Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Not easy to smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

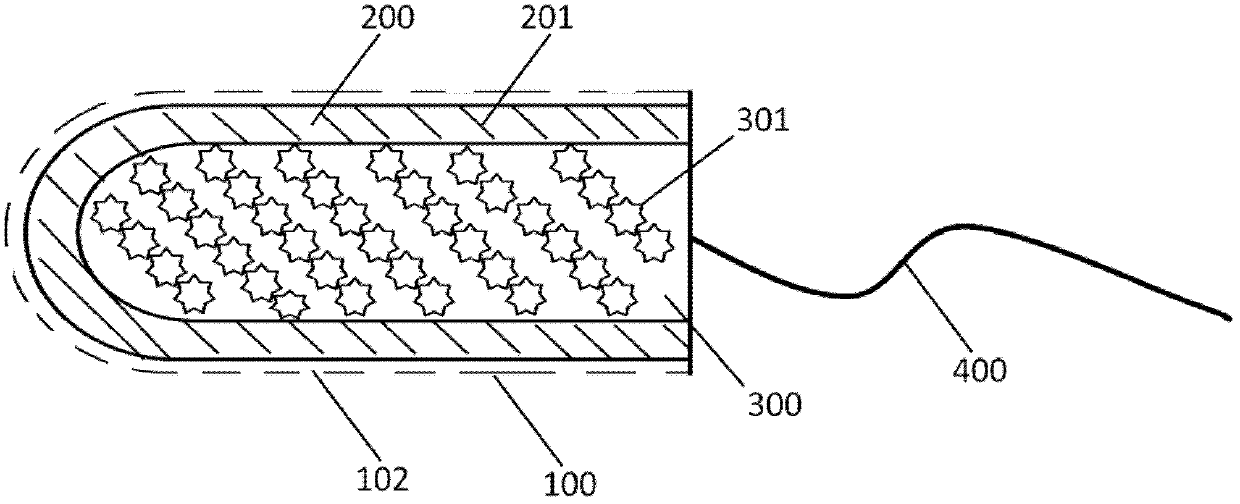

Method for manufacturing wheat germ oil microcapsule

InactiveCN102228249AKeep functional ingredientsPlay a protective effectFood shapingFood preparationAdditive ingredientLiquid state

The invention relates to a method for manufacturing a wheat germ oil microcapsule. The method comprises the following steps of preparing wall material phases, blending an emulsifier and preparing a core material phase, mixing, pre-emulsifying, homogenizing, spray-drying and the like. The encapsulation efficiency of a wheat germ oil microcapsule product prepared by the method disclosed by the invention is as high as 80-86%, and a surface oil content of the wheat germ oil microcapsule product is 14.5-19.1%; functional active ingredients of wheat germ oil are greatly kept, oxidation stability is strengthened, odor smell of the wheat germ oil is covered, and quality of products is improved; simultaneously, According to the method disclosed by the invention, the wheat germ oil is changed from liquid to more stable solid, thus the solid wheat germ oil is convenient to store and transport, and is more probably produced in various product forms; in addition, the application range is extended and varying requirements of consumers are met.

Owner:HEFEI UNIV OF TECH

Method for processing assembling type bamboo floor

The invention discloses a processing method of an assembled bamboo floor, which utilizes bamboo with a short growth period and abundant resources as a raw material, and after selecting bamboo, breaking bamboo, cooking, drying, matching colors, cutting materials, assembling, and gluing, Put it in a hot press and glue it together, then polish it with a heavy sand machine, cut it with mechanical equipment, paint it and dry it, and then it will be the finished product. The whole assembly process is simple, practical, and the finished product has no peculiar smell, and the assembled bamboo floor has a compact structure, is not easy to deform, has good pressure resistance, and feels comfortable on the feet. It avoids mold, insects, deterioration and other phenomena during the use of bamboo flooring, and uses the top layer of bamboo chips, carbonized bamboo chips or other colored bamboo chips to be placed regularly in the top layer, which greatly enriches the surface of the bamboo floor. It has the advantages of anti-mildew, anti-corrosion, waterproof, not easy to deform, energy saving and environmental protection.

Owner:孙长桥

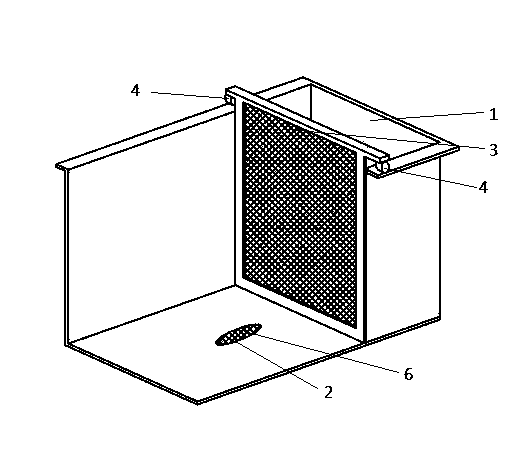

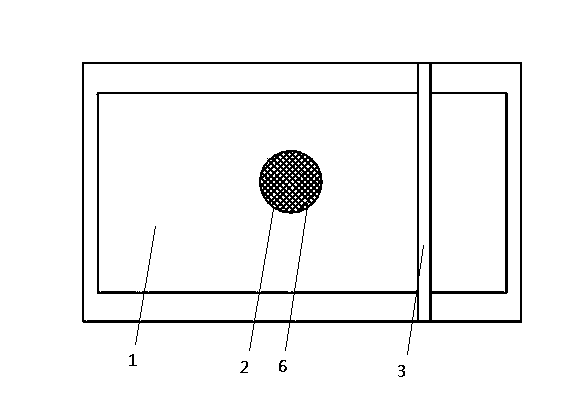

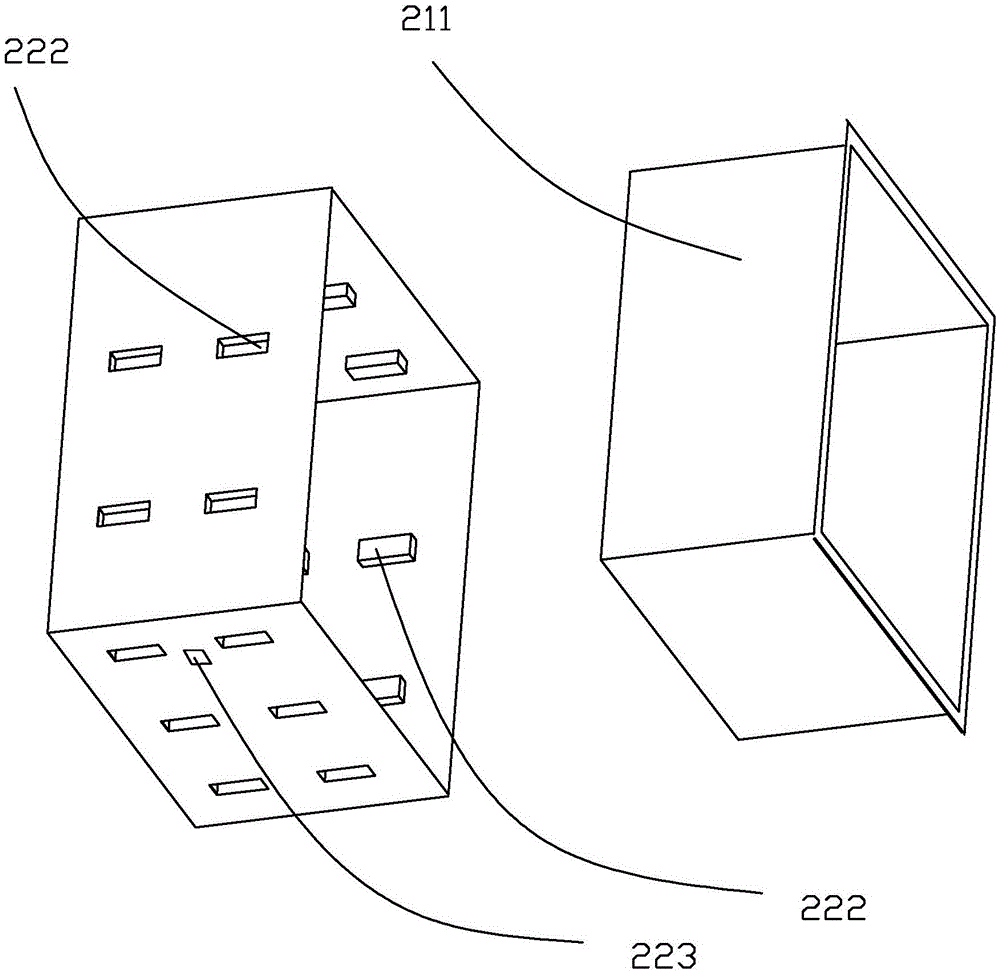

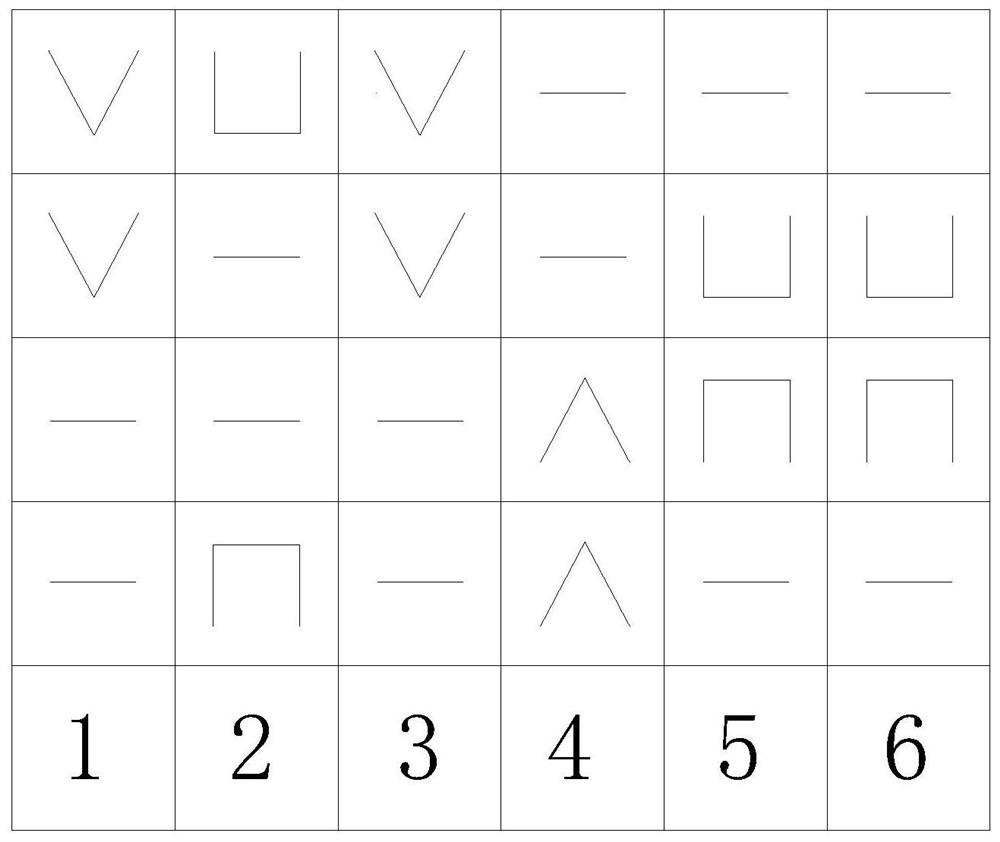

Water tank with filter net structure

The invention discloses a water tank with a filter net structure. The water tank with the filter net structure comprises a water tank body and a water outlet formed in the bottom of the water tank body, and is characterized in that a slidable filter net, which is perpendicular to the bottom of the water tank body, is arranged in the water tank body. The water tank with the filter net structure has the advantages that food residues can be isolated on one side of the water tank by pushing the filter net after the water tank disclosed by the invention is used for washing, and then sewage can be discharged by opening the water outlet, so that the sewage discharging can be accelerated; meanwhile, the sewage does not contain or contains an extremely small quantity of food residues, and thus the food residues are not easily accumulated in a drain pipe to produce odor.

Owner:易良娟

Antibacterial and anti-aging plastic container and preparation method thereof

The present invention provides an antibacterial and anti-aging plastic container and a preparation method thereof, wherein the raw materials of the plastic chopping board in the formula comprise, by weight, 75-95% of a polymer, 3-20% of a natural antibacterial agent, 1.2-3% of semen arecae seed, and 0.8-2% of a coupling agent, and the natural antibacterial agent is prepared from 75-90% by weight of loess powder, 5-15% by weight of a pomegranate peel extract, 3-6.5% by weight of a chestnut shell extract, and 2-3.5% by weight of a aruncus sylvester root extract. According to the present invention, the plastic container is prepared through the processing ways of the multiple approaches, and has characteristics of smooth surface, good size stability, strong, efficient, broad-spectrum, long-lasting and safe antibacterial effect, effective prolonging of the shelf lives of various types of food, medicine and cosmetics and other items during the holding process, excellent aging resistance, good mechanical property, and long service life; and the far-infrared radiation effect can further provide effects of air refreshing, environment purification and odor eliminating so as to easily achieve environmental protection.

Owner:陆思烨

Refrigerator

ActiveCN105091450ANot easy to smellNot easy to dryLighting and heating apparatusDomestic refrigeratorsCold airFrost

The invention discloses a refrigerator. The refrigerator comprises a refrigeration chamber, and a circulating air way for supplying cooling capacity to the refrigeration chamber, wherein the refrigeration chamber is encircled by a first liner and a door body. The refrigerator further comprises a second liner surrounding the outer side of the first liner; openings of the first liner and the second liner are tightly connected; the first liner and the second liner are encircled to form a cavity surrounding the outer side of the first liner; and the second liner is provided with an air inlet communicated with the circulating air way for entering cold air into the cavity and an air return port communicated with the circulating air way for entering the air in the cavity into the circulating air way. The cold air in the cavity performs the heat exchange with the refrigeration chamber through five liner walls of the first liner, so that the refrigeration chamber is synchronously and uniformly refrigerated from five surfaces to achieve effects of improving the heat exchange efficiency and reducing the energy consumption; and meanwhile, the cold air is not directly contacted with foods in the refrigeration chamber to achieve such beneficial effects as difficult food airing, difficult frost damage and difficult tainting by order among all refrigeration chambers.

Owner:SHENYANG HAIER REFRIGERATOR

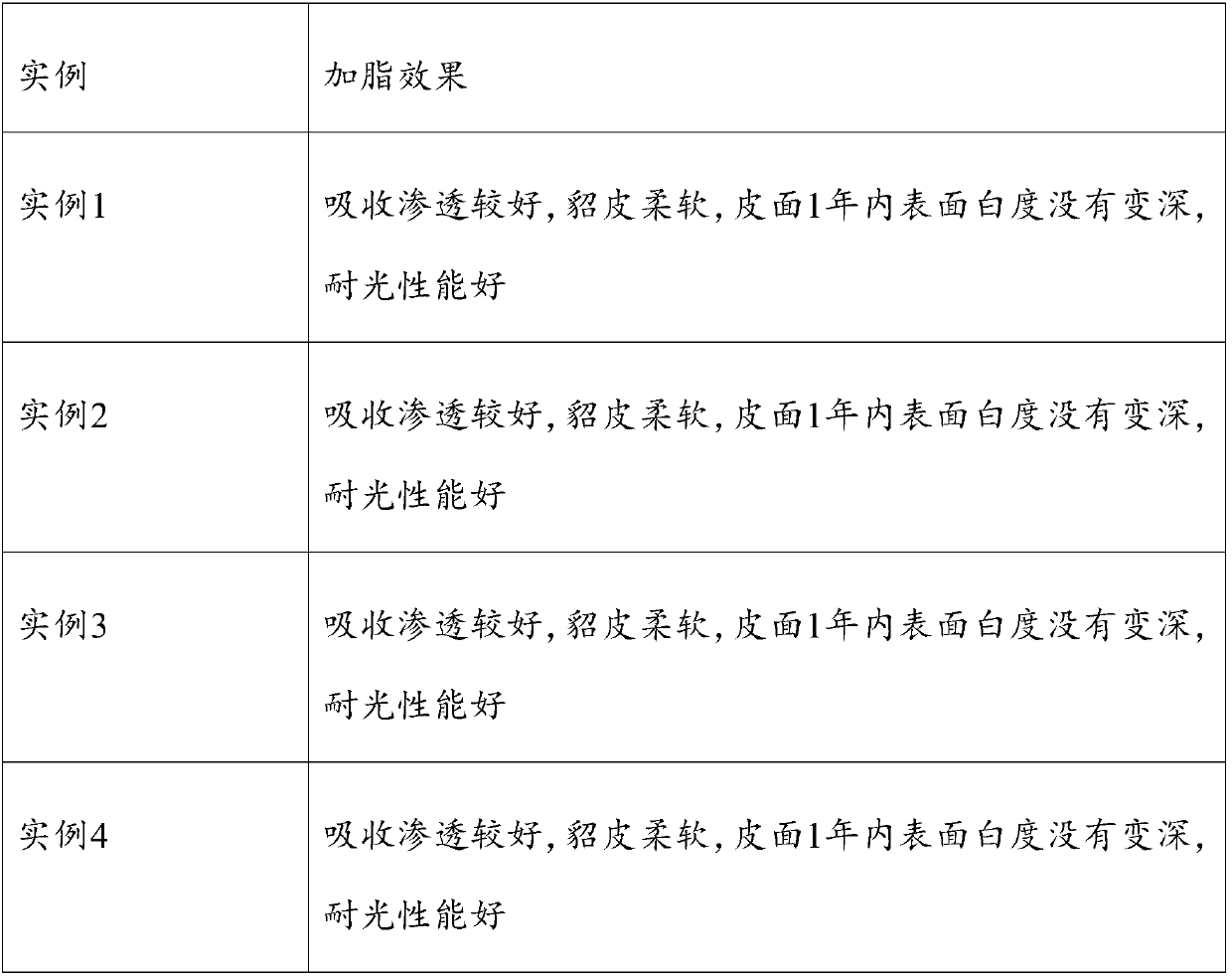

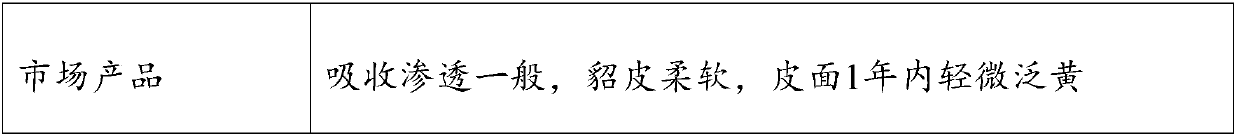

Fur fatting agent and formula and preparation method thereof

ActiveCN107794318ALong term storageGood light fastnessLeather impregnationMineral oilSodium hydroxide

The invention provides a fur fatting agent and a formula and preparation method of the fur fatting agent, and belongs to the technical field of leather. The formula of the fur fatting agent comprisesfatty alcohol-polyoxyethylene ether, C12-14 alcohol, mineral oil, epoxidized soybean oil, maleic anhydride, sodium pyrosulfite, sodium hydroxide, emulgator, penetrating agent, corrigent and antibacterial preservative. According to fur fatting agent white thick liquid prepared through the preparation method of the fur fatting agent, the effective solid content is 45%-55%, long-term storage can be achieved, the laying phenomenon is avoided, the fatting agent can be evenly and rapidly permeated into fur in the coating process, and the fattened fur is soft and good in light resistance.

