Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Protect ecological resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seeding medium made of vinasse methane-sludge and preparation method thereof

InactiveCN101606471APromote absorptionInhibitionCultivating equipmentsSoilless cultivationPhylum CyanobacteriaSludge

The invention relates to a seeding medium made of vinasse methane-sludge and a preparation method thereof, not only solving the problem of environment contamination caused by vinasse methane-sludge, but also effectively utilizing vinasse methane-sludge. The seeding medium comprises fresh sludge containing 90 percent of water after methane generated from vinasse in a methane tank, accessories, ferment strain I and ferment strain II, wherein the accessories comprise grass peat, vermiculite and perlite; the ferment strain I comprises saccharomycetes, lactobacillus, high-temperature actinomycetes and bacillus; and the ferment strain II comprises photosynthetic bacteria, lactobacillus, bacillus, saccharomycetes, actinomycetes and terrestrial cyanobacteria. The preparation method comprises the following steps of preparing fresh sludge, dehydrating, adding the ferment strain I for fermentation, adding the ferment strain II for secondary fermentation, air drying, adding accessories, crushing, screening and packing. The vinasse methane-sludge contains 40 to 50 percent of organic matter and 4.3 percent of available nitrogen (N), phosphorus (P) and kalium (K). The seeding medium made of vinasse methane-sludge has better hydrophilicity, and seeding can be carried out after loading the dry seeding medium and spraying water, thus saving both labor and time.

Owner:ANHUI FENGTIAN SEEDLESS WATERMELON TECH

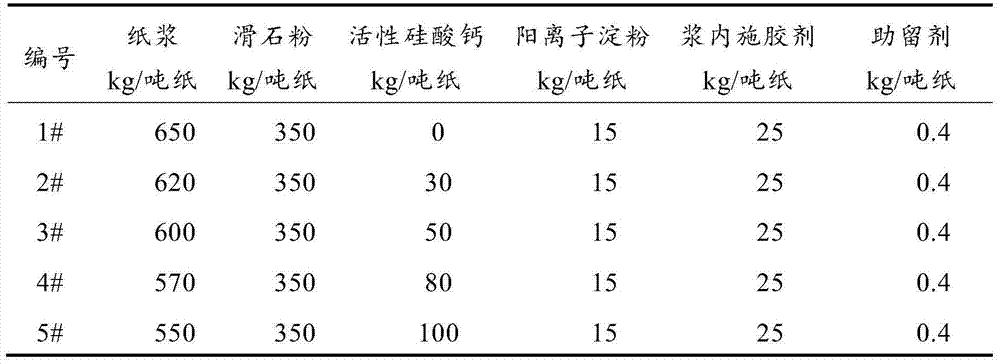

High-filler paper and production method thereof

InactiveCN102433796AHigh whitenessIncrease the addition ratioInorganic compound additionPulp material addition processesCalcium silicatePlant fibre

The invention discloses high-filler paper and a production method thereof. The high-filler paper contains 30 to 60 mass percent of filler, and the filler is active calcium silicate; in the step of adding the filler, after the active calcium silicate in an amount which is 40 to 70 percent of the total mass of the active calcium silicate and the pulp is fully stirred and dissolved to form emulsion,the emulsion is guided into a covered pulp storage tank or a pre-making pulp storage tank and fully stirred and mixed with plant fibers; the filler adding proportion of the high-filler paper is improved, so that the consumption of the plant fibers is greatly reduced at the same time of improving the performance of the paper; and according to the production method for the high-filler paper, the adding process of the papermaking filler is simplified, the filler and the plant fibers can be fully mixed uniformly, and the internal bonding force is increased, so that the performance of the paper isimproved.

