Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "No detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

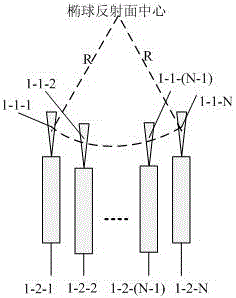

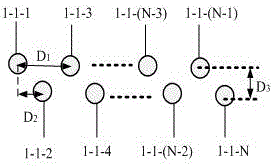

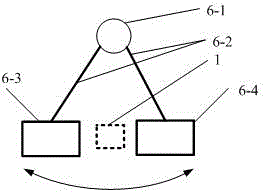

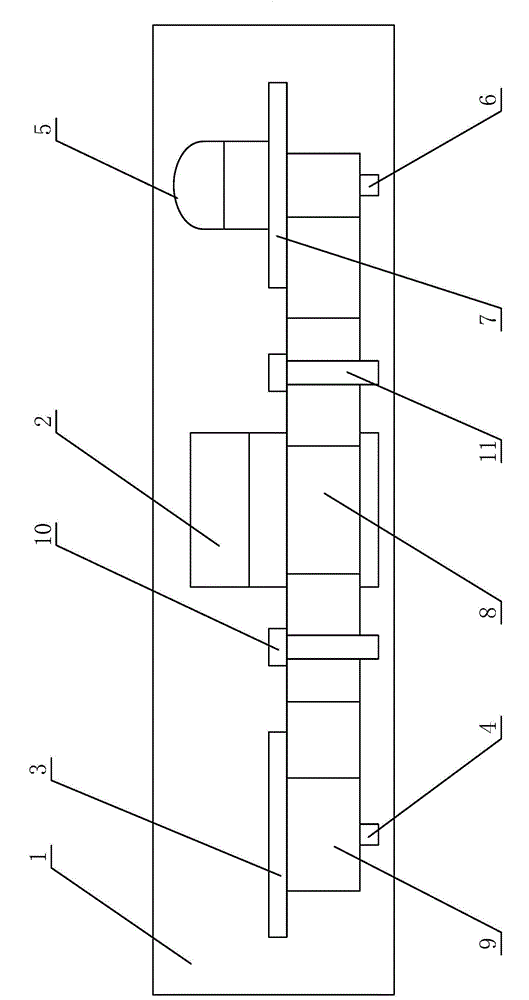

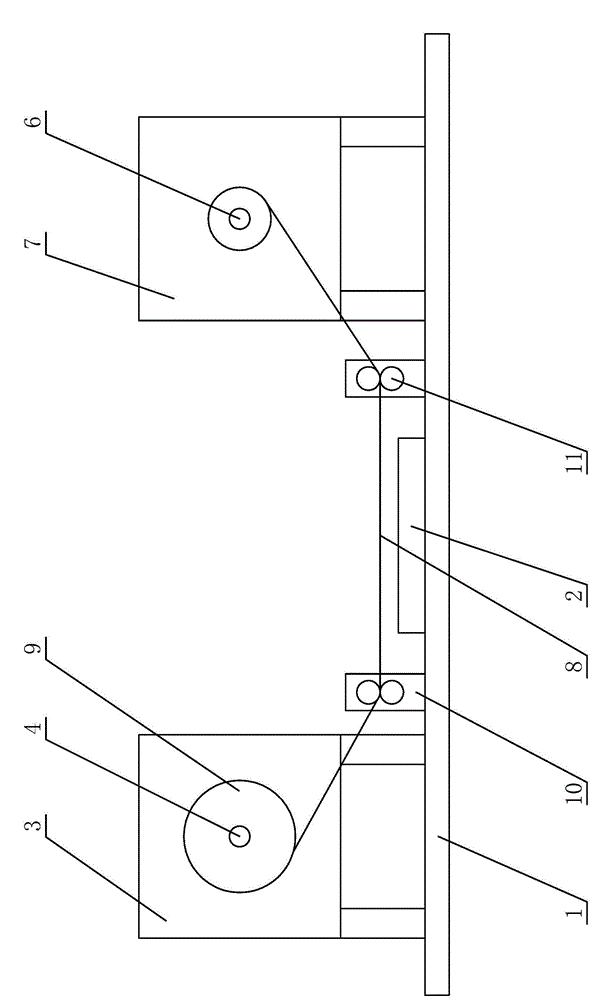

Passive millimeter wave imaging security inspection equipment

ActiveCN104076358ARealize detectionNo detectionGeological detection using milimetre wavesRadio wave reradiation/reflectionImaging qualityEngineering

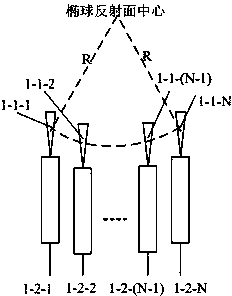

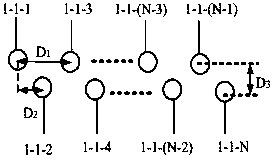

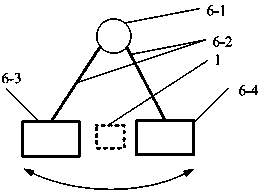

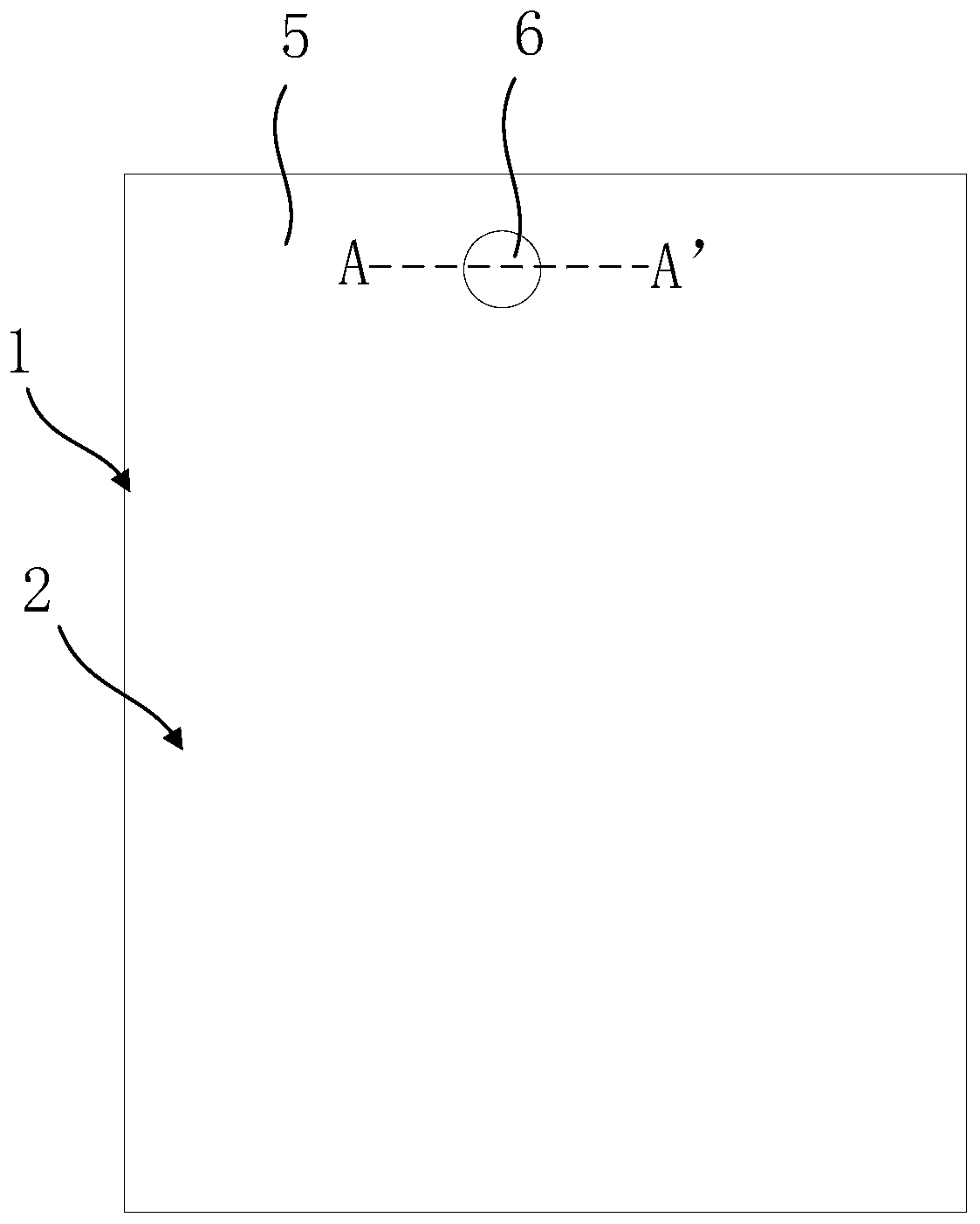

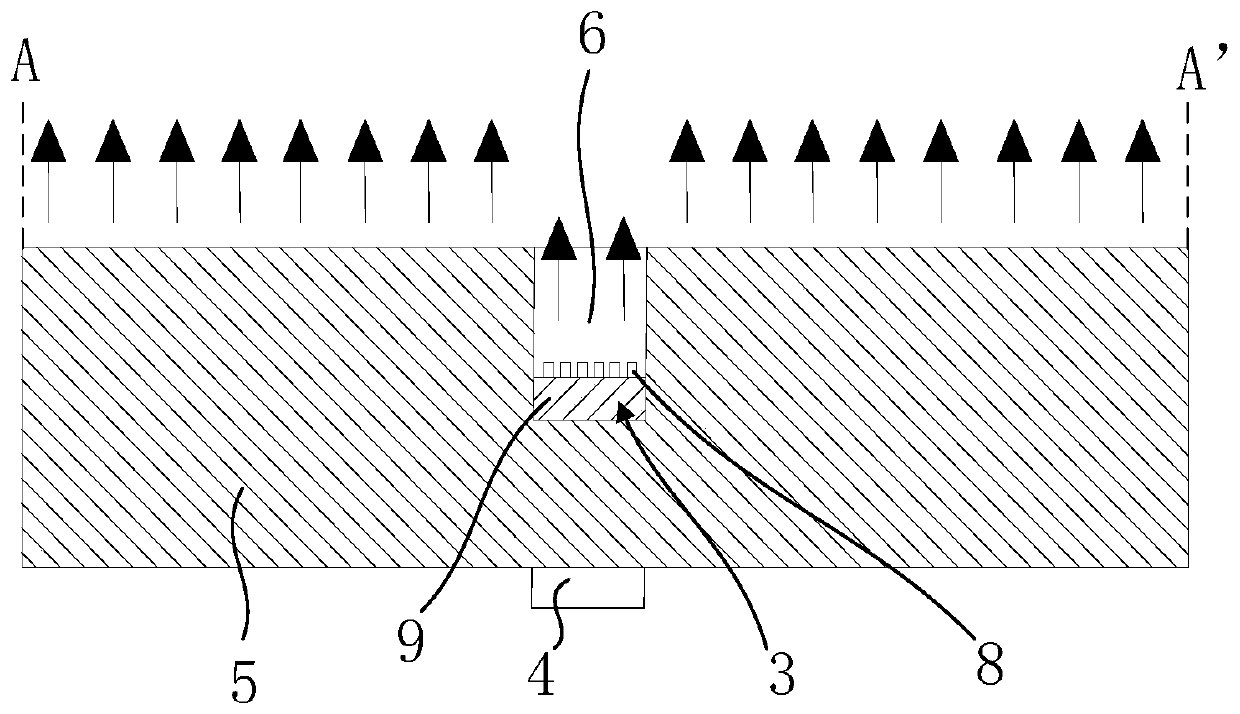

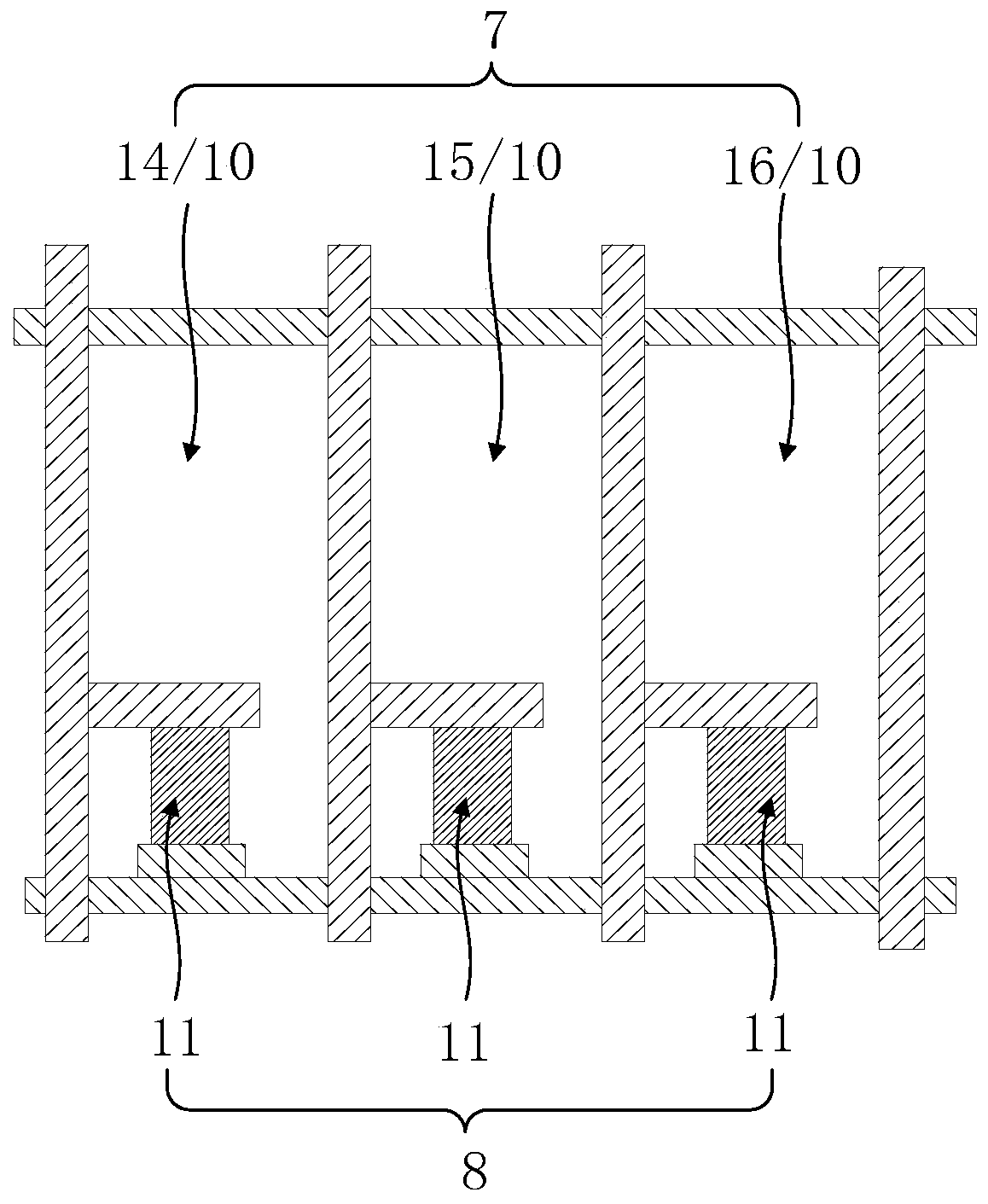

The invention discloses passive millimeter wave imaging security inspection equipment which comprises a one-dimensional focal plane array (1), a reflecting plate (3), a display control sub-system (4), a signal processor (5), an inner calibration combination (6), a reflecting plate rotating mechanism (7), a dielectric panel (8), a rack (9), a detecting table (11), an ellipsoid reflecting surface (2) and an outer calibration combination (10). The ellipsoid reflecting surface (2) focuses electromagnetic waves radiated by a human body, the one-dimensional focal plane array (1) converts the focused electromagnetic waves into voltage signals, the signal processor (5) collects the voltage signals and sends the voltage signals to the display control sub-system (4), and the display control sub-system (4) processes the voltage signals and then outputs two-dimensional grey-scale map. The inner calibration combination (6) and the outer calibration combination (10) are adopted for combined calibration, image quality can be improved, and metal and nonmetal forbidden objects can be detected. The passive millimeter wave imaging security inspection equipment has the advantages of being small in system loss, high in sensitivity and reliability, low in cost, light and the like.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