Owner:SHANGHAI GOLD LION CHEM CO LTD

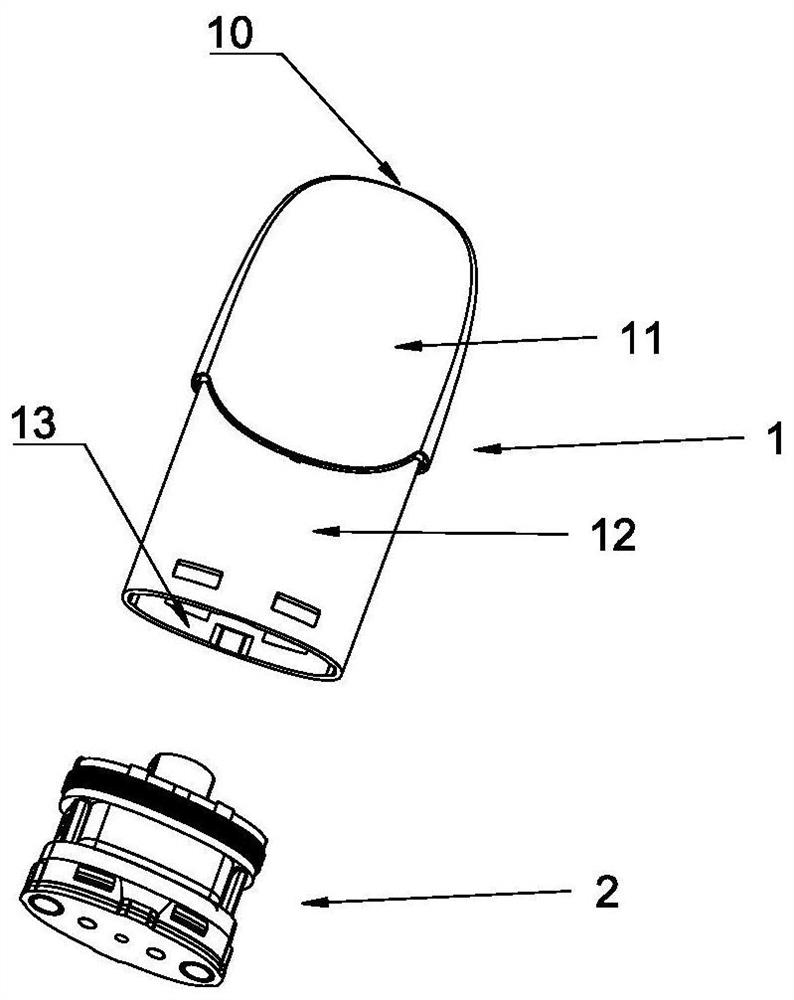

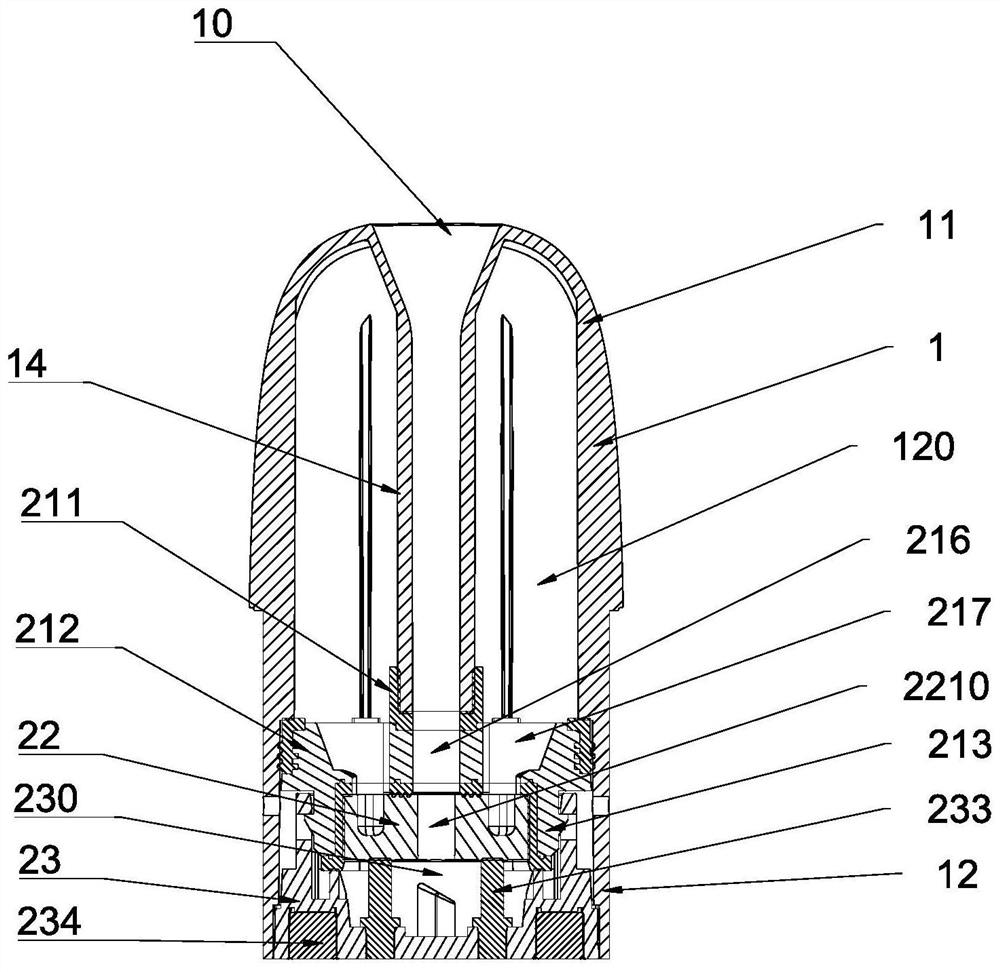

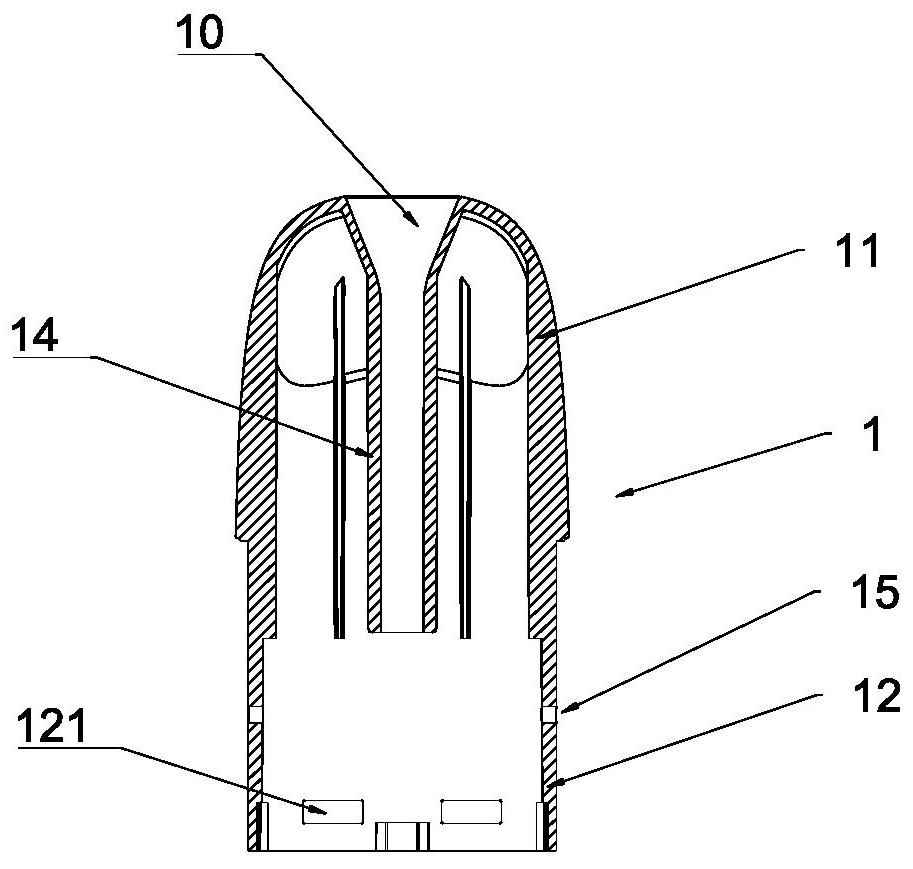

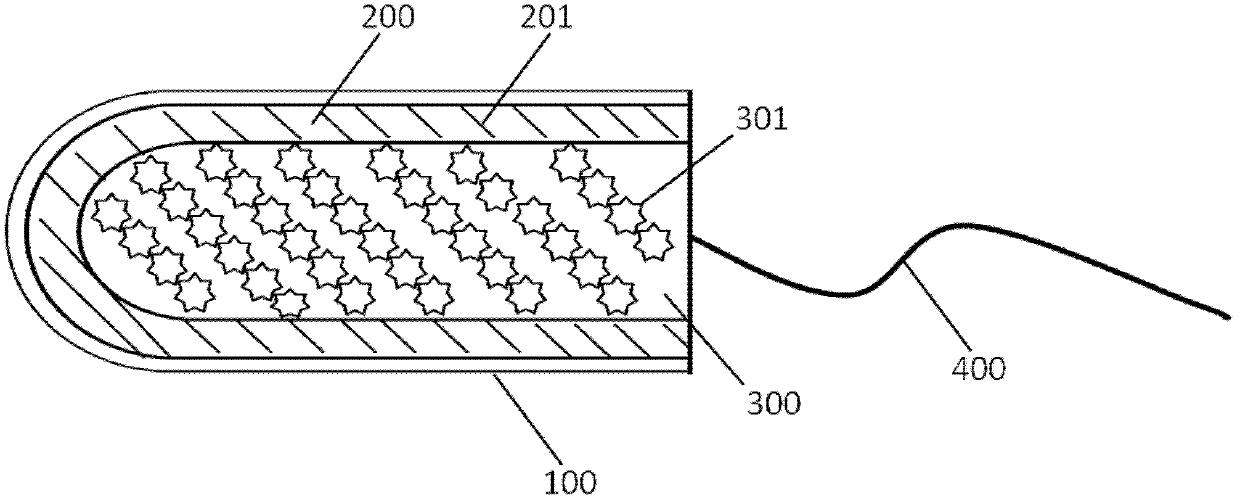

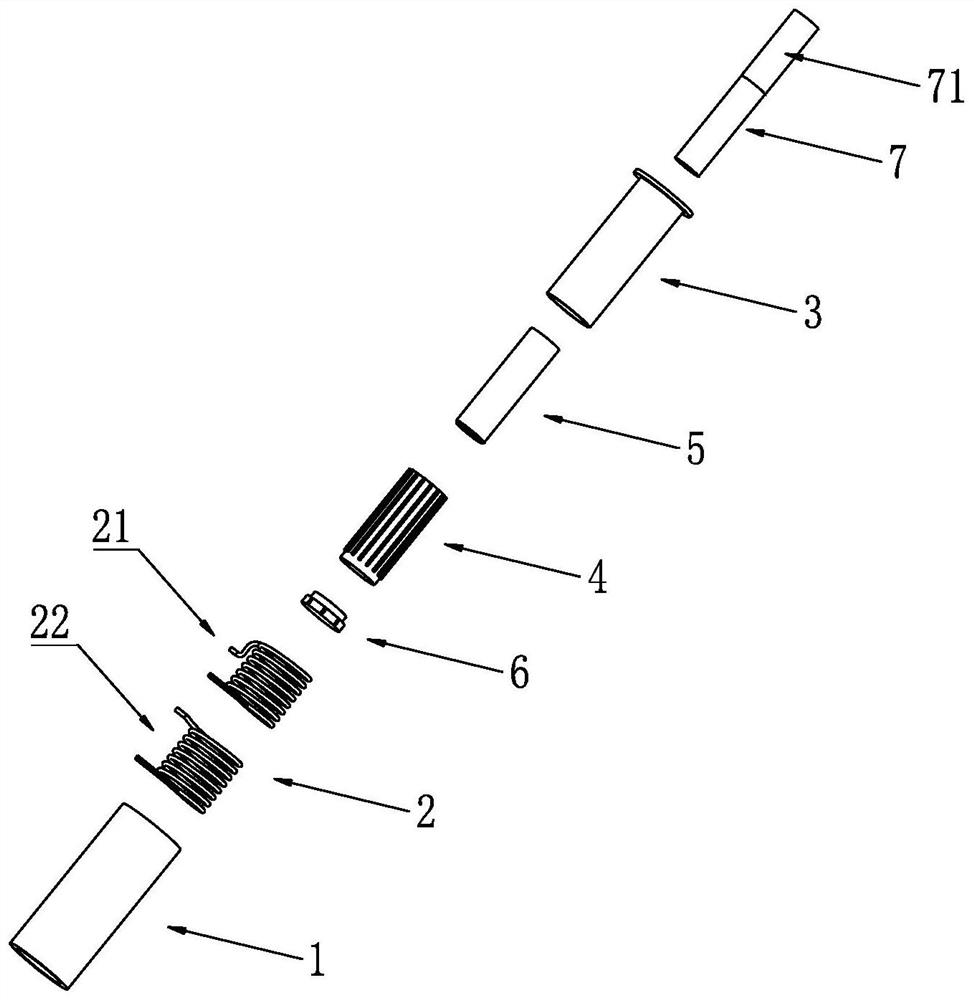

Atomizer with integrated atomization assembly

PendingCN112316261AFacilitate conductionEasy to storeRespiratorsMedical atomisersEngineeringMechanical engineering

The invention discloses an atomizer with an integrated atomization assembly. The atomizer comprises a shell and the integrated atomization assembly, wherein the shell comprises a suction nozzle end and a connecting end, the suction nozzle end is provided with a suction port, the connecting end is provided with an opening, the shell is connected with a battery assembly through the connecting end toform electronic atomization equipment, and the integrated atomization assembly is mounted in the shell from the opening. The integrated atomization assembly comprises an atomization core base, an atomization core and a base from top to bottom, wherein the atomization core base is connected with the base, an upward-concave groove is formed in the lower portion of the atomization core base, the atomization core is mounted in the groove, the atomization core comprises an atomization core body used for absorbing atomization liquid and a heating resistor used for heating the atomization liquid, and the atomization core body is provided with an atomization channel. An air inlet cavity communicating with the atomization channel is further formed between the atomization core and the base, and thebase blocks the opening of the shell. The atomizer has the beneficial effects that during heating atomization, atomization is uniform, the atomization effect is good, scorched smell caused by scorching is not liable to generate, the structure is firm, deformation is avoided, and the phenomena of liquid leakage and gas leakage are avoided.