Owner:GUONENG PAPER IND

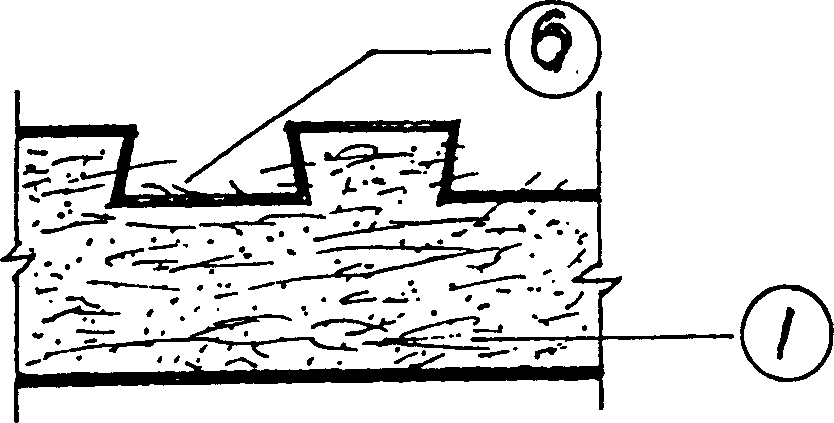

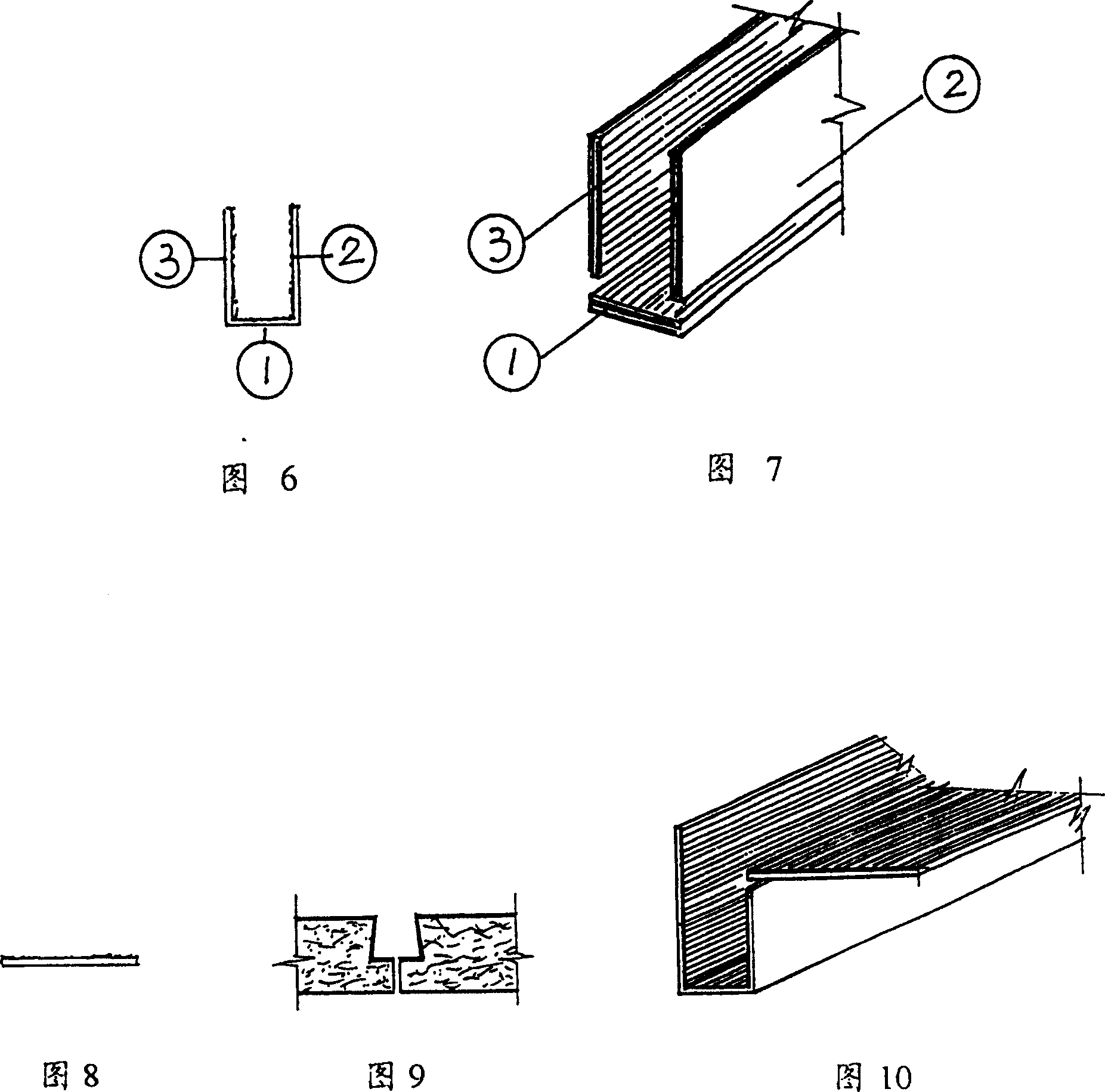

Construction process for building concrete structure and its used mould

InactiveCN1715573ASimple structureEasy to produceStrutsPillarsMaterial consumptionBuilding construction

The present invention relates to construction process and formwork for constructing concrete structure and aims at reducing formwork material consumption and omitting formwork detaching step. The present invention has new type formwork made and assembled based on specific concrete structure, and after depositing concrete and curing, the formwork as one part of the concrete structure is combined integrally with the deposited concrete. The present invention has greatly simplified construction process, saves great amount of formwork material and shortens the construction period, and the smooth formwork is face decorated directly in the later construction period.

Owner:季学宏

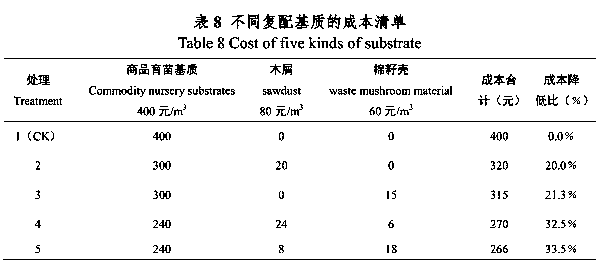

Seedling cultivation substrate using mushroom residue as raw material and preparation method thereof

InactiveCN101433176BHigh porosityGood physical propertiesCultivating equipmentsSoilless cultivationPorosityMicrobial agent

The invention provides a seedling cultivation matrix taking mushroom residue as raw material, as well as a manufacture method thereof. The matrix comprises the following components in volume portion: 1 to 3 portions of mushroom residue, 1 to 2 portions of vermiculite, 1 to 2 portions of perlite and 0.0001 to 0.0005 portion of fermentation promoter, wherein the fermentation promoter is a mixture of decay promoting microbial agent and bran with the weight ratio of 1 to 10. The matrix has the advantages of fully utilizing mushroom residue waste of agricultural production, using no peat at all and saving ecological resources, along with rich nutrition, good porosity, excellent physical properties, low cost and simple manufacture.

Owner:INST OF SOIL & FERTILIZER XINJIANG ACAD OF AGRI SCI

Application of calcium silicate as retention aiding intensifier in papermaking

InactiveCN104120621AGood strength performanceImprove paper ashInorganic compound additionRetention agents additionPapermakingIntensifier

The invention discloses application of calcium silicate as a retention aiding intensifier in papermaking and belongs to the technical field of applications of calcium silicate in papermaking. According to the invention, calcium silicate is adopted to serve as the retention aiding intensifier for the papermaking to be applied to the papermaking, wherein calcium silicate is preferably active calcium silicate. An application method comprises the following steps: (1) mixing calcium silicate with water to obtain a dispersion liquid; sieving the dispersion liquid by a screen and taking the slurry for later use; (2) adding papermaking filler into paper pulp and adding the slurry obtained in the step (1); or simultaneously adding the slurry obtained in the step (1) and the papermaking filler into the paper pulp; and (3) adding other papermaking additives and carrying out papermaking according to conventional papermaking processes. Calcium silicate is adopted to serve as the retention aiding intensifier to be applied to the papermaking and the operation is simple; the paper ash content and bulk are obviously increased; the plant fiber using amount is saved and the production cost is reduced.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