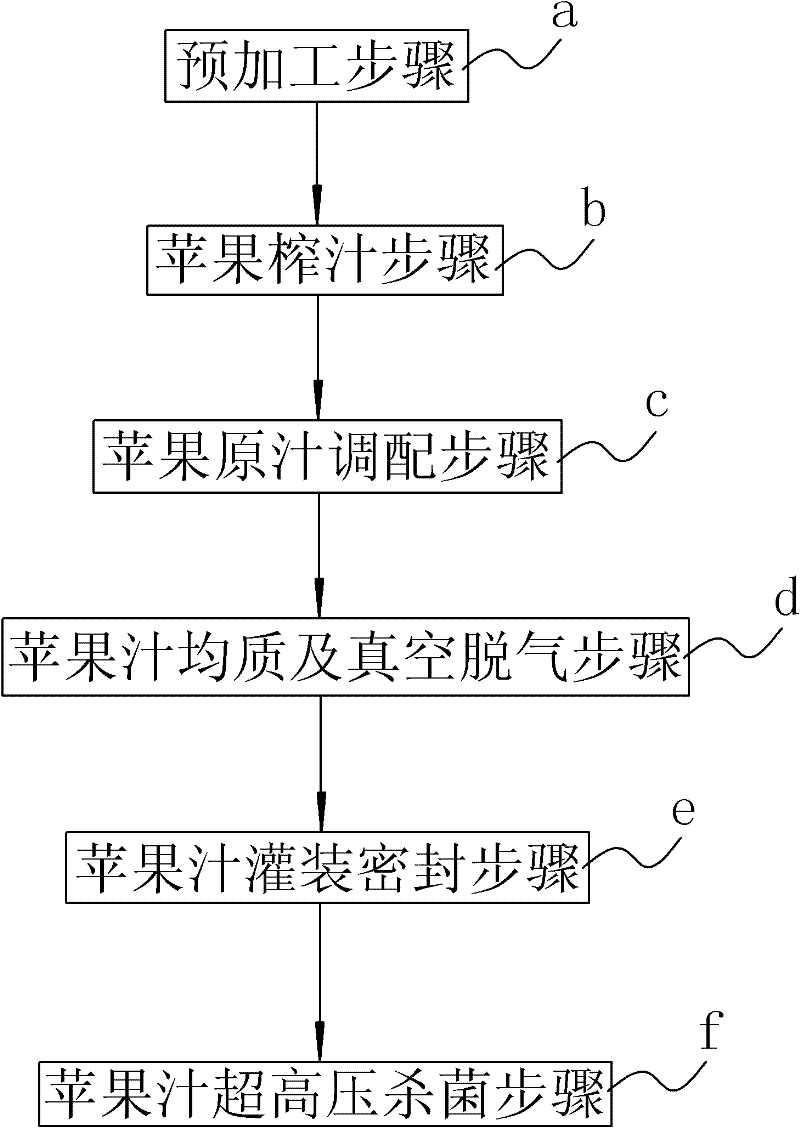

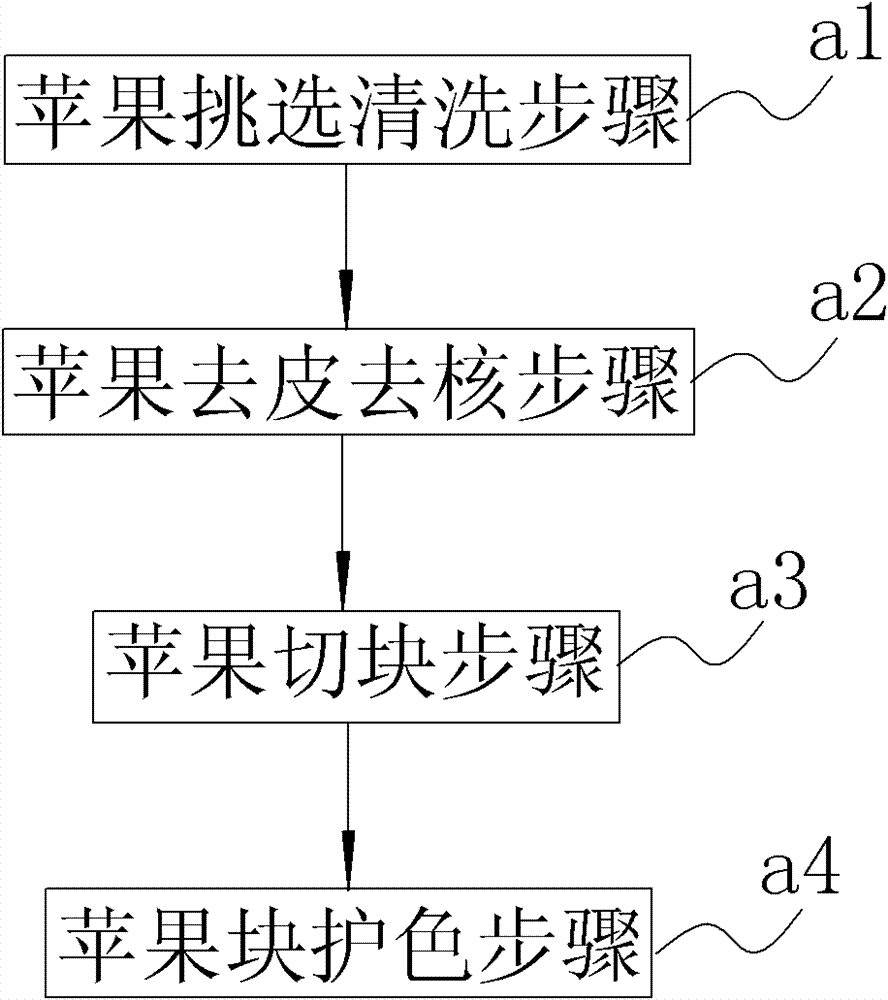

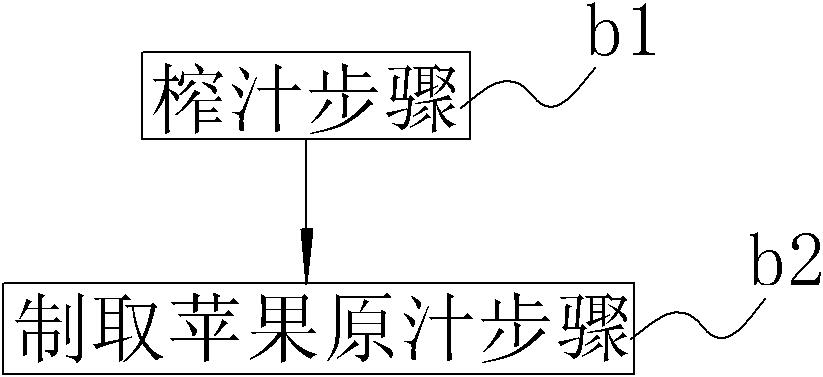

Apple juice and preparation method thereof

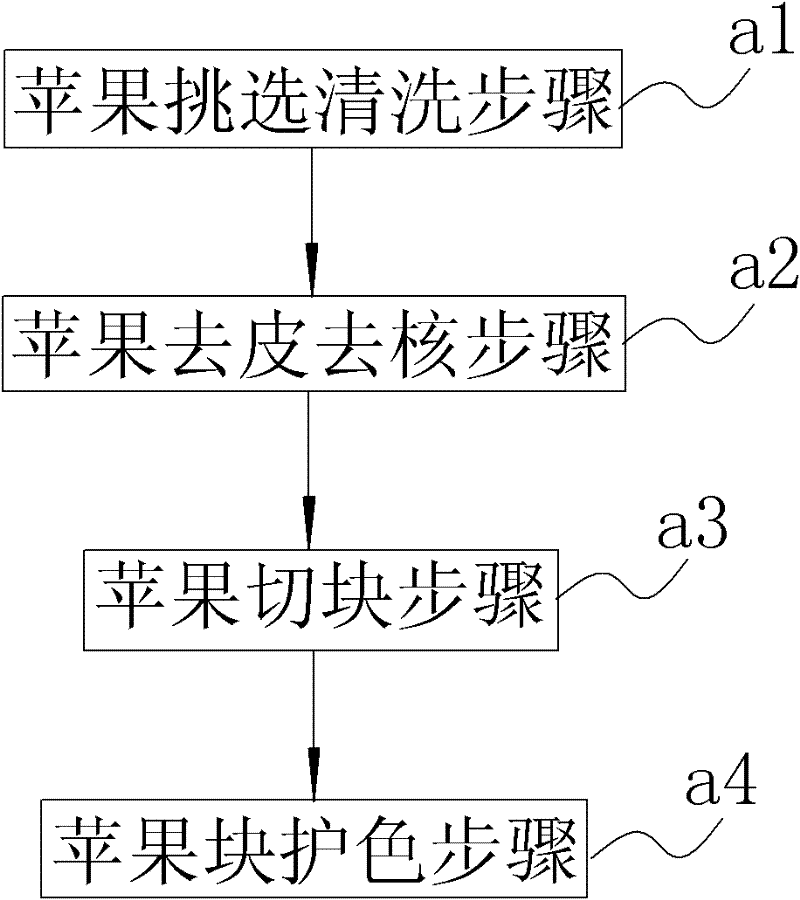

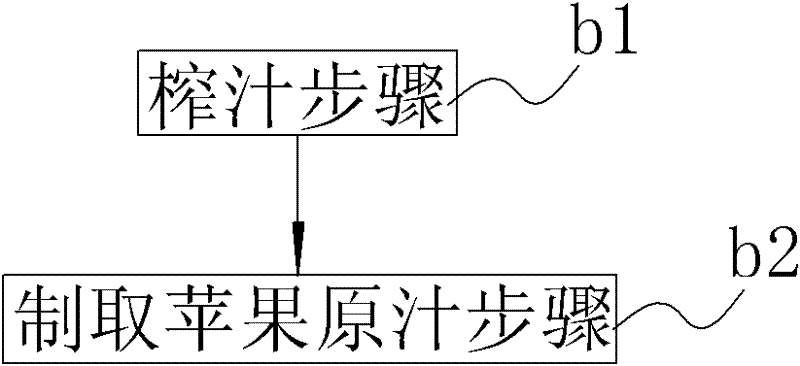

The invention relates to an apple juice and a preparation method thereof. The preparation method comprises the following steps: preprocessing; juicing apples; blending raw apple juice; homogenizing the apple juice, and carrying out vacuum degasification; filling the apple juice, and sealing; and carrying out extra-high-pressure sterilization on the apple juice. The apple juice is the product processed by the preparation method. By carrying out extra-high-pressure sterilization at normal temperature, the invention can effectively reduce enzymatic change and browning caused by thermal reaction in the processing course of the apple juice, solve the problems of mouthfeel and flavor degradation and nutrient loss of the product caused by high-temperature heating sterilization during the traditional thermal sterilization processing, and favorably keep the natural flavor and nutrient of the product.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

