Two-Stroke Internal Combustion Engine

a two-stroke, internal combustion technology, applied in combustion engines, machines/engines, cylinders, etc., can solve the problems of mixing charged into the combustion chamber and yet unburned is discharged outside, deteriorating fuel consumption, and inviting an increase in unburned components, so as to reduce short-cut phenomenon, improve directivity of the second, and flow velocity. low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Some embodiments of the invention is explained below with reference to the drawings.

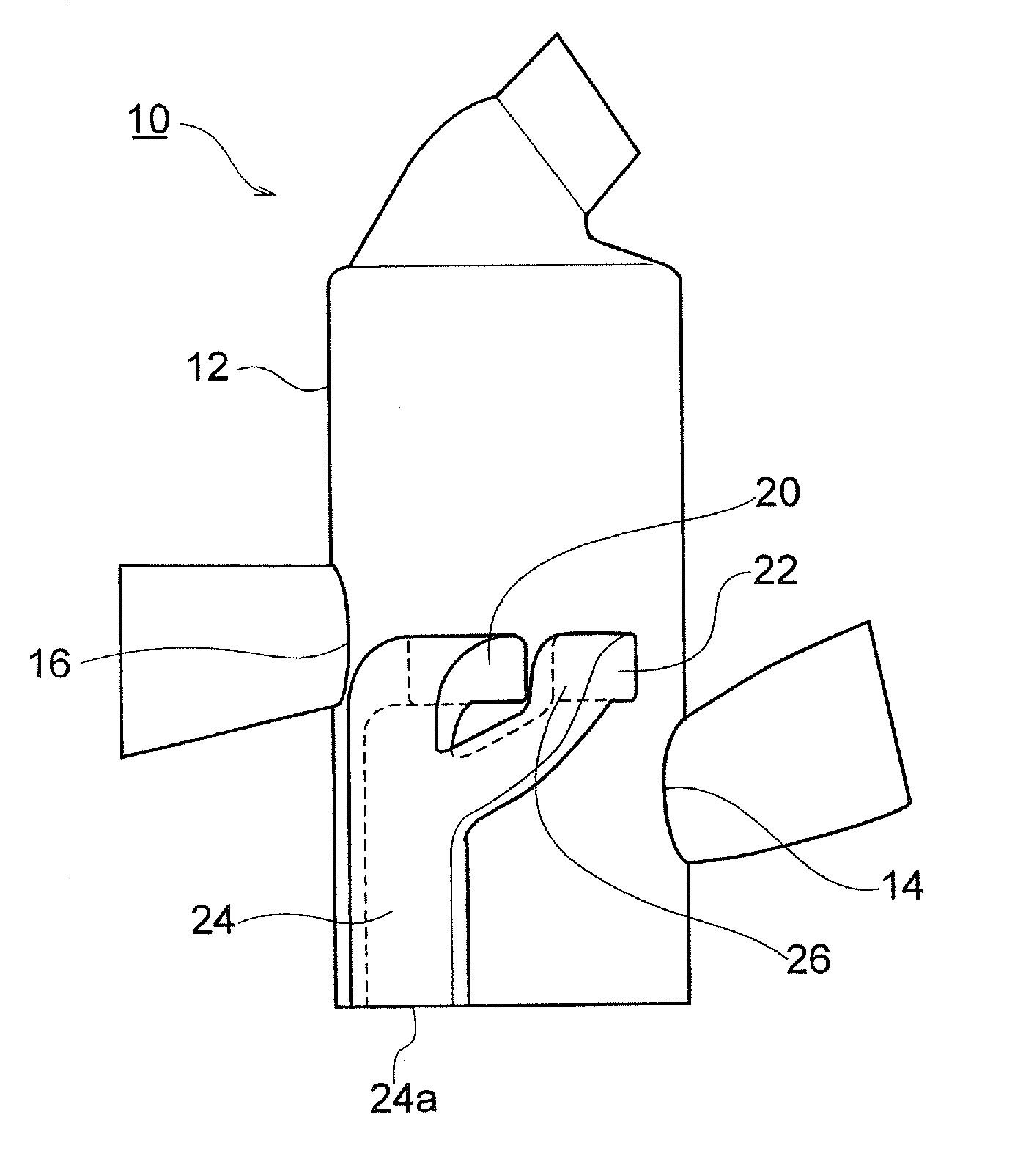

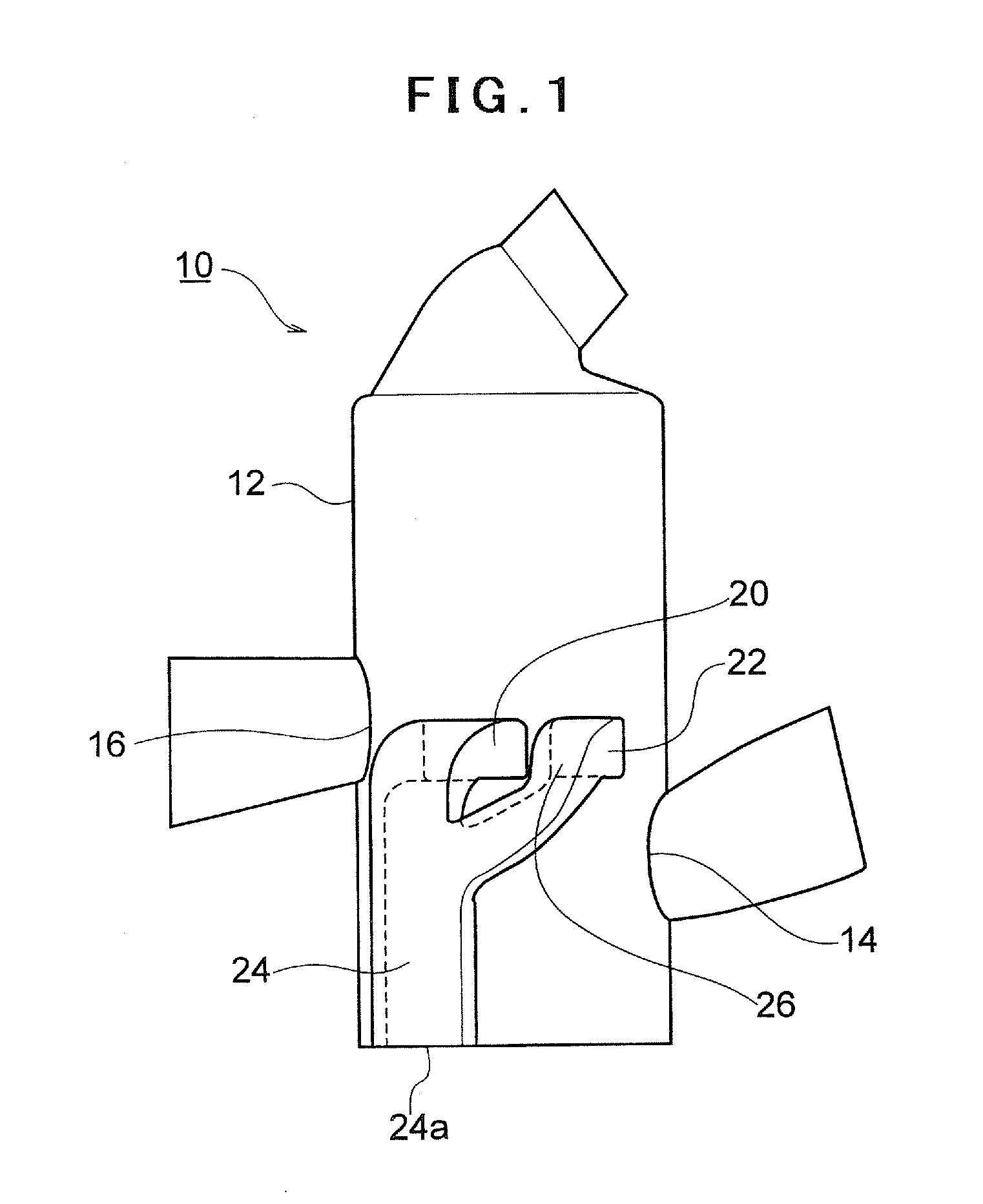

[0042]FIGS. 1 through 3 show an embodiment of the invention. As shown in FIG. 1, an air-cooled single-cylinder two-stroke internal combustion engine 10 has a cylinder bore 12 that may be, for example, an aluminum die cast product. An intake port 14 and an exhaust port 16 are formed at diametrically opposite positions of the cylinder bore 12. Air-fuel mixture introduced from the intake port 14 is charged in the crankcase (not shown).

