A commercial vehicle roof assembly welding fixture

A technology for welding fixtures and car roof covers, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as bumps and scratches on the outer surface of the roof cover, large parts size, and poor rigidity of parts, etc., to achieve Reduce bumps and scratches, reduce labor intensity, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

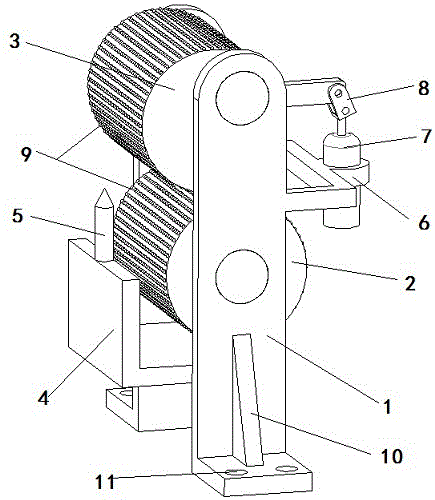

[0018] A commercial vehicle roof assembly welding fixture, including a base 1, a static roller 2, an eccentric roller 3, a baffle plate 4, a positioning pin 5, a fixing frame 6, a hydraulic cylinder 7, a connecting frame 8, a contact point 9, and a reinforcing rib 10 , positioning hole 11, a static roller 2 is arranged in the middle of the base 1, an eccentric roller 3 is arranged above the static roller 2 and between the base 1, and several contacts 9 are uniformly arranged on the surface of the static roller 2 and the eccentric roller 3, and the left side of the base 1 An L-shaped baffle 4 is arranged on the side, and a positioning pin 5 is vertically arranged on the upper end of the baffle 4. A fixed frame 6 is arranged on the right side of the base 1, and a hydraulic cylinder 7 is fixed in the middle of the fixed frame 6. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com