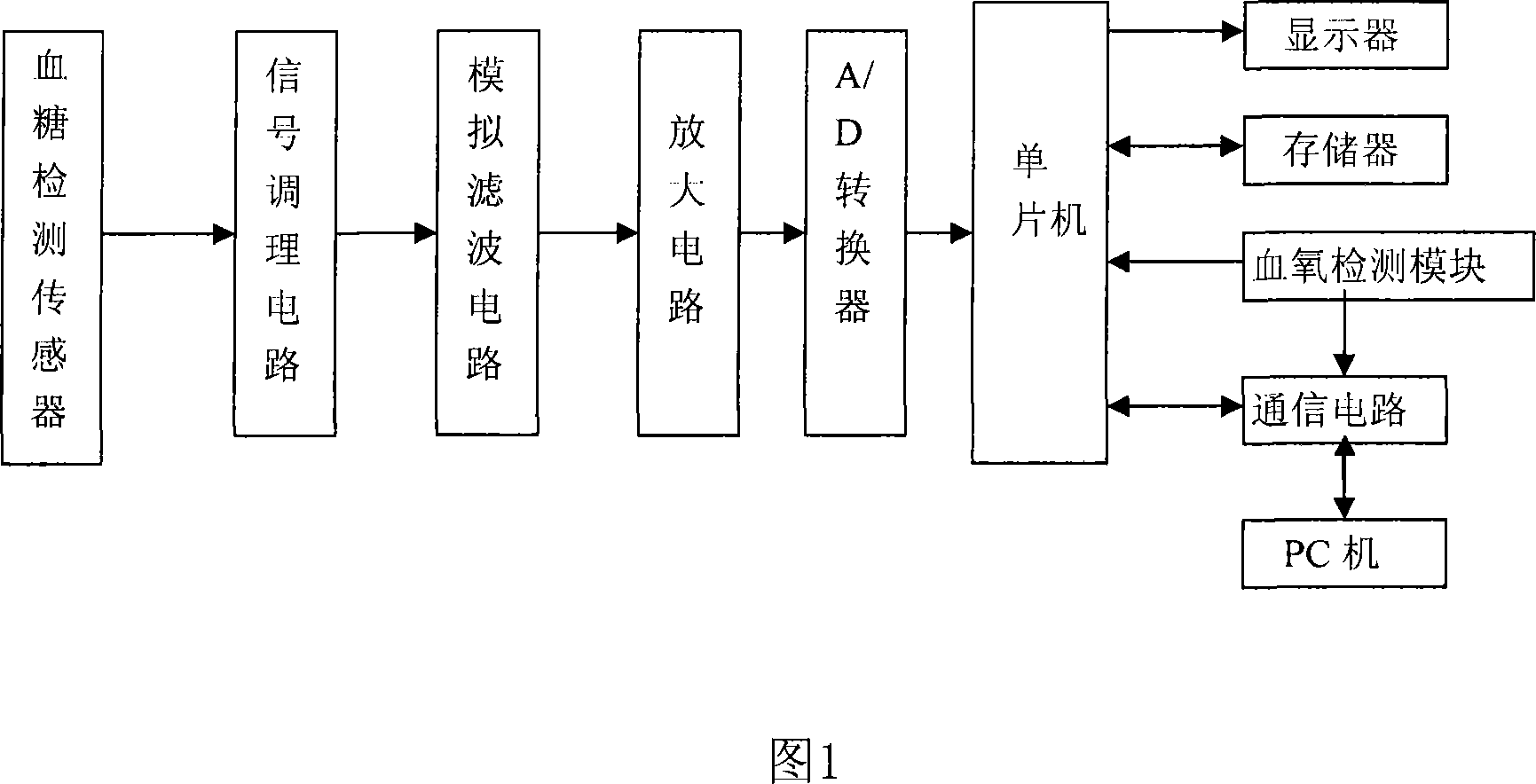

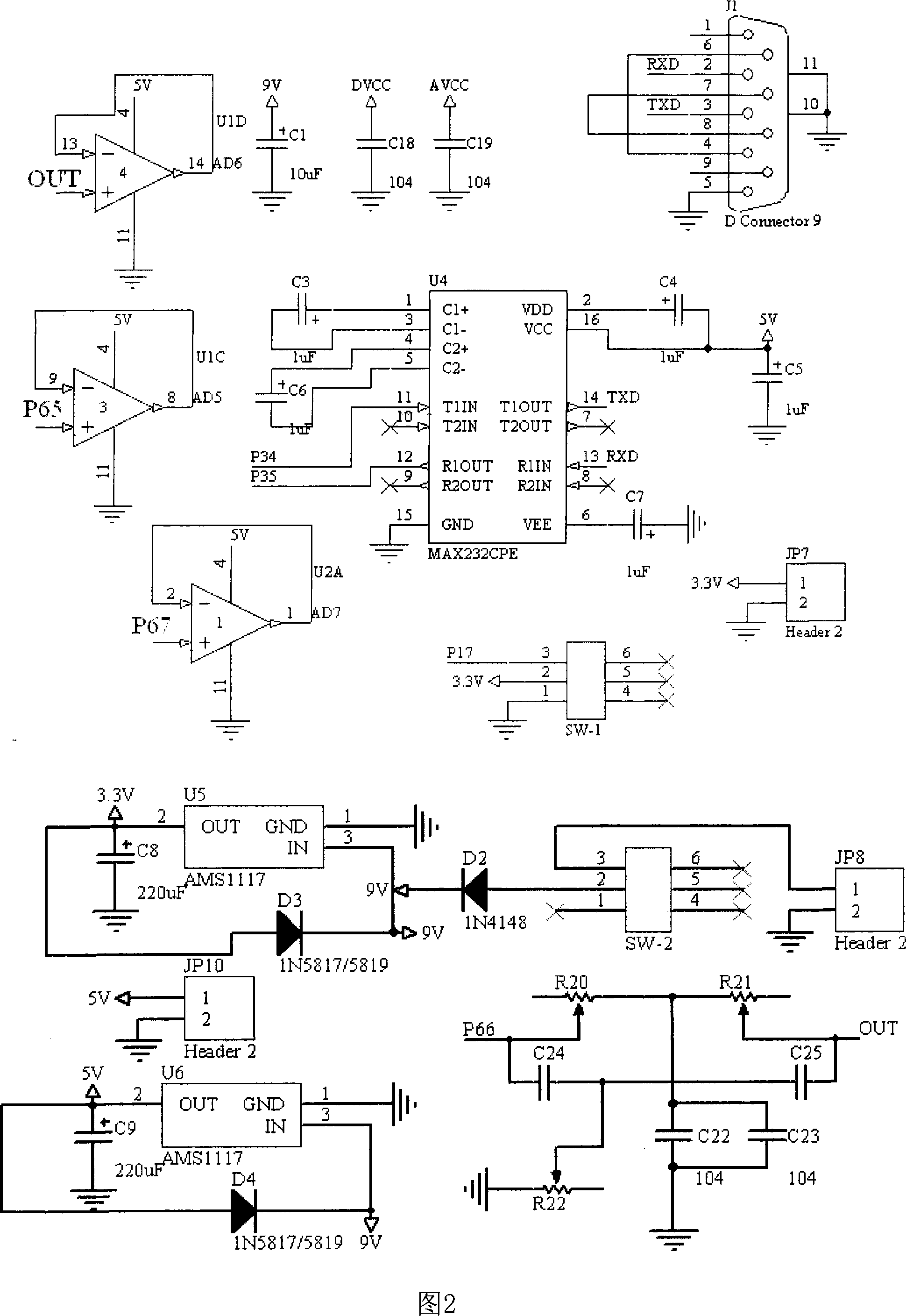

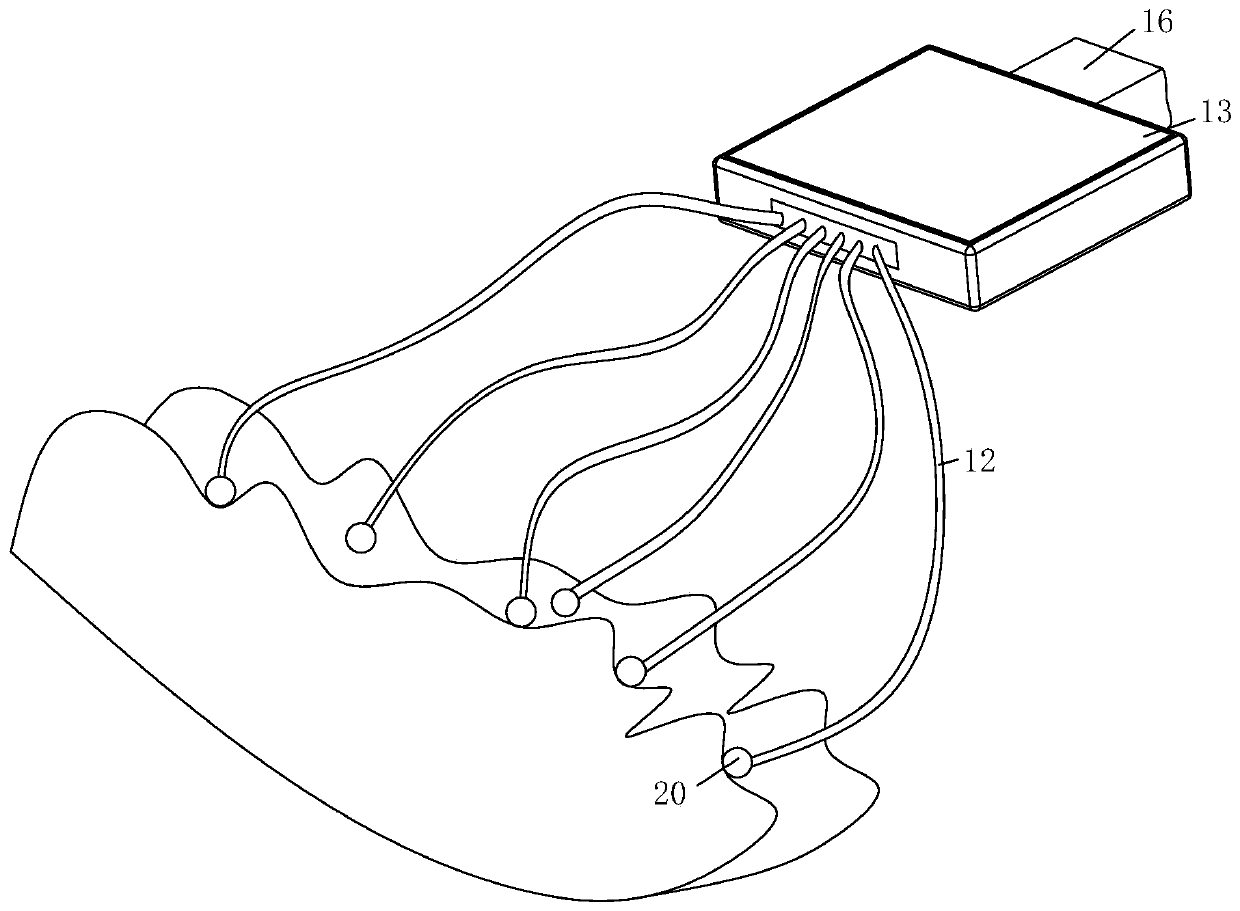

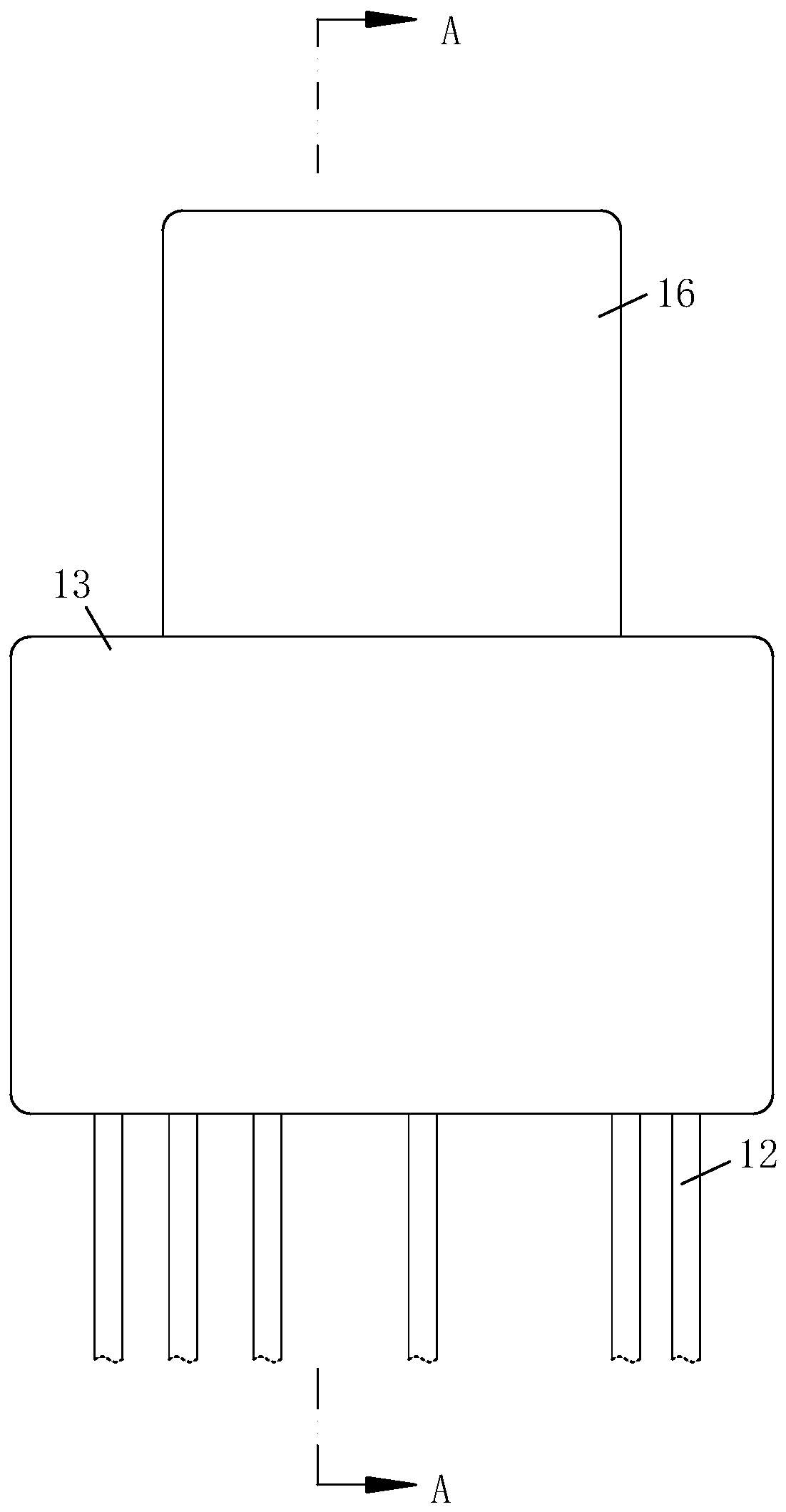

Non-invasive blood-sugar detecting instrument based on conservation of energy

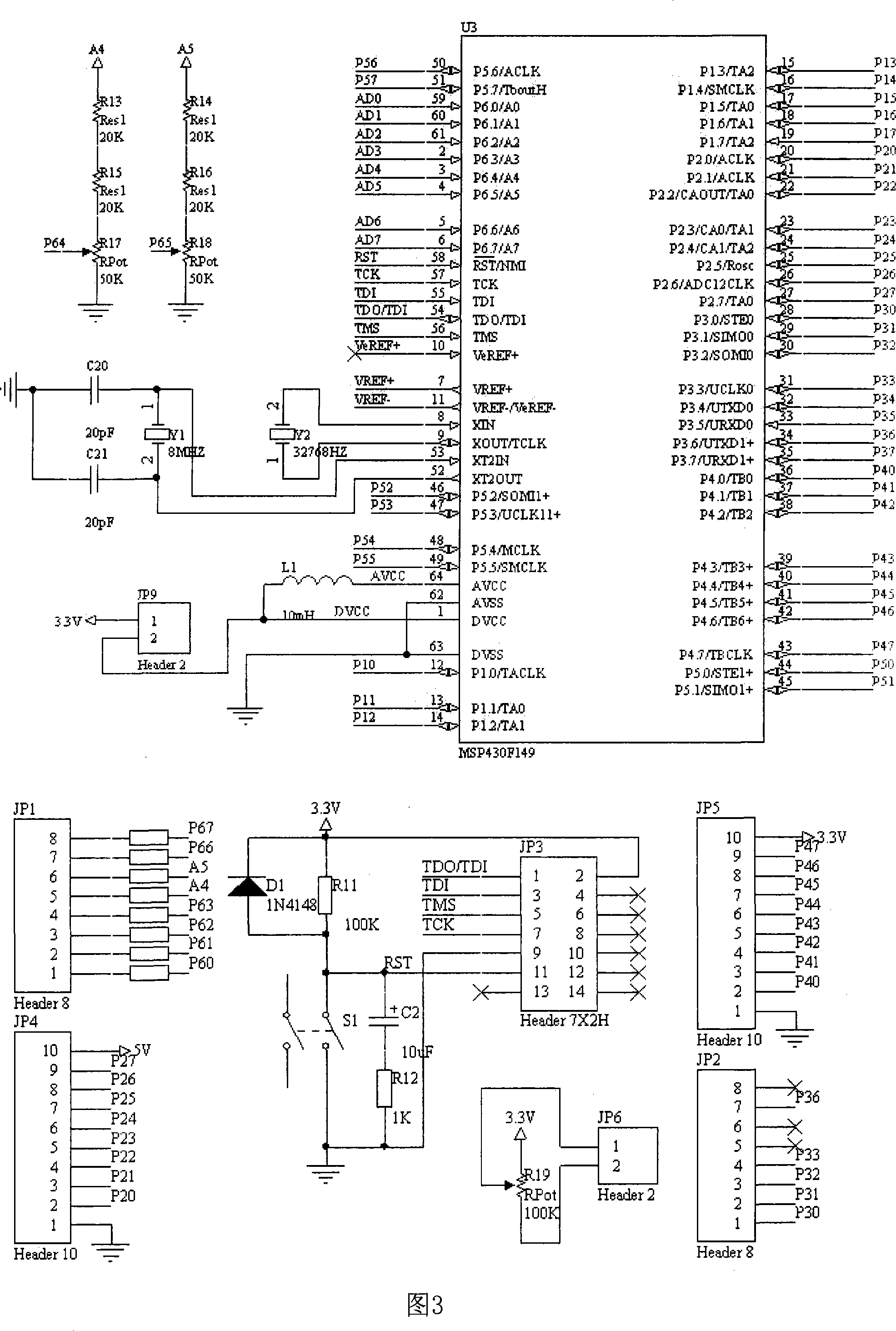

The present invention discloses a noninvasive blood glucose detection instrument basing on the energy conservation principle, which includes a blood glucose detection sensor, a signal processing circuit, a simulation filter circuit, an amplifying circuit, an A / D converter, a communication circuit, a display, a single chip microcomputer, a personal computer and a blood oxygen detection module. The blood glucose detection sensor, the signal processing circuit, the simulation filter circuit, the amplifying circuit and the A / D converter are connected successively in series. The blood glucose detection instrument detects physiological quantity signals of a human body. The signals are pretreated by the signal processing circuit, the simulation filter circuit and the amplifying circuit and are converted into digital signals by the A / D converter to be transmitted to the single chip microcomputer. Then, the digital signals are transmitted to the personal computer through a communication circuit. The personal computer processes the detected data, finishes the calculation of the blood glucose concentration and displays the calculation results. Through the parameters of the detections of the convection, the radiation and the heat evaporation dissipating capacity of finger surfaces, the blood flow and the blood oxygen saturation of local tissues, etc., the present invention realizes the blood glucose fast detection, which has the advantages of painless performance, disinfection and simple and rapid performances.

Owner:CENT SOUTH UNIV

Enteromorpha fermented beverage and production technique thereof

InactiveCN103584247ANo precipitationNo stratificationMulti-step food processesFood ingredient functionsBiotechnologyOff-flavour

The invention discloses a novel algae fermented beverage based on comprehensive utilization of marine green tide algae enteromorpha suddenly gathered, satisfies the demands of people to a healthy, nutritious and delicious beverage, and develops an effective way for comprehensively using the enteromorpha resource. The enteromorpha fermented beverage is fine and smooth, uniform, has no precipitate and no layer, is light green in color, has full-bodied enteromorpha aroma and fermented aroma, is sour and sweet, palatable, has no fishy smell and other peculiar smell, total sugar content of products is not lower than 10% and total acid content is between 0.65% to 0.70%, the beverage has the following advantages: (1) the fermented beverage uses enteromorpha as a fermentation matrix; the enteromorpha is rich in nutritive substances such as carbohydrate, protein, crude fiber, mineral substances, fat, vitamin and the like, so that the trophism and the functionality of the fermented beverage are improved; (2) desalination, color protection and deodorization are performed on the enteromorpha, so that the active nutritive substances in the enteromorpha and the fresh algae smell of the enteromorpha are retained, and the product palatability is improved; (3) raw materials of products are added with cane sugar, honey and sodium benzoate, so that the fermented beverage is sour and sweet and palatable, has no fishy smell and other peculiar smell.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

High-speed capping machine for high caps

ActiveCN113548614AImprove capping efficiencyMeet the needs of modern productionClosing machinesFlanged caps applicationMachineIndustrial engineering

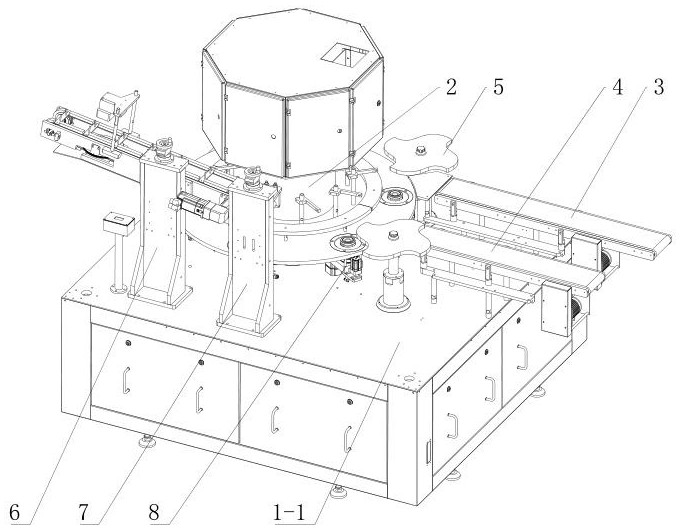

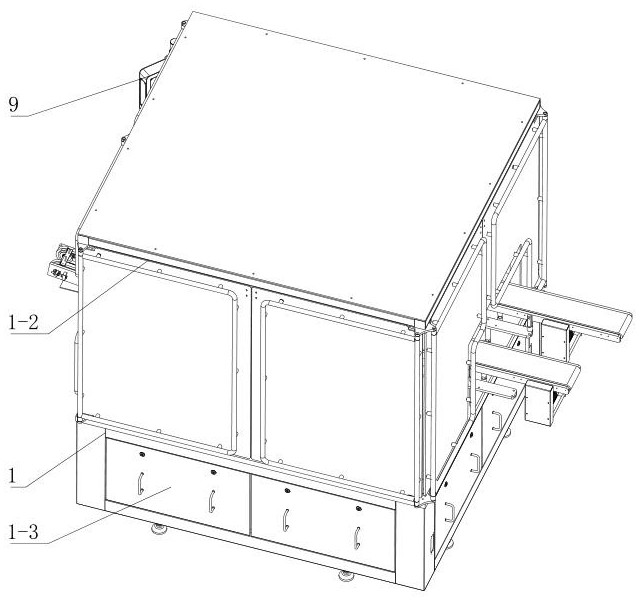

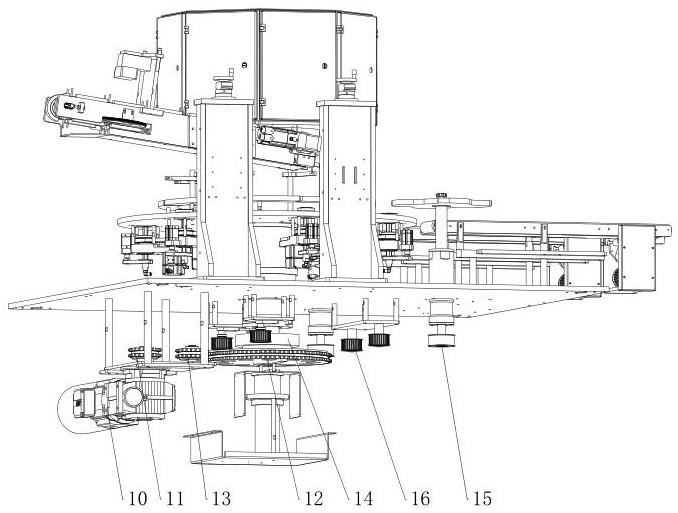

The invention relates to the technical field of canning equipment, in particular to a high-speed capping machine for high caps. The high-speed capping machine is provided with a rack, a rotating part, an inlet net chain part, an outlet net chain part, a star wheel part, a cap feeding part, a cap pressing part, a tank body positioning part and a control part, and the control part is arranged on the rack and electrically connected with the rotating part, the inlet net chain part, the outlet net chain part, the star wheel part, the cap feeding part, the cap pressing part and the tank body positioning part, so that an integral control effect is achieved. The cap pressing efficiency is improved, the cap pressing speed reaches 100 pieces or above per minute, and the requirement of modern production is met. Cap feeding operation can be conducted on tank bodies with different heights through the cap feeding lifting part, the efficiency is high, and full automation is achieved. A visual camera can monitor whether the cap feeding work is normally carried out or not in real time, cap neglected loading is prevented, and it is ensured that the positions of the caps are correct when the caps are conveyed to the next procedure.

