Cement mixer

A mixer and cement technology, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve the problems of insufficient cement slurry density, inability to mix cement and water uniformly, and affecting the health of employees. Achieve the effects of shortening the construction time of ash injection, reliable performance, and improving work efficiency and work quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

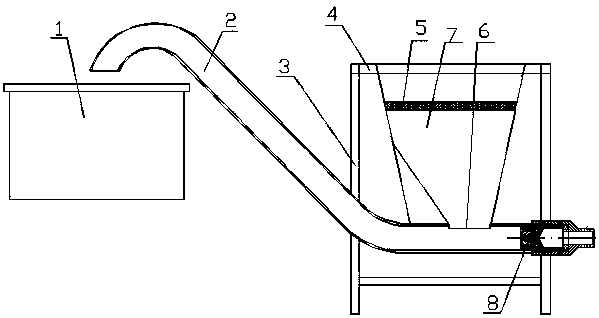

[0013] The cement mixer comprises a slurry tank 1, a slurry discharge pipeline 2, a material platform 4, a mixer 7 and a high-pressure nozzle 8, the mixer 7 is fixed on the material platform 4, and one end of the slurry discharge pipeline 2 is fixedly connected to a high-pressure The nozzle 8 is connected to the slurry tank 1 at the other end. The mixing port 6 at the lower end of the mixer 7 is connected to the inside of the slurry outlet pipeline 2. The mixer 7 is funnel-shaped and has a screen 5 inside.

[0014] During the uniform mixing of cement into cement slurry, the water is turned into a high-pressure jet through the high-pressure nozzle 8 and sprayed into the mixing port 6, so that a vacuum is formed at the mixing port 6. Because the vacuum has been formed at the mixing port 6, it can be Well and fully blend water and cement together to form cement slurry with uniform density without any hard lumps and scaling, and smoothly send it into the cement slurry tank 1 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com