Construction process for building concrete structure and its used mould

A construction technology and technology for building concrete, which is applied in building structures, buildings, columns, etc., can solve the problems of rough surface of concrete structures, deforestation of forest resources, and long labor time, so as to reduce construction costs and construction costs, protect the environment and Ecological resources, the effect of changing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

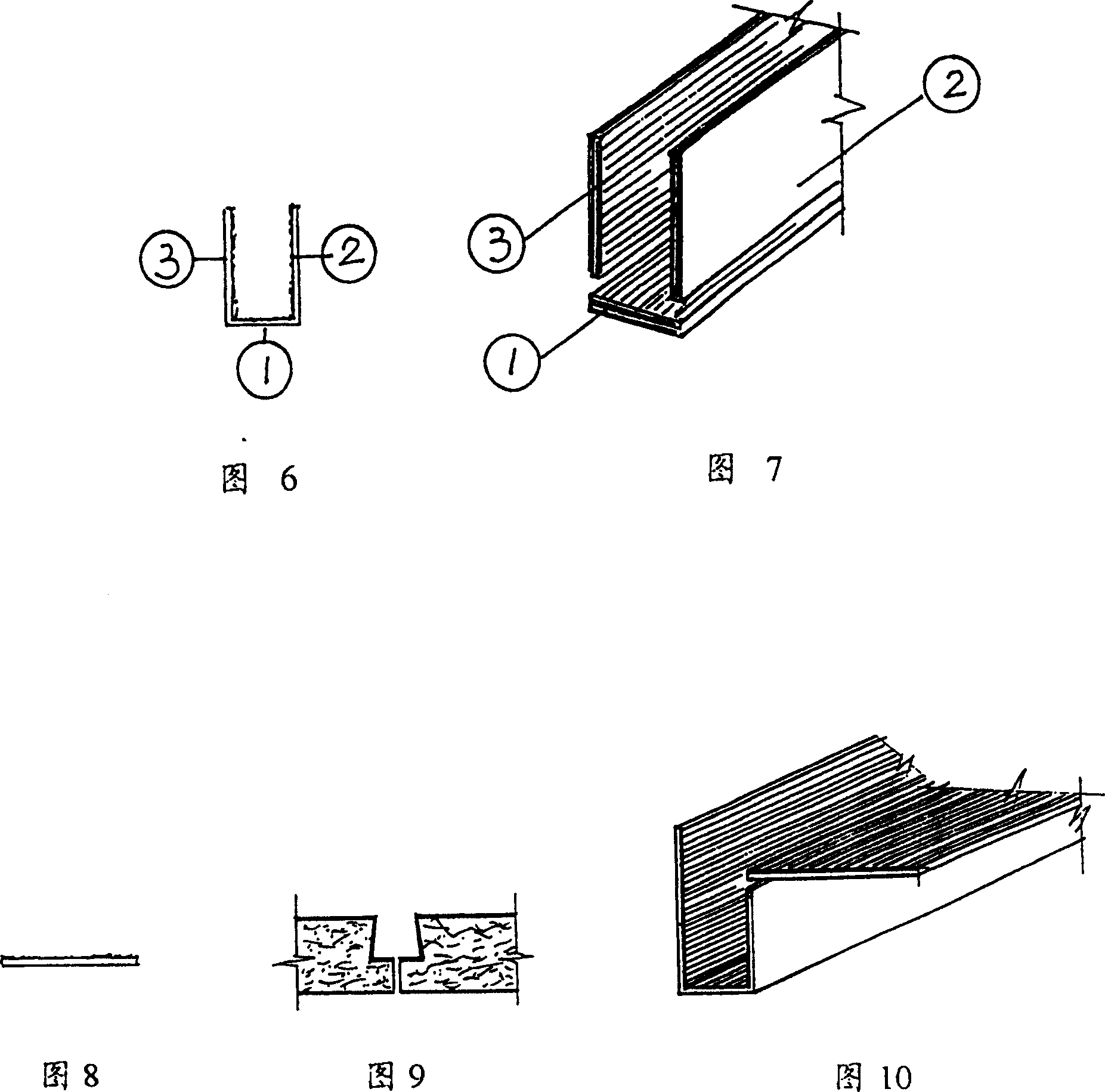

[0022] The structure disclosed in the above drawings is the structure of an embodiment of the present invention. In the figure, 1-4 are individual panels combined into formwork; 5 is structural concrete; 6 is dovetail groove.

[0023] Technical points of the present invention:

[0024] The technical gist of the invention is to change the existing concrete structure construction mode of construction engineering, and use less or no wooden formwork. Use prefabricated cement formwork to replace construction formwork such as wood, bamboo boards and steel formwork.

[0025] 1. The construction template of prefabricated cement concrete structure is cement mortar composed of cement as cement, fine river sand as filler, glass fiber (or other mineral wool material) as tensile material, and plaster of paris as material to speed up the initial setting time. , use this mortar to pour into a cement sheet in a special mold, then roughen and groove the surface where the formwork is combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com