Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

80results about How to "Optimize the acquisition method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of generating 3D house type model by 2D house type model based on camera shooting

InactiveCN104821011AAccurately Responds to Structural InformationThe generation method is simple3D modellingEssential matrixComputer graphics (images)

The invention discloses a method of generating a 3D house type model by a 2D house type model based on camera shooting. The method comprises steps: 1, a 2D house type picture is acquired through camera shooting; 2, an essential matrix reduction method is used for correcting the 2D house type picture acquired in the first step; 3, image enhancement processing is carried out on the2D house type picture after processing of the second step; 4, a contour line of the 2D image after processing of the third step is extracted; 5, a door and window model base is built, matching is carried out according to the contour line extracted in the fourth step, and door and window positions are recognized; 6, a wall structure is stretched to a fixed height position, and generation of a 3D house type model is completed. The method has the following advantages that automatic generation of the 3D house type model from the 2D house type model is realized, the generation method is simple, applicability is universal, the generation method can be embedded in a portable mobile device to form APP application software to be combined with a camera of the portable mobile device, and practicability is provided.

Owner:郭小虎

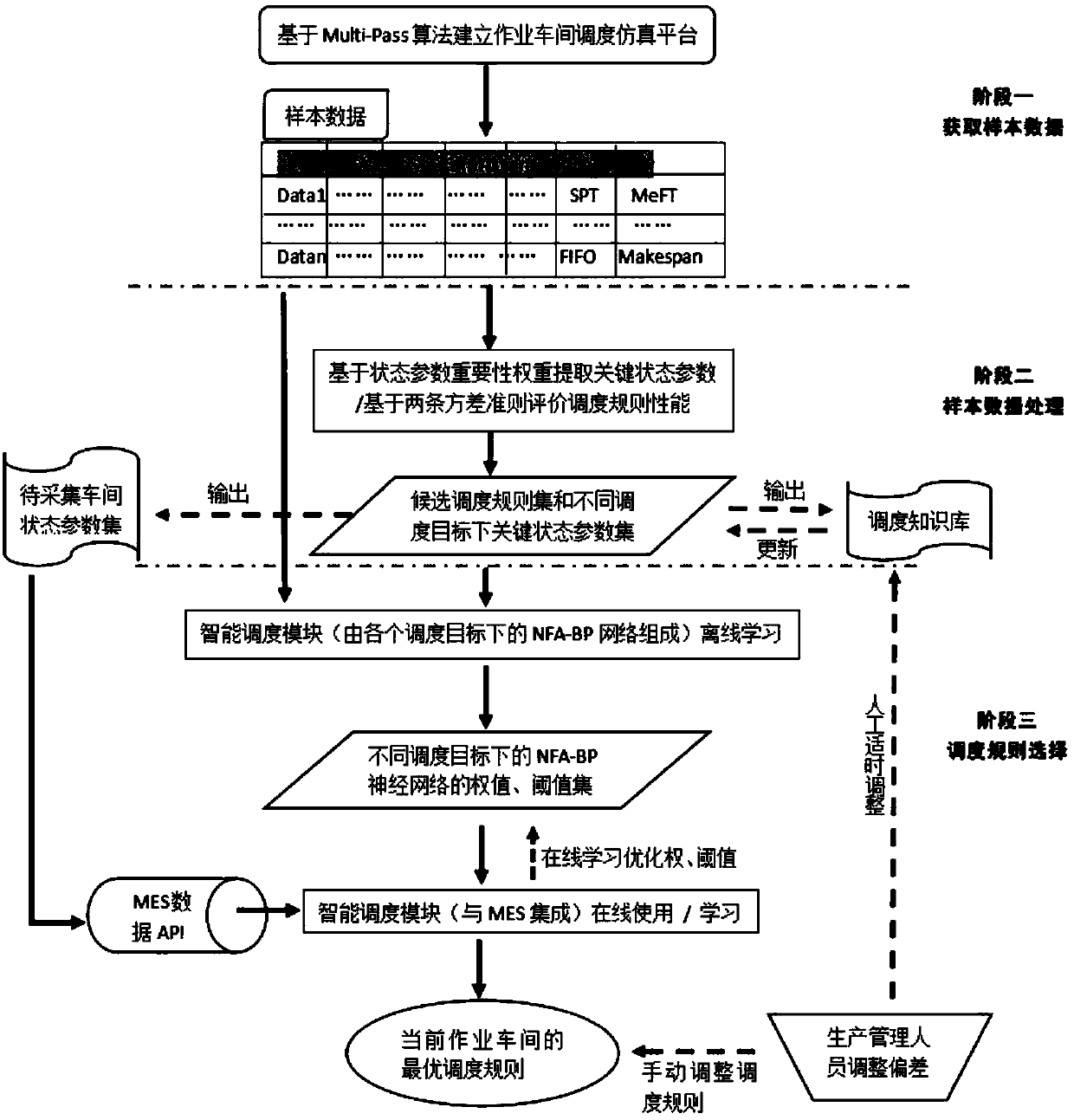

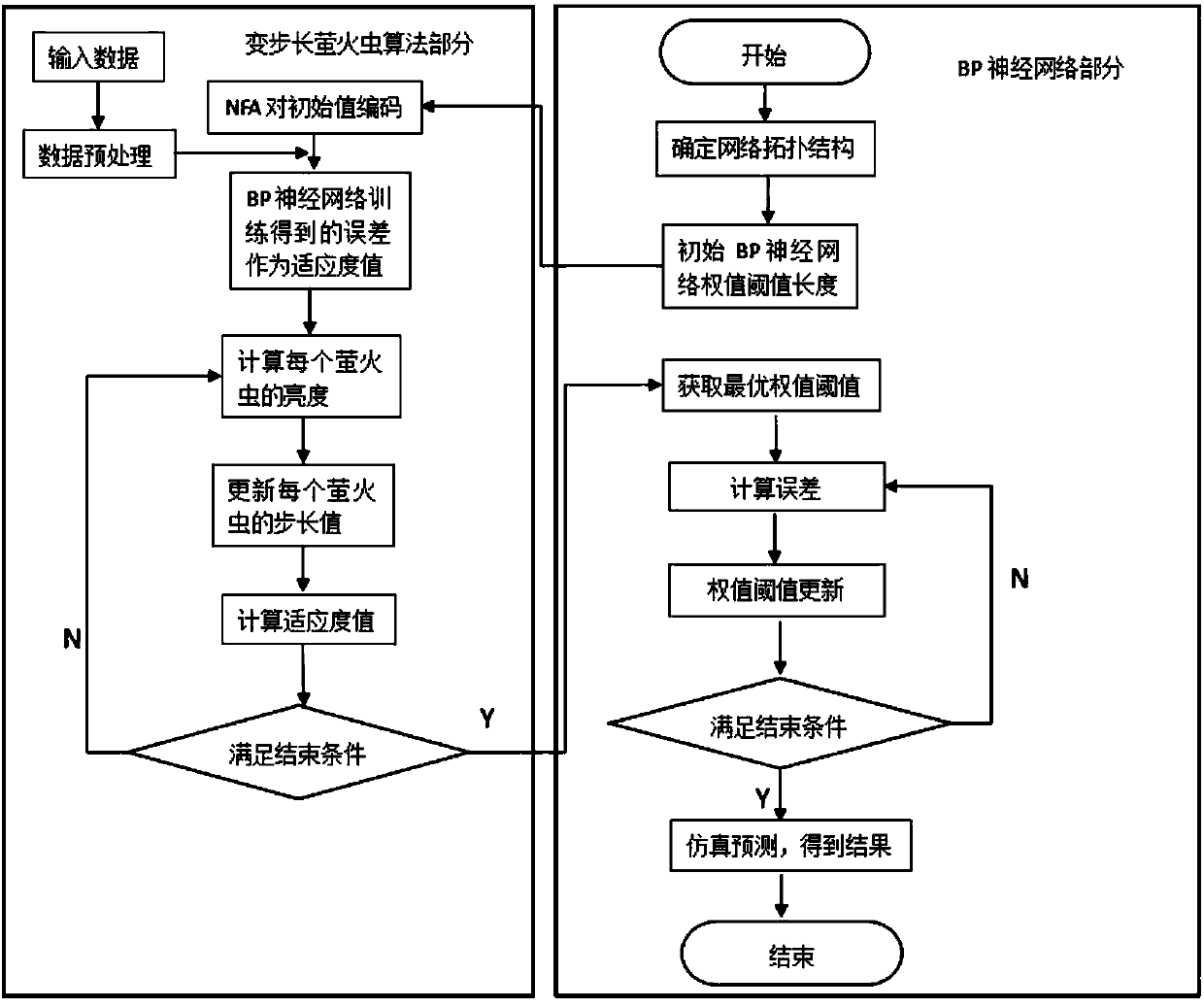

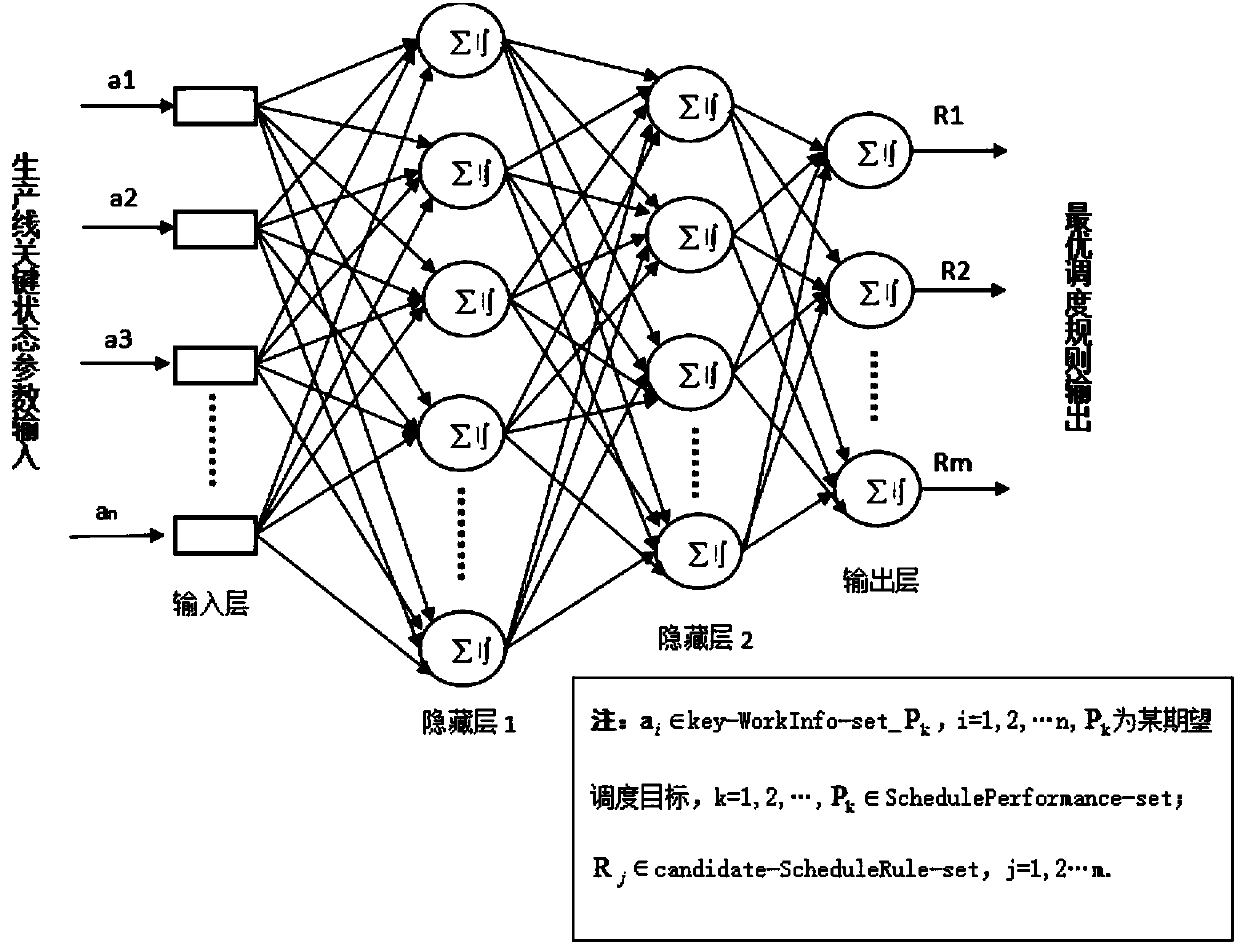

Production-data-driven dynamic job-shop scheduling rule intelligent selection method

ActiveCN107767022ATimely and accurate dynamic responseScheduling results are excellentGenetic modelsForecastingOptimal schedulingJob shop scheduling

The invention provides a production-data-driven dynamic job-shop scheduling rule intelligent selection method and belongs to the manufacturing enterprise job shop production planning and scheduling application field. The method mainly comprises the following steps: introducing a Multi-Pass algorithm simulation mechanism, establishing a job-shop production scheduling simulation platform, and generating production planning and scheduling sample data; screening the obtained sample data and generating a scheduling parameter set; designing BP neural network models for scheduling knowledge learningunder different scheduling targets; optimizing training of the BP neural networks through a new firefly algorithm to obtain NFA-BP models; integrating the NFA-BP models under various scheduling targets into an intelligent scheduling module, which is integrated with a job shop MES system to guide on-line scheduling; manually adjusting online production planning and scheduling deviation and updatingthe scheduling parameter set, and the intelligent scheduling module carrying out online optimization learning; and the intelligent scheduling module adapted to real workshop production status outputting optimal scheduling rules according to current job conflict decision points.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