Owner:CHANGZHOU JOYO AUTOMATION EQUIP CO LTD

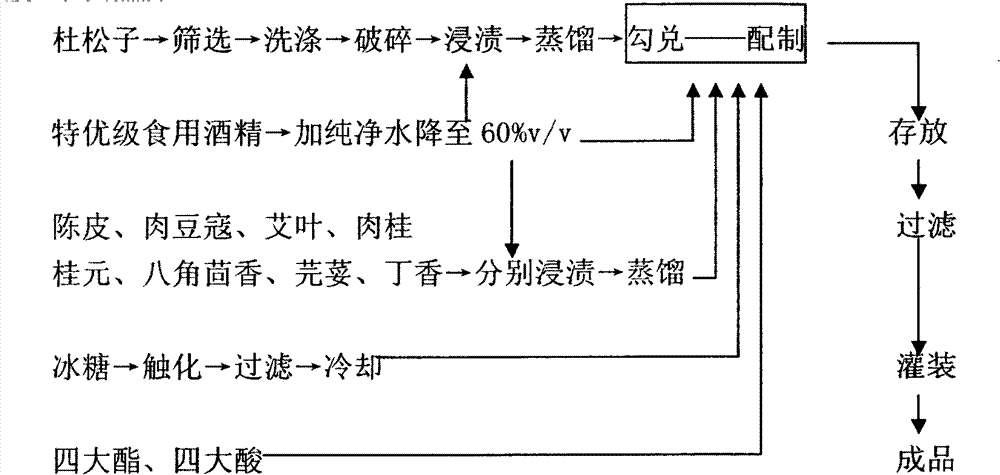

Mixed liquor with flavor of white spirit and aromatic aftertaste of gin (foreign wine)

The invention discloses mixed liquor with flavor of a white spirit and aromatic aftertaste of gin (a foreign wine). The traditional white spirit or edible alcohol is adopted as a liquor base, and components of ester and acid in the traditional white spirit are selected or added. Methanol, fusel oil and aldehyde substances are removed or reduced, juniper berries or extracting solution thereof is added to serve as a main aroma source, and aromatic Chinese herbal medicines are taken as an auxiliary aroma source. The mixed liquor is prepared by the following steps of: impregnating and distilling;flavoring and blending; and storing and filtering. A novel white spirit (mixed liquor) with the basic flavor of the traditional white and the aromatic aftertaste of the gin is obtained.

Owner:李良

Health-care herbal tea prepared from Chinese herbal medicines including gynostemma pentaphylla

The invention discloses health-care herbal tea prepared from gynostemma pentaphylla, which has the effects of clearing away heat and toxic materials, clearing damp, relieving summer heat and decreasing internal heat of the traditional herbal tea, and has the effects of resisting fatigue, promoting metabolism, enhancing immunity, resisting aging, reducing blood fat, protecting liver and benefiting gallbladder, and tonifying liver and kidney of Chinese herbal medicines such as gynostemma pentaphylla, lycium barbarum, mulberry and astragalus membranaceus. The health-care herbal tea comprises the following Chinese herbal medicines in parts by weight: 30-40 parts of gynostemma pentaphylla, 10-20 parts of honeysuckle, 10-20 parts of liquorice, 5-10 parts of chrysanthemum, 10-20 parts of lycium barbarum, 8-12 parts of mulberry, 3-5 parts of astragalus membranaceus, 2-5 parts of cordate houttuynia, 5-10 parts of buzhaye, 2-5 parts of plantain and 1-3 parts of rhizoma polygonati. The health-care herbal tea adopts an ultrasonic assisted secondary extraction process, the extraction rate of active substrates is high, the product palatability is high, and sucrose is replaced by isomaltose hypgather, so that the health-care herbal tea product is suitable for all the crowd including diabetic patients, the extraction rate in the production process is high, the requirement on equipment is relatively low, and large-scale industrial production is facilitated.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Display panel and display device

ActiveCN111370461AEffective lighting conditionsReduce in quantityStatic indicating devicesSolid-state devicesComputer hardwareDisplay device

The invention discloses a display panel and a display device. The display panel comprises a first display module and a second display module. The back of the first display module is provided with an electronic element area used for installing an optical sensor. The first display module comprises a display area and a light-transmitting area adjacent to the display area, and the light-transmitting area and the electronic element area are correspondingly arranged. The second display module is arranged in the light-transmitting area and is adjacent to the display area of the first display module.The second display module comprises a plurality of pixel areas which are distributed in an array. Each pixel area is provided with a self-luminous micro light-emitting unit, and any two adjacent microlight-emitting units are arranged at intervals. According to the invention, a comprehensive display function can be realized on the basis of providing a light transmission condition for the electronic component area.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

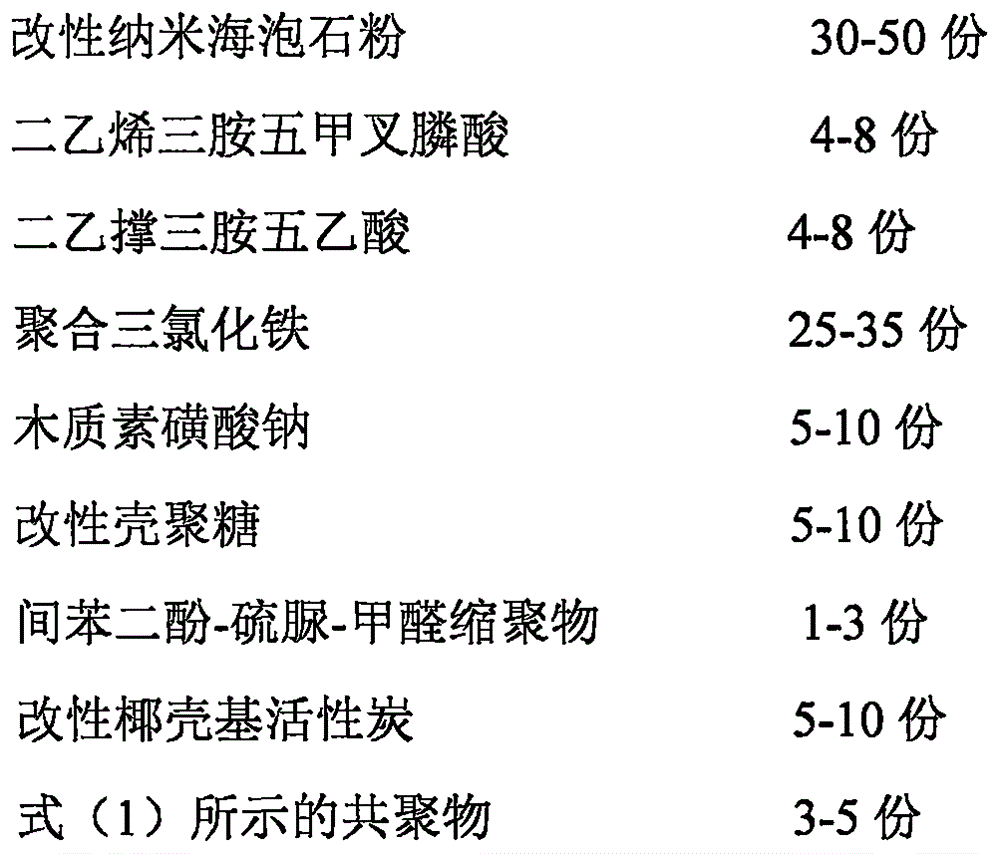

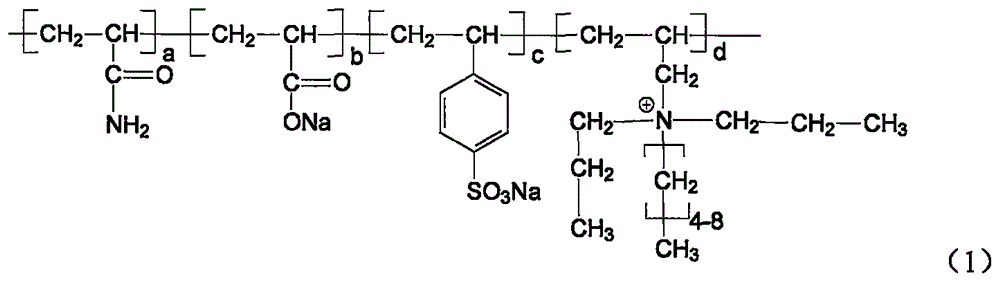

Sewage treating agent capable of realizing effective treatment of sewage and preparation method thereof

InactiveCN106396042AEasy to handleHigh decontamination efficiencyWater/sewage treatment by flocculation/precipitationThioureaCopolymer

The invention provides a high-efficiency sewage treating agent, comprising modified nanometer meerschaum powder, polyferric silicate sulfate, diethylenetriamine pentaacetate, polyferric chloride, sodium lignosulfonate, modified chitosan, resorcinol-thiourea-formaldehyde polycondensate, modified coconut shell-based active carbon and a copolymer as shown in a formula (I) which is defined in the specification. Through synergism of the above components of the sewage treating agent, the sewage treating agent has excellent comprehensive sewage treating capacity.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

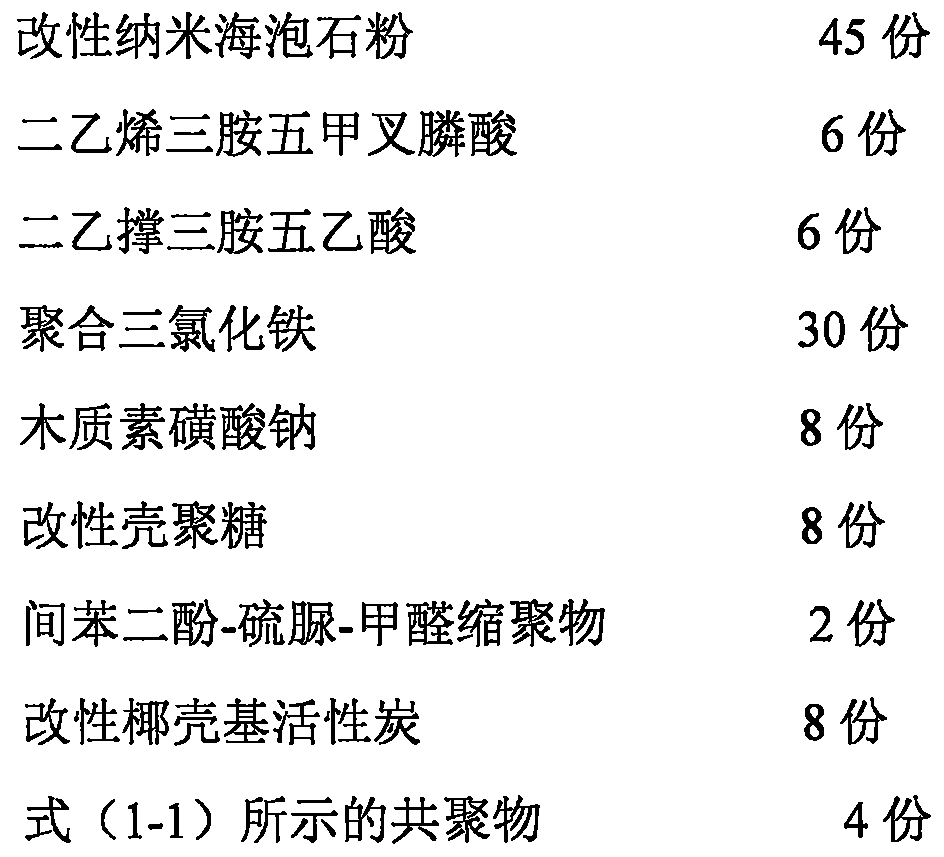

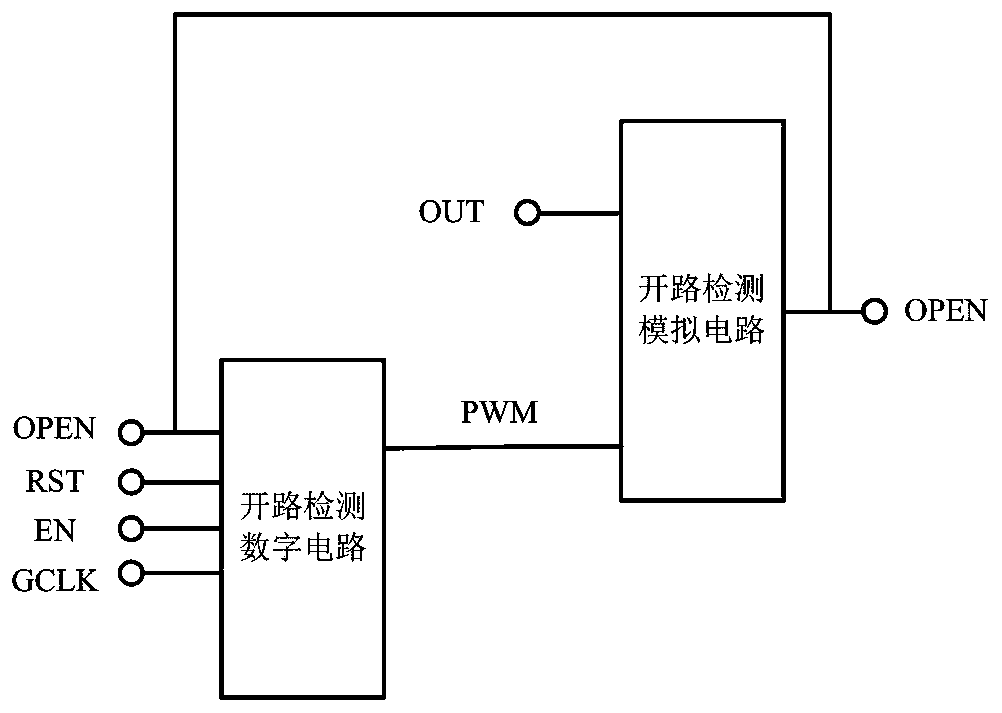

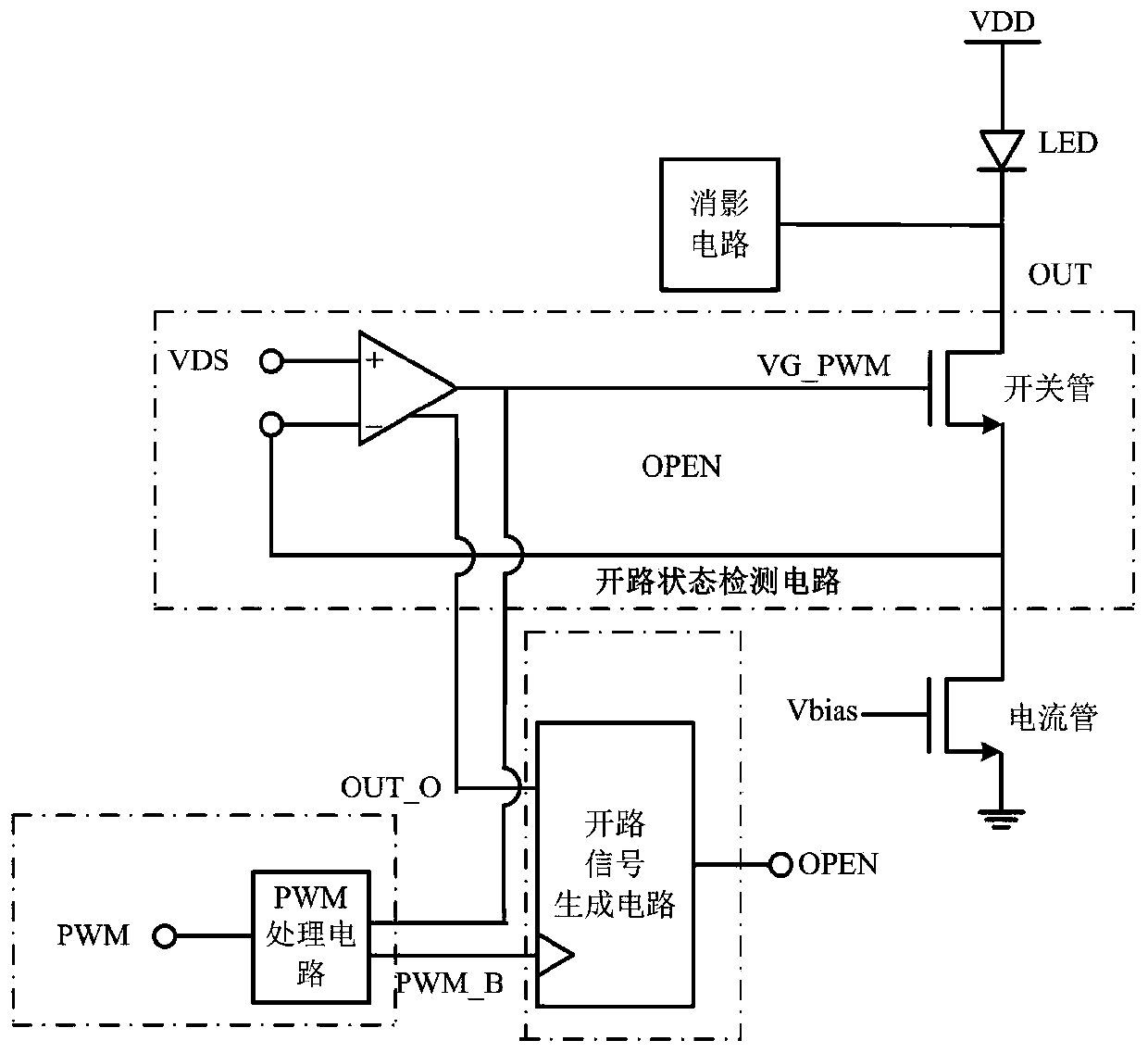

open circuit detection circuit for an LED driving chip

ActiveCN109801576AEasy to detectReduce complexityElectrical apparatusStatic indicating devicesLED displayLED lamp

The invention discloses an LED driving chip open circuit detection circuit, and belongs to the technical field of circuits. The LED driving chip open circuit detection circuit comprises an open circuit detection digital circuit and an open circuit detection analog circuit. And the open circuit detection digital circuit records the position information of the open circuit LED lamp at the rising edge of the clock GCLK according to the input enable signal EN, the input reset signal RST and the input open circuit signal OPEN, processes the output PWM, and shields the output display of the open circuit LED at the next sub-period. The open circuit detection analog circuit judges whether the working state of the open circuit detection analog circuit is open or not according to the OUT signal of the LED lamp, generates an open circuit signal OPEN and transmits the open circuit signal OPEN to the open circuit detection digital circuit, and meanwhile resets the OPEN signal judged to be in the open circuit state. According to the invention, the open circuit cross problem of the small-spacing LED display screen is solved, the detection complexity is reduced, the detection precision is improved, the circuit power consumption is reduced, the circuit area is reduced, and the detection method is successfully applied.

