Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Prevent blowby" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

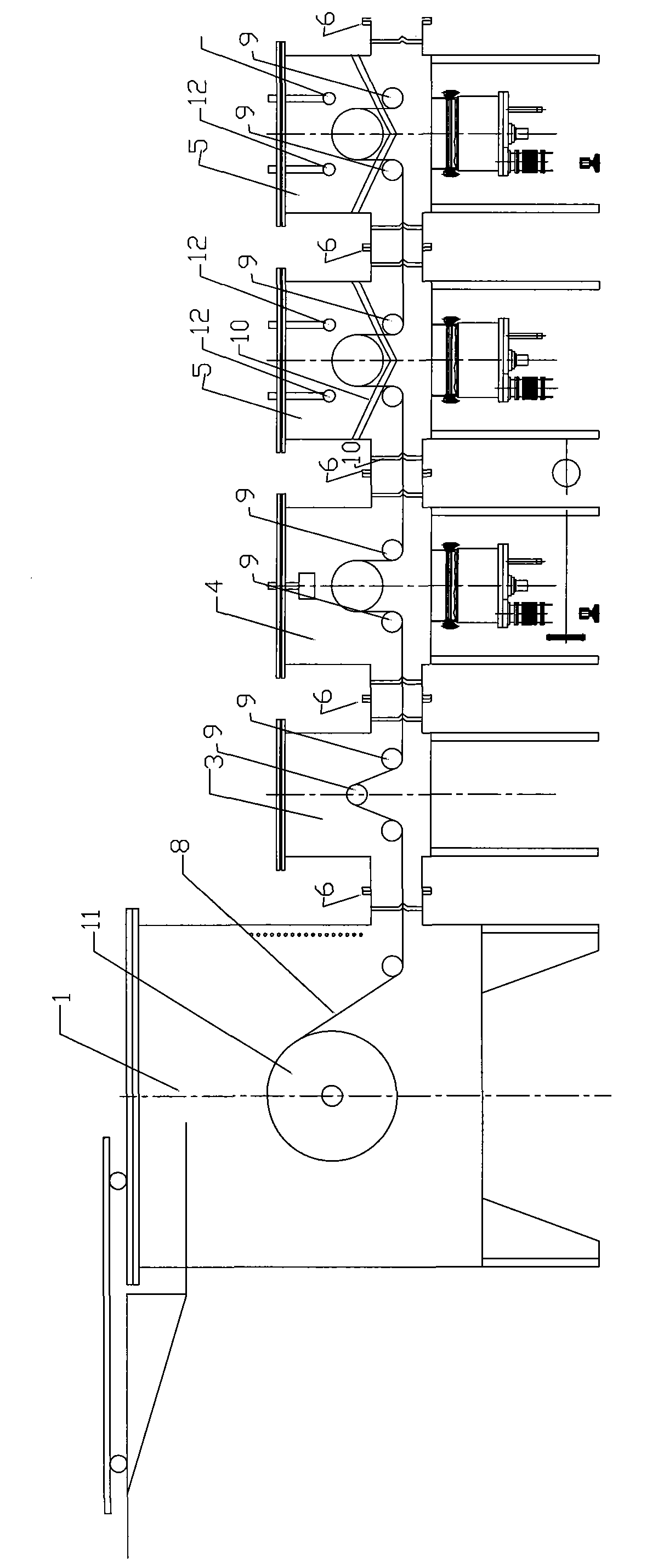

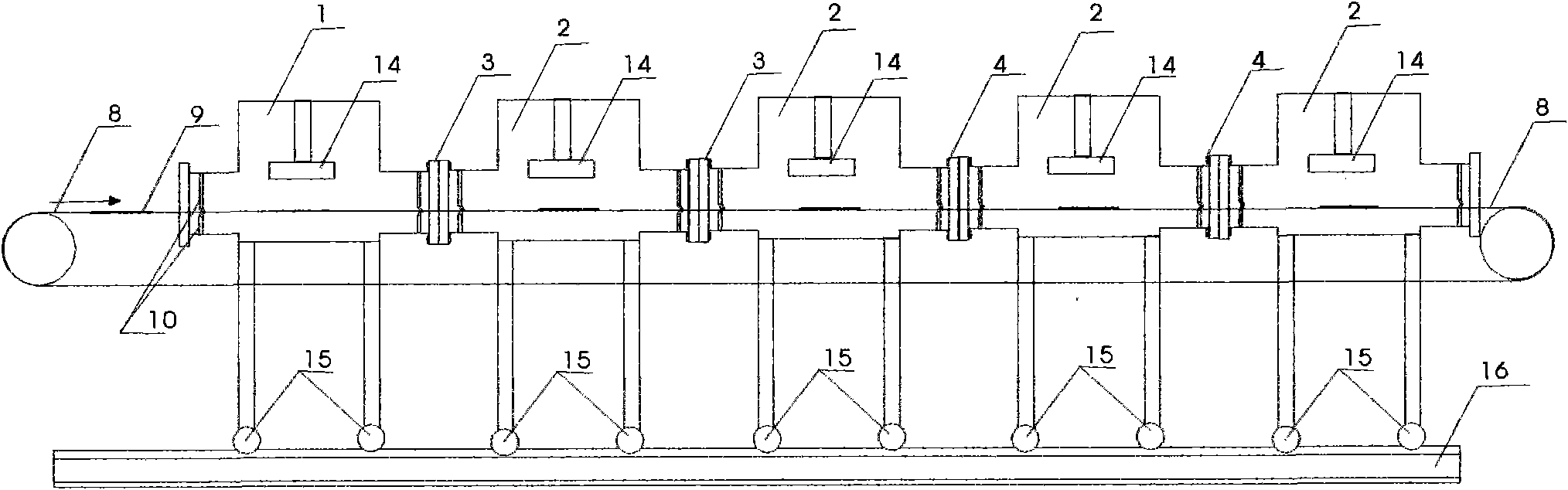

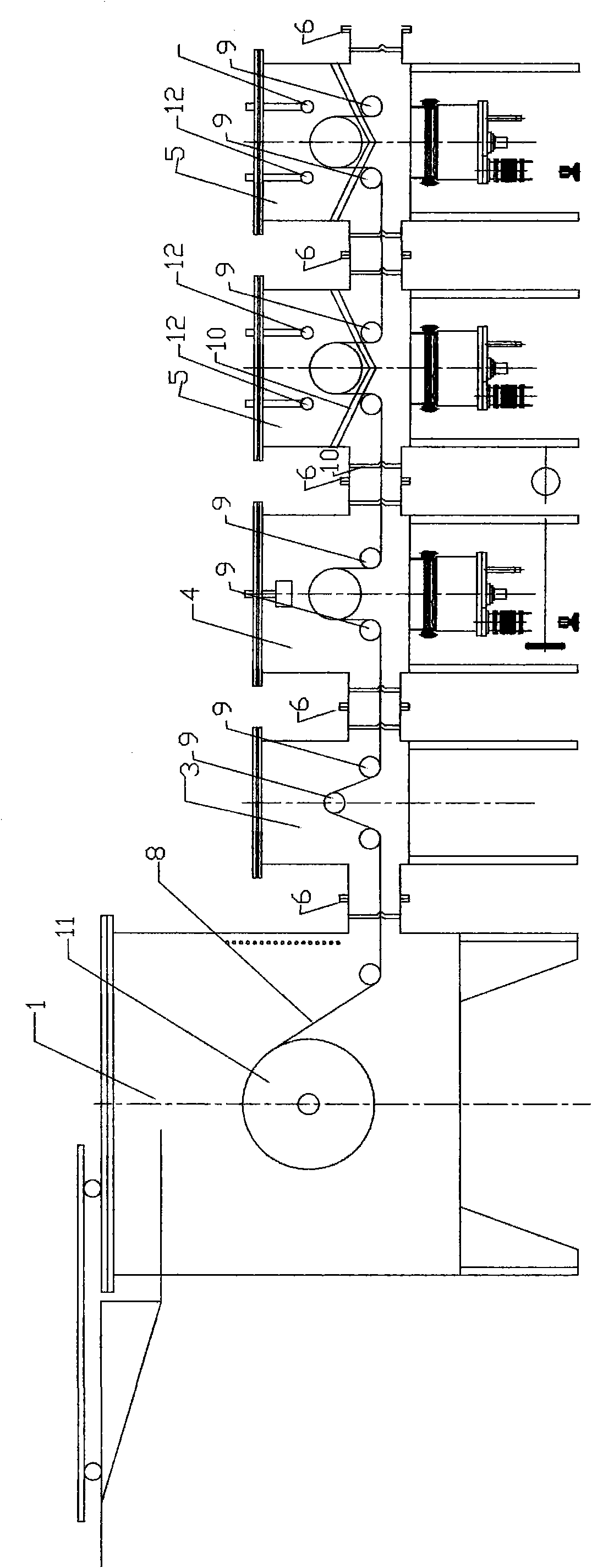

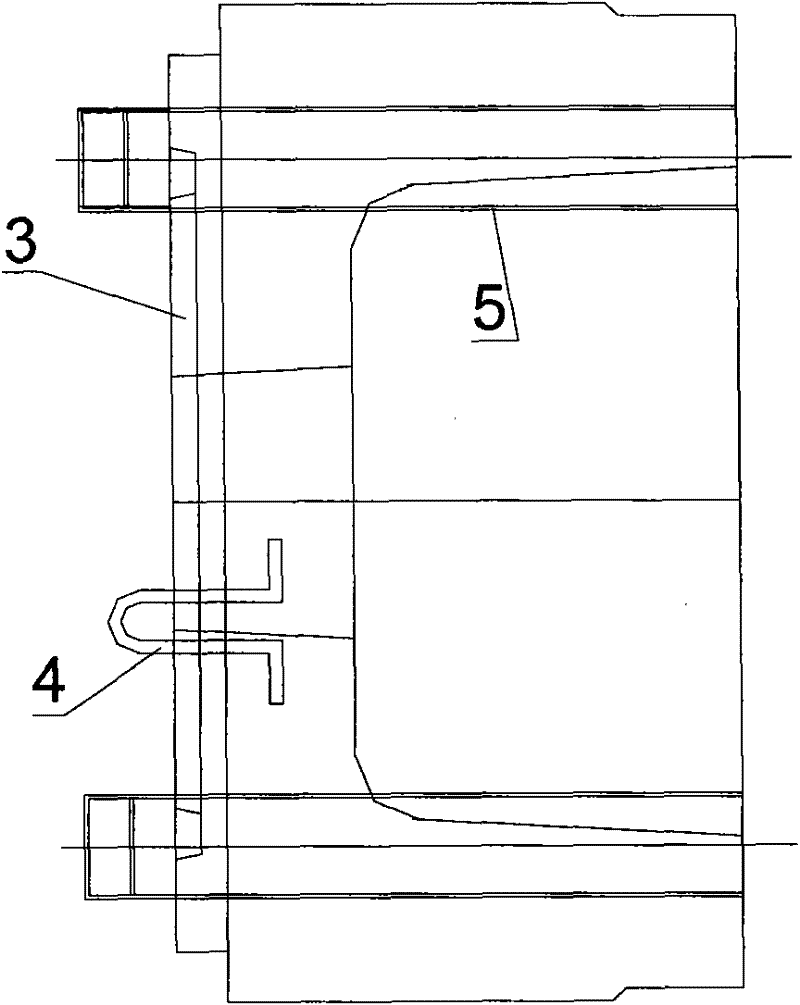

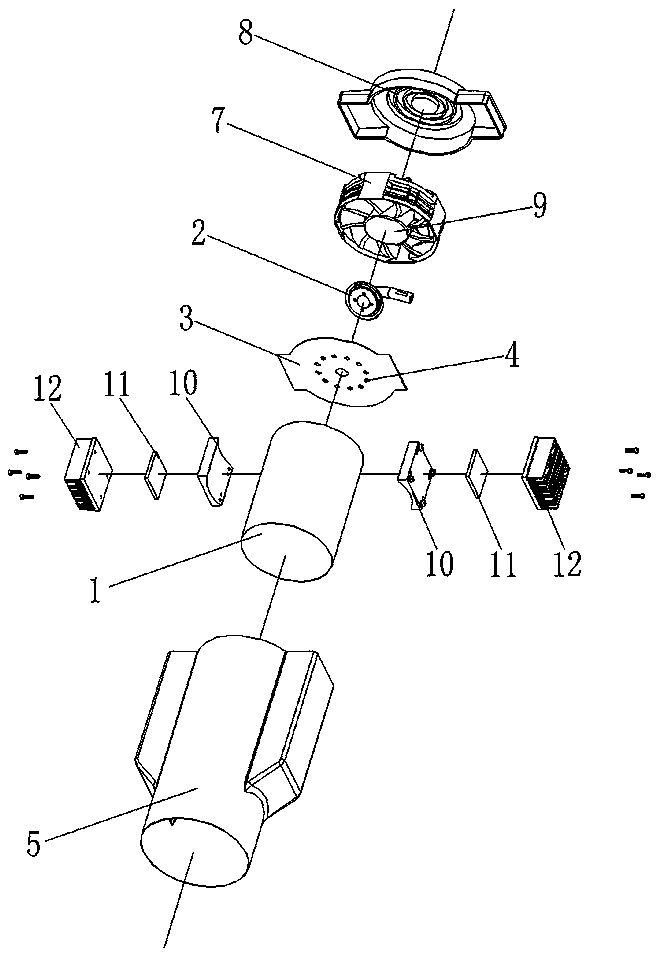

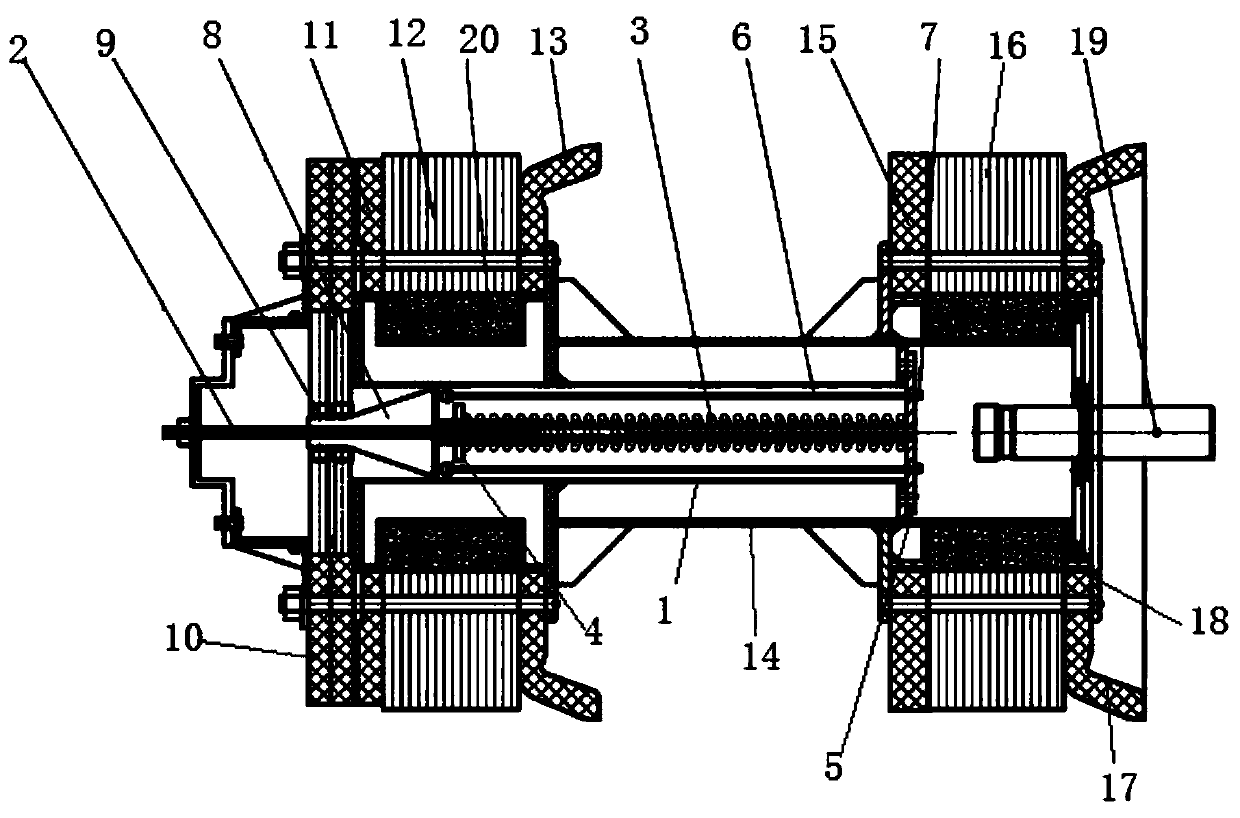

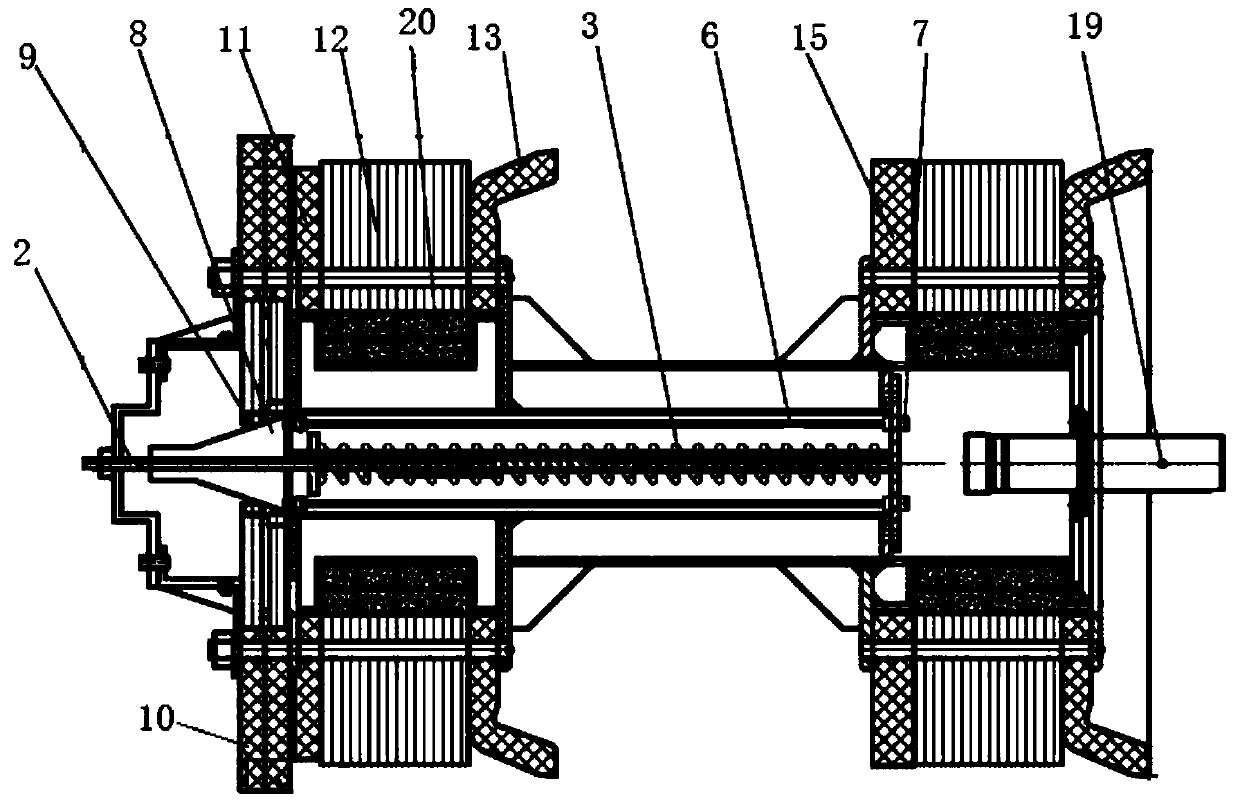

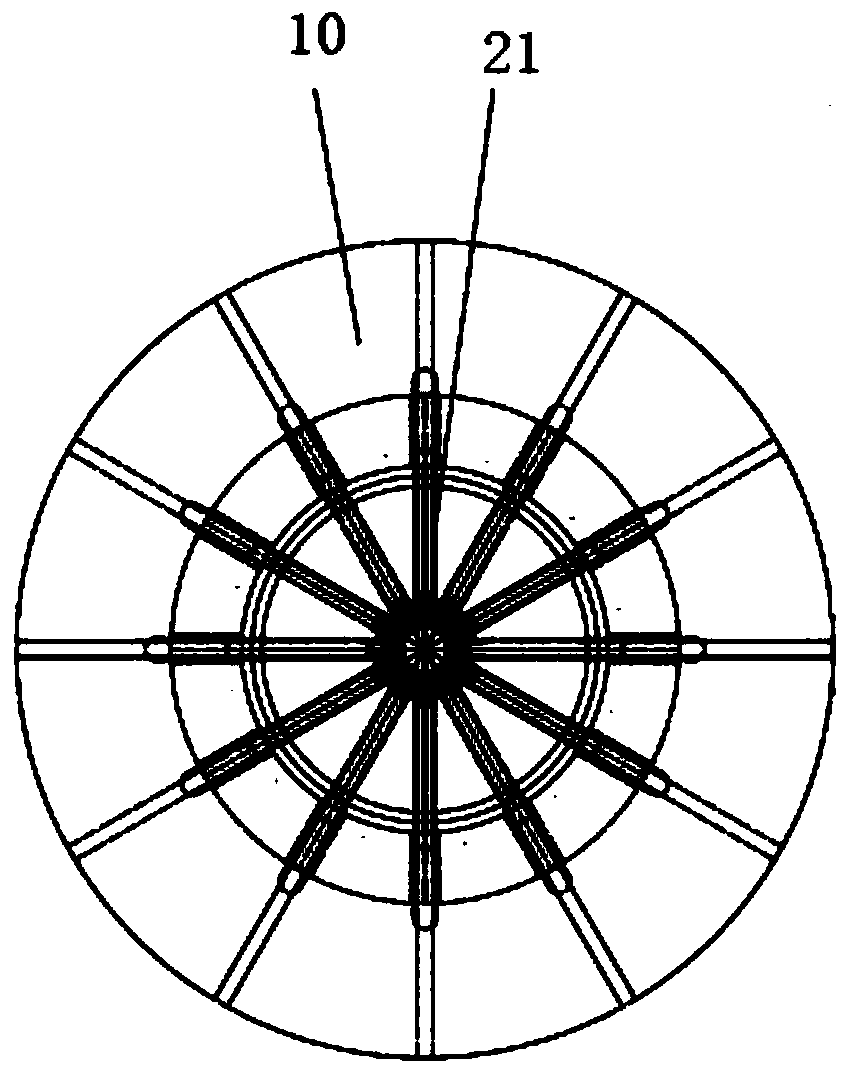

Continuous winding magnetic control sputtering vacuum coating device

InactiveCN101768726AComposable performancePrevent blowbyVacuum evaporation coatingSputtering coatingEngineeringControl room

The invention belongs to continuous coating device for solar selective absorption coating in plate-type solar apparatus, in particular relates to a continuous winding magnetic control sputtering vacuum coating device. The continuous winding magnetic control sputtering vacuum coating device comprises an unwinding chamber, a winding chamber, tension controlling chambers, a pre-processing chamber and craft chambers; the unwinding chamber and the winding chamber are respectively arranged at the head and tail ends of the device and respectively connected with a tension controlling chamber; the tension controlling chamber at one end of the unwinding chamber is connected with the pre-processing chamber; at least one craft chamber is arranged between the pre-processing chamber and the tension controlling chamber at one end of the winding chamber; one end of unwinding chamber, one end of winding chamber, two ends of tension controlling chambers, two ends of pre-processing chamber, and two endsof craft chambers are provided with flange plates of the same dimension, the unwinding chamber, the winding chamber, the tension controlling chambers, the pre-processing chamber and the craft chambers are connected into an integral by the flange plates. The invention provides a special coating device for long-term continuous solar selective absorption coating, and the device has the advantages ofhigh production efficiency, stable quality and outstanding film performance.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