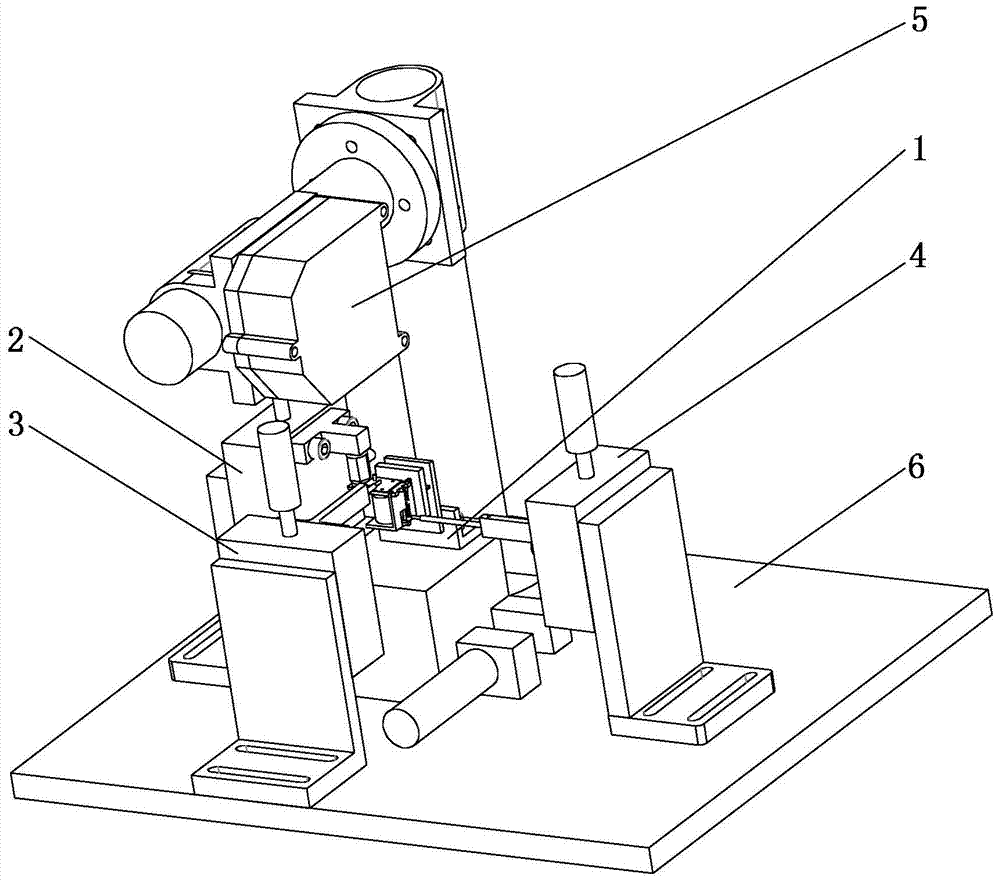

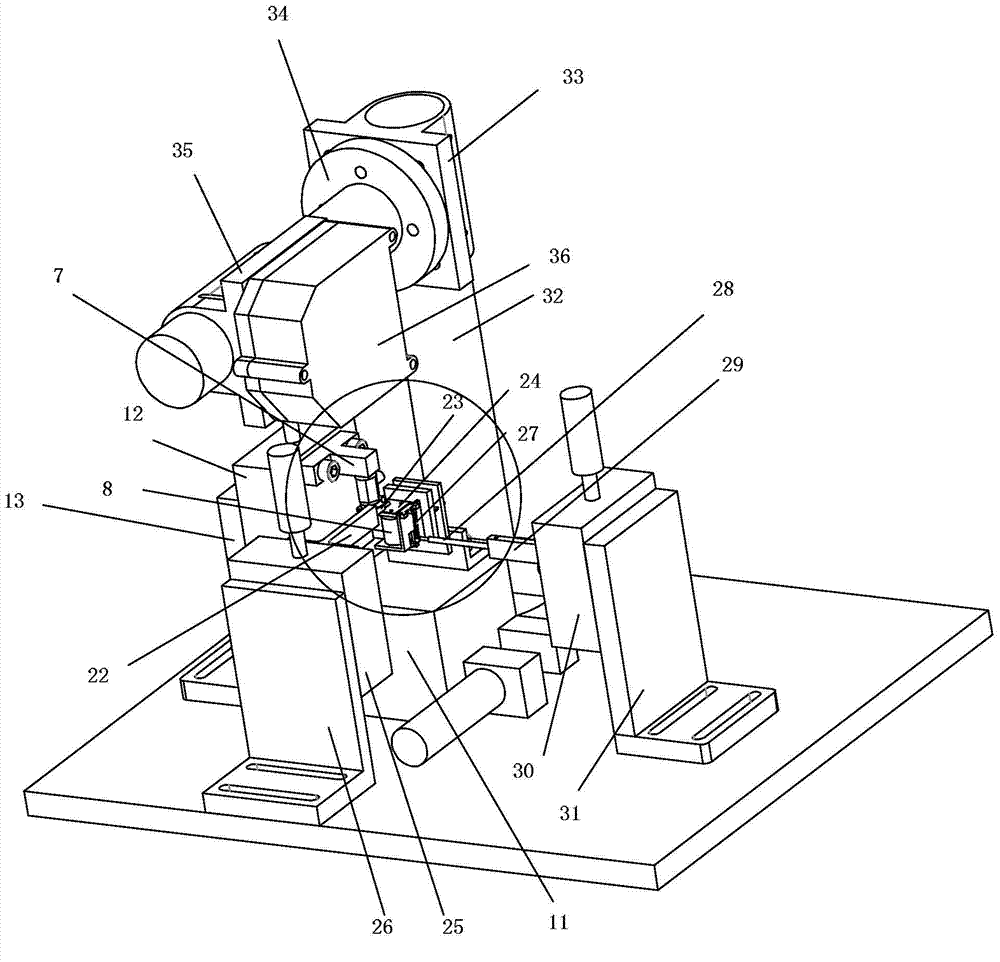

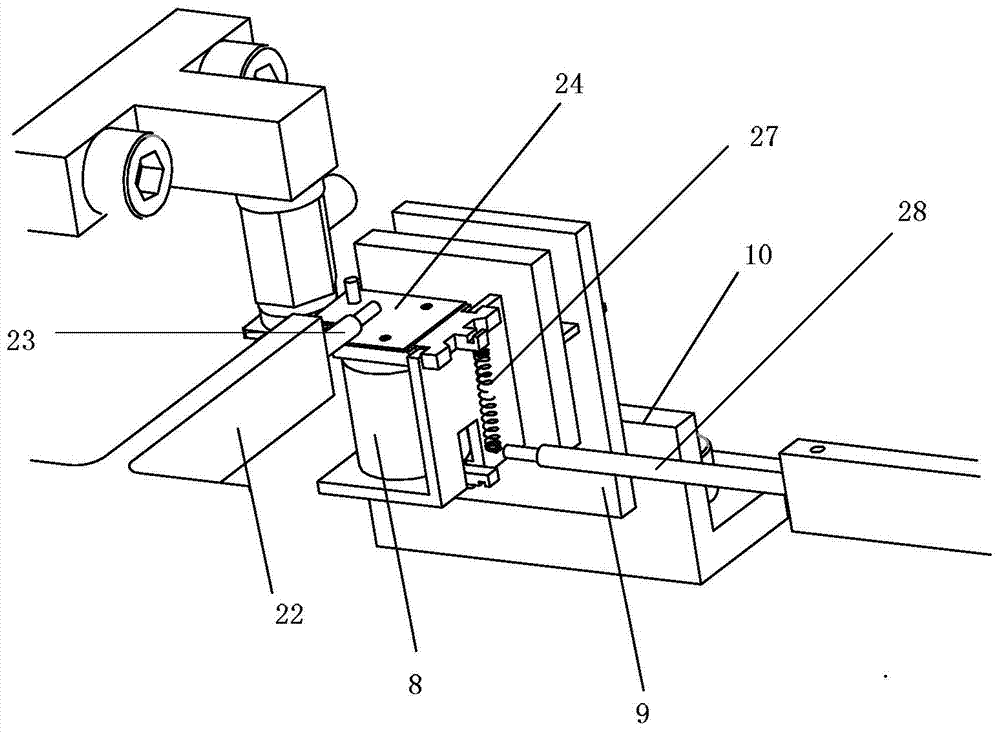

Relay capable of adjusting mechanical parameters and device and method for measuring fusion welding force of relay

ActiveCN104124106ASolve the problem that the adjustment of mechanical parameters cannot be realizedAdjust the size of the reaction forceApparatus for force/torque/work measurementElectromagnetic relay detailsSignal conditioning circuitsElectrical resistance and conductance

The invention provides a relay capable of adjusting mechanical parameters and a device and method for measuring fusion welding force of the relay and relates to the field of electrical contact. The relay solves the problems that existing relays cannot achieve adjustability of the mechanical parameters, fusion welding force measuring devices cannot directly measure fusion welding force of relay contacts, the breaking speed cannot reach the relay breaking speed level, and characteristic parameters of the relays cannot be learnt, so that the characteristic parameters cannot be applied to structural parameter optimization of actual relay products and contact material selection. The relay comprises a test relay, a test relay fixing device, a contact spacing adjusting device, a magnetic gap adjusting device, a mechanical counterforce adjusting mechanism, a contact speed measurement device and a vibration isolation base. The relay further comprises a resistance voltage division circuit, a signal processing circuit, a data collecting and processing circuit and an upper computer. According to the method for measuring the fusion welding force, a value of fusion welding force is obtained through the difference of a contact voltage rising edge front force signal jumping value and a contact voltage rising edge rear force signal jumping value. The device and method for measuring fusion welding force of the relay are further suitable for measuring other parameters of the relay.

Owner:HARBIN INST OF TECH

Preparation method of foamed-aluminum sandwiched-structure materials

ActiveCN103286404APlay a role in removingEfficient removalWelding/cutting media/materialsSoldering mediaFiller metalAtmosphere

The invention relates to a preparation method of foamed-aluminum sandwiched-structure materials and belongs to the technical field of aluminum brazing. The preparation method includes steps of mixing blazing filler metal with brazing flux into paste to apply on surfaces to be brazed of foamed aluminum and aluminum plates, assembling a to-be-brazed structure according to a mode of the aluminum plate / foamed aluminum / the aluminum plate, brazing in a furnace at the protective atmosphere to obtain the foamed-aluminum sandwiched-structure materials after totally drying. The brazing filler metal comprises, by mass percentage, 11-13% of Zn, 14-16% of Si, 0.8-1.2% of Fe, 0.1-0.3% of Mg, 0.2-0.4% of Mn and the balance of Al. The brazing flux comprises, by mass percentage, 40-50% of KF and 50-60% of AlF3. By adopting the novel brazing filler metal and the brazing flux and strictly controlling brazing temperature and time, the prepared foamed-aluminum sandwiched-structure materials have excellent performance. Complicated procedures in brazing are greatly reduced, operation efficiency is greatly improved, and cost is saved.

Owner:CENT SOUTH UNIV

Police resource scheduling method based on optimal route

InactiveCN102768736AOptimize the acquisition methodNarrow searchForecastingOptimal routeReal-time computing

The invention provides a police resource scheduling method based on an optimal route. The method comprises the steps of marking an alarm location; searching an optimal route and calculating the time in which the destination is reached; according to the time each policeman needs to reach the alarm location, finding the policemen who can reach the alarm location in the shortest time; and, finishing scheduling. The method uses the road information entirely and comprehensively, optimizes the obtaining method for the optimal route, adds ellipses to reduce the search range of the routes and uses dictionary-type storage data to quicken the speed of the algorithm.

Owner:IASPEC INFORMATION TECH CO LTD

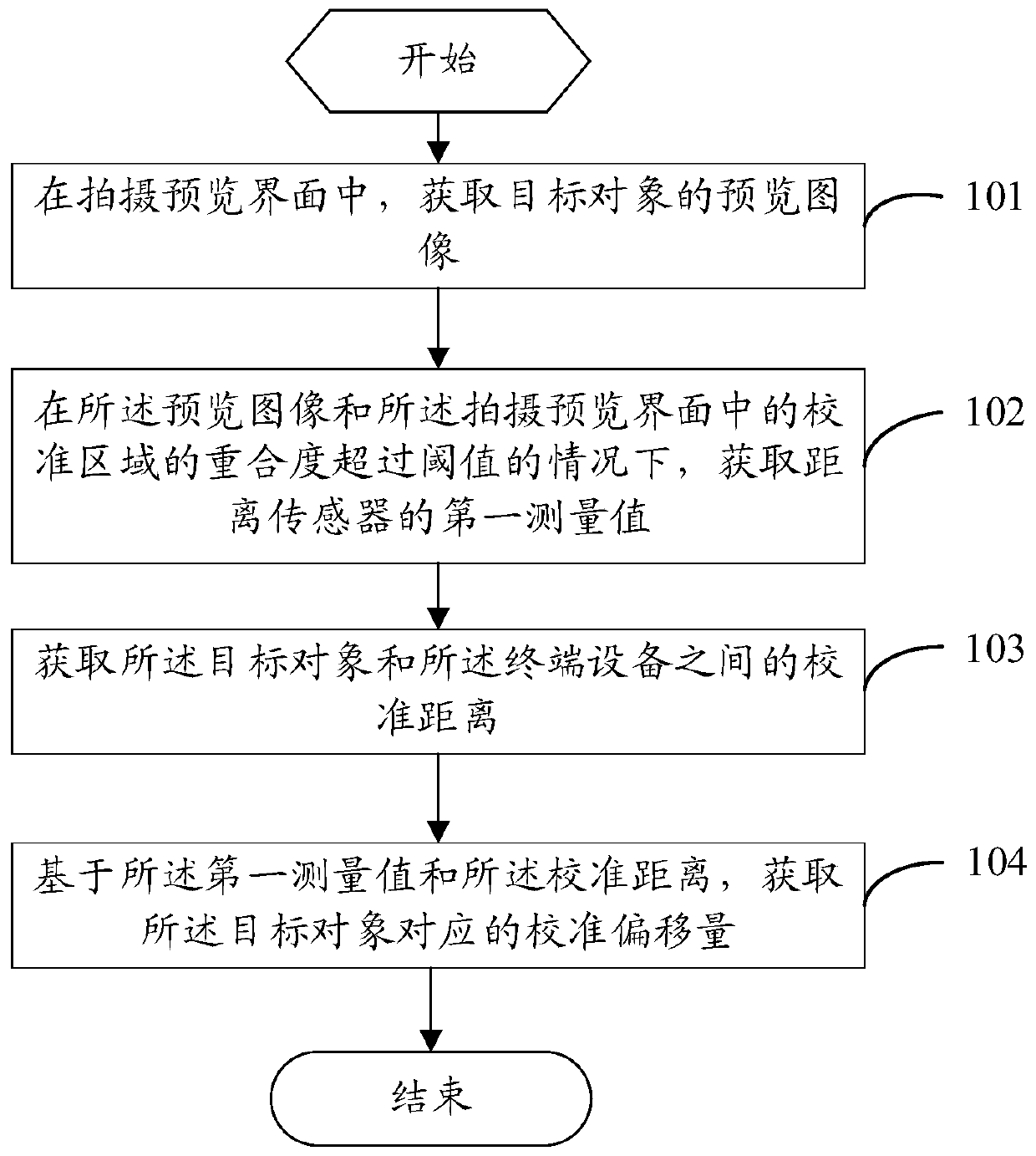

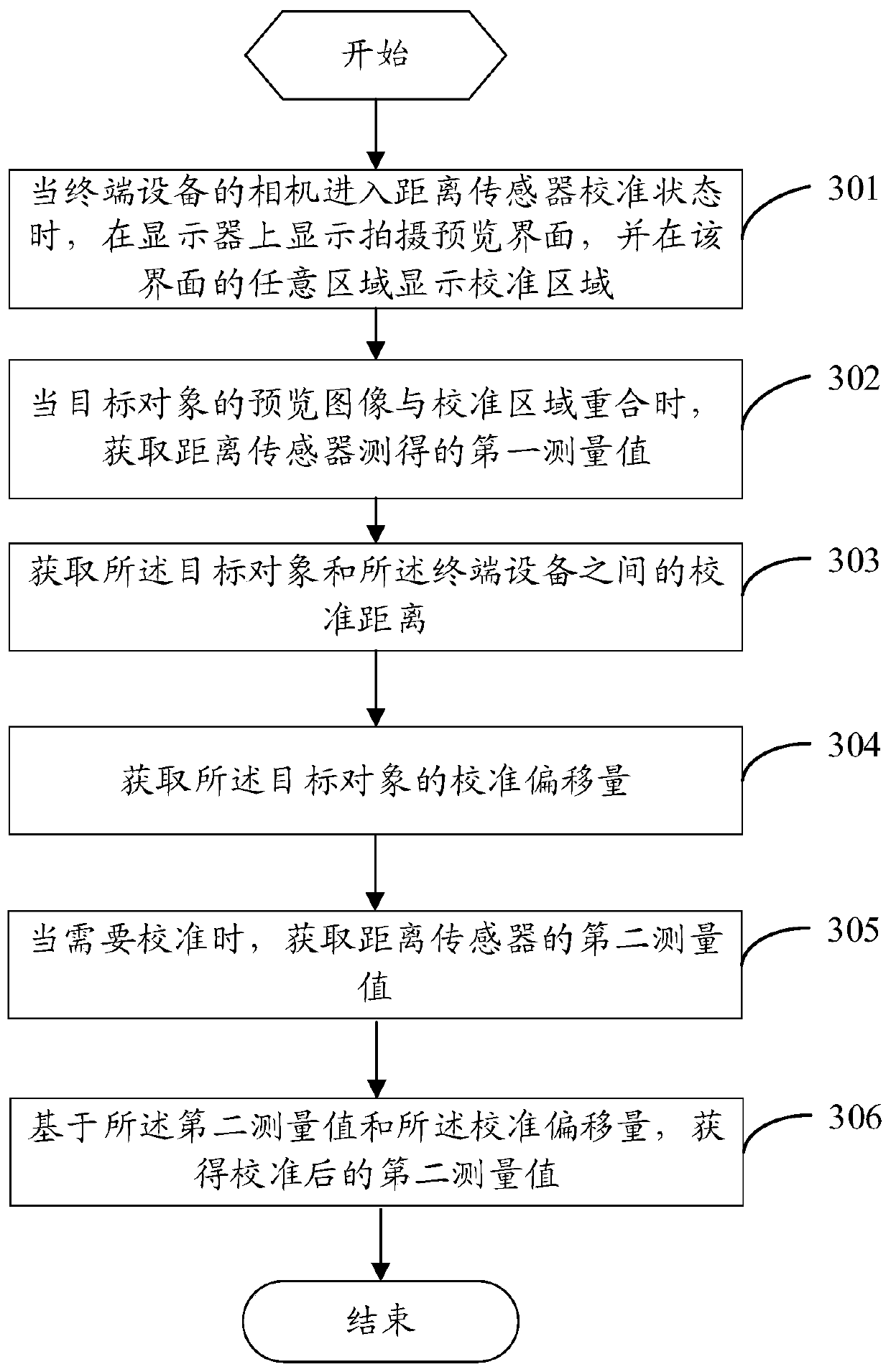

Parameter acquisition method and terminal equipment

ActiveCN110113528AReduce complexityOptimize the acquisition methodImage enhancementTelevision system detailsObject basedTerminal equipment

The invention discloses a parameter acquisition method and terminal equipment, relates to the technical field of communication, and aims to solve the problem that the calibration of a distance sensoris relatively complex. The method comprises the steps of obtaining a preview image of a target object in a shooting preview interface; when the coincidence degree of the preview image and a calibration area in the shooting preview interface exceeds a threshold value, obtaining a first measurement value of a distance sensor; and obtaining a calibration offset corresponding to the target object based on the first measurement value and the calibration distance. According to the embodiment of the invention, the calibration complexity of the distance sensor can be reduced.

