A kind of preparation method of plant-derived chitosan

A plant-derived chitosan technology, applied in the field of preparation of plant-derived chitosan, can solve problems such as environmental pollution, stench, and time-consuming, and achieve the effects of protecting the environment, reducing usage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

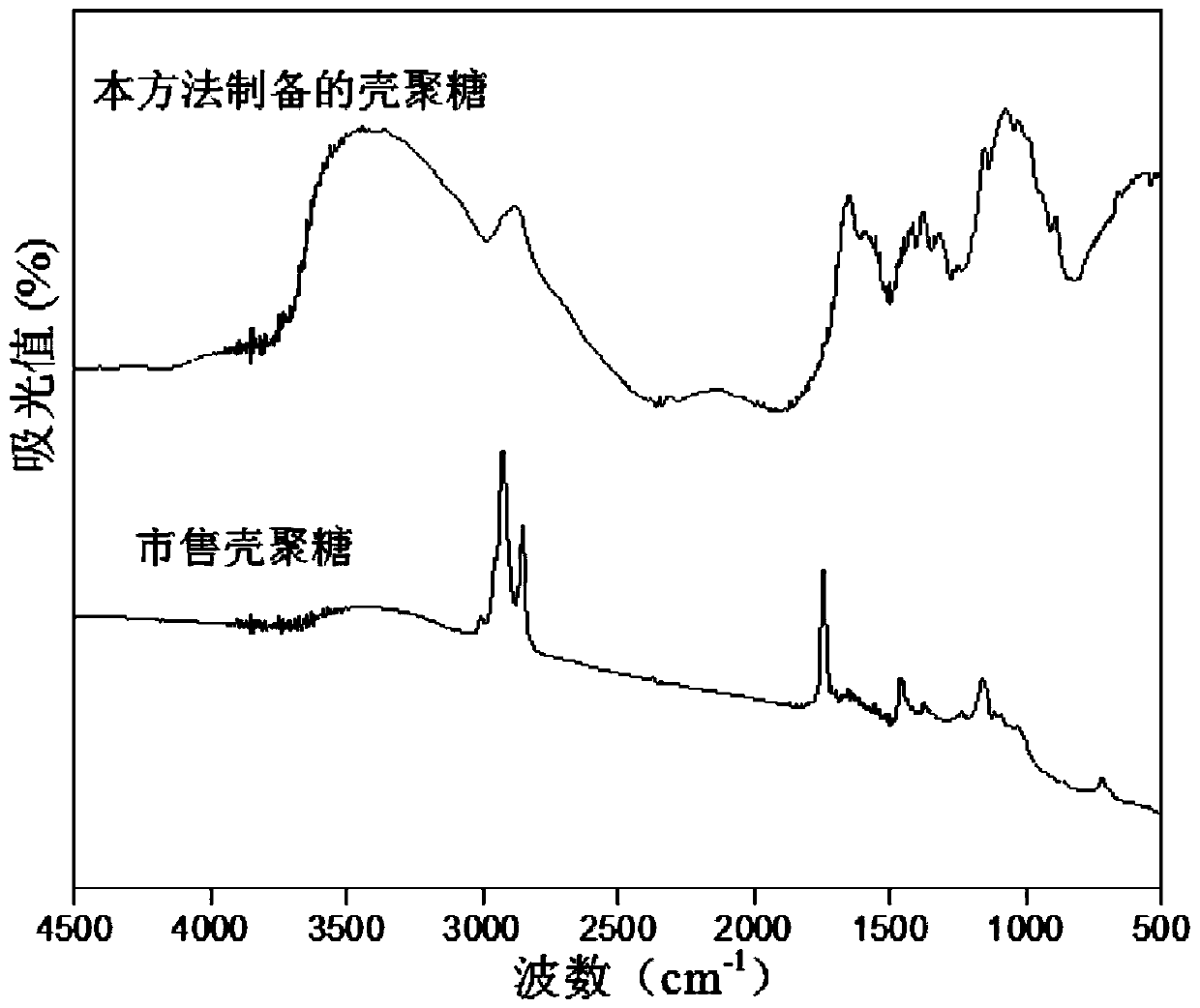

Image

Examples

Embodiment 1

[0028] (1) Take 1g of dried Ganoderma lucidum spore powder, add deionized water to the Ganoderma lucidum spore powder at a material-to-liquid ratio of 1:15 (g:ml), and extract the Ganoderma lucidum polysaccharide by ultrasonic (100W) in a water bath at 45°C for 1 time and then use 7000rpm Centrifuge for 10 minutes to remove the supernatant to obtain a sediment; add 95v / v% ethanol to the sediment at a material-to-liquid ratio of 1:15 (g:ml), and ultrasonically treat it at room temperature (25℃±1℃) for 1h to remove three Terpenoids, and then centrifuged under the same conditions to obtain the secondary sediment; add deionized water to the secondary sediment according to the material-to-liquid ratio of 1:30 (g:ml), soak for 3 hours at 25°C to remove water-soluble proteins. After centrifugation, the three precipitates obtained are dried at 55°C to obtain crude chitin;

[0029] (2) Take 1g of crude chitin and add 30% H 2 O 2 10ml, keep the temperature in a water bath at 70℃ for 1h. ...

Embodiment 2

[0045] (1) Take 1g of dried Ganoderma lucidum spore powder, add deionized water to the Ganoderma lucidum spore powder at a material-to-liquid ratio of 1:25 (g:ml), and extract 3 times of Ganoderma lucidum polysaccharides at 55℃ with ultrasonic (150W) at 10000rpm Centrifuge for 5 minutes to remove the supernatant to obtain a sediment; add 95v / v% ethanol to the sediment at a material-to-liquid ratio of 1:25 (g:ml), and ultrasonicate for 2h at room temperature (25℃±1℃) to remove the three Terpenoids, then centrifuged under the same conditions to obtain the secondary sediment; add deionized water to the secondary sediment according to the material-to-liquid ratio of 1:40 (g:ml), soak for 2h at 35°C to remove water-soluble proteins, After centrifugation, the three precipitates obtained are dried at 60°C to obtain crude chitin;

[0046] (2) Take 1g of crude chitin and add 30% H 2 O 2 20ml, keep the temperature in a water bath at 60℃ for 2h. Add 1wt% NaOH solution to adjust the pH to ...

Embodiment 3

[0050] (1) Take 1g of dried Ganoderma lucidum spore powder, add deionized water to the Ganoderma lucidum spore powder at a material-to-liquid ratio of 1:25 (g:ml), and extract 5 times of Ganoderma lucidum polysaccharides at 65℃ by ultrasonic (200W) at 8000rpm Centrifuge for 10 minutes to remove the supernatant to obtain a precipitate; add 95v / v% ethanol to the precipitate according to the material-liquid ratio of 1:25 (g:ml), and ultrasonicate for 3 hours at room temperature (25°C±1°C) to remove the three Terpenoids, then centrifuged under the same conditions to obtain the secondary sediment; add deionized water to the secondary sediment according to the material-to-liquid ratio of 1:50 (g:ml), soak at 45℃ for 1 hour to remove water-soluble proteins, After centrifugation, the three precipitates obtained are dried at 60°C to obtain crude chitin;

[0051] (2) Take 1g of crude chitin and add 30% H 2 O 2 30ml, keep the temperature in a water bath at 50℃ for 3h. Add 1wt% NaOH soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com