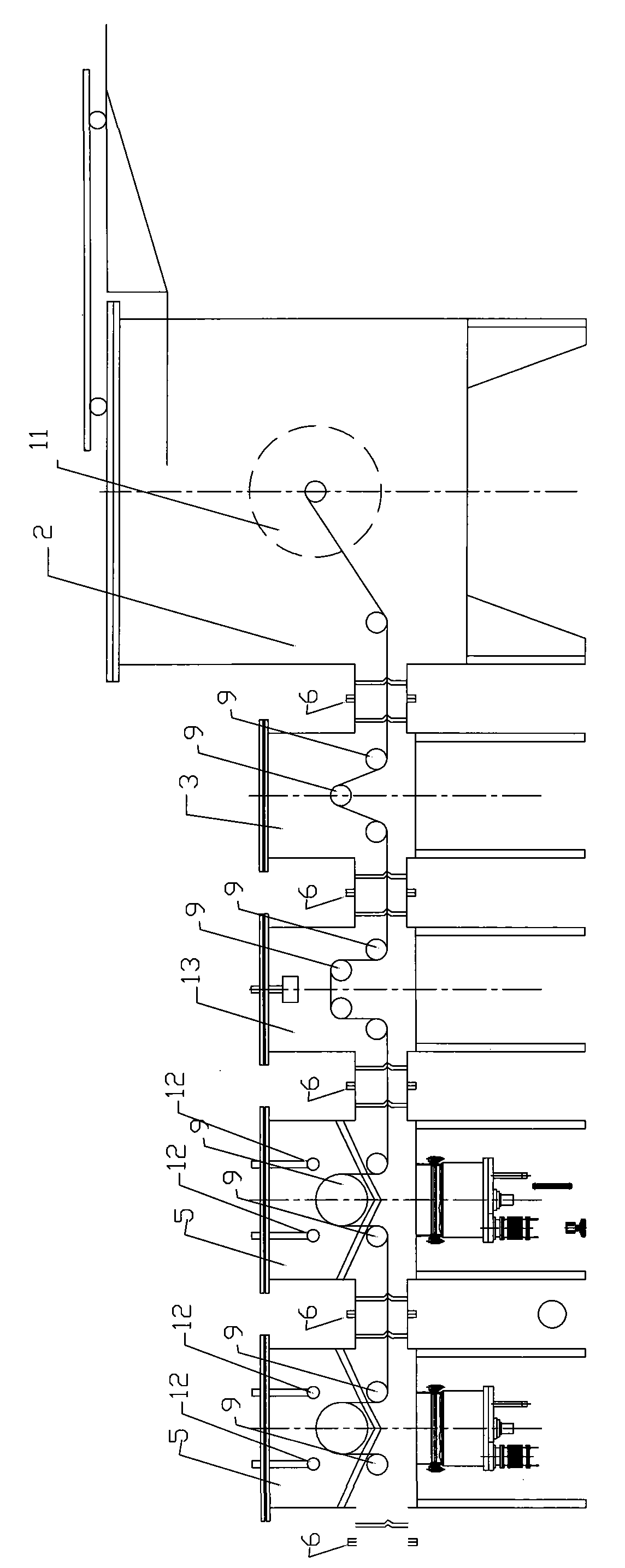

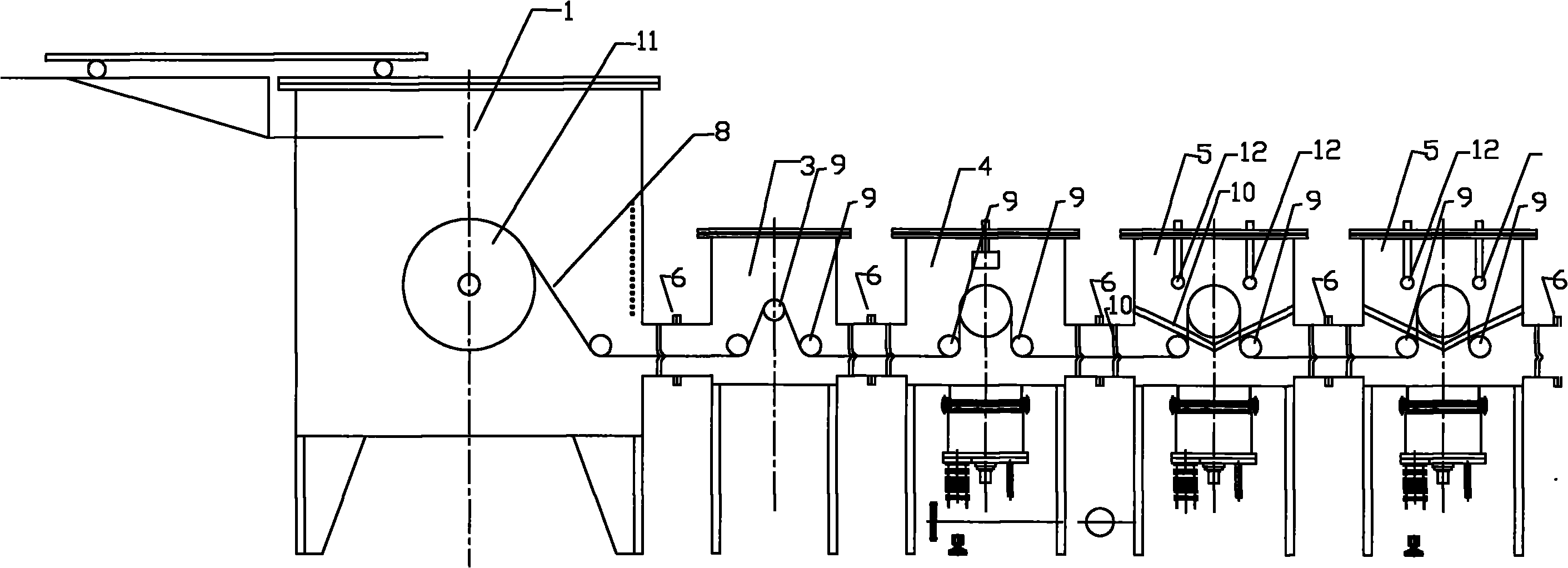

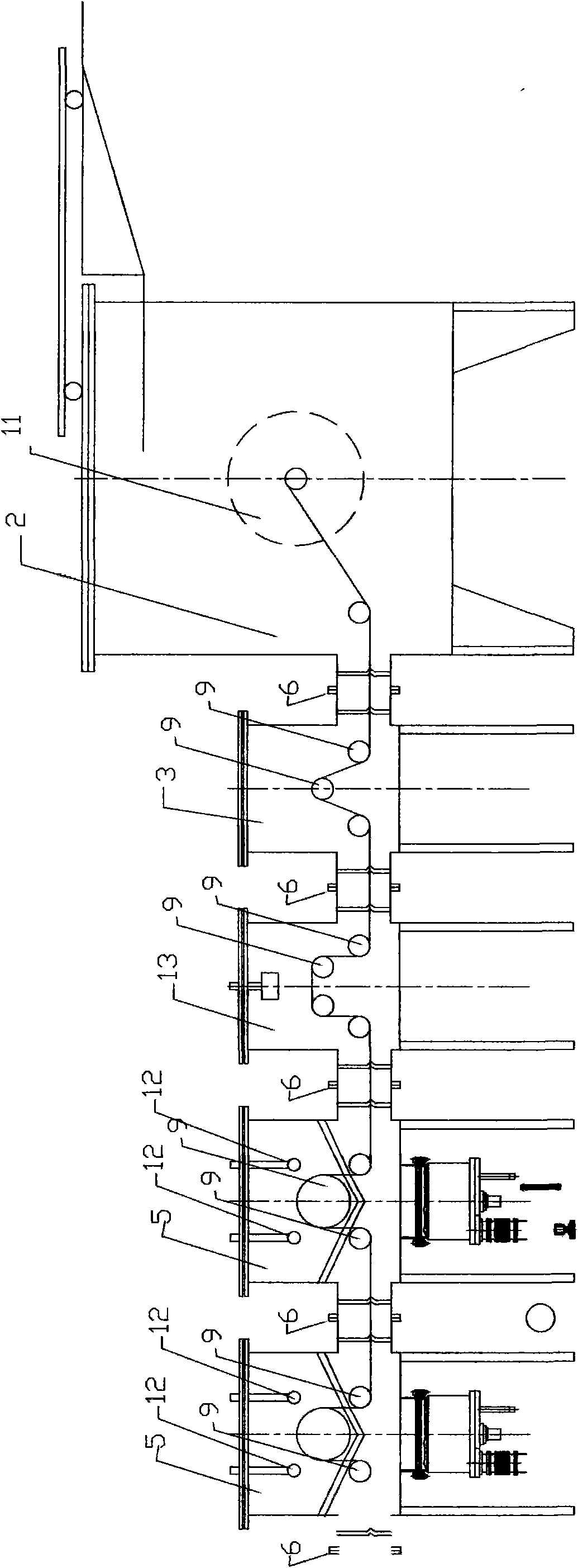

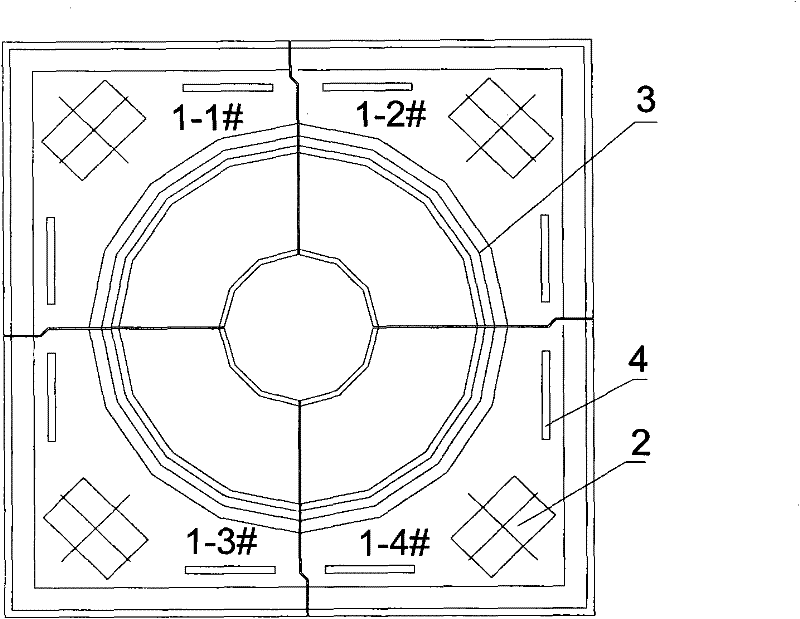

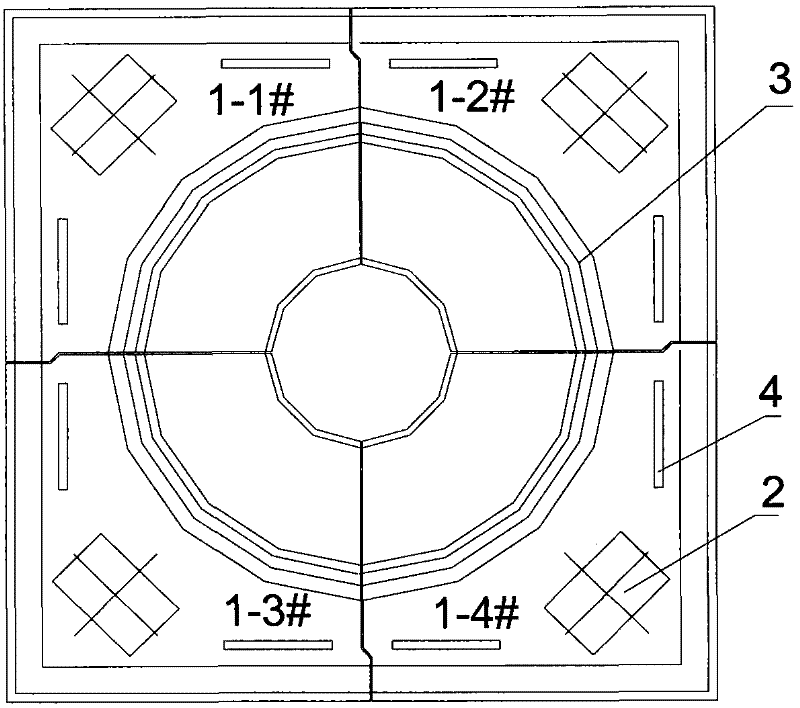

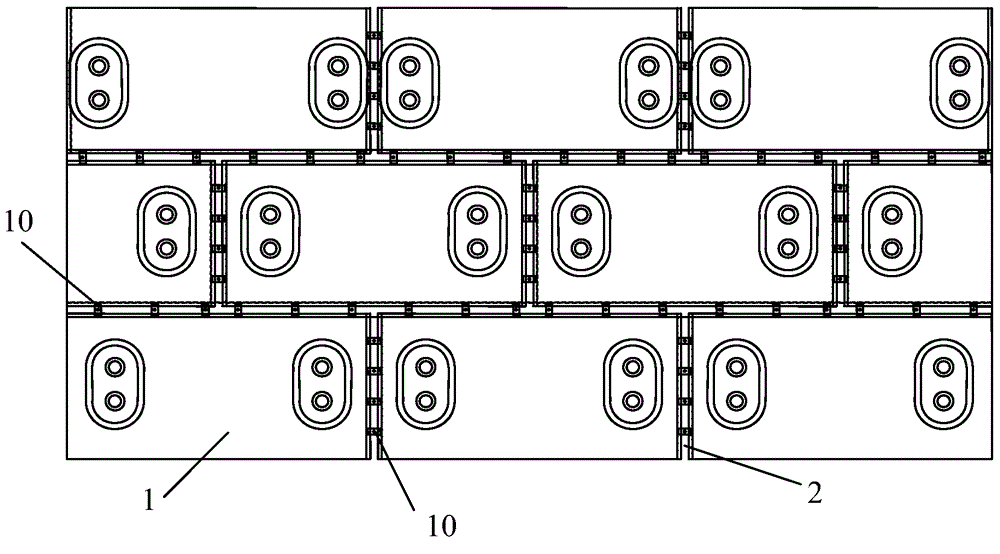

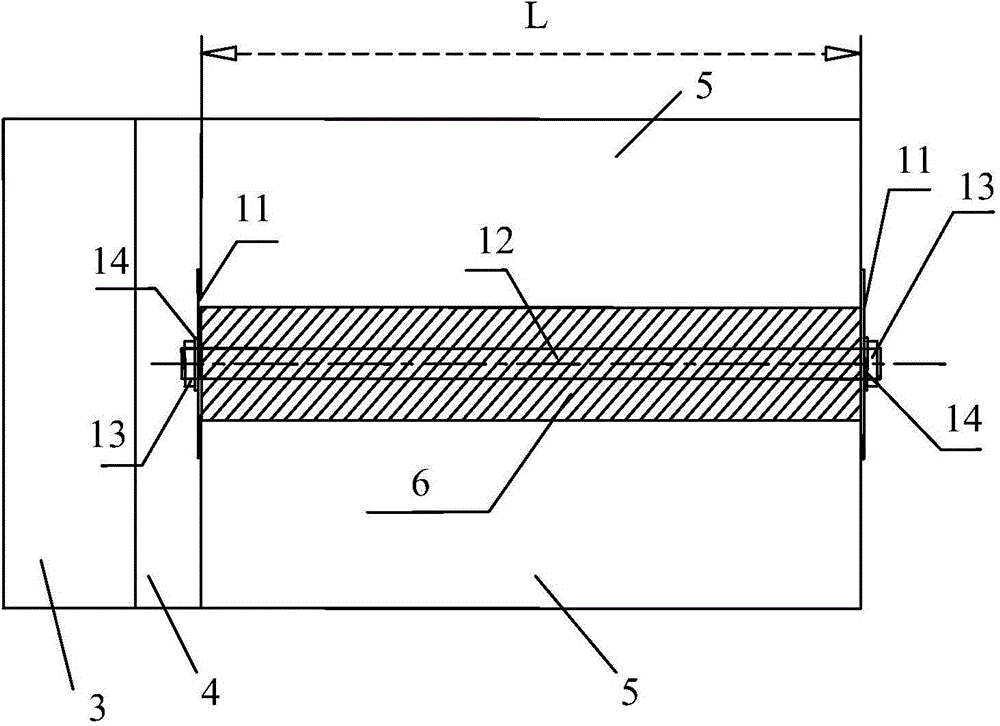

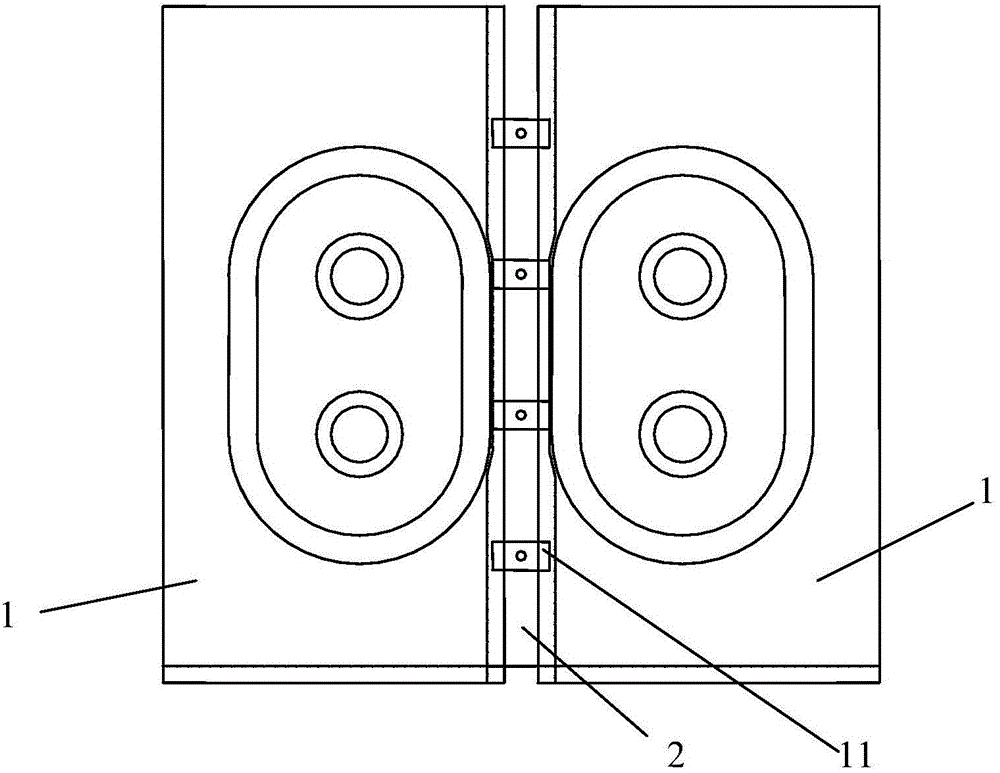

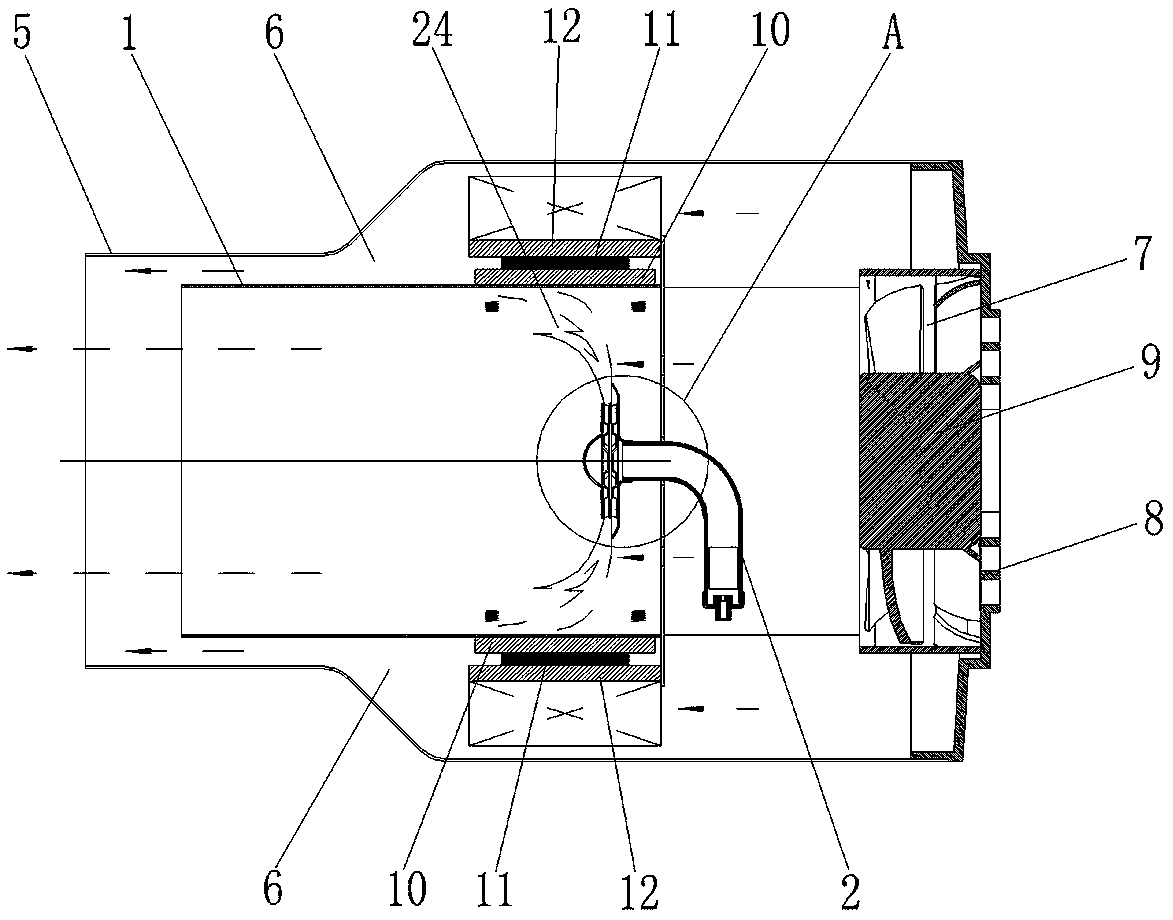

Modularization solar selective coat continuous coating device

InactiveCN101781754AFully playGuaranteed tightnessVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention belongs to the field of the heat collection plate coating in the solar equipment, and relates to a continuous solar selective absorption film coating production device which adopts the modularization design, can be flexibly assembled and adjusted and is applicable to different coating processes. The modularization solar selective coat continuous coating device comprises a pretreatment chamber and at least one process chamber, wherein both the pretreatment chamber and the process chamber are provided with a vacuum pump, two ends of the pretreatment chamber and the process chamber are respectively provided with a feeding port and a discharging port, both the feeding port and the discharging port on two ends of the pretreatment chamber and the process chamber are provided with a connection device with the same size and shape or being matched with each other, and the pretreatment chamber and the process chamber are sequentially connected through the connection devices to form an integral continuous coating device. The invention can provide a novel coating production device which adopts the modularization design and realizes different production and processing technologies by reducing different process chambers or by adjusting the position of the process chambers in the production line.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