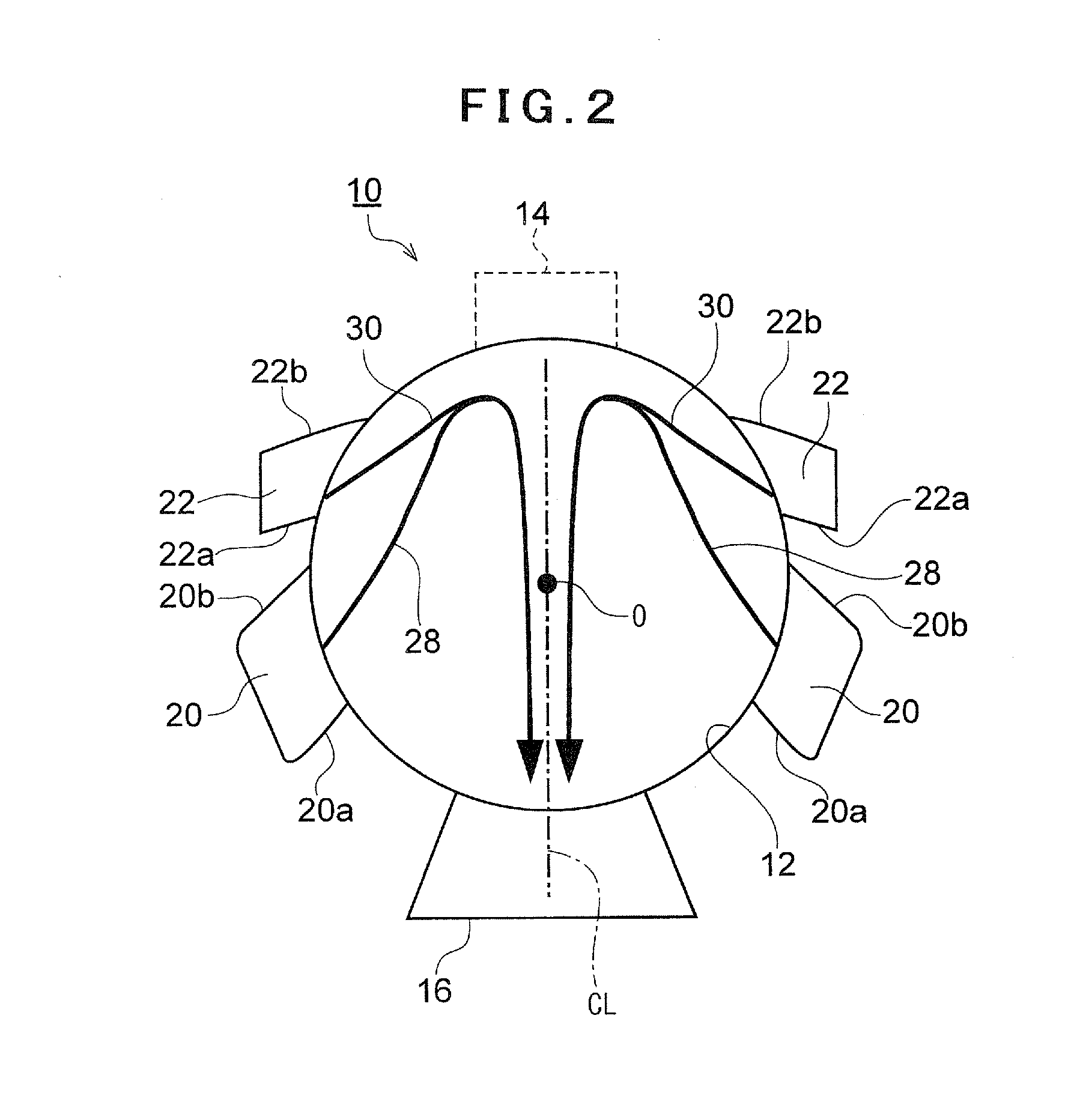

[0043]With reference to FIG. 2, a pair of the first and second scavenging ports 20 and 22 is provided at each of axisymmetric positions about an imaginary line CL that connects the center of the cylinder bore O and the center of the exhaust port 16. The first and second scavenging ports 20 and 22 are opened and closed by strokes of piston (not shown). These features of the two-stroke internal combustion engine 10 according to the embodiment of the invention so far de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com