Beer spear

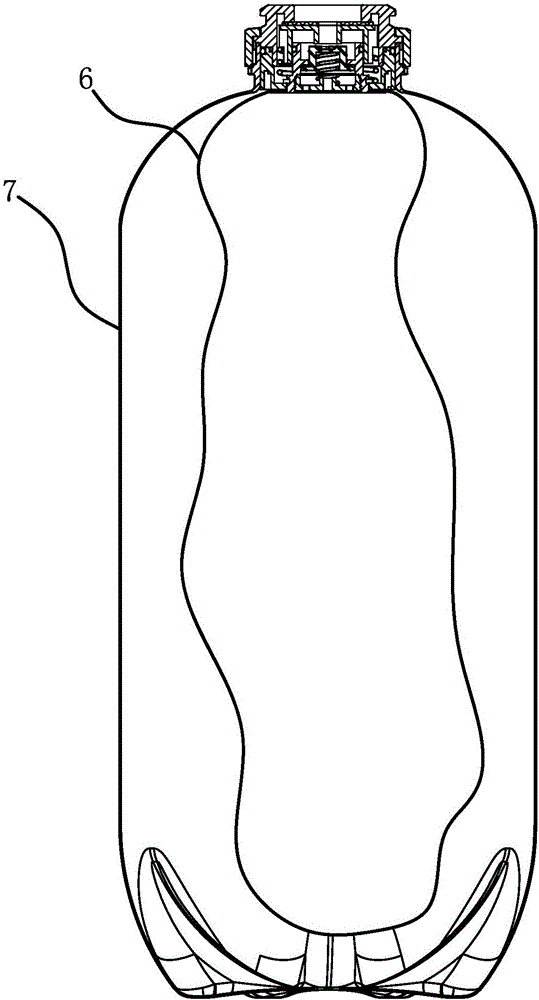

The technology of a wine spear and a valve core is applied in the field of wine drinking equipment, which can solve the problems of high cost of metal wine barrels, affecting the sealing performance, and deteriorating the quality of beer and wine, and achieves the effects of improving operation stability and reliability and improving sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

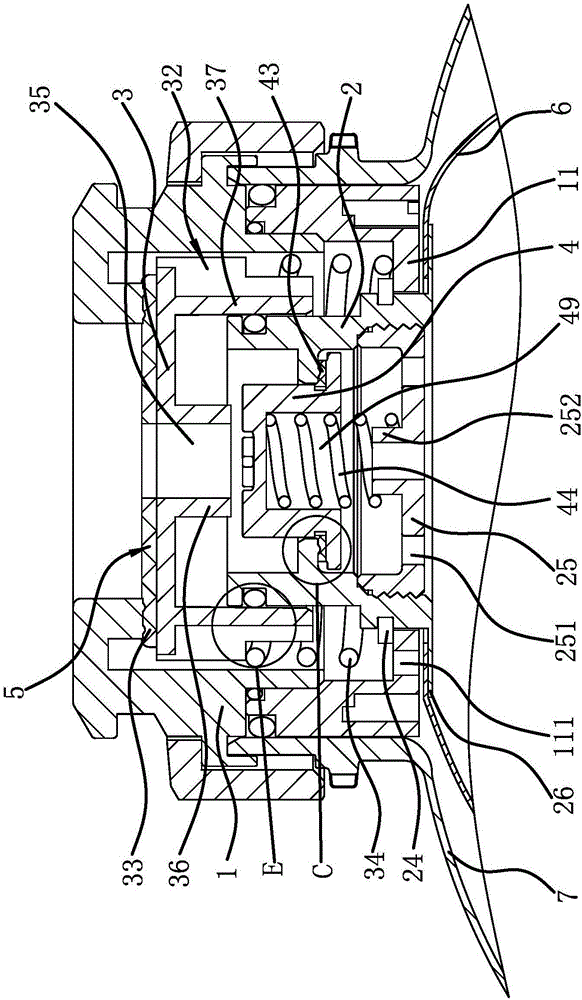

[0060] The structure of the wine spear is basically the same as in the first embodiment, the difference lies in Picture 12 , Figure 13 As shown, since the wine outlet pipe 81 of the dispenser 8 used in conjunction with the wine spear is connected with a sealing sleeve 82, the wine outlet pipe 81 of the dispenser 8 is pressed against the valve seat 3 through the sealing sleeve 82 when wine is taken. Therefore, the valve seat 3 of the wine spear does not need a sealing structure 5, but has an annular abutting convex edge 38 on the upper end surface of the valve seat 3, and the sealing sleeve 82 on the wine outlet pipe 81 of the distributor 8 is pressed against Sealing is achieved on the abutting flange 38, and the guide rib on the valve core 4 is wider. When the valve seat 3 moves downward, the contact portion 36 is pressed against the upper end of the guide rib to realize the valve core 4 and the valve The seat 3 moves down together.

Embodiment 3

[0062] The structure of the wine spear is basically the same as in the first embodiment, the difference lies in Figure 14 , Figure 15 As shown, since the wine outlet pipe 81 of the dispenser 8 used in conjunction with the wine spear is connected with a sealing sleeve 82, the wine outlet pipe 81 of the dispenser 8 is pressed against the valve seat 3 through the sealing sleeve 82 when wine is taken. Therefore, the valve seat 3 of the wine spear does not need a sealing structure 5, but an annular abutting groove 39 is circumferentially opened on the upper end surface of the valve seat 3, and the sealing sleeve 82 on the wine outlet pipe 81 of the distributor 8 is pressed against Sealing is achieved in the abutting groove 39, and the guiding rib on the valve core 4 is wider. When the valve seat 3 moves downwards, the contact portion 36 is pressed against the upper end surface of the guiding rib to realize the valve core 4 and the valve seat 3 move down together.

Embodiment 4

[0064] The structure of the wine spear is basically the same as in the first embodiment, the difference lies in Figure 16 As shown, the sealing gasket 33 is fixedly connected to the upper end surface of the valve seat 3 and can move together with the valve seat 3 to realize the sealing of the intake passage 32, and the function of the sealing gasket 33 only needs to ensure the sealing of the intake passage 32 That is, the sealing structure 5 includes a sealing ring 51 fixedly connected to the upper end surface of the valve seat 3, and the sealing ring 51 is located inside the sealing gasket 33, and the wine outlet pipe 81 of the dispenser 8 can be pressed against the seal when pressed down. The ring 51 realizes the sealing between the wine outlet pipe 81 of the dispenser 8 and the valve seat 3, and has a better sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com