Split type head tent structure of tricycle and tricycle with structure

A tricycle, split technology, used in bicycle accessories, weather guards, transportation and packaging, etc., can solve the problems of high production cost, affecting the service life of the whole vehicle, and occupying a large space, so as to achieve long service life and reduce scratches. Injury situation, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

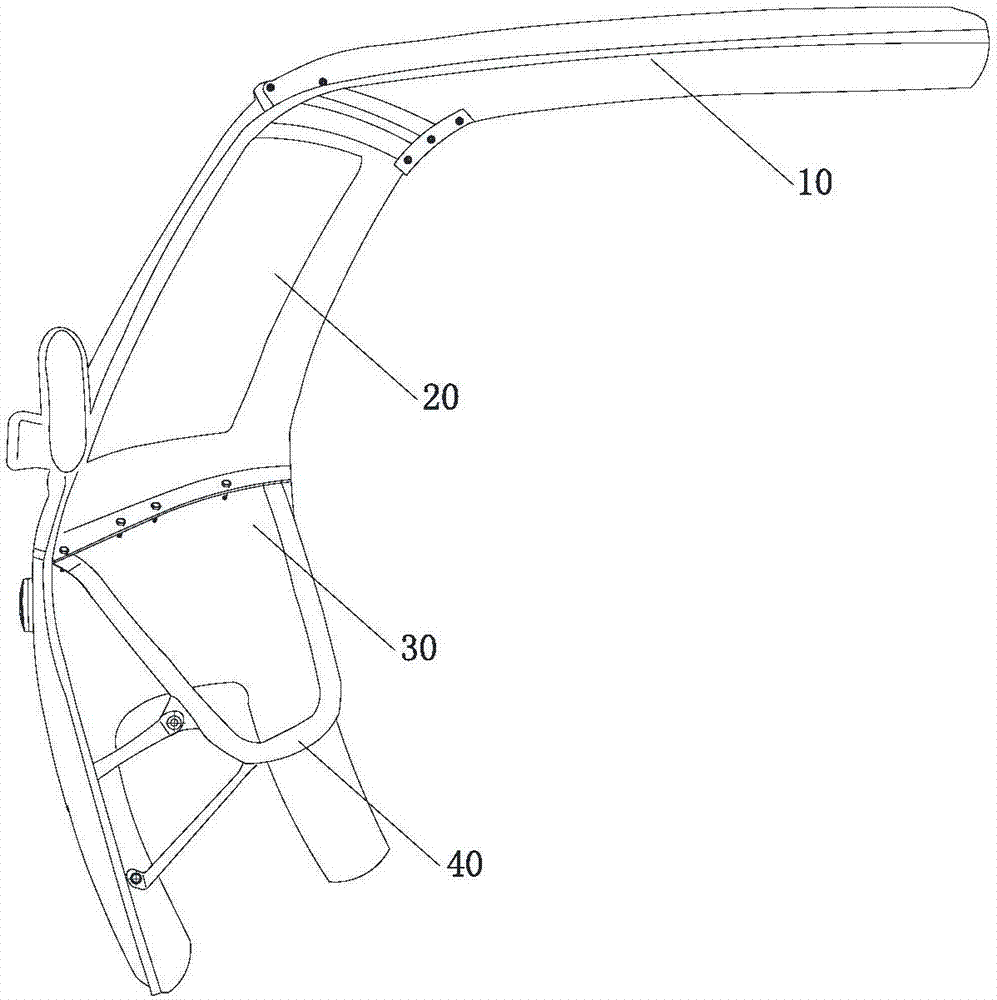

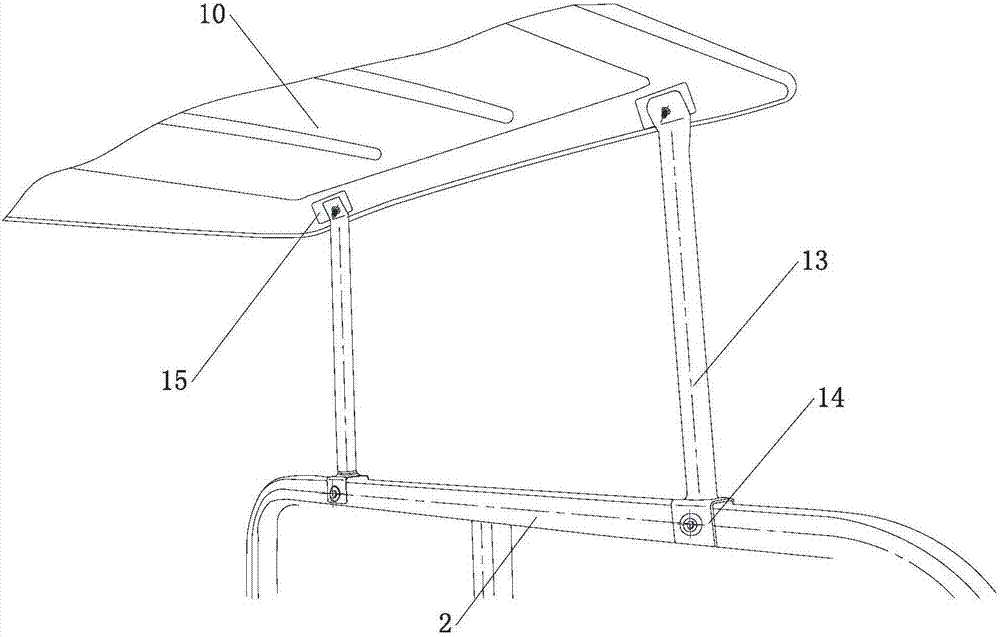

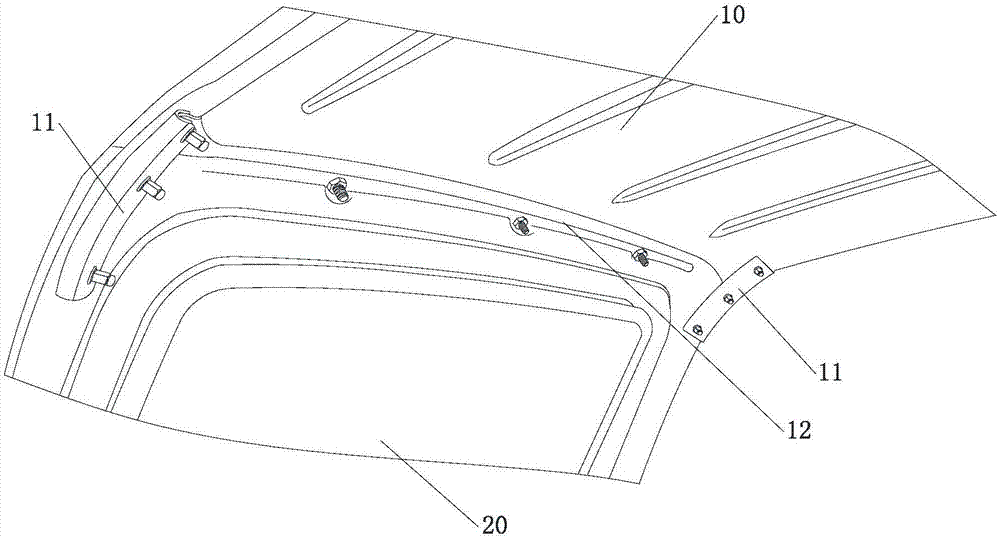

[0020] a kind of like Figure 1-5 The shown tricycle split-type hood structure comprises a hood upper top cover 10, a hood front windshield 20, a hood lower windshield 30 and a hood lower windshield support rod 40, and the hood upper top cover 10 front The upper edge is overlapped on the upper edge of the front windshield 20 of the hood, and is fixedly connected by a locking member, and the two ends of the connection position of the top cover 10 on the hood and the front windshield 20 of the hood are provided with arc-shaped hemming connections Block 11, the arc-shaped hemming connection block 11 is connected with the upper cover 10 of the hood or / and the front windshield 20 of the hood by a locking member; The flanging is arranged inwardly, and the front windshield 20 of the hood and the windshield 30 under the hood are tightly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com