Owner:58TH RES INST OF CETC

Method for cultivating spring tea

InactiveCN1342396AIncrease the average yield per muNo impact on qualityBiocideAnimal repellantsRare earthTea garden

A method for cultivating spring tea leaves includes usch steps as closing tea garden from November 15 to 25, trimming in December 10, irrigation, applying fertilizer from October 20 to 30, and spraying the solution of rare-earth nitrate from Decomber 20 to 30. Its advantages are high quality, proleptic leaves of spring tea, and greatly raised output perunit area.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

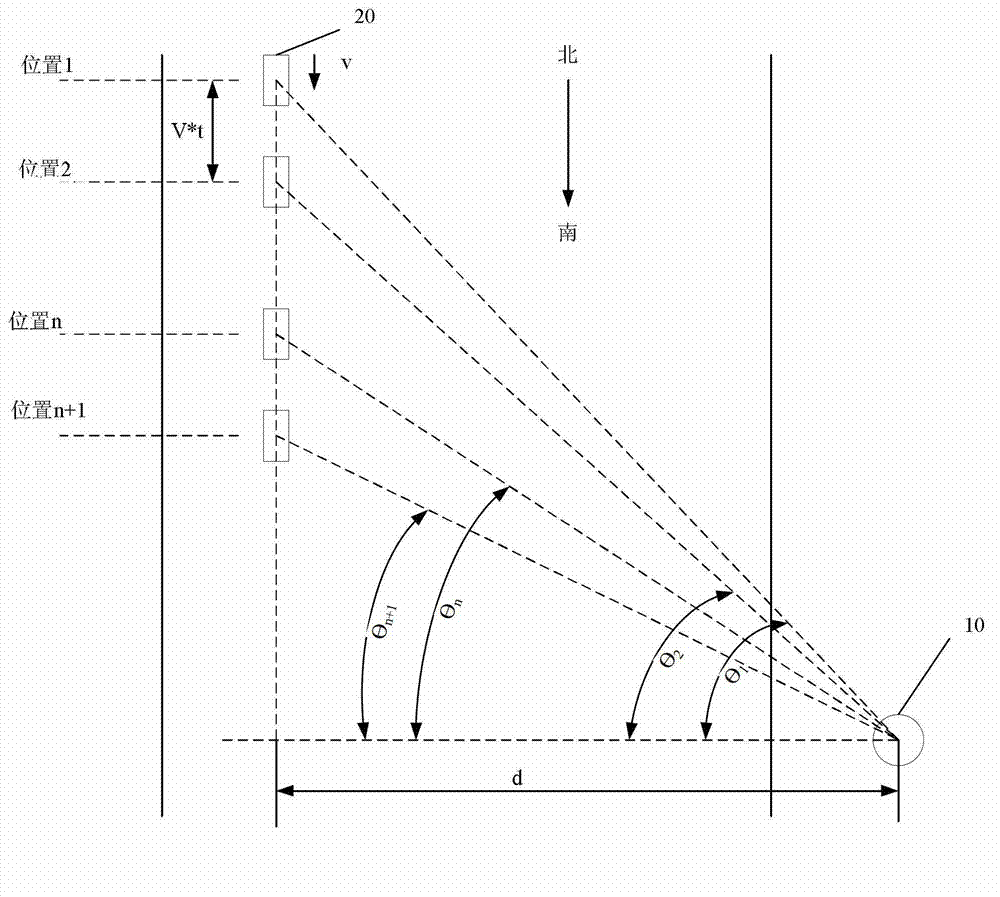

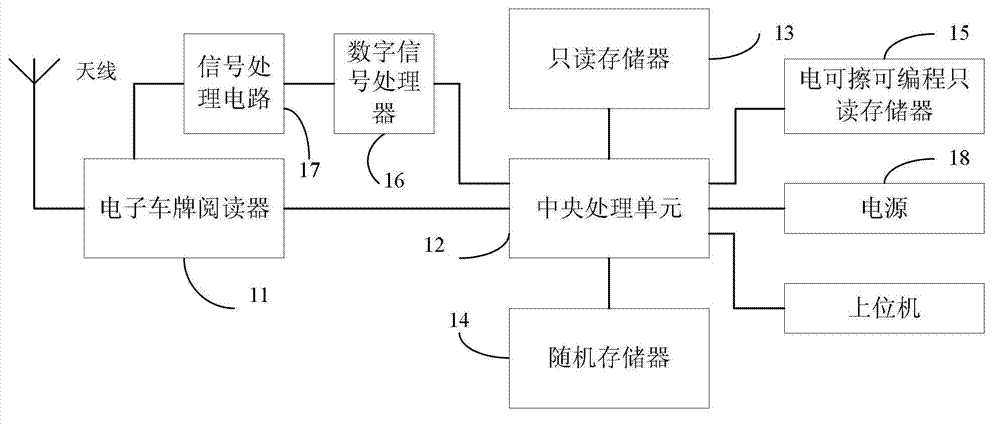

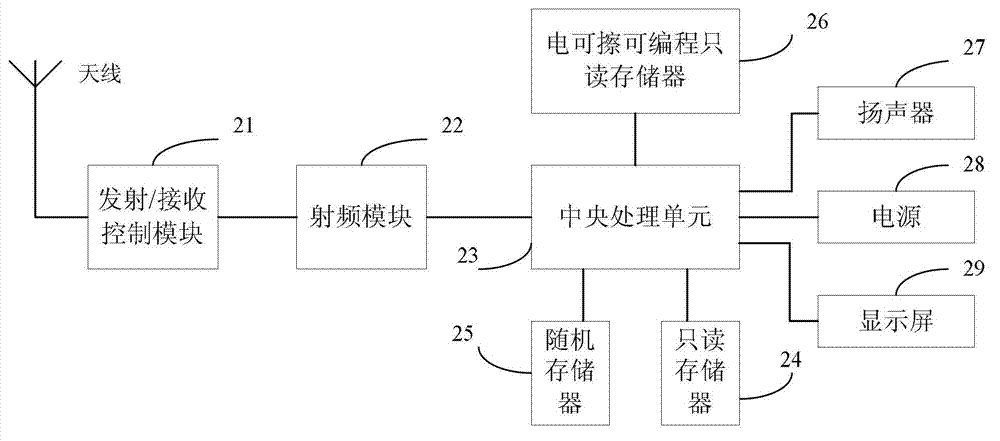

Vehicle management method and system based on radio frequency

InactiveCN102855761ANo detectionAvoid positioningRoad vehicles traffic controlSensing record carriersPasswordRadio frequency

The invention discloses a vehicle management method based on radio frequency. The vehicle management method comprises the steps as follows: sending a reading command to an electronic license plate through a monitoring device; transmitting a verifying password and an electronic license plate label to the monitoring device after the electronic license plate receives the reading command; and transmitting the reading password to the electronic license plate through the monitoring device after receiving the verifying password and the electronic license plate label and finishing the verification; receiving the reading password via the electronic license plate, and continuously transmitting information at equal time intervals after passing the verification; and calculating the speed and the position of a vehicle through the monitoring device based on the information sent by the electronic license plate. According to the invention, the monitoring device includes an electronic license plate reader, therefore, the information of the electronic license plate can be read in real time, and the detection by an electronic dog is prevented; with the adoption of the method and the system, the vehicle violating the law can be quickly found out; the vehicle can be positioned while the speed is measured, the phenomenon that the emergency vehicle lane is occupied can be avoided, and a truck and a motor bus which occupy the lane and violate the laws can be identified.

Owner:庞成鑫

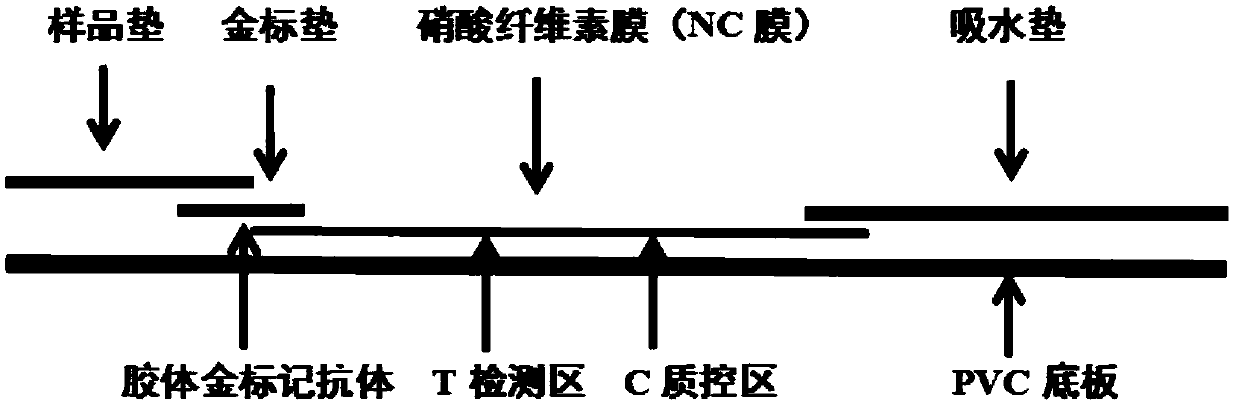

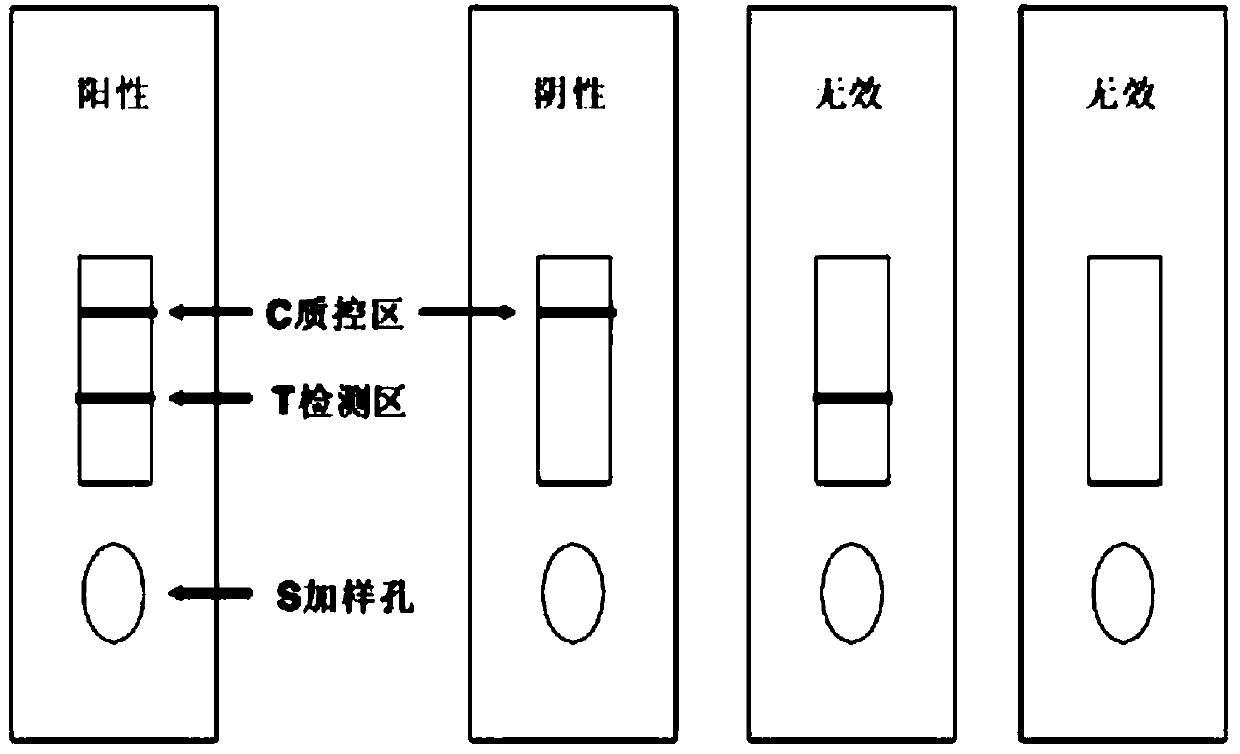

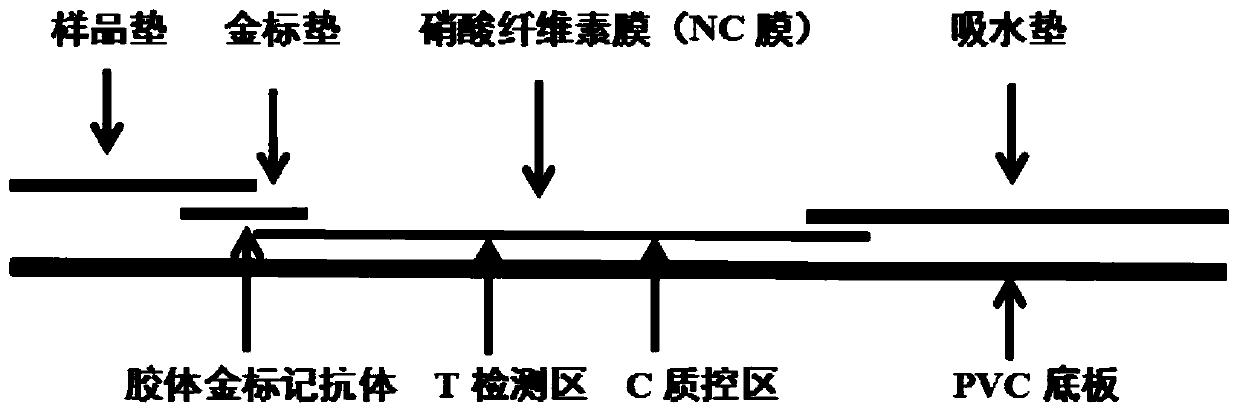

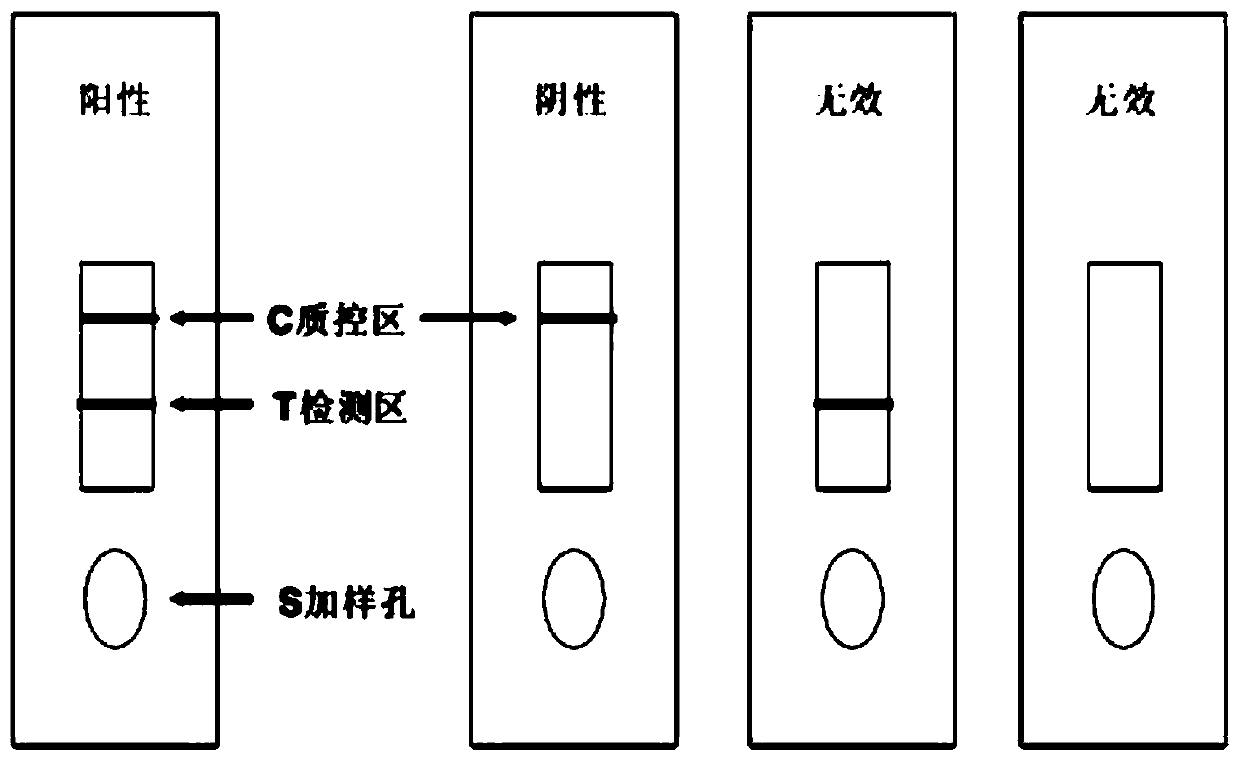

Colloidal gold immunological test paper for detecting paeniBacillus larvae of bee, preparation and applications thereof

InactiveCN107907680AStrong specificityGood sensitivityBiological material analysisPolyclonal antibodiesGold standard

The invention discloses colloidal gold immunological test paper for detecting the paeniBacillus larvae of bee, preparation and applications thereof. The colloidal gold immunological test paper specifically comprises a sample pad, a gold standard pad, a nitrocellulose membrane, a water absorption pad and a bottom plate, wherein the gold standard pad contains colloidal gold-labeled PLMP protein polyclonal antibody, and the nitrocellulose membrane has a PLMP protein polyclonal antibody pre-coated detection line and a goat anti-rabbit IgG solution pre-coated quality control line. According to thepresent invention, the prepared colloidal gold immunological test paper has advantages of strong specificity, good sensitivity, good detection repeatability and stable performance, and provides the negative results for negative bacteria liquids, wherein the specificity can be 100%, the minimum detection concentrations of the bacterial liquid and the positive sample of the paeniBacillus larvae respectively are 10<5> CFU / mL and 10<6> CFU / mL, and the preservation period of the colloidal gold immunological test paper is 3 months.

