Silk-screen printing ink composition and preparation method thereof, printed matter and preparation method thereof

An ink composition, screen printing technology, applied in the direction of ink, household appliances, applications, etc., can solve problems such as worries, odor, affecting the use experience, etc., to reduce irritation, reduce odor, and improve the effect of grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

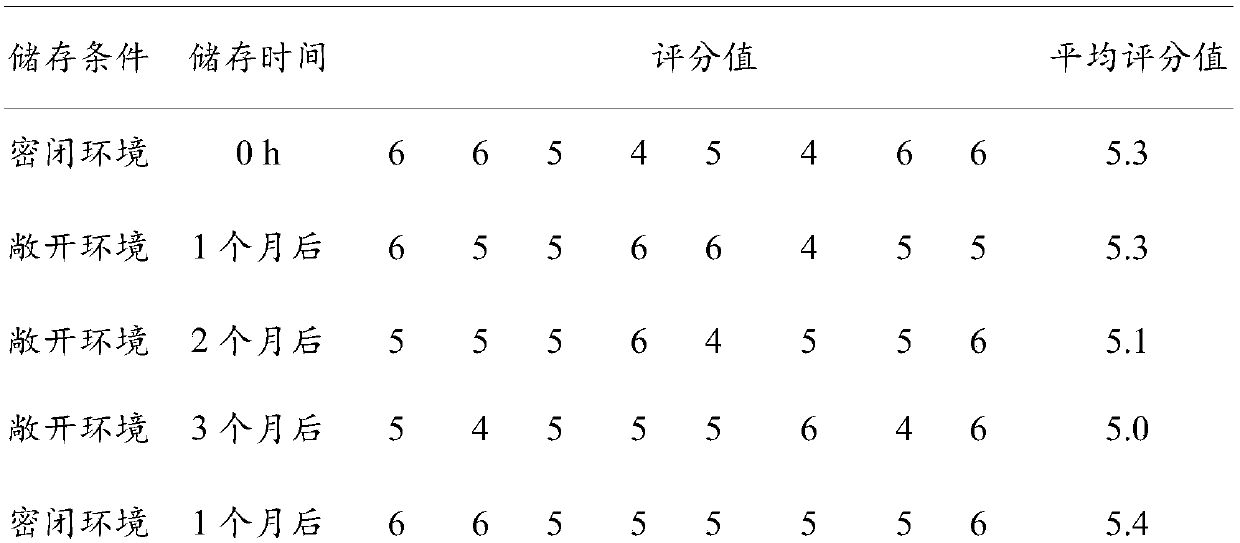

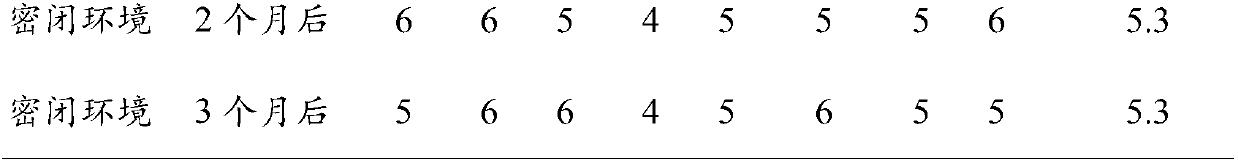

Examples

Embodiment 1

[0043] In this example, in parts by mass, 5 parts of carbonized chlorophyll were added to 4000 parts of screen ink, stirred evenly and left to stand for 3 hours, then 5 parts of molecular sieve soaked with essence were added and stirred evenly to obtain a screen printing ink composition. Among them, the mass ratio of essence to molecular sieve in the molecular sieve impregnated with essence is 5:0.4, the molecular sieve is SBA-15, the diameter of molecular sieve is 0.01mm~0.05mm, the essence is a mixture of peppermint oil and tobacco essential oil, peppermint oil and tobacco essential oil The mass ratio is 1:6, and the screen ink is UV type ink.

[0044] The cigarette trademark paper of this embodiment is prepared through the following steps:

[0045] 1) Fix the cleaned and dried screen plate on the screen machine to prepare for screen printing;

[0046]2) Add the screen ink composition of this example to the screen plate, transfer the screen ink composition to the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com