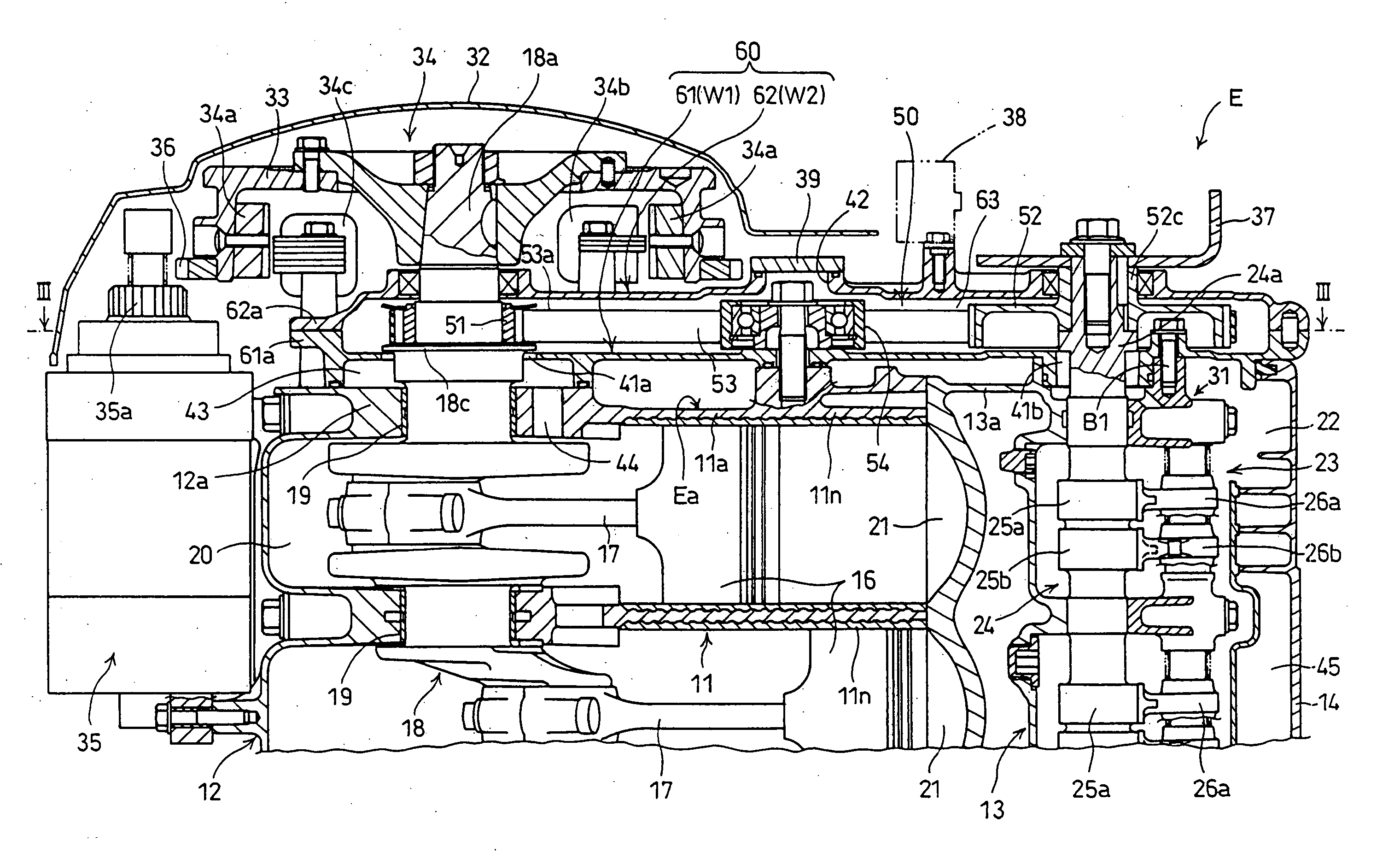

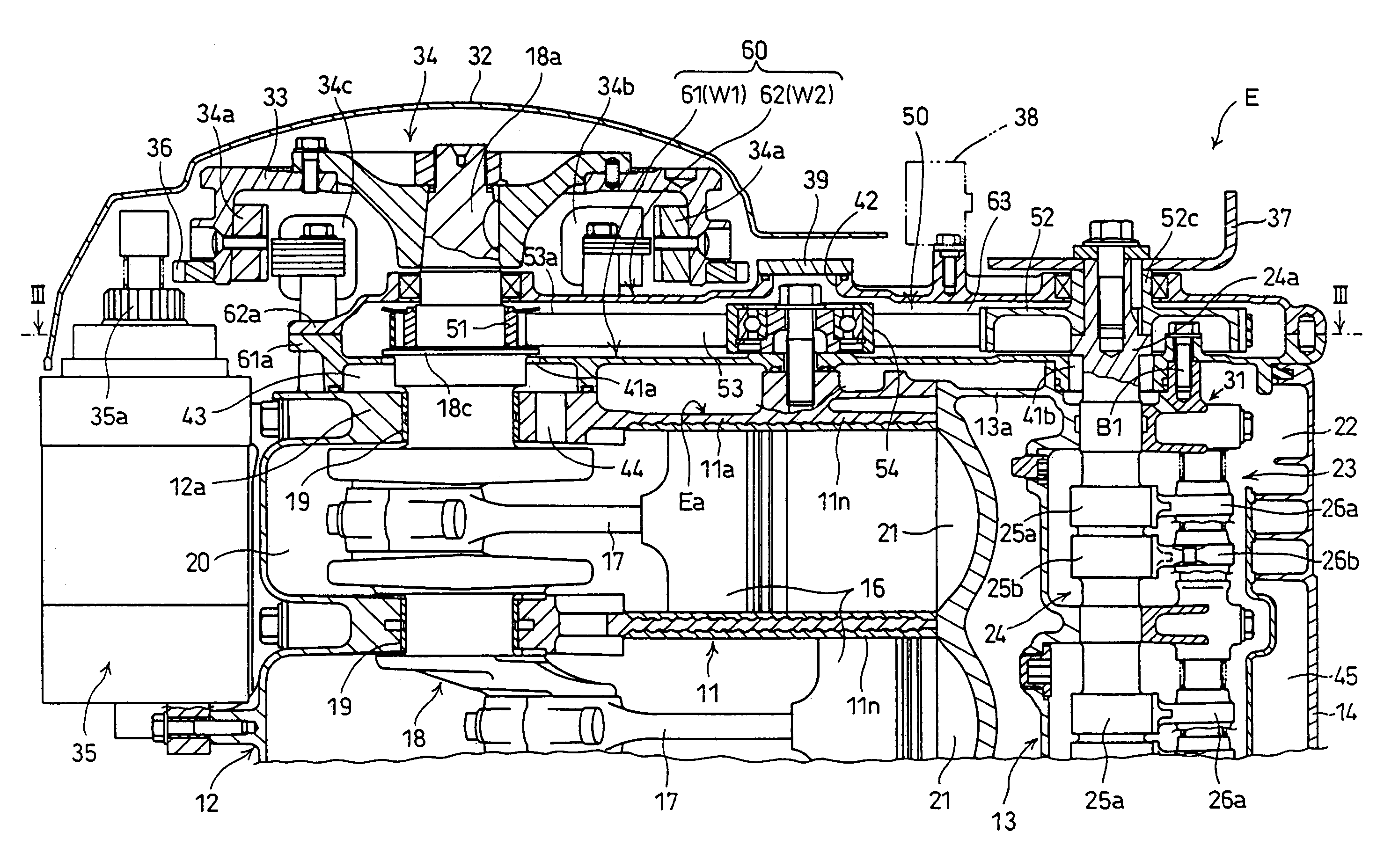

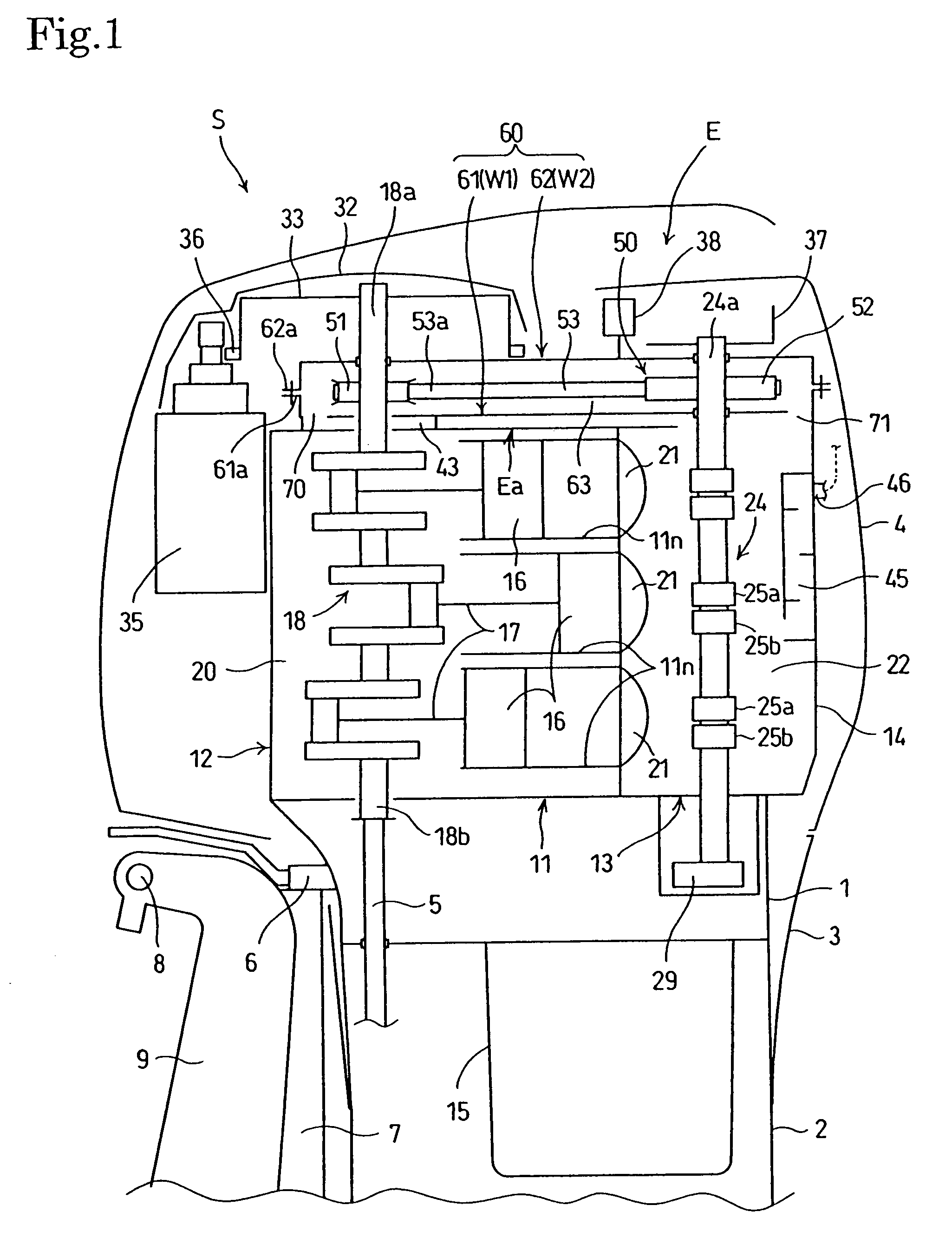

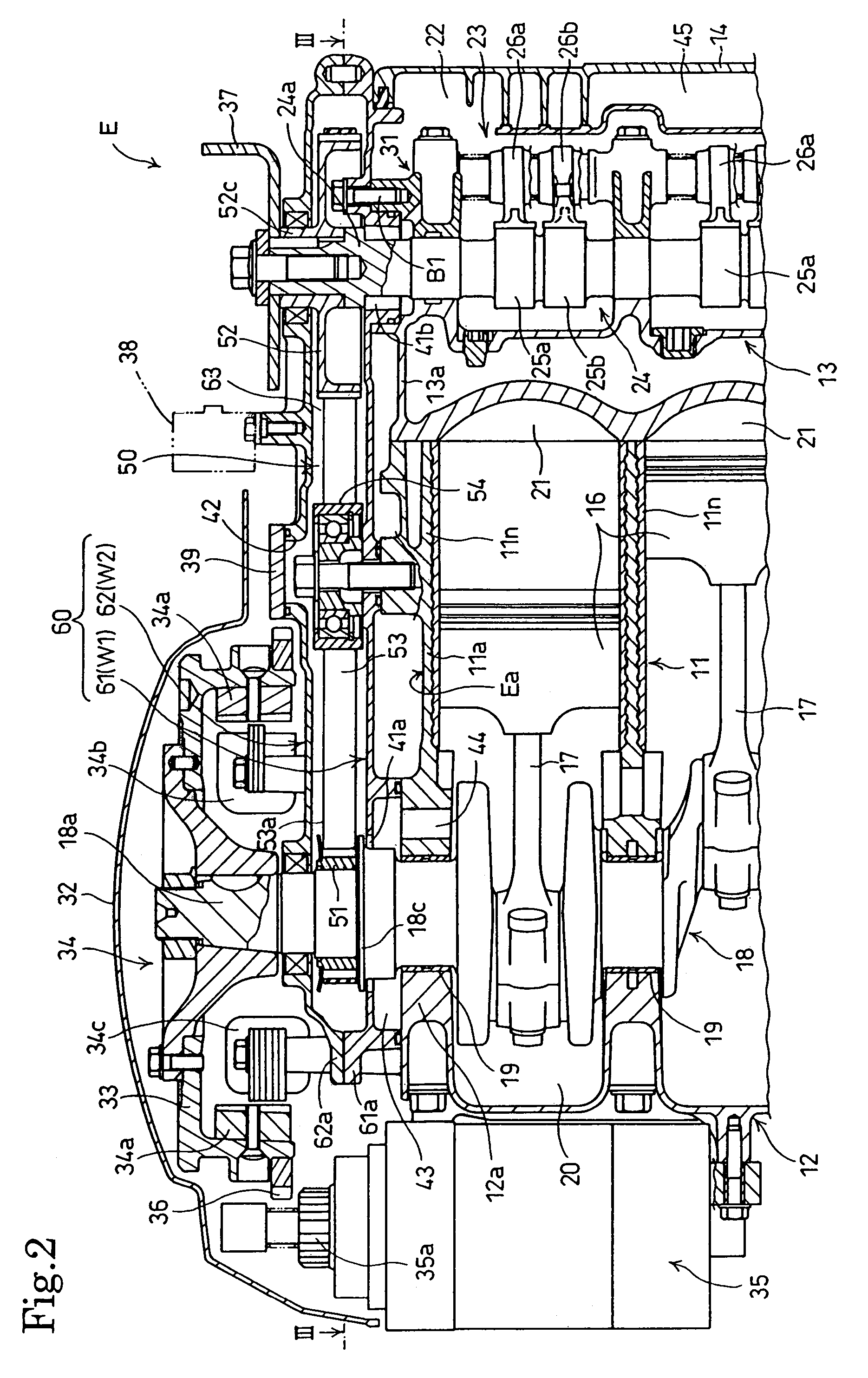

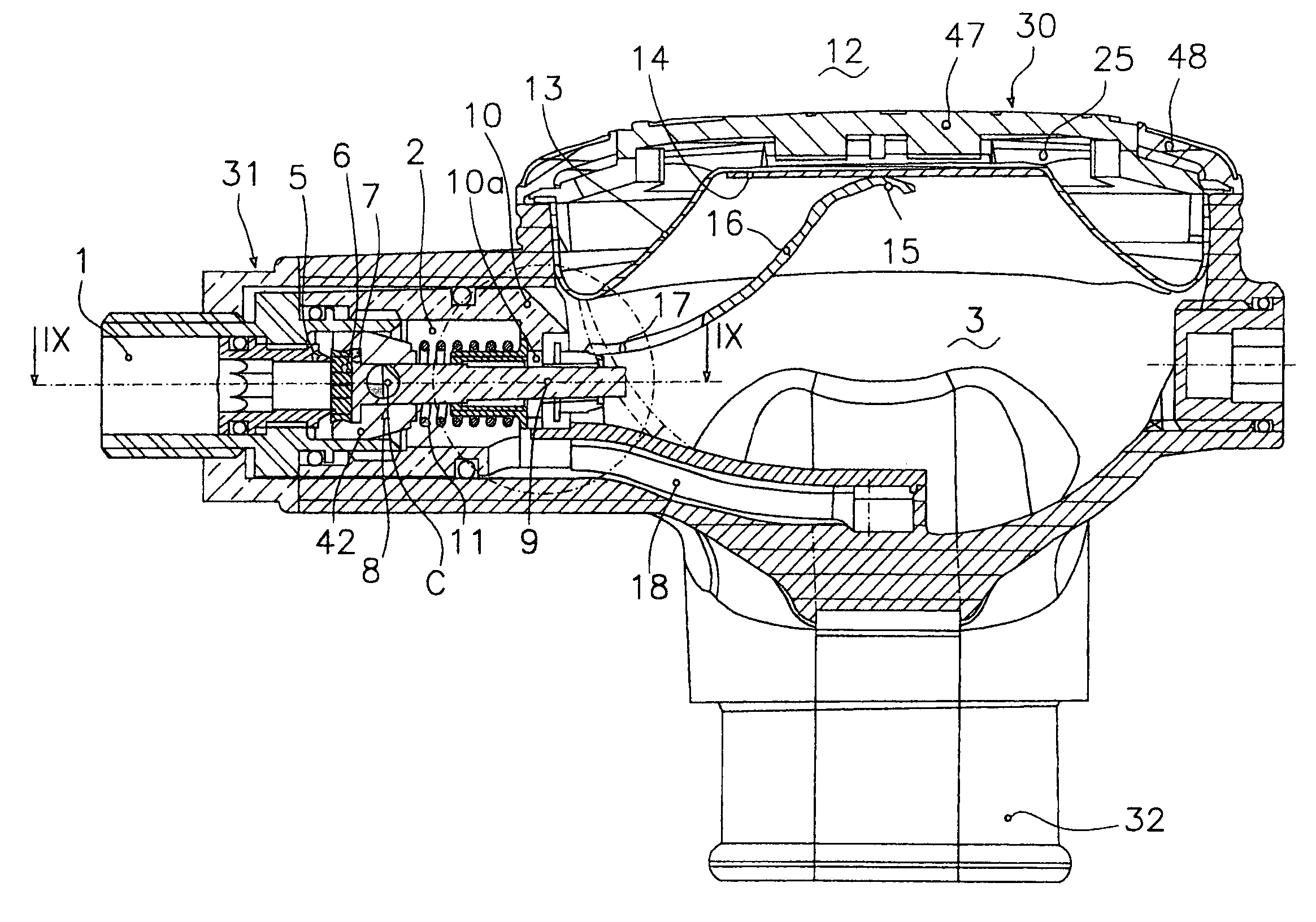

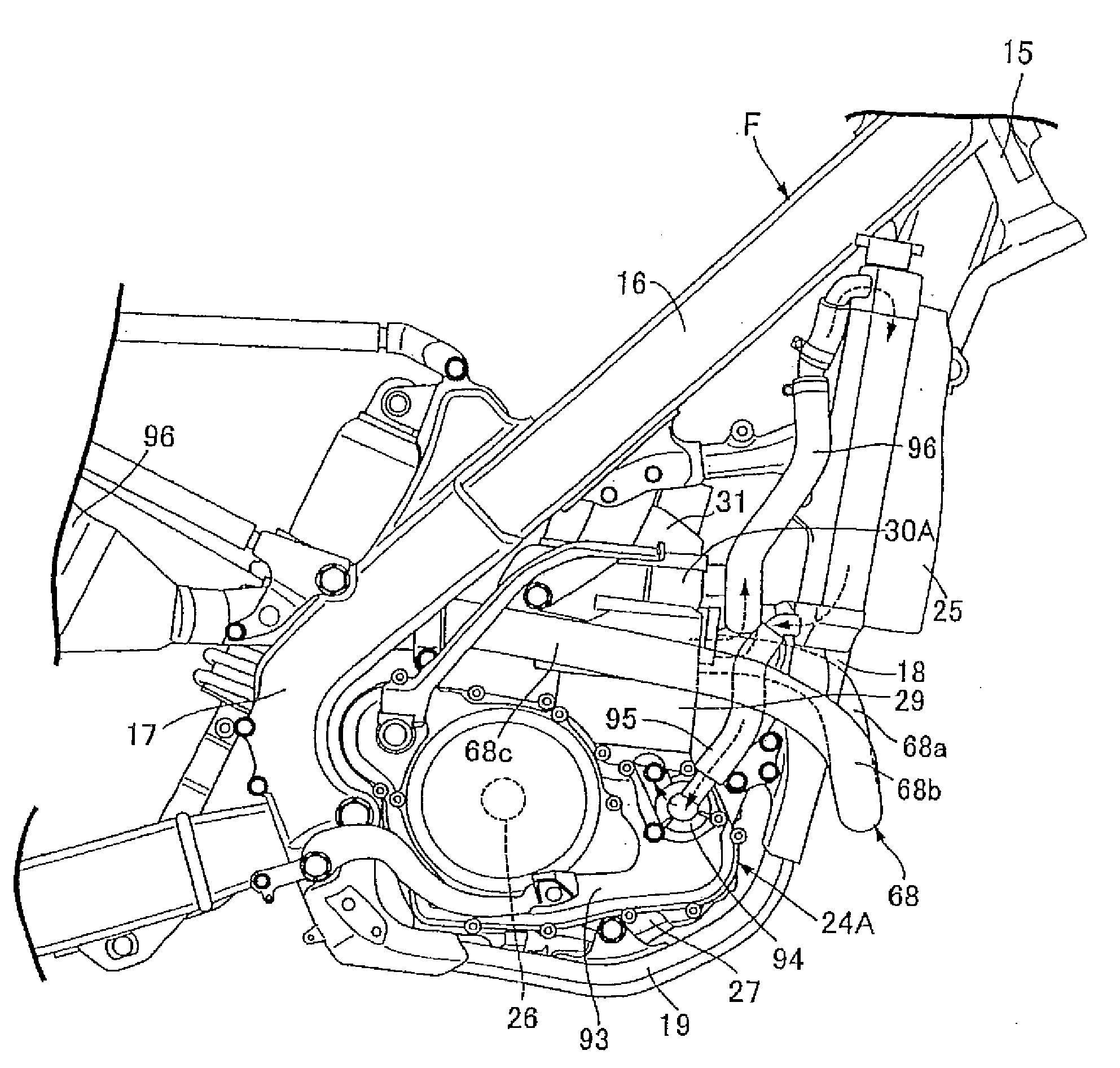

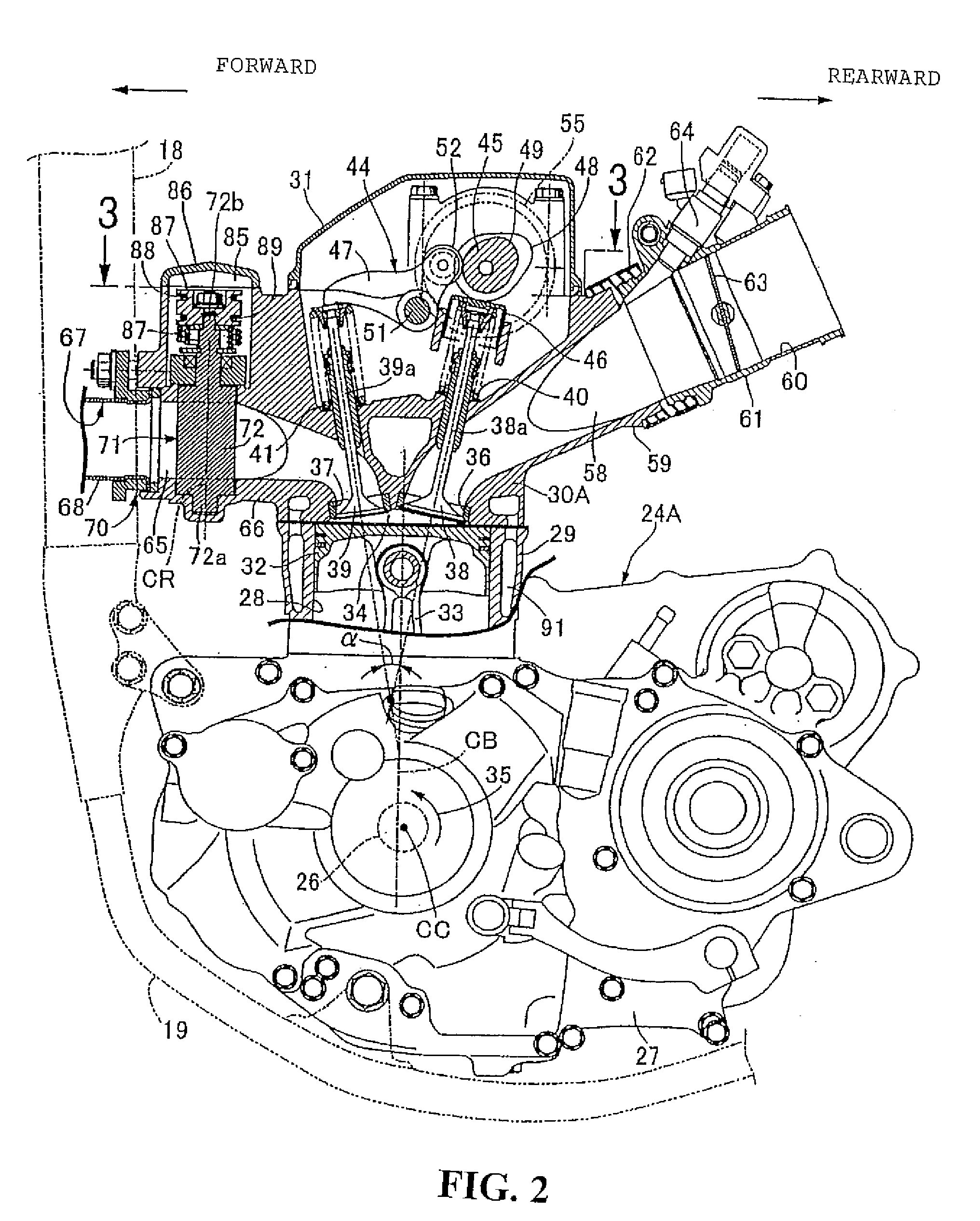

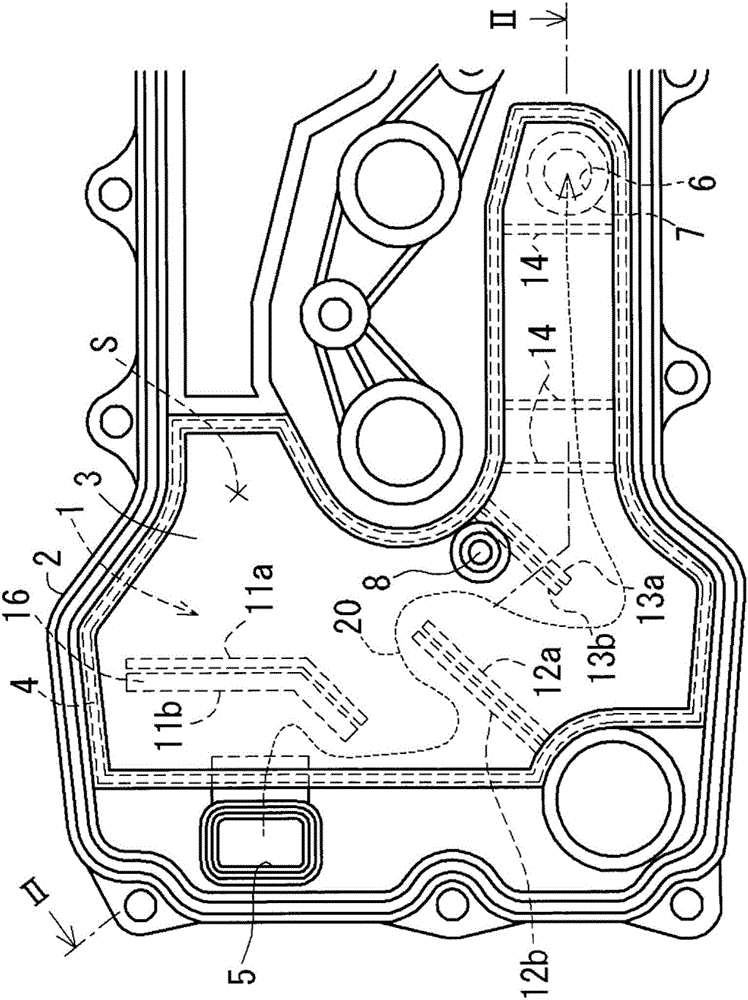

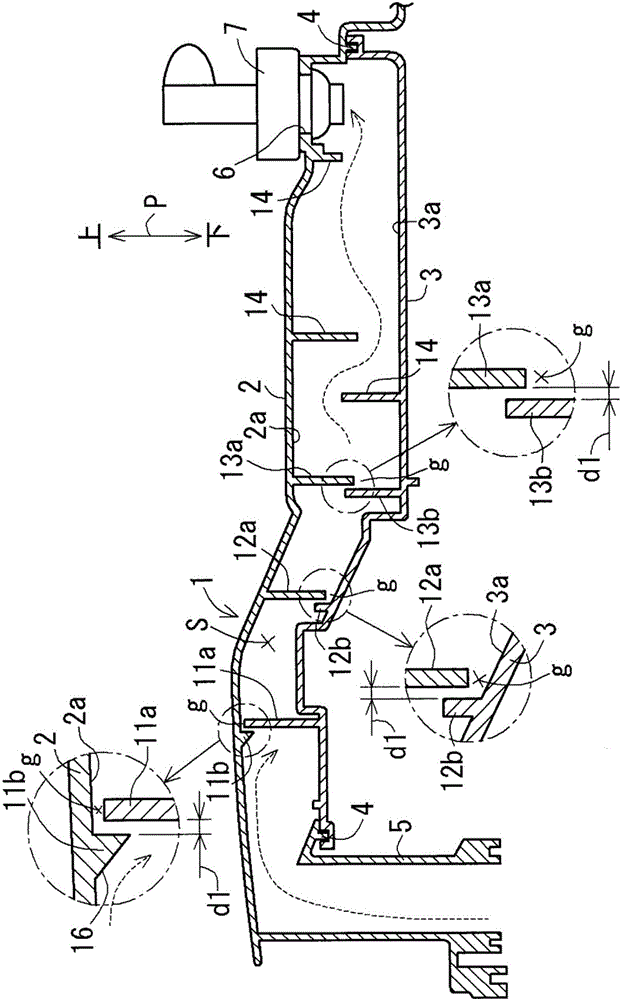

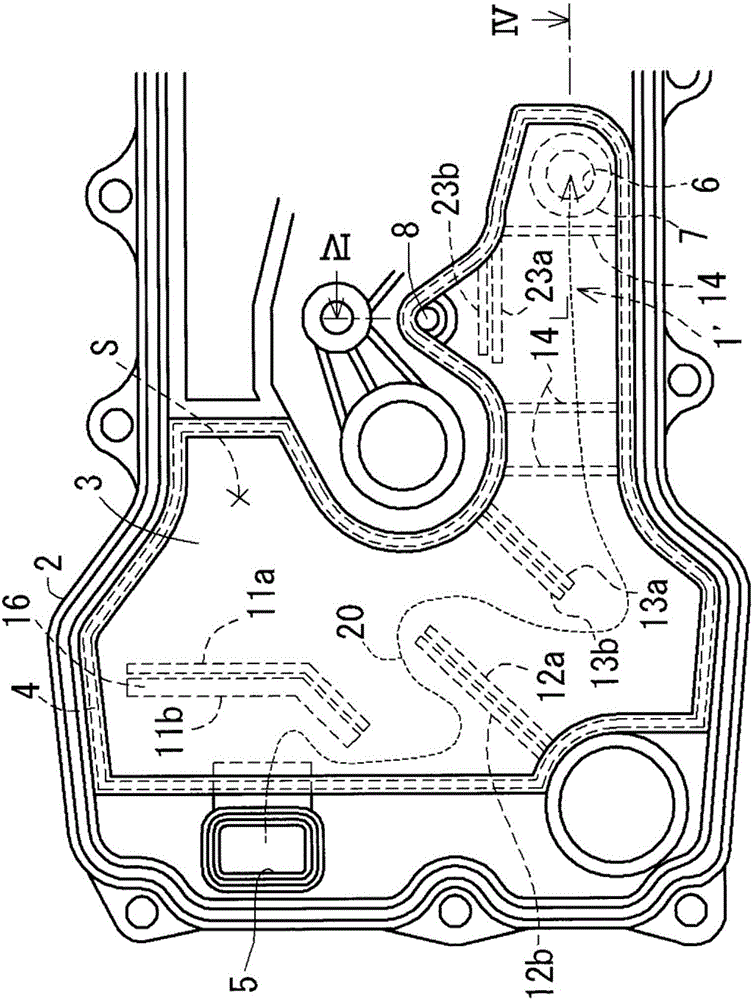

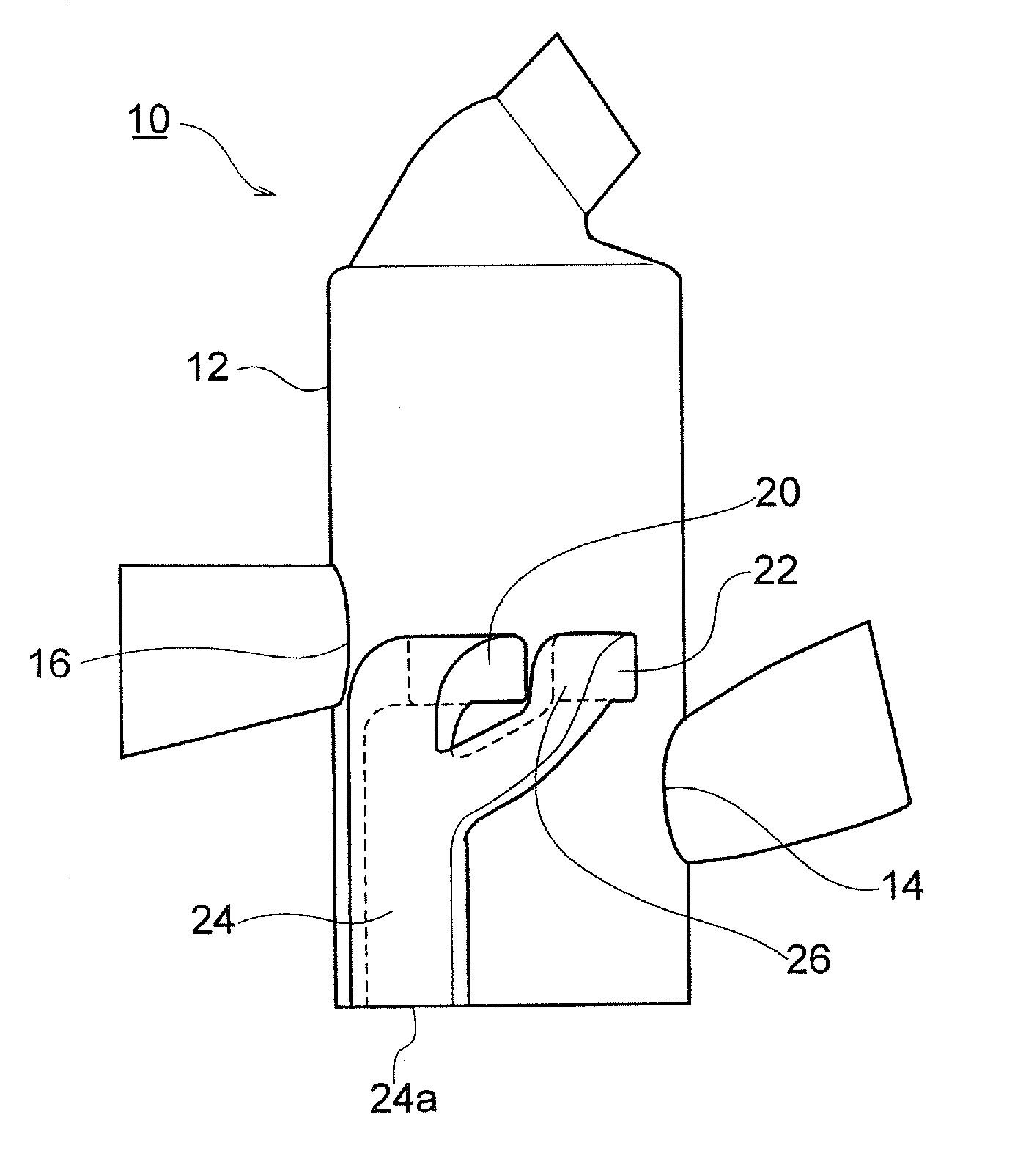

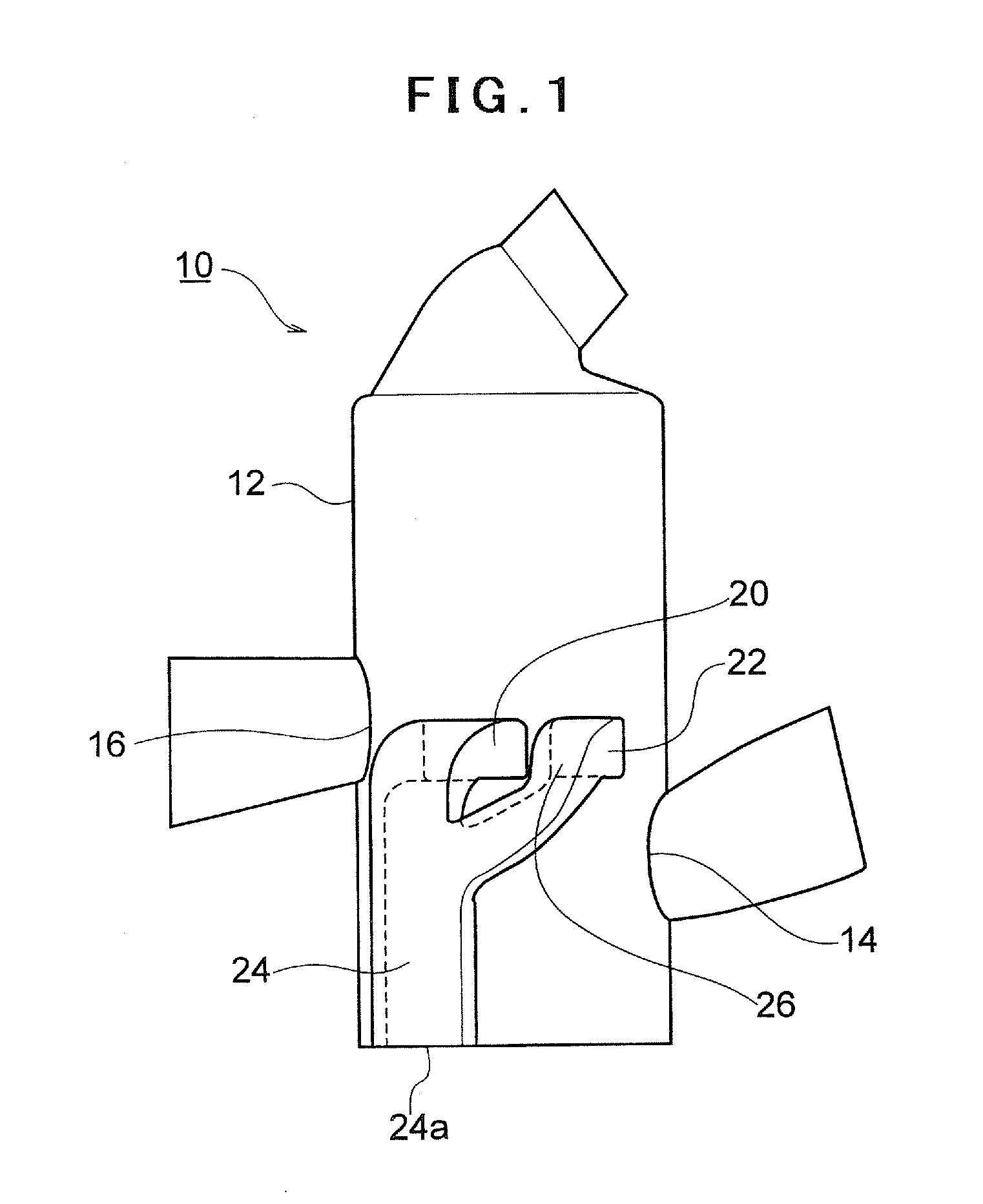

Vertical internal combustion engine provided with belt-drive transmission mechanism

InactiveUS20070251479A1Avoid contactProlong lifeLubrication of auxillariesGearboxesTransmitted powerEngineering

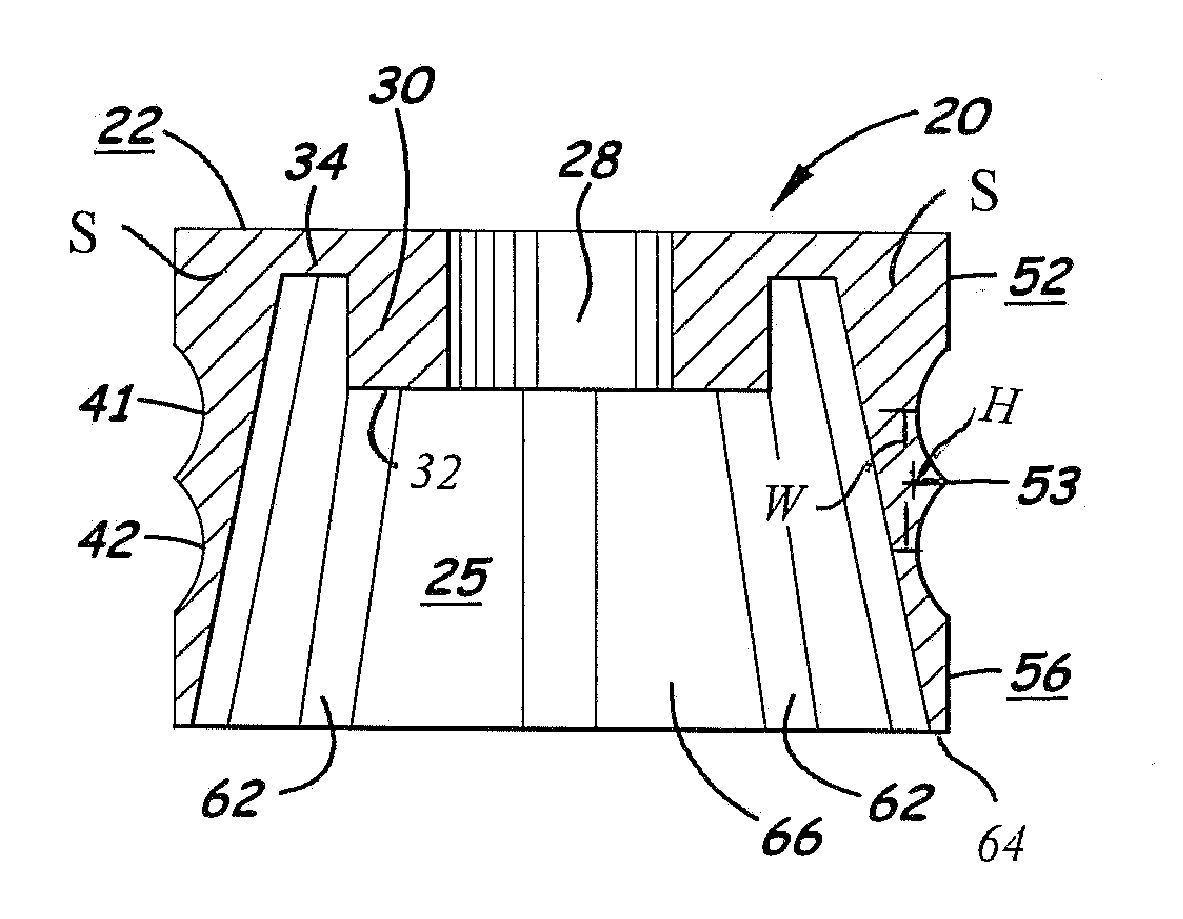

A vertical internal combustion engine E includes a crankshaft 18 enclosed in a crank chamber 20, a belt-drive transmission mechanism 50 held in a belt chamber 63 and including a rubber belt 53 for transmitting power of the crankshaft 18 to a camshaft 24 included in a valve train 23, and a transmission case 60 defining the belt chamber 63. The transmission case 60 has a lower case 61 between the crank chamber 20 and the belt chamber 63. The belt 53 has a part 53a extending over the crank chamber 20, and the lower case 61 is disposed to screen the part 53a of the belt 53 from the crank chamber 20. The belt 53 is lubricated by oil in oil-containing gas from the crank chamber 20. Thus the oil-containing gas is prevented from excessively contacting the rubber belt, so that the life of the belt is extended.

Owner:HONDA MOTOR CO LTD

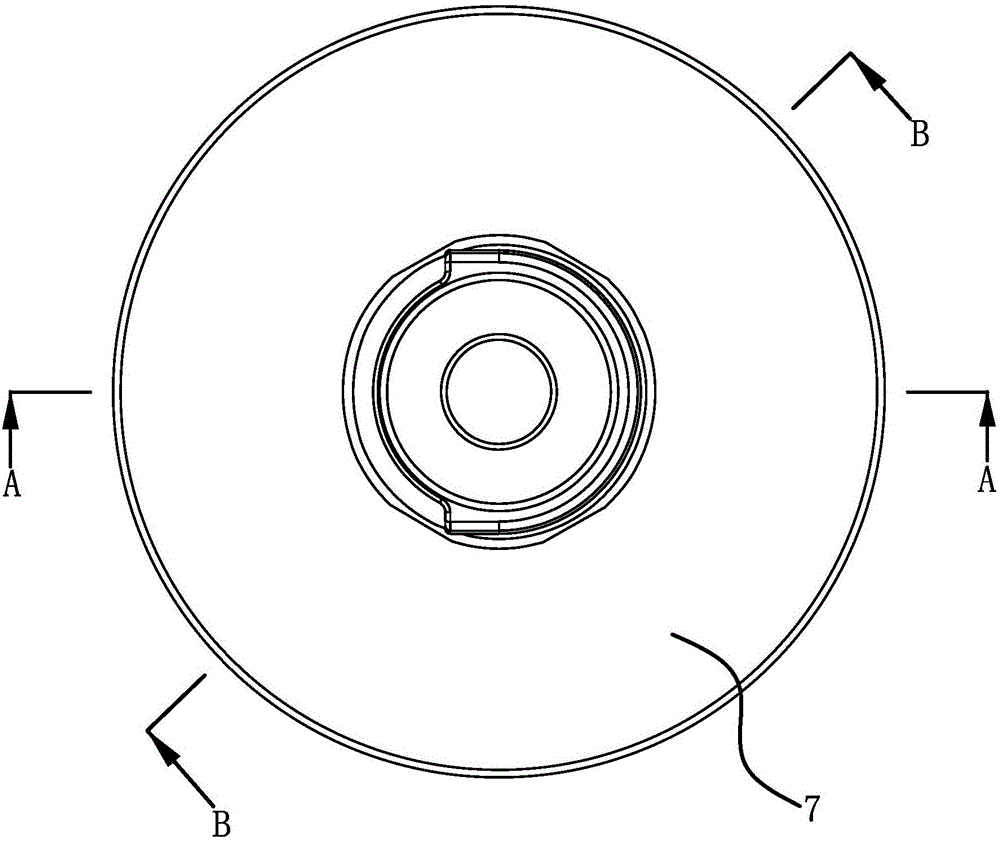

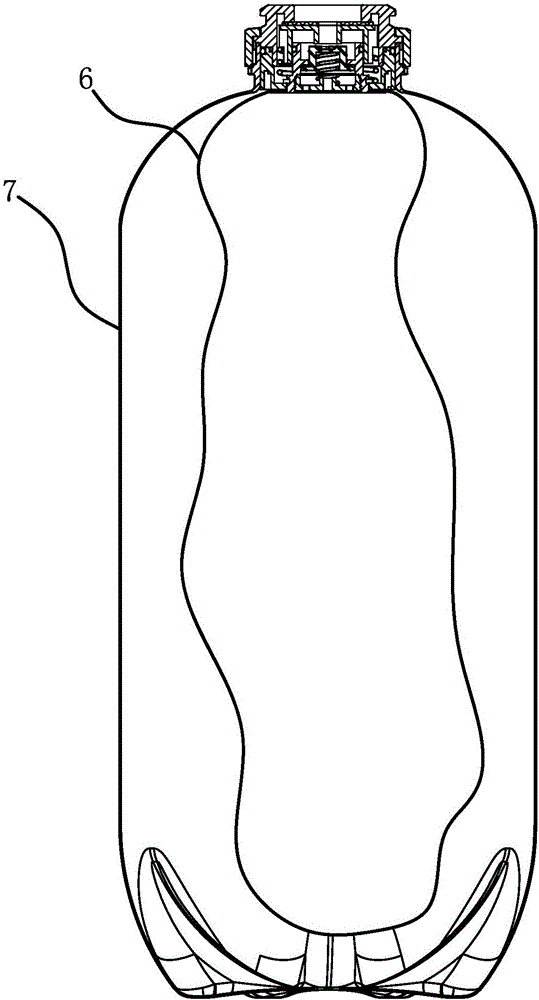

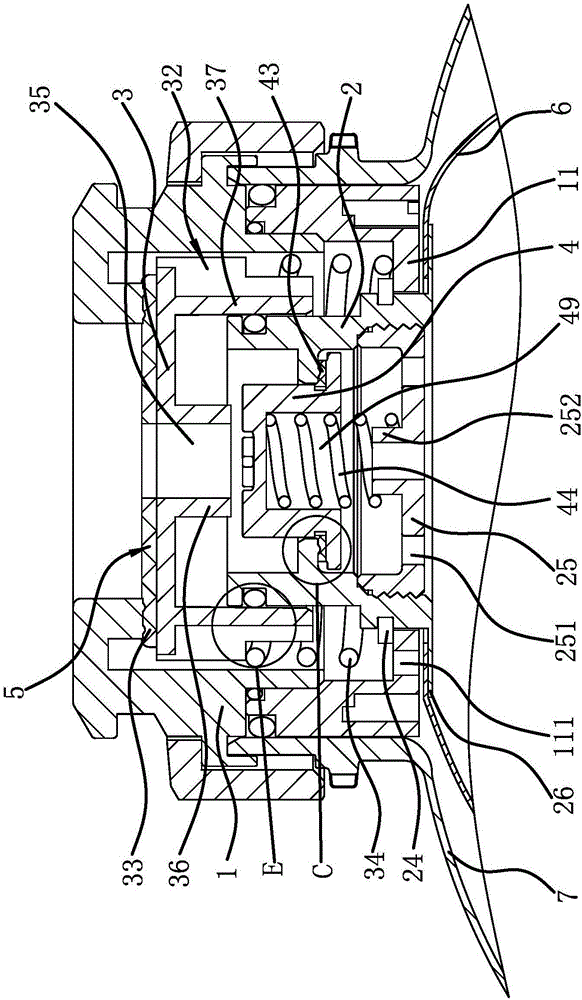

Beer spear

The invention provides a beer spear, and belongs to the technical field of beer drinking equipment. The problem of poor sealing performance of an existing beer spear is solved. The beer spear comprises a valve body. A fixing seat is connected inside the valve body. The upper end of the fixing seat is sleeved with a valve seat in a sliding mode. An air inlet passage is formed between the outer wall of the valve seat and the inner wall of the valve body. A spring I which enables the valve seat to move upwards and abut against the valve body to seal the air inlet passage is arranged in the valve body. A valve element is arranged in the fixing seat in a sliding mode. A beer outlet passage is formed between the outer wall of the valve element and the inner wall of the fixing seat. A spring II is arranged in the fixing seat. The valve element abuts against the fixing seat to form sealing under the action of the spring II. The valve seat is provided with a contact portion protruding downwards, or the valve element is provided with a contact portion protruding upwards. When the valve seat moves downwards to open the air inlet passage, the valve seat enables the valve element to move downwards to open the beer outlet passage through the contact portion. The beer spear has good sealing performance.