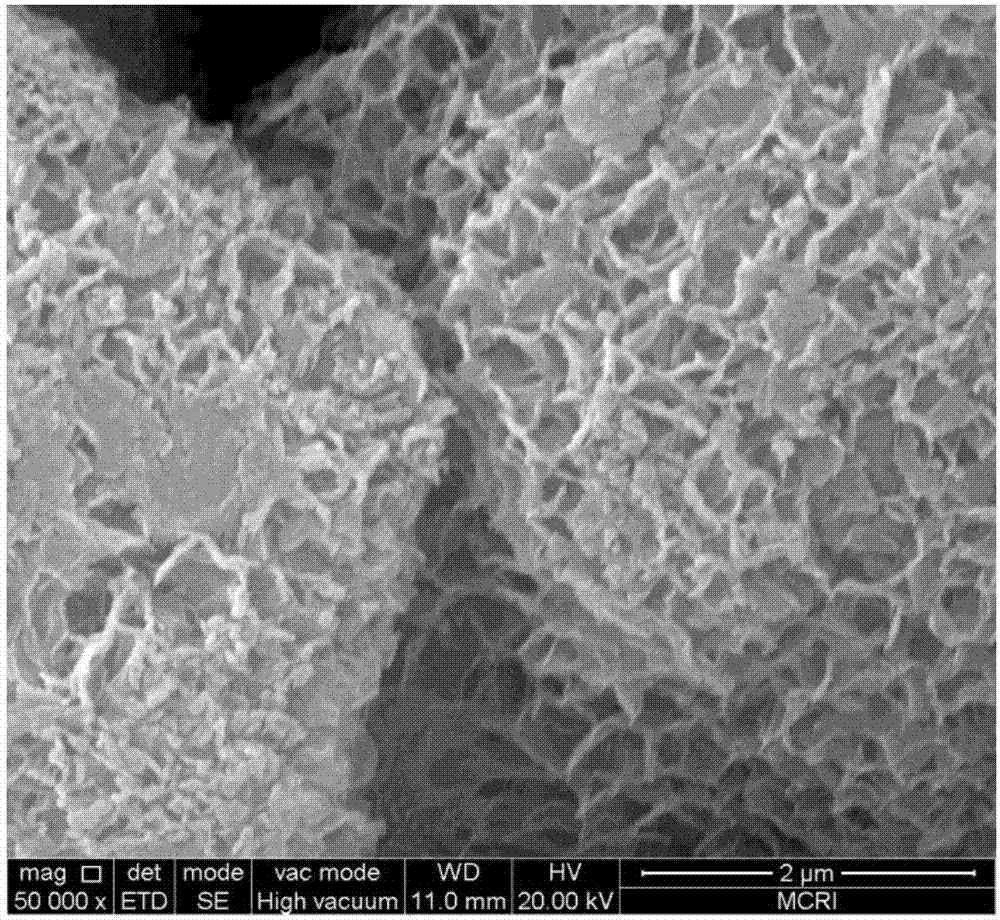

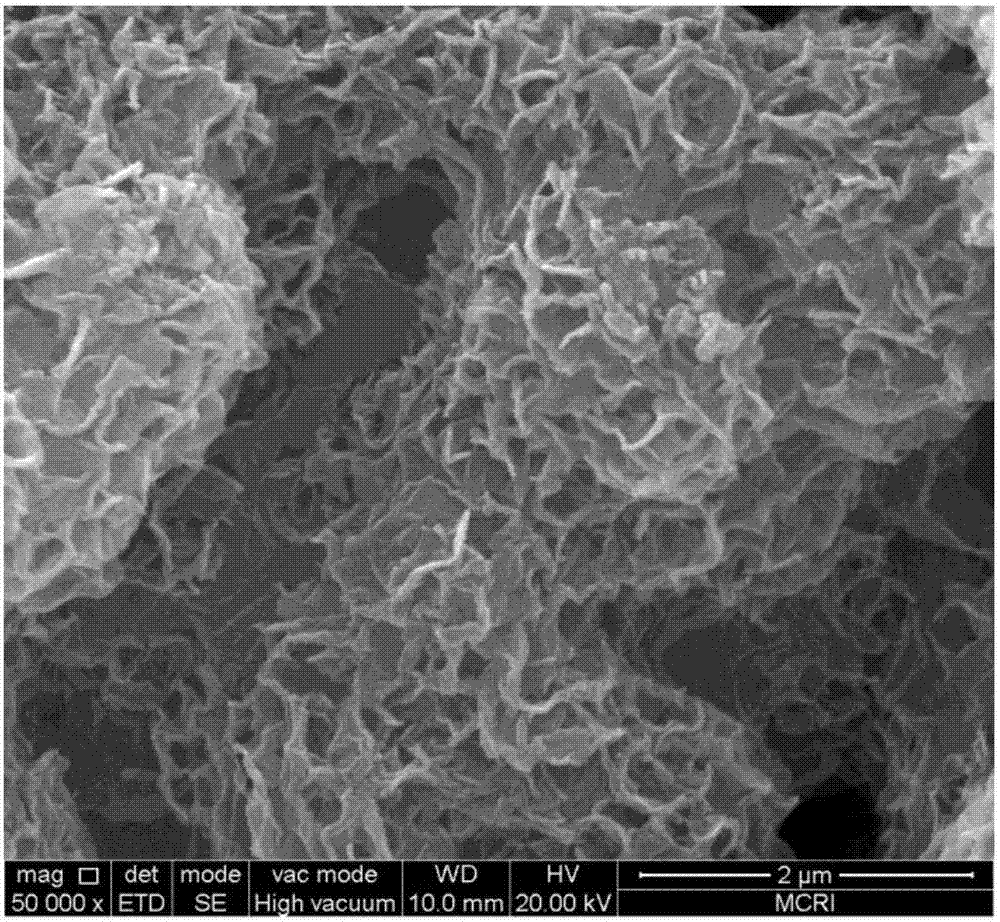

Application of synthetic calcium carbonate as high paper filler and preparation method of high paper filler

InactiveCN107287980AHigh total retentionHigh opacityInorganic compound additionFiberCalcium silicate

The synthetic calcium carbonate, as the application of papermaking filler, belongs to the papermaking technical field. The plant pulp fiber material is as the skeleton, synthetic calcium silicate power is as the filler, and the high paper filler is produced by paper-making technics. The synthetic calcium silicate power is as the hydrated calcium aluminate, and the object composition includes C-S-H polymer gel and tobermorite, and the brightness of synthetic calcium silicate power is greater than or equal to 90%, the specific surface area is greater or equal to 120 square meters per gram, the bulk density is from 0.12 grams per centimeter to 0.30 grams per centimeter, the oil-absorbed value is 120-200 milliliters per milligram, and the average grain diameter is (D50) from 12 microns to 40 microns . Meanwhile, the invention also discloses the preparation method of synthetic calcium carbonate: the synthetic calcium silicate power is the paper filler, then under the premise that paper properties are guaranteed, the usage of plant fiber can be decreased at the greatest extent. Replacing the traditional paper filler by synthetic calcium silicate power can not only reduce the usage of plant filler at the greatest extent, but also increase the retention rate of calcium carbonate, decrease the waste of filler and improve the paper ash content.

Owner:内蒙古普诺思新材料科技有限公司

Porous high-water-seepage permeable floor tile doped with waste ash

The invention discloses a porous high-water-seepage permeable floor tile doped with waste ash. The floor tile is prepared from, by weight, 40-43 parts of sludge of a sewage plant, 6-7 parts of rice hull, 4-5 parts of potassium feldspar powder, 10-12 parts of flyash, 10-12 parts of sodium silicate, 12-14 parts of the waste ash, 18-20 parts of abandoned ceramics, 5-7 parts of quartz sand, 2-3 parts of methyl methacrylate, 2-3 parts of redispersible rubber powder, 1.5-2 parts of ammonium carbonate and 4-5.5 parts of papermaking black liquid. The abandoned ceramics, the waste ash, the quartz sand and the like are added as aggregate and matched with binding agents such as the redispersible rubber powder and methyl methacrylate to prepare tile adobe with good plasticity, as continuous through holes are formed in a tile body through sintering, the floor tile has high permeability, and meanwhile high bending strength and high compressive strength are reserved. The raw materials of the prepared product are wide in source, low in cost and beneficial for protecting mineral resources and ecological resources.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Building waste material utilization method

