Device and method for utilizing biological substance for monobed self-heating oil manufacturing with coke separation function

A biomass and self-heating technology, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, coke ovens, etc., can solve the problems of gas blow-by, large volume, large investment, etc., to prevent condensation and blockage, compact device structure, Effect of preventing blow-by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

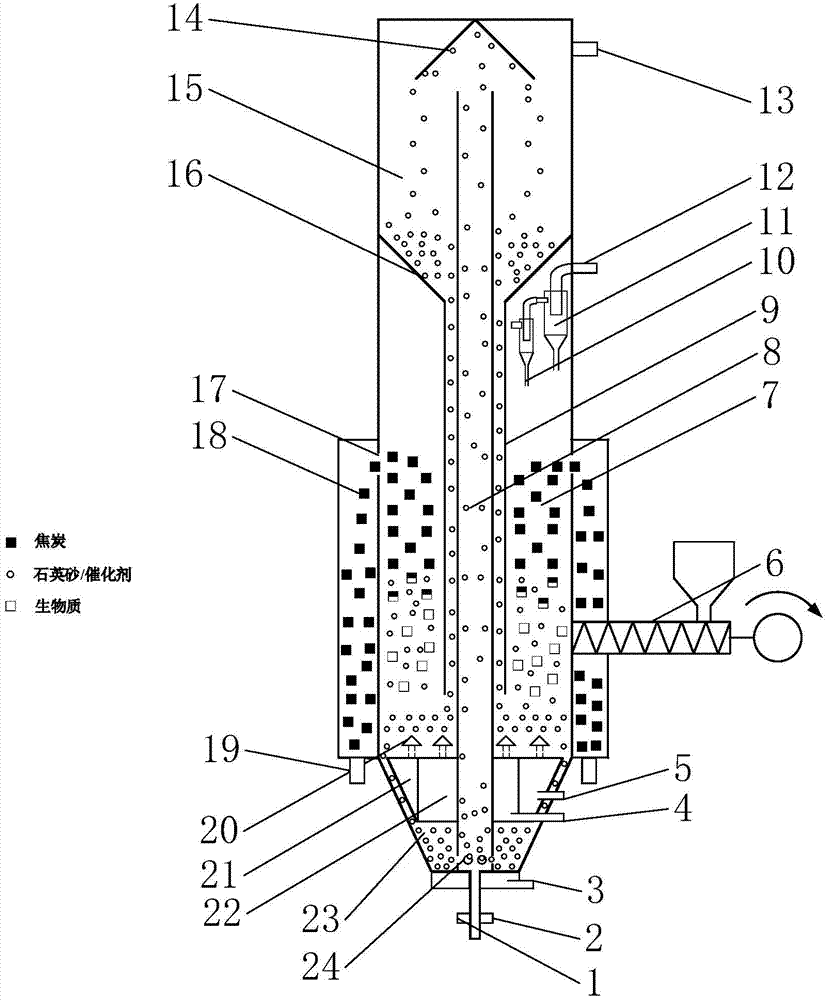

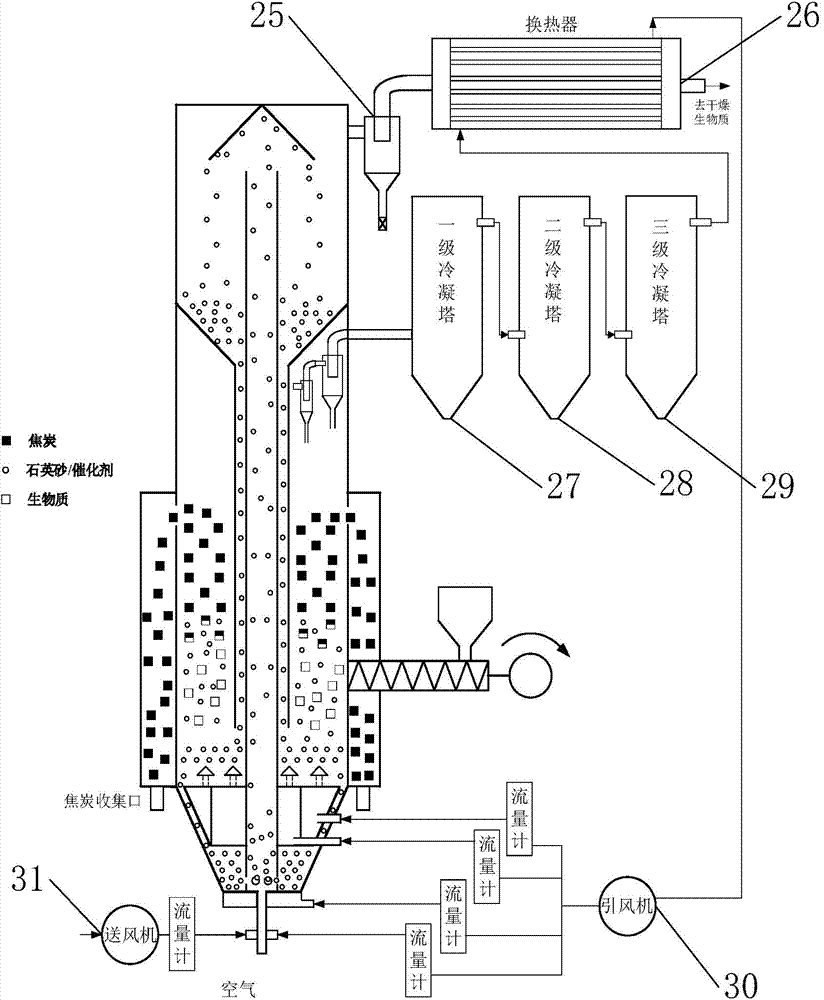

[0035] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

[0036] like figure 1 As shown, a single-bed self-heating biomass oil production unit with coke separation of the present invention includes three systems: a combustion system, a pyrolysis and coke separation system, and an air distribution and entrainment system. The air inlet 1 and the pyrolysis non-condensable gas inlet 2 of the combustion system are arranged at the bottom of the guide pipe 8; the first dipleg 9 is arranged on the outer ring of the guide pipe 8, installed coaxially, and its upper end is connected to the partition plate 16, and the lower part extends into the In the bed material, there is a gap with the top of the inner ring air chamber 22; the top of the guide pipe 8 communicates with the combustion zone 15; the partition plate 16 separates the combustion zone 15 and the pyrolysis zone 7, and the top of the partition plate 16 is fixed Conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com