Building waste material utilization method

A technology for construction waste and particles, applied in the field of environmental protection, can solve the problems of inapplicable calcium-containing waste, the scope of utilization can only be reused within the scope of construction projects, and high-purity calcium carbonate cannot be obtained, so as to save the amount of mining and realize a closed loop. The effect of recycling and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings.

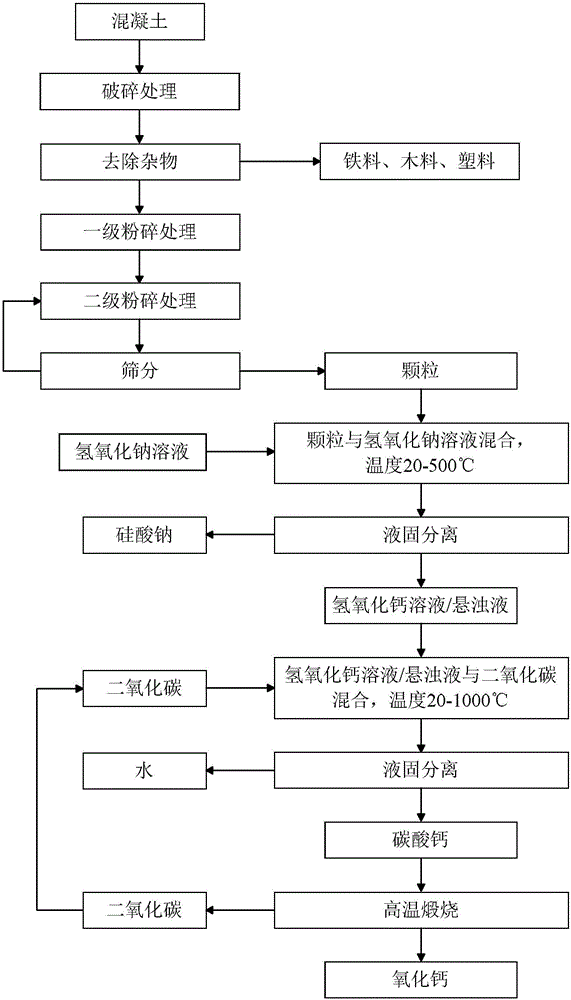

[0048] figure 1 A process flow diagram showing a construction waste utilization method according to a first embodiment of the present invention, the construction waste utilization method includes: firstly, preprocessing the construction waste to obtain particles in a predetermined size range, and then extracting from the particles to obtain useful compounds.

[0049] Described pretreatment step comprises again:

[0050] First, the construction waste is crushed. The calcium element contained in the construction waste is, for example, waste cement, gypsum board, concrete, stones, bricks, red mud and the like produced in the demolition of waste buildings. In this embodiment, the construction waste is concrete. The construction waste, that is, concrete, is collected, and crushed uniformly, so as to obtain construction waste blocks, that is, concrete blocks,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com