Owner:TALOS TECH CORP

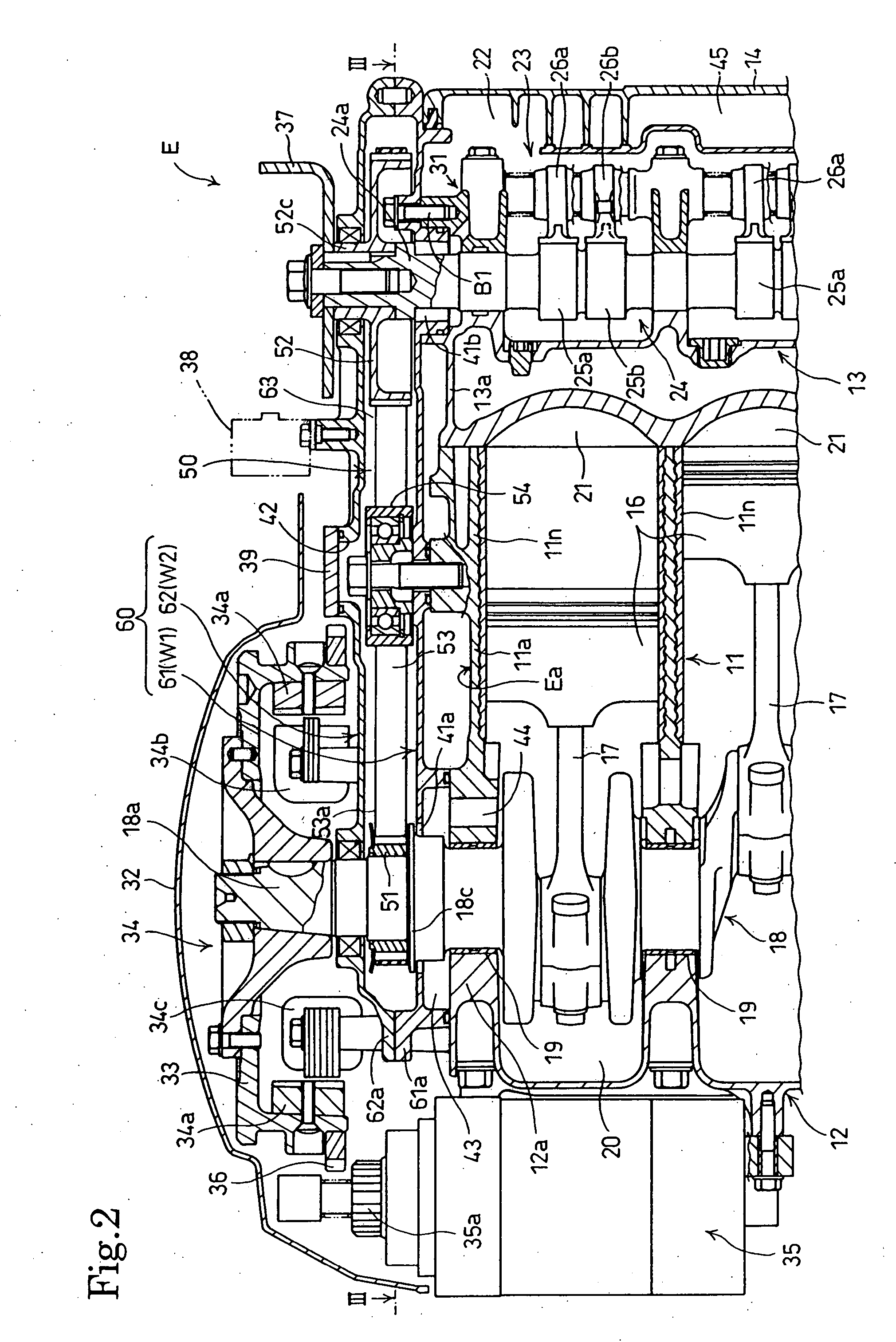

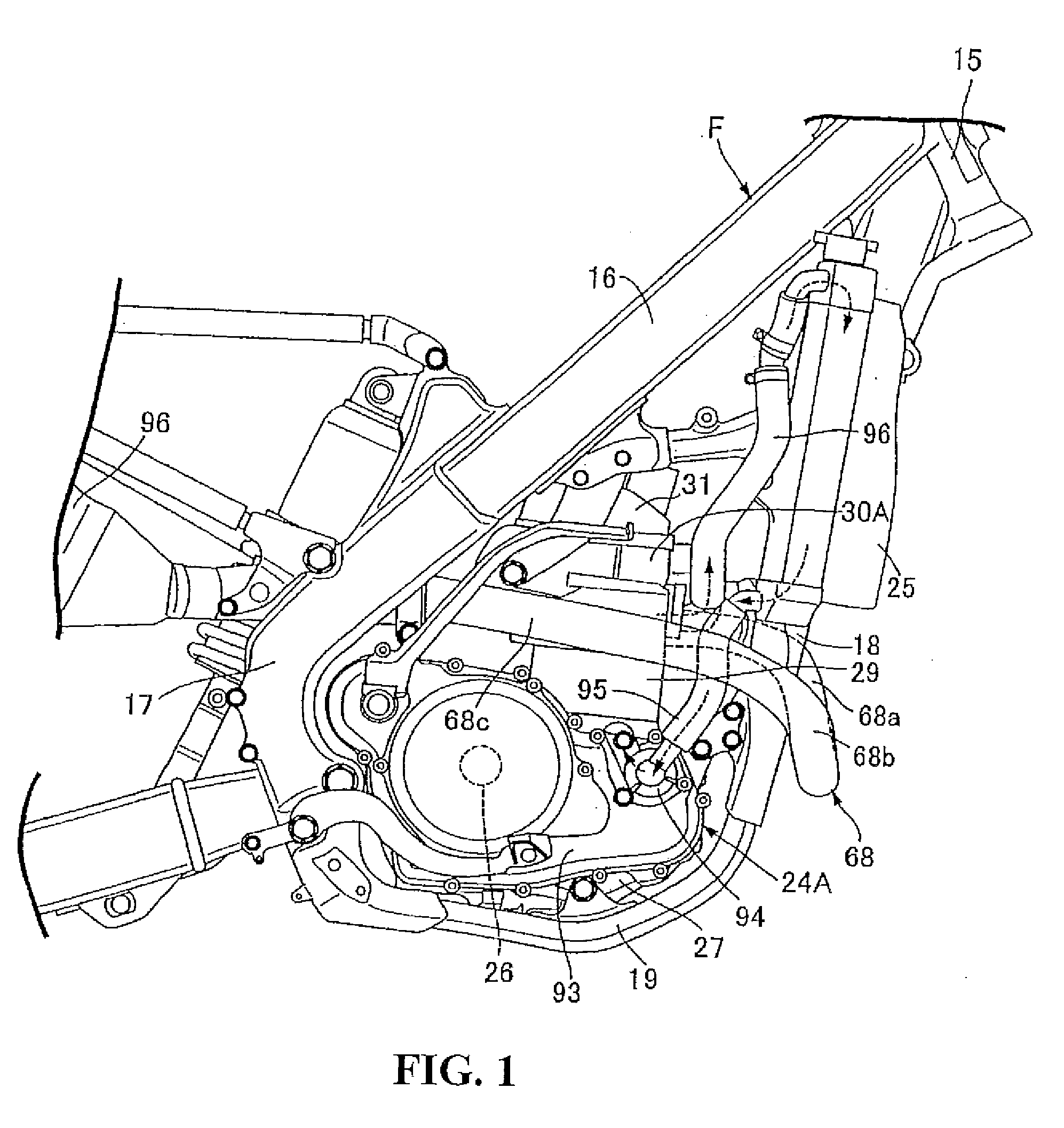

Vertical internal combustion engine provided with belt-drive transmission mechanism

InactiveUS7704174B2Avoid contactProlong lifePower plants using condensersCasingsTransmitted powerInternal combustion engine

A vertical internal combustion engine includes a crankshaft enclosed in a crank chamber, a belt-drive transmission mechanism held in a belt chamber and including a rubber belt for transmitting power of the crankshaft to a camshaft included in a valve train, and a transmission case defining the belt chamber. The transmission case has a lower case between the crank chamber and the belt chamber. The belt has a part extending over the crank chamber, and the lower case is disposed to screen the part of the belt from the crank chamber. The belt is lubricated by oil in oil-containing gas from the crank chamber. Thus the oil containing gas is prevented from excessively contacting the rubber belt, so that the life of the belt is extended.

Owner:HONDA MOTOR CO LTD

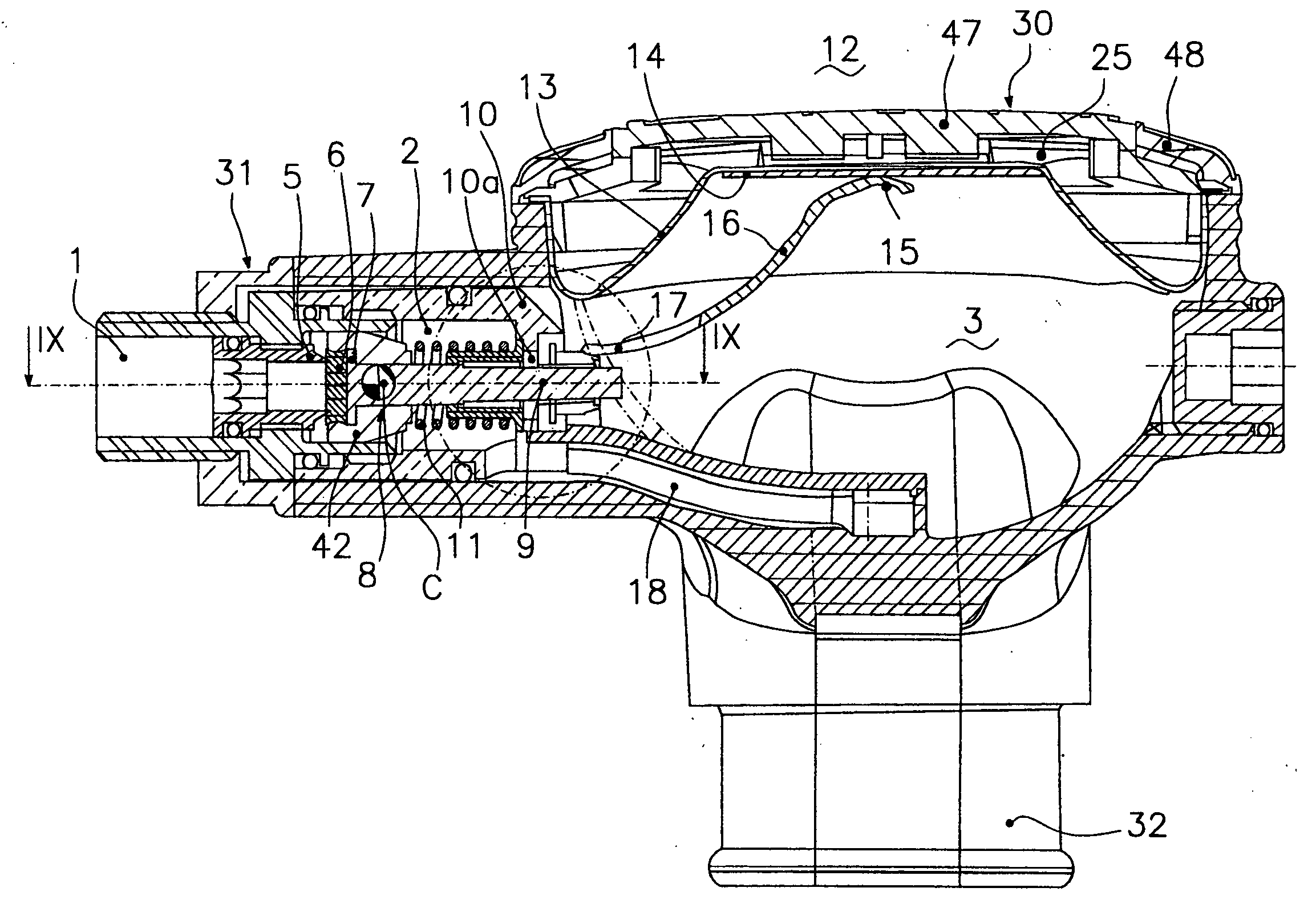

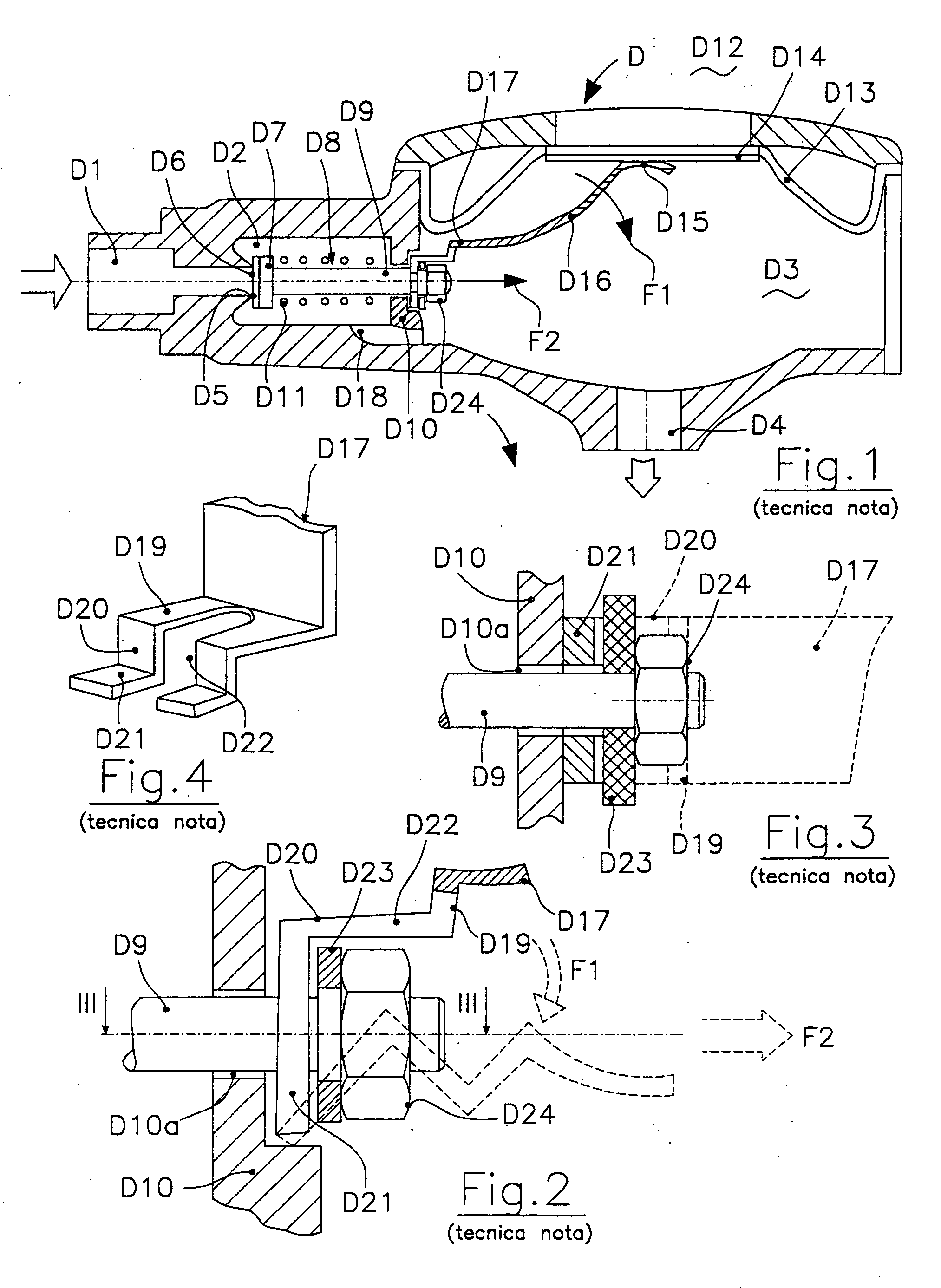

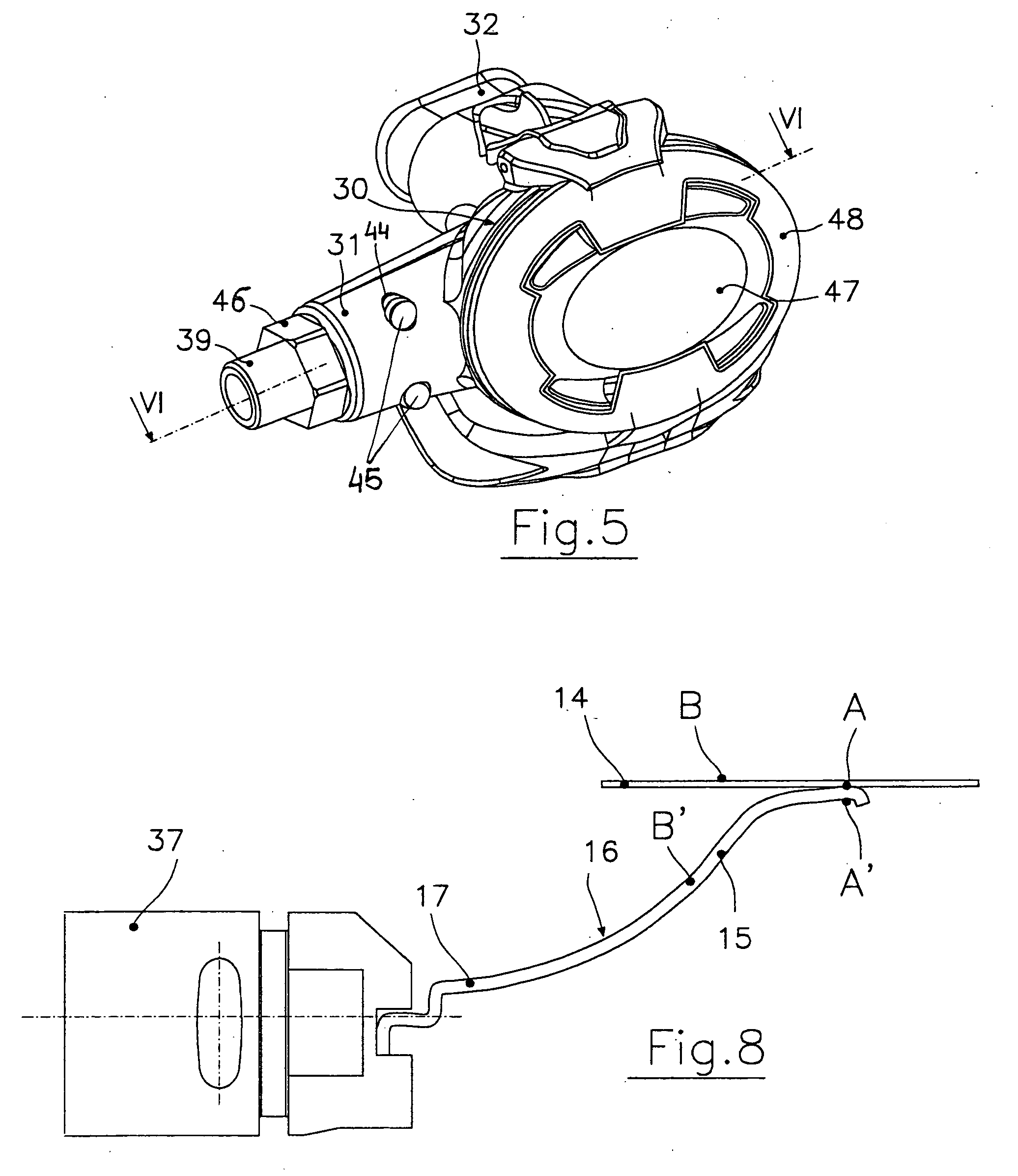

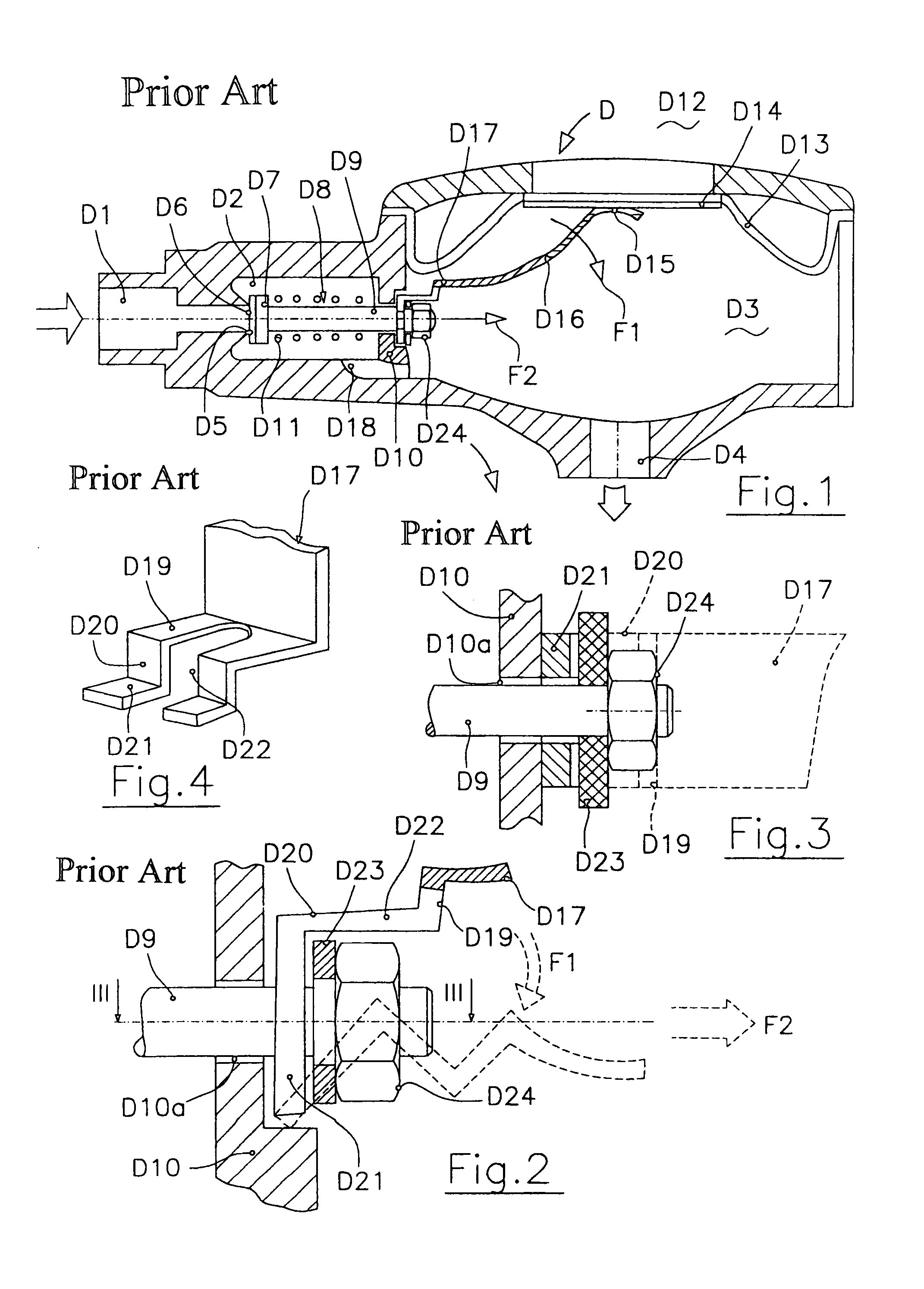

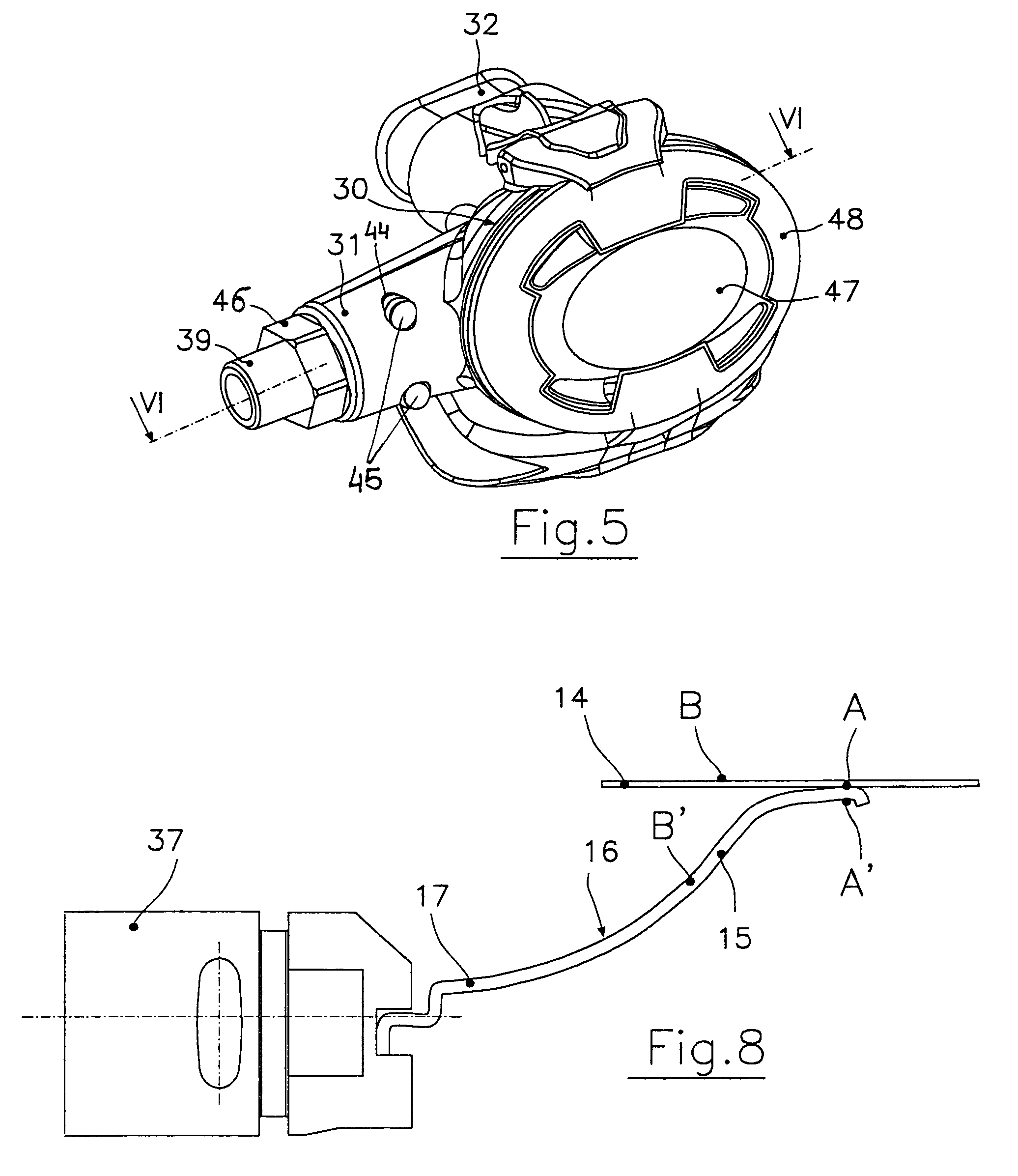

Second-stage regulator for scuba divers

ActiveUS20050016537A1Facilitate actionLess effortRespiratorsBreathing protectionSecondary stageEngineering

A second-stage regulator for scuba divers, wherein the user's inhalation effort is lessened considerably by the reduction of the friction between selected components thereof. Coaxially to the regulator poppet, a flexible sleeve is sealingly connected to the poppet and the baffle, so as to avoid blow-by of gaseous mixture through the baffle opening through which there extends the tail of the poppet connected to the lever of the regulator extending in the outlet chamber thereof. The poppet head is placed in ferrule with an at least part-circular profile abutting the inner part of the intermediate chamber to allow the poppet oscillation. The lever end contacting the diaphragm, separating the outlet chamber from the outside, has a generally arched shape with a profile such that the length of the arch between two adjacent contact points measured along the lever is generally equal to the length of the segment between the same adjacent contact points measured along the diaphragm.

Owner:CRESSI SUB

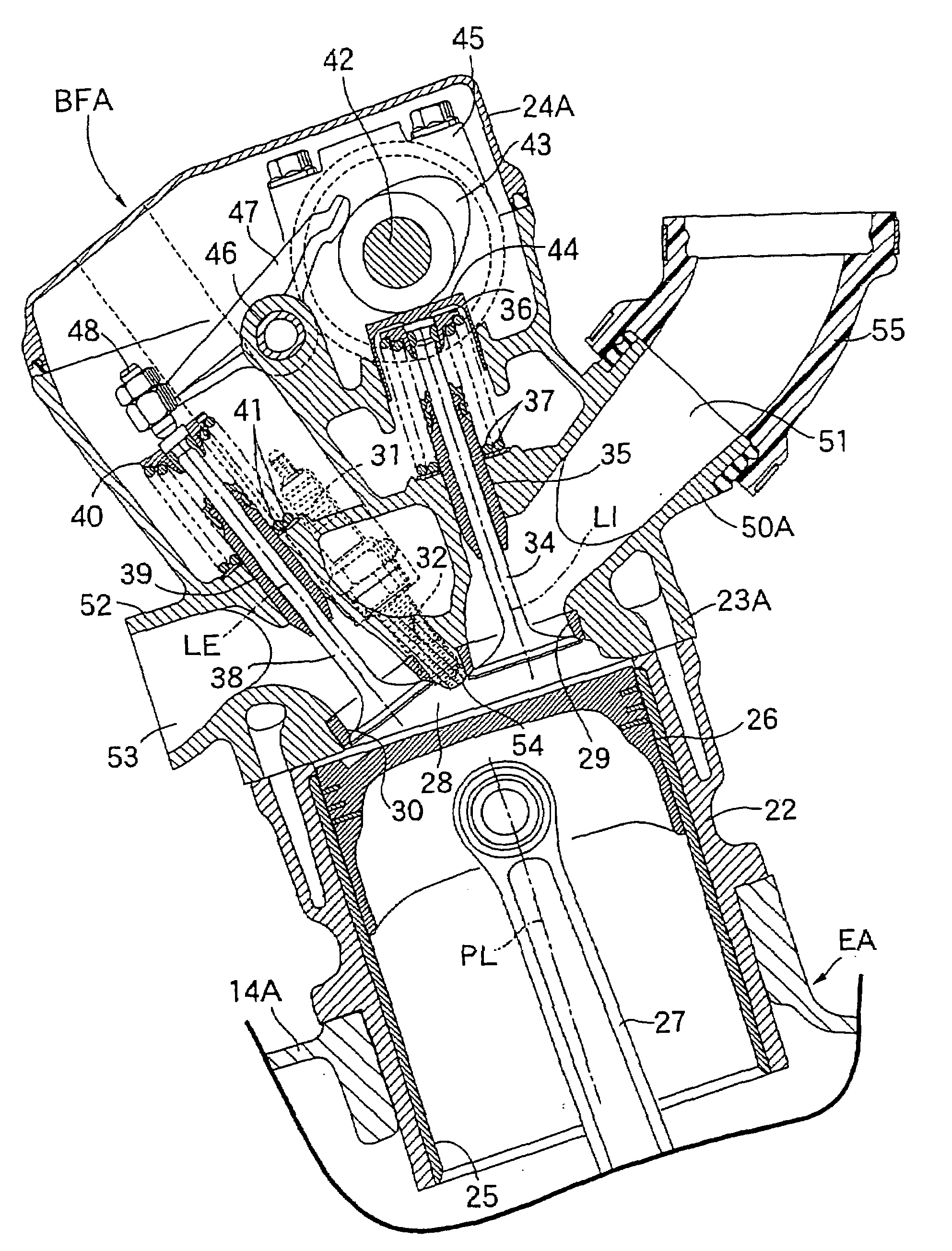

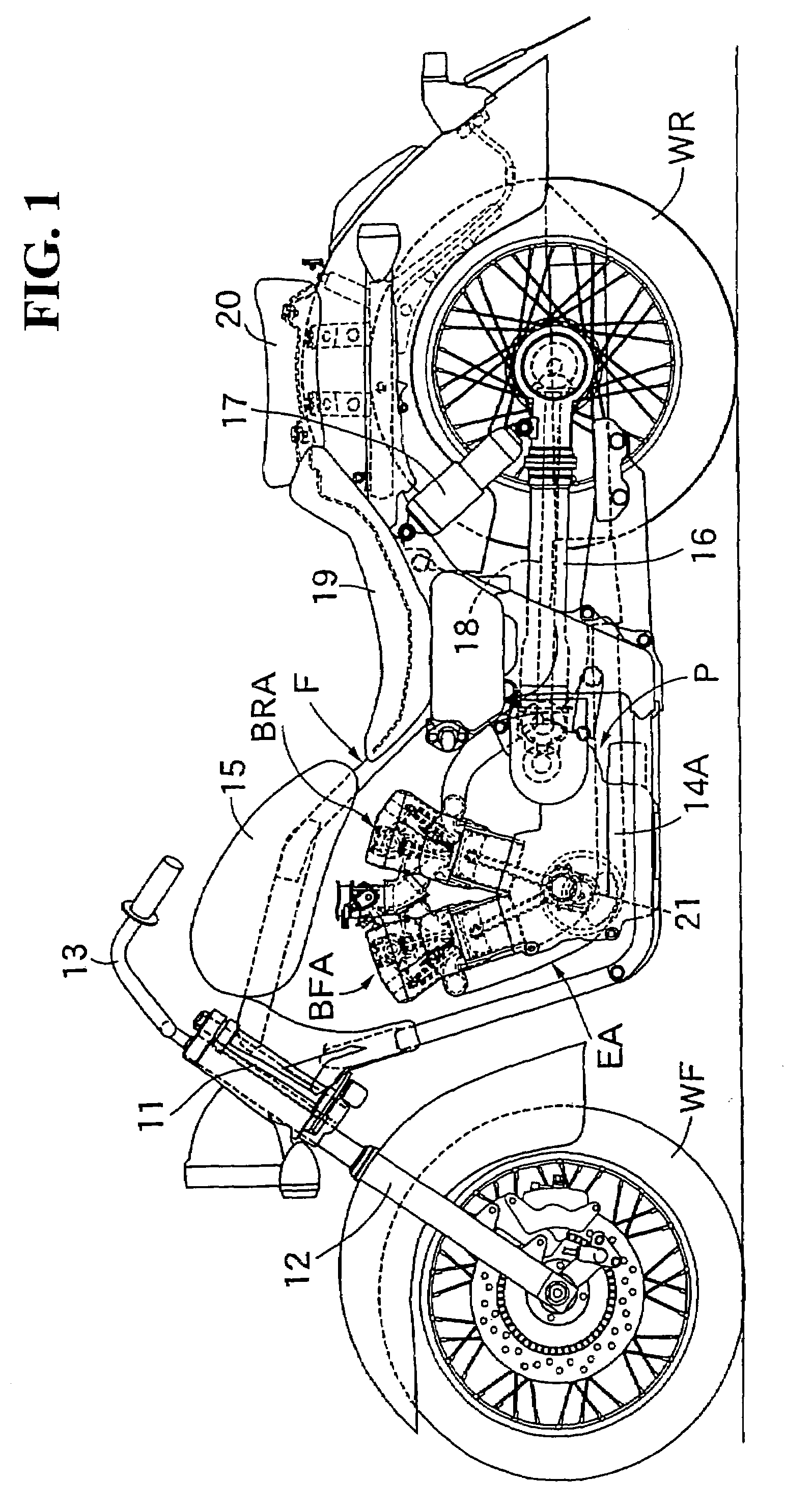

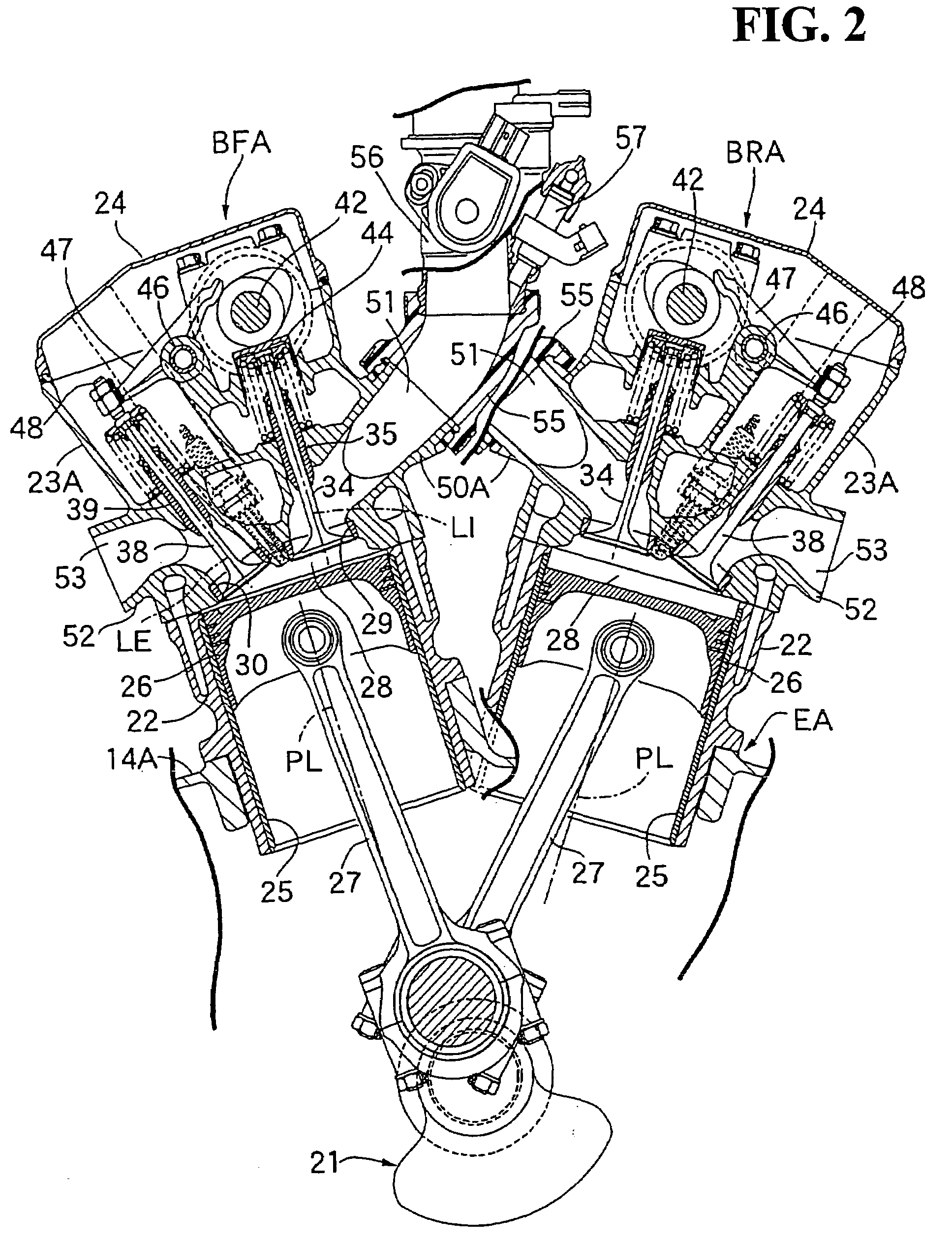

Internal combustion engine

InactiveUS20070199543A1Prevent blowbyMuscle operated startersCylinder headsExhaust valveExternal combustion engine

In an internal combustion engine includes an intake valve port that opens into a combustion chamber on one side of a plane containing the axis of a cylinder bore. An exhaust valve port opens into the combustion chamber on the other side of the plane. A spark plug has a tip end that fronts a substantially central portion of the combustion chamber. The spark plug is disposed between the intake valve and the exhaust valve. In order to restrain the blow-by of an unburned fuel-air mixture, and to suppress the bulging of the cylinder head to the intake system side, the operation axis of an intake valve is set to be substantially parallel to the axis of the cylinder bore. In addition, one side surface of a cylinder head is formed to be substantially parallel to the axis of the cylinder bore.