Owner:COMPREHENSIVE TECH SERVICE CENT YILI ENTRY EXIT INSPECTION & QUARANTINE BUREAU +2

Environmentally-friendly hand sanitizer and preparation method thereof

InactiveCN102429833BDecontaminationWith cleanCosmetic preparationsToilet preparationsOLEAMIDOPROPYL BETAINEGlycerol

The invention relates provides an environmentally-friendly hand sanitizer and a preparation method thereof. The raw materials for the hand sanitizer comprise alkyl glycoside, coco oil amide propyl lycine, sodium fatty acid methyl ester sulfonate, coconut oil amide propyl amine oxide, glycerol, sodium citrate, lactic acid, hydroxypropyl cellulose, sodium chloride,1,2-benzoisothiazolizone-3-ketone, essence and deionized water. In the hand sanitizer and the preparation method thereof provided by the invention, sodium fatty acid methyl ester sulfonate with good detergency, calcium soap dispersibility, emulsibility, thickening property, hard water resistance, no toxicity and complete biodegradability is adopted, and amphoteric surfactants namely coconut oil amide propyl lycine and coconut oil amide propyl amine oxide with rich foam, mildness and low irritation are matched with alkyl glycoside to generate synergism, thus the hand sanitizer can defecate and clean hands and has the efficacy of mild protection on skin; and glycerol and lactic acid are adopted to improve moisture retention capability of the system, thus skin is not tight after the hand sanitizer is used.

Owner:北京绿伞科技股份有限公司

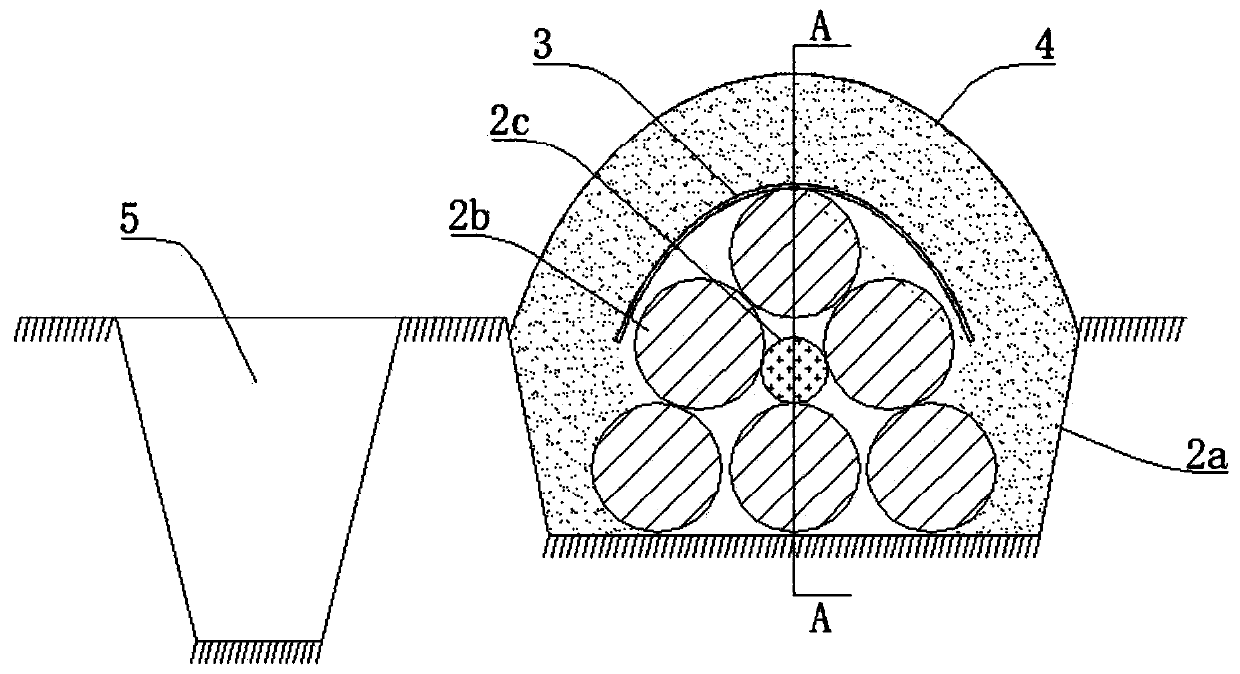

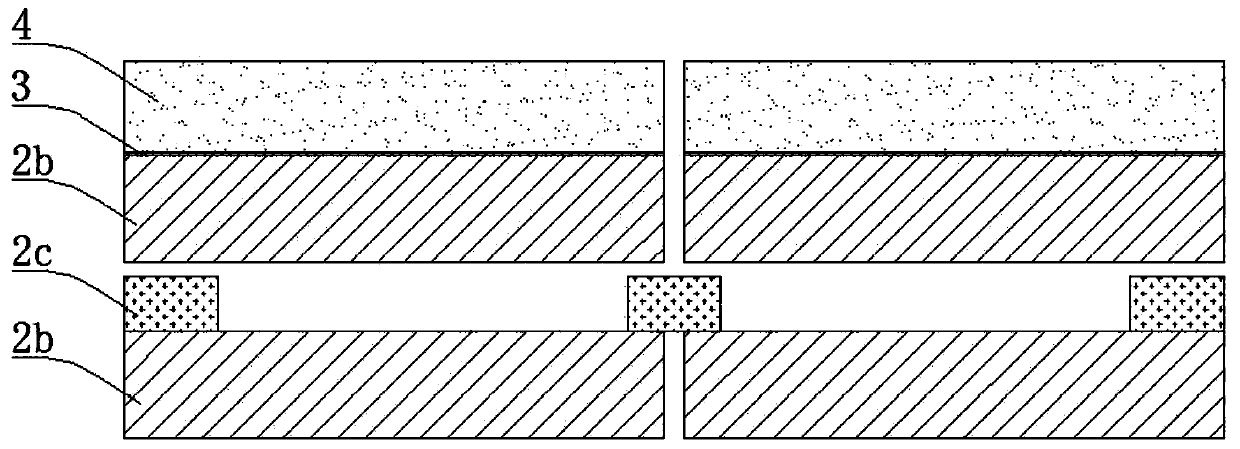

Poria cultivation and inoculation kiln and poria cultivation method

InactiveCN110604006APromote growthNo detectionCultivating equipmentsPlant protectionEngineeringHypha

The invention discloses a poria cultivation and inoculation kiln which comprises at least two rows of kiln bodies 1. Each row of kiln bodies 1 comprises at least two unit kilns, and each unit kiln comprises a soil ditch 2a, a charging barrel pile 2b and a strain block 2c, wherein the soil ditch 2a is formed in a soil body, the charging barrel pile 2b is arranged along the extension direction of the soil ditch 2a, and the strain block 2c is arranged in the middle of the charging barrel pile 2b. The charging barrel piles 2b are stacked into a triangular prism, the top of each charging barrel pile 2b with the strain block 2c or the top of each whole charging barrel pile 2b is covered with films 3, and the peripheries of the charging barrel piles 2b are filled with soil layers 4. The poria cultivation method includes the steps: preparing charging barrels; selecting and preparing lands; opening the kiln, performing inoculation and finishing inoculation in an inoculation kiln structure according to any claim of 1-4 claims; harvesting matured poria 10-14 months after inoculation; controlling diseases and pests. According to the poria cultivation and inoculation kiln and the poria cultivation method, poria mycelia more easily grow by the aid of the inoculation kiln, yield is high, heavy metal content is within a hygienic index range, no pathogenic bacteria are detected, and the contentof poria ethanol-soluble extractives is higher than or equal to 2.5%.

Owner:广元市佳华中药材种植有限公司

Emulsification equilibrium fatty powder product applicable to fur-bearing animals, and preparation method of emulsification equilibrium fatty powder product

InactiveCN108077586AHigh energyPromote absorptionFood processingAnimal feeding stuffWeight gainingAnimal science

The invention relates to an emulsification equilibrium fatty powder product applicable to fur-bearing animals, and a preparation method of the emulsification equilibrium fatty powder product, belonging to the field of feeding of the fur-bearing animals. In order to overcome the technical defects that the fur-bearing animals slowly grow in a growth process and are low in nutrient utilization rate,the invention provides emulsification equilibrium fatty powder applicable to the fur-bearing animals, and a preparation method of the emulsification equilibrium fatty powder; the emulsification equilibrium fatty powder is prepared from the following nutrient substances: mutton fat, puffed soybean meal powder, corn flour, walnut oil and the like, has the characteristics of being high in energy, easy to absorb, high in immunity and good in palatability, and being capable of promoting growth, can remarkably increase the average daily weight gain and nutrient digestibility of the fur-bearing animals, and obviously reduces a ratio of feed to gain, thus having a very good application prospect.

Owner:SHANDONG BINZHOU ANIMAL SCI & VETERINARY MEDICINE ACADEMY

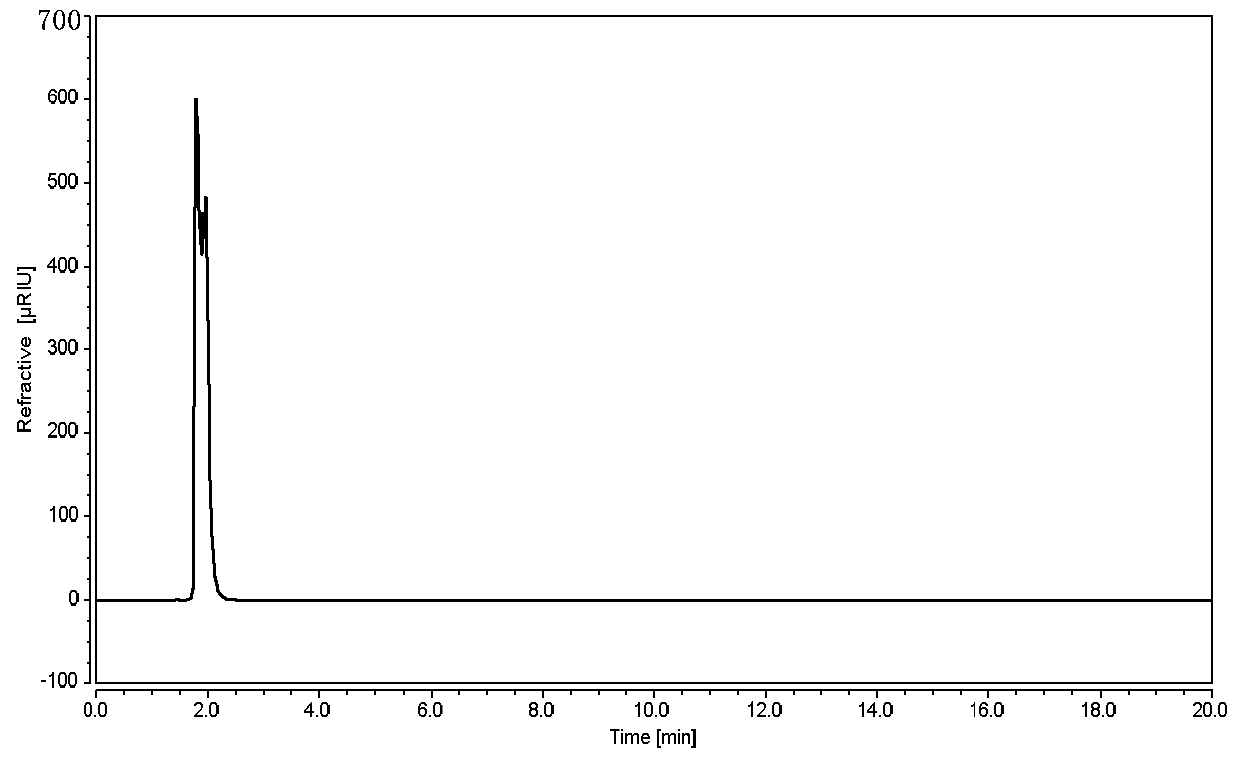

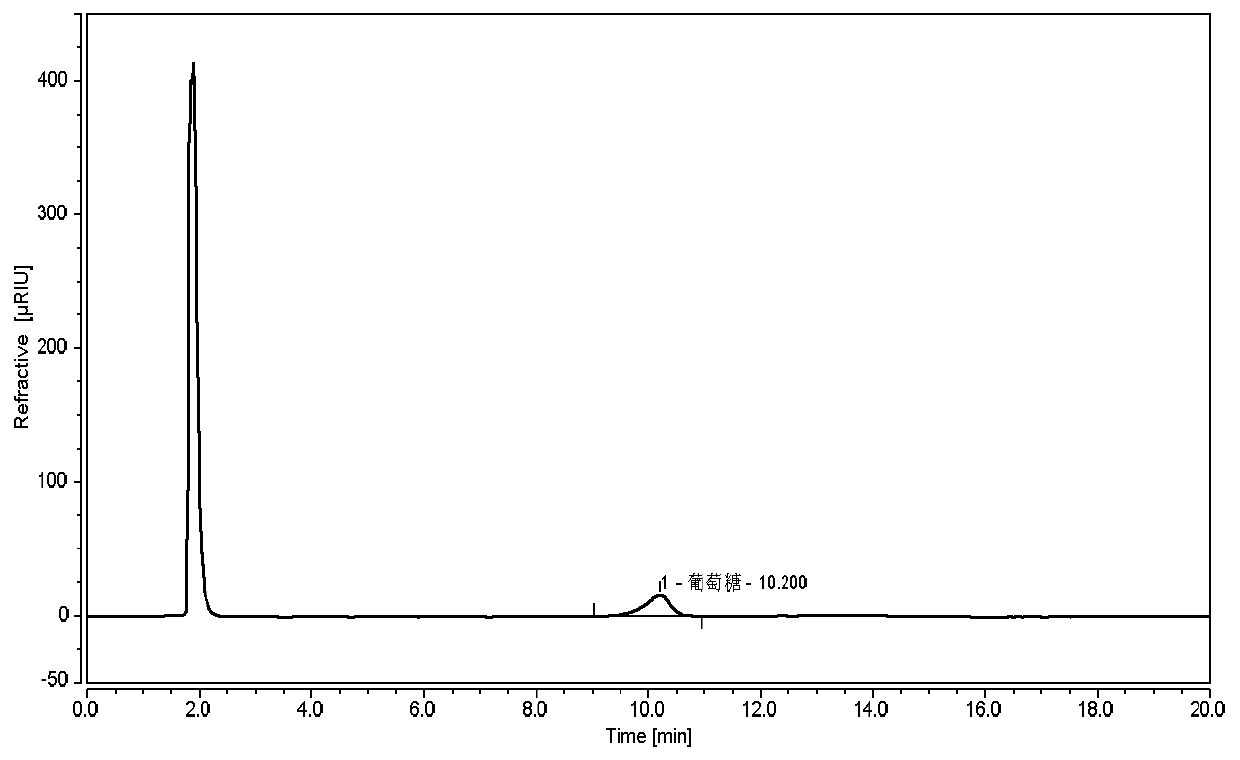

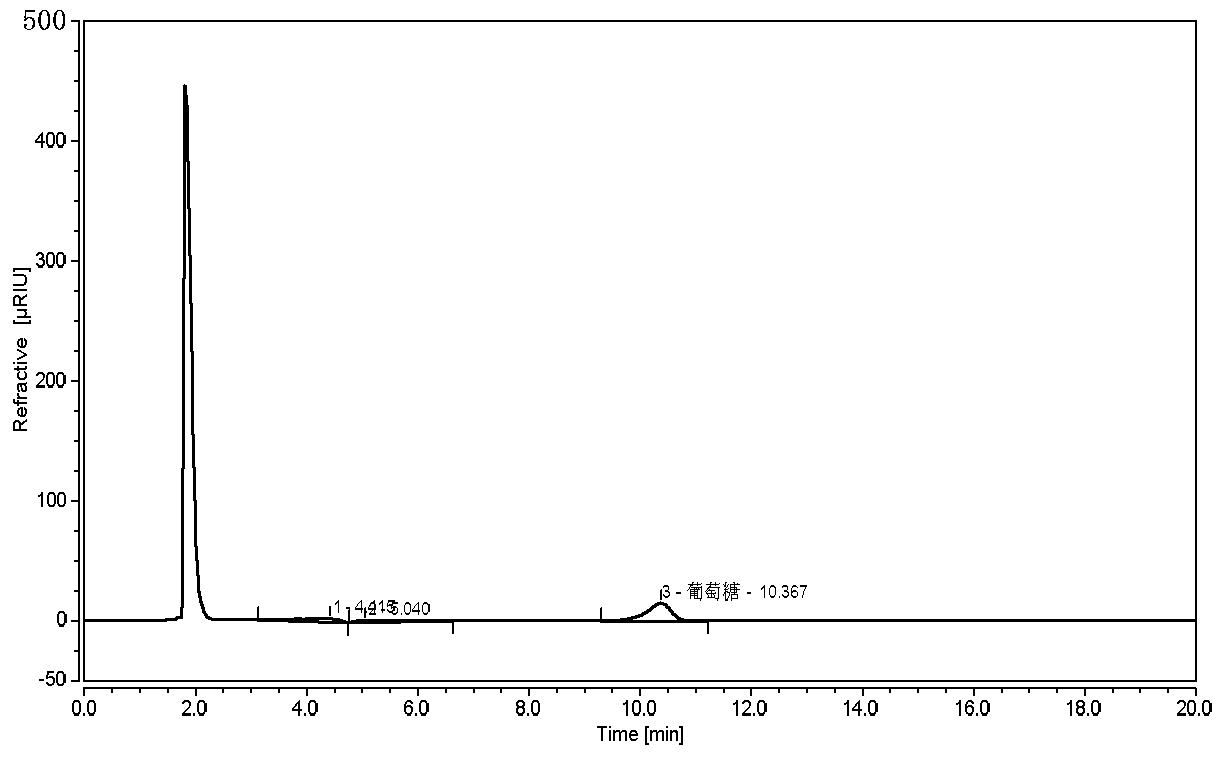

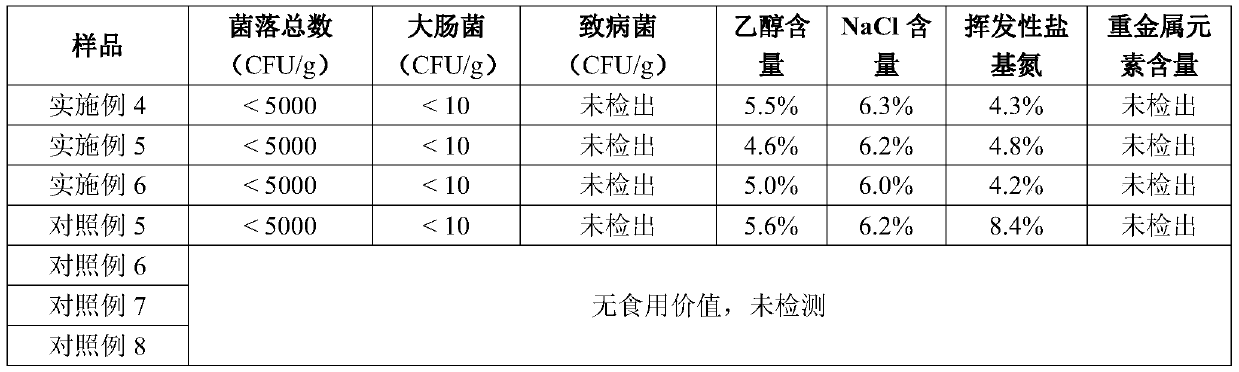

Method for determining content of glucose in compound electrolyte glucose injection