Owner:HUIZHOU HAPPY VAPING TECH LTD

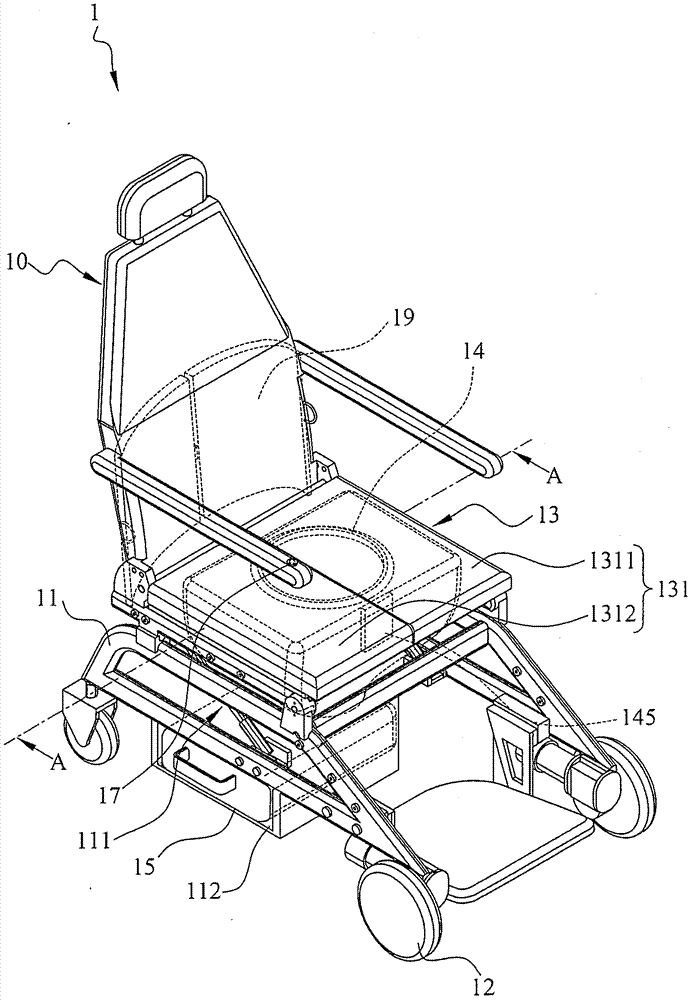

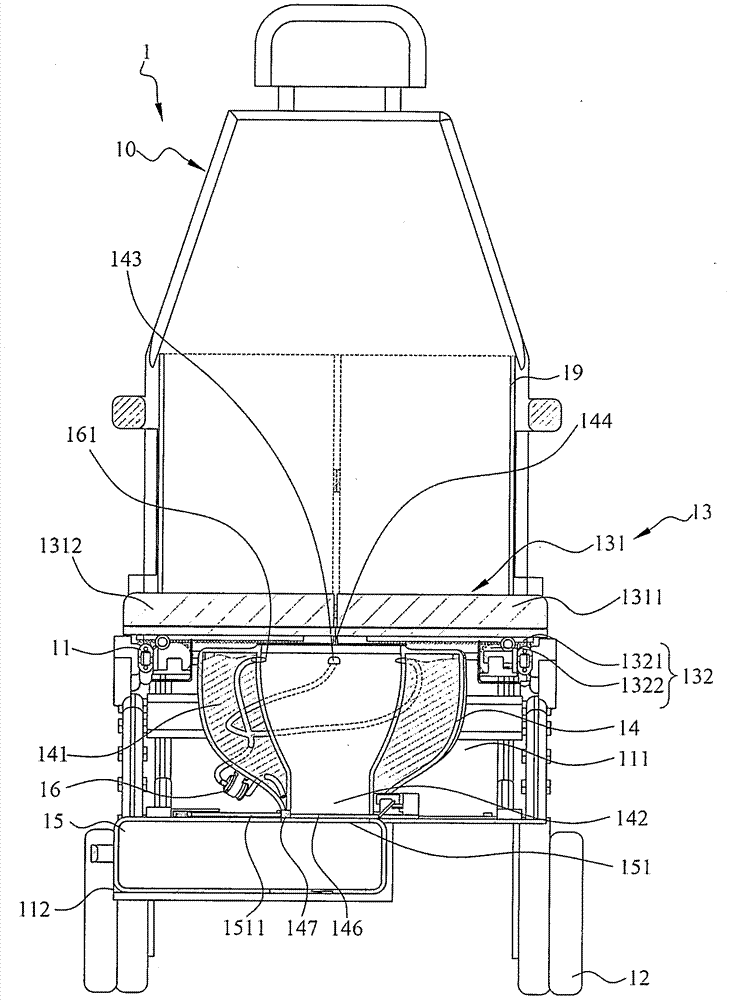

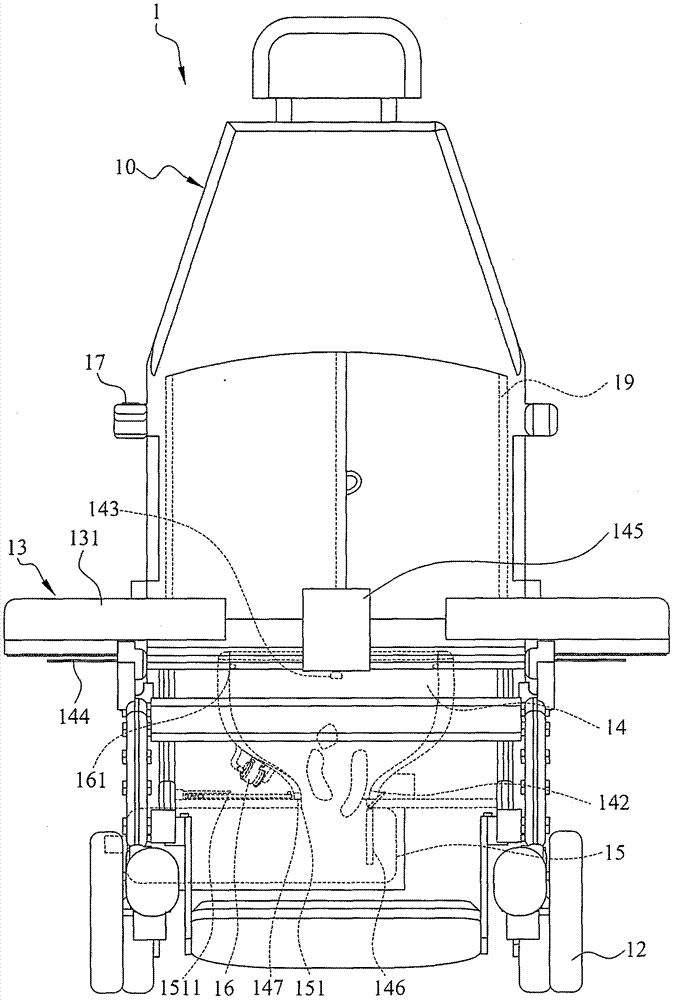

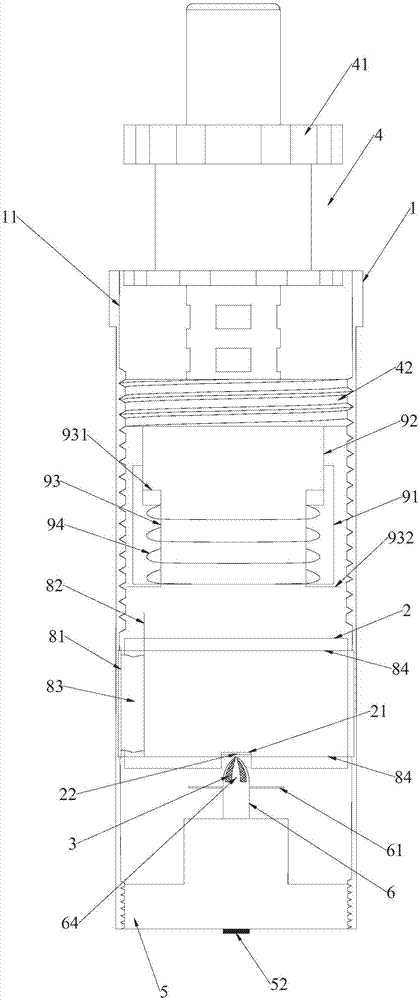

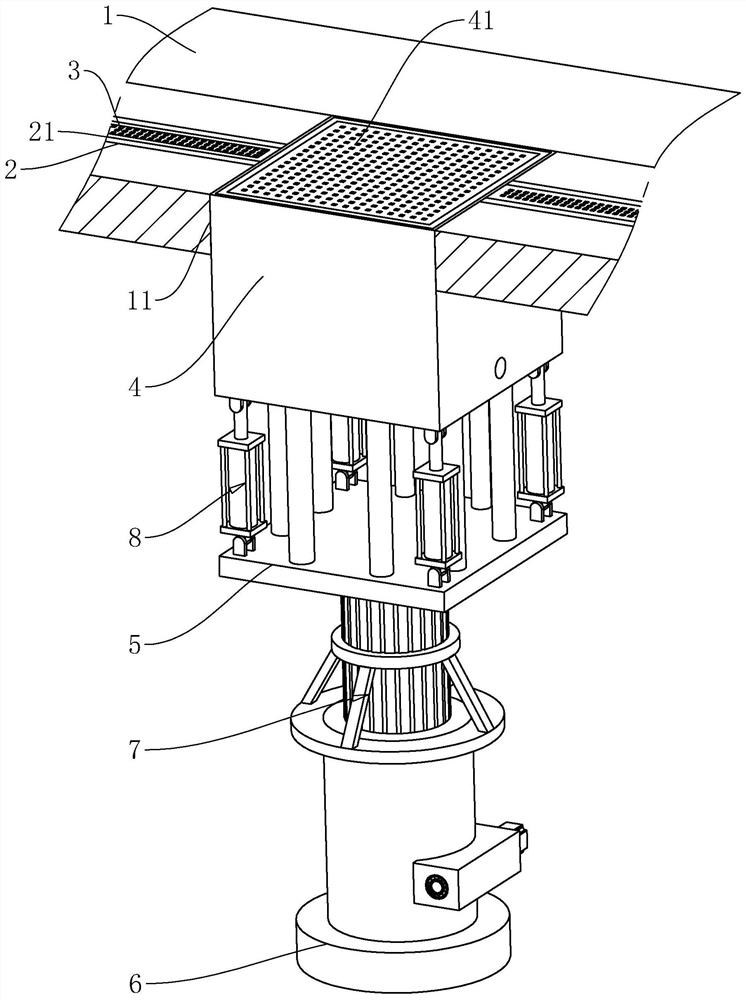

Nursing robot with flushing and feces collecting functions

InactiveCN107242941AHas the function of collecting stoolNot easy to smellWater closetsFlushing devicesWater storage tankAnimal feces

The invention relates to an intelligent robot vehicle, and particularly relates to an intelligent robot vehicle with flushing and feces collecting functions. The intelligent robot vehicle comprises a body, a bedpan, a feces collecting box, a water storage tank, a decontamination device and an electric control module. The body comprises a bearing support, a wheel set and a chair cushion set, the chair cushion set is provided with a movable cushion and a chair cushion driving mechanism, and an accommodating portion is arranged below the bearing support; the bedpan is arranged at the accommodating portion, and a connector is arranged at the bottom of the bedpan; the feces collecting box is inserted in the accommodating portion, and a feces collecting opening is formed in the feces collecting box, is opposite to the bottom of the bedpan and is connected with the connector; the water storage tank is connected with the bedpan; water in the water storage tank can be pumped by the decontamination device, and the bedpan can be flushed by the water; actuation of the wheel set, the decontamination device and the chair cushion driving mechanism can be controlled by the electric control module.

Owner:嘉兴得米富智能科技有限公司

Cleaning agent for air conditioner

InactiveCN104073375AAromaNot easy to moldOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsThiocyanic acidTetramine

The invention belongs to the technical field of detergents and air conditioners, and particularly relates to a cleaning agent for an air conditioner. The cleaning agent is characterized in that the cleaning agent is prepared by the following raw materials in parts by weight: 4-8 parts of hexamethylene tetramine, 1-3 parts of sodium sulfocyanate, 2-4 parts of rodine, 1-3 parts of aniline, 20-40 parts of hydrochloric acid, 3-6 parts of benzene sulfonic acid sodium salt, 5-10 parts of ethyl alcohol, 15-30 parts of chlorinate dodecyl dimethyl benzyl ammonium, 3-6 parts of octadecyl diethoxy amine oxide, 1-2 parts of jasmine essence or lemon essence and 50-80 parts of distilled water. The cleaning agent has the benefits as follows: the product is acidulous, not harmful to human body, and fragrant in odor; the air conditioner is not easy to mildew after the air conditioner is cleaned; the cleaning agent has no bad odors, and is low in cost and easy to prepare.

Owner:方秀琴

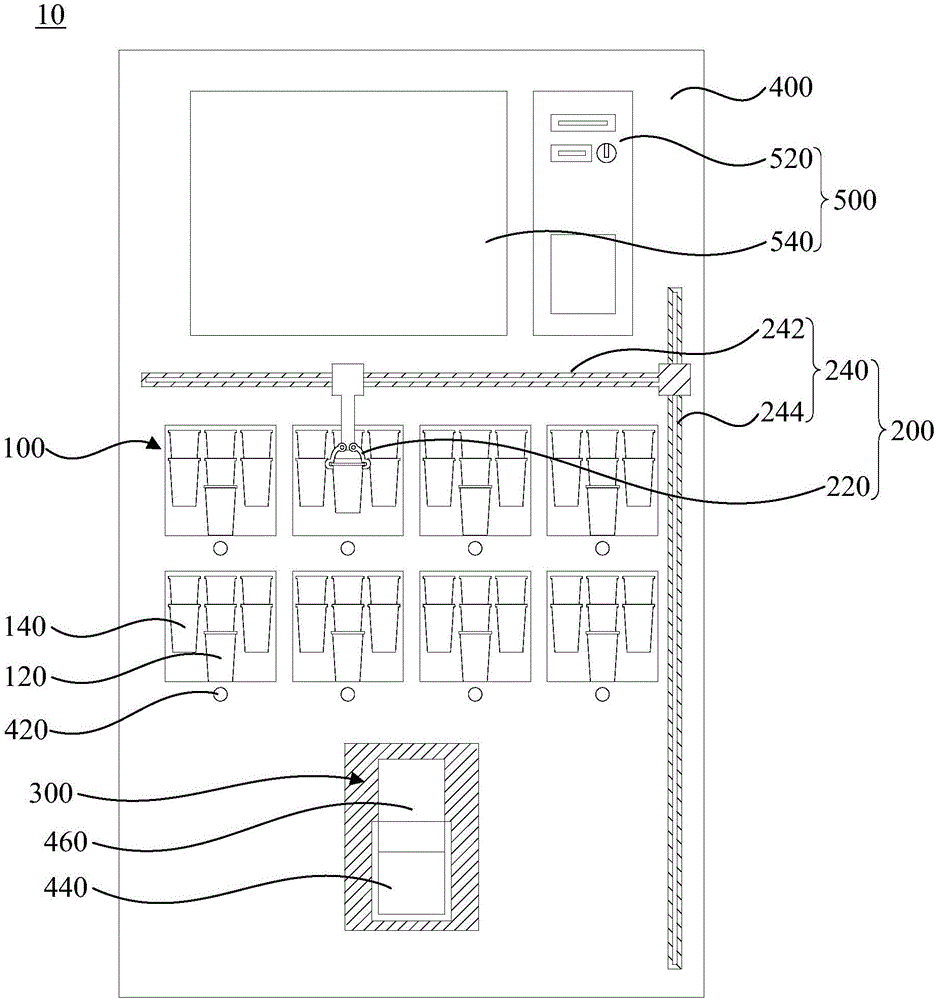

Selling device

InactiveCN106251489ANot easy to smellGreat tasteCoin-freed apparatus detailsApparatus for dispensing fluids/granular materialsFruit juiceFood material

The invention relates to a selling device, which comprises a storage module, a grabbing module and a processing module, wherein a first storage position and a plurality of second storage positions are arranged in the storage module; the first storage position is used for storing an independently packed food material; the plurality of second storage positions are used for storing a plurality of independently packed food materials in a one-to-one corresponding way; the grabbing module comprises a grabbing hand and a slide rail; the grabbing hand can grab the food material in the first storage position, and is glidingly connected onto the slide rail so as to convey the food material; after the food material in the first storage position is grabbed, one food material in the second storage position is moved to the first storage position; the grabbing hand can convey the food material to the processing module, and the processing module can process the food material. The food material stored in the storage module is independently packed; different kinds of fruit can be independently packed and can be used for processing different kinds of fruit juice; the food materials are independently packed, and cannot be easily tainted by other odor, so that the mouthfeel can be improved.

Owner:沈迪

Garbage centralized collection device for smart city

InactiveCN111924376AImprove collection efficiencyNot easy to smellWaste collection and transferRefuse receptaclesEnvironmental geologyMechanical engineering

The invention discloses a garbage centralized collection device for a smart city, and particularly relates to the field of smart cities. The garbage centralized collection device comprises a collection box body, wherein a collection box liner is arranged on one side inside the collection box body, a first connection block is detachably mounted on one side inside the collection box liner, a bufferdevice is detachably mounted on one side of the first connection block, and a protection net pipe is detachably mounted on the other side inside the collection box liner. According to the garbage centralized collection device, through the mutual cooperation between the buffer device and a drying device, the effect of high collection efficiency is achieved; and meanwhile, liquid in garbage can alsobe separated from solid, so that the situation that when an existing garbage centralized collection device for the smart city works, due to the fact that liquid is mixed with garbage, once collected,the garbage is needed to be separated, which causes the problems that the garbage is not convenient to collect, thereby reducing the collection efficiency of the device and not facilitating the development is avoided.

Owner:蒋方方

Woman sanitary article

ActiveCN103300973AImprove adsorption capacityNot easy to festerTamponsBandagesSurface layerFeminine Hygiene Products

Owner:FENG CHIA UNIVERSITY

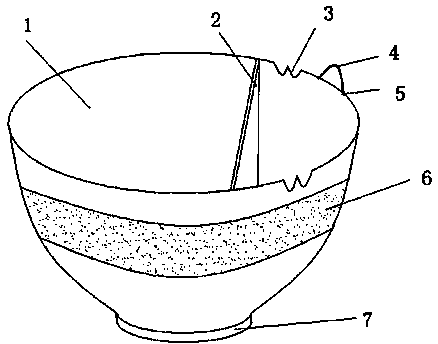

Convenient bowl for children

InactiveCN103356025ASimple structureNot easy to slipPlatesStructural engineeringMechanical engineering

The invention discloses a convenient bowl for children. The convenient bowl for children comprises a bowl body and a bowl bottom, wherein the bowl body is in a wooden structure; a wooden baffle structure is arranged in the bowl body; the bowl body is divided into a rice containing area and a dish containing area of which the volume is 6:4 by the baffle; the bowl edge of the dish containing area is provided with one pair of chopstick storage tank structures and a spoon fixing ring structure; and the spoon fixing ring is movably connected with the bowl body via a rotary shaft. According to the convenient bowl for children, which is disclosed by the invention, children can conveniently store chopsticks and a spoon onto the bowl body by the chopstick storage tank structures and the spoon fixing ring structure. The convenient bowl for children has the advantages of simple structure and small possibility of causing chopsticks to fall, good eating habit of the children can be cultivated, the bowl body is divided into different areas by the baffle structure, thereby being convenient for eating, staple food and side dishes are unlikely to taint by other odors when food is eaten, and the practical effect is good.

Owner:XUZHOU YUANHUA FOOD

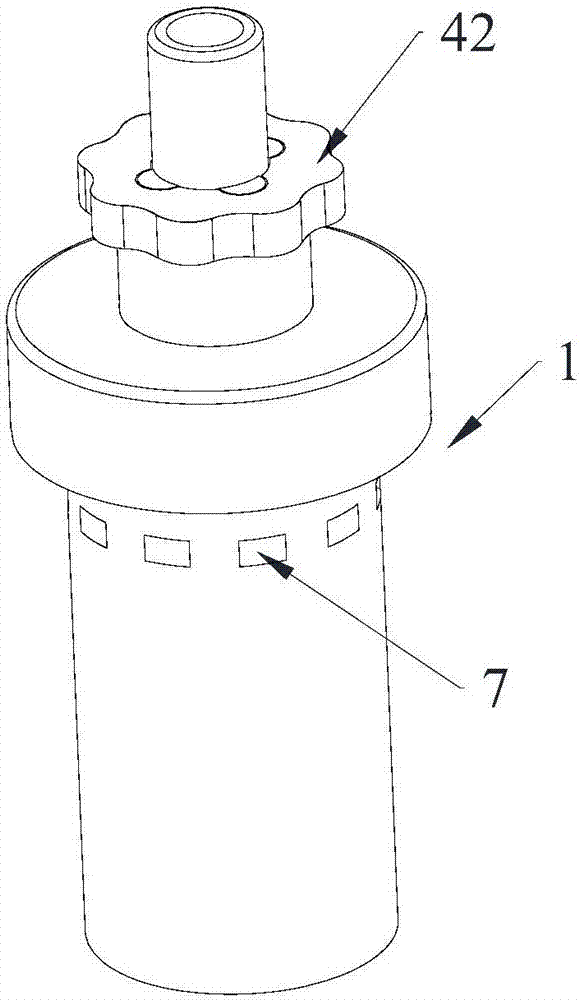

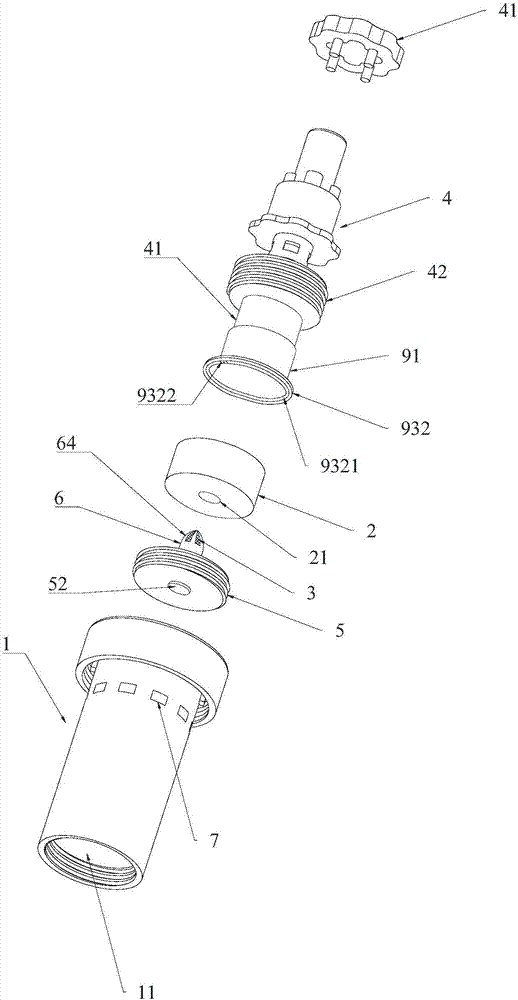

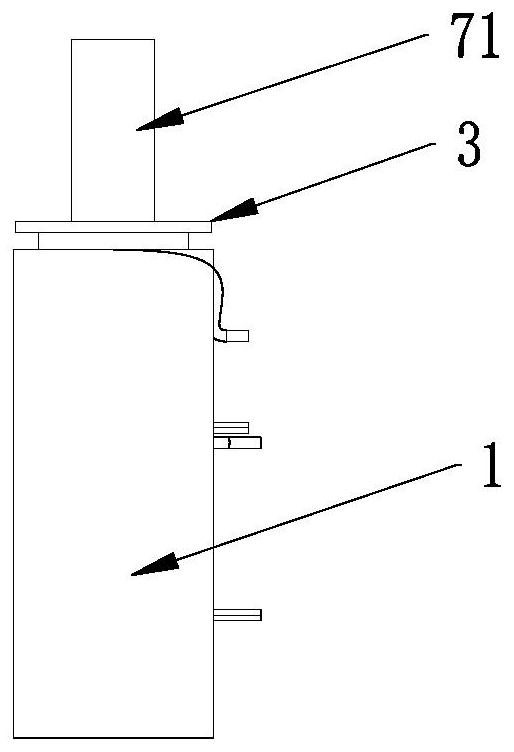

Plug barrel and beverage bottle provided with same

The invention provides a plug barrel and a beverage bottle provided with the same and relates to the technical field of beverage containers. The technical problems that a brewing content cavity of the beverage bottle is directly communicated with the outside world, the sealing performance is poor, and solid solute can be easily contaminated are solved. The plug barrel comprises a plug body which is provided with an up-down-through through hole; an autolysis cup for containing brewing contents is arranged in the through hole; and a closed space is defined by the wall faces of the autolysis cup. A bottom plate of the autolysis cup is provided with a water inlet; a puncture part is arranged below the water inlet; the autolysis cup is arranged on the puncture part; and a spiral pushing rod used for downwards pressing the autolysis cup is arranged above the autolysis cup. The solid brewing contents are closed in the autolysis cup, cannot be contaminated and are not prone to going bad, and the quality of the brewing contents is guaranteed; the autolysis cup is convenient to replace, and the plug body can be repeatedly used; a filter screen is arranged, and is suitable for both the fine-particle solute and the brewing contents needing to be brewed many times; and the side wall of the plug barrel is provided with a showing window which plays roles of showing, propagandizing and individuation.

