A lifting and translation equipment based on circular pipe transfer noise reduction transmission

A noise-reducing, circular tube technology, applied in the field of mechanical equipment, can solve problems such as easy shaking, increased fluctuations, and large friction and impact sounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

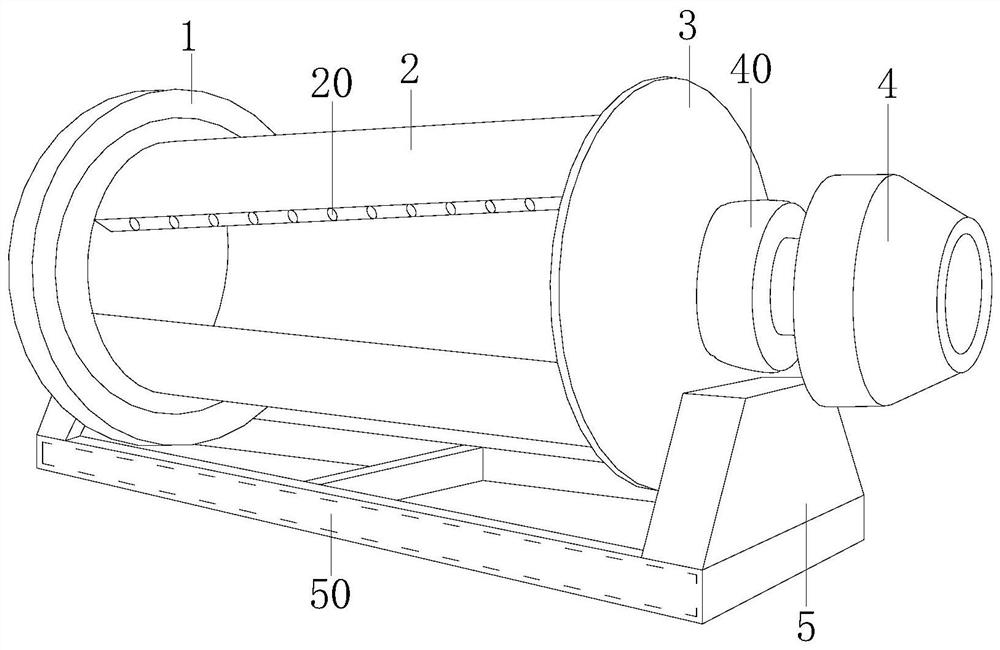

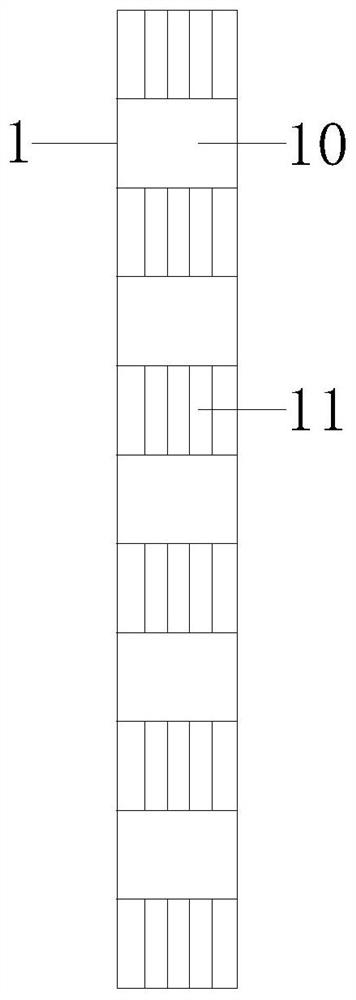

[0028] Example 1 see Figure 1-5 , the present invention provides a technical solution for lifting and translation equipment based on circular tube transfer and noise reduction transmission: its structure includes a left gear lifting plate 1, a pipe cover 2, a right gear lifting plate 3, a falling block 4, and a bottom bracket 5. The pipe cover 2 is installed and connected with the left gear lifting plate 1 and the right gear lifting plate 3, and the pipe cover 2, the left gear lifting plate 1 and the right gear lifting plate 3 will drive the pad wheel structure 20 when returning to the position The transmission puts the round tube stably into the pipe cover 2, the transmission is flexible and the utilization rate is high. The right gear lifting plate 3 is connected with the falling block 4 shafts, the left gear lifting plate 1 and the right gear lifting plate 3 is installed and connected with the bottom bracket 5, the structure of the left gear lifting plate 1 is the same as ...