Owner:VIVO MOBILE COMM CO LTD

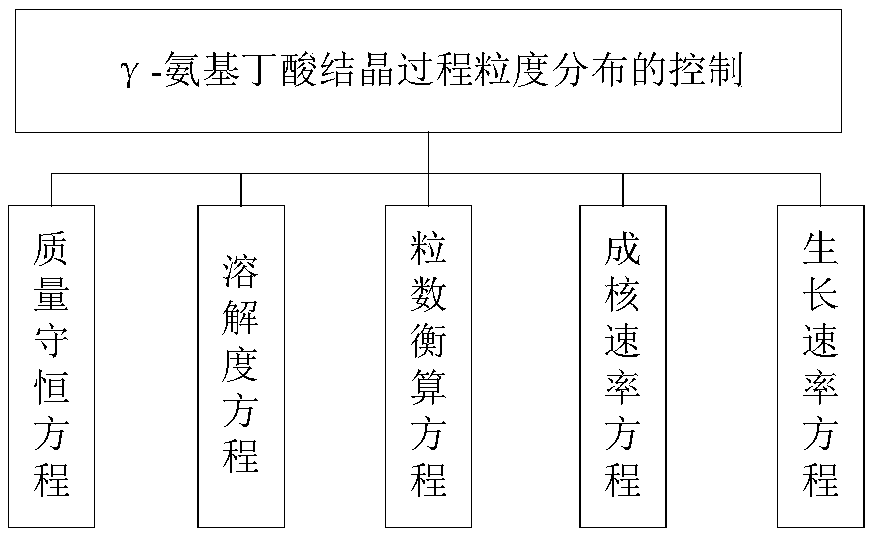

Particle size distribution modeling and control method in crystallization process

ActiveCN108490793AImprove crystallization yieldImprove particle size distributionAdaptive controlControl vectorChemical physics

The invention discloses a particle size distribution modeling and control method in a crystallization process. The particle size control method in the crystallization process comprises the following steps: establishing an optimal control module of particle size distribution in the crystallization process by taking the average crystal particle size as index for measuring the crystal particle size distribution and combining with crystallization process constraint conditions on the basis of a particle size distribution model in the crystallization process; performing discretization and parameterization processing on particle size control vectors in the crystallization process, to solve the optimal control model of the particle size distribution in the crystallization process, so as to obtainan optimal control curve in the crystallization process, and realize maximization of average particle size of crystals. According to the method, an acquiring method of a control curve in the crystallization process can be improved, and the crystallization efficiency and average crystal particle size can be improved.

Owner:SHANDONG UNIV

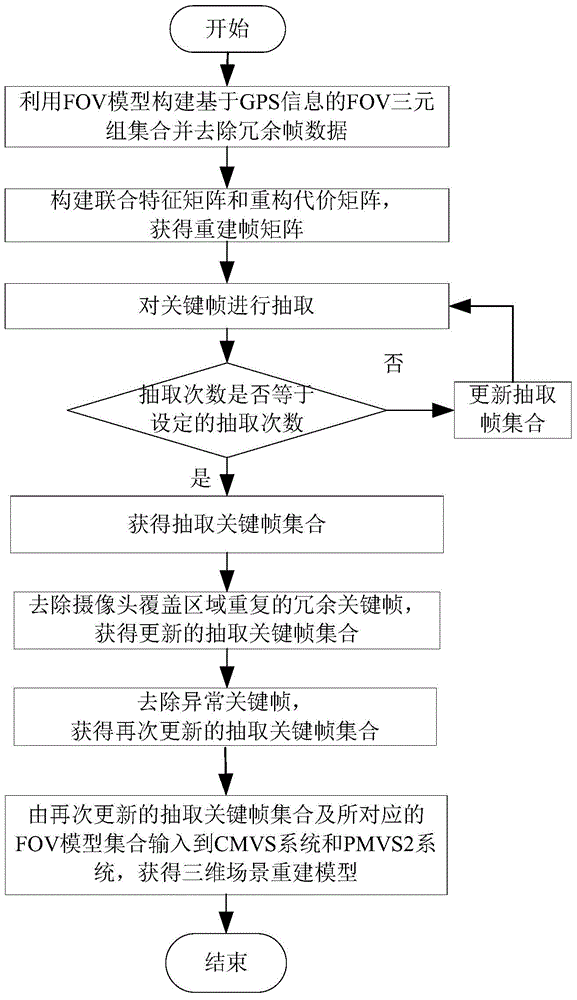

Three-dimensional scene reconstruction method based on GPS information video

ActiveCN104463962AInexpensive to rebuildGuaranteed validity3D modellingReconstruction methodKey frame

The invention discloses a three-dimensional scene reconstruction method based on a GPS information video. The method comprises the following steps that 1, an FOV model set based on GPS information is constructed and redundancy frame data are removed; 2, a reconstruction frame matrix is constructed; 3, a key frame is extracted; 4, a target scene is reconstructed in a three-dimensional mode. According to the three-dimensional scene reconstruction method based on the GPS information video, the video key frame can be rapidly and accurately extracted, and therefore the precision and efficiency of the three-dimensional scene reconstruction method are improved.

Owner:HEFEI UNIV OF TECH

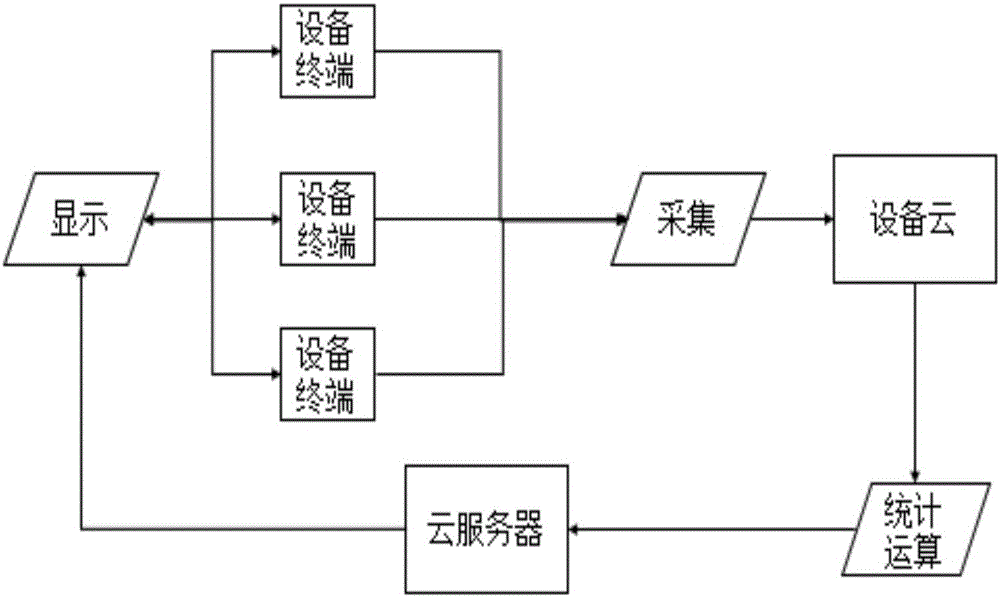

Intelligent terminal traffic condition acquisition system based on IOT

ActiveCN106530703AOptimize the acquisition methodImprove real-time performanceDetection of traffic movementComputer terminalVehicle driving

The invention relates to the field of Internet of Things (IOT) and discloses an intelligent terminal traffic condition acquisition system based on IOT. The system uses vehicle driving speed as the basis for judging a traffic condition and solves a problem that the traffic information acquisition in the prior art is restricted by the number of samples and weather condition factors and thus data reliability is influenced. The system comprises intelligent device terminals, a device cloud server, and a storage cloud server. The intelligent device terminals are installed on respective vehicles for collecting the current position information of the vehicles and the current vehicle speed information and transmitting the information to the device cloud server. The device cloud server is used for statistic calculation according to the position information and the current vehicle speed information uploaded by the intelligent device terminals of the vehicles to obtain the traffic information of respective areas where the vehicles are located and transmit the traffic information to the storage cloud server. The storage cloud server is used for storing the traffic information of respective areas and feeding back or automatically pushing to the user the traffic information of the area where the user is located when receiving a user request.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

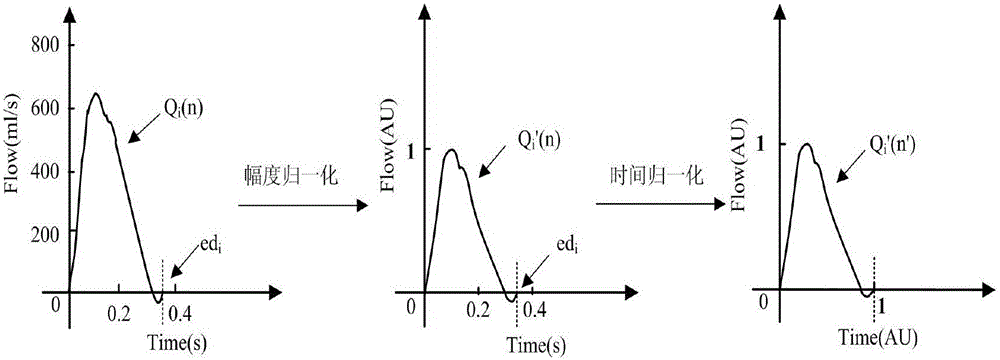

Central pulse systole average normalization blood flow waveform model and method for obtaining aorta pulse wave transmission time based on same

ActiveCN104983412AOptimize the acquisition methodGet method securityBlood flow measurement devicesInfrasonic diagnosticsObject basedSystole

The invention provides a central pulse systole average normalization blood flow waveform model and a method for obtaining aorta pulse wave transmission time based on the same. The method comprises establishing a central pulse systole average normalization blood flow waveform model, and obtaining central pulse pressure waveform and central pulse blood waveform of a measured object based on the above model; and carrying out Fourier analysis on the central pulse pressure waveform and the central pulse blood waveform to calculate the characteristic impedance, and the calculating the aorta pulse wave transmission time (aoPTT). The central pulse blood waveform can be obtained without a blood flow detector by using the central pulse systole average normalization blood flow waveform model and the method for obtaining aorta pulse wave transmission time based on the same, so a method for obtaining the central pulse blood waveform can be simpler and safer. The central pulse blood waveform acquired using the model and the method is closer to human actual central pulse blood waveform, and the accuracy of calculation of aoPTT and the measurement of aoPWV can be raised.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Information acquisition method and information acquisition apparatuses

InactiveCN105550235AOptimize the acquisition methodWill not affect call effectSpecial data processing applicationsWeb data retrieval using information identifiersSpeech soundInformation acquisition

The invention provides an information acquisition method and information acquisition apparatuses, belonging to the technical field of communications. The method comprises the steps of after acquired first voice information is converted into character information during a call, analyzing the character information to obtain at least one piece of to-be-searched information; displaying at least one piece of to-be-searched information, when a search confirmation operation for any one piece of to-be-searched information by a user is detected, sending any one piece of to-be-searched information to a server, acquiring a corresponding search result according to any one piece of to-be-search information and returning the search result by the server; and after the search result is received, displaying the research result. During the call by the user, information that is likely to be searched can be acquired automatically according to call content, the search result can be directly acquired according to a selection operation by the user, and the user does not need to input the to-be-searched information by hands to search the information, so that the call effect can be ensured. The information acquisition method is more convenient and delivers a good call effect.

Owner:XIAOMI INC

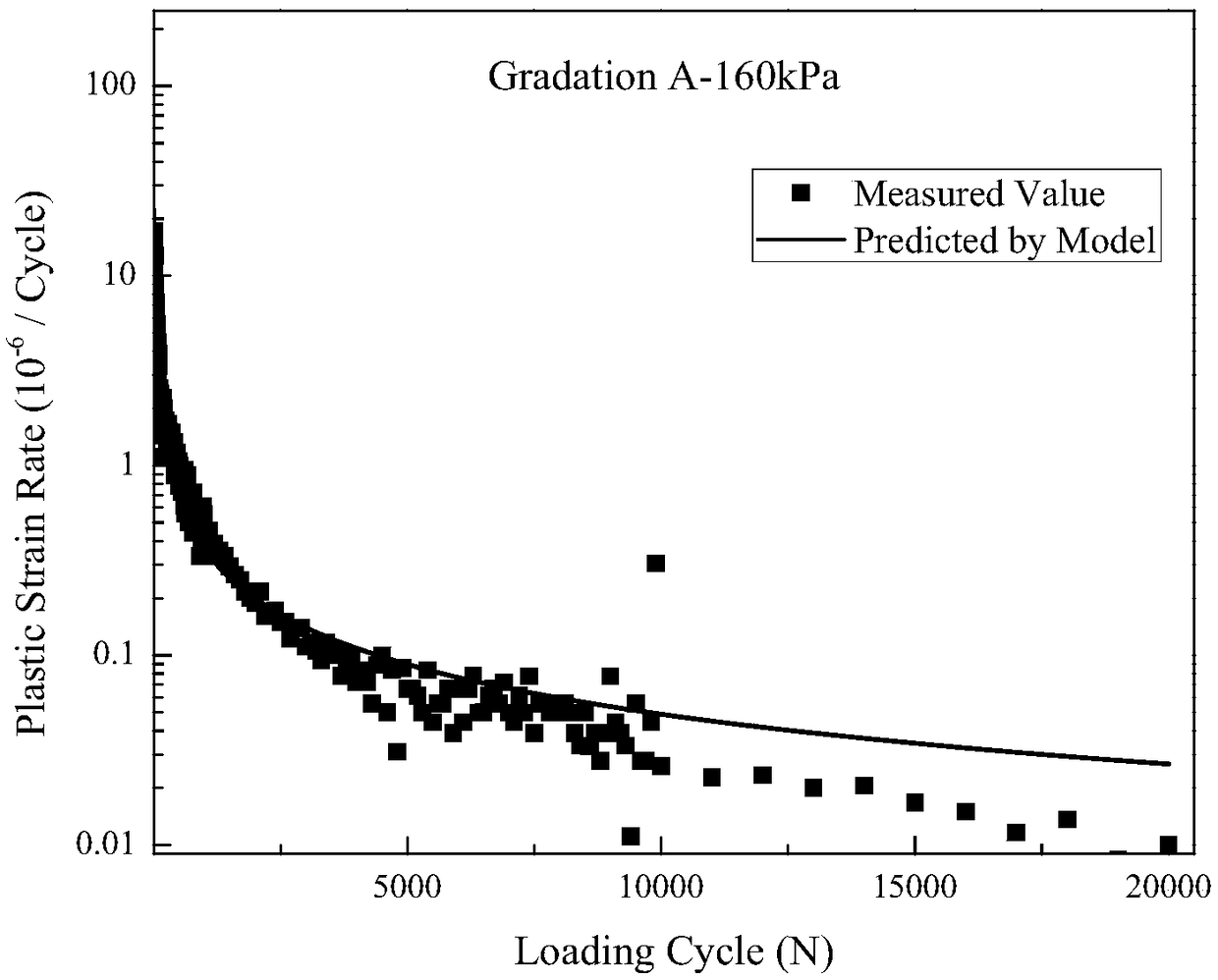

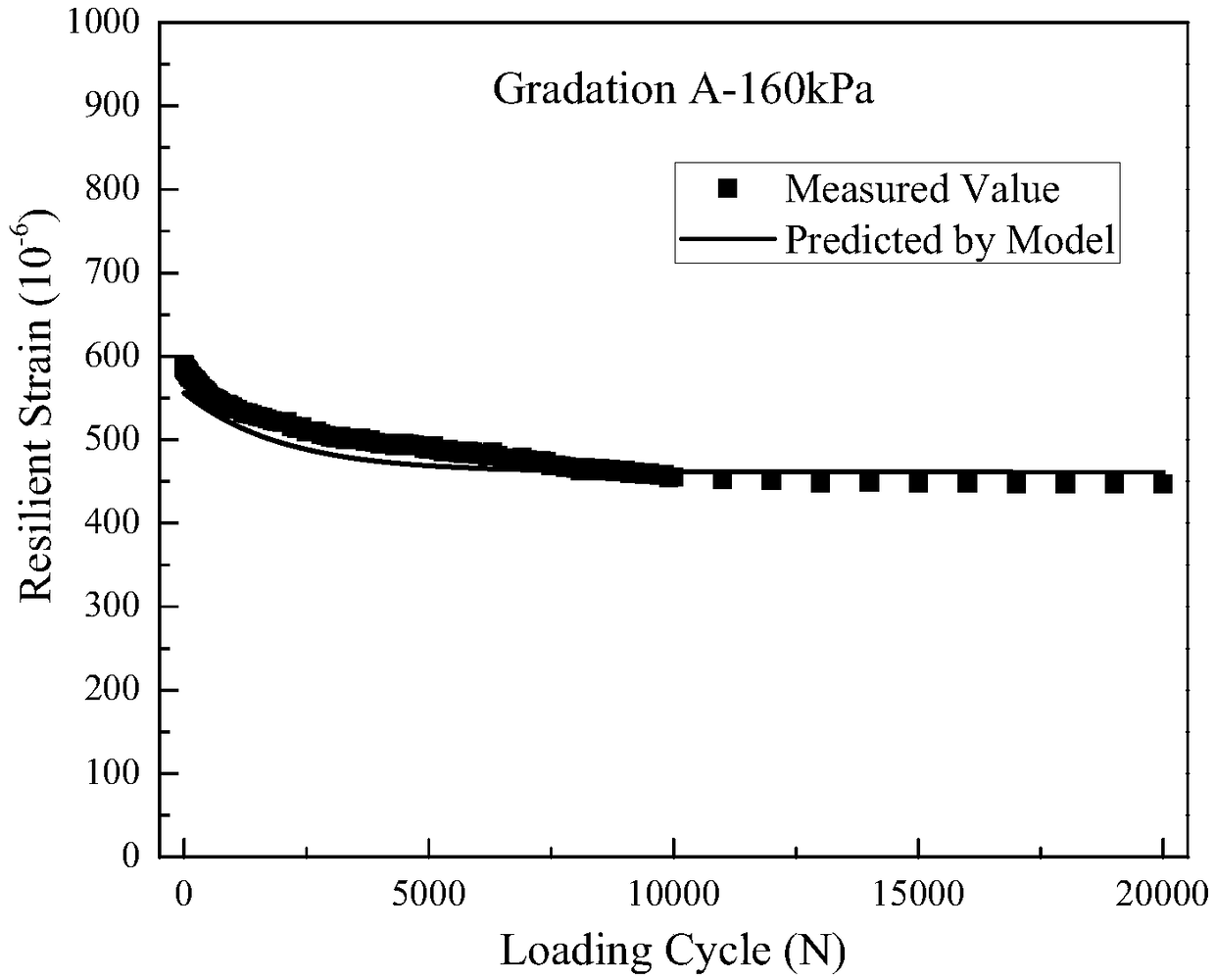

Graded broken stone repeated load experiment elastoplasticity yield point stress determining method

ActiveCN108732048AOptimize the acquisition methodRepresentative meaning is clearMaterial strength using repeated/pulsating forcesModel compositionLoad time

The invention relates to a graded broken stone repeated load experiment elastoplasticity yield point stress determining method. The method is characterized in that according to the deformation processof granule materials such as graded broken stone under the repeated load effect, a stability analysis method is used; the stability of graded broken stone under the repeated load effect is evaluatedthrough plastic strain; a plastic strain rate model and a rebound strain model of the graded broken stone under the repeated load effect are built; by analyzing the relationship between the plastic strain rate and the rebound strain and the SMP yield criterion, a calculation model of the yield stress along with the change of the load intensity and the load times is provided. The yield stress and the elastic-plastic state of granule materials under different load intensity and load action times can be judged; the conditions are provided for elastic-plastic stress strain calculation; the foundation is laid for realizing the application of a graded broken stone elastic-plastic model. The experiment method and the parameter obtaining method are convenient; the model composition part representative significance is defined; the elastic-plastic yield point yield stress calculation process is concise.