Owner:青海纳瑞亚生物科技有限公司

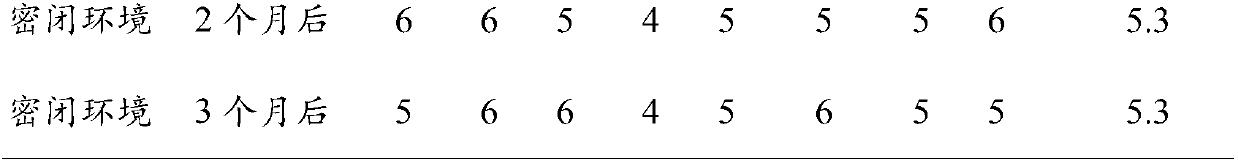

Pine nut oil microcapsule and preparation method thereof

The invention provides a pine nut oil microcapsule and a preparation method thereof, belongs to the technical field of processing of functional oil and fat products, and aims to solve the conventional problems of pine nut in food application. The microcapsule is prepared from raw materials as follows: 50%-65% of maltodextrin, 3.5%-4.5% of sucrose ester, 0.5%-1.5% of glycerol monostearate and 30%-45% of pine nut oil. The preparation method comprises steps of preparation of an aqueous phase solution, preparation of an oil phase solution, high-speed mixing, homogenizing, spray drying and the like. The method is simple in process, the source of raw materials is wide, carbohydrate is taken as the main wall material, both entering of oxygen and overflow of off flavor of grease are inhibited after microcapsule formation, the functional active ingredients of the pine nut oil are kept greatly, the oxidation stability of the pine nut oil is improved, and bad flavor of the pine nut oil is covered up.

Owner:HARBIN INST OF TECH

Silk-screen printing ink composition and preparation method thereof, printed matter and preparation method thereof

The invention belongs to the technical field of silk-screen printing, and particularly relates to a silk-screen printing ink composition and a preparation method thereof, a printed matter and a preparation method thereof. The invention provides the silk-screen printing ink composition comprising silk-screen ink, carbonized chlorophyll and molecular sieve infiltrated with an essence, wherein the mass ratio of the silk-screen ink to the carbonized chlorophyll to the molecular sieve infiltrated with the essence is 4000:(3-8):(0.1-0.8). In the invention, the carbonized chlorophyll has the effect of filtering peculiar smell; the carbonized chlorophyll has a light green grass fresh scent; the carbonized chlorophyll can adsorb peculiar smell in the silk-screen ink, and makes the peculiar smell inthe silk-screen ink significantly reduced and makes the silk-screen ink smell become fresh; the essence is infiltrated into the molecular sieve, and the molecular sieve has a slow release effect, sothat the fragrance lasting time of the essence is long, the silk-screen ink has fragrance, and the printed matter subjected to silk-screen printing is easily accepted by consumers.

Owner:CHINA TOBACCO GUIZHOU IND +1

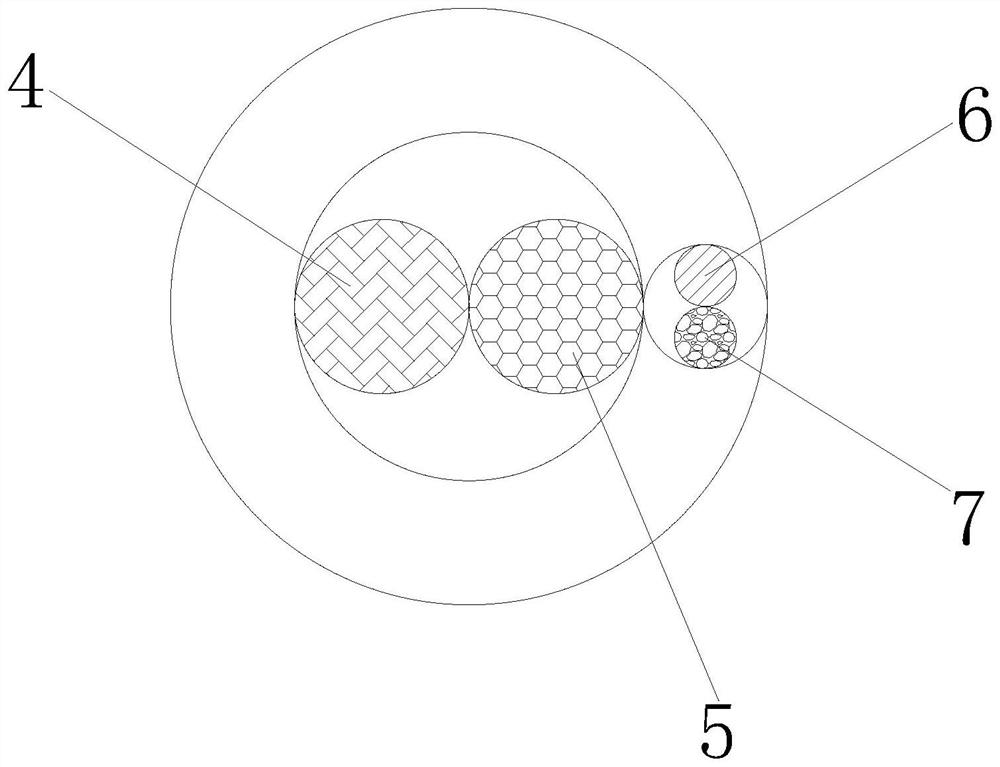

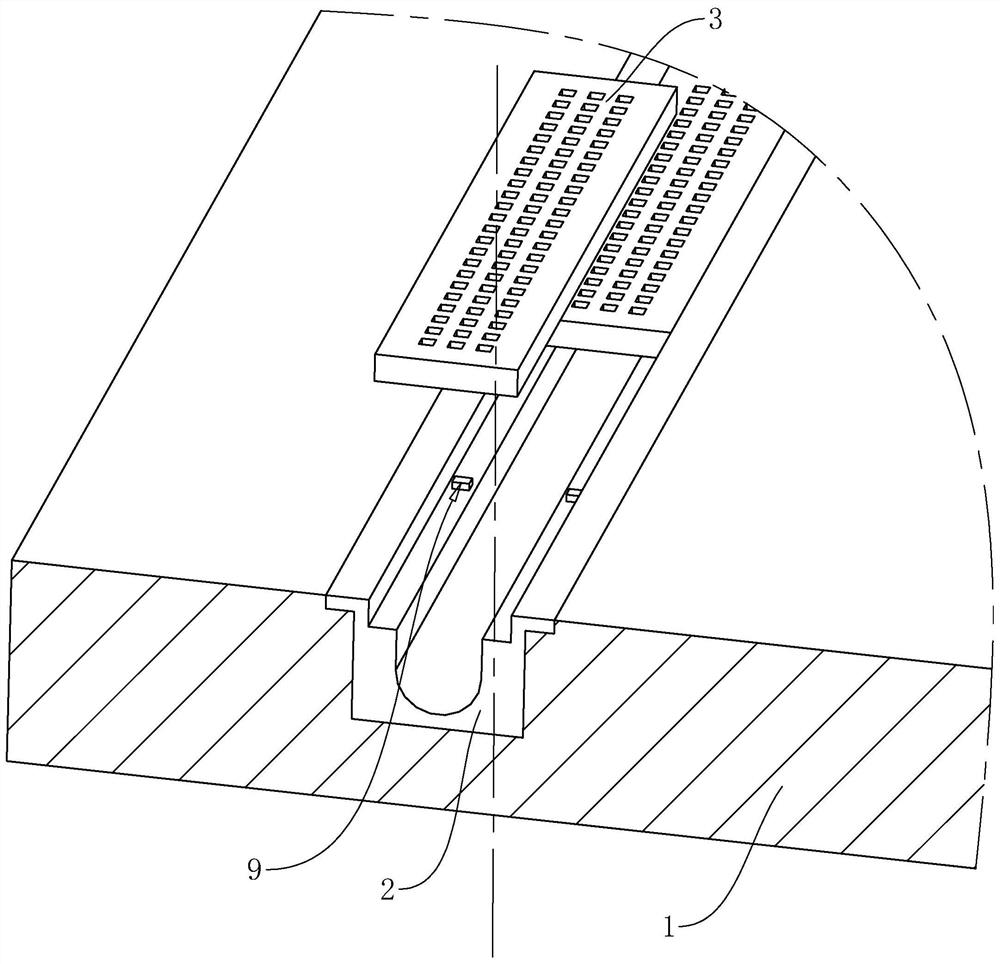

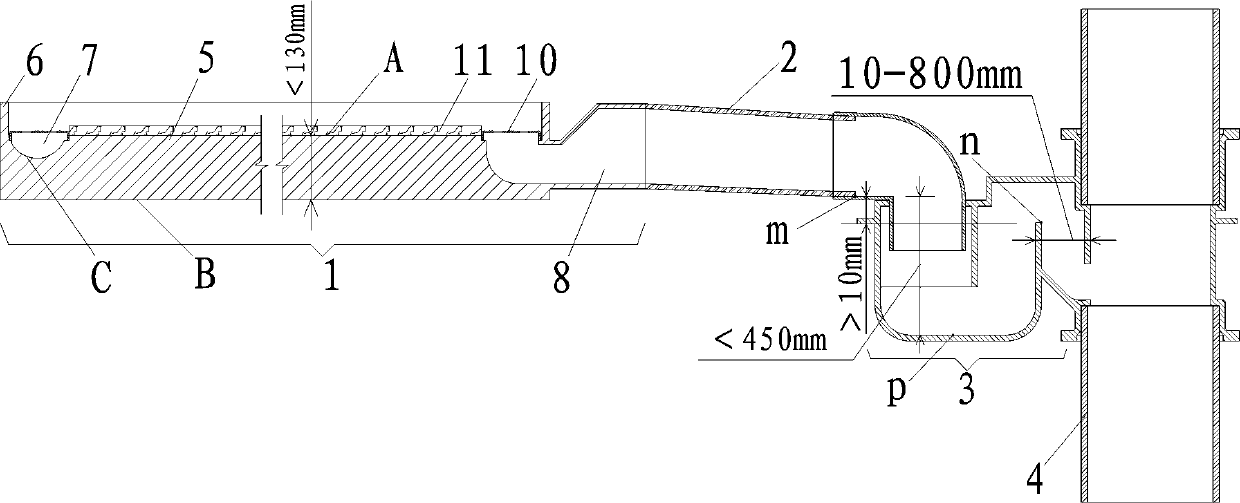

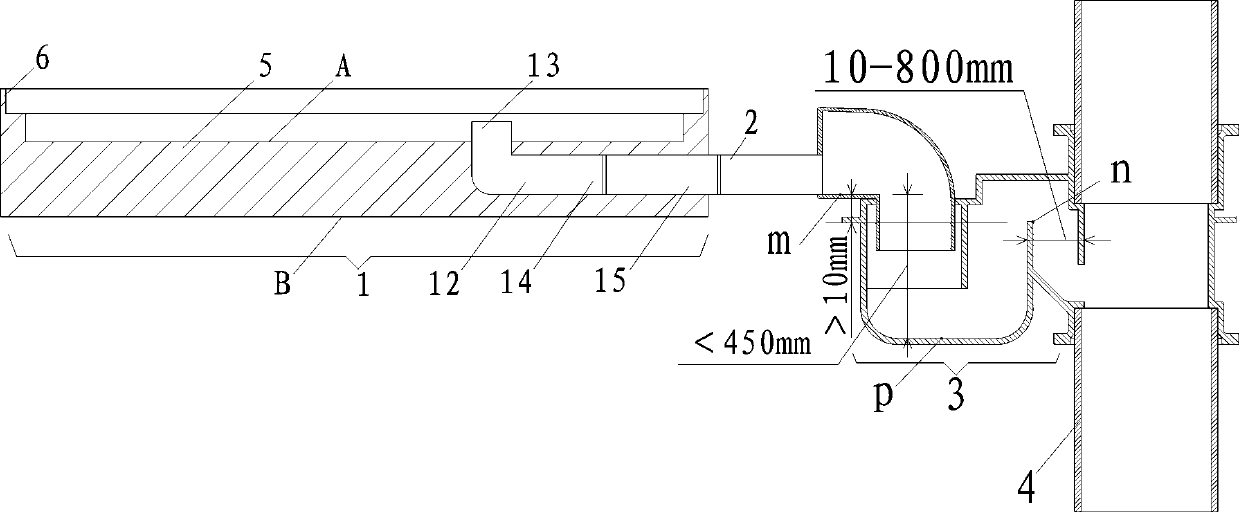

Integrated bathroom water discharging system

PendingCN110578364AIncrease profitSolve the problem of easy cloggingSewerage structuresDomestic plumbingWater dischargeEngineering

An integrated bathroom water discharging system is composed of a waterproof base plate, a water discharging transverse branch pipe, an integrated water seal and a water discharging vertical pipe. Thewaterproof base plate is composed of waterproof grounds and a waterproof stop strip, and an integrated structure is formed by the waterproof stop strip and the waterproof grounds. At least one waterproof ground close to the waterproof stop strip is provided with a ground water outlet, a water discharging outlet of the ground water outlet is connected with the water discharging transverse branch pipe, the water discharging transverse branch pipe is connected with the integrated water seal, and the integrated water seal communicates with the water discharging vertical pipe. The integrated bathroom water discharging system can solve the problems that a water discharging transverse branch pipe of a current integrated bathroom water discharging system needs to be arranged below a waterproof base plate, a water discharging branch pipe needs to vertically penetrate through the waterproof base plate, consequently, the usage clear height in a bathroom is reduced, and seepage hidden danger and difficult overhauling exist; by usage of the integrated water seal, the problem that water seals are independently arranged at various water discharging points of the bathroom water discharging system,and dryness is likely to be caused is solved, the bathroom plane and height space utilization rate can be increased, and the water discharging sanitation performance of the bathroom is improved.

