Aluminum alloy workpiece disc type automatic all-in-one machine

A disc-type, all-in-one machine technology, applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the surface of the workpiece, low work efficiency, high processing cost, etc., and achieve improved yield and high work efficiency , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

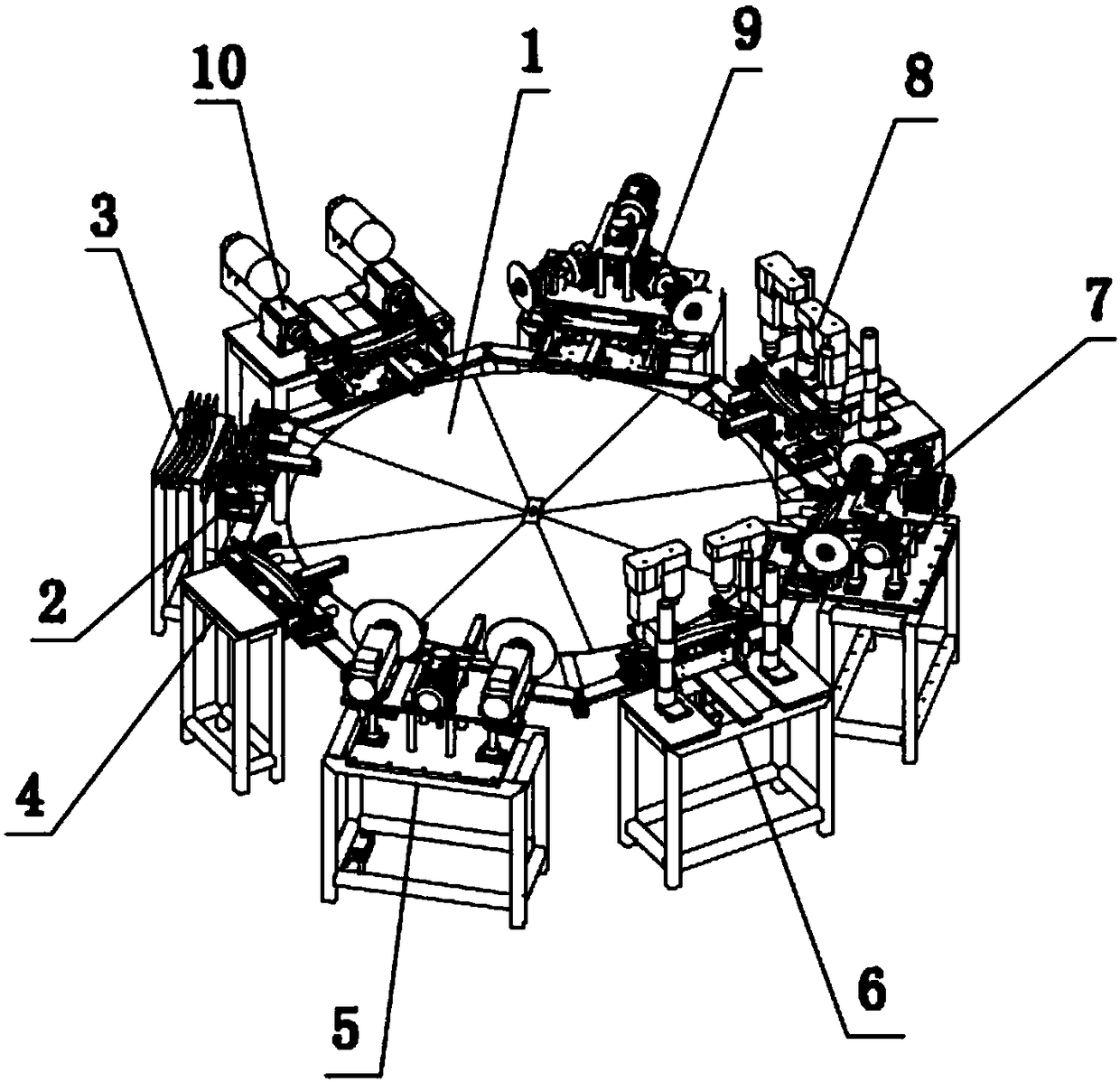

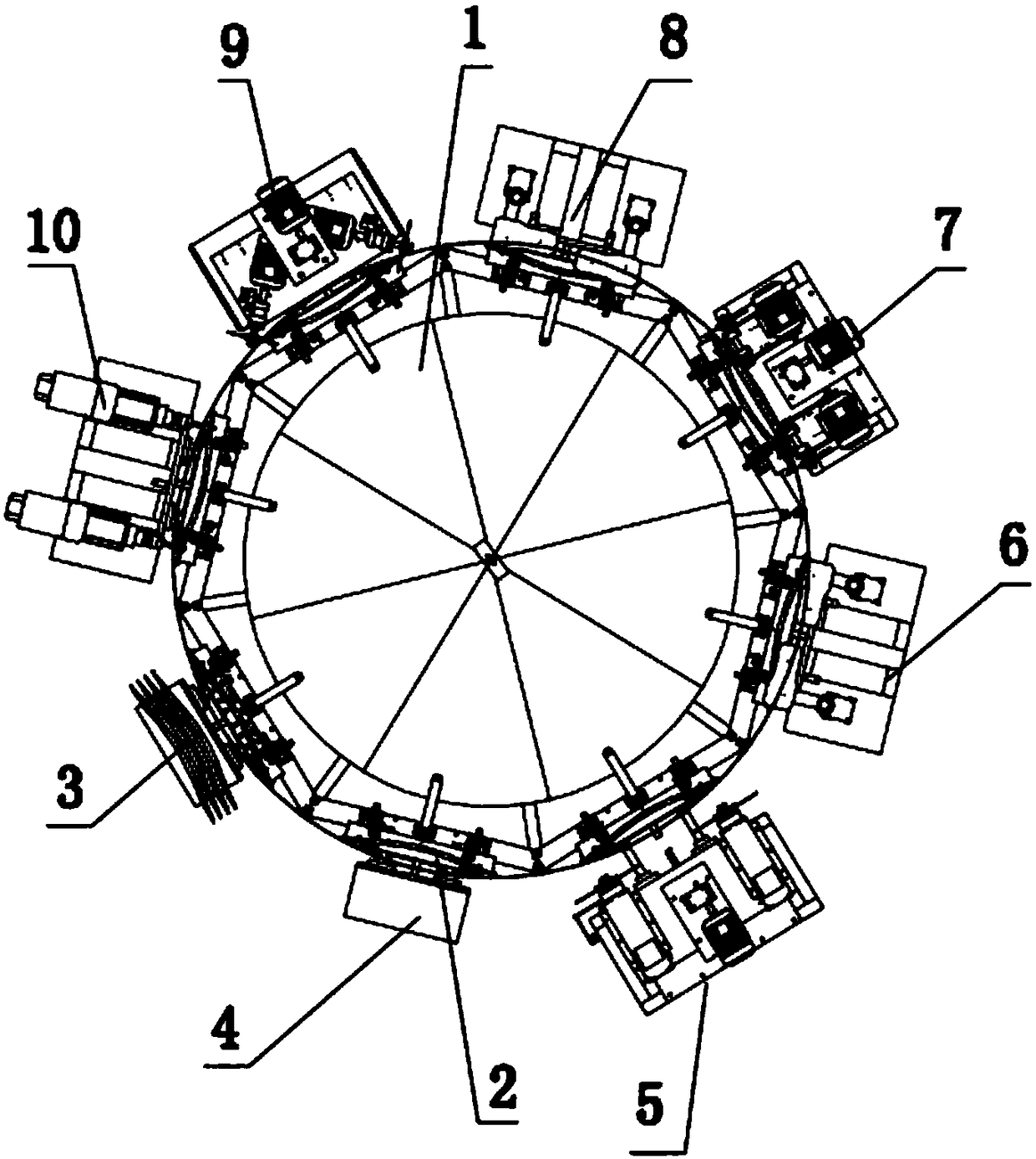

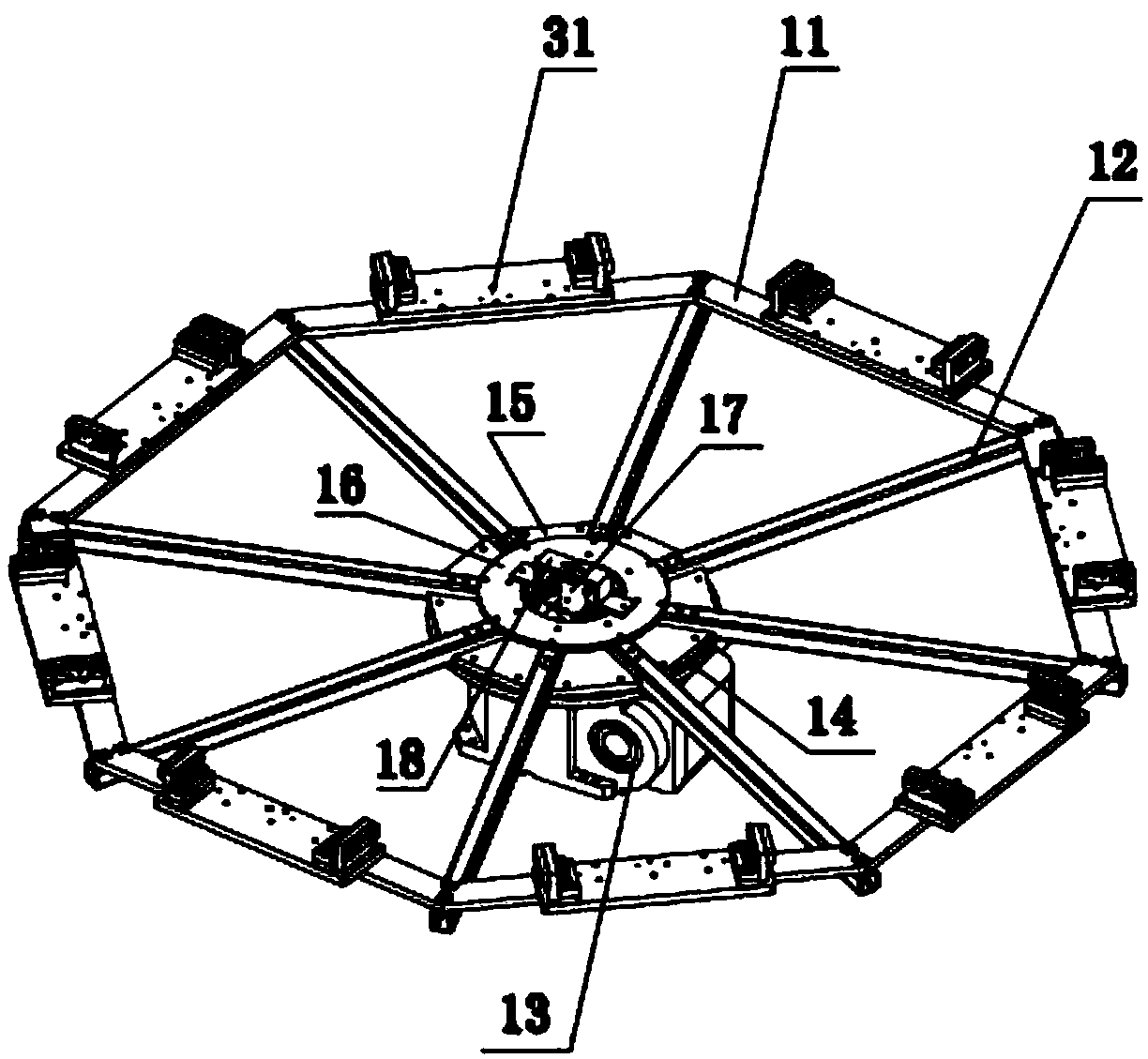

[0033] Such as Figure 1-3As mentioned above, a disc-type automatic integrated machine for aluminum alloy workpieces of the present invention is characterized in that it includes a disc mechanism 1, a tooling assembly 2, a loading and unloading station 3, a reserved station 4, a sawing device 5, Side hole drilling device 6, fixed-length saw device 7, tapping device 8, chamfering saw device 9 and large hole milling device 10, the plurality of tooling assemblies 2 are arranged along the edge of the disc mechanism 1; the loading and unloading Station 3, reserved station 4, large surface sawing device 5, side hole drilling device 6, fixed-length saw device 7, tapping device 8, chamfering saw device 9 and large hole milling device 10 surround the disc mechanism in turn 1 is arranged in front of the tooling assembly 2; the disc mechanism 1 includes a connecting plate 11, a square channel 12, a divider 13, a disc 14 and a ring 16, and one end of several square channels 12 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com