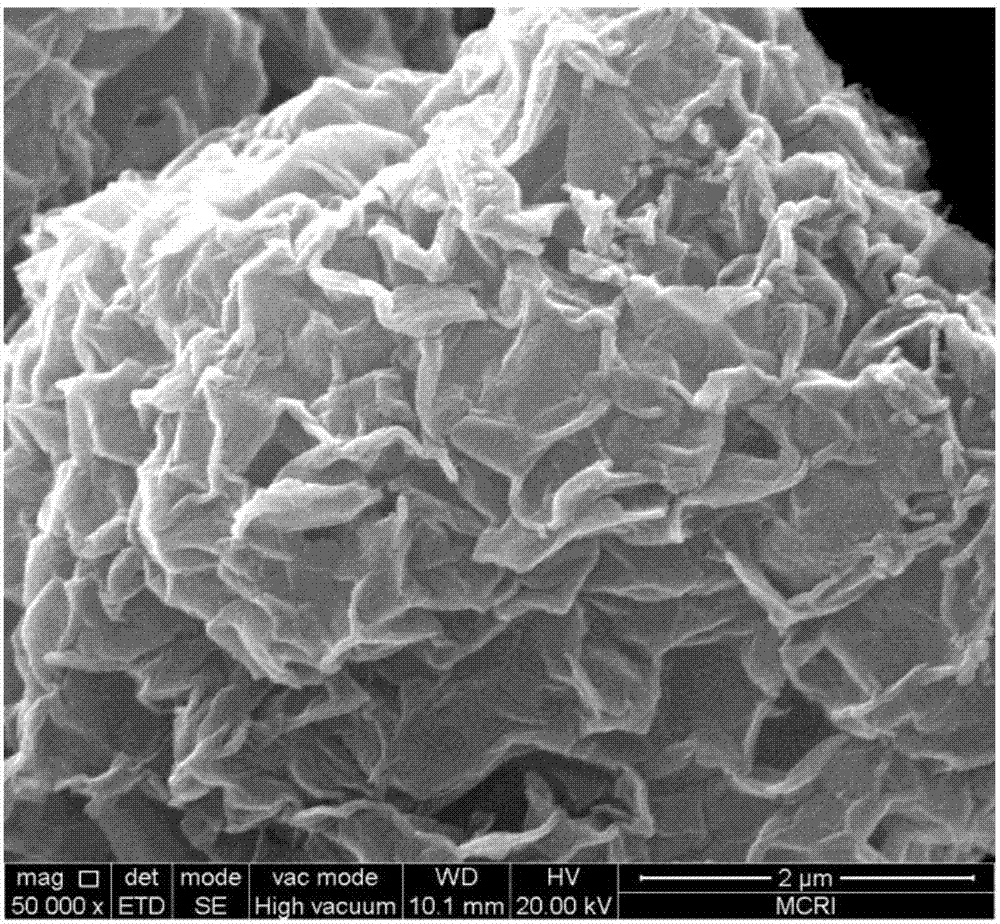

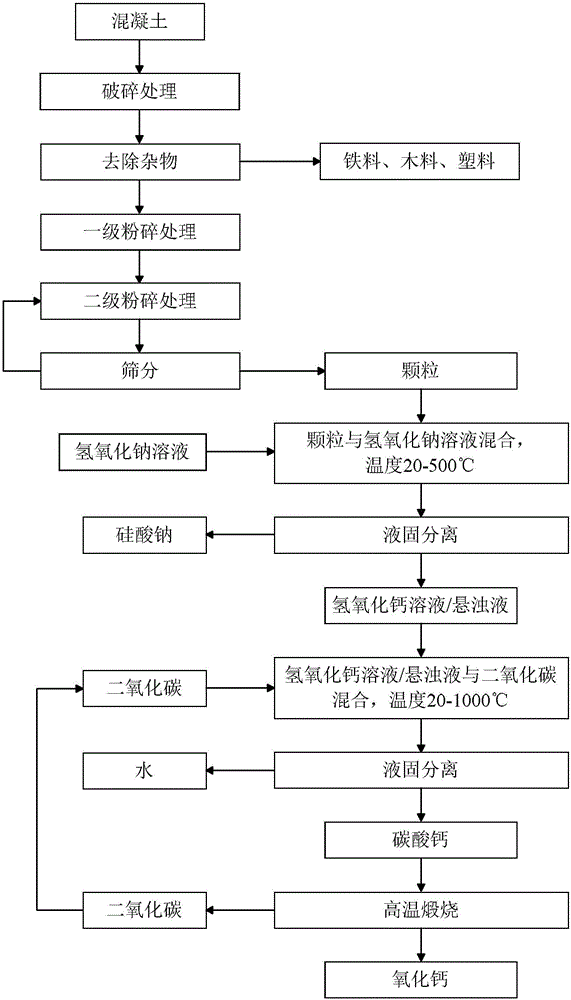

InactiveCN106348331AReduce miningEmission reductionCalcium/strontium/barium carbonatesSilicaPre treatmentMaterials science

The invention discloses a building waste material utilization method. The building waste material utilization method comprises the steps of pretreating building waste materials into particles with size in a preset size range; and obtaining calcium carbonate from the particles. According to the building waste material utilization method provided by the invention, the range of the usable building waste materials is wider, and useful compounds which have higher purity and facilitate wider application can be obtained.