Owner:林国强

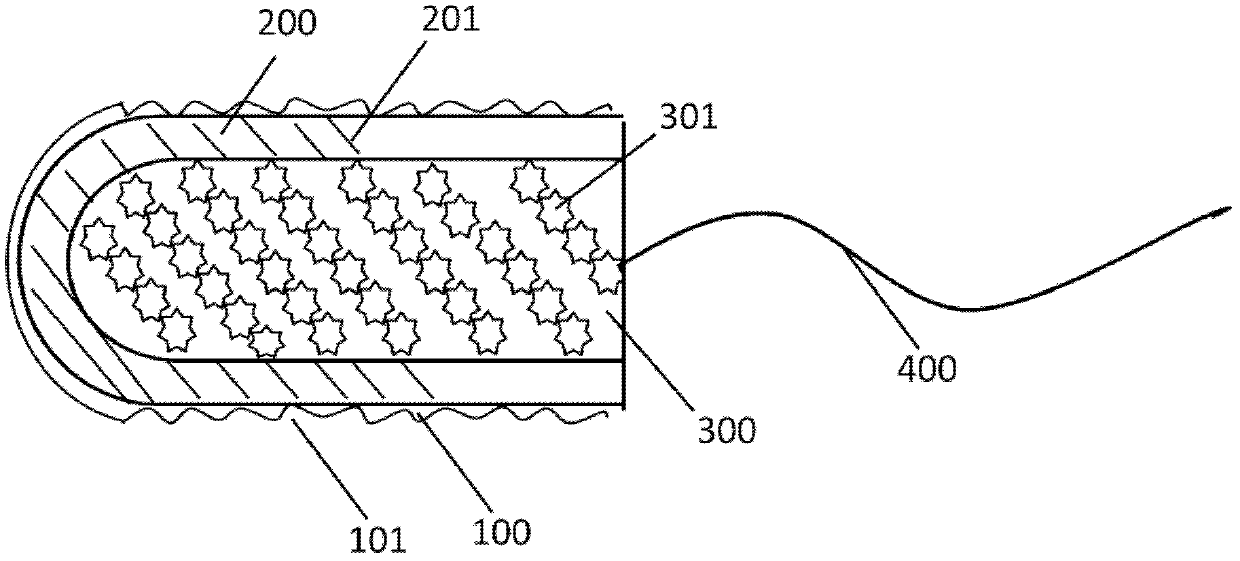

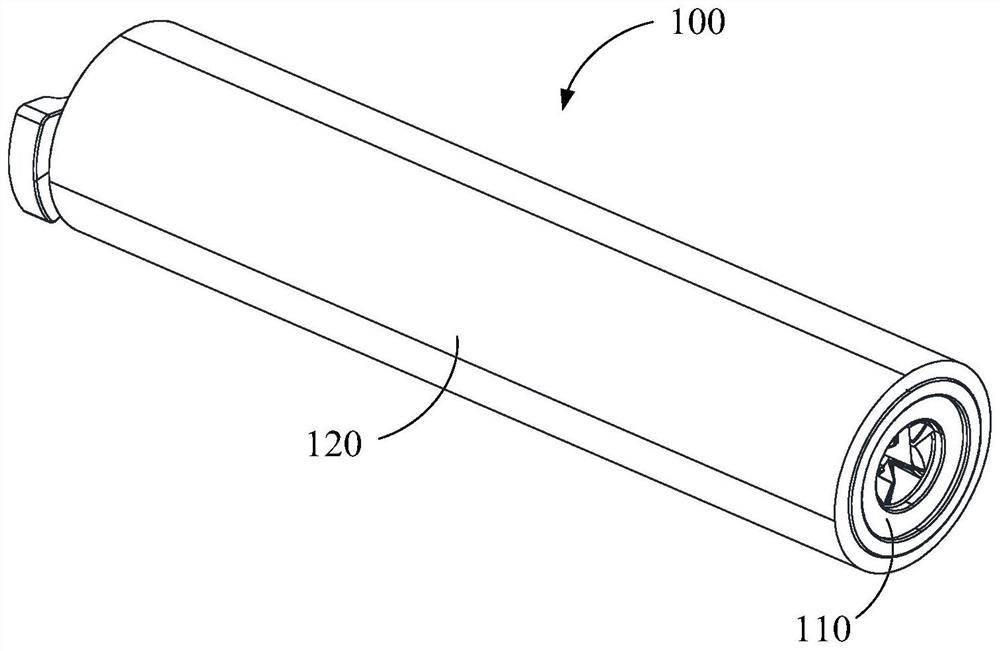

Aerosol generating device with induction heating tube

The invention discloses an aerosol generating device with an induction heating tube, which comprises an outer tube, an electromagnetic coil, an insulating tube, an induction heating tube and an inner tube which are sleeved from outside to inside, and a bottom cover. The inner tube is provided with an inner cavity used for housing a solid smoke generating substance. The electromagnetic coil is arranged in a surrounding mode in the axial direction of the outer wall of the insulating tube and can enable the induction heating tube to heat when powered on to work. A plurality of outer ribs are arranged on the outer side wall of the induction heating tube in a protruding mode, a second airflow channel is formed by a gap between the insulating tube and the induction heating tube, and a first airflow channel is formed by a gap between the induction heating tube and the inner tube. When the induction heating tube emits heat, outside air sequentially enters the second airflow channel and the first airflow channel and is heated into hot airflow, and the hot airflow is gathered to the bottom of the inner tube and then upwards flows through the interior of the solid smoke generating substance to heat and bake the solidsmoke generating substance. The aerosol generating device has the beneficial effects that the heating is uniform, the airflow heating effect is better, the possibility of scorching to generate scorched smell is low, the hand scalding feeling is avoided, and the user experience is good.

Owner:HUIZHOU HAPPY VAPING TECH LTD

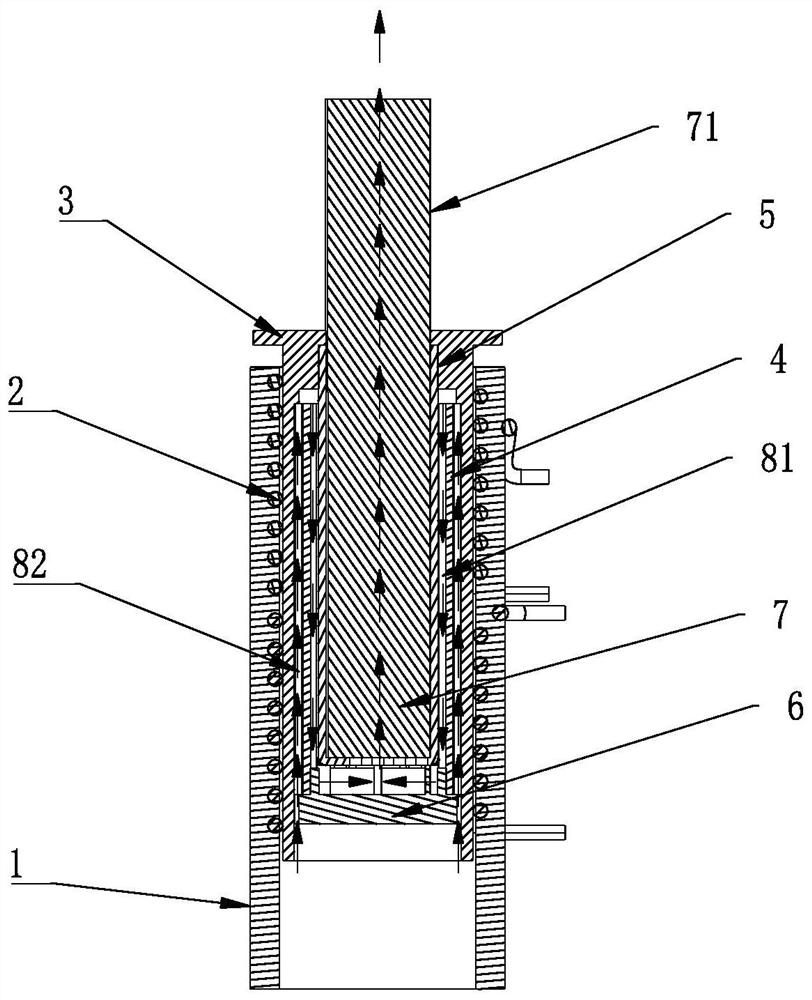

A kind of preparation method of plant-derived chitosan

The invention discloses a preparation method of plant-derived chitosan. The method comprises the steps that 1, deionized water is added to ganoderma lucidum spore powder, water-bath ultrasonic extraction and centrifugation are conducted, ethyl alcohol is added to the mixed solution, the mixed solution is subjected to ultrasonic treatment and centrifuged, deionized water is added to the mixed solution, and soaking, centrifugation and drying are conducted to obtain rough chitin; 2, the rough chitin is placed in an H2O2 solution, the mixed solution is placed in water bath, adjusted to be neutralby using a NaOH solution and centrifuged, an alkaline solution is added to the mixed solution, water bath treatment is conducted, the mixed solution is adjusted to be neutral by using an HCI solutionand dried, and a chitosan rough product is obtained. According to the preparation method of plant-derived chitosan, the ganoderma lucidum spore powder is used as a raw material and quickly and conveniently converted into chitosan through a low-concentration chemical solvent and a low-temperature reaction condition, and the preparation method is suitable for large-scale production. The chitosan prepared by means of the method is stable in property, the integrated utilization value of resources is increased, the production cost of chitosan is lowered, the environmental pollution is reduced, chitosan has excellent biological characteristics, novel plant-derived chitosan is effectively provided, and the source of the raw material of chitosan is widened.

Owner:ZHEJIANG UNIV +1

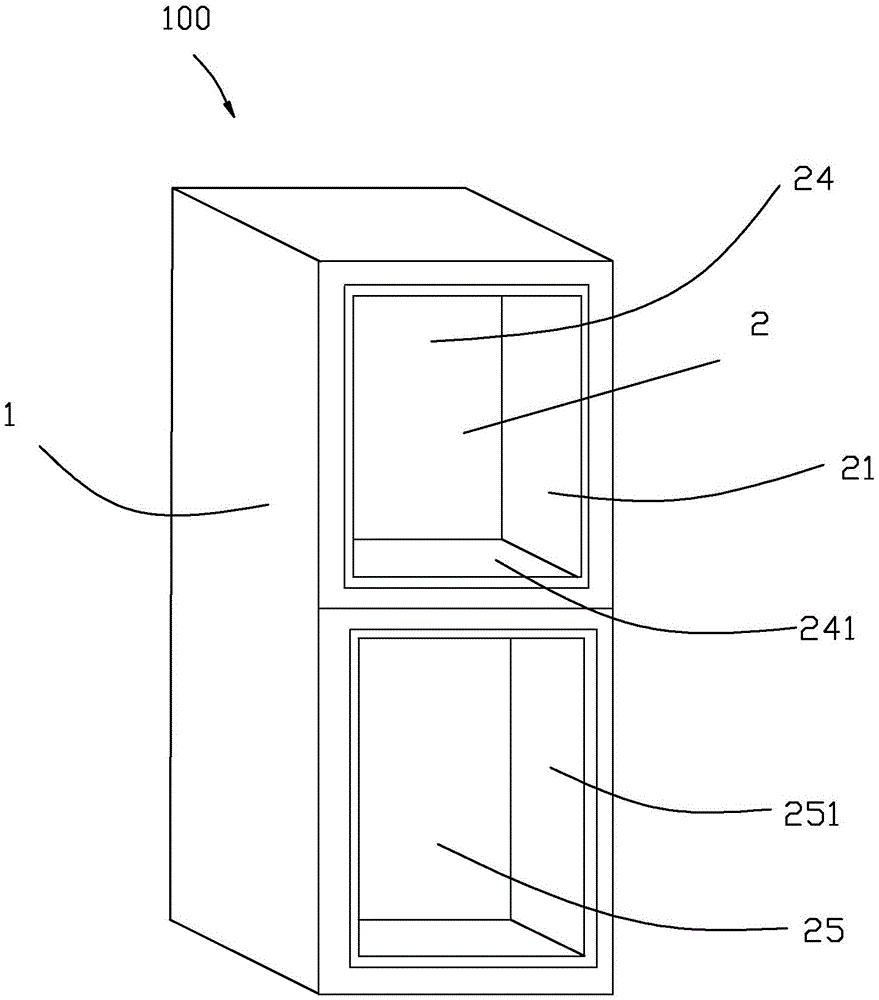

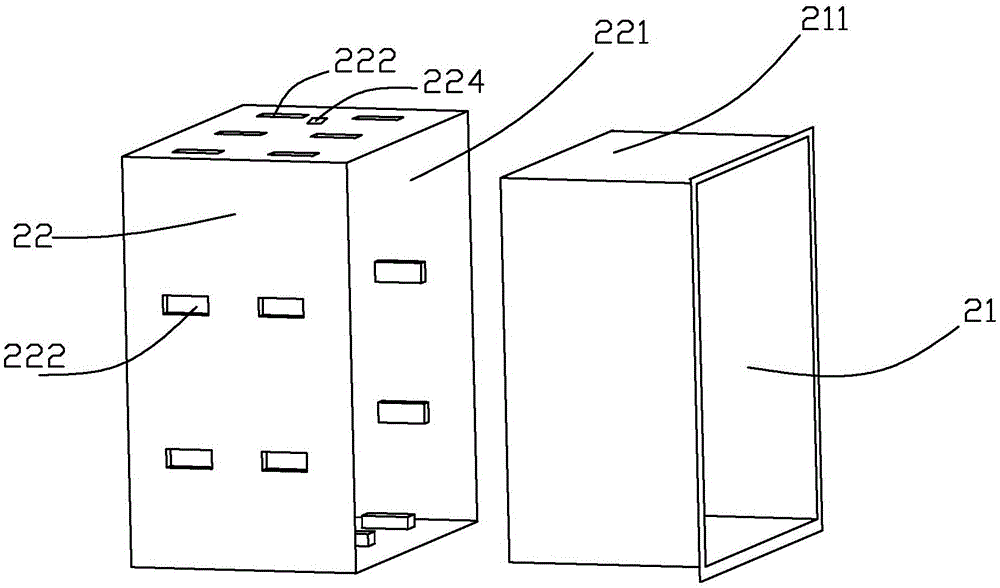

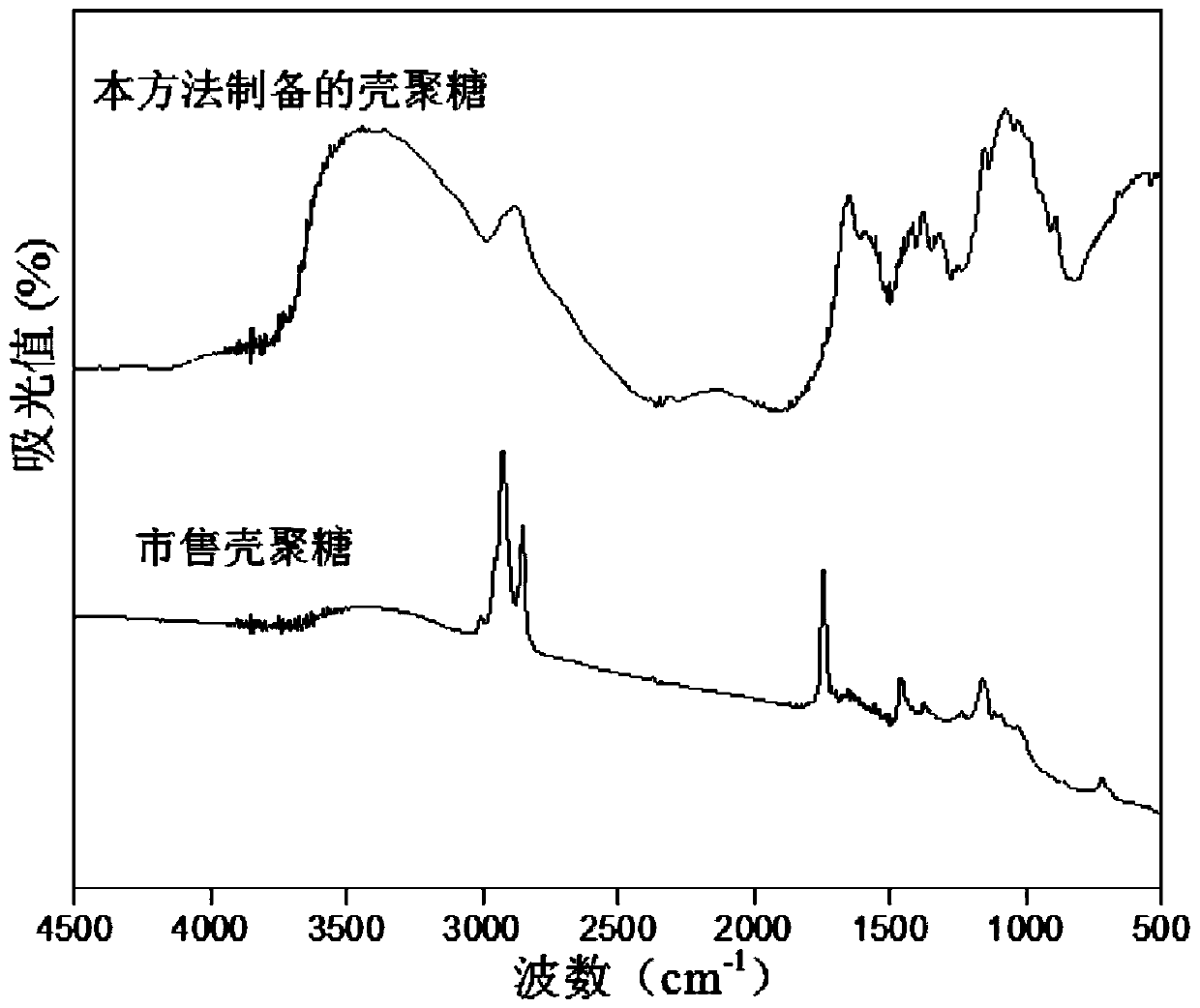

refrigerator

ActiveCN103994627BAvoid odorNot easy to smellLighting and heating apparatusSupportEngineeringRefrigeration

The invention discloses a refrigerator. The refrigerator comprises a refrigerator body, multiple shelves, multiple turnover covers and a door body. A refrigeration chamber is arranged in the refrigerator body. The shelves are arranged in the refrigeration chamber and used for dividing the refrigeration chamber into multiple shelf spaces with the front open surfaces. Each turnover cover is arranged at the position, between a front face opening position for opening the corresponding shelf space and a front face closing position for closing the corresponding shelf space, in the refrigeration chamber. The door body is arranged on the refrigerator body and used for opening and closing the refrigeration chamber. The refrigerator is provided with the multiple closed spaces independent in temperature and has the advantages that articles different in temperature requirement are convenient to store and not prone to be tainted by other odor.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

