the problems of knitting defective products, waste products, time-consuming and laborious, etc., and achieve the effect of improving production efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

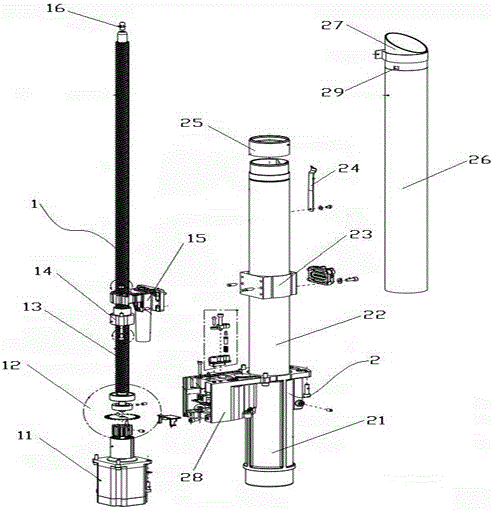

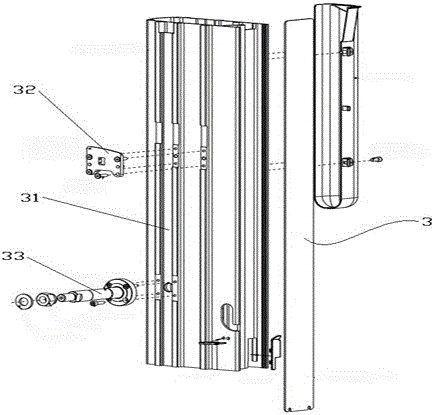

[0020] Embodiment: hosiery machine overturning device (see attached figure 1 , 2 , 3), including a driving mechanism 1, a turning mechanism 2 and a tilting mechanism 3, the turning mechanism 2 includes a turning cylinder 21, the turning cylinder 21 is provided with a fixed tube 22, and the fixed tube 22 is covered with a turning tube 26. The overturning tube 26 is slidingly connected to the fixed tube 22. The driving mechanism 1 includes a driving motor 11 and a driving screw 13. The driving screw 13 is fixedly connected to the driving motor 11. The tilting mechanism 3 includes a fixed shell 31, the fixed shell 31 is provided with a tilting shaft 33, the tilting shaft 33 is fixedly connected with the fixed shell 31, the screw nut 14 is set on the driving screw 13, and the screw nut 14 is set on the screw The nut 14 is sleeved on the outside of the driving screw 13, the screw nut 14 is connected with a pushing block 15, the fixing tube 22 is provided with a connecting block 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com