Owner:YUANCHU TECH (BEIJING) CO LTD

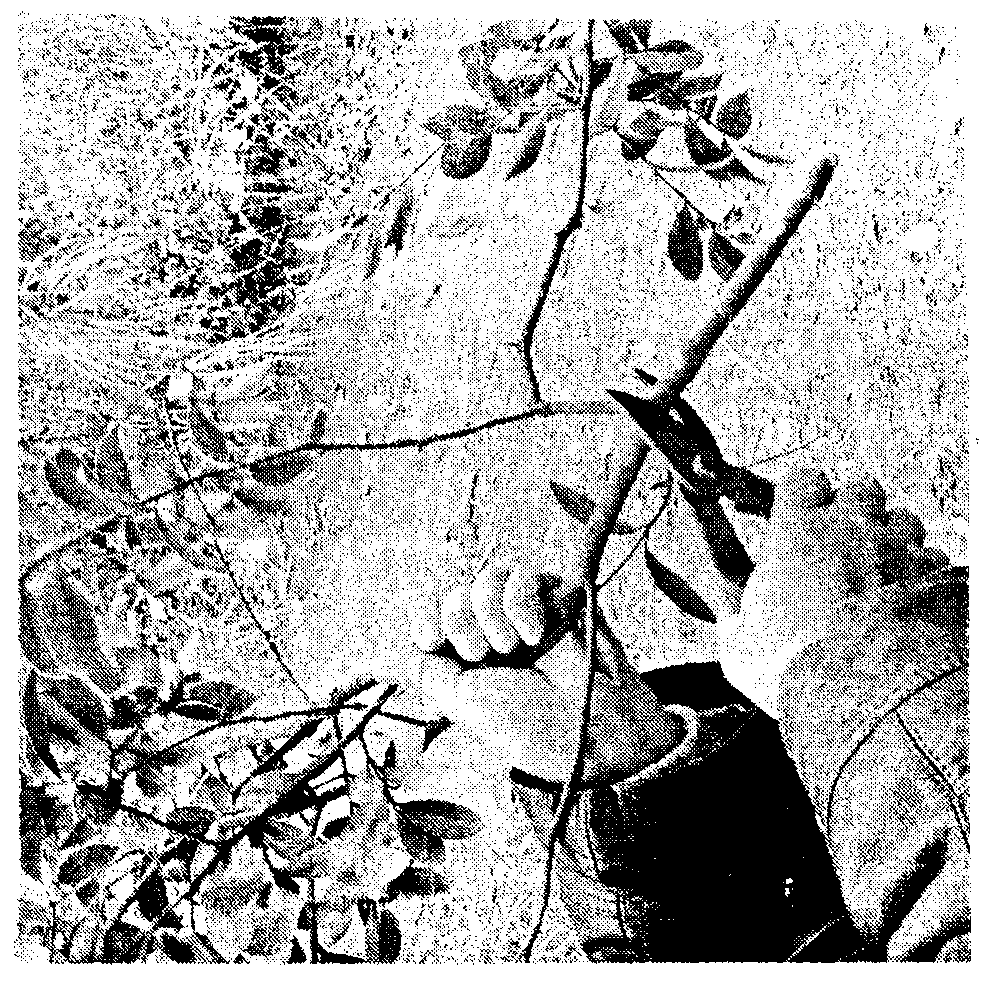

Method for cultivating and acclimating wild indocalamus leaves artificially

InactiveCN102379205ATo promote metabolismImprove germination rateHorticultureMedium densityBamboo shoot

The invention relates to a method for cultivating and acclimating wild indocalamus leaves artificially. The method is characterized by comprising the following steps of: 1) selecting transplanting varieties, namely selecting wild indocalamus seedlings which grow in relatively poor conditions and have vigorous growth vigor and large laminae; 2) transplanting and propagating, namely selecting a transplanting field, making preparation for ploughing and sowing; intertilling, so that the depth of loosening soil is between 25 and 35 centimeters, dividing ridges, and arranging a drainage ditch; lifting seedlings, transplanting, and performing vegetative propagation, namely transplanting from October in the current year to May in the next year; after the seedlings are lifted, pruning the original root whips completely and reserving fibrous roots; planting in a large field in the original natural growth direction of the indocalamus leaves in a medium density mode, wherein the planting depth is between 20 and 30 centimeters; 3) performing fertilizer and water management, namely fertilizing according soil fertility and a soil measuring formula, and preferably applying an organic fertilizer to the roots; and 4) picking and cultivating rationally, namely avoiding picking in the current year, and picking seldom in the second year to achieve an effect of closing in the third year. By the method, the problem of cultivating and acclimating the wild indocalamus leaves artificially is solved, the metabolism of indocalamus and the flourishing of the root whips are promoted, and the germination rate of bamboo sprouts is improved.

Owner:黄山市徽顶箬业有限公司

Culture method for improving benefits of crayfishes, June hairy crabs and freshwater shrimps

PendingCN111387109AImprove "June Yellow"Improve the benefit of freshwater shrimpClimate change adaptationAccessory food factorsMixed cultureEcological environment

The present invention discloses a culture method for improving the benefits of crayfishes, June hairy crabs and freshwater shrimps. The method comprises the following steps of S1, selecting a pond, wherein the selection requirements of the pond are that the area is 30 mu and the direction is from east to west. According to the culture method for improving the benefits of the crayfishes, the June hairy crabs and the freshwater shrimps, the culture pond is spaced half and half by a net sheet in a same culture unit, or a culture region is spaced by a purse net, and crayfish, crab and freshwater shrimp seeds are subjected to single culture, alternate culture and mixed culture in different culture regions, so that a culture water body is fully utilized, the growth advantages of different species are exerted, differential culture of the different species is realized, management and intensive catching are facilitated, and intensive market sale of products is facilitated; in the first stage, the low-density crayfishes and June hairy crabs are subjected to single culture, so that the culture time is staggered, the products come into the market in advance, and the culture benefits are greatly improved; and ecological resources of the pond are protected to provide a good ecological environment for alternate culture and mixed culture of the crabs and the shrimps in the second stage.

Owner:陈晓方

Artificial island and construction method thereof

InactiveCN112407173AReduce manual interventionProtect ecological resourcesLand reclamationFloating buildingsMarine engineeringStructural engineering

The invention relates to an artificial island and a construction method thereof. The artificial island comprises at least one fixed island and a group of floating islands surrounding each fixed island, each floating island comprises a single point mooring system, more than two floating island prefabricated unit modules and an inter-module connecting system, the floating island prefabricated unit modules float in a sea surface fixed sea area through the single point mooring systems, and the floating island prefabricated unit modules are hinged through the inter-module connecting systems. By means of the construction mode of the fixed and floating islands, facilities or devices are transferred to the floating islands, manual intervention on the fixed island is reduced as much as possible, and therefore original ecological resources of the island are protected. The floating islands adopt the form of prefabricated modules, the floating island prefabricated unit modules are built on the fixed island, the mainland or a nearby island in advance, and construction to the tail can be facilitated through tugboats.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

Environment-friendly aerated concrete block and preparation method thereof

InactiveCN108218375AHigh strengthReduce base chargesCeramicwareEnvironmental resistanceAdhesion force

The invention relates to an environment-friendly aerated concrete block and a preparation method thereof and belongs to the field of building materials. The environment-friendly aerated concrete blockis prepared from the following raw materials in parts by weight: 70-80 parts of fly ash, 50-60 parts of building wastes, 30-36 parts of sands, 24-28 parts of fine sands, 62-68 parts of limes, 45-49 parts of gypsum, 26-36 parts of portland cement, 14-16 parts of aluminum powder, 5.4-6.0 parts of polycarboxylic series of water reducer, 6-12 parts of glycyl-D-leucine and 6-12 parts of 4-carboxyl benzocyclobutene. The environment-friendly aerated concrete block is uniform in interior air holes and consistent in water absorption rate, is relatively high in adhesion force to mortar which is smearedto the outer surface of the block and lowers the probability that the mortar falls off from the surface of the aerated concrete block.