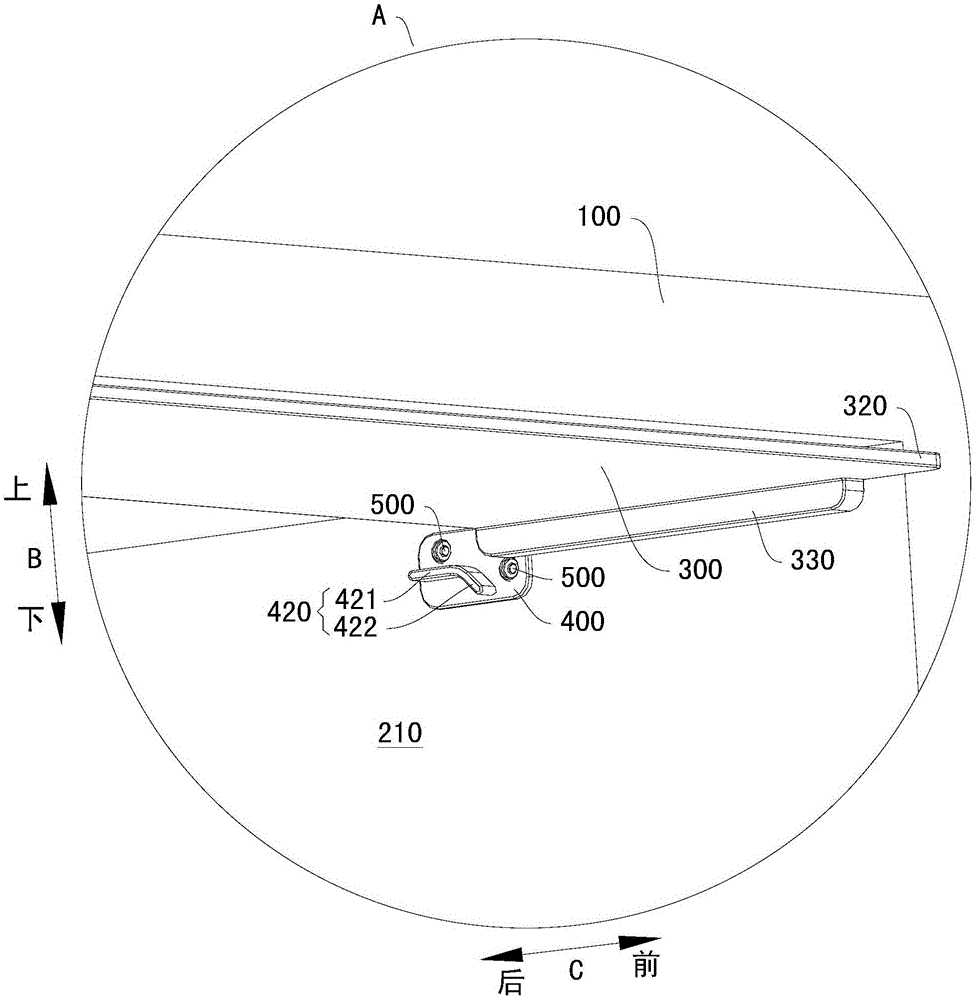

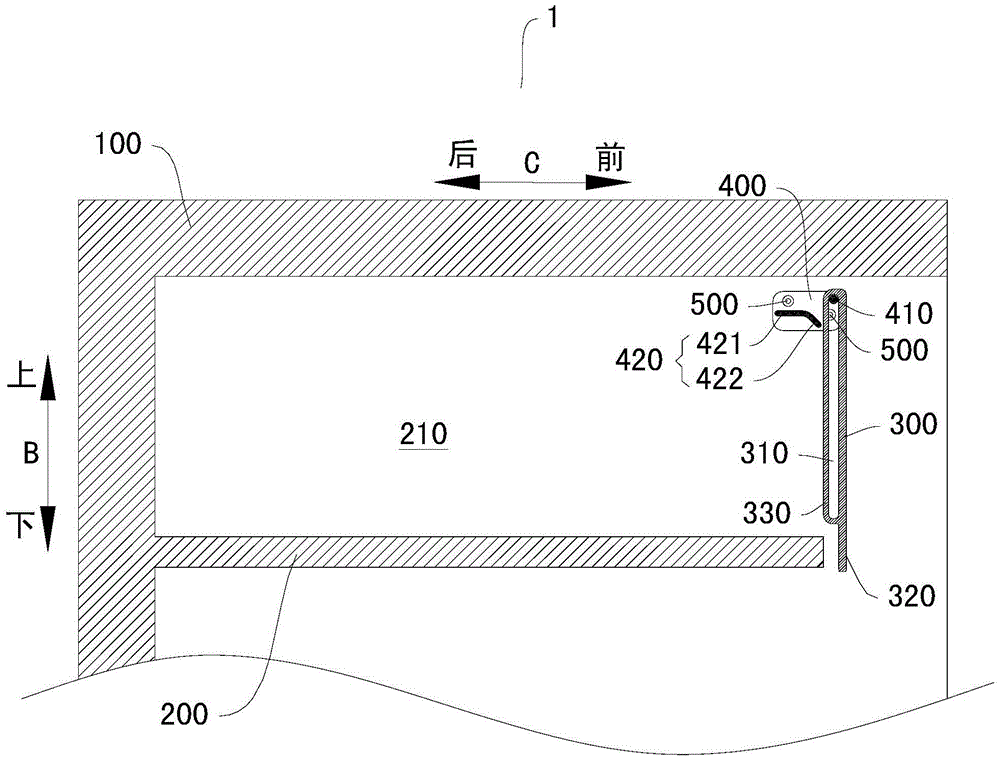

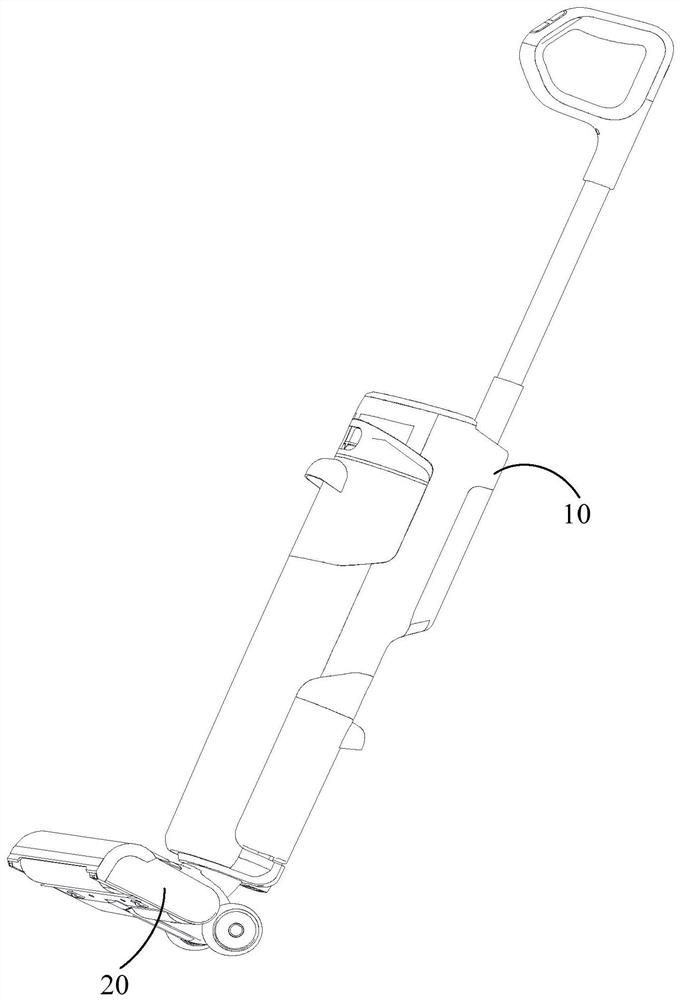

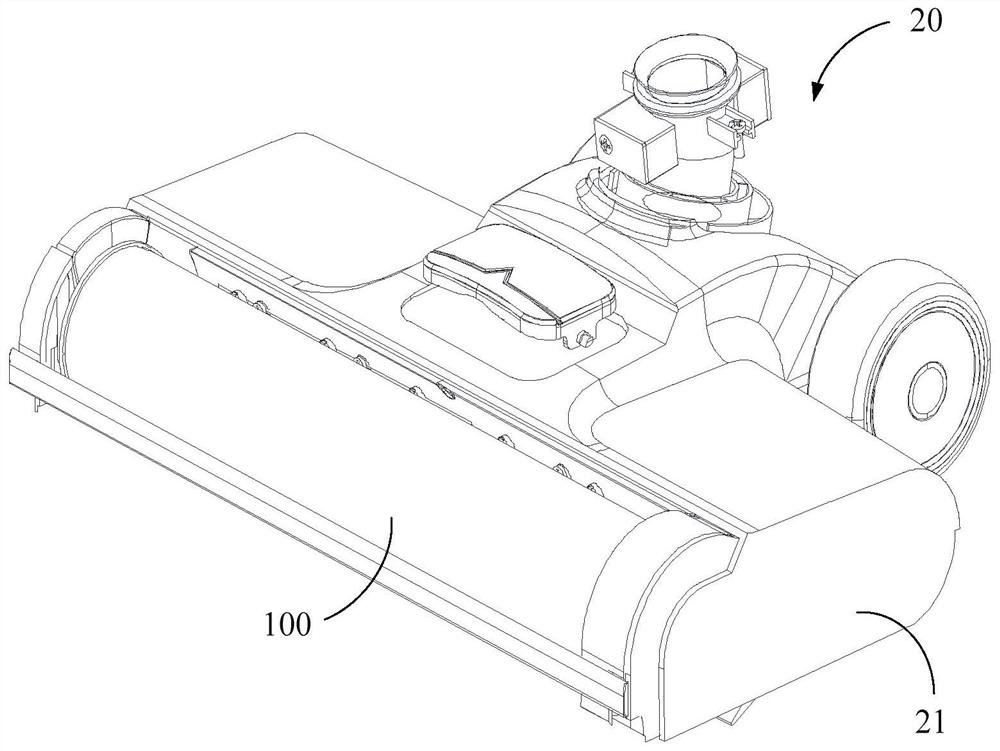

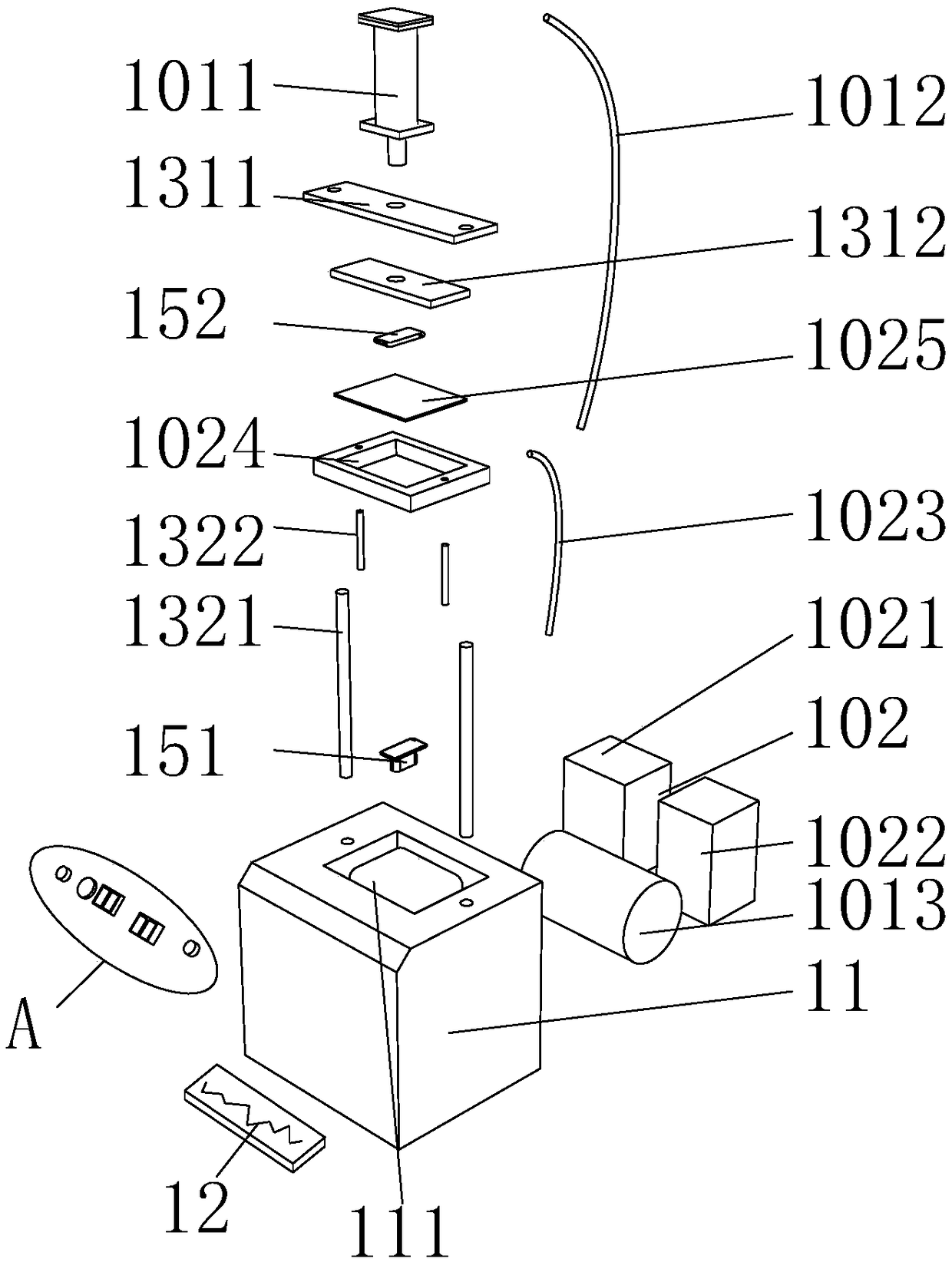

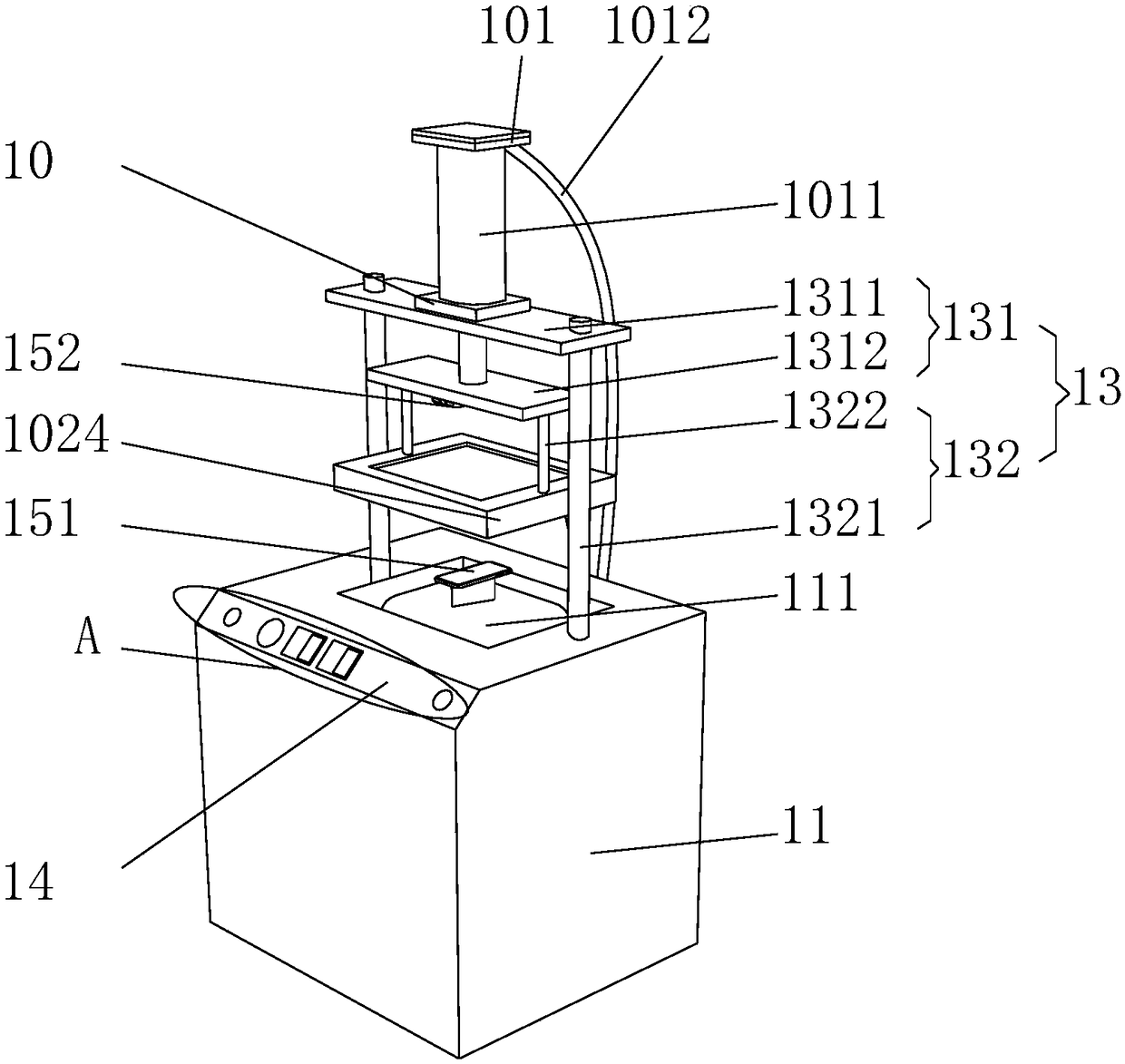

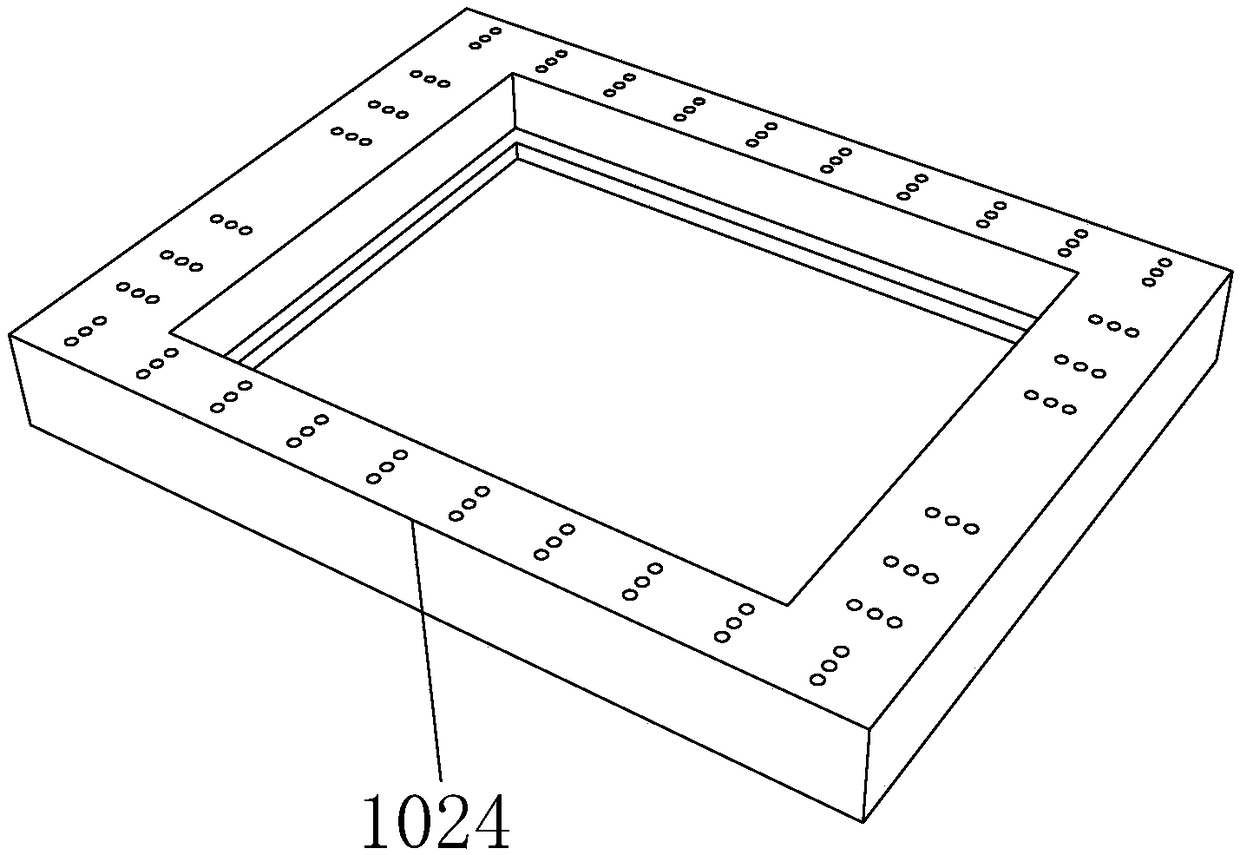

Brush shaft assembly, floor brush assembly and floor cleaning equipment

PendingCN113303726AAvoid breedingImprove experienceCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention relates to a brush shaft assembly, a floor brush assembly and floor cleaning equipment. The brush shaft assembly comprises a brush shaft structure mounted in a brush shaft mounting cavity of the floor brush assembly, a brush covering the outer surface of the brush shaft structure, and a heating mechanism connected to the brush shaft structure. The problems that in the prior art, a brush shaft assembly is wet and not prone to drying, bacteria breeding and mildewing are prone to occurring, and the user experience effect is affected can be solved.

