Welding production line for evaporator assembly

A welding assembly line and evaporator assembly technology, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of bumps and scratches on the surface of parts, large floor space, and high labor intensity, and achieve small floor space and high efficiency. Labor efficiency and the effect of reducing auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

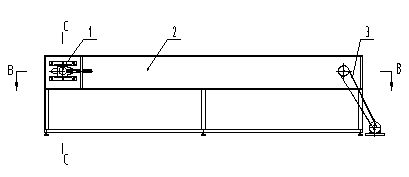

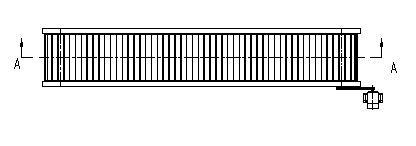

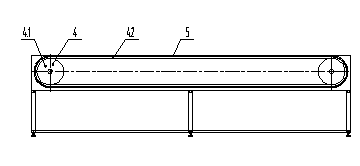

[0017] The evaporator assembly welding line shown in the accompanying drawings includes a bracket assembly 2, a tensioning mechanism 1, a power drive device 3, a sprocket drive support device 4, and a support plate 5; the sprocket support drive device 4 is supported on the bracket assembly 2 Inside, it consists of two sets of sprocket transmission mechanisms of the same size arranged in parallel on one set of sprocket shaft 4.3, including sprocket 4.1, chain 4.2 and sprocket shaft 4.3, and one end of sprocket shaft 4.3 is connected with power drive device 3; supporting plate 5 It is laterally fixedly connected to the outsides of several groups of chains 4.2 arranged in parallel, and is made of composite metal and non-metal wear-resistant materials. In this embodiment, the support plate 5 is compositely made of metal and hard plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com