Owner:CHANGAN UNIV

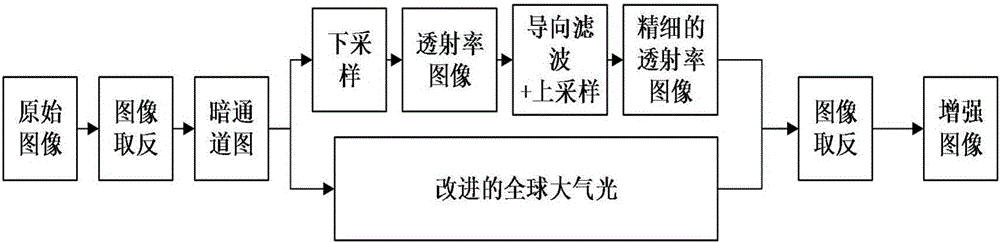

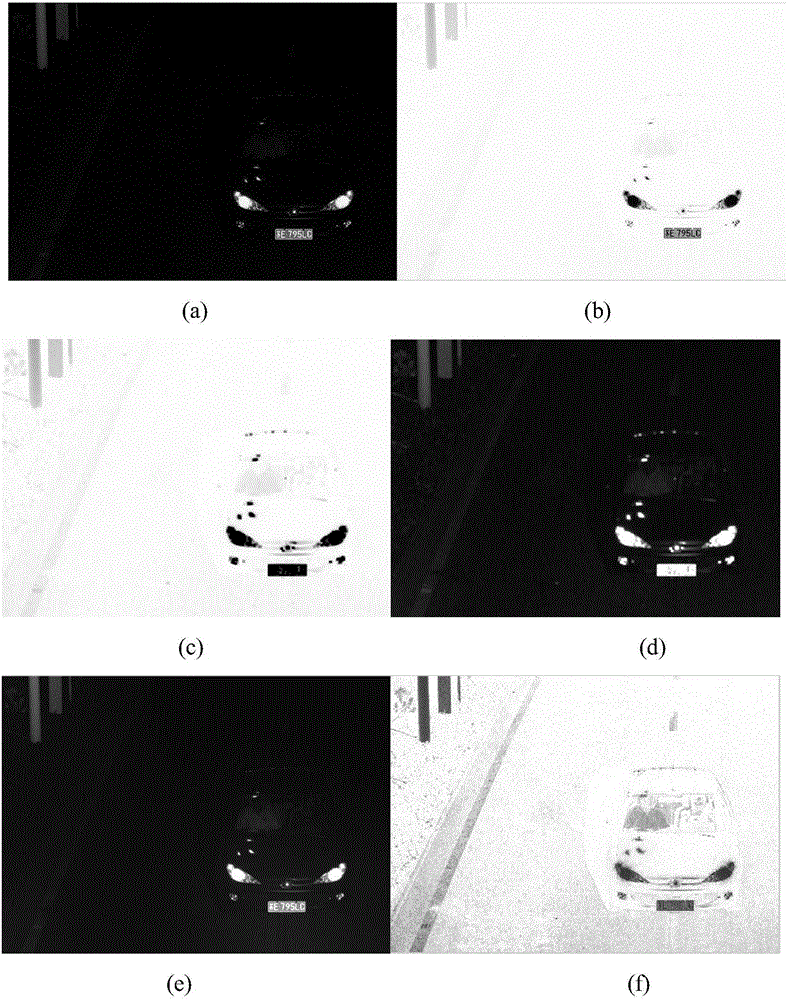

Night traffic block port image enhancement method based on dark channel prior

InactiveCN105931193AOptimize the acquisition methodEnhance detailsImage enhancementImage analysisTransmittanceImage enhancement

The invention relates to a night traffic block port image enhancement method based on dark channel prior, and the method comprises the following steps: a night traffic block port image is inputted, and a night image dark channel is inversed to obtain an inversed night block port image; the inversed block port image is used to acquired a dark channel image; global airglow in an atmospheric scattering model is calculated; according to the global airglow, a transmissivity image is obtained; guiding filtering makes the transmissivity image to be fine; according to the global airglow and fine transmissivity image, a inversed image of an enhanced night traffic block port image is obtained based on the atmospheric scattering model; the inversed image is inversed again, a final enhanced night traffic block port image is obtained.

Owner:NANJING UNIV OF SCI & TECH

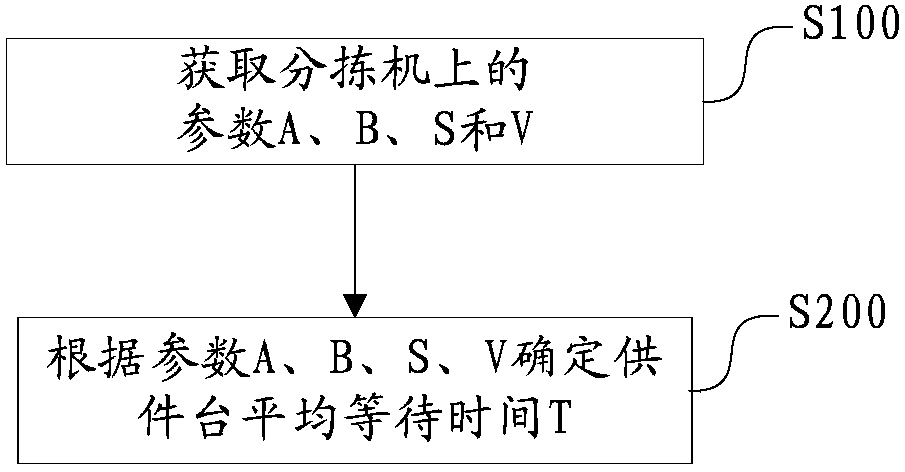

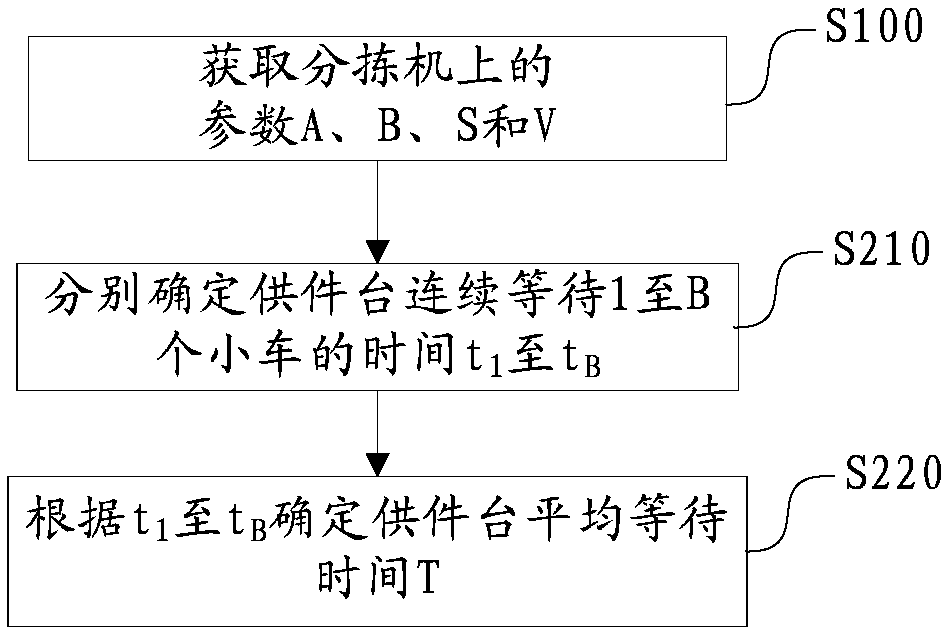

Sorting machine and supply table waiting time configuration method and system

ActiveCN108304980AOptimize the acquisition methodEasy to controlResourcesLogisticsComputer scienceUtilization rate

The invention discloses a sorting machine and a supply table waiting time configuration method and system. The supply table waiting time configuration method includes acquiring parameters A, B, S andV of the sorting machine wherein A is the total quantity of carts, B is the quantity of carts that are occupied between a sorting channel which is the nearest to the supply table and the supply tablein the sorting machine conveying direction, 0<=B<=A, S is the distance between the carts and V is the operation speed of the carts; determining the average waiting time T of the supply table accordingto the parameters A, B, S and V. According to the invention, the mathematic model is simple and the calculation results are direct and reliable. Through the above configuration method, the average waiting time and a cargo handling volume in unit time of each supply table on the sorting machine can achieve an accurate numerical value, so that modulation of sorting machine field cargo and staff isfacilitated, reasonable utilization rate of resource in cargo sorting is improved and production cost is reduced.

Owner:SF EXPRESS

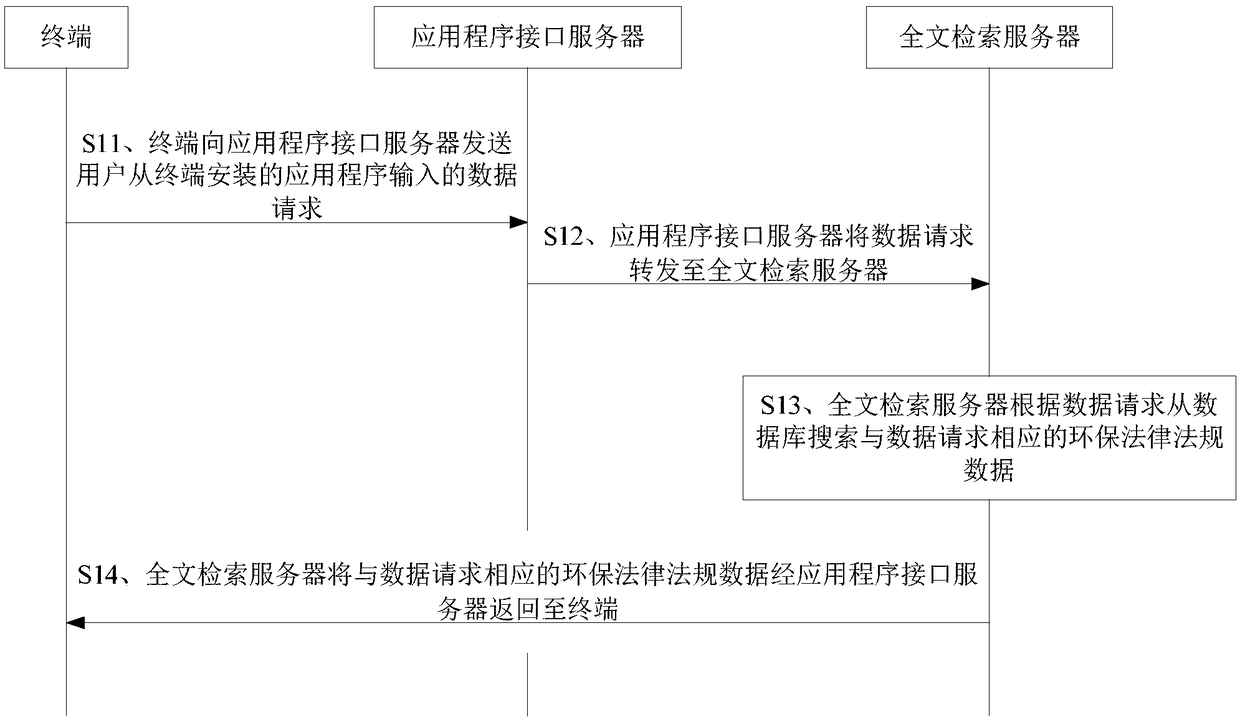

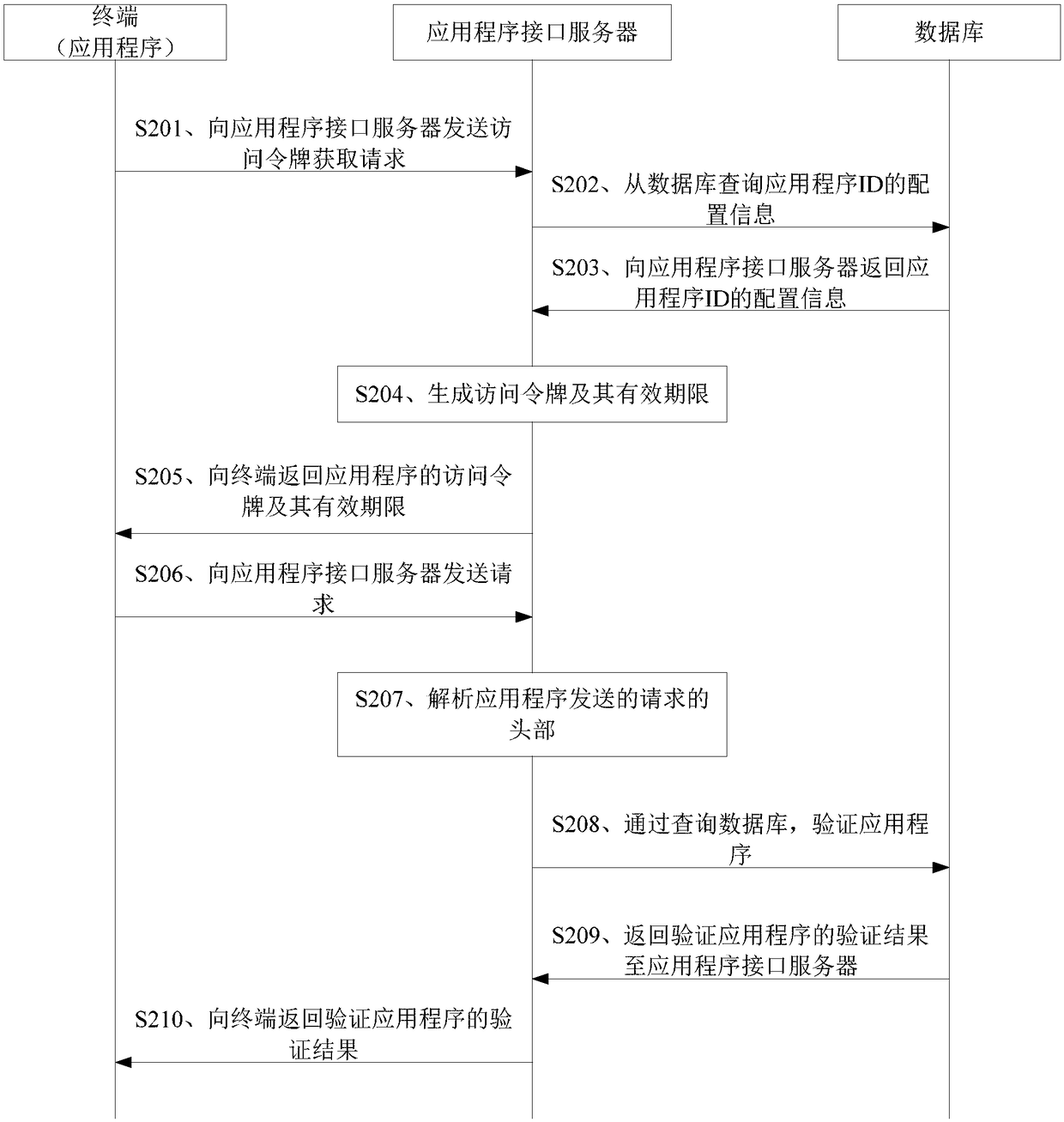

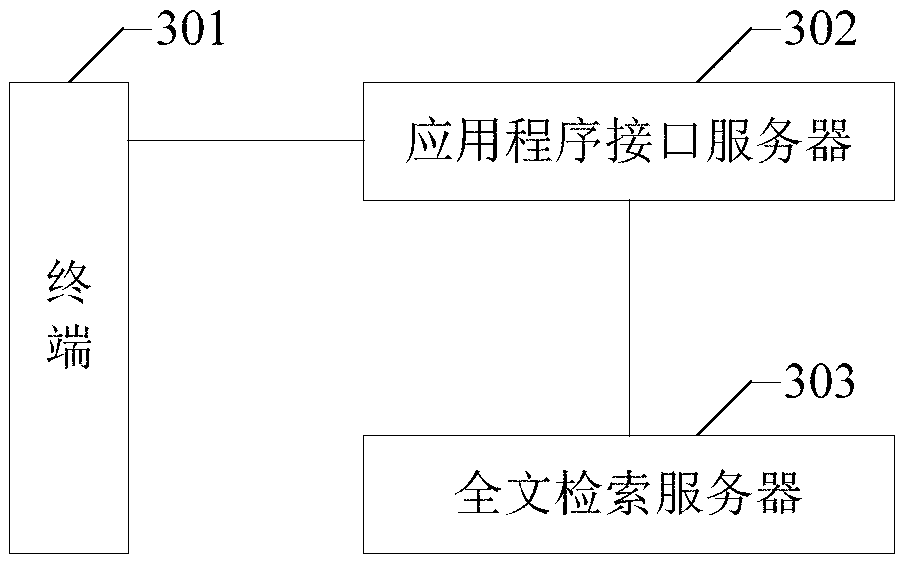

Environmental protection laws and regulations data acquisition method and system and related equipment

PendingCN109165342AEasy way to getAccurate law enforcement norms and legal characterizationWebsite content managementSpecial data processing applicationsApplication softwareEnforcement

An environmental protection laws and regulations data acquisition method and system and related equipment are disclosed. The method comprises the following steps: a terminal sends a data request inputted by a user from an application program installed at the terminal to an application program interface server; the application program interface server forwards the data request to the full-text retrieval server; the full-text retrieval server searches the corresponding environmental protection laws and regulations data from the database; the full-text retrieval server searches the environmentalprotection laws and regulations data corresponding to the data request from the database according to the data request; the terminal displays the environmental protection laws and regulations data tothe user through the application program. The technical scheme provided by the application enables the law enforcement personnel to obtain the data of environmental laws and regulations at any time ina more convenient manner, and the data of environmental laws and regulations are comprehensive and up to date, thereby facilitating the law enforcement norms and legal characterization of the environmental law enforcement personnel to be accurate.