Owner:KA FUNG IND TECH HUIZHOU CO LTD

Production technology and production equipment for product paper shell

The invention discloses a production technology and production equipment for a product paper shell. The production technology comprises the steps that firstly, Dupont paper and a plastic rubber sheetare cut into a first Dupont paper layer, a plastic rubber sheet layer and a second Dupont paper layer according to the needed shape size, the first Dupont paper layer, the plastic rubber sheet layer and the second Dupont paper layer are glued together through hot melting glue, and a waterproof abrasion resisting rough paper board is formed; secondly, the waterproof abrasion resisting rough paper board obtained in the first step is placed on a forming male die in a vacuum adsorption groove; thirdly, at the time, high-temperature steam is used for heating and humidifying the waterproof abrasionresisting rough paper board through a steam baking disc, vacuum pumping is conducted after a vacuum silica gel layer is downwards in butt joint with the vacuum adsorption groove for seal, the waterproof abrasion resisting rough paper board is wrapped and tensioned on the forming male die, meanwhile, a forming female die downwards applies a certain pressure to the waterproof abrasion resisting rough paper board, and a paper shell product is formed under the action of the dies; and fourthly, after pressing is finished, the dies return to the original positions, and the paper shell product is taken down from the dies. The paper shell product is resistant to tearing, waterproof, resistant to abrasion, light in texture, resistant to corrosion, free of peculiar smells and capable of being widelyapplied to consumption product decoration shells and structure components.

Owner:邓鑫元

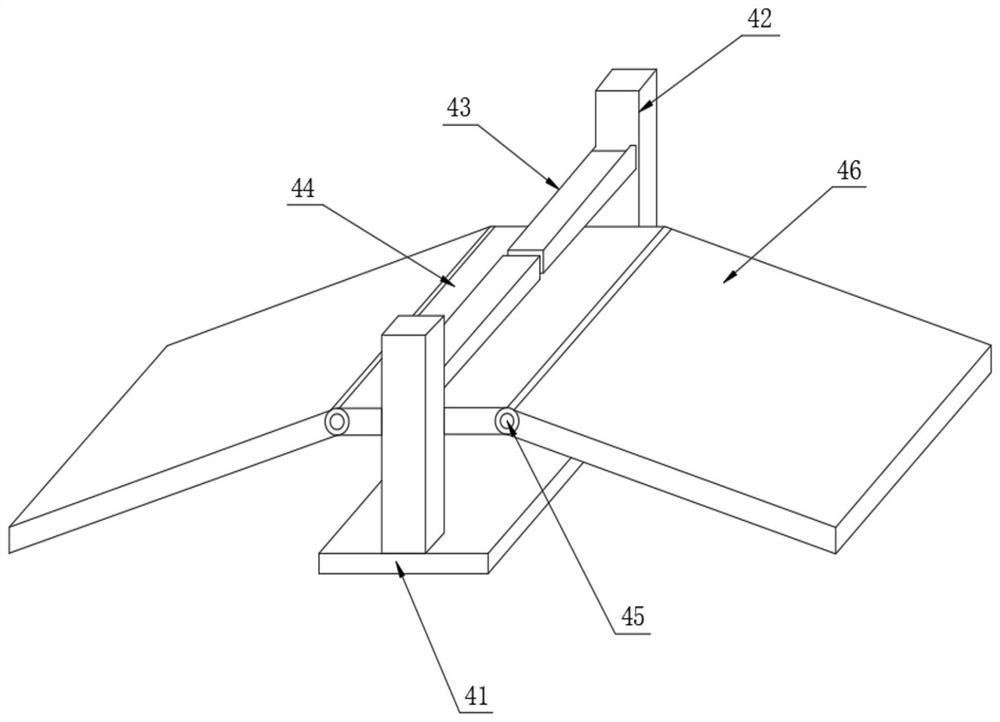

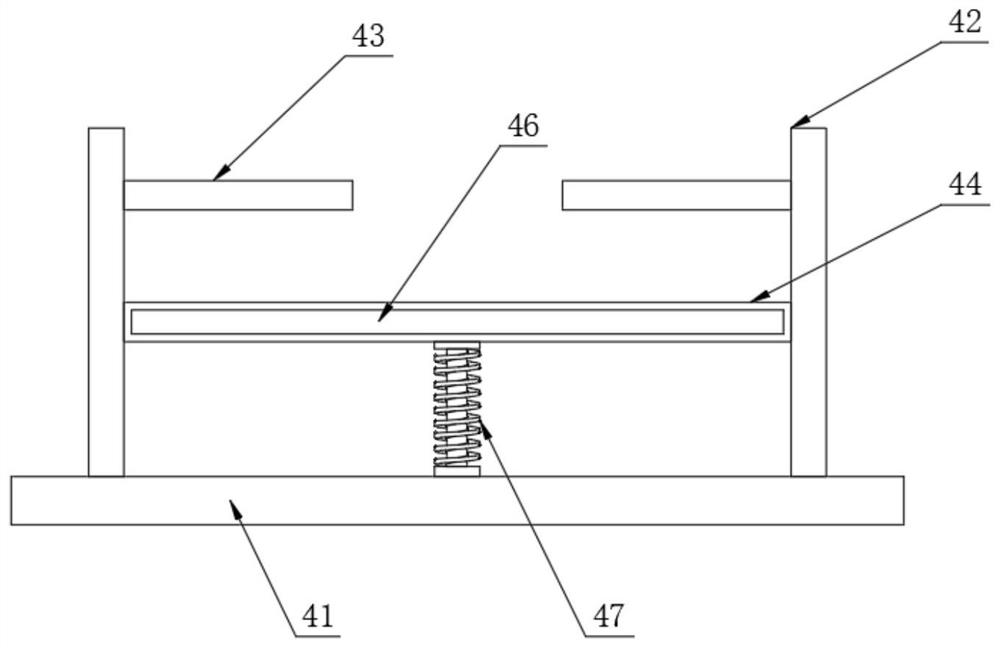

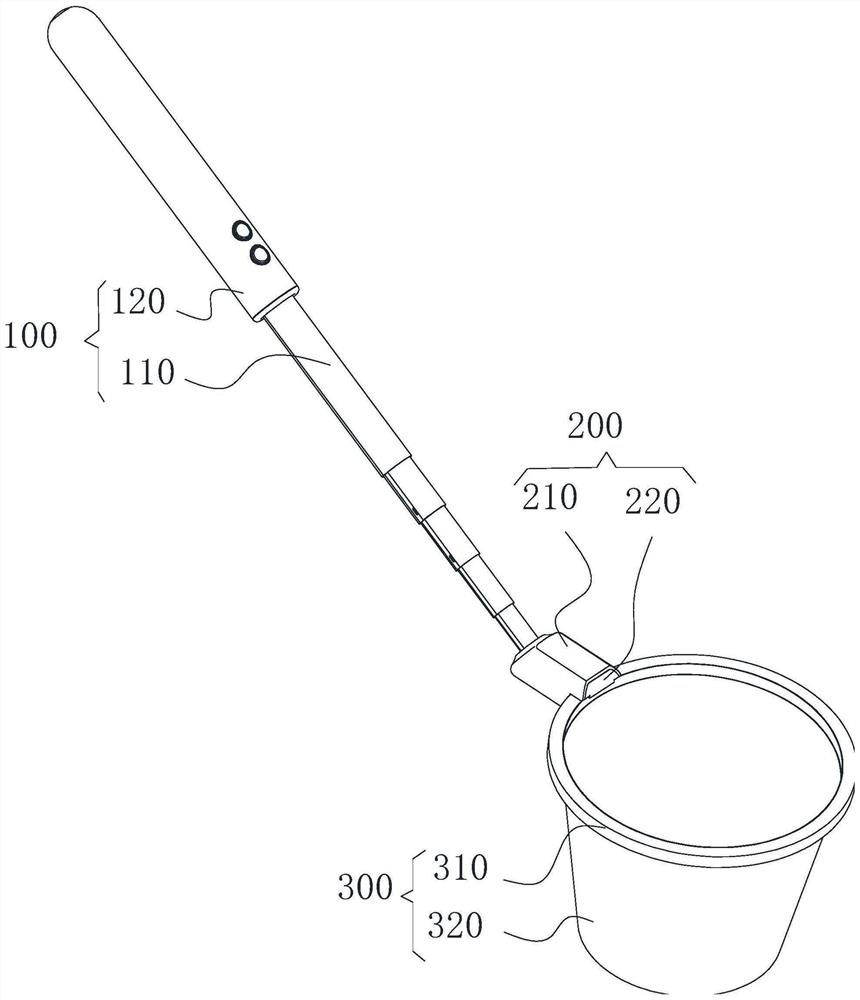

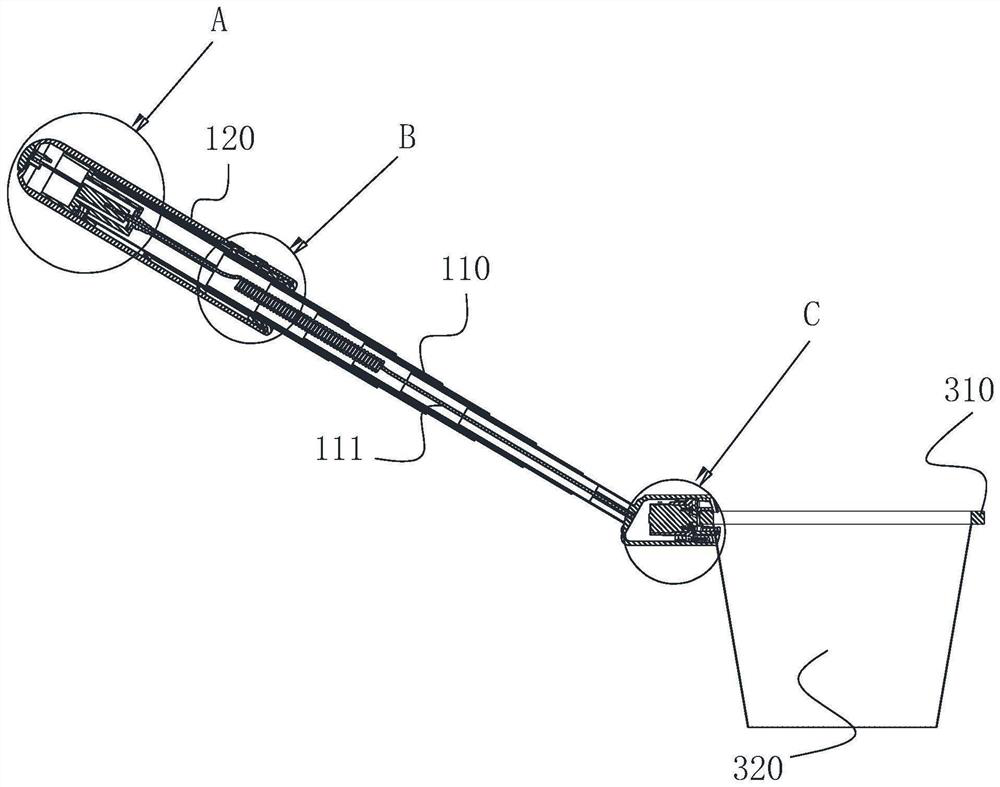

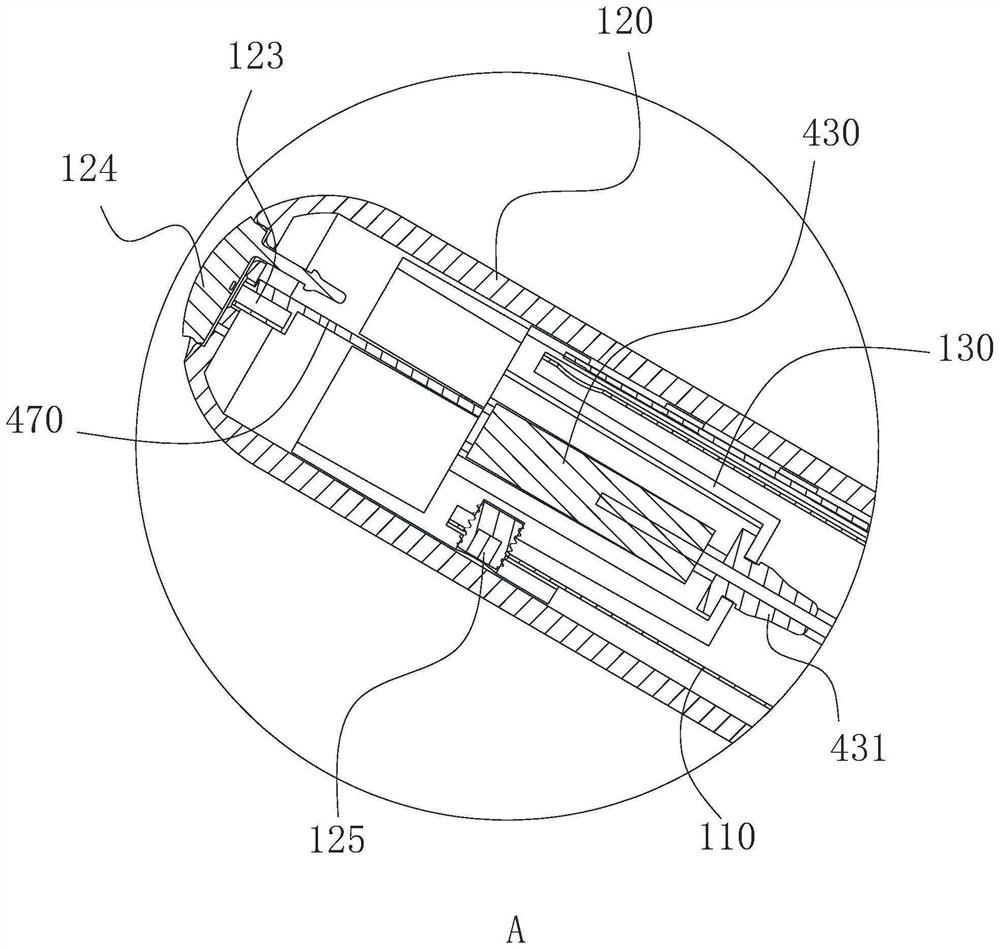

Electric pet excrement collecting device

PendingCN113774849ANot easy to reachNot easy to smellRoad cleaningCompanion animalMechanical engineering

The invention relates to the technical field of pet supplies, in particular to an electric pet excrement collecting device. The device comprises a handheld mechanism, a front end connecting mechanism, a collecting mechanism and a control mechanism, wherein the front end connecting mechanism is arranged at one end of the handheld mechanism; the collecting mechanism is detachably connected to the front end connecting mechanism, and the collecting mechanism is used for collecting pet excrement; and the control mechanism is used for fixing the collecting mechanism to the front end connecting mechanism or separating the collecting mechanism from the front end connecting mechanism. The hand-held mechanism is arranged, a certain distance exists between the hand-held mechanism and the material receiving mechanism during operation of a user, the user is not prone to smelling the smell of excrement and seeing the excrement clearly, and the use comfort is higher; meanwhile, the collecting mechanism is a disposable article, a user is not prone to being in close contact with excrement, and cleanliness and sanitation are achieved; by using the control mechanism, automatic excrement throwing can be achieved, and use is very convenient.

Owner:深圳市魔创优品科技集团有限公司

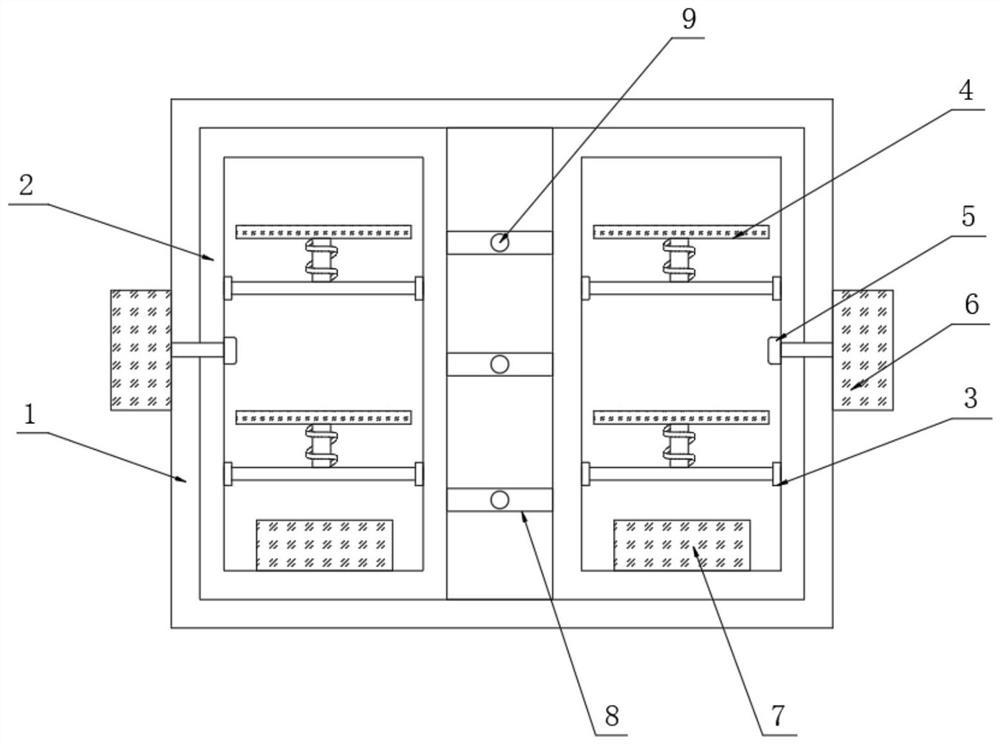

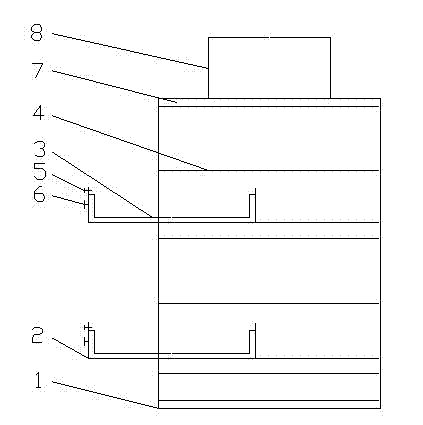

Layered tea leaf box

InactiveCN102807019ANot easy to smellKeep freshContainers preventing decayDrawer-and-shell containersInsulation layerEngineering

The invention discloses a layered tea leaf box. The tea leaf box comprises a tea leaf box body, wherein a plurality of sliding inner box bodies are movably arranged in the tea leaf box bodies; insulation layers are formed in the tea leaf box body; a sealing layer is formed between every two sliding inner box bodies; a hasp is arranged on each sliding inner box body; a handle is arranged outside each sliding inner box body; and an antibacterial layer is formed in each sliding inner box body. By the method, a plurality of kinds of tea leaves can be stored simultaneously, a phenomenon that tastes of the tea leaves are mixed is avoided, and the tea leaves are easy to refresh.