Owner:青岛广润丰建筑材料有限责任公司

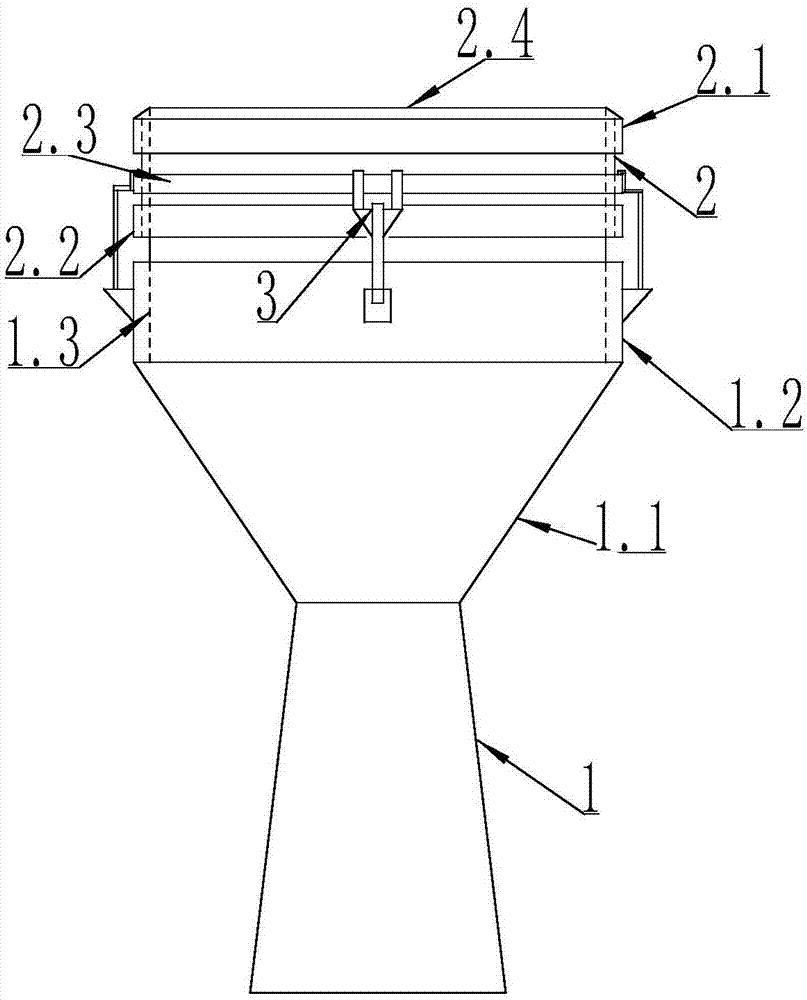

Method for assembling detachable drum

ActiveCN107464547ARich soundEasy to processPercussion musical instrumentsPolyvinyl chlorideAgricultural engineering

The invention discloses a method for assembling a detachable drum. A funnel-shaped middle drum body is arranged between a cylindrical upper drum body and an inverted funnel-shaped lower drum body; the height of the middle drum body is smaller than that of the lower drum body; the conical surface of the middle drum body is larger the conical surface of the lower drum body; a cylindrical supporting ring is arranged in the upper drum body; a drum cover is arranged at the periphery of the upper part of the supporting ring; at least four tone tuning connecting pieces are uniformly distributed between the upper drum body and the drum cover; the upper ends of the tone tuning connecting pieces are arranged at the periphery of the drum cover; the lower ends of the tone tuning connecting pieces are arranged at the periphery of the upper drum body; and the drum cover and the upper drum body are connected into a whole by virtue of the tone tuning connecting pieces. According to the drum disclosed by the invention, the drum body, the supporting ring and the drum cover are made of composite boards, drum skin is a PVC (Polyvinyl Chloride) film, the drum is convenient to process and install, and bolts of the tone tuning connecting pieces can be adjusted according to needs of the drum during tone tuning, so that the drum can give different tones and is convenient in tone tuning. Moreover, the drum disclosed by the invention has the effects of reducing waste of resources and protecting ecological resources and is easy to make, convenient to mount, solid and durable in use.

Owner:洛阳典乐文化科技有限公司

Preparation method of environment-friendly autoclaved aerated concrete block

The invention discloses a preparation method of an environment-friendly autoclaved aerated concrete block. The method comprises the following steps: mixing and grinding a ceramic waste, loess, quicklime and desulfurized gypsum, and feeding the mixture into a sintering machine to obtain mixed aggregates; feeding methyl acrylate, ethylene oxide and an Al / Mg / Ce inorganic salt composite catalyst into a sealed reactor, carrying out heating, stirring, standing and cooling under nitrogen protection, adding rosin, phenol, sodium polynaphthalene sulfonate and concentrated sulfuric acid for mixing, and carrying out heating and stirring; sequentially adding sodium hydroxide and water for stirring to obtain a foaming agent; adding powdery sodium silicate, calcium lignosulphonate and anhydrous sodium sulfate to the mixed aggregates for ball-milling, and adding cement, polyvinyl alcohol and the foaming agent for stirring to obtain mixed slurry; and casting the mixed slurry into a mold for molding, and carrying out heating, pre-curing, demolding, cutting, autoclaved curing and cooling to obtain the environment-friendly autoclaved aerated concrete block.

Owner:浙江德义建筑设备有限公司

Formula and preparation method of novel environment-friendly biological hydrocarbon oil

The invention discloses a formula of novel environment-friendly biological hydrocarbon oil and a preparation method of the novel environment-friendly biological hydrocarbon oil. The novel environment-friendly biological hydrocarbon oil is prepared by mixing the following raw materials: 1-1000kg of polyester-grade diethylglycerol, tap water, 0.5-500kg of purified water and a catalyst, no black smoke and no peculiar smell are discharged, no waste is discharged in the production process, no pollution is caused to the environment, and no harm is caused to human health; the oil is high in calorific value and low in price, all indexes of the oil meet national standards through detection, the oil can replace diesel oil to become new energy of enterprises, the oil is high in flash point, limit 1.9%, high in ignition point, free of open fire, free of fire, safe to use and wide in raw material source, waste is utilized, waste is turned into wealth, ecological resources are protected, and the oil belongs to renewable energy and is worthy of popularization. The method has good economic benefits and social benefits, and has good popularization value.

Owner:贵州邦凯环保科技有限公司

Preparation method of autoclaved-aerated concrete building block

ActiveCN107162513AWide variety of sourcesEffective dispersionCeramicwarePolyethylene glycolMelamine formaldehyde resin

The invention discloses a preparation method of autoclaved-aerated concrete building block. The preparation method includes following steps: mixing and grinding coal ash waste, basalt powder, calcium carbonate and zeolite powder, and feeding into a sintering machine for sintering to obtain mixed aggregate; adding river sand, sulfonated melamine-formaldehyde resin and cellulose fiber into the mixed aggregate, ball milling, adding cement, polyethylene glycol and modified foamer, and stirring to obtain mixed slurry; pouring the mixed slurry into a mould, increasing temperature for pre-curing, demoulding, cutting, autoclaved curing, and cooling to obtain the autoclaved-aerated concrete building block. The coal ash waste is used, so that the building blocks are low in cost, extremely high in extreme load and compressive strength and conducive to overcoming the quality defects of flaking and cracking of walls built by the building block; the inside of the building block contains a lot of uniform air holes, so that the building block has extremely high pressure bearing capacity and remarkable economic benefit and social benefit.