Owner:HONDA MOTOR CO LTD

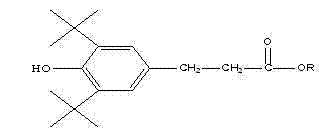

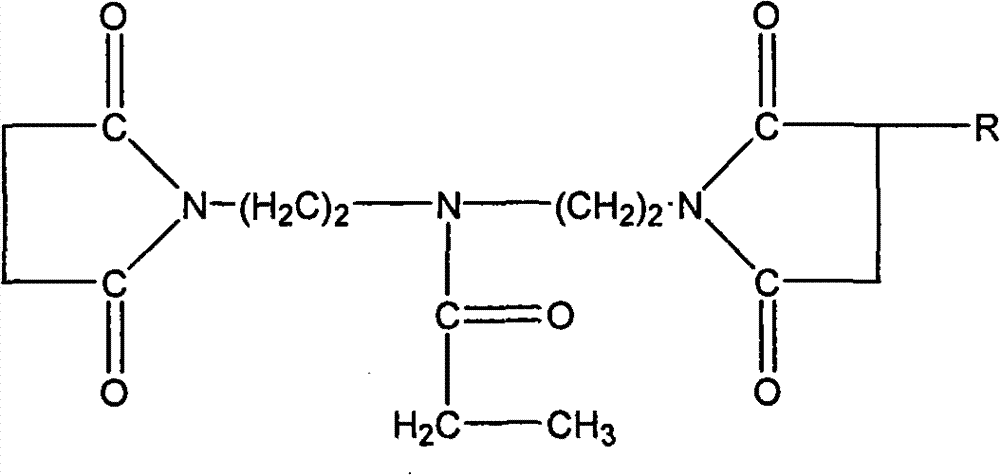

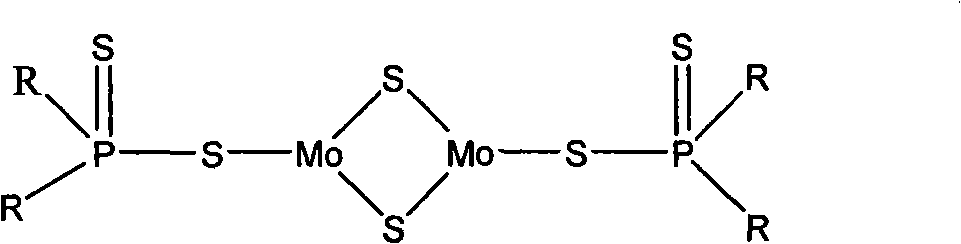

Composite of engine lubricant and preparation method thereof

ActiveCN101880586BGood dispersionImprove thermal stabilityLubricant compositionIsopreneMaterials science

The invention relates to a composite of lubricant and a preparation method thereof, in particular to a composite of engine lubricant and a preparation method thereof, which belong to the lubricant technical field. Alkyl naphthalene and naphthenic bright stock are added to base oil and at the same time thiophosphoric acid molybdenum additive containing nitrogen, ashless dispersing agent boride, hydrostyrene-isoprene VI improver (Infineum SV 261) and the like are added. Through the mutual coordination of the components, the lubricant composite has obvious compatibility adaptability of a rubber sealing ring, engine oil leakage is avoided, gas blowby is prevented, the dynamic property of the engine is improved, engine oil consumption is reduced, the emission property of the engine is improved and the oil draining period of engine oil and the service life of the engine are prolonged. The invention is particularly applicable to the vehicles which have run more than 100000km or have been overhauled.

Owner:JIANGSU LOPALTECH

Second-stage regulator for scuba divers

ActiveUS8166974B2Less inhalation effortBreathe with greater easeRespiratorsBreathing protectionInhalationMechanical engineering

A second-stage regulator for scuba divers is disclosed that reduces considerably the inhalation effort required by the user through reduction in friction between selected components of the regulator. A flexible sleeve is sealingly connected to the regulator poppet and the baffle, and coaxially with the poppet, so as to avoid blow-by of gaseous mixture through an opening in the baffle. A tail of the poppet extends through the opening, the tail being connected to a lever of the regulator projecting into an outlet chamber thereof. The head of the poppet is or includes a ferrule with an at least partially-circular profile and abuts a selected inner portion of the inlet's intermediate chamber to allow oscillation of the poppet. The lever end of the regulator contacts a diaphragm, the diaphragm separating the outlet chamber from the external environment. The lever end has a generally arched shape with a profile such that the length of the arch between two adjacent contact points measured along the lever is generally equal to the length of the segment between the same adjacent contact points measured along the diaphragm.

Owner:CRESSI SUB

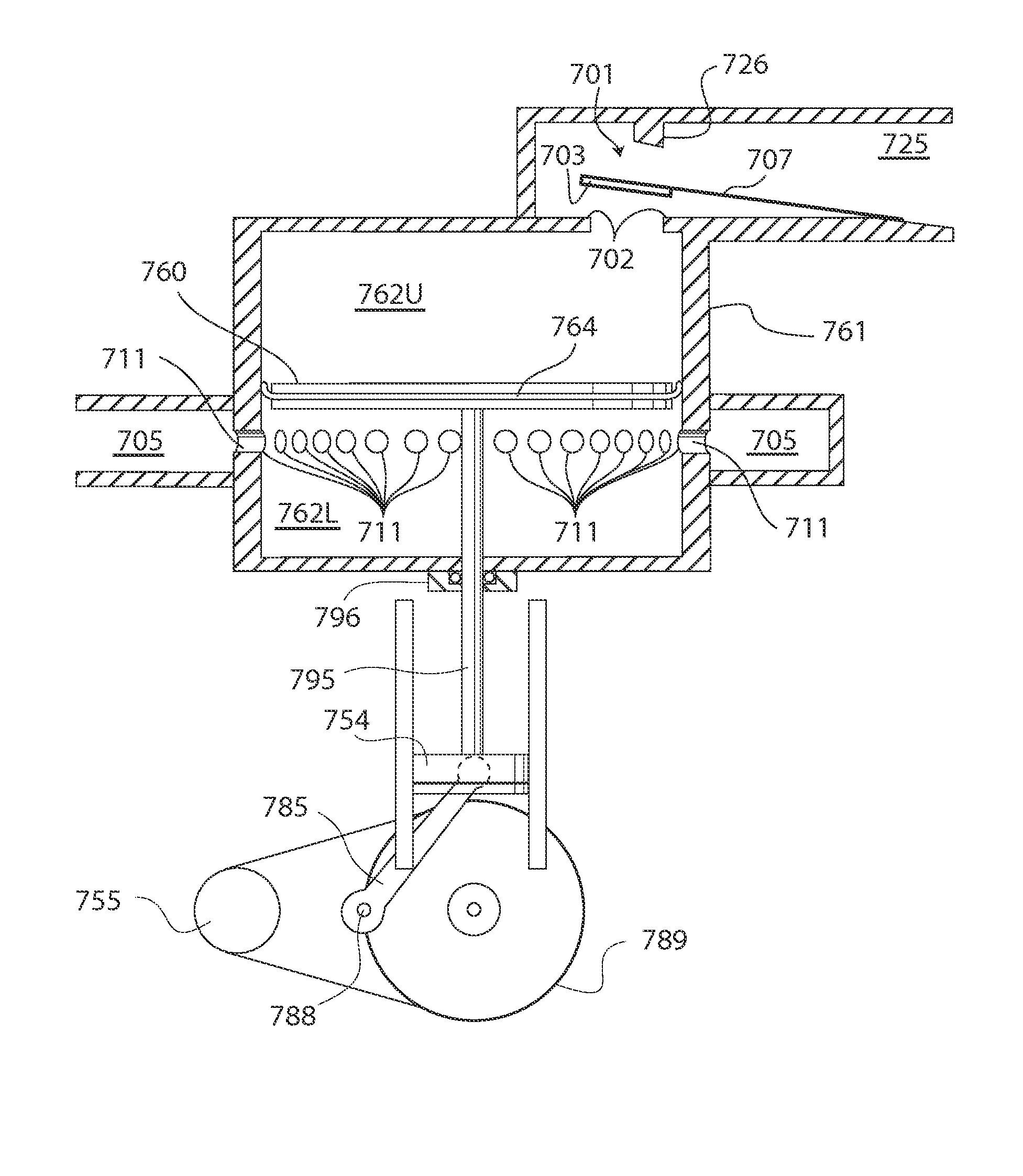

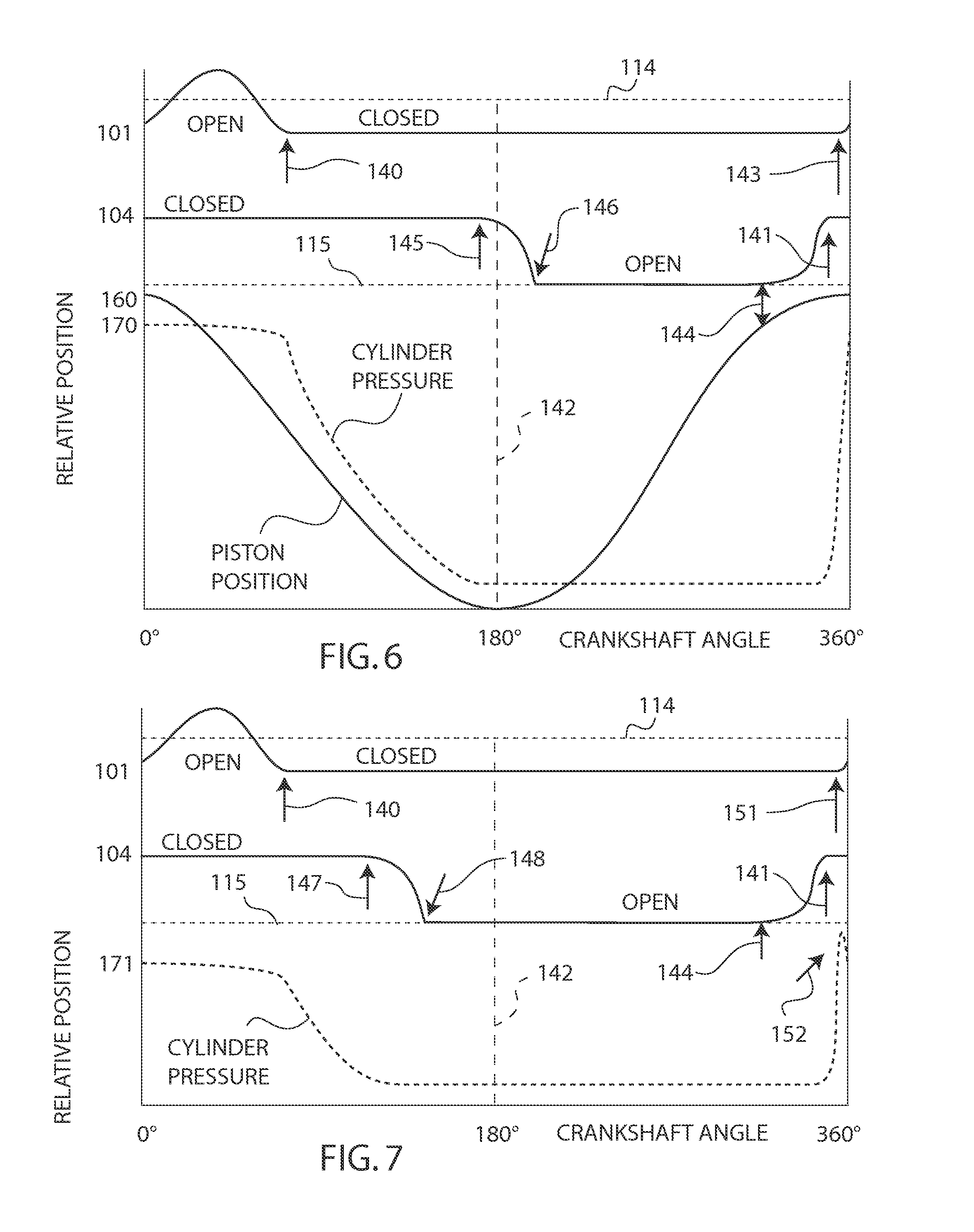

Harmonic uniflow engine

ActiveUS20140318363A1Prevent blowbyAct quicklyPositive displacement pump componentsServomotor componentsPistonResonator

A reciprocating-piston uniflow engine includes a harmonic oscillator inlet valve capable of oscillating at a resonant frequency for controlling the flow of working fluid into the engine. In particular, the inlet valve includes an inlet valve head and a spring arranged together as a harmonic oscillator so that the inlet valve head is moveable from an unbiased equilibrium position to a biased closed position occluding an inlet. When released, the inlet valve head undergoes a single oscillation past the equilibrium position to a maximum open position and returns to a biased return position close to the closed position to choke the flow and produce a pressure drop across the inlet valve causing the inlet valve to close. In other embodiments, the harmonic oscillator arrangement of the inlet valve enables the uniflow engine to be reversibly operated as a uniflow compressor.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

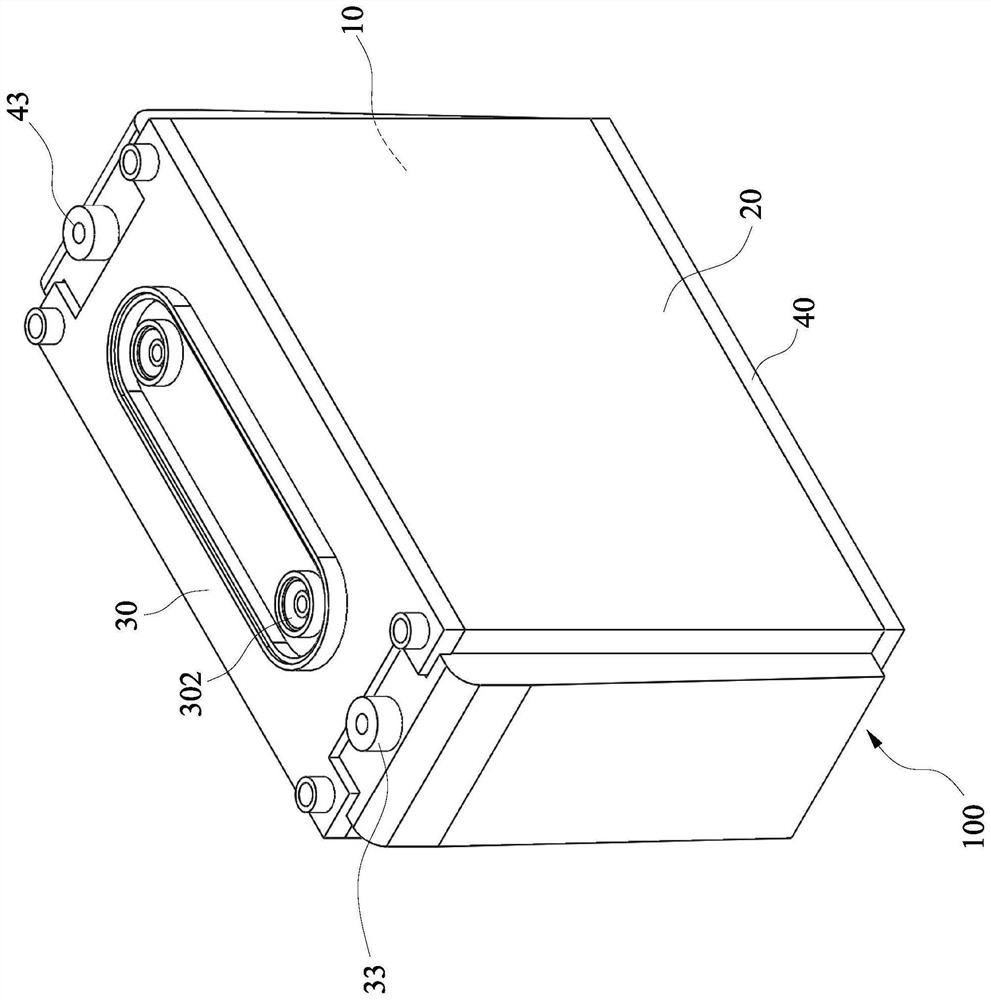

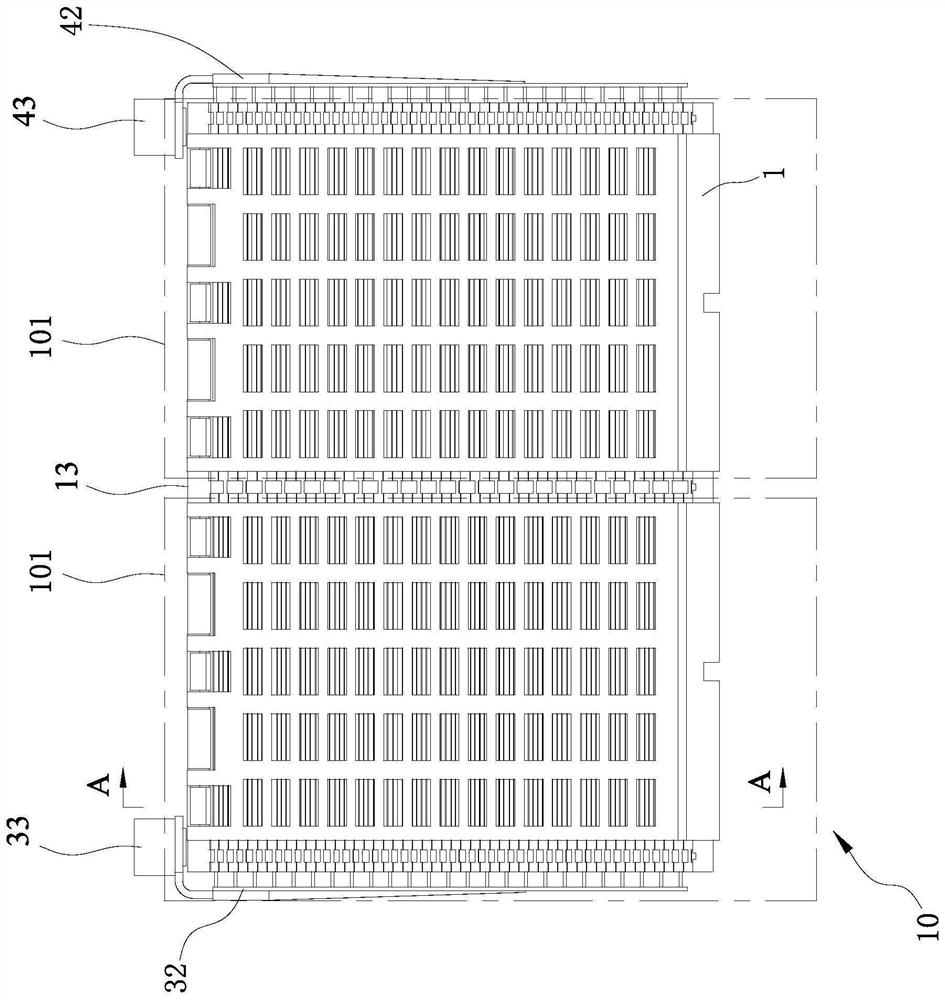

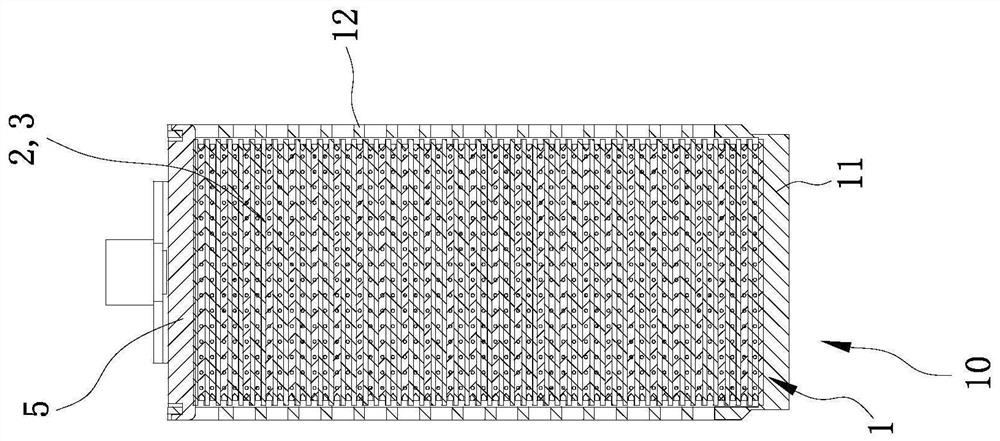

Method for manufacturing bipolar horizontal battery and bipolar horizontal battery

The invention relates to a method for manufacturing a bipolar level battery and the bipolar level battery. The method comprises the following steps: providing a battery core of a horizontal battery; putting the battery cell as an embedded part into an injection mold; a battery shell is formed in an injection mold through injection molding, the battery shell surrounds the battery core, the battery shell and the battery core are combined into a whole, and a circulation channel is formed between the battery core and the battery shell so that the electrolyte can circulate in the circulation channel; a top cover and a bottom cover are respectively arranged on the top surface and the bottom surface of the battery shell and are sealed, so that a sealed space is formed in the battery shell and is used for storing electrolyte; and injecting an electrolyte into the battery case. According to the horizontal battery manufactured by the method, the battery core and the battery shell can be directly, conveniently and stably fixed together, and the sealing among the battery monomers of the battery core can be conveniently and effectively realized.

Owner:易德维能源科技(江苏)有限公司

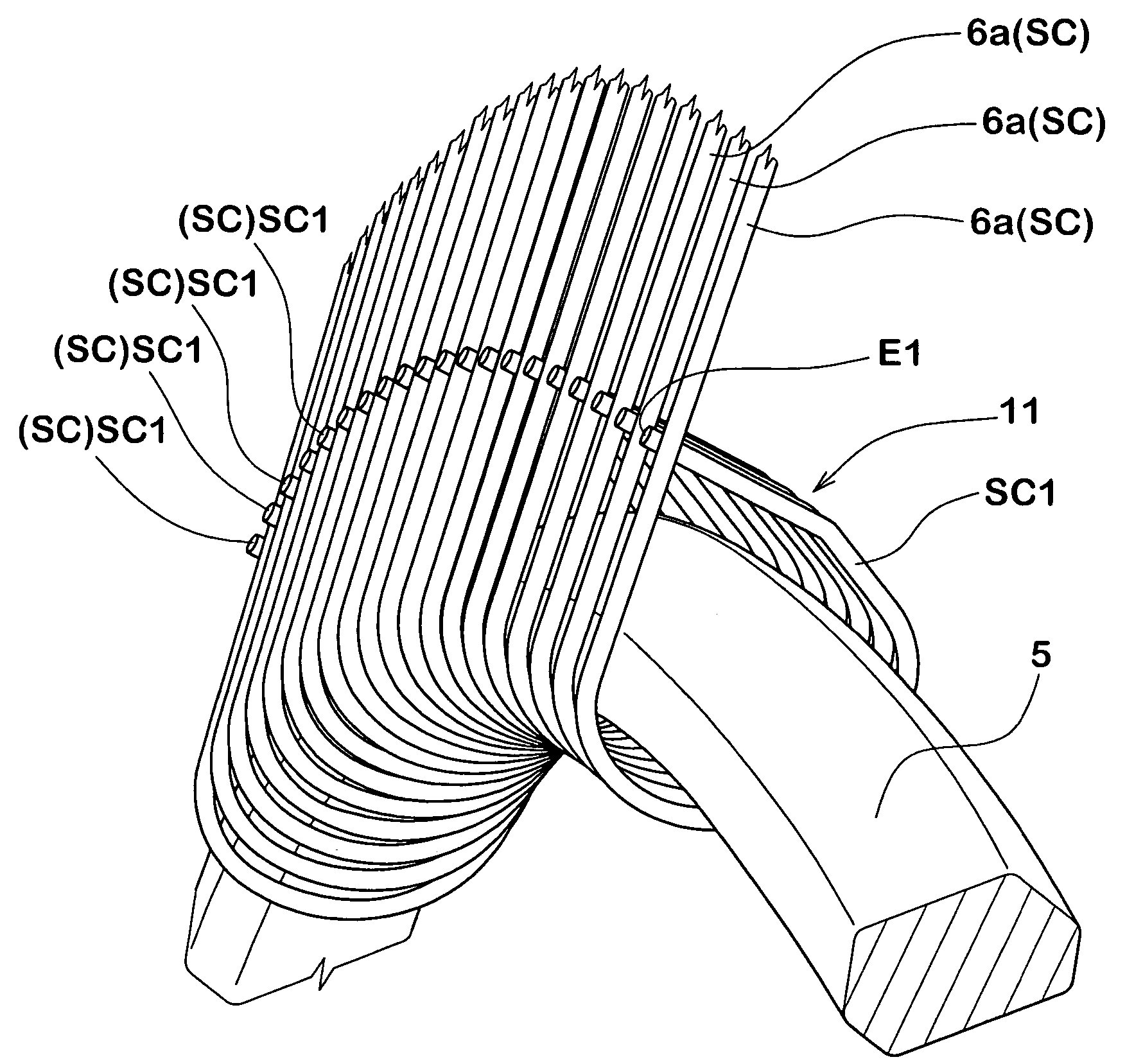

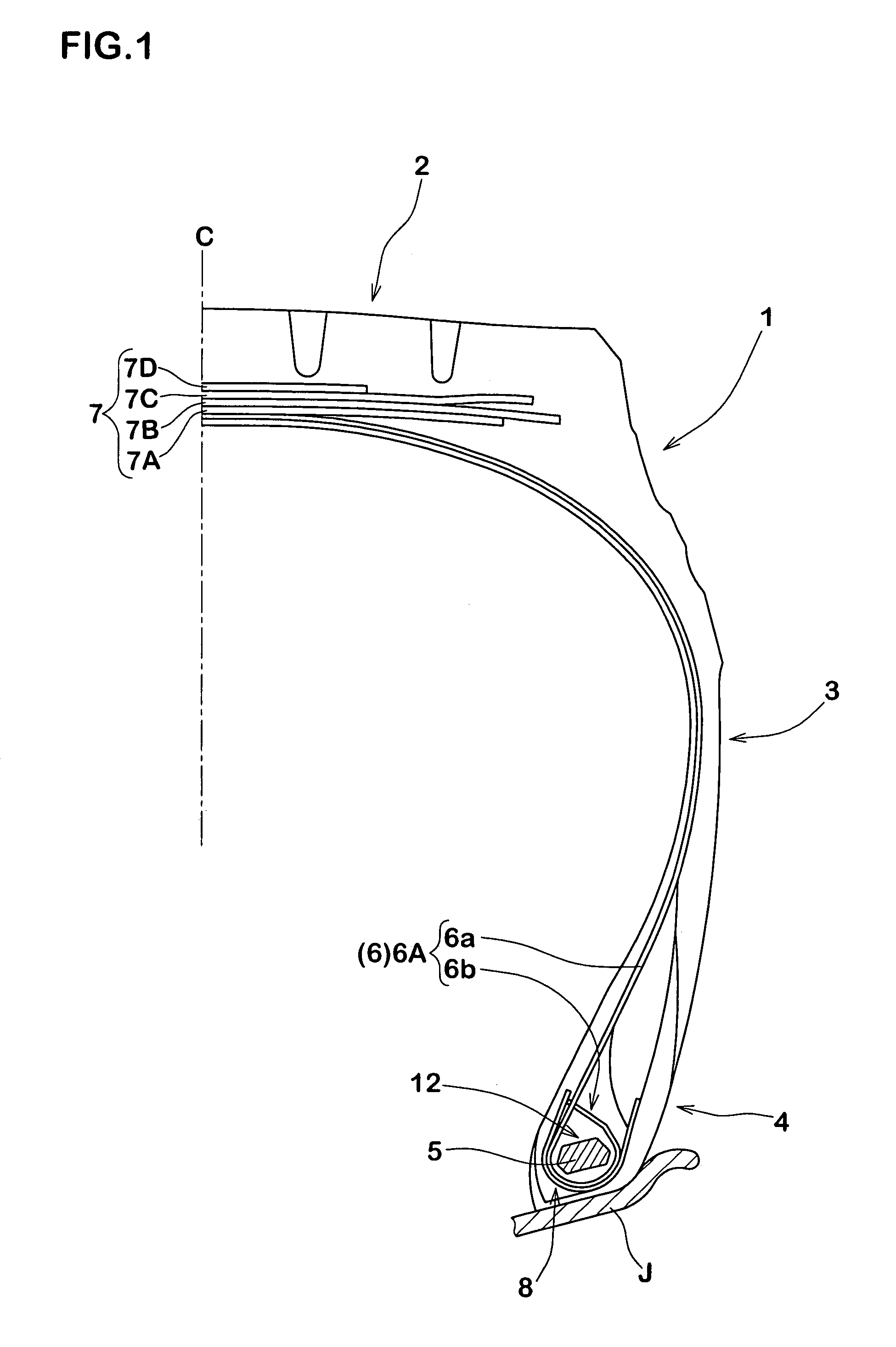

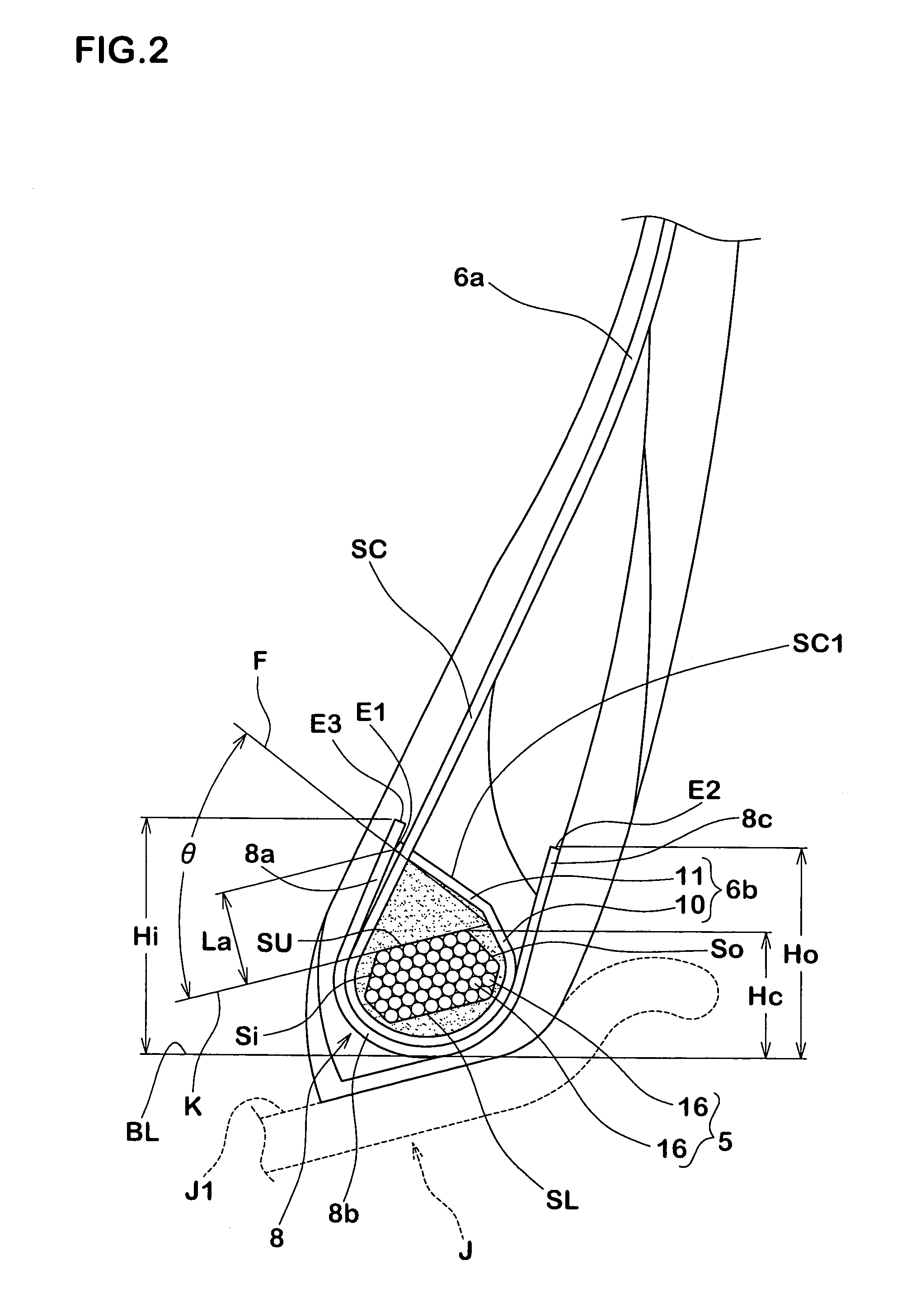

Tire for heavy load use

InactiveUS7011127B2Improve bindingImprove bead durabilityWithout separate inflatable insertsPneumatic tyre reinforcementsHeavy loadWire rope

A tire for heavy load use includes a carcass ply made of steel cords including ply turn-up portions that are turned up around bead cores from inside to outside in a tire axial direction. Each ply turn-up portion includes a turn-up sub-portion that is first turned up around the bead core and that extends in an inclined manner towards the ply main portion at an angle θ, that is less than 90°, with respect to an outer surface of the bead core in the tire radial direction. The steel cords of the turn-up sub-portion include piercing steel cords that pass through the steel cords of the ply main portion. As a result, the durability of the bead portions is improved while achieving a light-weighted structure.

