Method for extracting essential oil from wood processing waste Chinese fir chips to co-produce chemical method activated carbon

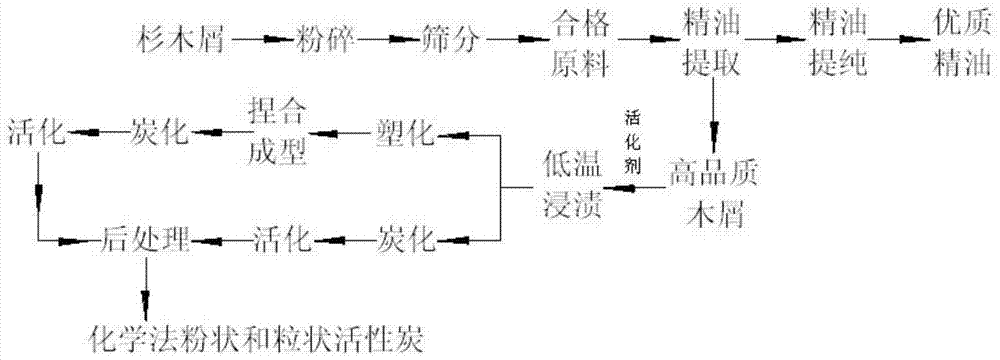

A technology of fir wood chips and chemical method, which is applied in chemical instruments and methods, inorganic chemistry, essential oils/fragrances, etc., can solve the problems of imperfect industrialization of sawdust powdered activated carbon, failure to achieve comprehensive utilization of fir wood chips, and low market competitiveness. , to achieve the effect of reducing natural resource exploitation, efficient and comprehensive utilization of waste, and enhancing industrial competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Use the waste heat boiler to recover the steam generated during the preheating of the activated carbon production process to distill the screened fresh fir chips with a water content of 30%. The distillation temperature is 110°C. After 3 hours of distillation, the active ingredients contained in the fir chips Enter the cooling process together with the steam to obtain liquid crude oil water, and obtain fir essential oil after oil-water separation, and the residue is fir sawdust after oil extraction;

[0038] 2) After oil extraction, mix fir chips and 60%wt phosphoric acid solution according to the ratio of phosphorus to wood 2.0:1, and add catalyst concentrated sulfuric acid (98%wt) according to 1% of the mass of phosphoric acid, and send the mixture into a closed insulation barrel Keep the constant temperature at 70°C for 3 hours and then transfer to the carbonization converter for carbonization. The temperature of the carbonization furnace is 250°C, and the residenc...

Embodiment 2

[0040] 1) Use the waste heat boiler to recover the steam generated by the preheating in the production process of activated carbon to distill the screened fresh fir chips with a water content of 30%. The distillation temperature is 110°C. After 3 hours of distillation, the effective The components enter the cooling process together with the steam to obtain liquid crude oil water, and the fir essential oil is obtained after the oil and water are separated, and the residue is fir sawdust after oil extraction;

[0041] 2) After oil extraction, the fir sawdust and 65%wt phosphoric acid solution were mixed according to the ratio of phosphorus to wood 2.0:1, and the catalyst concentrated sulfuric acid (98%) was added according to 2% of the mass of phosphoric acid, and the mixture was sent into a closed insulation barrel at 80 Keep the temperature at ℃ for 1.5 hours and then transfer to the plasticizing converter. The plasticizing temperature is 150℃ and the residence time is 1 hour. ...

Embodiment 3

[0043] 1) Use the waste heat boiler to recover the steam generated by the preheating in the production process of activated carbon to distill the screened fresh fir chips with a water content of 30%. The distillation temperature is 110°C. After 3 hours of distillation, the effective The components enter the cooling process together with the steam to obtain liquid crude oil water, and the fir essential oil is obtained after the oil and water are separated, and the residue is fir sawdust after oil extraction;

[0044] 2) Mix fir chips after oil extraction with 65%wt phosphoric acid solution according to the ratio of phosphorus to wood 2.0:1, and add catalyst concentrated sulfuric acid (98%) according to 1% of the mass of phosphoric acid, and send the mixture into a closed insulation barrel at 70 Keep the constant temperature at ℃ for 2 hours, then transfer to the plasticizing converter for plasticization, the plasticizing temperature is 150℃, and the residence time is 1 hour. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

| Iodine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com