Owner:唐山市致臻建筑材料有限公司

Papermaking filler and pretreatment method thereof

InactiveCN102433795BHigh whitenessIncrease the addition ratioInorganic compound additionPigment physical treatmentCalcium silicatePretreatment method

The invention discloses a papermaking filler and a pretreatment method thereof, and belongs to the technical field of papermaking processes. The filler is active calcium silicate. The pretreatment method for the filler comprises the following steps of: adding the active calcium silicate into hot water of 50 to 100 DEG C, and fully stirring and dissolving the active calcium silicate to form emulsion. The raw material for the filler is extensive in source and low in cost; particularly, waste fly ash in a power plant can be comprehensively utilized for producing the filler, so that the ecological environment and the mineral resources are effectively protected; the filler has short dissolution time, low energy consumption and high activity, and meets the high-filler papermaking requirement; the flow in the pretreatment method is simple, and the filler is fully dispersed and activated; and the pretreated filler can be fully mixed uniformly with plant fibers, so that the internal bonding force between the filler and the fibers is increased and the performance of the paper is improved.

Owner:GUONENG PAPER IND

Construction process for building concrete structure and its used mould

The present invention relates to construction process and formwork for constructing concrete structure and aims at reducing formwork material consumption and omitting formwork detaching step. The present invention has new type formwork made and assembled based on specific concrete structure, and after depositing concrete and curing, the formwork as one part of the concrete structure is combined integrally with the deposited concrete. The present invention has greatly simplified construction process, saves great amount of formwork material and shortens the construction period, and the smooth formwork is face decorated directly in the later construction period.

Owner:季学宏

A kind of titanium gypsum-based semi-rigid base material and preparation method thereof

The invention relates to the field of building materials, in particular to a titanium gypsum-based semi-rigid base material and a preparation method thereof, comprising the following components: original titanium gypsum, cement, fly ash, mineral powder, recycled aggregate, water, and an excitation activator , viscosity reducing dispersant; wherein the excitation activator includes the following components: quicklime, calcium acrylate, magnesium fluorosilicate, alunite, sodium tripolyphosphate, potassium sulfate, sodium metaaluminate, and the viscosity reducing dispersant is grafted cis-butyl Polytetrafluoroethylene of olefinic anhydride. The semi-rigid base material of the present invention meets the strength requirements of the road pavement base, and the original titanium gypsum is added in a large amount, which can consume a large amount of the original titanium gypsum and reduce pollution, and the industrial by-product titanium gypsum is added in its original state without drying, calcination, dehydration and powder. Grinding and other processes also protect ecological resources and have a wide range of social benefits, obvious economic benefits, and ecological and environmental benefits.

Owner:SHANDONG JIAOTONG UNIV

Cabbage soilless culture composite matrix

A cabbage soilless culture composite matrix is provided; cottonseed hulls with wide sources and low cost in Zhoushan region and sawdust are mixed and combined with product seedling growing matrix according to certain ratio so as to form the cabbage culture matrix; comparing with the product seedling growing matrix and according to comparison tests, the high efficiency and low cost composite matrix is selected to suit the cabbage culture, thus replacing a normal soilless culture matrix using peat as main material, reducing culture cost, protecting non-renewable ecology resources, improving production efficiency, and laying foundations for demonstration popularization of large scale soilless culture production of green-leaf vegetables like cabbage on fishing vessels.

Owner:舟山市农林科学研究院

High-filler paper and production method thereof

InactiveCN102433796BHigh whitenessIncrease the addition ratioInorganic compound additionPulp material addition processesCalcium silicatePlant fibre

The invention discloses high-filler paper and a production method thereof. The high-filler paper contains 30 to 60 mass percent of filler, and the filler is active calcium silicate; in the step of adding the filler, after the active calcium silicate in an amount which is 40 to 70 percent of the total mass of the active calcium silicate and the pulp is fully stirred and dissolved to form emulsion,the emulsion is guided into a covered pulp storage tank or a pre-making pulp storage tank and fully stirred and mixed with plant fibers; the filler adding proportion of the high-filler paper is improved, so that the consumption of the plant fibers is greatly reduced at the same time of improving the performance of the paper; and according to the production method for the high-filler paper, the adding process of the papermaking filler is simplified, the filler and the plant fibers can be fully mixed uniformly, and the internal bonding force is increased, so that the performance of the paper isimproved.

Owner:GUONENG PAPER IND

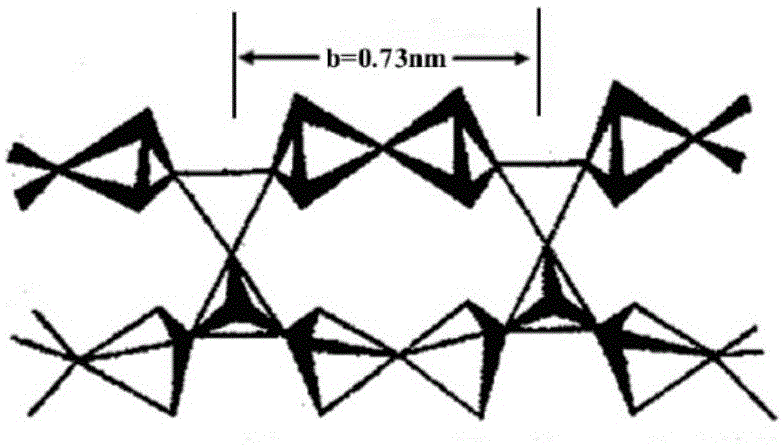

Use of xonotlite as filler in papermaking

ActiveCN103669104BWide variety of sourcesLow costReinforcing agents additionPaper/cardboardFiberXonotlite

The invention discloses application of xonotlite as a paper making filler. High-filler-content paper is produced with 40-60 percent of plant pulp fibrous raw material serving as a framework, 40-60 percent of the xonotlite serving as the paper making filler and a water-soluble macromolecular multipolymer serving as a reinforcing agent according to the conventional paper making process method. Compared with the conventional paper making method, the method adopted in the invention has the advantages that the xonotlite is taken as the paper making filler, so that the phenomenon of powder falling of the filler on a paper making surface is avoided in a paper making process, the retention rate of the filler is generally 55-85 percent after being loaded onto a net of a paper machine, being 20-50 percent higher than that of the conventional paper making filler, and waste of the filler is reduced effectively; paper produced with the method has the advantages of low extension rate, high opacity, high smoothness, no pollution, degradability, recyclability, low cost and the like.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

A kind of preparation method of autoclaved aerated concrete block

ActiveCN107162513BWide variety of sourcesEffective dispersionCeramicwarePolyethylene glycolCellulose fiber

The invention discloses a preparation method of autoclaved-aerated concrete building block. The preparation method includes following steps: mixing and grinding coal ash waste, basalt powder, calcium carbonate and zeolite powder, and feeding into a sintering machine for sintering to obtain mixed aggregate; adding river sand, sulfonated melamine-formaldehyde resin and cellulose fiber into the mixed aggregate, ball milling, adding cement, polyethylene glycol and modified foamer, and stirring to obtain mixed slurry; pouring the mixed slurry into a mould, increasing temperature for pre-curing, demoulding, cutting, autoclaved curing, and cooling to obtain the autoclaved-aerated concrete building block. The coal ash waste is used, so that the building blocks are low in cost, extremely high in extreme load and compressive strength and conducive to overcoming the quality defects of flaking and cracking of walls built by the building block; the inside of the building block contains a lot of uniform air holes, so that the building block has extremely high pressure bearing capacity and remarkable economic benefit and social benefit.