Owner:SUMITOMO RUBBER IND LTD

A rapid replacement method for burner bricks of annular heating furnace

InactiveCN102297595AShort maintenance timeShort downtimeLinings repairFurnace typesEngineeringHeating furnace

The invention relates to a method for maintaining an annular heating furnace, in particular to a method for replacing a burner of an annular heating furnace. A method for quickly replacing burner bricks of an annular heating furnace, which comprises the following steps: offline prefabricating burner bricks; installing prefabricated burner bricks; using quick-drying refractory castables of the same material as the prefabricated burner bricks for on-site integral casting step. The invention is a simple and effective method for rapidly replacing the burner bricks of the heating furnace, which can realize the maintenance and replacement of the burner bricks within one day.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Exhaust control device for vehicle engine

InactiveUS20090084098A1Reduce amount of exhaustHigh exhaust flow rateElectrical controlNon-fuel substance addition to fuelEngineeringExhaust valve

An exhaust control device for a vehicle engine includes an exhaust control valve capable of changing the opening area of an exhaust passage. The exhaust control valve is disposed in exhaust passage forming means so as to be able to change a bent-internal side partial passage sectional area of the passage sectional area of an exhaust passage. Specifically the exhaust control valve is disposed at a bent portion of the exhaust passage that is closest to an exhaust valve port. With this configuration, the exhaust flow rate can be controlled satisfactorily.

Owner:HONDA MOTOR CO LTD

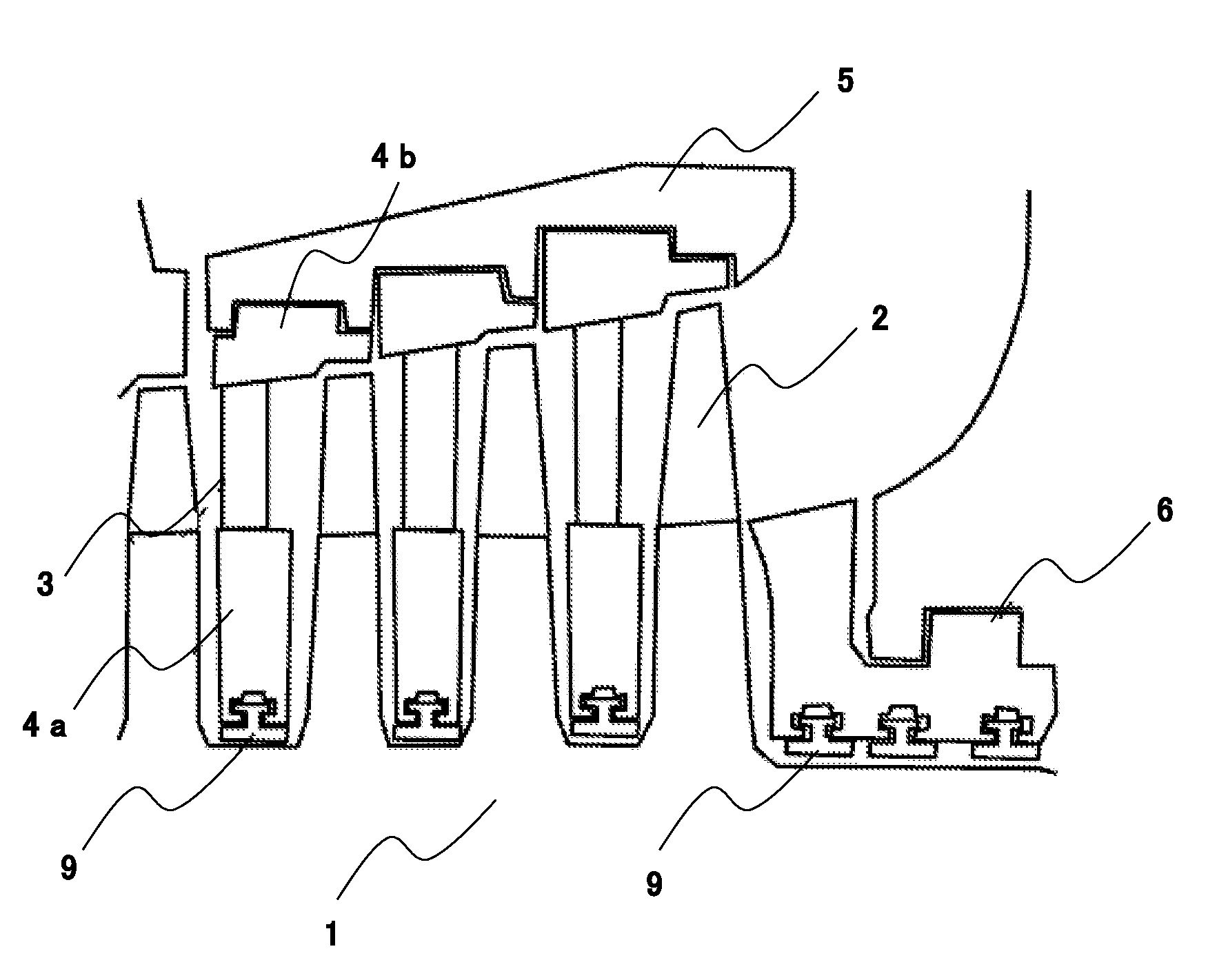

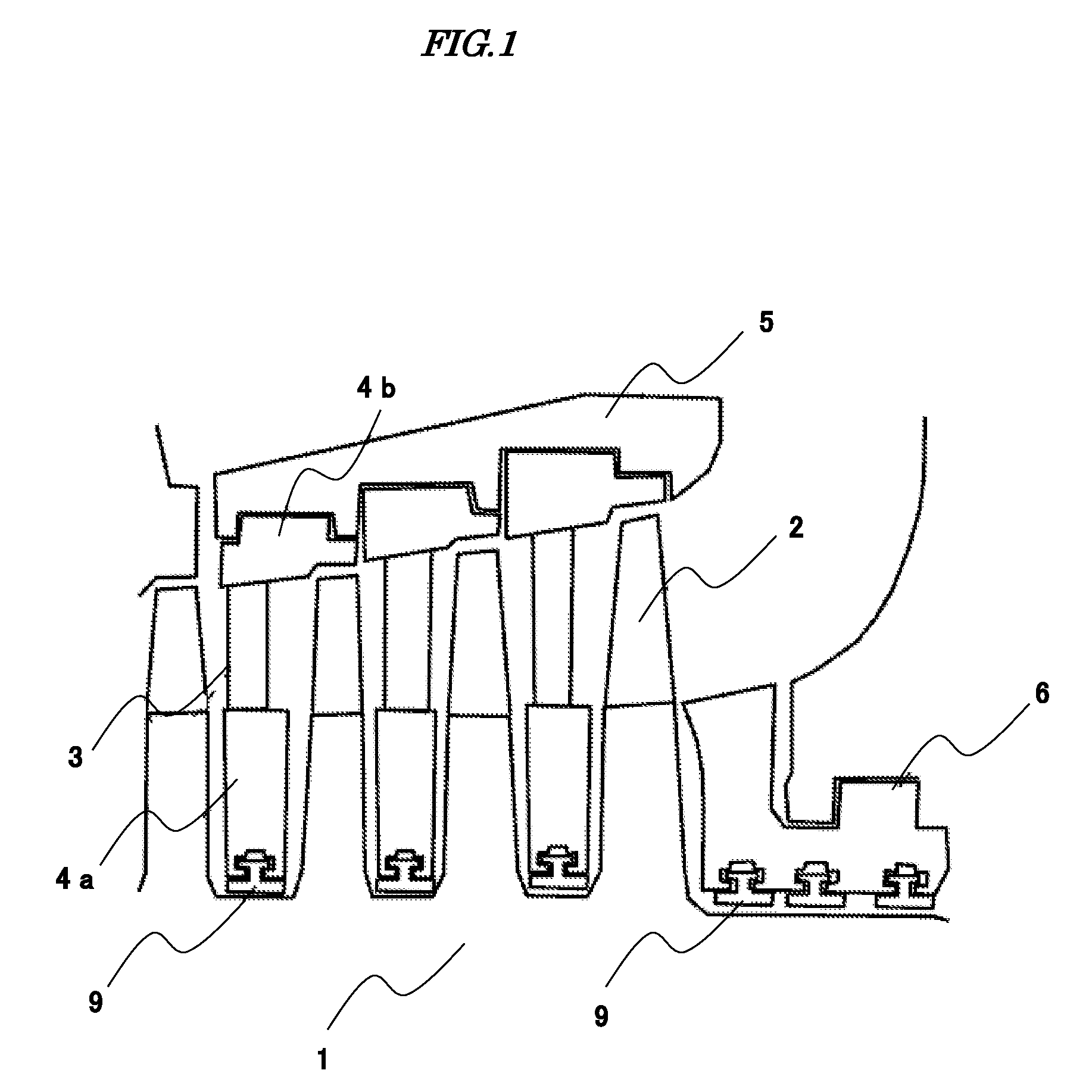

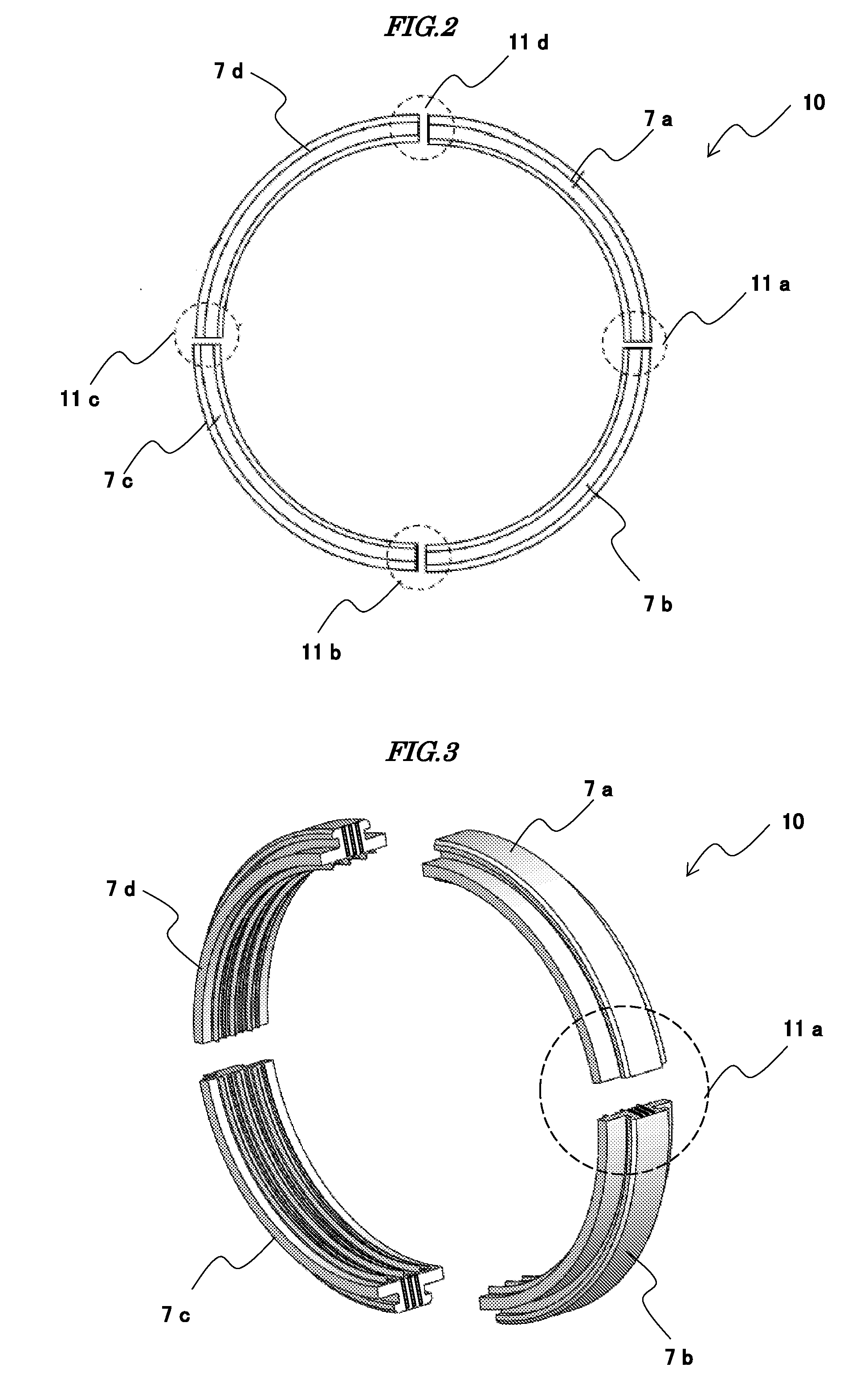

Sealing Device, Rotating Machine, and Method for Manufacturing Sealing Device

InactiveUS20160169023A1Increased riskReduce unnecessary leakageEngine sealsMetal-working feeding devicesJoint surfaceWorking fluid

It is an object of the present invention to provide a sealing mechanism that, while preventing a clearance that passes in an axial direction through an entire abutting surface without involving large resistance and that invites blow-by of a working fluid, can prevent adjacent seal segments from sticking to each other, and a method for manufacturing the sealing mechanism. A sealing device includes: an annular sealing ring that includes a plurality of seal segments annularly juxtaposed; a plurality of seal fins provided in an axial direction on an inner peripheral surface of the sealing ring; a joint surface on a circumferential end of the seal segment, the joint surface facing a joint surface on an adjacent seal segment; a groove that extends in a radial direction in the joint surface; and a protrusion formed by bending part of a surface that constitutes a long side of the groove toward an outside of the joint surface.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Blow-by Gas Passage Structure

ActiveCN106150598AFully detoured blowby gasEfficient separationCasingsMachines/enginesCylinder headEngineering

The present invention provides a blow-by gas passage structure which can improve the separation efficiency of the oil component contained in a blow-by gas. The blow-by gas passage structure is provided inside a separator chamber that is formed between a cylinder head cover and a baffle plate joined to the cylinder head cover by vibration welding. A first rib is provided on the opposite surface of one member of the cylinder head cover and the baffle plate, while a second rib is provided on the opposite surface of the other member, at positions upstream of the first rib in the flow of the blow-by gas and adjacent a gap formed between the distal end of the first rib and the opposite surface of the other member. The second rib has a height that is equal to or larger than the height of the gap so as to prevent passing of the blow-by gas through the gap.

Owner:TOYOTA BOSHOKU KK

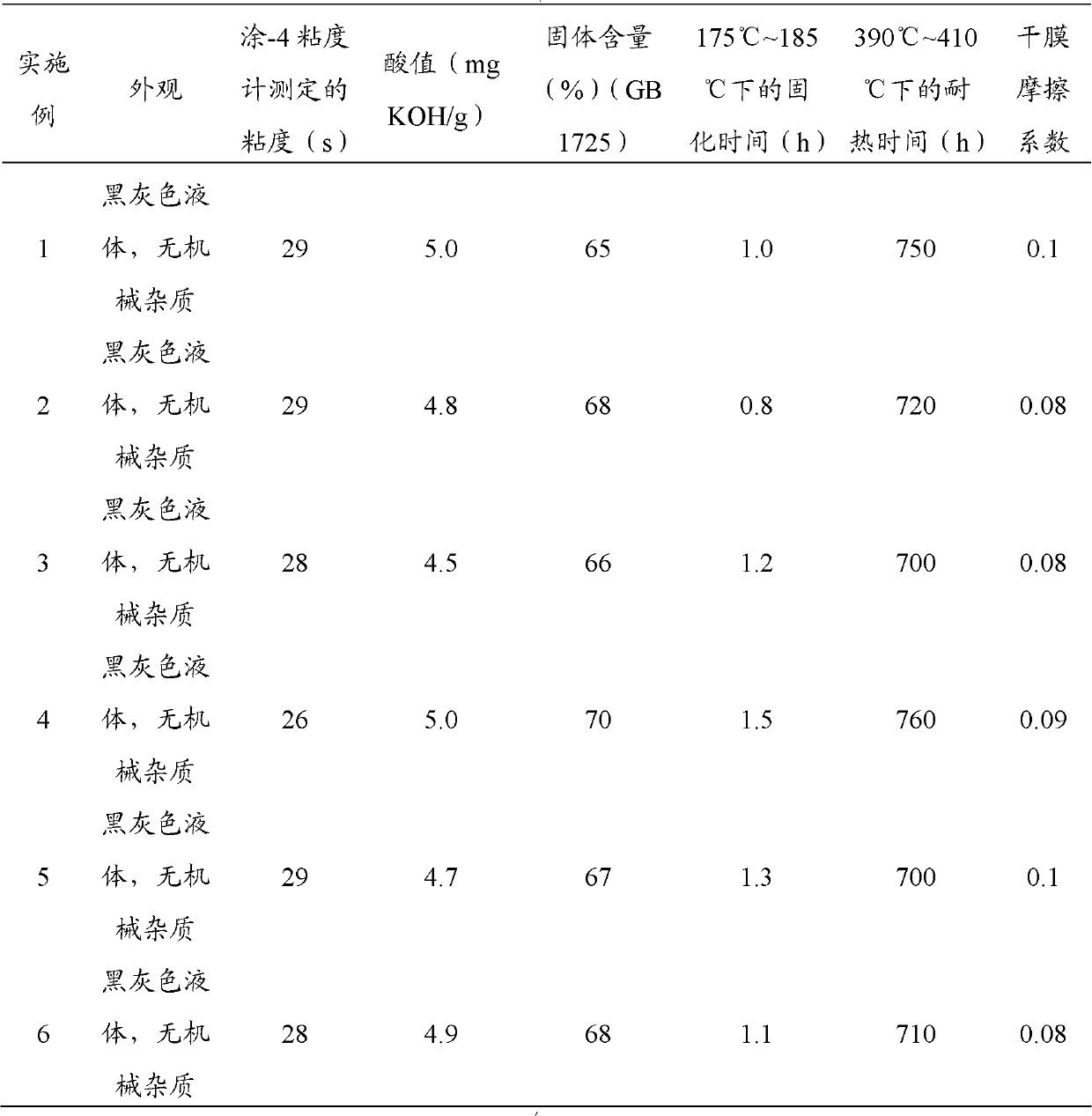

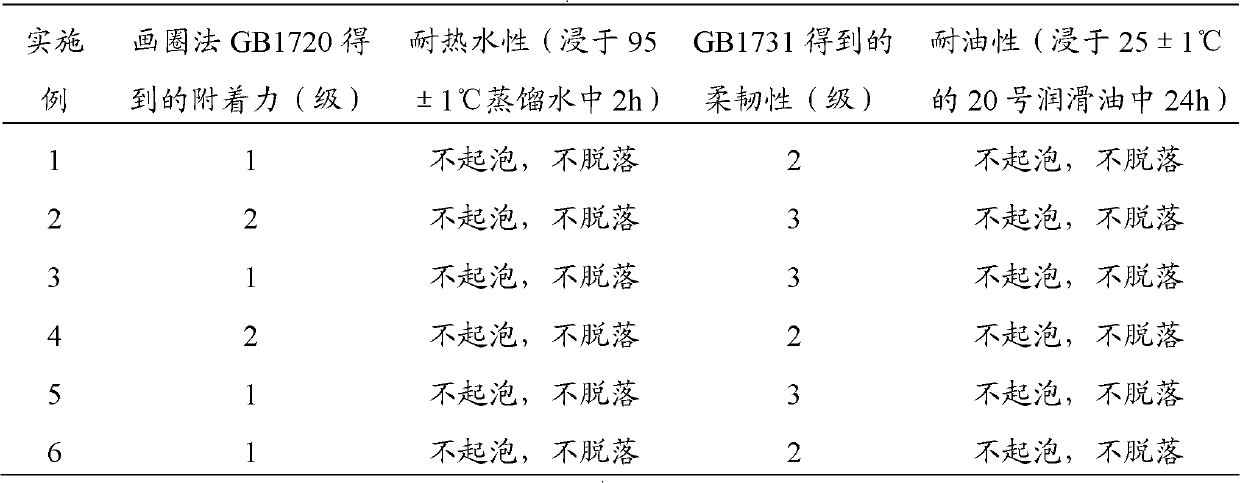

Dry film lubricant composition

ActiveCN102559349AImprove the lubrication effectImprove adhesionLubricant compositionPolymer sciencePliability

The invention provides a dry film lubricant composition. Based on a liter, the composition comprises the following components: 40 to 80 grams of graphite powder; 230 to 300 milliliters of aid, 450 to 650 milliliters of main solvent, 30 to 100 milliliters of auxiliary solvent and 50 to 150 milliliters of lubrication improver. With low requirements on curing environment, the dry film lubricant composition provided by the invention can cure after being placed at a curing temperature. The curing temperature of the composition is low, and the curing time is short. In addition, the dry film lubricant composition obtained by the invention has high heat resistance, hot water resistance, oil resistance, lubricating performance and high adhesion force and flexibility and therefore can adapt to various working environments. Without self-curing capacity, the dry film lubricant composition provided by the invention avoids blocking spraying equipment in a spraying process. Meanwhile, the dry film lubricant composition provided by the invention has long period of validity.

Owner:湖南江滨机器(集团)有限责任公司

Ramming clamp and method for cooling wall expansion gap

The invention discloses a ramming clamp for a cooling wall expansion gap. The ramming clamp is composed of steel plates, a screw rod, fastening nuts, spacers and other assemblies. The whole clamp has enough rigidity and strength and is tightened and fixed through the nuts, it can be avoided that baffles move due to strength generated in the ramming process, carbon materials can enter a cooling surface, and the requirement for ramming compactness and uniformity in the ramming process can be met; and furthermore, the structure is simple, fixation is facilitated through the threaded manner, exposed parts can be quickly cut and removed after ramming is finished, and a brick lining in the hot surface of the cooling wall can be built without influences. The invention further discloses a ramming method for the cooling wall expansion gap. The ramming method is improved by arranging ramming clamps and carrying out layered multi-time ramming, the uniformity of rammed materials can be improved, and thus the heat conductivity of the rammed material is ensured; and the phenomena that the cooling wall of a blast furnace leaks air due to poor ramming compactness, and the cooling strength is affected are avoided, and the service life of a hearth of the blast furnace is ensured.

Owner:BAOSHAN IRON & STEEL CO LTD

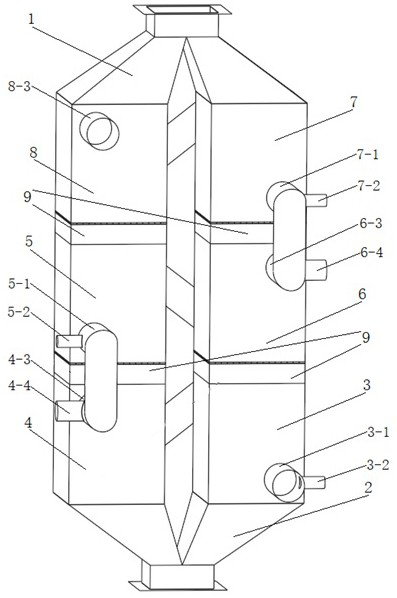

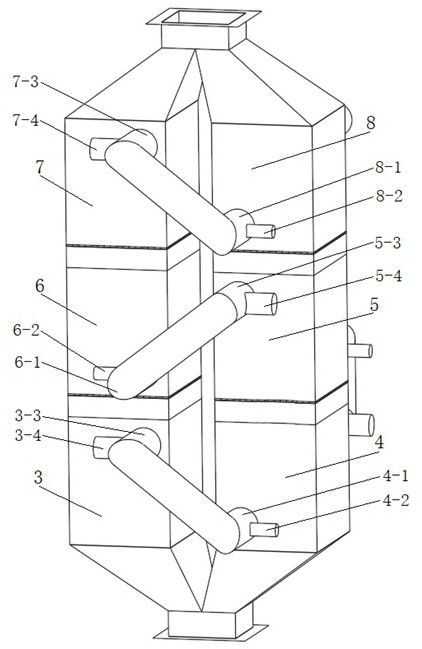

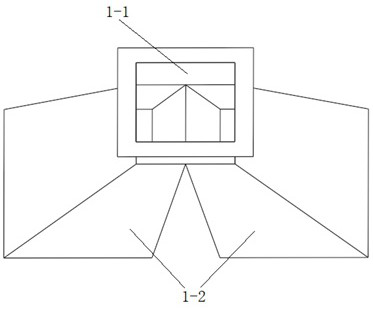

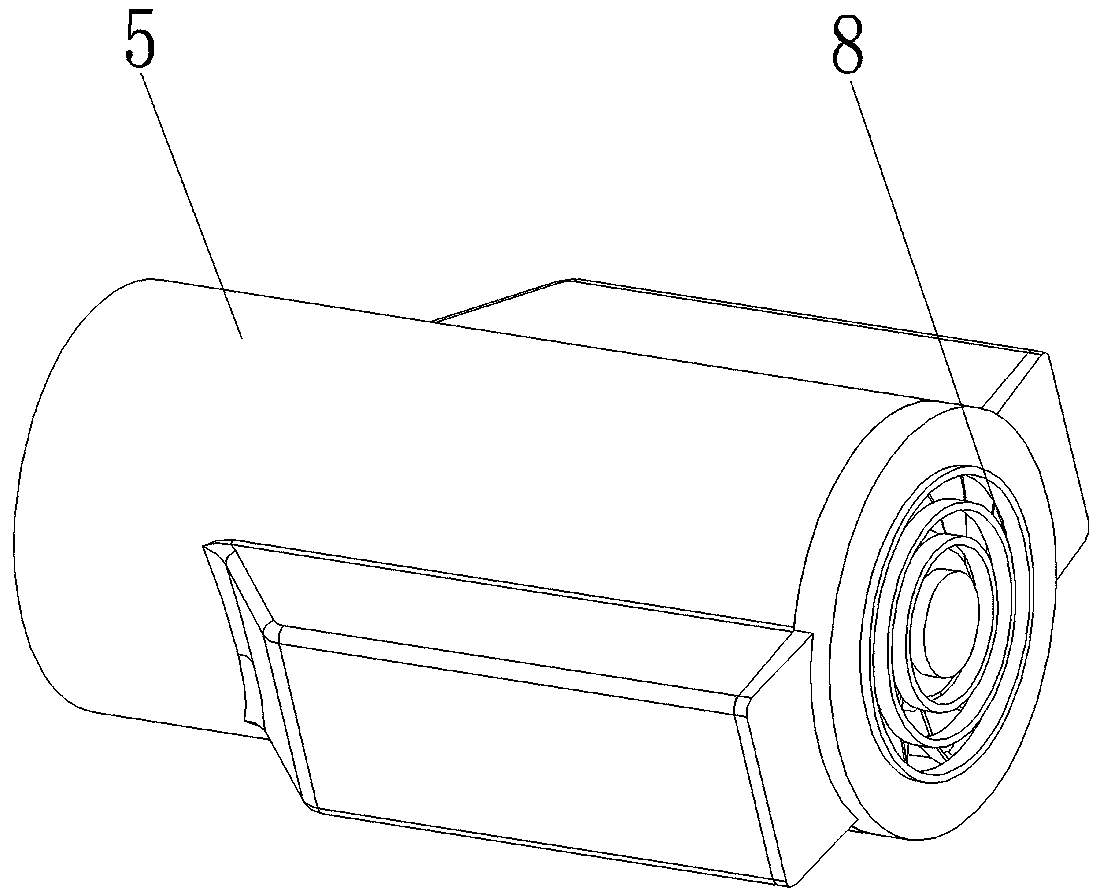

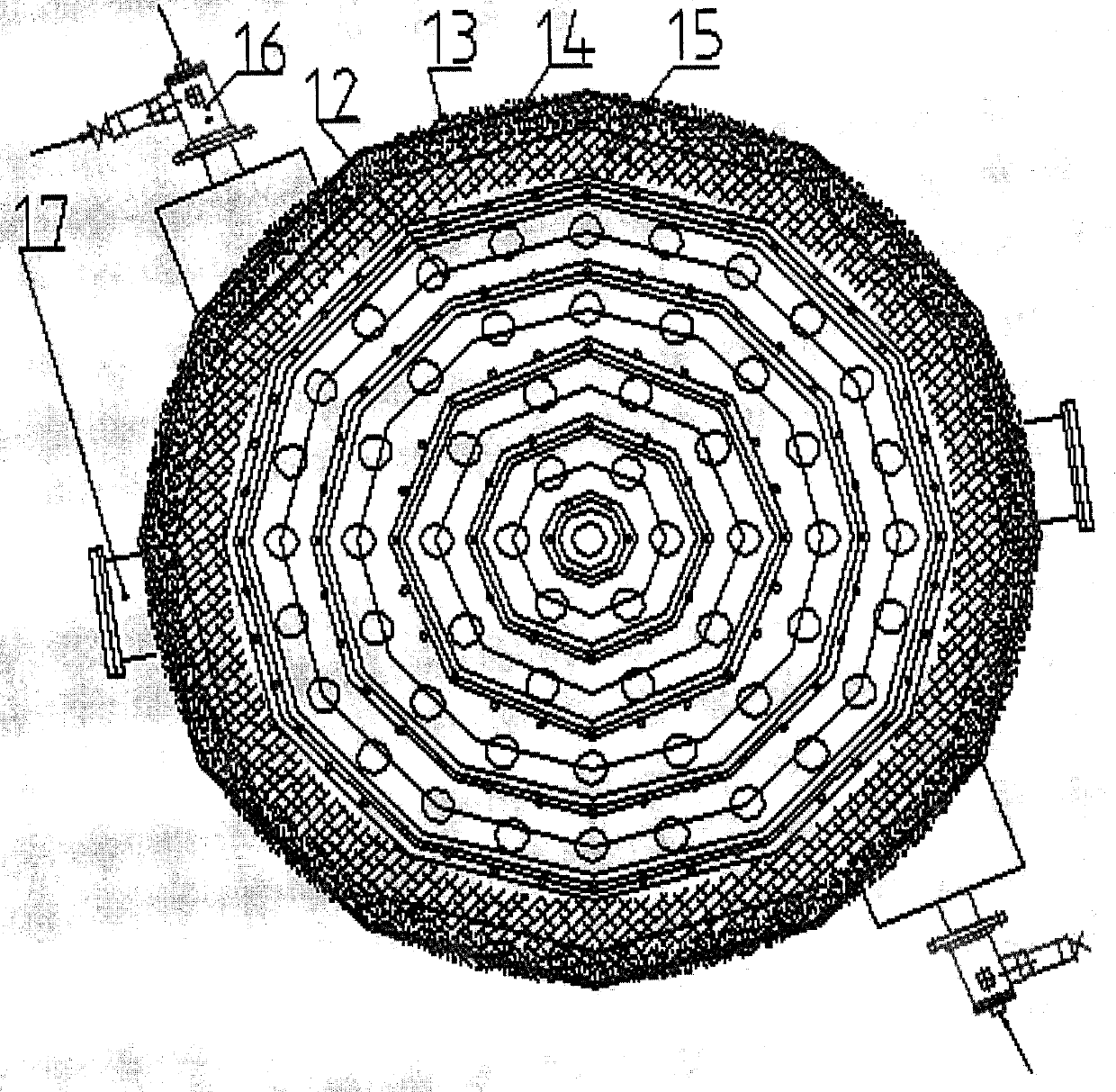

Industrial tail gas treatment multi-cycle adsorption tower

PendingCN113144825AReduce construction costsIncrease throughputGas treatmentDispersed particle separationFlue gasEngineering

The invention relates to an industrial tail gas treatment multi-cycle adsorption tower which comprises a plurality of tower bodies arranged side by side, each tower body comprises an active coke feeding section, at least two flue gas purification sections and an active coke discharging section which are sequentially arranged from top to bottom, the flue gas purification sections in each tower body are the same in number and at least two, and a transition sealing section is arranged between two adjacent flue gas purification sections on the same tower body; a gas inlet pipe and a gas outlet pipe are respectively arranged at the lower part and the upper part of each flue gas purification section; the gas outlet pipe of one flue gas purification section is connected with the gas inlet pipe of another corresponding flue gas purification section at the same height of other tower bodies or the gas inlet pipe of the adjacent flue gas purification section above the same tower body; and the gas inlet pipe of the flue gas purification section at the bottom is the gas inlet pipe of the adsorption tower, and the gas outlet pipe of the flue gas purification section at the top is the gas outlet pipe of the adsorption tower. The adsorption tower improves the utilization rate of active coke in the adsorption tower.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

Self-generating electricity air blowing mechanism for outdoor heater

PendingCN108679700ASimple and reasonable structureEasy to useDomestic stoves or rangesLighting and heating apparatusElectricityEngineering

The invention provides a self-generating electricity air blowing mechanism for an outdoor heater. The self-generating electricity air blowing mechanism comprises a combustion barrel, a combustion headarranged inside the combustion barrel and an ignition device which is arranged inside the combustion barrel and opposite to the combustion head and further comprises an air distribution plate, a cooling barrel, an air fan, a motor and a self-generating electricity component, wherein the air distribution plate is located at the rear end of the combustion barrel; the combustion barrel is arranged inside the cooling barrel, and the gap between the combustion barrel and the cooling barrel forms a cooling air passage; the air fan is used for supplying air to the cooling air passage and the combustion barrel; the motor is in transmission connection with the air fan; and the self-generating electricity component comprises heat conduction blocks, temperature difference electricity generating pieces and heat dissipation devices, the heat conduction blocks are used for conducting heat, the temperature difference electricity generating pieces are attached to the corresponding heat conduction blocks and are in electric connection with the motor, and the heat dissipation devices are used for performing heat dissipation and cooling on one end surfaces of the temperature difference electricity generating pieces. The self-generating electricity air blowing mechanism for the outdoor heater is simple and reasonable in structure and convenient and fast to use, the outdoor heater is made to havethe self-generating electricity function, running of the motor and the air fan can be realized, thus the heat inside the combustion barrel is transferred outwards, the convection effect is realized, so that the better outdoor heating effect is obtained.