Owner:深圳博沃智慧科技有限公司

Shooting data output method and electronic equipment

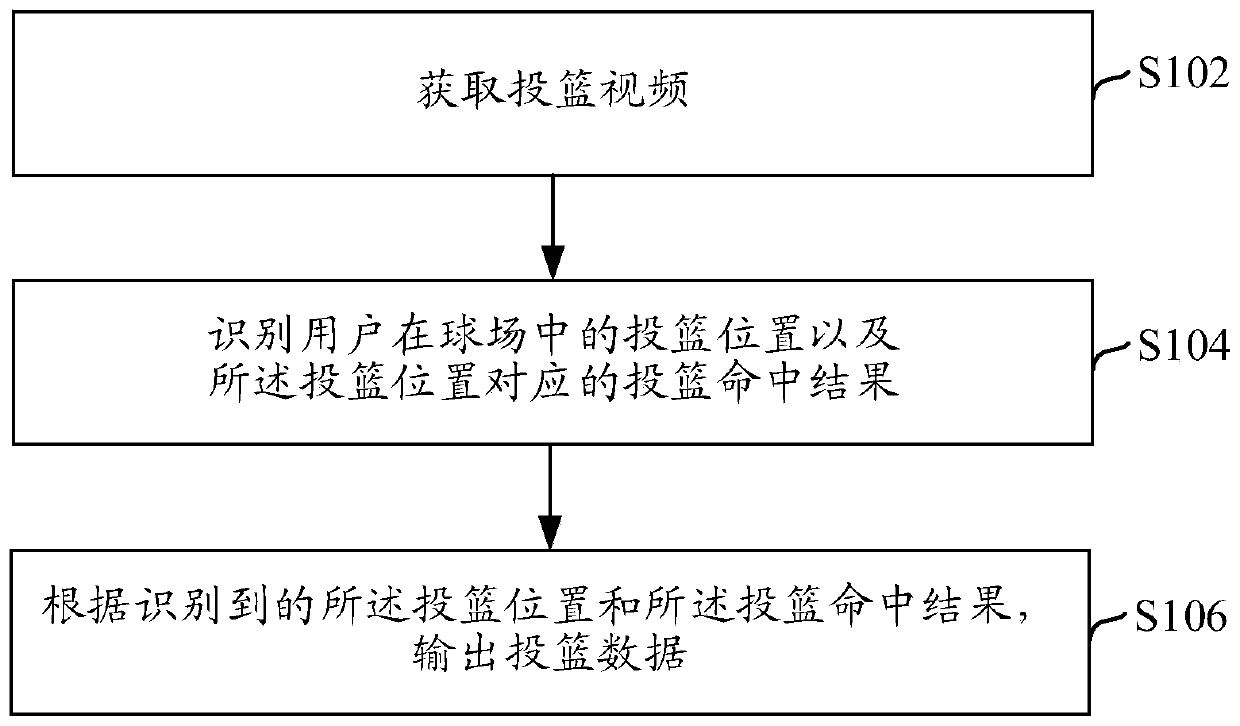

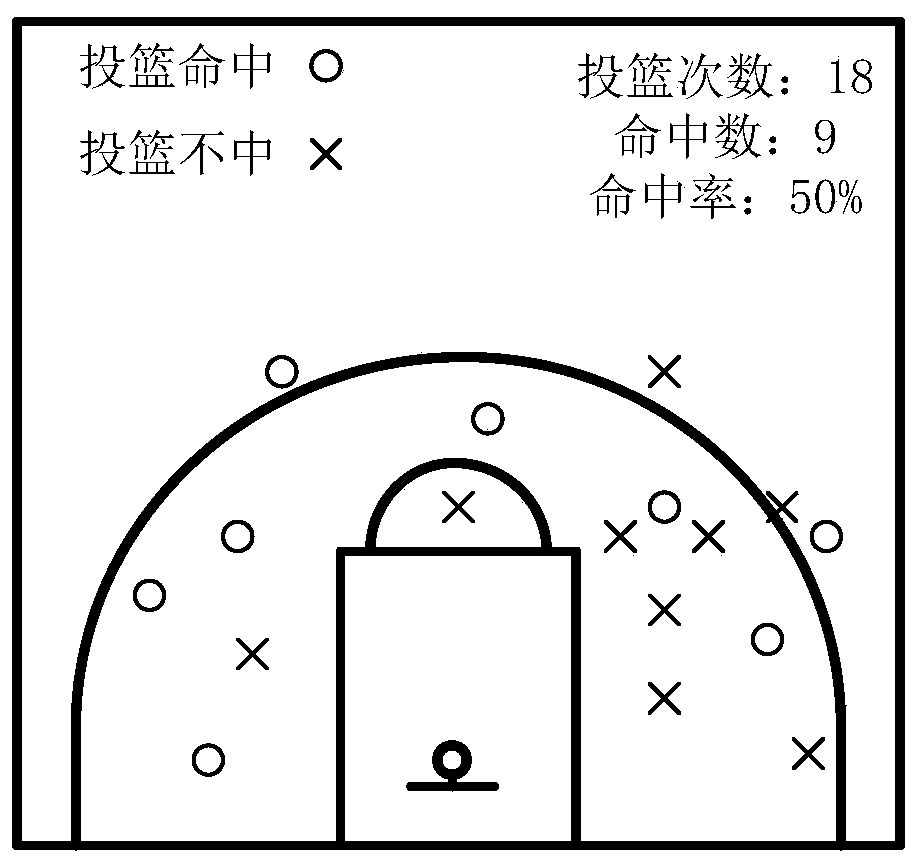

PendingCN110942022AEasy way to getOptimize the acquisition methodCharacter and pattern recognitionCollections dataReal-time computing

The embodiment of the invention discloses a shooting data output method and electronic equipment, and aims to solve the problem of complexity in obtaining shooting data by a user in related technologies. The method comprises the following steps: acquiring a shooting video; identifying a shooting position of the user in the court and a shooting hit result corresponding to the shooting position; andoutputting shooting data according to the identified shooting position and the shooting hit result. According to the embodiment of the invention, the shooting data output method is provided by adopting an image recognition mode, the operation is simple and convenient, the requirement on equipment is low, for a user, the shooting data can be output in real time only by one part of electronic equipment with a camera, and the shooting data collection mode is simple and convenient.

Owner:VIVO MOBILE COMM CO LTD

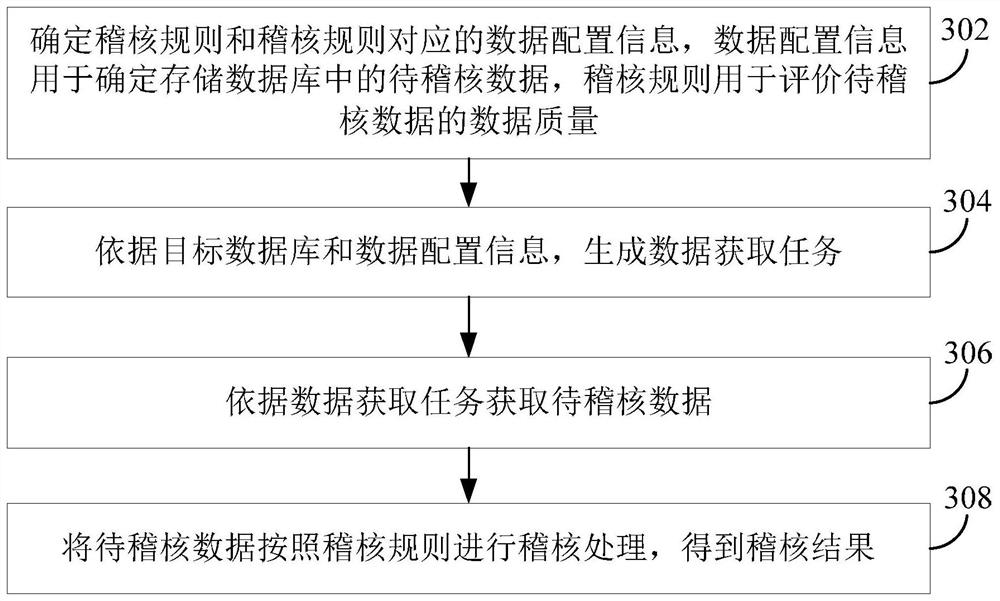

Data quality auditing method and device, equipment and storage medium

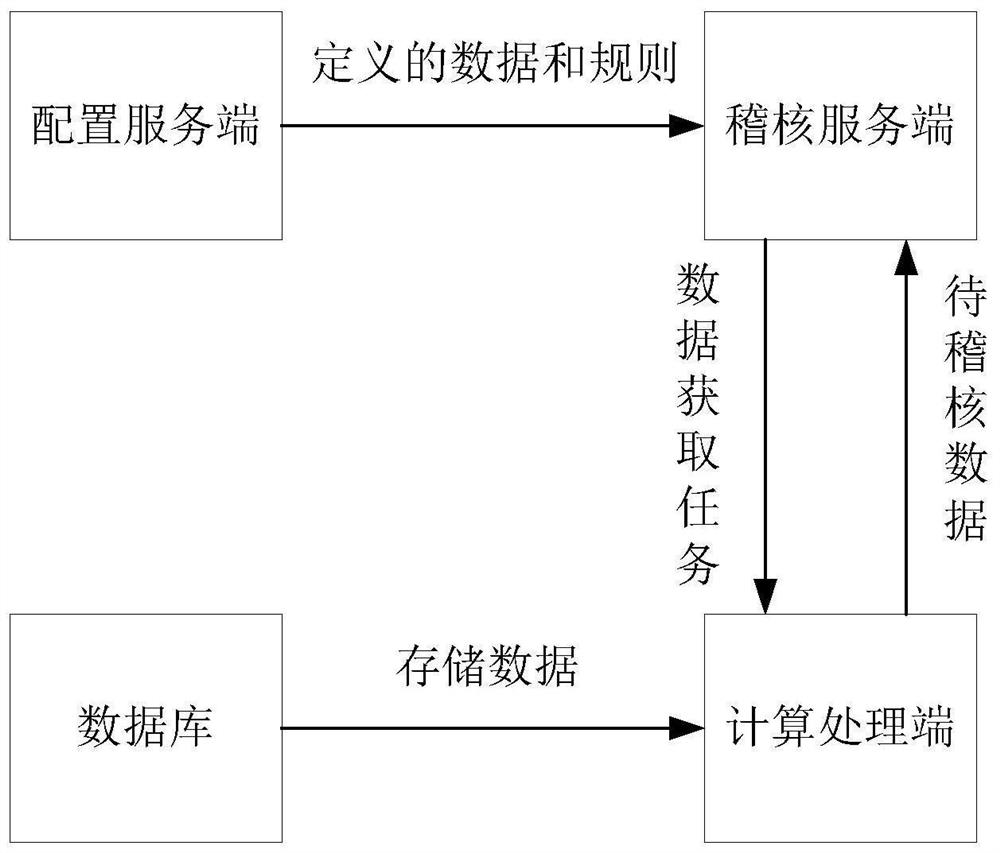

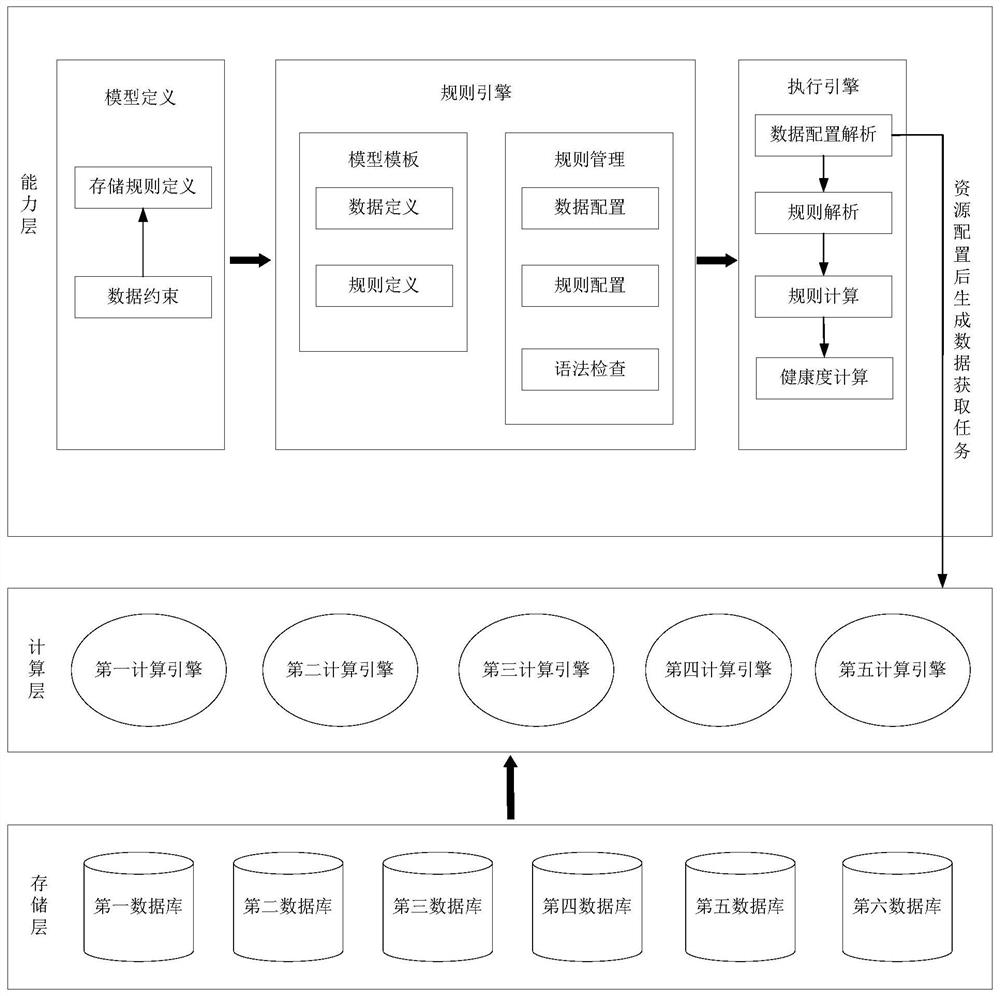

PendingCN113010502AOptimize the acquisition methodImprove general performanceDigital data information retrievalSpecial data processing applicationsEngineeringData quality

The embodiment of the invention provides a data quality auditing method, device and equipment and a storage medium. The method comprises the steps: determining an auditing rule and data configuration information corresponding to the auditing rule, the data configuration information is used for determining to-be-auditing data in a storage database, and the to-be-auditing data is stored in the storage database; the auditing rule is used for evaluating the data quality of the to-be-audited data; generating a data collection task according to a target database and the data configuration information; acquiring the to-be-audited data according to the data collection task; and performing auditing processing on the to-be-audited data according to the auditing rule to obtain an auditing result. The auditing data determination and collection mode is convenient and fast, the universality is high, and the data quality auditing efficiency can be improved.

