Deflection supporting piece, shaft holding clamp deflection follow-up supporting mechanism and using method of shaft holding clamp deflection follow-up supporting mechanism

A technology of support mechanism and support, applied in the direction of grinding frame, grinding drive device, grinding feed movement, etc., can solve the problems of limited and reduced labor cost, reduce manual operation, improve production efficiency, reduce scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

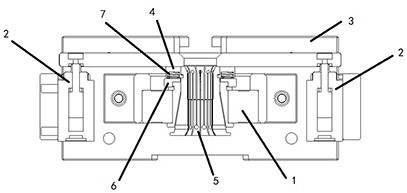

[0026] see figure 1 , is a structural schematic diagram of the displacement support of the present invention, the displacement support includes a ball bearing 1, a telescopic cylinder 2, a push plate 3, a spring fixing plate 4, a collet 5, a backing plate 6 and a spring 7. Both sides of the ball bearing 1 are respectively provided with a telescopic cylinder 2, the push plate 3 is installed on the telescopic cylinder 2, the spring fixing plate 4 is arranged on one side of the push plate 3, and is connected with the spring clamp The head 5 is connected, the collet 5 is arranged in the ball bearing 1, the ball bearing 1 is provided with the backing plate 6, and the gap between the backing plate 6 and the spring fixing plate 4 is used to install the spring 7. Wherein, the collet 5 has elasticity, can maintain the normally open state when not subjected to external force, and can be pushed by the push plate 3, and the push plate 3 is installed on the telescopic cylinder 2 to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com