Production-data-driven dynamic job-shop scheduling rule intelligent selection method

A technology of job shop and production data, applied in the field of intelligent selection of dynamic job shop scheduling rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

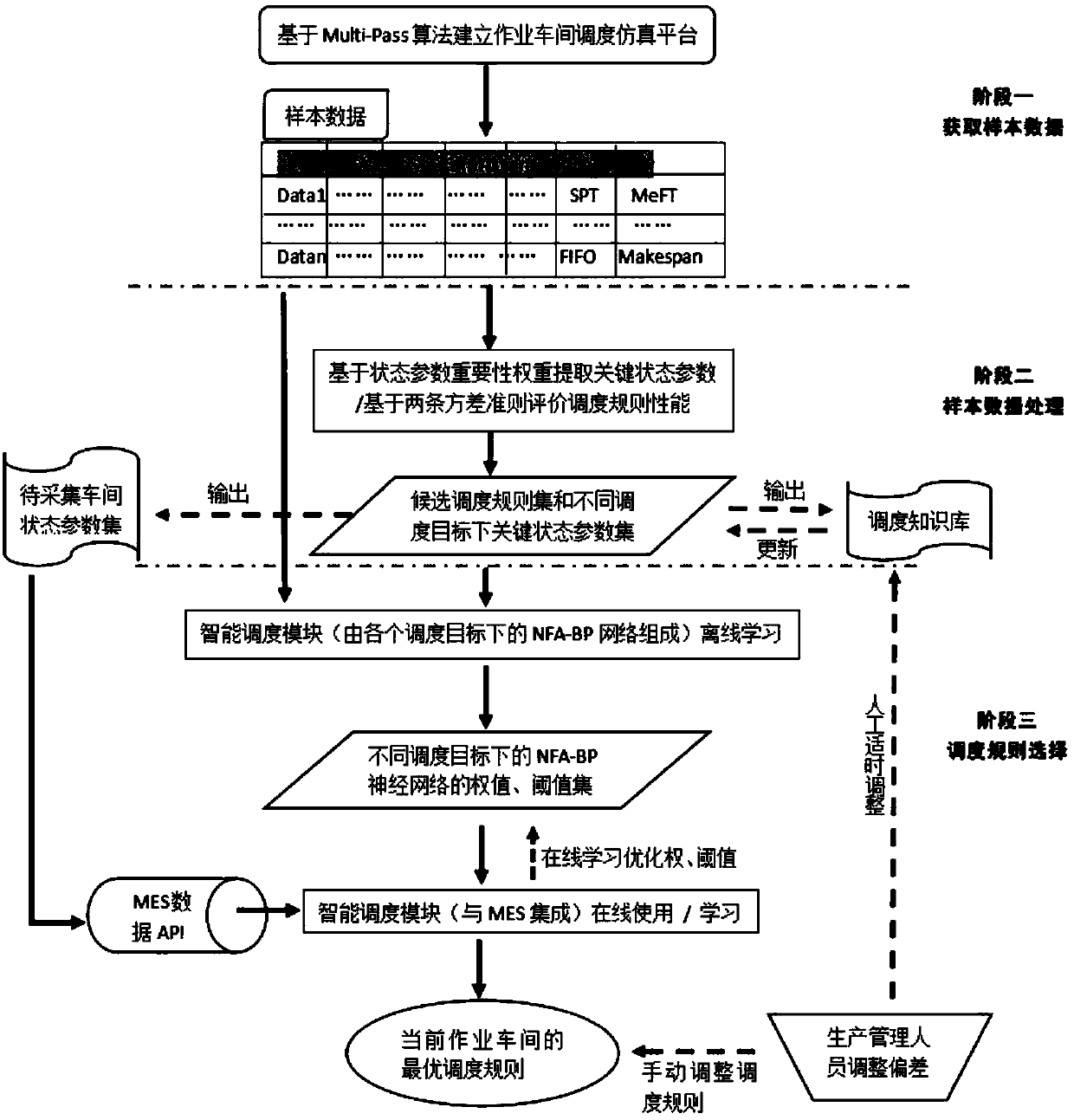

[0088]The first stage is the acquisition of sample data. The simulation model of job shop scheduling takes the classic ft10 (MT10) problem as an example. Its scale is 10*10, that is, it includes 10 kinds of workpieces, 10 processing equipment, and has definite workpiece processing time information and processing path information. The establishment of a job shop production scheduling simulation platform based on Multi-Pass simulation technology can be realized through, for example, Siemens' professional production system simulation software Siemens Tecnomatix Plant Simulation 11TR3. Multiple modules such as control are input as control parameters, and software modules such as Simtalk language are used to realize various scheduling rules. The simulation platform is divided into five parts: job shop scheduling model, model initialization and order information management, scheduling rule implementation, workpiece flow control and Experimental control and output, the main function ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com