Owner:ALIBABA GRP HLDG LTD

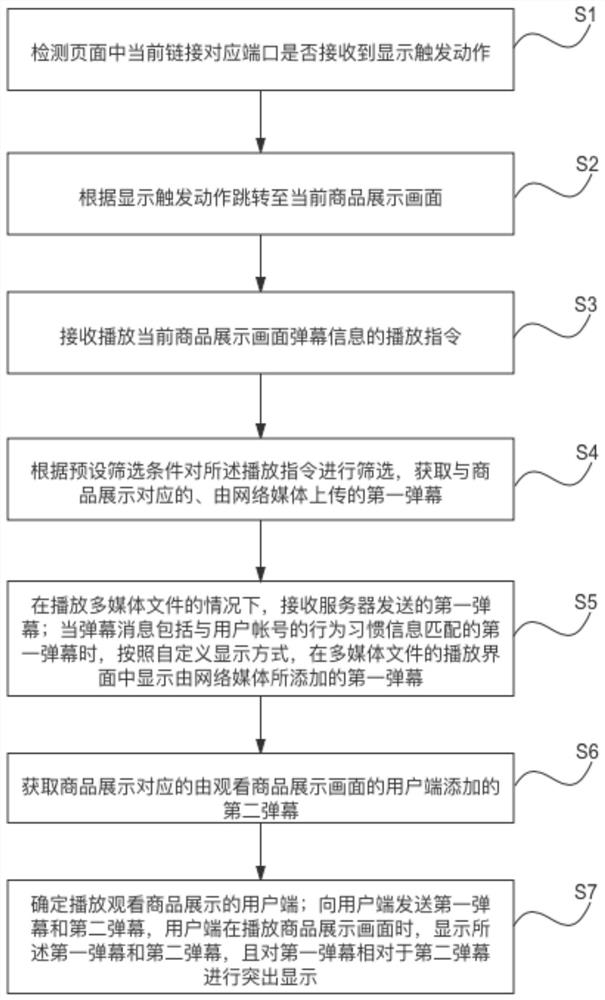

Bullet screen display method and system based on commodity information

InactiveCN111757188AReal-time acquisition methodReal way to getSelective content distributionComputer graphics (images)Engineering

The invention provides a bullet screen display method and system based on commodity information. The bullet screen display method comprises the steps of: detecting whether a port corresponding to a current link in a page receives a display triggering action or not; skipping to a current commodity display picture according to the display triggering action to receive playing instructions for playingbullet screen information of the current commodity display picture; screening the playing instructions according to a preset screening condition, and acquiring bullet screen information correspondingto commodity display; when the multimedia file is played, receiving a bullet screen message sent by the server; when the bullet screen message contains a first bullet screen matched with the behavioral habit information of a user account, displaying the first bullet screen added by network media; further acquiring a second bullet screen which corresponds to the commodity display and is added by auser side watching the commodity display; and after the played user side is determined, sending the first bullet screen and the second bullet screen to the user side, displaying the first bullet screen and the second bullet screen by the user side during commodity display, and displaying the first bullet screen in highlighted manner relative to the second bullet screen. Therefore, the watching frequency and the user experience are improved.

Owner:浙江炬光电气有限公司

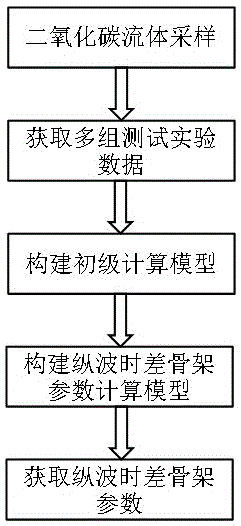

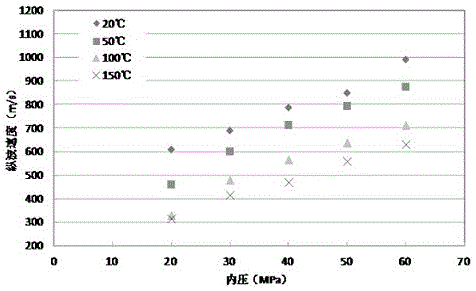

Method for obtaining CO2 fluid longitudinal wave time difference framework parameters of high-temperature and high-pressure reservoir

The invention provides a method for obtaining CO2 fluid longitudinal wave time difference framework parameters of a high-temperature and high-pressure reservoir. The method comprises the step S1 of sampling CO2 fluid; the step S2 of obtaining multiple groups of test experimental data; on the conditions of different temperature and pressure, performing determination tests of longitudinal wave speed on CO2 fluid samples and obtaining multiple groups of data formed by longitudinal wave speed parameters, temperature parameters and pressure parameters; the step S3 of establishing a primary calculation model; the step S4 of establishing a longitudinal wave time difference framework parameter calculation model; and the step S5 of obtaining the longitudinal wave time difference framework parameters. By utilizing the method, the accuracy of obtaining the CO2 fluid longitudinal wave time difference framework parameters can be remarkably improved, the accuracy of calculating well logging interpretation evaluation porosity of a high-temperature and high-pressure gas reservoir rich in CO2 by means of acoustic logging information is improved, and the method is high in universality. The better and quicker obtaining method is provided for selection of the CO2 fluid longitudinal wave time difference framework parameters in high-temperature and high-pressure gas reservoir well logging interpretation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

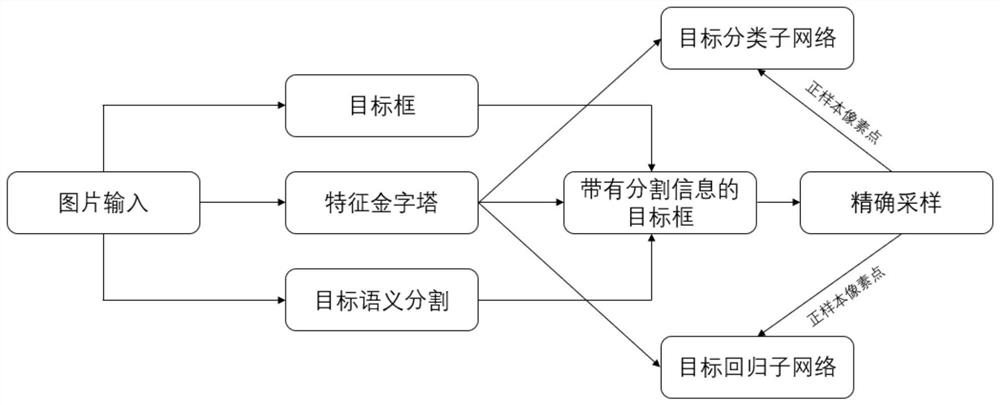

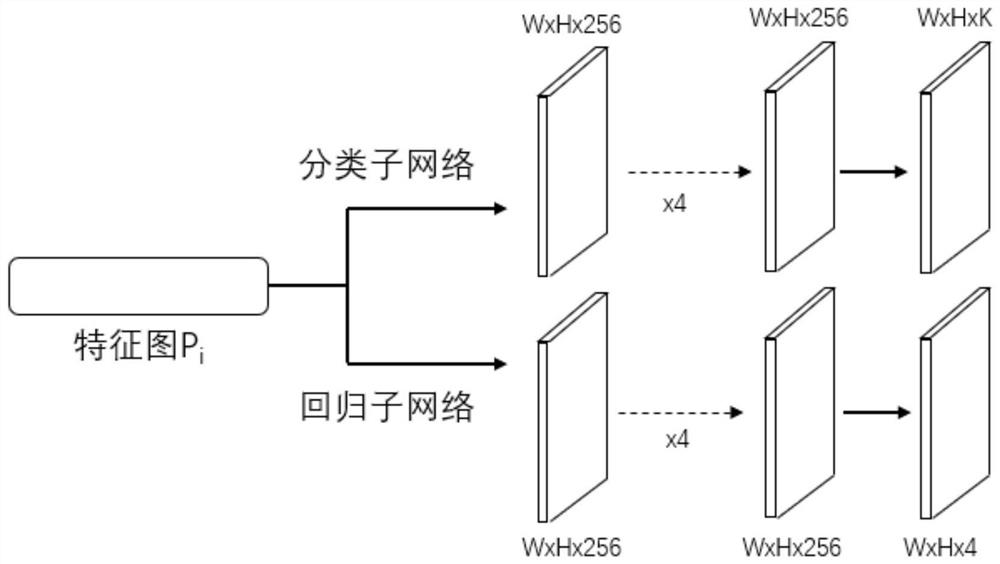

Remote sensing image vehicle target detection method based on anchor-point-free accurate sampling

ActiveCN111738114AImprove discriminationOptimize the acquisition methodInternal combustion piston enginesScene recognitionFeature extractionNeural network nn

The invention discloses a remote sensing image vehicle target detection method based on anchor-point-free accurate sampling, and the method comprises the following steps: S1, carrying out the featureextraction of an original image through a multilayer convolution neural network, and forming a top-down feature pyramid according to feature maps with different scales; S2, for each layer of featuresof the feature pyramid, generating category prediction of all pixel points on the feature map; S3, for each layer of features of the feature pyramid, generating target box prediction of all pixel points on the feature map; S4, determining a feature map to which the current vehicle target belongs according to the real frame area information in the input picture; S5, determining a positive sample pixel point of the target in the layer of features by means of target instance segmentation information in the real box, and calculating a difference value from the pixel point to four edges of the realbox; and S6, calculating category loss of all positive sample pixel points and regression loss about a real box.

Owner:HANGZHOU DIANZI UNIV

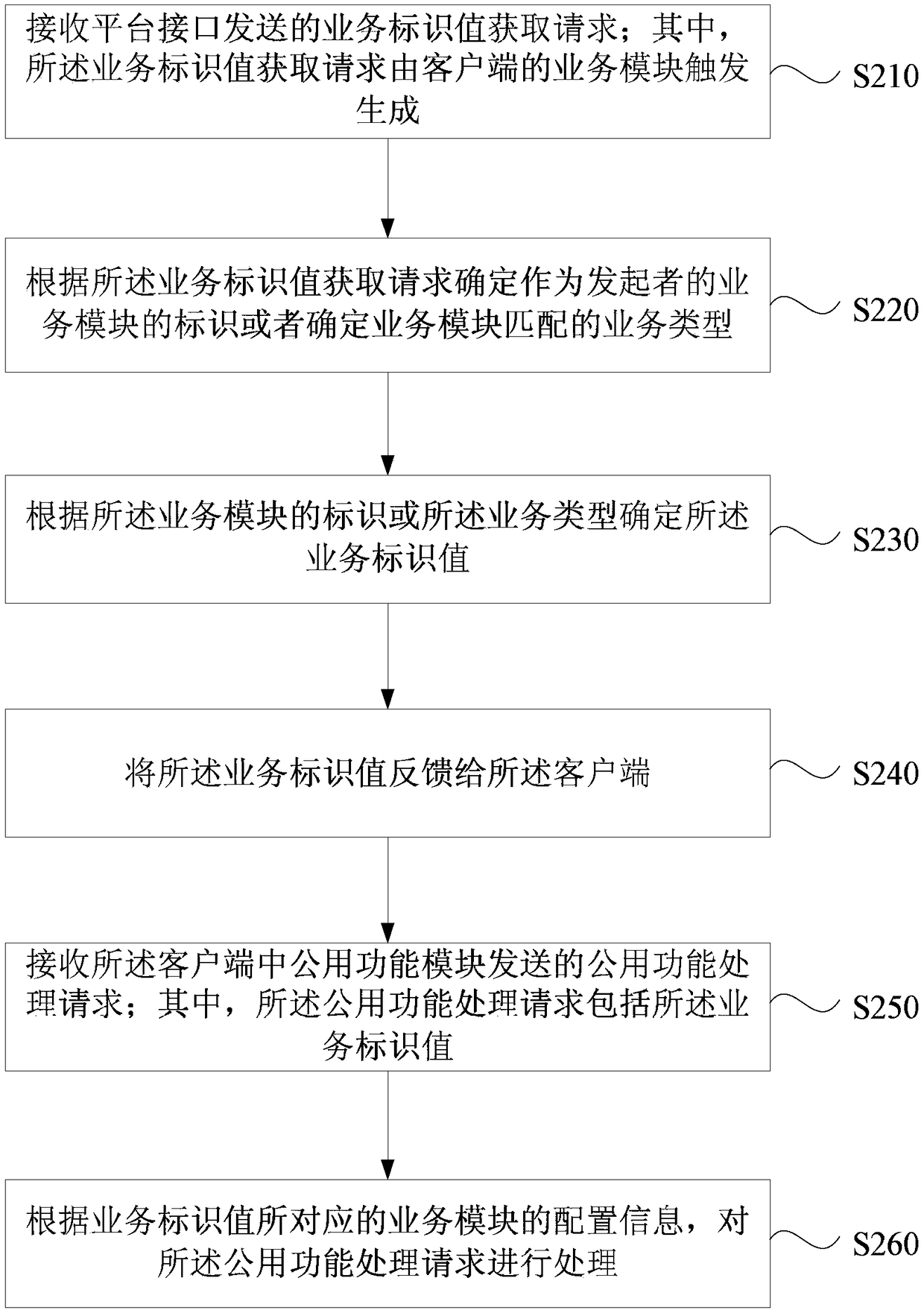

Service identifier acquisition method, device and equipment and storage medium

ActiveCN109408116AOptimize the acquisition methodImprove development performance and user experienceVersion controlProgram code adaptionApplication softwareSoftware engineering

The embodiment of the invention discloses a service identifier acquisition method and device, equipment and a storage medium. The method comprises the following steps: receiving a service identifier value acquisition request sent by a platform interface, wherein the service identification value acquisition request is generated by triggering of a service module of a client; obtaining a service identification value matched with a service module initiating the service identification value obtaining request; and the service identification value is fed back to the client, and the service identification value is used for being transmitted to the public function module for use when the service module calls the public function module in the client. According to the technical scheme, the obtainingmode of the service identification value in the application software platform can be optimized, and therefore the development performance and the user experience of the application software platform are improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

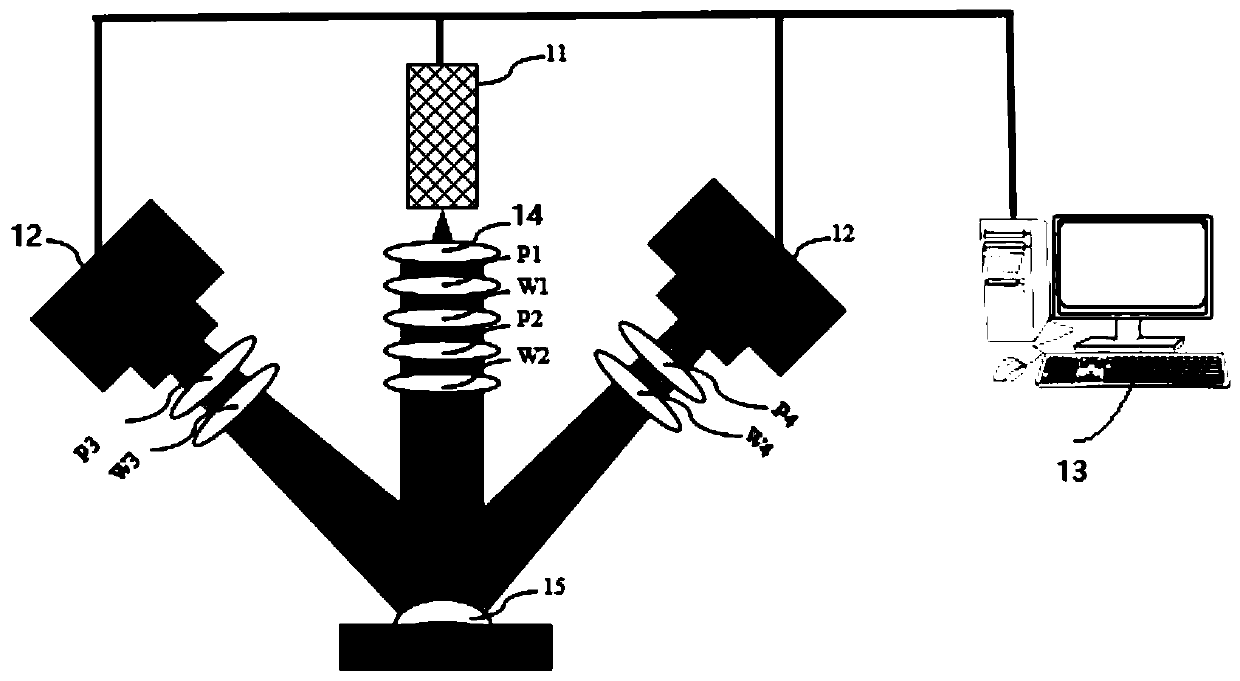

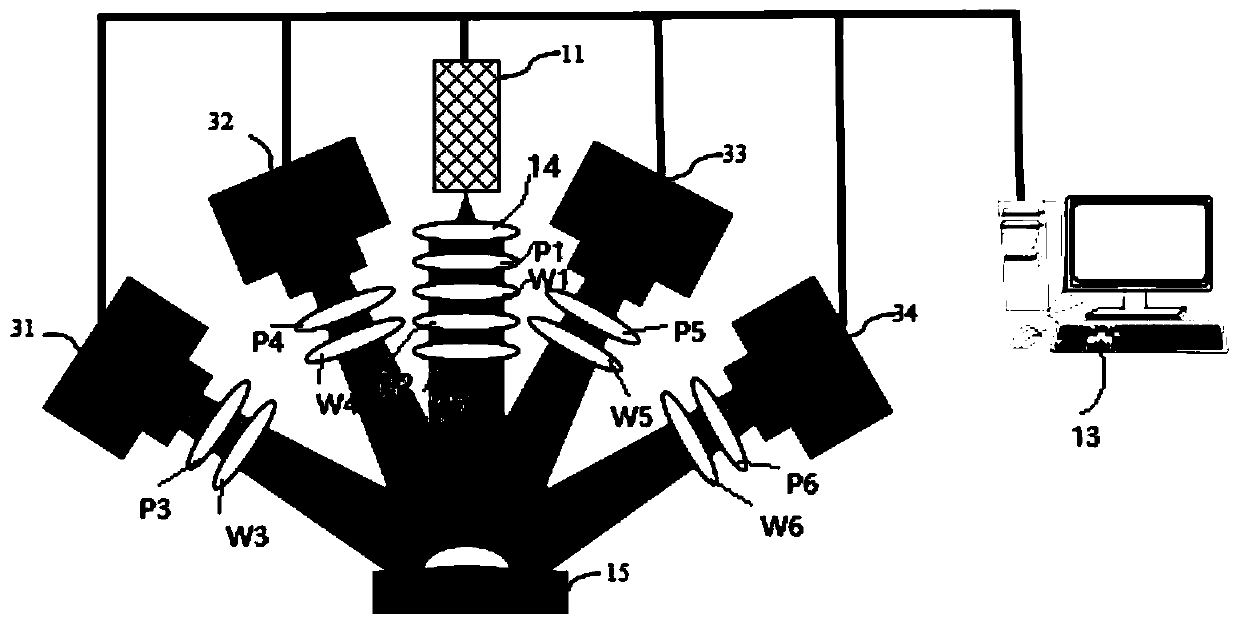

Composition analysis device and composition analysis method

ActiveCN111328370AOptimize the acquisition methodRapid identification of surface defect detectionPolarisation-affecting propertiesOptically investigating flaws/contaminationThermodynamicsComposition analysis