Owner:唐山市致臻建筑材料有限公司

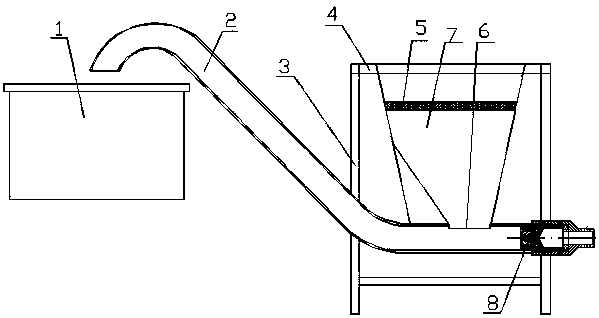

Cement mixer

InactiveCN103372916AReduce labor intensityImprove work efficiency and work qualityDischarging apparatusCement mixing apparatusTruckEcological environment

The invention relates to a cement mixer. The cement mixer comprises a mortar tank, a mortar outlet pipeline, a material platform, a mixer and a high-pressure nozzle, wherein the mixer is fixed on the material platform; one end of the mortar outlet pipeline is fixedly connected with the high-pressure nozzle, and the other end of the mortar outlet pipeline is connected with the mortar tank; and a material mixing port in the lower end of the mixer is connected with the interior of the mortar outlet pipeline. According to the cement mixer, the labor intensity of an operator is reduced, and the working efficiency and the working quality are improved, so that the mortar injection construction time is shortened, the safety of mortar injection construction is improved, and the cement mixer is not limited by the size of a site and is conveniently connected with a cement truck; and in a cement mixing process, cement dust can be effectively reduced, mortar and grease dirt cannot remain on the ground, the aim of clean mortar injection is safely achieved, environment protection capacity is improved, and ecological environment and resources are greatly protected.

Owner:扬州睿德石油机械有限公司

Method for propagating camellia japonica quickly

InactiveCN102217482BReduce incubation timeProtect ecological resourcesHorticultureRootstockEconomic benefits

Owner:贵州宏晨山茶花资源开发研究所

Artificial propagation method of Ptychobarbus kaznakovi

PendingCN113331087AEasy to operateProtect ecological resourcesClimate change adaptationPisciculture and aquariaBroodstockCaptive bred

The invention provides an artificial propagation method of Ptychobarbus kaznakovi, which comprises the following steps: parent fish rearing: selecting wild Ptychobarbus kaznakovi with no body surface injury and body weight of 400-1300 g as parent fish for rearing, wherein in the rearing process, the daily feeding amount of feed is 0.1-1% of the body weight of the parent fish; parent fish selection: selecting disease-free and robust mature Ptychobarbus kaznakovi as a spawning induction parent; artificial spawning induction: firstly, only injecting a first spawning induction agent into female fish in spawning induction parents for compatibility; after 24 h, continuously injecting a second oxytocic into the female fish for compatibility, and injecting a third oxytocic into the male fish in the oxytocic parents for compatibility; artificial insemination: temporarily rearing the induced spawning parents in an induced spawning pond at the water temperature of 9-14 DEG C, and checking female fishes in the induced spawning parents once every 8 h after 48 h; pressing the belly of the female fish slightly, if roes are discharged, squeezing the roes into a basin, then squeezing the semen of the male fish into the basin, and conducting stirring, standing and cleaning to obtain fertilized roes; and hatching: hatching fertilized roes obtained by using flowing water, and obtaining the Ptychobarbus kaznakovi fry after the hatching is completed.

Owner:武汉中科瑞华生态科技股份有限公司 +1

Seeding medium made of vinasse methane-sludge and preparation method thereof

InactiveCN101606471BGrow vigorouslyImprove water absorptionCultivating equipmentsSoilless cultivationPhylum CyanobacteriaSludge

The invention relates to a seeding medium made of vinasse methane-sludge and a preparation method thereof, not only solving the problem of environment contamination caused by vinasse methane-sludge, but also effectively utilizing vinasse methane-sludge. The seeding medium comprises fresh sludge containing 90 percent of water after methane generated from vinasse in a methane tank, accessories, ferment strain I and ferment strain II, wherein the accessories comprise grass peat, vermiculite and perlite; the ferment strain I comprises saccharomycetes, lactobacillus, high-temperature actinomycetesand bacillus; and the ferment strain II comprises photosynthetic bacteria, lactobacillus, bacillus, saccharomycetes, actinomycetes and terrestrial cyanobacteria. The preparation method comprises the following steps of preparing fresh sludge, dehydrating, adding the ferment strain I for fermentation, adding the ferment strain II for secondary fermentation, air drying, adding accessories, crushing,screening and packing. The vinasse methane-sludge contains 40 to 50 percent of organic matter and 4.3 percent of available nitrogen (N), phosphorus (P) and kalium (K). The seeding medium made of vinasse methane-sludge has better hydrophilicity, and seeding can be carried out after loading the dry seeding medium and spraying water, thus saving both labor and time.

Owner:ANHUI FENGTIAN SEEDLESS WATERMELON TECH

Method for making high temperature charcoal

InactiveCN100513519CAchieve recyclingProtect ecological resourcesBiofuelsSolid fuelsTarProcess engineering

The process of making high temperature charcoal includes the steps of: treating biomass material, charring the biomass material,, crushing charcoal, forming in a forming machine, stoving formed charcoal rod, and packing high temperature charcoal product. The present invention needs additional heat source for baking high temperature charcoal, has wood tar added into crushed charcoal, can produce high temperature charcoal with agricultural and forestry wastes and make best utilization of resource, and is environment friendly.

Owner:江国庆

A kind of green environment-friendly aerated concrete block and preparation method thereof

The invention relates to a green environment-friendly aerated concrete block and a preparation method thereof, belonging to the field of building materials. The raw materials of the green and environment-friendly aerated concrete block include, by weight, 70-80 parts of fly ash, 50-60 parts of construction waste, 30-36 parts of sand, 24-28 parts of fine sand, and 62-60 parts of lime. 68 parts, 45-49 parts of gypsum, 26-36 parts of Portland cement, 14-16 parts of aluminum powder, 5.4-6.0 parts of polycarboxylate superplasticizer, 6-12 parts of glycyl-D-leucine, 6-12 parts of 4-carboxybenzocyclobutene. The green and environment-friendly aerated concrete block has uniform internal pores and consistent water absorption, and the mortar applied to the outer surface of the block has a high adhesion to the block, reducing the probability of the mortar falling off the surface of the aerated concrete block.

Owner:青岛广润丰建筑材料有限责任公司

A kind of tomato seedling raising substrate and its preparation method

Owner:ZHANGYE ECONOMIC CROPS TECH PROMOTION STATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com