Owner:慈溪市恒进电子有限公司

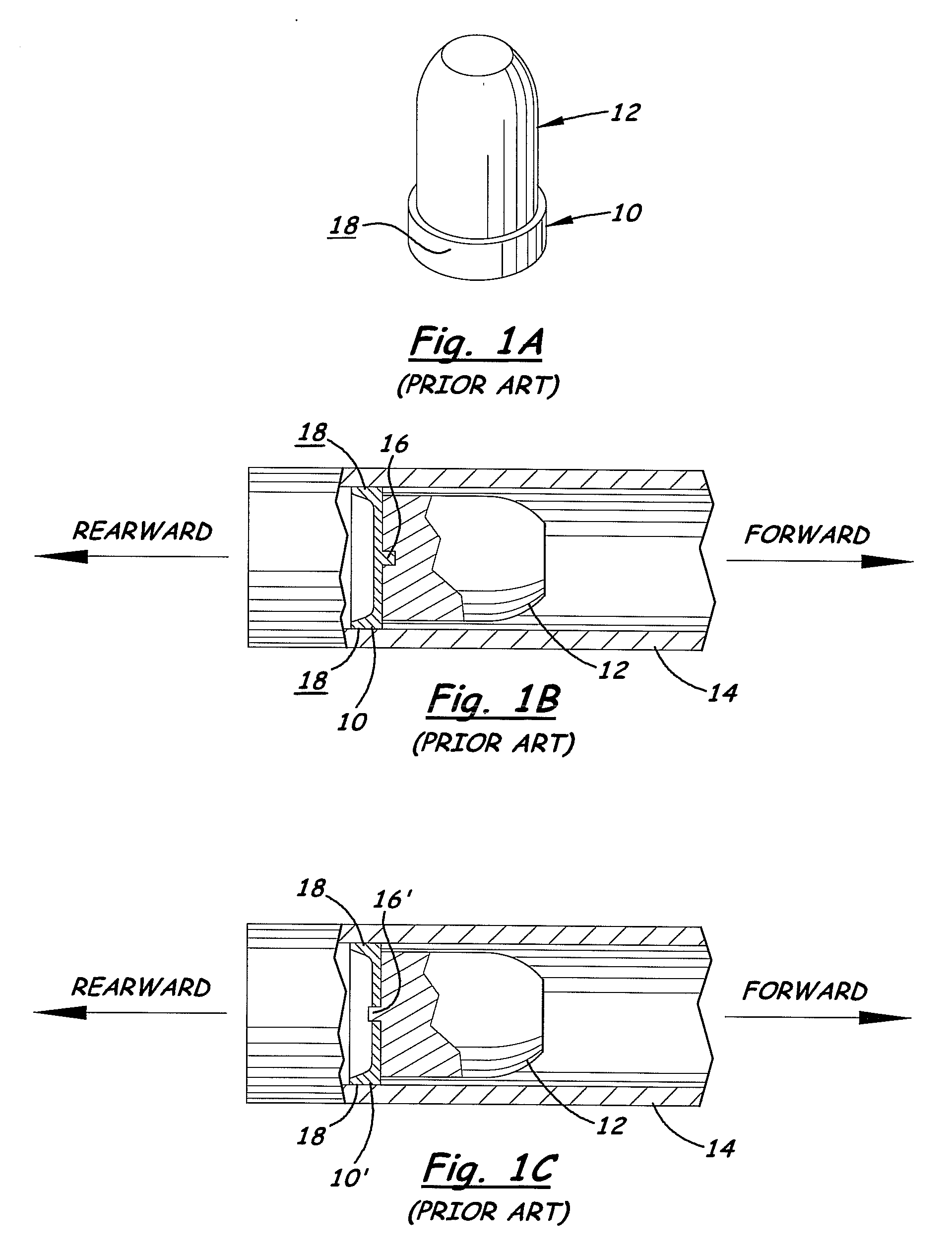

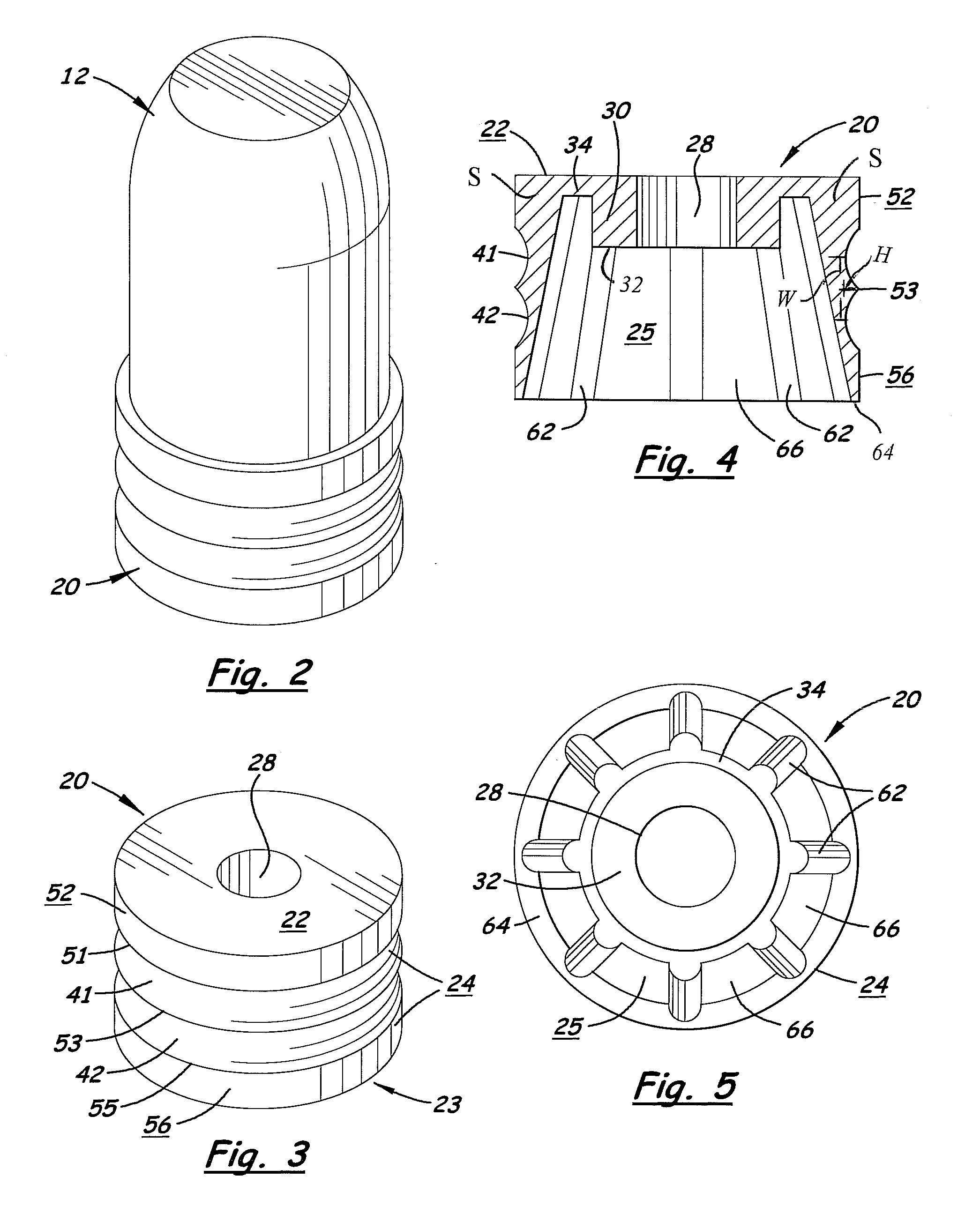

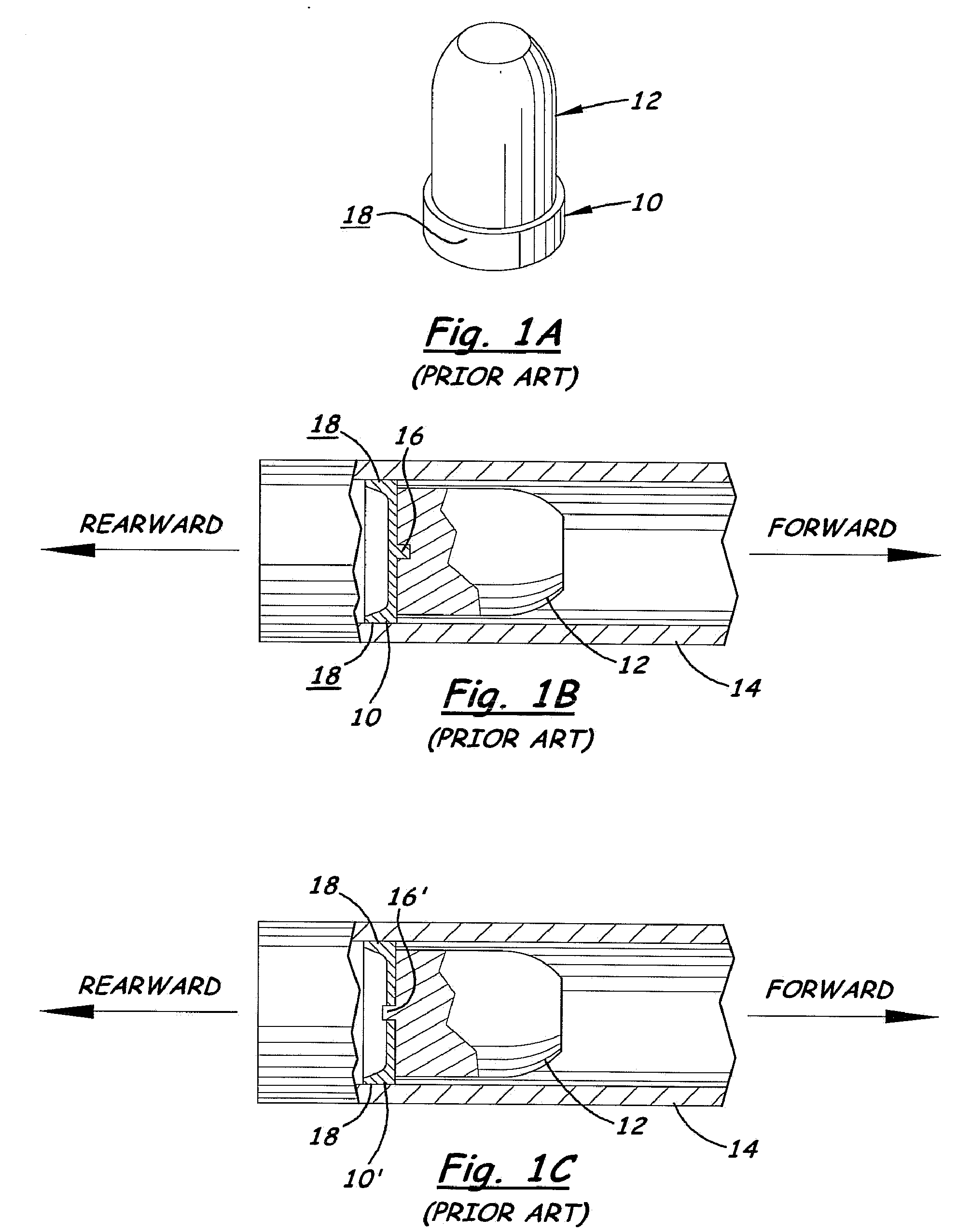

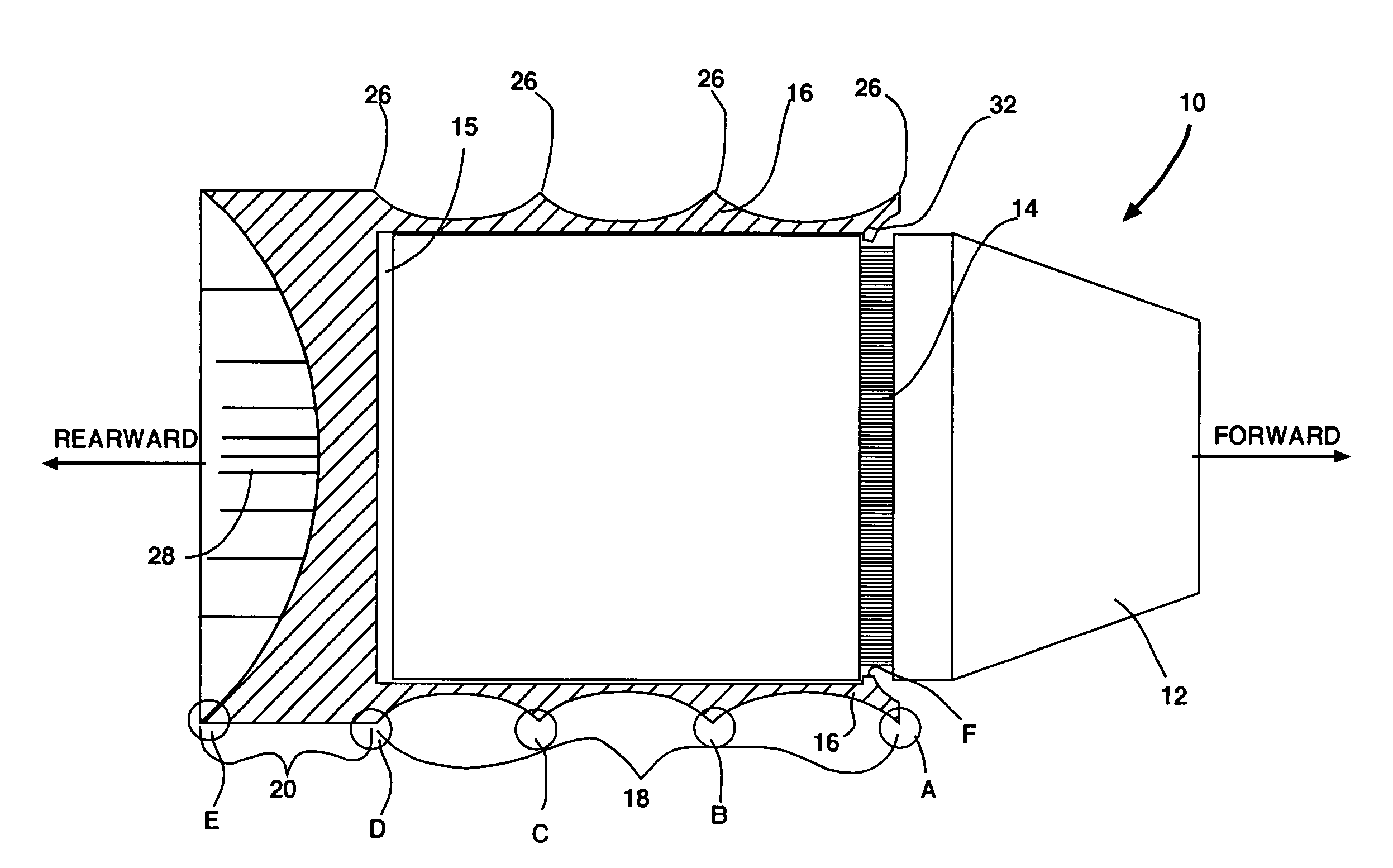

Gas check with system for improved loading and retention in bore of muzzleloading firearms

ActiveUS20100269725A1Easy loadingDrag minimizationAmmunition projectilesCartridge extractorsEngineeringRidge

A muzzle loading bullet gas check has external recess and ridge system, and / or an internal locking ridge system. The preferred gas check has an opening or recess on its front end for receiving and frictionally engaging a rearwardly extending post of the bullet, the opening also preferably including an internal radial ridge for gripping the post and / or locking with an indent on the post. The barrel-interacting part of the gas check has one or more external recesses and adjacent radial ridges / edges protruding relative to the recesses, which serves to reduce the total surface area of the gas check contacting the bore. The recesses do not touch the bore of the firearm, resulting in less friction and easier loading, while the outer ends / surfaces of the ridges / edges do touch the bore to retain the bullet in the bore during handling and hunting and to effectively capture gasses after the firing explosion.

Owner:ACCURA BULLETAB

Gas check with system for improved loading and retention in bore of muzzleloading firearms

InactiveUS20110048272A1Easy loadingDrag minimizationAmmunition projectilesProjectilesEngineeringRidge

A muzzle loading bullet gas check has external recess and ridge system, and / or an internal locking ridge system. The preferred gas check has an opening or recess on its front end for receiving and frictionally engaging a rearwardly extending post of the bullet, the opening also preferably including an internal radial ridge for gripping the post and / or locking with an indent on the post. The barrel-interacting part of the gas check has one or more external recesses and adjacent radial ridges / edges protruding relative to the recesses, which serves to reduce the total surface area of the gas check contacting the bore. The recesses do not touch the bore of the firearm, resulting in less friction and easier loading, while the outer ends / surfaces of the ridges / edges do touch the bore to retain the bullet in the bore during handling and hunting and to effectively capture gasses after the firing explosion.

Owner:HALL DANIEL W +1

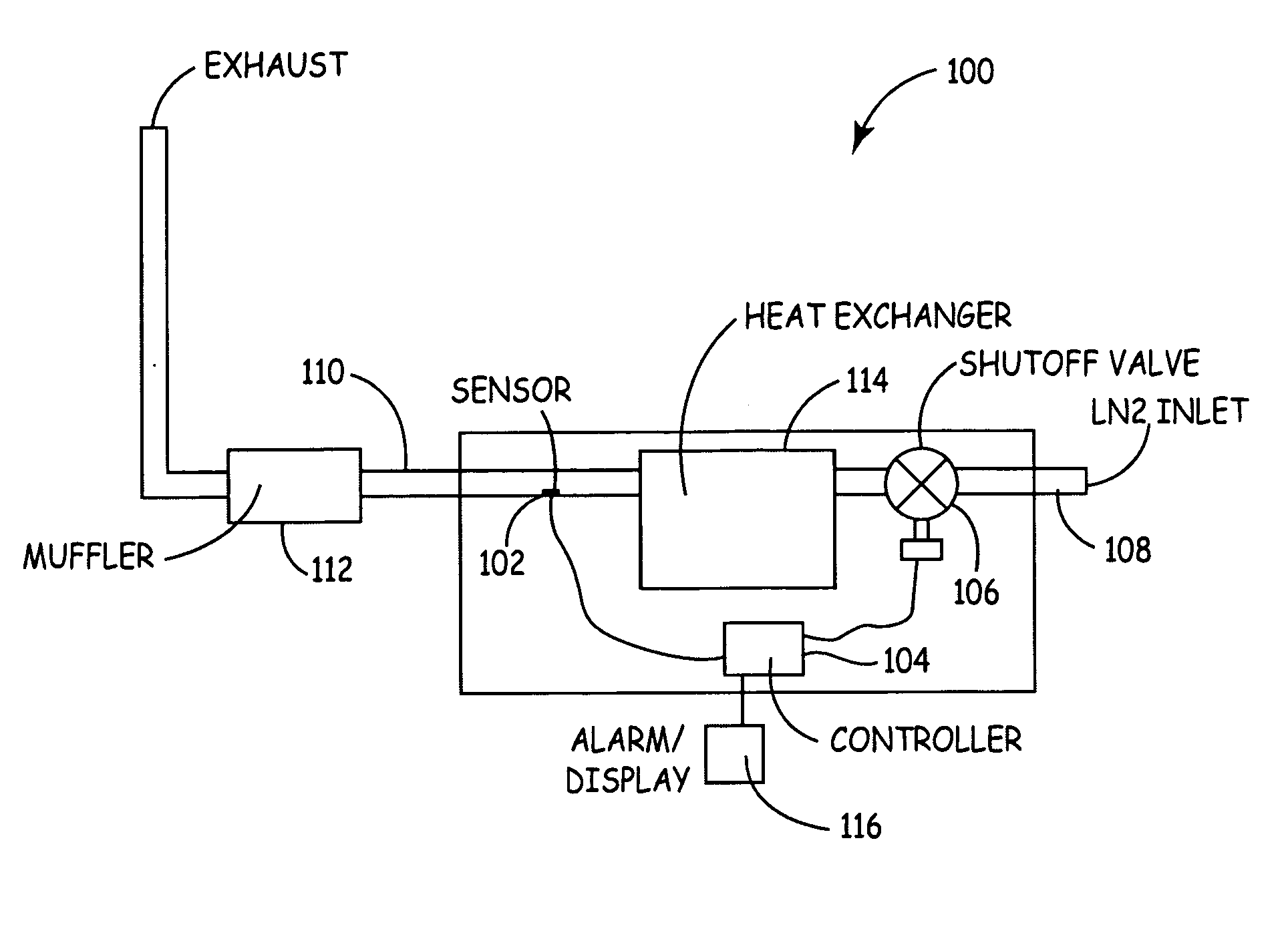

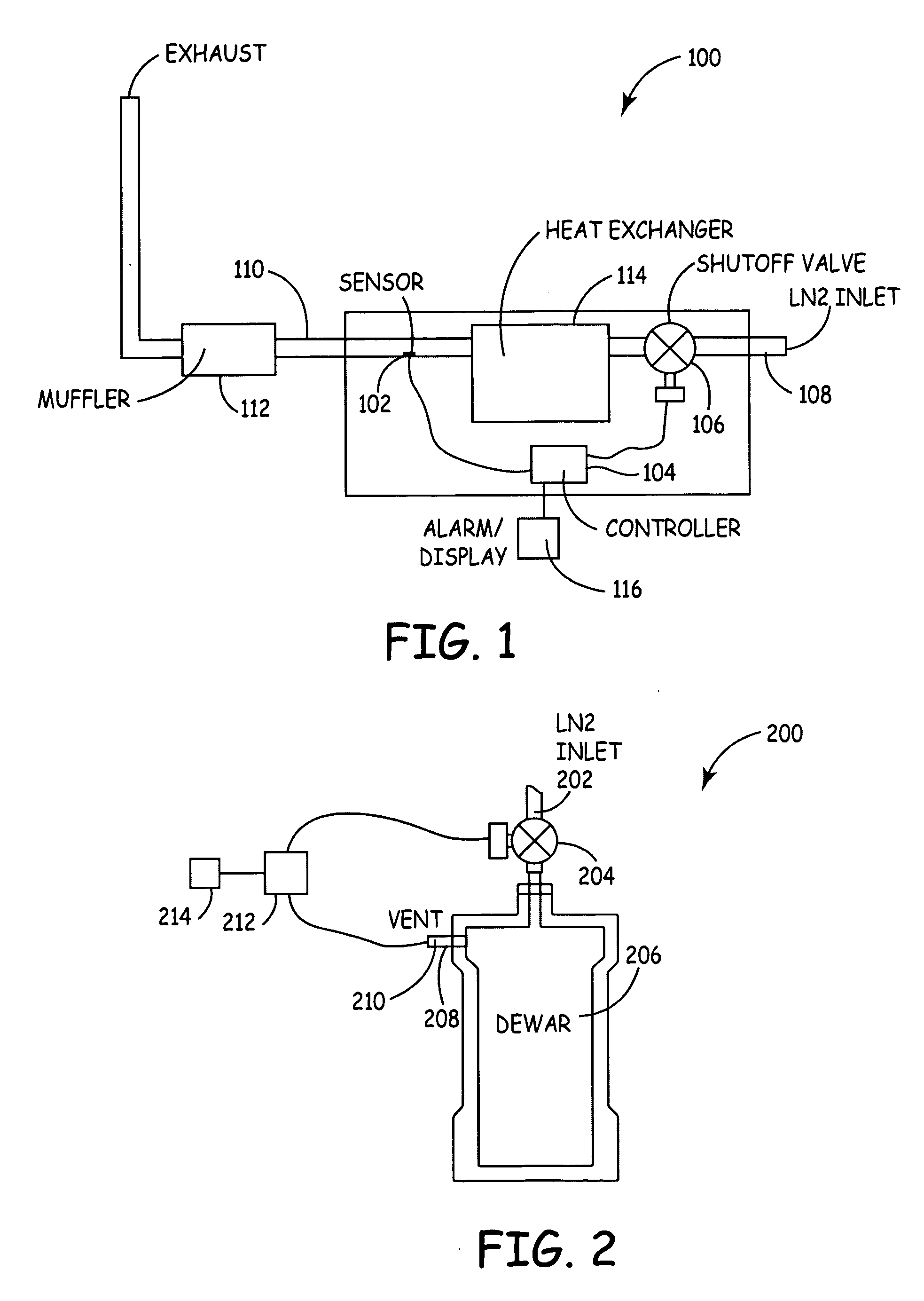

System and method for preventing blow-by of liquefied gases

InactiveUS20070181208A1Prevent blowbyGas handling applicationsMedical devicesTemperature controlLine tubing

A system and method for preventing blow-by of liquefied gases is disclosed, which senses the occurrence of blow-by and shuts off the source of the liquefied gas. As one example, a system for preventing blow-by of LN2 is disclosed, which includes a temperature sensor located near an exhaust line of a heat exchanger, a shutoff valve located in an inlet line, and a controller coupled to the temperature sensor and the shutoff valve. The sensor measures the temperature of the exhaust, and provides a signal to the controller that indicates if the temperature of the exhaust approaches the temperature of LN2. If the exhaust temperature approaches the temperature of LN2, the controller sends a signal to the shutoff valve, which causes the valve to close and stops the flow of LN2 to the heat exchanger involved. The controller can also send an alarm signal to a display, which indicates to a user that the blow-by is occurring. If the exhaust temperature increases significantly above the temperature of LN2 (e.g., blow-by is no longer occurring), the controller can send a second signal to the shutoff valve, which causes the valve to open and resume the flow of LN2.

Owner:HONEYWELL INT INC

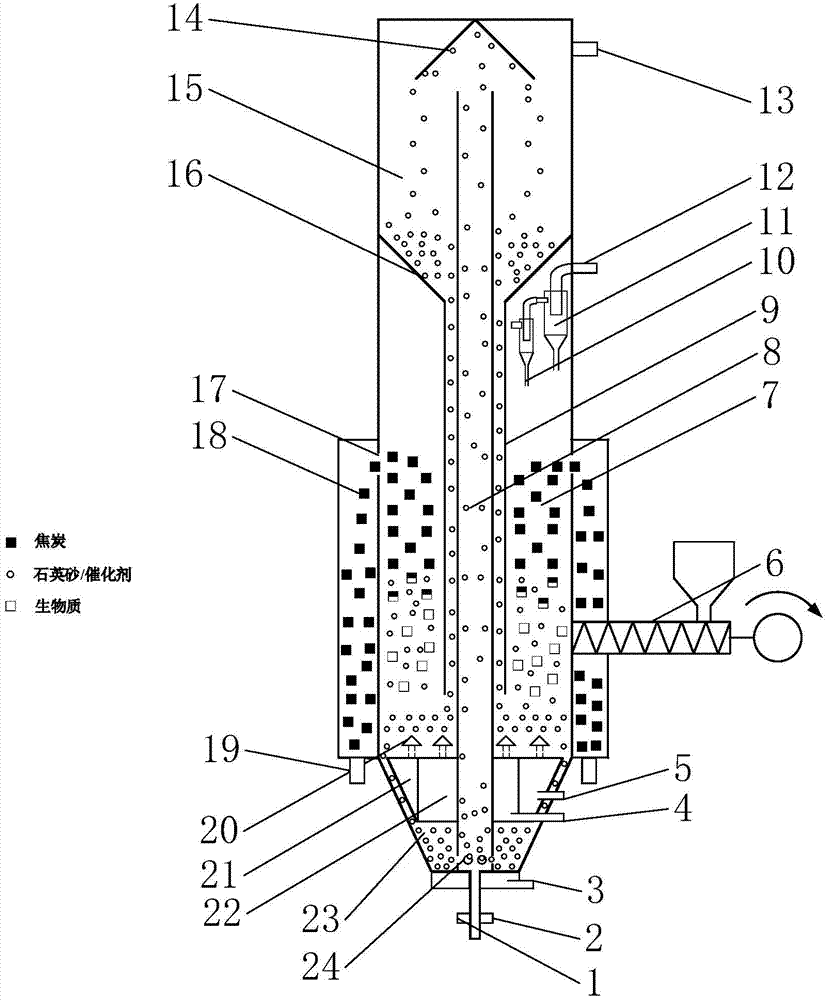

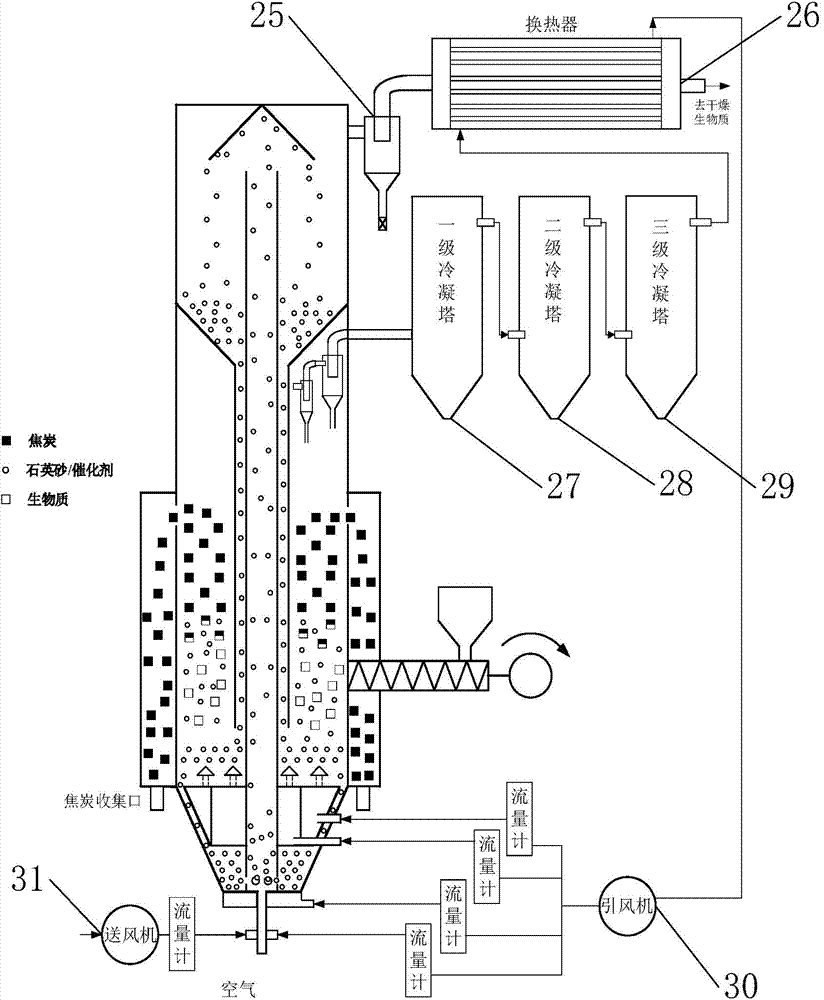

Device and method for utilizing biological substance for monobed self-heating oil manufacturing with coke separation function

ActiveCN104711003APrevent blowbyRealize automatic separationDirect heating destructive distillationBiofuelsCombustion systemHeat carrier

The invention provides a device and a method for utilizing a biological substance for monobed self-heating oil manufacturing with a coke separation function. The device comprises a combustion system, a pyrolysis and coke separation system, as well as an air distribution and entrainment system, wherein a guide tube is positioned in the center; a combustion zone is positioned above the guide tube; a pyrolysis zone is positioned outside the guide tube. The method comprises the following steps: through a conical second dipleg, a heat carrier is entrained into the guide tube; the entrained heat carrier is heated in the guide tube and the combustion zone; a redirector is utilized for changing the flow direction, so as to form a fountain state; a combustion product slips into a first dipleg, and then enters the pyrolysis zone to heat the biological substance. The device and the method have the advantages that the coke is collected by combusting non-condensable gas, and automatic coke separation is achieved, so that high-performance coke can be obtained; the whole process can be realized in a monobed, so that the device is compact in structure and suitable for a movable platform, and can be placed in the fields for biological substance processing; through the conical second dipleg, the blow-by phenomenon can be effectively prevented.