Provided are a composition analysis device and a composition analysis method whereby composition analysis of a by-product gas generated in an ironmaking process can be performed easily, composition analysis and heat calculation can be performed continuously, and the heat of the by-product gas can be measured with higher reliability. A composition analysis device (10) for analyzing the compositionof a gas to be analyzed is provided with: a first measurement means (11) for measuring the concentrations of a plurality of gases to be measured contained in the gas to be analyzed; a conversion heatamount calculation means (13) that includes a second measurement means (12) for measuring the refractive index of the gas to be analyzed and the sound velocity propagating through the gas to be analyzed, and that calculates the conversion heat amount of the gas to be analyzed for each of the refractive index and the sound velocity; a reference miscellaneous gas total error heat amount calculationmeans (14) that calculates, on the basis of the converted heat amount of the gas to be analyzed, an error heat amount that is a reference among error heat amounts generated by miscellaneous gas contained in the gas to be analyzed; and a first non-measured gas concentration calculation means (15) for calculating the concentration of the first gas on the basis of the respective concentrations of themeasured gases and the amount of error heat that is the reference.

Owner:HEREN KEJI SHENZHEN LLC

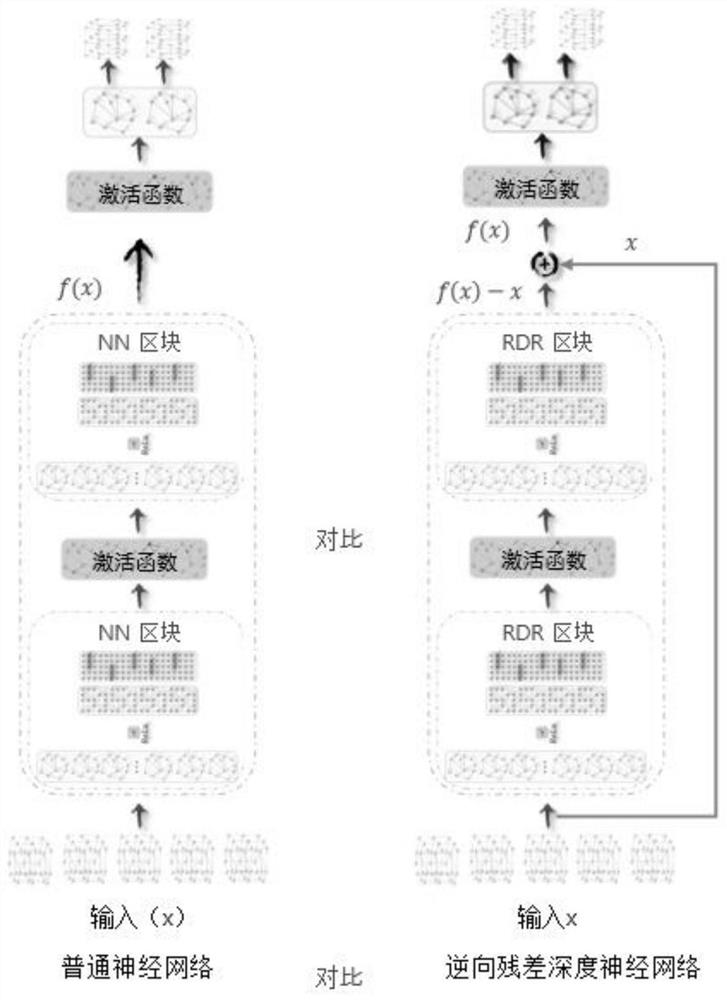

Salinized soil water and fertilizer strategy acquisition method and system, storage medium and electronic equipment

ActiveCN113221446AHigh precisionMeet the simulation requirementsData processing applicationsDesign optimisation/simulationAgricultural engineeringResidual neural network

The invention relates to the technical field of agriculture, and provides a salinized soil water and fertilizer strategy acquisition method and system, a storage medium and electronic equipment, and the method comprises the steps: obtaining a preset value of soil conductivity used for representing the soil salinization degree at a preset time point, and determining a target value of each parameter associated with soil salinization at the preset time point; and inputting the preset value and all the target values into a trained reverse residual neural network to obtain a salinized soil water and fertilizer strategy corresponding to the soil with the soil conductivity being the preset value. The constructed reverse residual neural network can better fit an actual application scene of irrigation and water conservancy, the reverse residual neural network can directly simulate and optimize according to the target soil salinity corresponding to the preset value of the soil conductivity to obtain a salinized soil water and fertilizer strategy, the model precision is high, the simulation requirement can be met, a powerful technical means is provided for optimizing a field irrigation and fertilization strategy, and the analysis efficiency is improved.

Owner:兰州里丰正维智能科技有限公司 +2

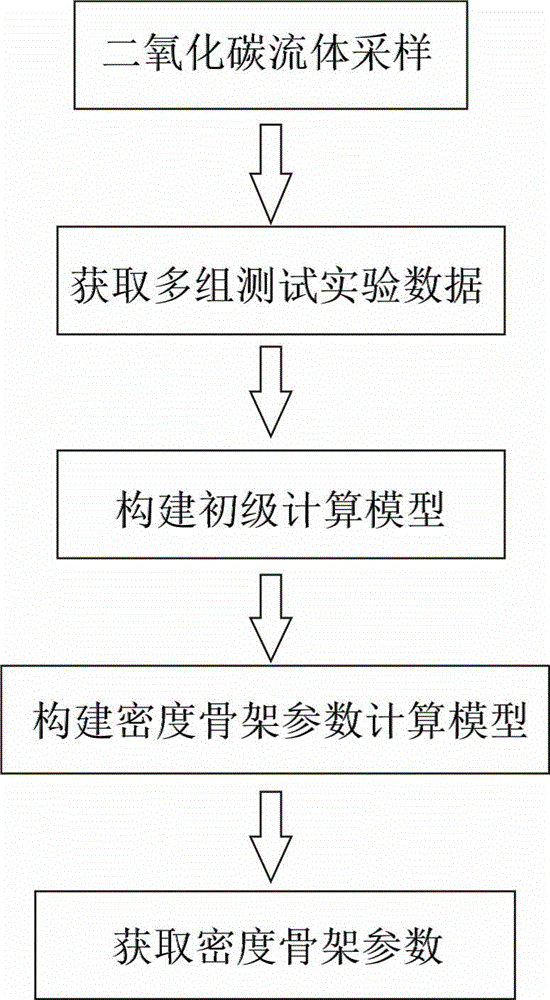

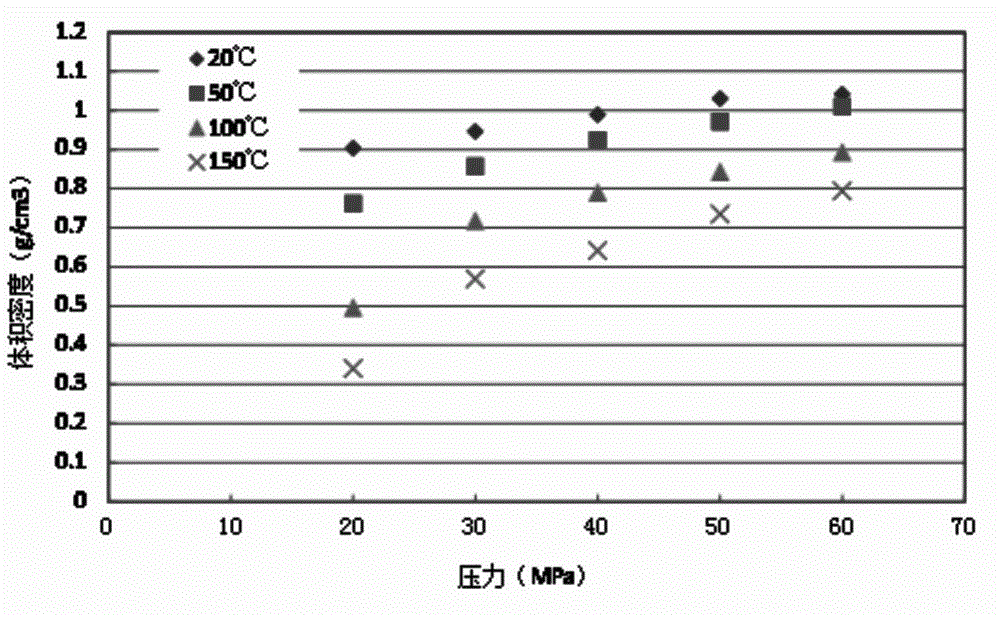

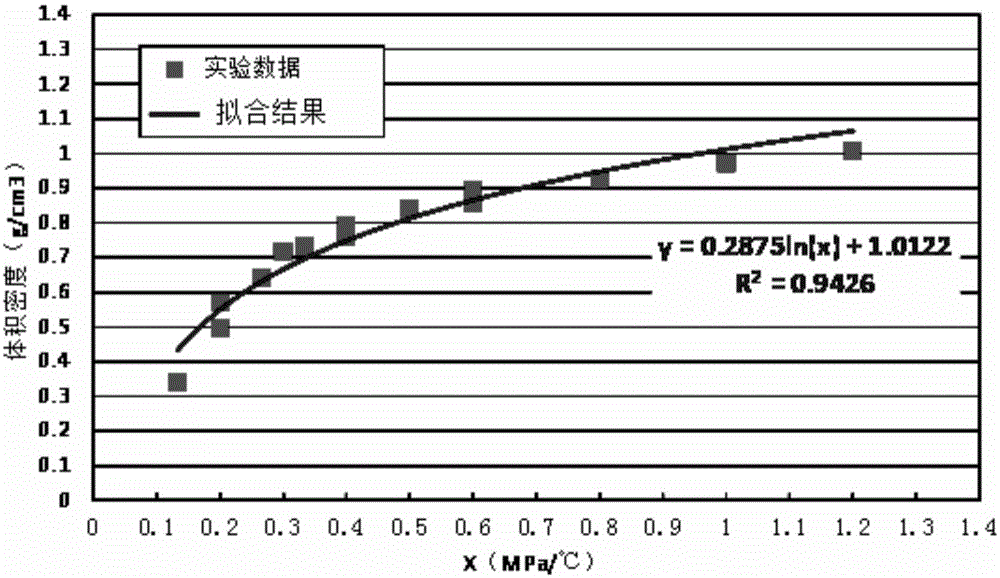

Acquisition method of high-temperature high-pressure reservoir carbon dioxide fluid density skeleton parameters

The invention discloses an acquisition method of high-temperature high-pressure reservoir carbon dioxide fluid density skeleton parameters. The method includes the following steps: sampling carbon dioxide fluid; acquiring multiple groups of test experiment data; constructing a primary computing model, to be more specific, utilizing a data fitting analysis method to perform parameter fitting analysis on the multiple groups of data so as to obtain the primary computing model; constructing a density skeleton parameter computing model, to be more specific, on the basis of the primary computing model, utilizing a density well logging response principle to convert volume density of the carbon dioxide fluid into an apparent volume density value so as to obtain the density skeleton parameter computing model; substituting a measured temperature value and a pressure value into the density skeleton parameter computing model to obtain the density skeleton parameters off the carbon dioxide fluid in a high-temperature high-pressure reservoir. By the method, accuracy in acquisition of the carbon dioxide fluid skeleton density parameters can be improved remarkably, further precision in porosity evaluation of high-temperature high-pressure carbon-dioxide-enriched gas reservoir well logging interpretation is improved, and high universality is obtained.

Owner:CHINA NAT OFFSHORE OIL CORP +1

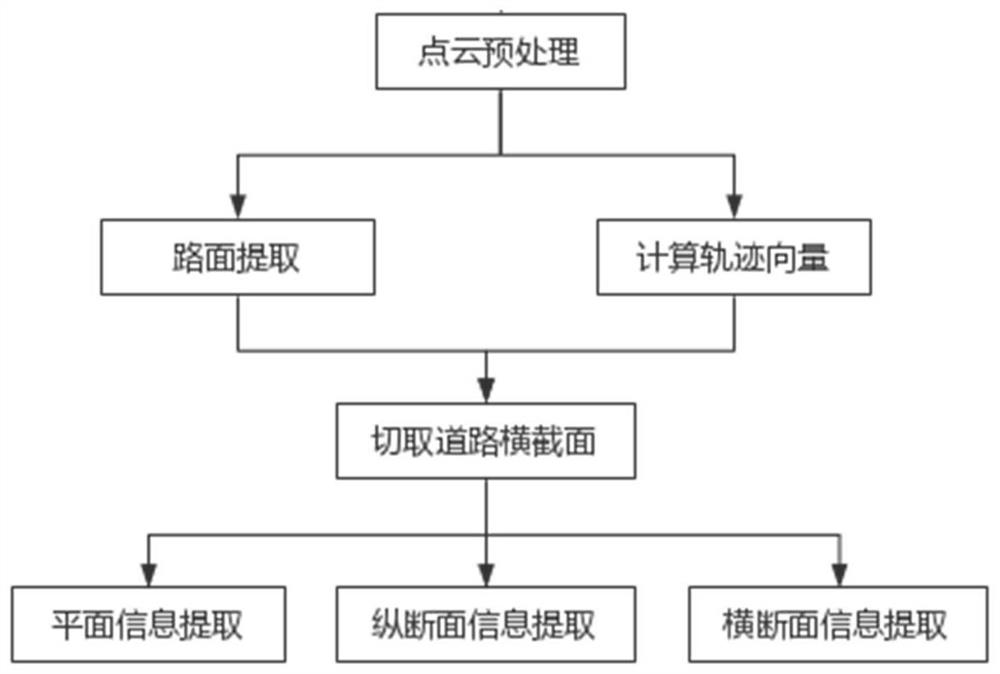

Road geometric information extraction method based on laser point cloud

PendingCN114170149ASimple methodOptimizing the Algorithm for Extracting Road Geometric InformationImage enhancementImage analysisLeast squaresEngineering

The invention discloses a road geometric information extraction method based on a laser point cloud. The method comprises the following steps: performing radius filtering and grid downsampling on a point cloud to simplify the point cloud; in consideration of concentrated elevation distribution of road surface points and smoother road surface, elevation features and local normal vector features of point clouds are extracted to distinguish ground points from non-ground points; connecting the road surface points on the ground points by using a region growing method, and obtaining a complete road surface point cloud after the mistakenly deleted points are recovered; and finally, calculating a trajectory vector and cutting a road cross section according to the acquired trajectory information of the vehicle, and acquiring geometric parameters of the road by using a least square method. According to the method, the extraction precision and the program operation efficiency are considered at the same time, and automatic extraction of road geometric information in different road environments can be comprehensively considered.