Owner:常州金海棠茶果专业合作社

Preparation method of chia ice cream

InactiveCN105360563AHigh in fatty acidsCholesterol freeFrozen sweetsFood ingredient functionsAdditive ingredientAntioxidant

The invention provides a preparation method of chia ice cream. The preparation method of chia ice cream includes: raw material treatment; raw material mixing; homogenization; sterilization; aging; freezing; and hardening. The ice cream prepared by the method is a pure natural food safe to eat, has high fatty acid content, is free of cholesterol, does not cause allergy, does not contain nutrient enriched marine pollutants, does not contain any ingredients harmful to the human body, also contains natural antioxidants, is not easy to rot and go bad, and does not produce toxic substances and peculiar smell. Also the chia ice cream has relatively high nutrient content, and the content of soluble dietary fiber is 12 times that of whole wheat bran. The chia ice cream can effectively enhance satiety, promote intestinal peristalsis and prevent constipation, and is an eating and health care integrated novel food suitable for people of all ages.

Owner:荣成恒顺海洋生物科技有限公司

brake pads

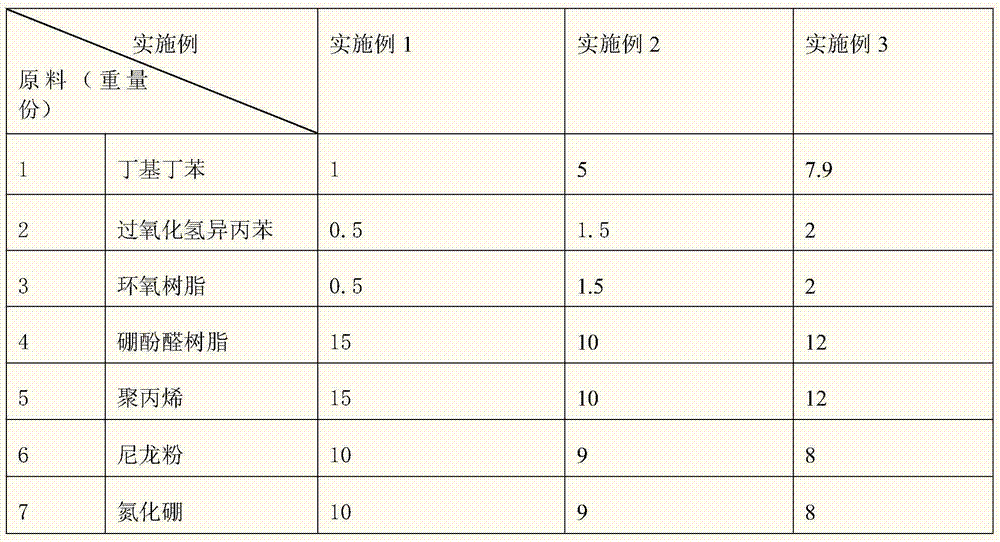

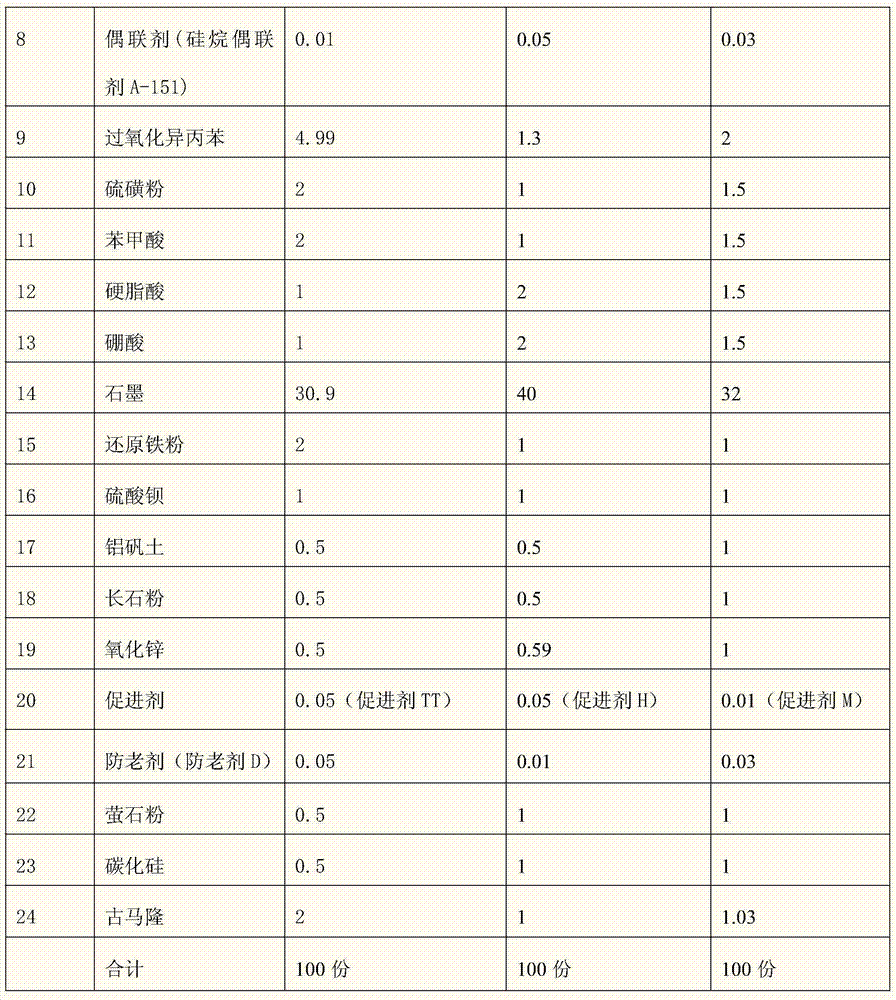

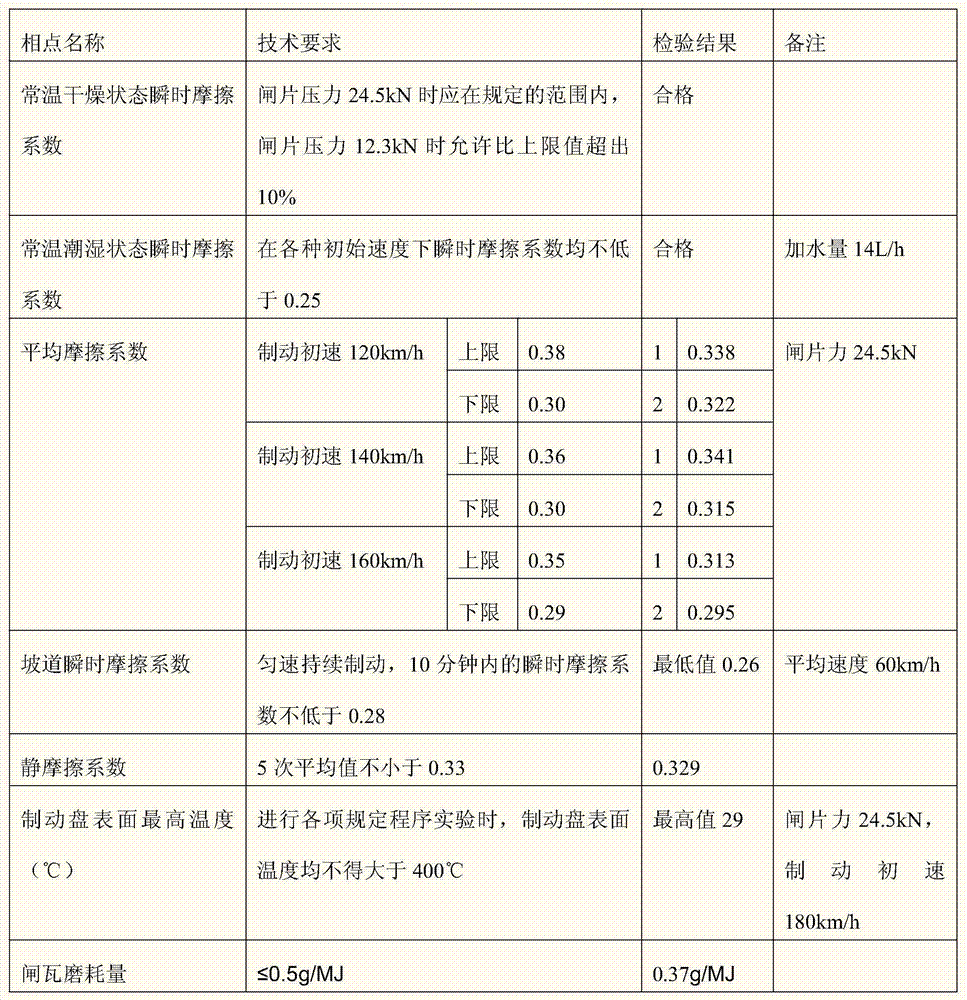

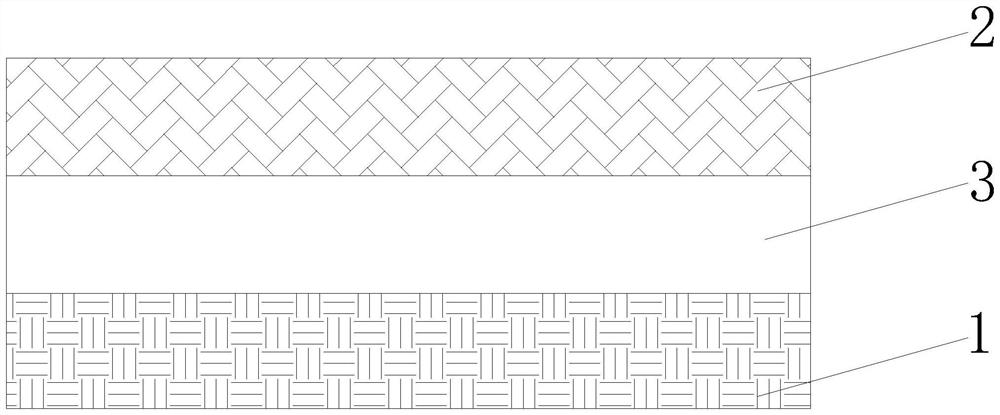

The invention discloses a brake pad which comprises a steel backing and friction materials. The friction materials are prepared from components including, by weight, 1-10 parts of butyl butylbenzene, 0.5-2 parts of cumyl hydroperoxide, 0.5-2 parts of epoxy resin, 1-15 parts of boron containing phenolic resin, 1-15 parts of polypropylene, 6-10 parts of nylon powder, 5-10 parts of boron nitride, 0.01-0.05 part of coupling agent, 1-5 parts of dicumyl peroxide, 1-2 parts of sulfur powder, 1-2 parts of benzoic acid, 1-2 parts of stearic acid, 1-2 parts of boric acid, 30-50 parts of graphite, 1-2 parts of reduced iron powder, 1-2 parts of barium sulfate, 0.5-2 parts of bauxite, 0.5-2 parts of feldspar powder, 0.5-2 parts of zinc oxide, 0.01-0.05 part of accelerator, 0.01-0.05 part of anti-aging agent, 0.5-2 parts of fluorite powder, 0.5-2 parts of silicon carbide and 0.5-2 parts of coumarone. The brake pad has the advantages of abrasion resistance, long service life, no spark, no smell, low noise and fine heat dissipation performance.

Owner:NINGBO JIA XUAN NEW MATERIALS

Novel fabric and preparation process thereof

PendingCN114571804ANot easy to smellNot easy to breedMechanical cleaningPressure cleaningYarnPolymer science

The invention discloses a novel fabric, and relates to a textile fabric, the novel fabric comprises a base cloth layer and a surface layer, a middle layer is arranged between the base cloth layer and the surface layer, the base cloth layer, the middle layer and the surface layer are sewn together through yarns, and the middle layer is obtained by padding gray fabric in an antibacterial and antiviral finishing agent and a fragrance finishing agent. The preparation method has the beneficial effects that the preparation process flow of yarn manufacturing, fabric weaving, gray fabric treatment, fabric preparation, rinsing and drying, fabric inspection, surface brushing and impurity removal, fabric folding and finishing, defect repairing and packaging and warehousing is adopted, so that the fabric has the antibacterial and antiviral effects and can remove odor, and the use effect is good after the fabric is made into sportswear.

Owner:绍兴舒涛针纺有限公司

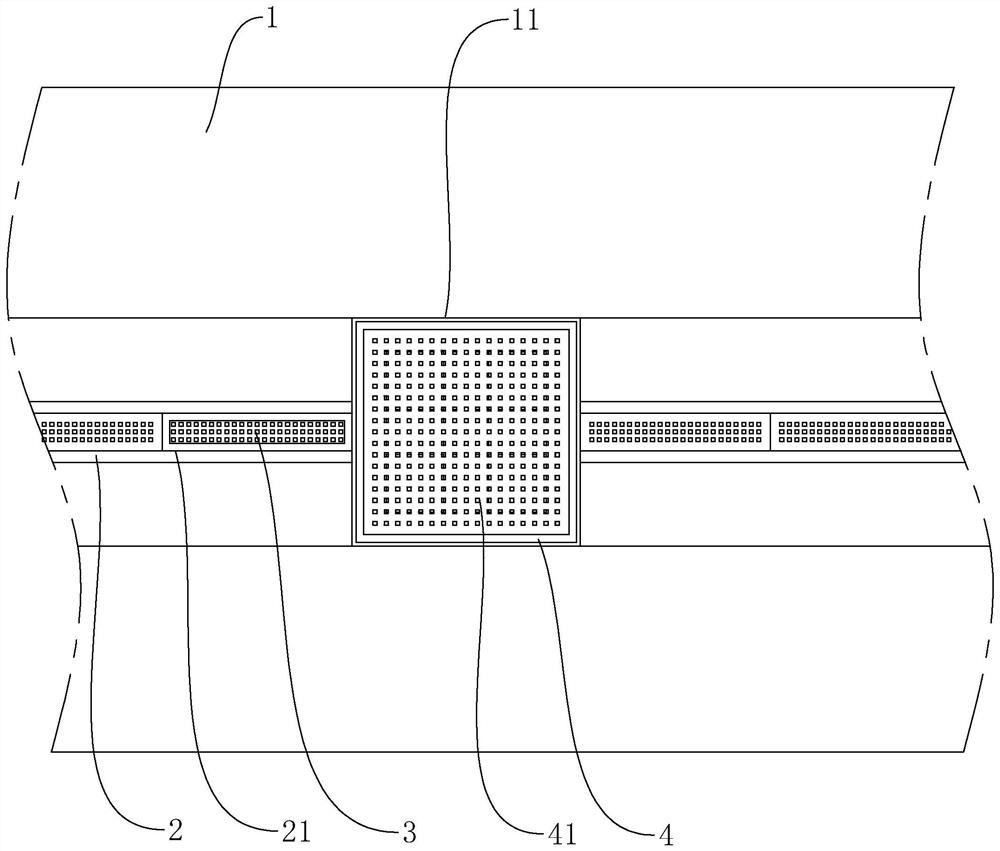

A garden landscape drainage pavement

ActiveCN113235354BIncrease profitEasy to removeIn situ pavingsFatty/oily/floating substances removal devicesWater resourcesEnvironmental engineering

This application relates to a garden landscape drainage pavement, and relates to the field of garden landscape pavement drainage. The drainage pavement includes a pavement body, a drainage pipe arranged in the pavement body, a plurality of drainage covers abutting on the drainage pipe for preliminary filtering of impurities, The water collection tank arranged in the road body, the buckle cover fastened to the top of the water collection tank, the support platform arranged under the bottom of the water collection tank at intervals, the bearing platform arranged under the support platform at intervals, and the bearing platform arranged between the bearing platform and the support platform. The lifting mechanism that controls the lifting of the support platform, and the impurity removal mechanism that is installed between the support platform and the bottom of the water collection tank to facilitate the removal of impurities in the water collection tank; there is an installation groove in the road surface body, and the water collection tank is located at In the installation groove, the drainage pipe communicates with the water collection box, and the drainage pipe abuts against the side wall of the water collection box. The application has the effect of facilitating the utilization of water resources recovered from the pavement.

Owner:ZHEJIANG CHANHIGH MUNICIPAL GARDEN CONSTR CO LTD

Preparation method of cotton blending pantyhoses

InactiveCN106333392AGood moisture absorptionNot easy to smellWeft knittingWarp knittingPlain weaveDyeing

The invention discloses a preparation method of cotton blending pantyhoses. The preparation method comprises the following steps of (1) putting raw materials for 96 h at constant temperature in the conditions that the temperature is 23 to 28 DEG C and the humidity is 60 to 80%, and then putting into production on a machine; (2) keeping the workshop temperature at 23 to 28 DEG C and the humidity of 60 to 80%; (3) stabilizing the tension of yarns, so that the tension reaches 1.5 g; (4) taking half-finished pantyhoses from the machine so as to be levelled, and vacuumizing each package which contains 150 pantyhoses for 30 min at the temperature of 85 DEG C; (5) simultaneously feeding two strands or more than two strands of yarns into a knitting machine for plain weave; (6) dyeing the half-finished pantyhoses at the dyeing temperature of 95 DEG C, and adding softeners during dyeing; (7) shaping the half-finished pantyhoses at the shaping temperature of 122 DEG C and under the air pressure of 1.9 kg; (8) uniformly pulling legs of the half-finished pantyhoses; (9) inspecting the thread-off proof effect and the light transmission; (10) packaging finished products.The breathing pantyhoses have the advantages of easiness in permeability, good moisture absorption effect, difficulty in generating odor and high comfortability.

Owner:浙江永春科技股份有限公司

Integrated toilet water draining system

PendingCN110593363AIncrease profitSolve the problem of easy cloggingSewerage structuresDomestic plumbingEngineeringToilet

The invention discloses an integrated toilet water draining system. The integrated toilet water draining system is composed of a waterproof chassis, a water draining transverse branch pipe, an integrated water seal and a water draining vertical pipe. The waterproof chassis is composed of a waterproof ground and a waterproof blocking strip, the waterproof ground is divided into a top face and a bottom face, the waterproof blocking strip is higher than the top face and surrounds the edge of the top face or is close to the edge of the top face, and the waterproof blocking strip and the waterproofground are of an integrated structure. A ground water draining opening is formed in at least one waterproof ground close to the waterproof blocking strip, a water draining outlet of the ground waterdraining opening is connected with the water draining transverse branch pipe, the water draining transverse branch pipe is connected with the integrated water seal, and the integrated water seal is connected with the water draining vertical pipe. The problem that an existing toilet water draining system needs a toilet structure to descend or rise, a chassis is prone to generating seepage, the water seal of a floor drain is prone to drying up to generate peculiar smell can be solved, the system is applied to a building, descending is not needed or little descending is needed, the toilet sanitary water draining smoothness and sanitation conditions can be improved, and the seepage of the waterproof chassis can be completely eradicated.

Owner:KUNMING QUNZHIYING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com