Embodiment 2

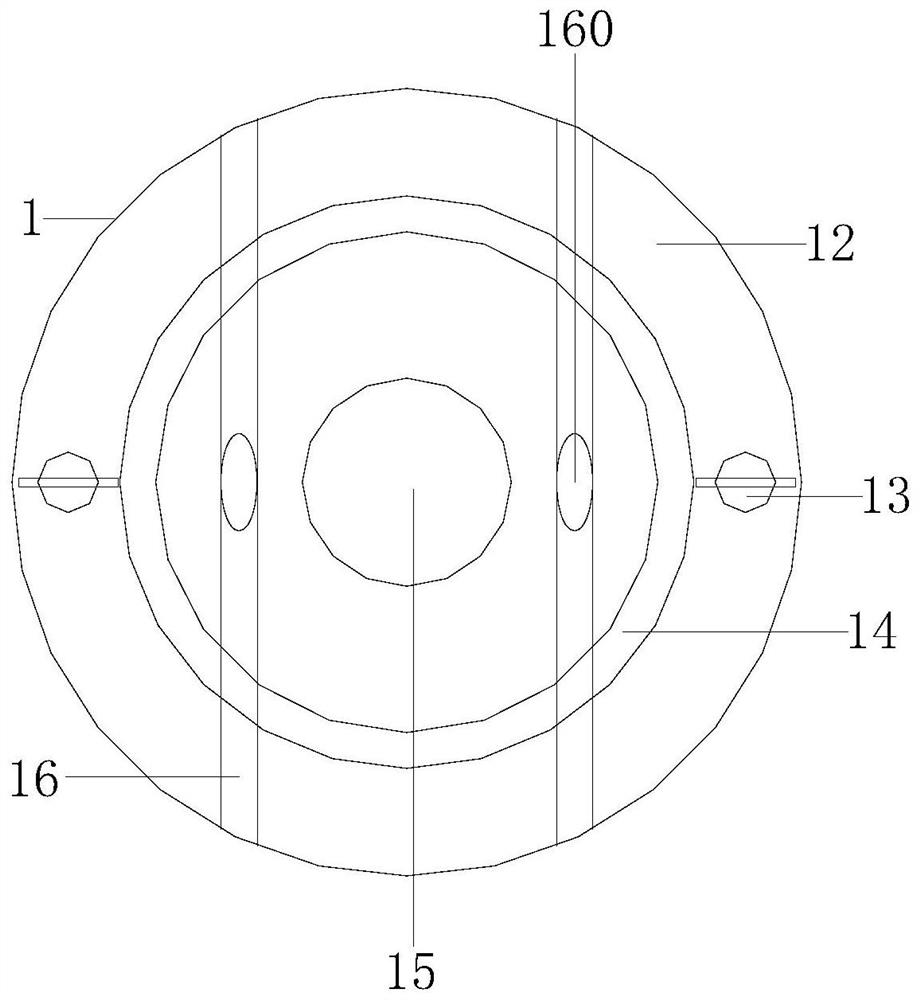

[0030] Example 2 see Figure 6-9 , the present invention provides a technical solution for lifting and translation equipment based on circular pipe transfer and noise reduction transmission: in its structure, the rail 16 is equipped with a track lock 160, and the track lock 160 includes a joint rod 1600, a joint ring lock 1601, Link ring 1602, hook lock 1603, the link rod 1600 is fastened with the link lock 1601, the link bar 1600 is track-connected with the link ring 1602, the link lock 1601 is connected with the link The connecting ring 1602 is fastened, and the connecting ring 1602 is used to further strengthen the locking of the connecting ring lock 1601, so that the pipe cover 2 can move down stably, and there will be no moving noise when moving down. The joint ring lock 1601 is locked with the hook lock 1603. The rack structure 50 includes a tooth bolt device 500 and an inner rack 501. The screw teeth 11 are driven to move in conjunction with the rack structure 50 when r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com