Owner:SOUTHEAST UNIV

Enterprise portrait service construction method, device and equipment based on grid technology

PendingCN114429265AOptimize the acquisition methodRealize acquisitionResourcesInformation resourceBusiness enterprise

The invention provides an enterprise portrait service construction method and device based on a grid technology, a computer readable storage medium and electronic equipment. The method comprises the following steps: acquiring related data of an enterprise portrait from different information resources by utilizing an information grid technology according to a data label of the enterprise portrait; according to a pre-constructed enterprise portrait model, the related data of the enterprise portrait obtained from different information resources is fused by using a big data engine technology, and data fusion results of different dimensions are regarded as different data micro-services; and then linking different data micro-services together according to a dependency relationship among the data micro-services to form a callable enterprise portrait micro-service. According to the invention, a full-dimensional enterprise portrait model can be scientifically constructed in an efficient information resource management mode.

Owner:北京比格大数据有限公司

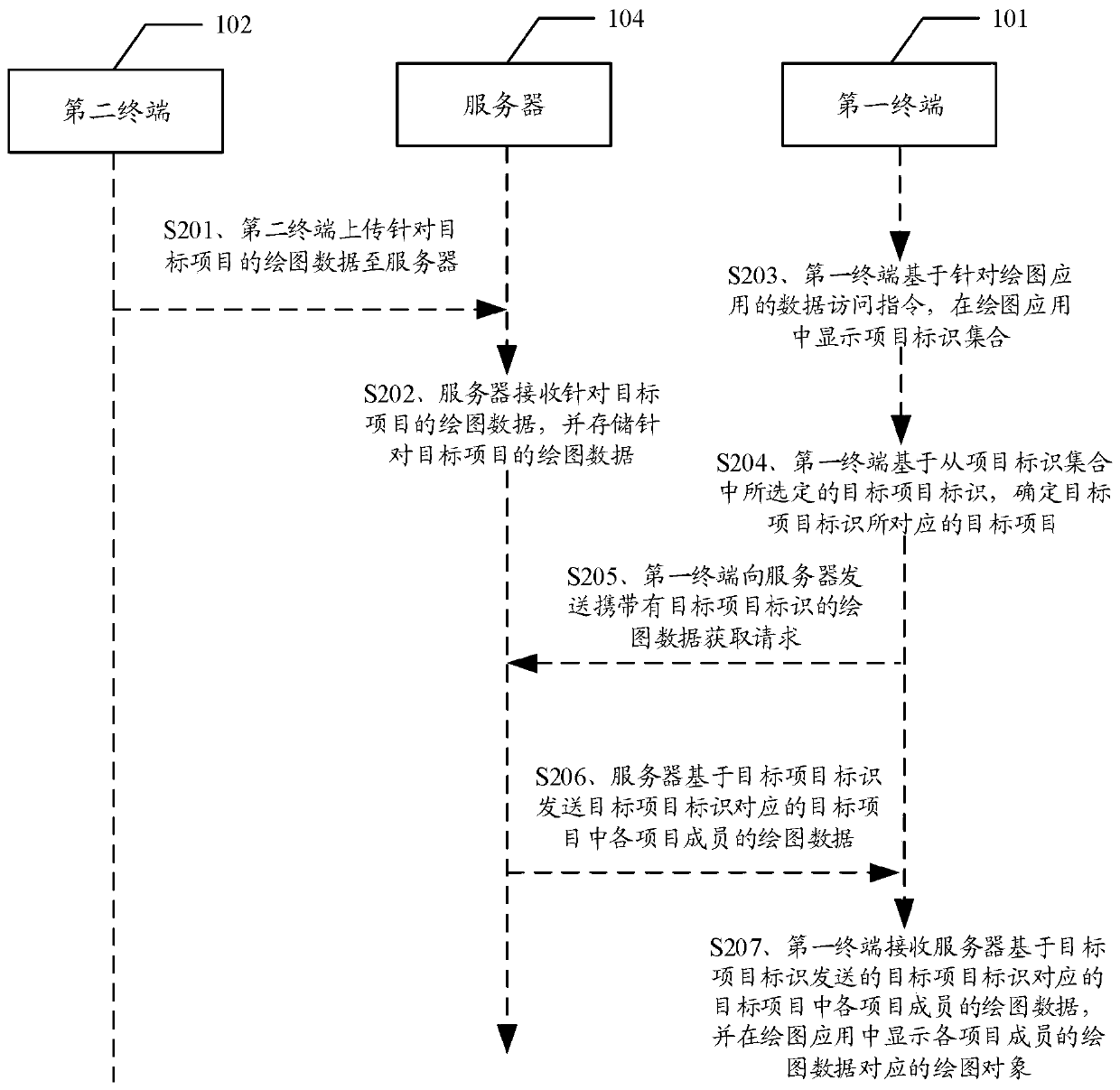

Drawing data acquisition method and device, storage medium and terminal

InactiveCN110221891AOptimize the acquisition methodImprove acquisition efficiencyExecution for user interfacesData acquisitionData access

The invention discloses a drawing data acquisition method and device, a storage medium and a terminal, and relates to the technical field of computers. The method comprises the steps of firstly accessing an instruction based on the data for a drawing application; and displaying an item identifier set in the drawing application, then determining a target item corresponding to the target item identifier based on the target item identifier selected from the item identifier set, finally obtaining the drawing data of each item member in the target item, and displaying a drawing object correspondingto the drawing data. If the user wants to check or know the progress of other members of the same drawing item, and the drawing object which is finished or is designed currently, the user can selecta target item identifier corresponding to the target item according to the item identifier set displayed in the drawing application, and obtain the drawing data of each project member in the target project, and check the drawing object corresponding to the drawing data, so that the drawing data obtaining mode is simple and convenient, the time is saved, and the drawing data obtaining efficiency isimproved.

Owner:BEIJING DA MI TECH CO LTD

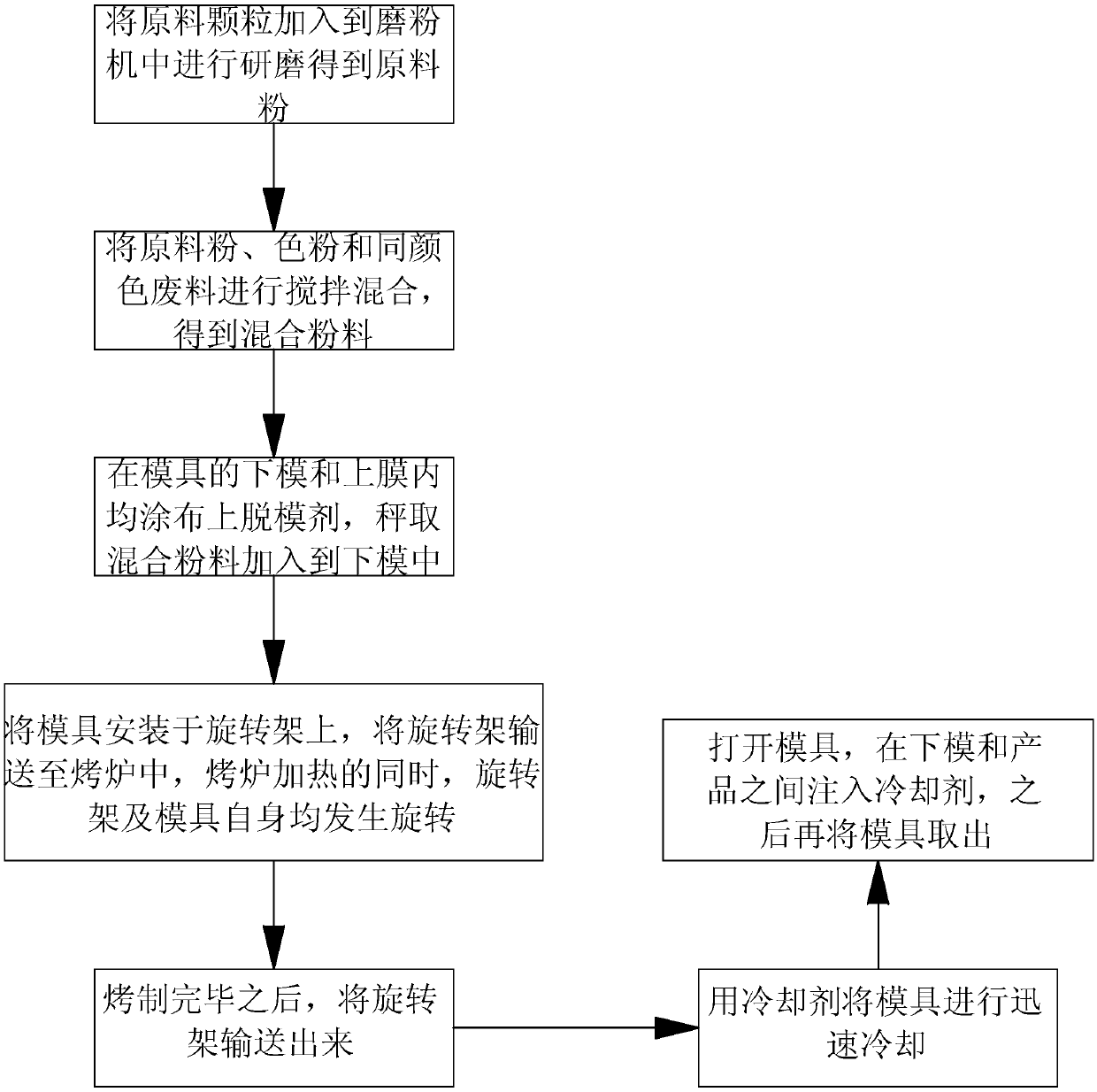

Rotational moulding preparation process of air mover shell

InactiveCN109986732AUniform detachmentOptimize the acquisition methodCoatingsRelative displacementCoolant

The invention discloses a rotational moulding preparation process of an air mover shell. The rotational moulding preparation process comprises the following steps: S1, raw material particles are ground, and raw material powder is obtained; S2, the raw material powder, color powder and waste with the same color are all stirred, and mixed powder is obtained; S3, the mixed powder is weighed and poured into a designated lower mould; S4, the mould is placed on a rotating frame, and the rotating frame is conveyed into an oven; S5, the mould is heated, meanwhile, the rotating frame drives the mould to rotate, and the mould also rotates along the axis of the mould; S6, after the mould is baked in the oven for 1300 s, the rotating frame is conveyed out from the oven; S7, the outer surface of the mould is rapidly cooled through a coolant; and S8, the mould is opened, and a product is taken out from the mould. After baking in the oven is completed, the mould is rapidly cooled through the coolant,thus the mould is shrunk, but the product is still in an expansion state, thus the mould and the product generate relative displacement and then are easy to separate, and burrs are not prone to beinggenerated.

Owner:CRM PLASTIC INC

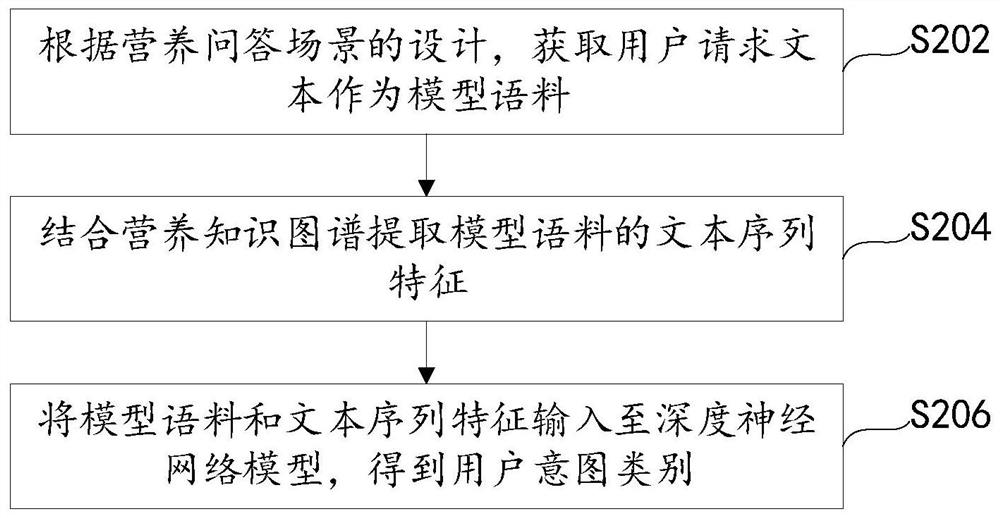

Intention recognition method and nutritional knowledge question and answer method and device

PendingCN111831807AImprove accuracyImprove experienceCharacter and pattern recognitionNutrition controlNutritionQuestions and answers

The invention provides an intention recognition method and a nutritional knowledge question and answer method and device. The method comprises the steps of obtaining a session text input by a user; determining text sequence features corresponding to the session text according to a preset knowledge graph, wherein the preset knowledge graph comprises a plurality of nutrition knowledge entities and association relationships among the nutrition knowledge entities; and recognizing the session intention of the user based on the session text and the text sequence features through an intention prediction model obtained by pre-training. According to the invention, the accuracy of intention recognition can be effectively improved, and the user experience is further improved.

Owner:BEIJING MORE HEALTH TECH GRP CO LTD

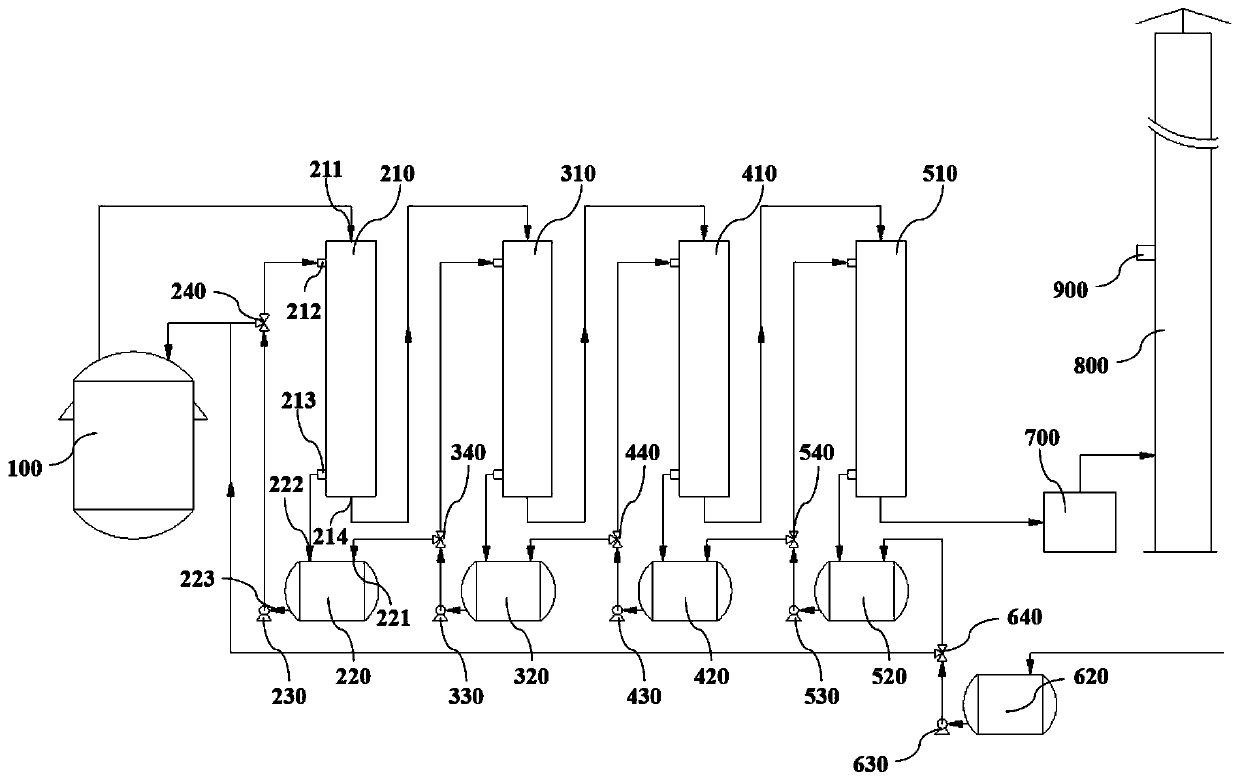

Trimethylamine tail gas recovery system and method in parylene production process

InactiveCN110479059AAchieve recyclingReduce lossDispersed particle separationParyleneRoom temperature

The invention discloses a trimethylamine tail gas recovery system and method, and belongs to the technical field of chemical engineering and waste gas treatment. Trimethylamine tail gas generated by areaction kettle enters from the top of an absorber through a gas pipe; an absorbent in a circulating tank is pumped into the upper part of an absorber through a pump to form a liquid film; absorptionliquid after reaction is discharged into the circulating tank from the lower part of the absorber; and tail gas is discharged into a vacuum unit from the bottom of the absorber; the tail gas is pumped to an exhaust funnel through a vacuum unit, and is discharged at high altitude after being detected to reach the standard by an on-line monitor; when the discharge rate of trimethylamine in the online monitor is greater than 80% of the discharge standard, the absorption liquid in the circulating tank is pumped into the reaction kettle to realize recovery of trimethylamine in the tail gas, and finally p-methylbenzyl chloride in a metering tank is pumped into the circulating tank. According to the system and the method, the recovery of trimethylamine in the tail gas is realized, the tail gas emission can reach the standard, and gas-liquid parallel flow is controlled; the method can be carried out at room temperature without heating, so that the energy consumption is reduced, and the comprehensive economic benefit is improved.

Owner:江苏南大华兴环保科技股份公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com