Reinforcing lifting appliance for van vehicle top plate welding assembly oil paint line passing

An assembly and paint technology, which is applied to the field of paint over-line reinforcement spreaders for the welding assembly of van roof panels, can solve the problems of mutual collision, easy twisting and deformation, easy shaking and swinging of chamber bodies, etc., so as to improve safety, The effect of eliminating shaking and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

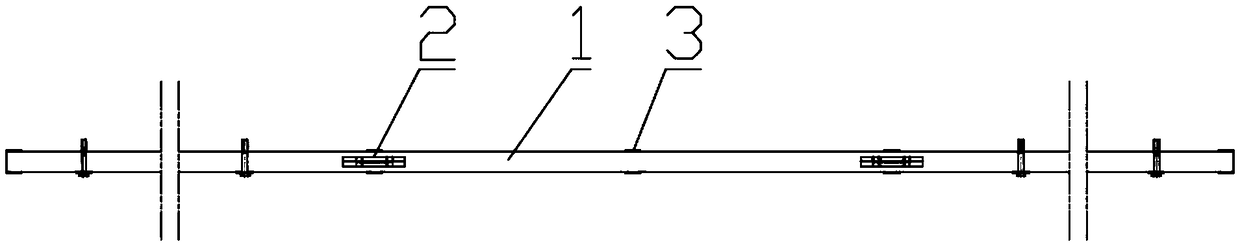

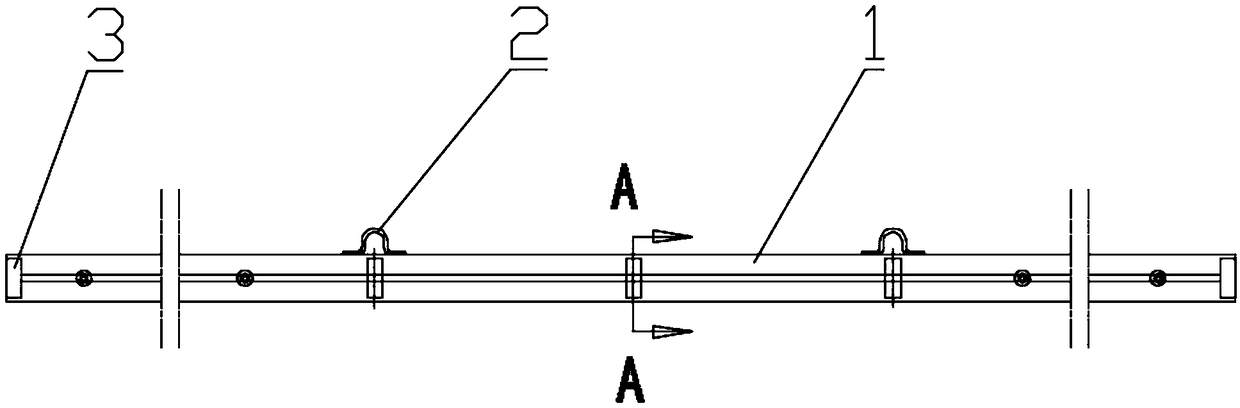

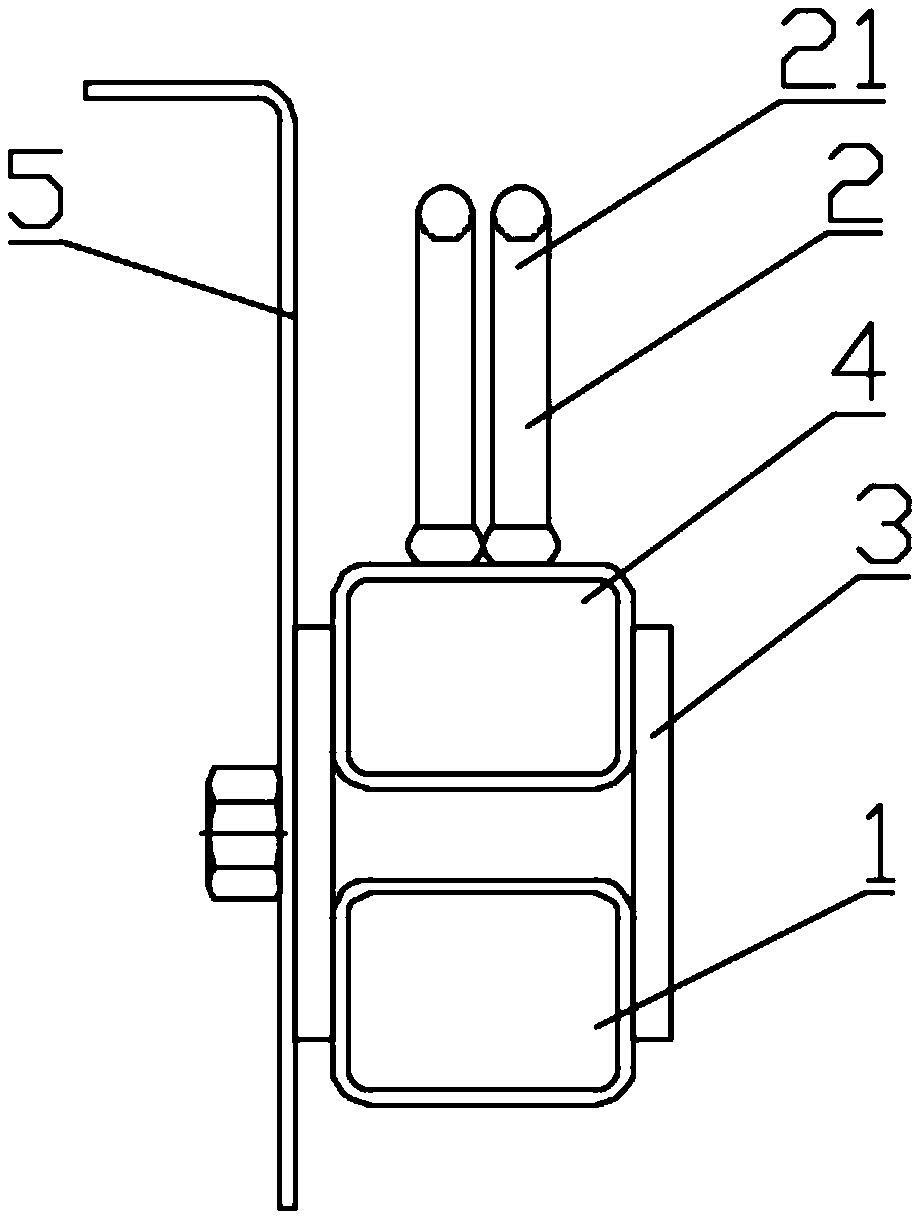

[0020] see Figure 1~3 , in Embodiment 1 of the present invention, a van roof panel welding assembly paint line reinforcement hanger includes a fixed beam assembly 1, and the fixed beam assembly 1 is composed of two rectangular tubes 4 welded by steel plates 3 , the rectangular tubes 4 are spliced together, the steel plates 3 are welded on the sides of the rectangular tubes 4, the rectangular tubes 4 are arranged to facilitate rigidity, a gap is provided between the two rectangular tubes 4 to facilitate the passage of bolts, The upper end of the fixed beam assembly 1 is provided with a hook 2, which is convenient for lifting. The hook 2 is composed of two chain rings 21 welded side by side. Fix the hanging reinforcement bracket 5, and the suspension reinforcement bracket 5 is welded on the van roof plate welding assembly.

Embodiment 2

[0022] see Figure 4 , the main difference between this embodiment 2 and embodiment 1 is that an elastic pad 6 is provided on the contact side of the fixed beam assembly 1 and the van roof plate welding assembly to prevent the fixed beam assembly 1 from moving the van roof plate The welding assembly is bruised.

[0023] The working principle of the present invention is:

[0024] The invention and the workpiece pass through the paint line at the same time, ensuring a certain rigidity of the van roof panel assembly, eliminating shaking during transfer, and reducing bumps and scratches. On the groove of the corrugated board, two rows of hanging reinforcement brackets are welded, the fixed beam is fixed on the hanging reinforcement bracket, and the roof assembly passes through the line together. After adding two rows of fixed beam assemblies, the roof assembly is strengthened. The resulting overall rigidity ensures the safety of the paint line passing through and solves the prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com