Owner:SOUTHEAST UNIV

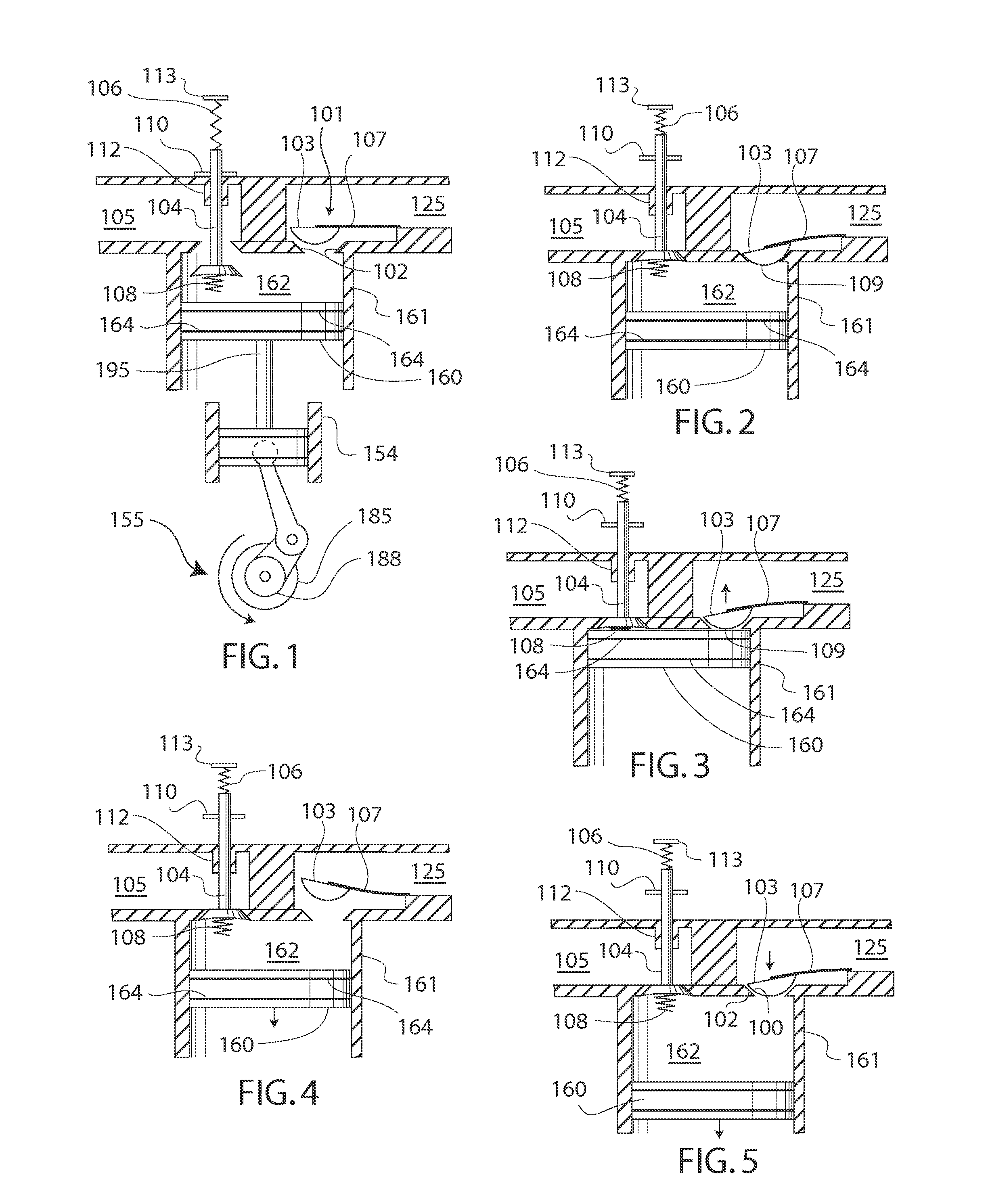

Two-Stroke Internal Combustion Engine

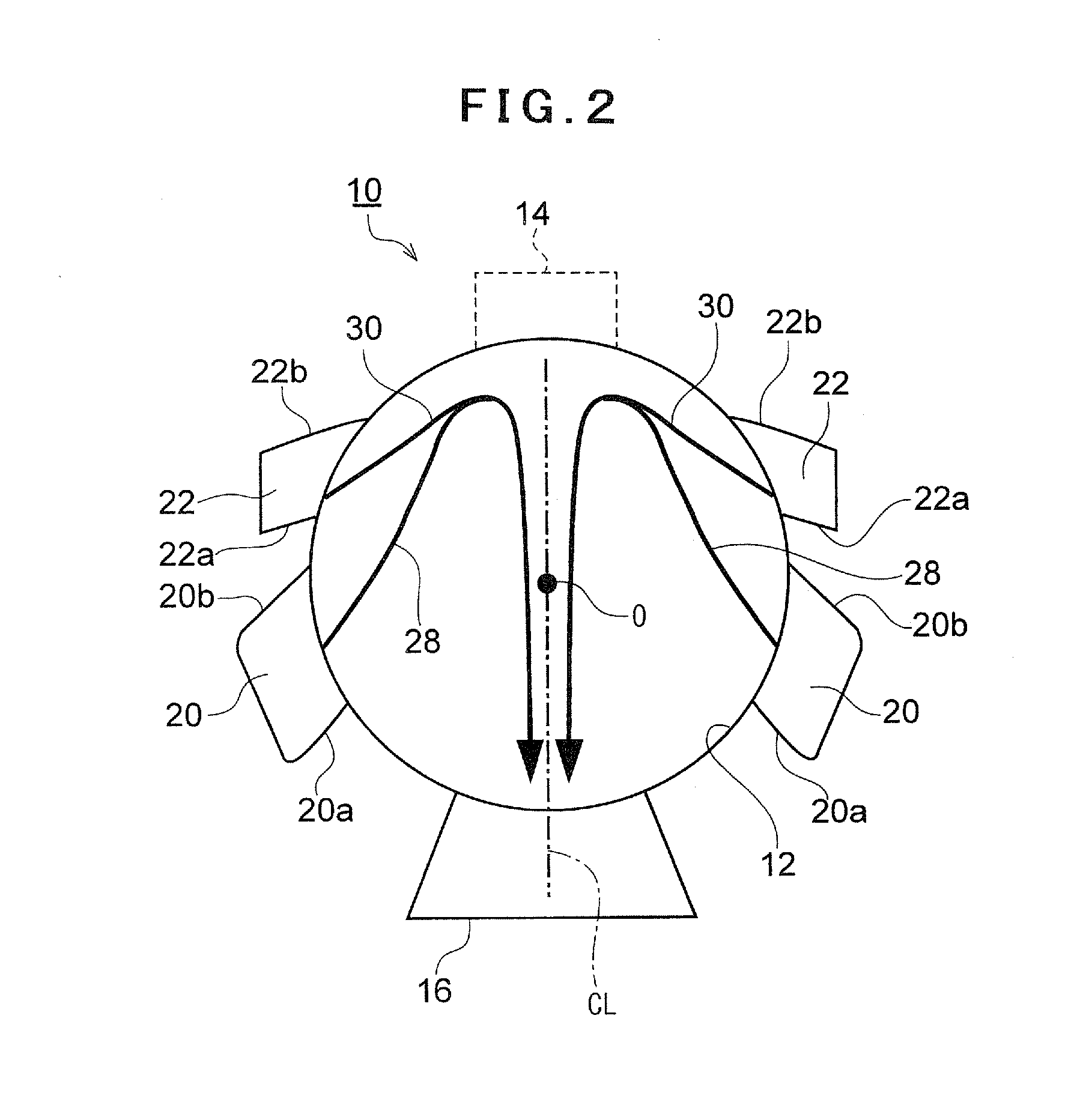

ActiveUS20130037011A1Reduce flow rateImprove directivityCylinder headsCombustion enginesExternal combustion engineEngineering

It is intended to effectively prevent blow-by with no need for large changes in typical structures of two-cycle internal combustion engines. A main scavenging passage (24) for supplying air-fuel mixture from a crankcase to a combustion chamber for scavenging purposes has a branch scavenging passage (26) that extends upward aslant toward an intake port (14). The main scavenging passage (24) communicates with a first scavenging port (20) located nearer to an exhaust port (16). The branch scavenging passage (26) communicates with a second scavenging port (22). A mean cross-sectional area of the branch scavenging passage (26) is smaller than that of the main scavenging passage (24). Cross-sectional area of a portion (24b) next to an inlet port (24a) of the main scavenging passage (24) opening to the crankcase is smaller than the sum of cross-sectional areas of the first and second scavenging ports (20, 22).

Owner:YAMABIKO CORP

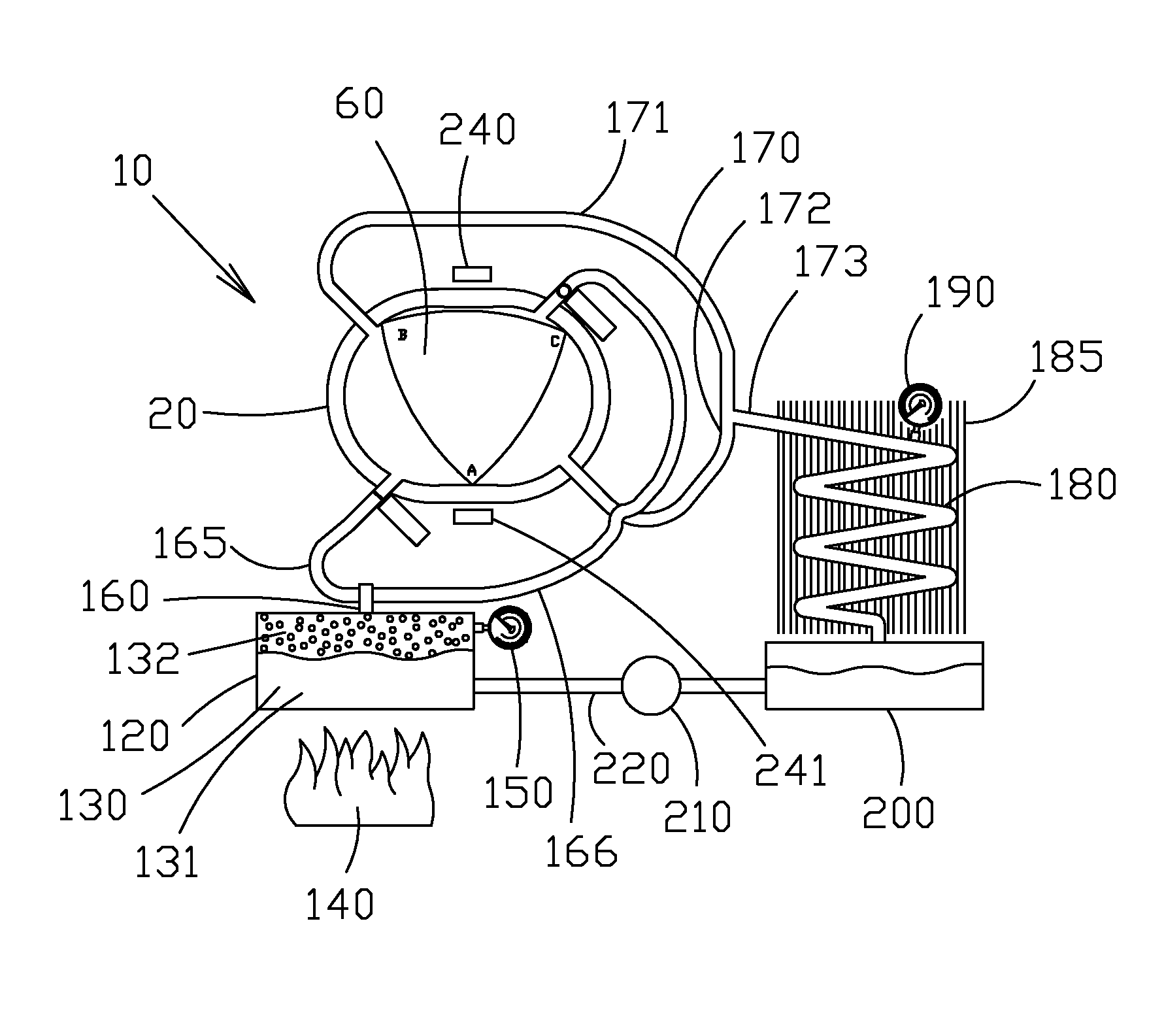

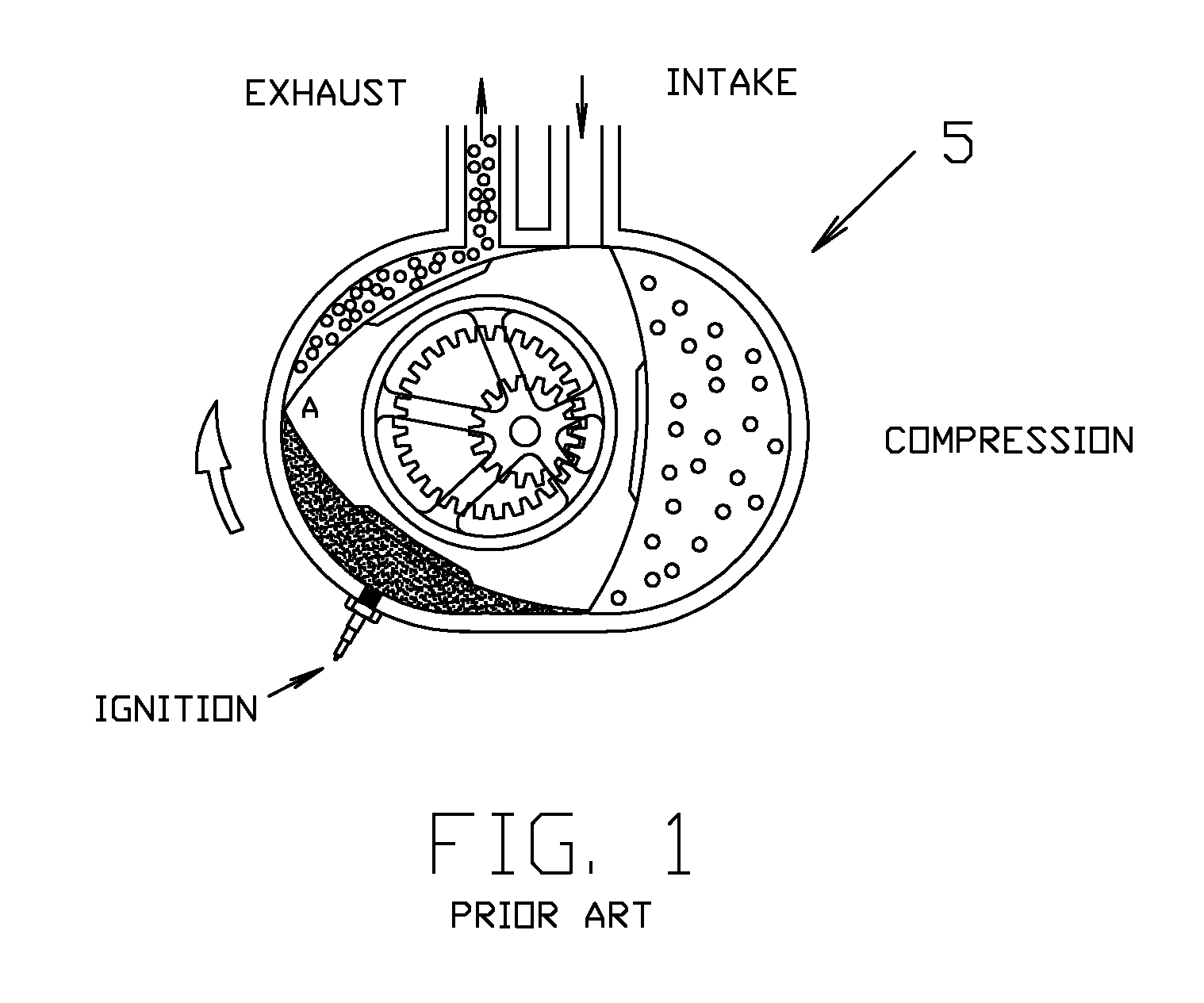

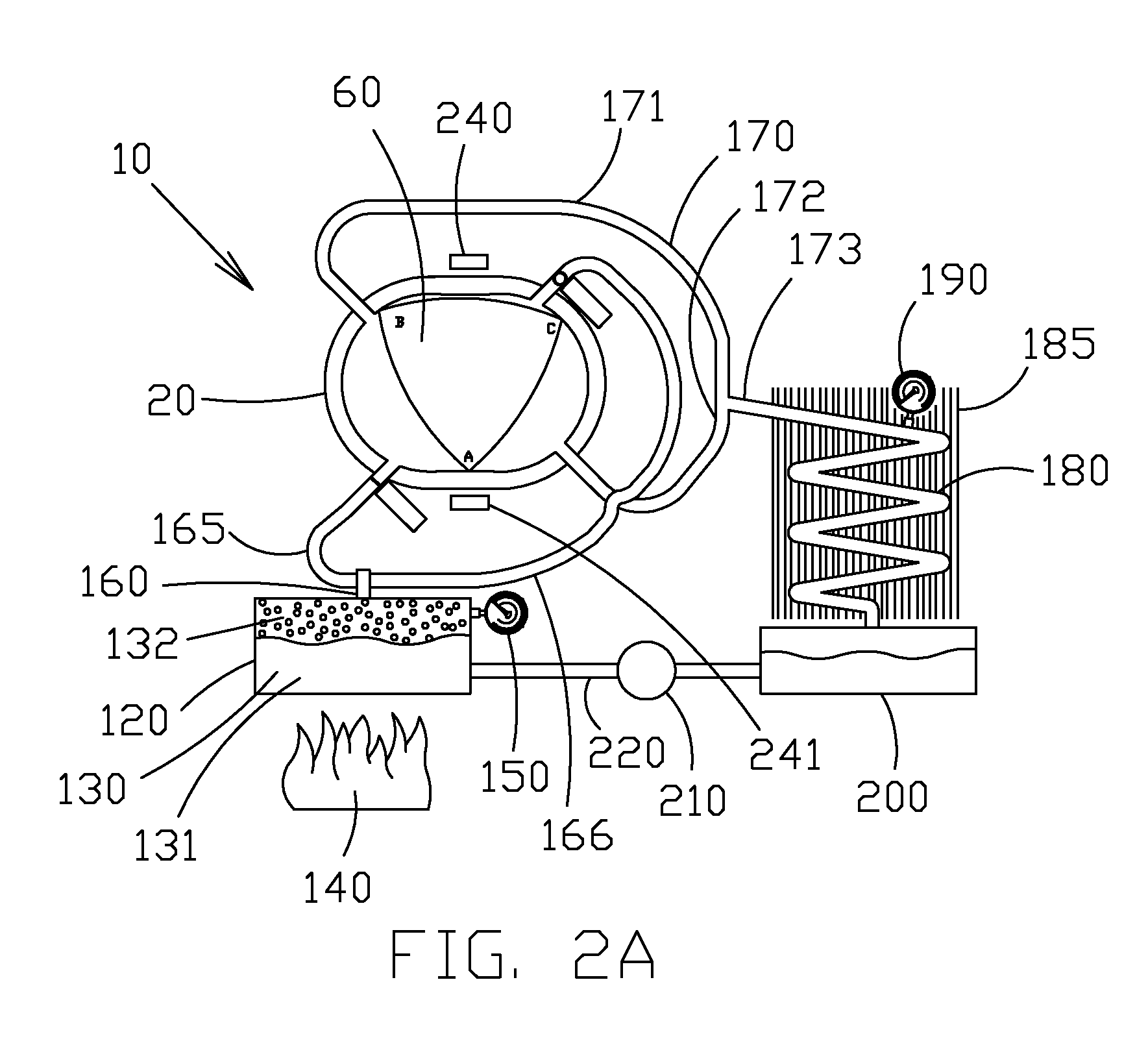

Heat engine

ActiveUS8978618B2Minimized volumeElongated driving forceInternal combustion piston enginesEngine of arcuate-engagement typePower cycleHigh pressure

The present invention relates to a heat engine having a housing. A generally triangular shaped rotor can drive an offset crank as it eccentrically rotates within the housing. Two inlets with valves and two exhausts are provided. The volume between each face of the rotor and the housing defines three expansion chambers. Six power cycles are provided (one by each expansion chamber times two inlets) per revolution of the rotor. Each valve controls the length of time that high pressure gas is allowed to enter each expansion chamber. The valves are controlled by a processor and close when enough pressure is supplied so that the pressures inside and outside the expansion chamber are equal when the chamber is fully expanded just prior to exhaust. Gates can provide a mechanical advantage to the rotor by reducing the amount of pressure applied to the back side of the fulcrum.

Owner:DAVIS BRIAN

Automatic compensating type magnetic descaling pipe clearing device

The invention discloses an automatic compensating type magnetic descaling pipe clearing device, which comprises a cylindrical shell. A main guiding shaft is arranged in the shell and provided with a thrust spring in a sleeved mode; one end of the thrust spring is connected with a top plate, and the other end of the thrust spring is connected with a bottom plate; the outer diameter of the bottom plate is larger than that of the shell; the inner side of the top plate is connected with a spring compression rope, and the tail end of the spring compression rope is connected with the bottom plate through a pull rope release; a cone body is arranged on the outer side of the top plate and sleeves the main guiding shaft; a universal ball is annularly arranged at the front end of the cone body and located at the other end of the shell; a plurality of fan-shaped sealing straight plates are arranged on the universal ball in a surrounding mode and can move in the radial direction of the main guiding shaft; and one sides of the sealing straight plates are sequentially provided with fixed guiding plates, steel brushes and leather cups. According to the automatic compensating type magnetic descaling pipe clearing device, in the traveling process of the pipe clearing device, the fan-shaped sealing straight plates automatically move outwards for compensating after being abraded, and the problemthat sealing straight plates of a pipe clearing device are not resistant to abrasion is solved.

Owner:SHENYANG XINLIAN PETROCHEM EQUIP CO LTD

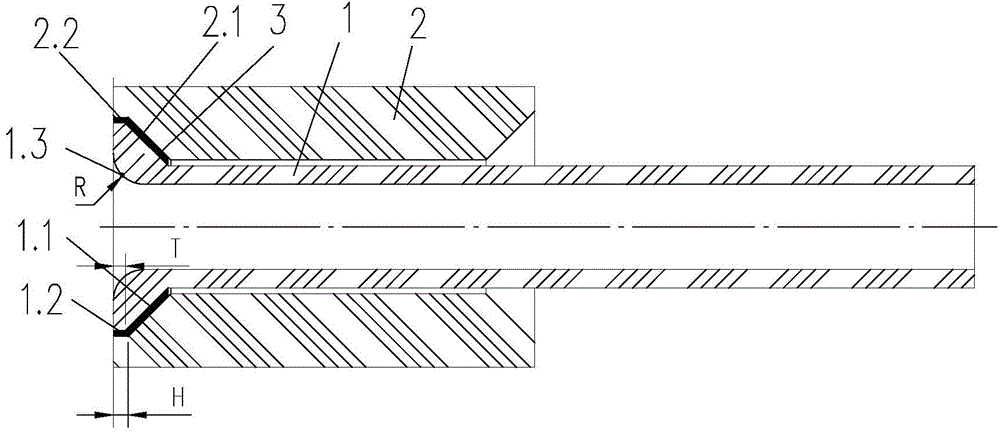

Combined inserting protective sleeve of waste heat boiler

InactiveCN104676144AReduce abrasionSimple structureEngine sealsRigid pipesArchitectural engineeringWaste heat

The invention discloses a combined inserting protective sleeve of a waste heat boiler, and solves the problem of the current protective sleeve that the actual forming quality is poor and the dimensional tolerance is difficult to control because the section size of a cone section is too small so that this position easily generates the fit clearance of gas carry-over. The technical scheme comprises an outer protective pipe and an inner protective pipe sleeved in the outer protective pipe; the outer pipe wall of the inlet end of the inner protective pipe and the inner pipe wall of the inlet end of the outer protective pipe are the conical surface fit; and the rear sections of the conical surfaces of the inner protective pipe and the outer protective pipe are provided with steps correspondingly. The combined inserting protective sleeve of the waste heat boiler has the characters of simple structure, convenient maintenance, low size fit requirement of the inner and outer pipes, difficult gas carrying-over, and good sealing performance.

Owner:WUHUAN ENG

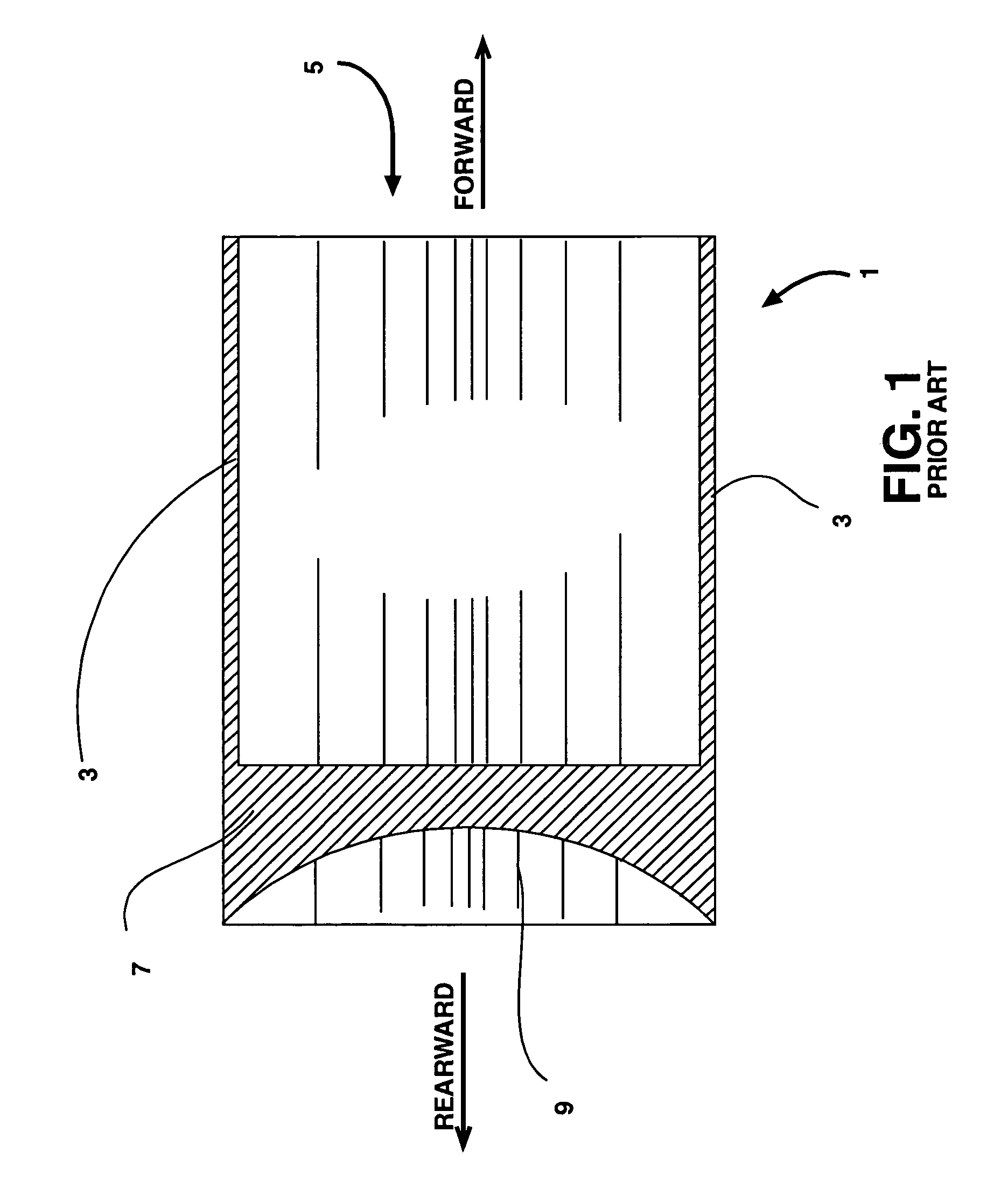

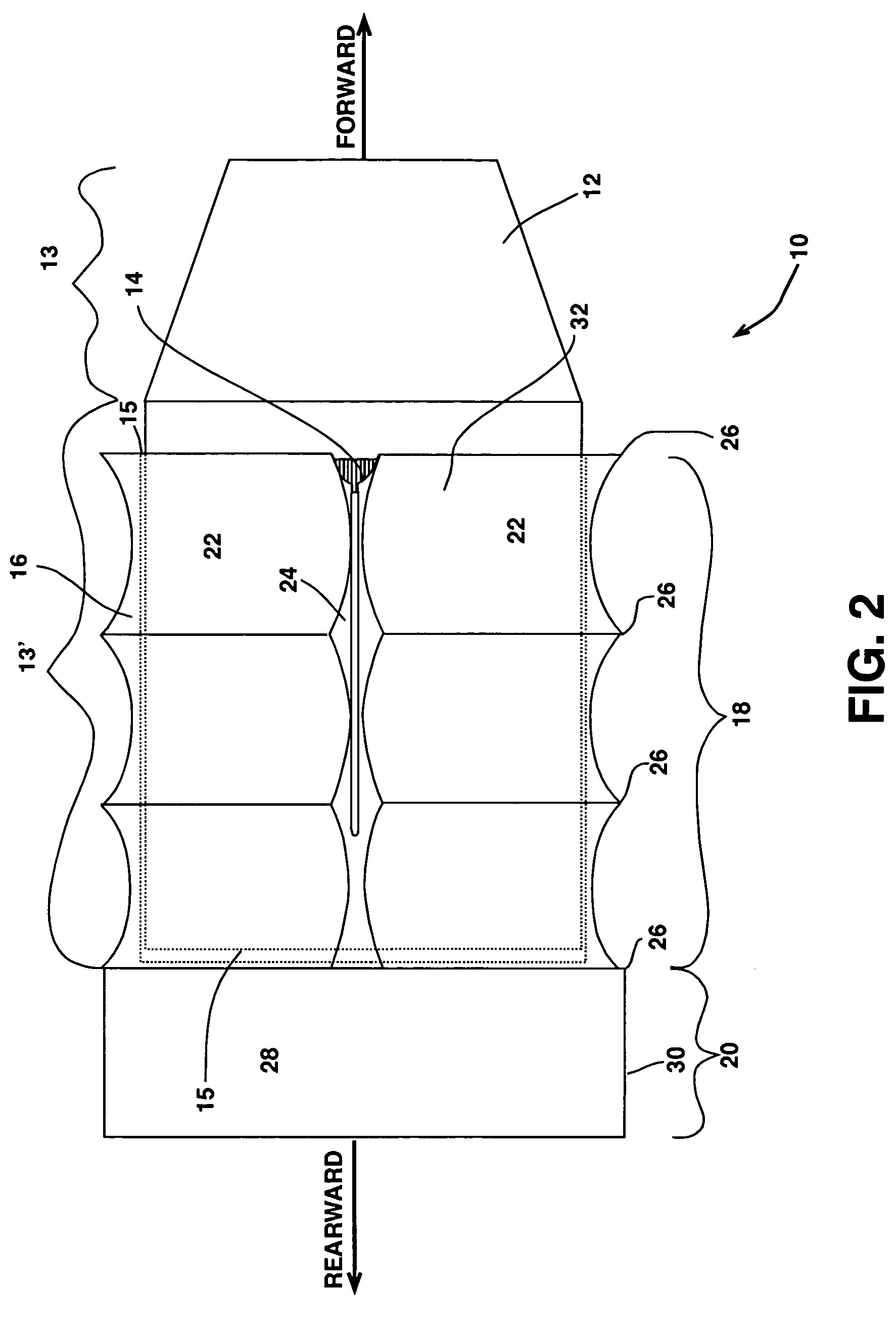

Saboted projectile with external ridges and/or internal locking edge for muzzleloading firearms

ActiveUS7444942B2Easy loadingEfficient captureAmmunition projectilesMuzzle-loading smallarmsEngineeringGun barrel

The present invention is a saboted projectile with external ridges and / or an internal locking edge for muzzleloading firearms. Also, the present invention is a sabot with the ridges and / or locking edge for receiving a muzzleloading projectile. The sabot has a forward part and a rearward part. The forward part has a plurality of axial panel sections separated by narrow, axial slots. The panels have radial ridges on their outside, or external surfaces. Also, the panels have a radial ridge on their inside, or internal surfaces. The external radial ridges assist in convenient loading of the muzzleloading projectile, while still providing enough contact with the inside of rifle barrel to capture exploding gases and prevent blow-by. The internal radial ridge assists in securing the sabot to the bullet, especially when the bullet has been provided with a cooperating radial indent, cannelure or retaining ring. Consequently, when the saboted projectile of the present invention is seated in the bore in front of the power charge, the bullet will not easily separate from the sabot, and therefore, the bullet will not easily fall out of the barrel.

Owner:ACCURA BULLETAB

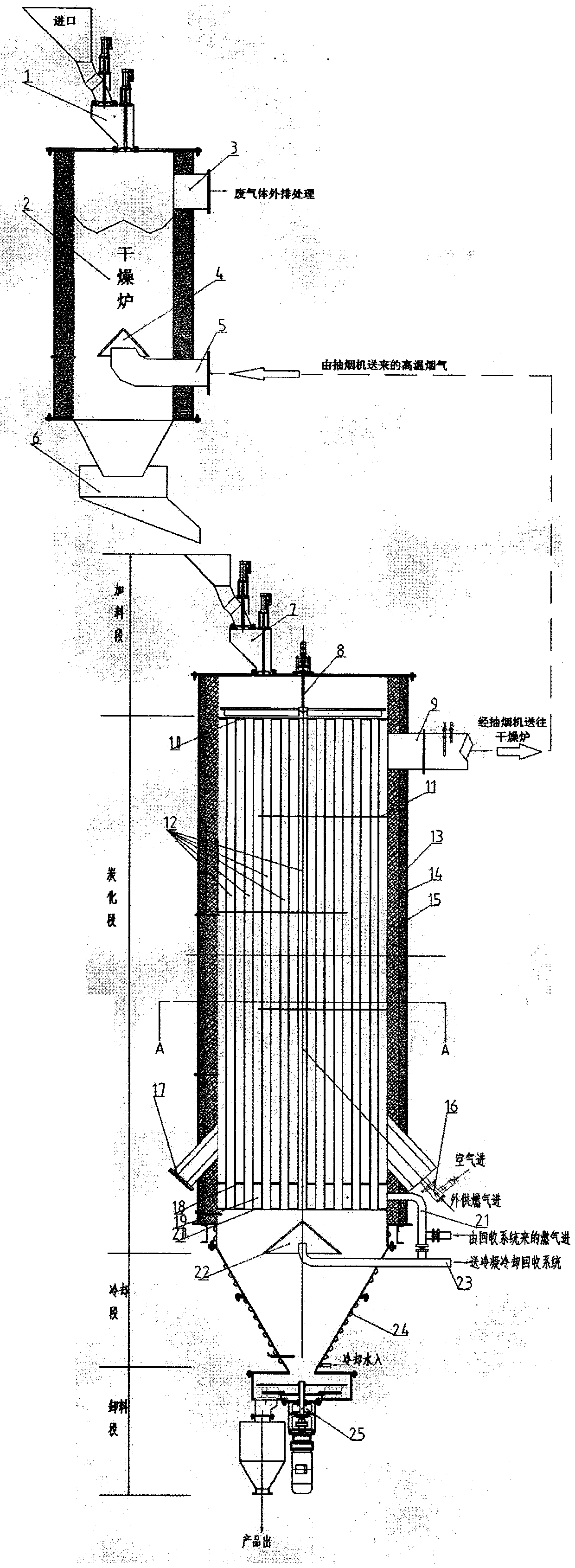

Vertical-shaft tube carbonization furnace

InactiveCN110240914AControl outputPrevent blowbyBiofuelsIndirect heating destructive distillationMetallurgyCarbonization

The invention relates to a vertical-shaft tube carbonization furnace, and belongs to the field of carbonization of carbon-containing organic matter. The carbonization furnace is particularly suitable for carbonization of agricultural straw waste, and is also suitable for carbonization of waste biomass including municipal sludge. The carbonization furnace provided by the invention has the following advantages: 1, a material is located in a pipe, so that the carbonization furnace cannot have uneven material falling and dead angles, and even if material attachment occurs, the furnace does not need to be stopped for cleaning; 2, a yield of wood vinegar can be regulated and controlled according to the market of the wood vinegar; and 3, a drying furnace and the carbonization furnace are respectively provided with one material adding machine, so that the possibility of gas blowby is avoided

Owner:吴植仁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com