InactiveCN110531003AEfficient separationEfficient detectionComponent separationConcentrations glucoseTest sample

The invention discloses a method for determining the content of glucose in a compound electrolyte glucose injection. The method comprises the following steps of (1) preparing a reference substance solution, namely weighing a glucose standard substance, adding ultrapure water to dissolve, dilute and uniformly shake to obtain the reference substance solution, (2) preparing a test sample solution, namely measuring and taking the compound electrolyte glucose injection, adding ultrapure water to dilute and shake uniformly to obtain the test sample solution, wherein the ratio of the concentration ofglucose in the reference substance solution in the step (1) to the concentration of glucose in the test sample solution is 1 to 1, and (3) detecting and reading the chromatographic peak areas of thereference substance solution and the test sample solution through a high-performance liquid chromatographic instrument and calculating the glucose concentration by combining the concentration of the reference substance solution and adopting an external standard method. The method has the advantages of high measurement precision and simple and convenient operation.

Owner:CHINA PHARM UNIV

Colloidal gold immunoassay paper for detecting bacillus in bee larvae and its preparation and application

InactiveCN107907680BStrong specificityIncreased sensitivityBiological material analysisCellulosePaenibacillus validus

The invention discloses colloidal gold immunological test paper for detecting the paeniBacillus larvae of bee, preparation and applications thereof. The colloidal gold immunological test paper specifically comprises a sample pad, a gold standard pad, a nitrocellulose membrane, a water absorption pad and a bottom plate, wherein the gold standard pad contains colloidal gold-labeled PLMP protein polyclonal antibody, and the nitrocellulose membrane has a PLMP protein polyclonal antibody pre-coated detection line and a goat anti-rabbit IgG solution pre-coated quality control line. According to thepresent invention, the prepared colloidal gold immunological test paper has advantages of strong specificity, good sensitivity, good detection repeatability and stable performance, and provides the negative results for negative bacteria liquids, wherein the specificity can be 100%, the minimum detection concentrations of the bacterial liquid and the positive sample of the paeniBacillus larvae respectively are 10<5> CFU / mL and 10<6> CFU / mL, and the preservation period of the colloidal gold immunological test paper is 3 months.

Owner:COMPREHENSIVE TECH SERVICE CENT YILI ENTRY EXIT INSPECTION & QUARANTINE BUREAU +2

Microorganism sensor

PendingCN110716004AReduce storage difficultyExpand the scope of detectionChemical analysis using catalysisBioreactor/fermenter combinationsMicroorganismEngineering

The invention belongs to the technical field of microorganism detection, and particularly relates to a microorganism sensor. The microorganism sensor comprises a shell, a signal identification element, a signal receiving sheet, an electric conductive substrate, an insulating substrate, a detection electrode, a reaction layer, an injection needle cylinder, a needle tube fixing groove, a piston rod,an extrusion rotary knob, a detection tentacle, an electric signal box, an injection port and a shunt tube; a signal identification element is fixedly connected inside the shell; the signal receivingelement is arranged at one end of the signal identification element; the needle tube fixing groove is formed in the middle of the shell; the injection needle cylinder is used for independently storing the microorganism or microorganism derivatives for detection, and is used for independently injecting into the microorganism sensor to use, the used microorganism or microorganism derivatives can beindependently stored, the storage difficulty is reduced, and the different microorganisms or microorganism derivatives can be used for detection, so that the microorganism sensor is not the disposable consumables.

Owner:吴彬

Mixed liquor with flavor of white spirit and aromatic aftertaste of gin (foreign wine)

The invention discloses mixed liquor with flavor of a white spirit and aromatic aftertaste of gin (a foreign wine). The traditional white spirit or edible alcohol is adopted as a liquor base, and components of ester and acid in the traditional white spirit are selected or added. Methanol, fusel oil and aldehyde substances are removed or reduced, juniper berries or extracting solution thereof is added to serve as a main aroma source, and aromatic Chinese herbal medicines are taken as an auxiliary aroma source. The mixed liquor is prepared by the following steps of: impregnating and distilling; flavoring and blending; and storing and filtering. A novel white spirit (mixed liquor) with the basic flavor of the traditional white and the aromatic aftertaste of the gin is obtained.

Owner:李良

A method for regenerating carbonaceous waste from an aluminum electrolytic cell into a raw material for the production of calcium carbide

ActiveCN107159688BHigh carbon contentHigh removal recoverySolid waste disposalCalcium carbideDesorptionActive agent

The invention provides a method for regenerating aluminum electrolysis cell carbon-base waste into a raw material for calcium carbide production. The method comprises the following steps that (1) the aluminum electrolysis cell carbon-base waste is broken; (2) the broken aluminum electrolysis cell carbon-base waste is placed into a leaching pond, a stirring leaching device or a rolling mixing leaching device, water is added firstly, then caustic soda or a solution of the caustic soda, quick lime and a drastic oxidation active agent are added, oxidization leaching is conducted, filtering separating is conducted, an aluminum alkali solution and solid filter residues are obtained, and after the solid filter residues are washed with water and dried, activated carbon residues containing carbon and calcium fluoride are obtained; and (3) the activated carbon residues are placed into a rolling mixing machine, a hydrocarbon binder is added, or quick lime is further added, rolling mixing and forming are conducted, and the raw material for calcium carbide production is obtained. According to the method for regenerating the aluminum electrolysis cell carbon-base waste into the raw material for calcium carbide production, the obtained raw material for calcium carbide production is high in carbon content, low in impurity content and high in aluminum and alkali desorption recovering rate; the obtained raw material for calcium carbide production is applied to calcium carbide production, the yield is increased, the average power consumption of calcium carbide of per ton is reduced, the calcium carbide gas yield is increased, and no cyanide is detected; and the method is safe, simple, large in processing quantity and low in energy consumption and cost.

Owner:长沙紫宸科技开发有限公司

Apple juice and preparation method thereof

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

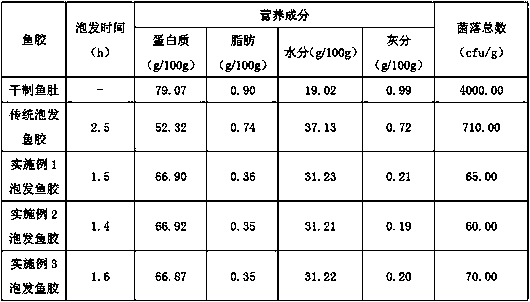

Method for assisting in fish glue soaking by combining ultrasonic waves with microwave vacuum frying

The invention discloses a method for assisting in fish glue soaking by combining ultrasonic waves with microwave vacuum frying. According to the method, microwaves are adopted for assisting in an oilsoaking process of the fish glue, ultrasonic waves are adopted for assisting in softening and oil removing processes, and the time, the temperature, the frequency and the power of the microwaves and the ultrasonic waves for assisting in soaking are controlled, so that the effects of shortening the soaking time, carrying out sterilization and improving the texture are achieved, and the quality of products is obviously improved. The method provided by the invention has the advantages of quick soaking and remarkable sterilization effect, can improve the texture of the fish glue, and can effectively reduce the loss of nutrient components in the soaking process.

Owner:FUJIAN AGRI & FORESTRY UNIV

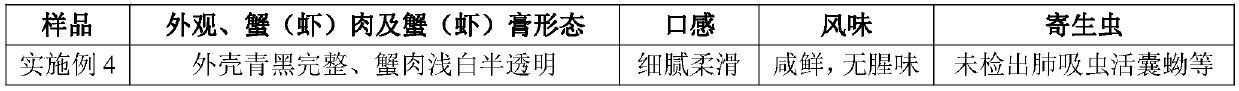

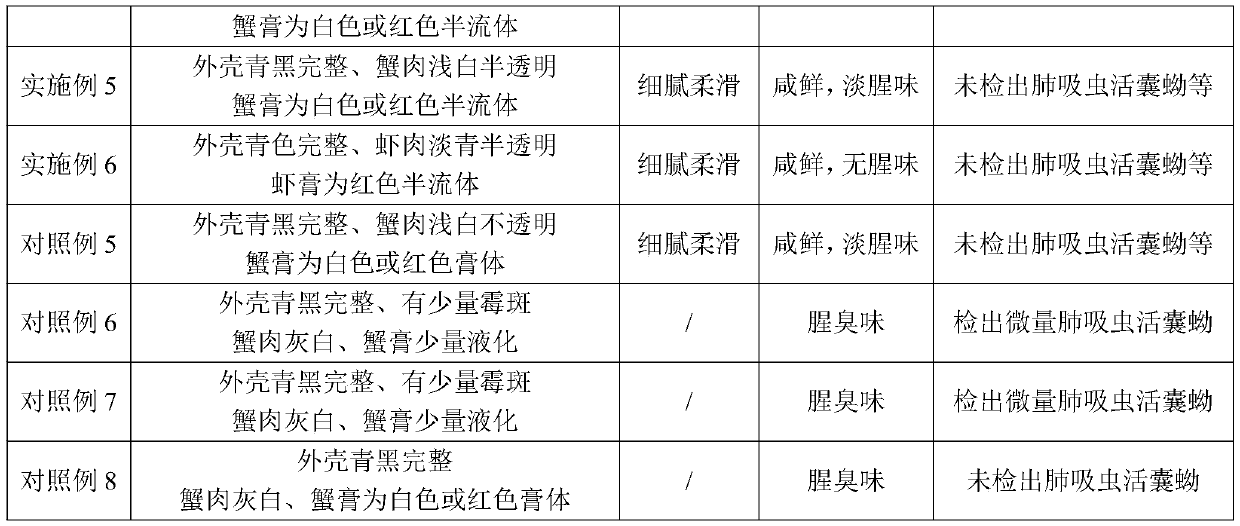

Liquor-saturated material as well as production method and use method thereof

The invention discloses a liquor-saturated material as well as a production method and a use method thereof. The production method comprises the steps: uniformly mixing cinnamon, anise, myrcia, Chinese prickly ash, clove, dried orange peel, onion sections, ginger slices and other spices with water, boiling with big fire, concentrating with small fire, quickly cooling, filtering, taking the filtrate, and mixing with yellow rice wine, light soy sauce, table salt, sugar, white spirit, bromelain, a papaya extract and the like. The preparation method of the liquor-saturated material provided by theinvention is simple and prone to mass production, raw material sources are wide, the cost is low, the shelf life is long and up to 18 months, the method is used for preparing drunken shrimps and drunken crabs. The obtained drunken river shrimp and drunken crab products are rich in nutrition, similar to fresh shrimps or fresh crabs in appearance, fresh, fragrant and tender in meat quality, uniquein flavor, detection of no pathogenic bacteria, parasites or other harmful elements, sanitary, safe, same in quality of many batches of products, long in storage life, convenient to store and transport, basically unchanged in appearance, taste and flavor after long-term storage, ready to eat and convenient to eat.

Owner:朱佶熠

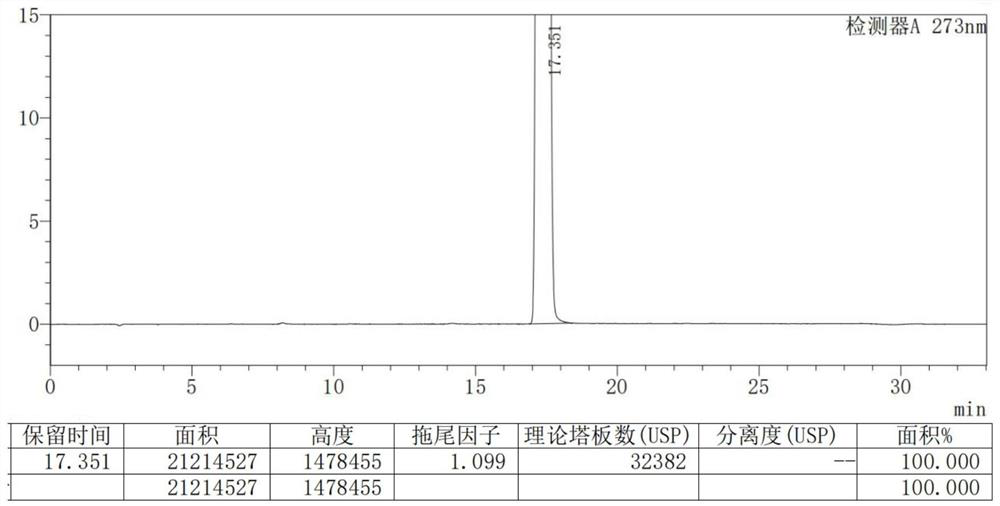

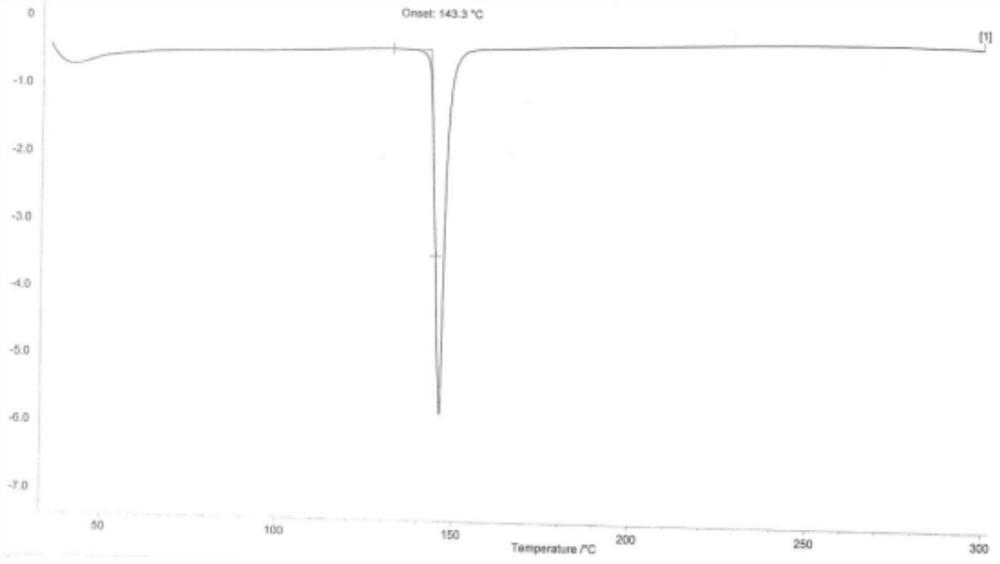

Crystal form of doxofylline and preparation method of crystal form of doxofylline

PendingCN111978324AGood water solubilityNo detectionOrganic chemistry methodsPharmaceutical delivery mechanismDoxofyllineAlcohol

The invention discloses a crystal form of doxofylline. The crystal form shows characteristic peaks at 8.60 + / -0.1 degrees, 11.31 + / -0.1 degrees, 15.02 + / -0.1 degrees, 16.91 + / -0.1 degrees, 17.32 + / -0.1 degrees and 18.63 + / -0.1 degrees according to an X-ray diffraction spectrum expressed by a 2 theta angle; the differential scanning calorimetry determines that an absorption single peak exists at 143.3 DEG C, and the crystal form is formed by recrystallizing doxofylline with a mixed solvent of methylbenzene, absolute ethyl alcohol and water. The invention provides a novel crystal form of doxofylline, the novel crystal form has high water solubility, the API purity can reach 99% or above and is close to 100%, almost no impurity is detected, and the novel crystal form is suitable for injectiondosage forms.

Owner:开封康诺药业有限公司 +1

A passive millimeter wave imaging security inspection device

ActiveCN104076358BRealize detectionNo detectionGeological detection using milimetre wavesRadio wave reradiation/reflectionImaging qualityElectromagnetic electron wave

The invention discloses passive millimeter wave imaging security inspection equipment which comprises a one-dimensional focal plane array (1), a reflecting plate (3), a display control sub-system (4), a signal processor (5), an inner calibration combination (6), a reflecting plate rotating mechanism (7), a dielectric panel (8), a rack (9), a detecting table (11), an ellipsoid reflecting surface (2) and an outer calibration combination (10). The ellipsoid reflecting surface (2) focuses electromagnetic waves radiated by a human body, the one-dimensional focal plane array (1) converts the focused electromagnetic waves into voltage signals, the signal processor (5) collects the voltage signals and sends the voltage signals to the display control sub-system (4), and the display control sub-system (4) processes the voltage signals and then outputs two-dimensional grey-scale map. The inner calibration combination (6) and the outer calibration combination (10) are adopted for combined calibration, image quality can be improved, and metal and nonmetal forbidden objects can be detected. The passive millimeter wave imaging security inspection equipment has the advantages of being small in system loss, high in sensitivity and reliability, low in cost, light and the like.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

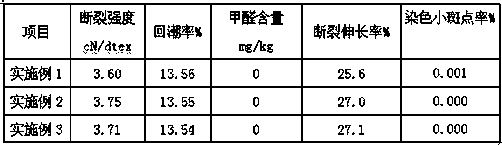

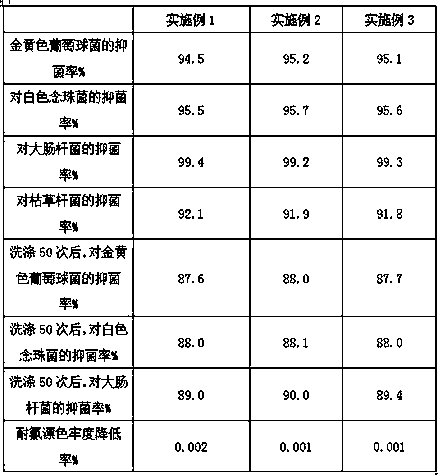

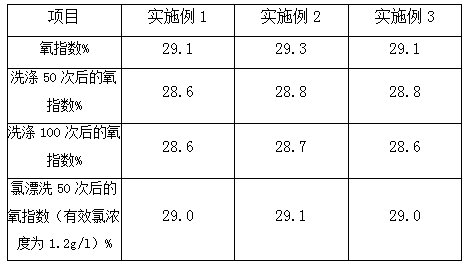

Silk fiber prepared by modifying plant extracts and preparation method of silk fiber

InactiveCN109811561ALow reduction rate of color fastness to chlorine bleachingHigh oxygen indexPhysical treatmentDyeing processChemistryRoom temperature

The invention provides a silk fiber prepared by modifying plant extracts. According to the silk fiber, the breaking strength is 3.60-3.75 cN / dtex, the elongation at break is 25.6-27.1%, the dye smallspeck rate is less the or equal to 0.001%, the bacteria inhibitive rate against bacillus subtilis is 91.8-92.1%, and the oxygen index after chlorine rinsing for 50 times is 29.0-29.1%. The invention further provides a preparation method of the silk fiber prepared by modifying the plant extracts. The preparation method comprises the steps of pretreatment and secondary treatment of the silk fiber, wherein the pretreatment comprises the steps that ultrasonic cleaning is carried out with deionized water and 1% of dilute hydrochloric acid for 10-15 min, then washing is carried out with ultrapure water, immersing is carried out at room temperature for 10-30 min, temperature is controlled at 25-50 DEG C and standing is carried out for 20-50 h. After the silk fiber is washed for 50 times, the bacteria inhibitive rate against staphylococcus aureus, candida albicans and escherichia coli is almost not reduced; and the flame retardant performance is good, and the oxygen index is reduced little after washing is carried out for 50 times and 100 times.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

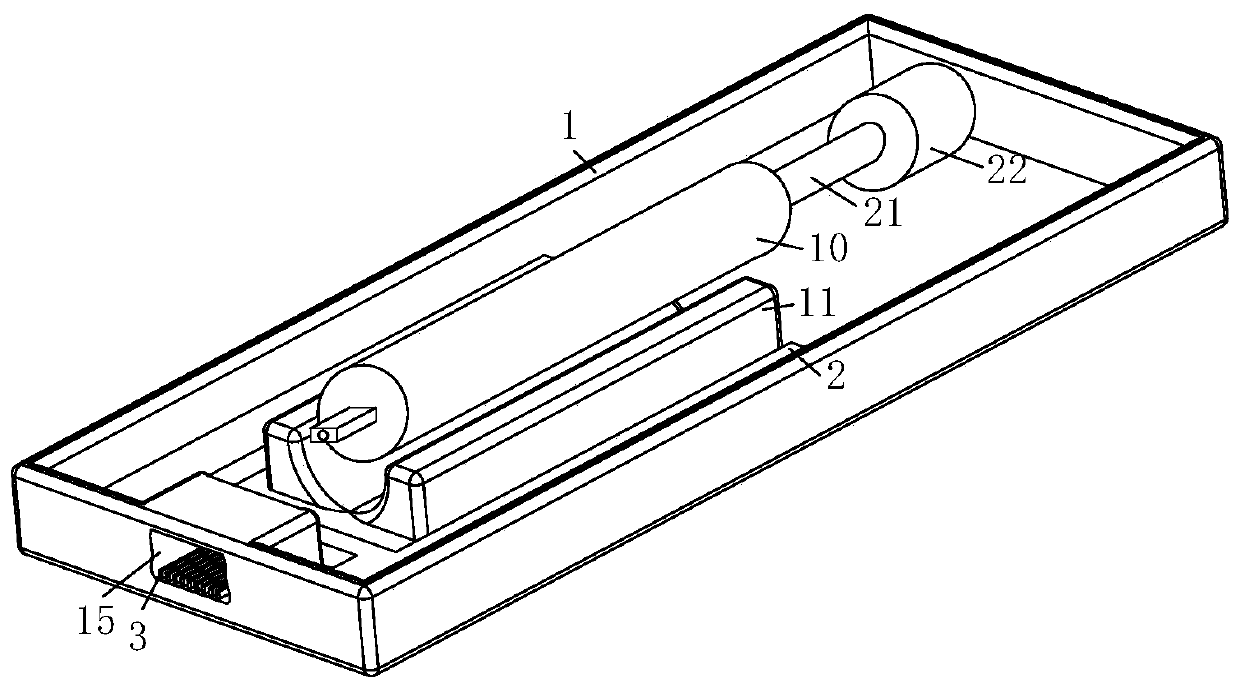

Continuous detection mechanism for RFID chip ticket

InactiveCN105574575ARealize continuous detectionThere will be no missed detectionElectronic circuit testingRecord carriers used with machinesEngineering

The invention discloses a continuous detection mechanism for an RFID chip ticket and aims at solving the problems that traditional single detection is complicated and generates missing detection. The continuous detection mechanism comprises a worktable, a ticket roll fixing bracket, a ticket rolling rotating shaft and an RFID chip detection device, wherein the ticket roll fixing bracket is fixed on the worktable and is fixedly connected with a support rod; a ticket roll sleeves the support rod; one end of the ticket roll is fixed on a main shaft of a ticket rolling device; the main shaft is driven to rotate by a stepping motor which is fixedly connected with the main shaft; the RFID chip detection device is arranged under the ticket between the ticket roll fixing bracket and the ticket rolling device; roll shaft brackets are arranged at the left side and the right side of the RFID chip detection device; two roll shafts are fixed on the roll shaft brackets respectively; and the ticket passes through a gap between the two roll shafts, so that continuous detection is achieved.

Owner:WUXI HONGYI LOGISTICS EQUIP CO LTD

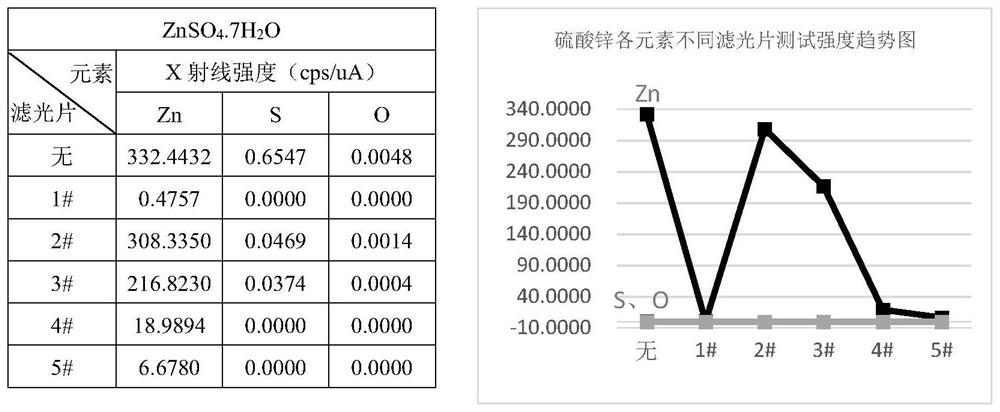

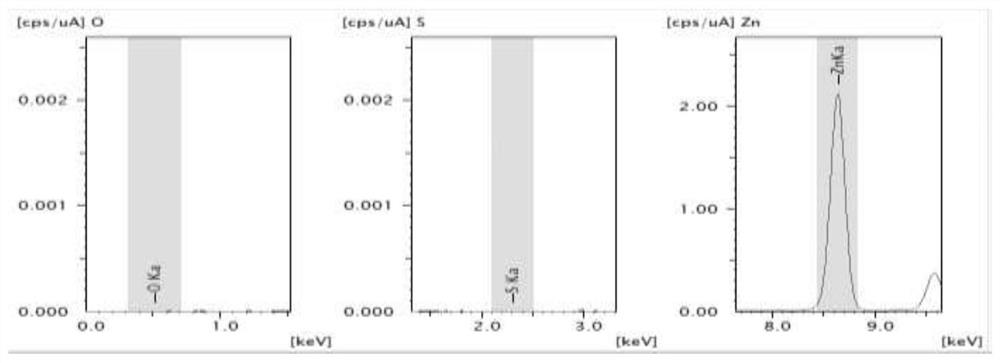

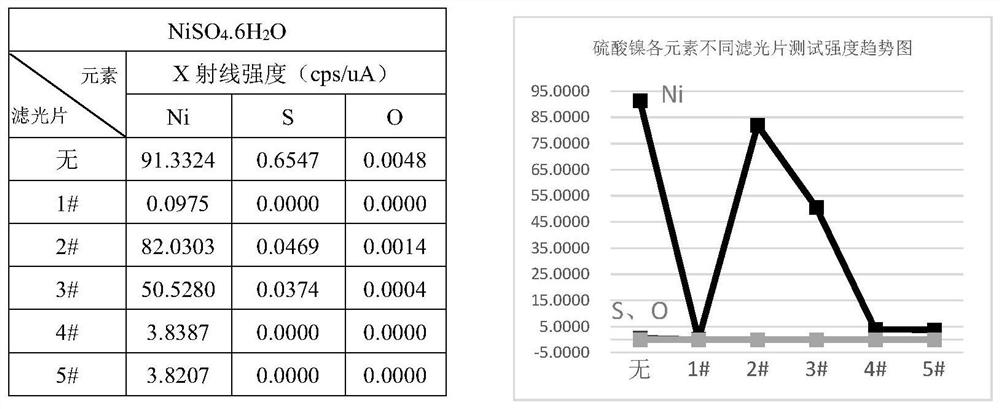

Rapid determination method for copper foil electroplating solution

ActiveCN114486972AMeet testing needsNo detectionMaterial analysis using wave/particle radiationOxidation resistantCopper foil

The invention provides a rapid determination method for a copper foil electroplating solution, in surface anti-oxidation treatment of copper foil production, zinc, nickel, potassium pyrophosphate and other substances are frequently used in the electroplating solution, and the stability of the content of the substances directly determines the appearance color, the impurity content and the oxidation resistance of the copper foil, so that in the production process, the content of impurities in the copper foil is greatly reduced. How to rapidly and accurately detect the content of the substance becomes a key point of quality assurance, and the method can be used for rapidly determining zinc, nickel and potassium pyrophosphate in the copper foil surface treatment electroplating liquid; compared with an artificial titration or spectrophotometric method for testing zinc-nickel potassium pyrophosphate in the electroplating solution, the method has the advantages of high detection efficiency, no detection waste liquid and the like; according to the analysis, the content of zinc, nickel and potassium pyrophosphate in the copper foil electroplating solution is determined by using the X-fluorescence spectrometry, the test result is accurate, the deviation is small, the solution detection requirement can be completely met, and the determination method of a titration method and a spectrophotometric method can be replaced.

Owner:云南惠铜新材料科技有限公司

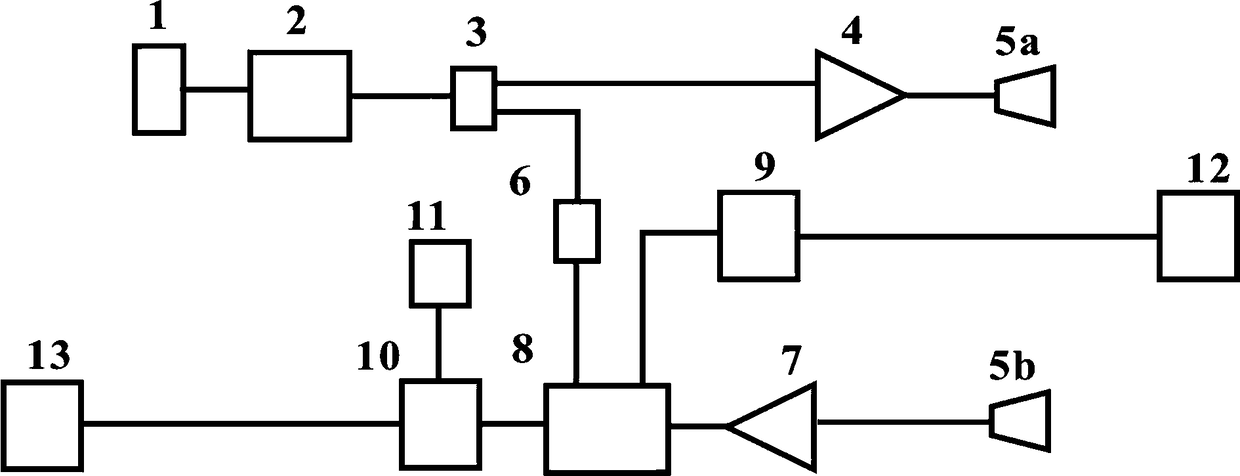

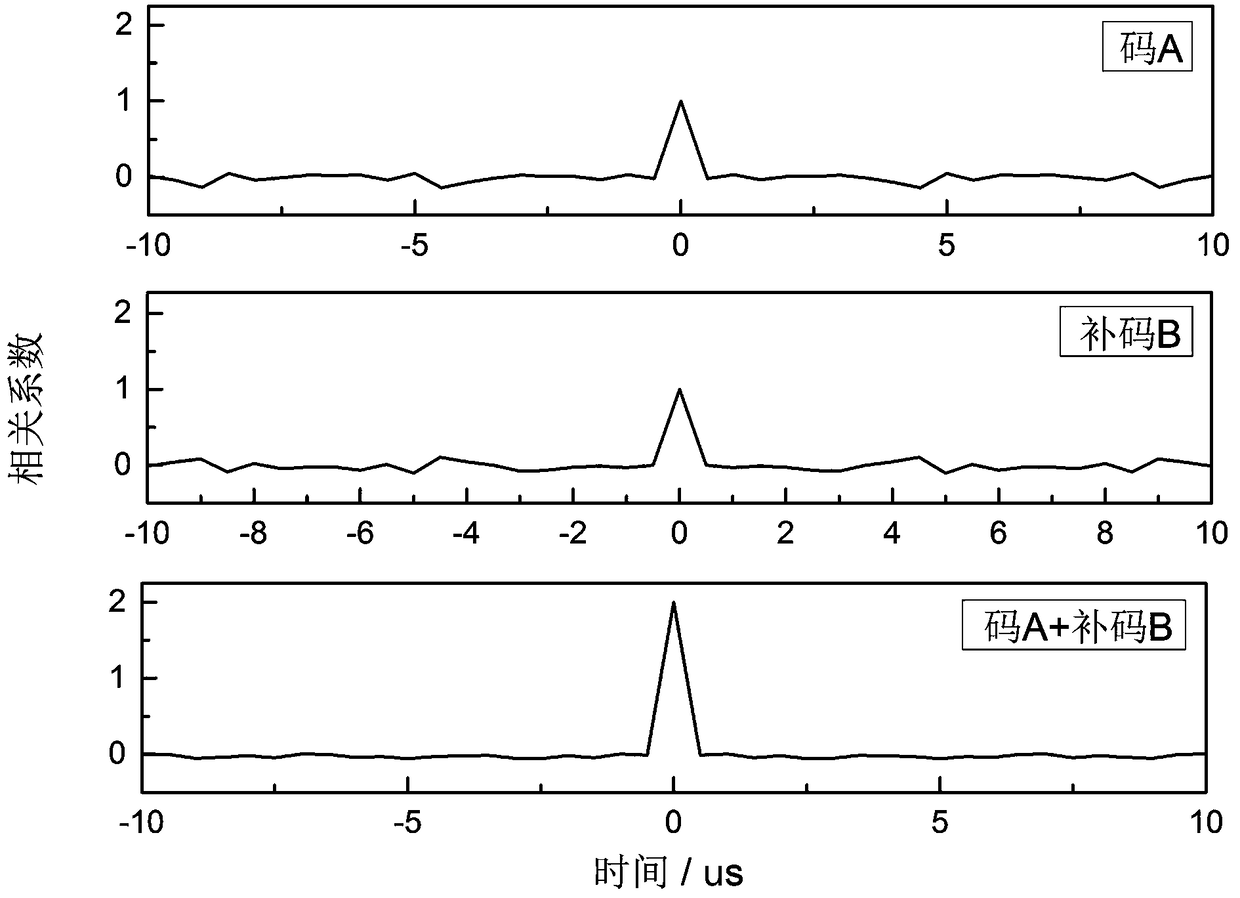

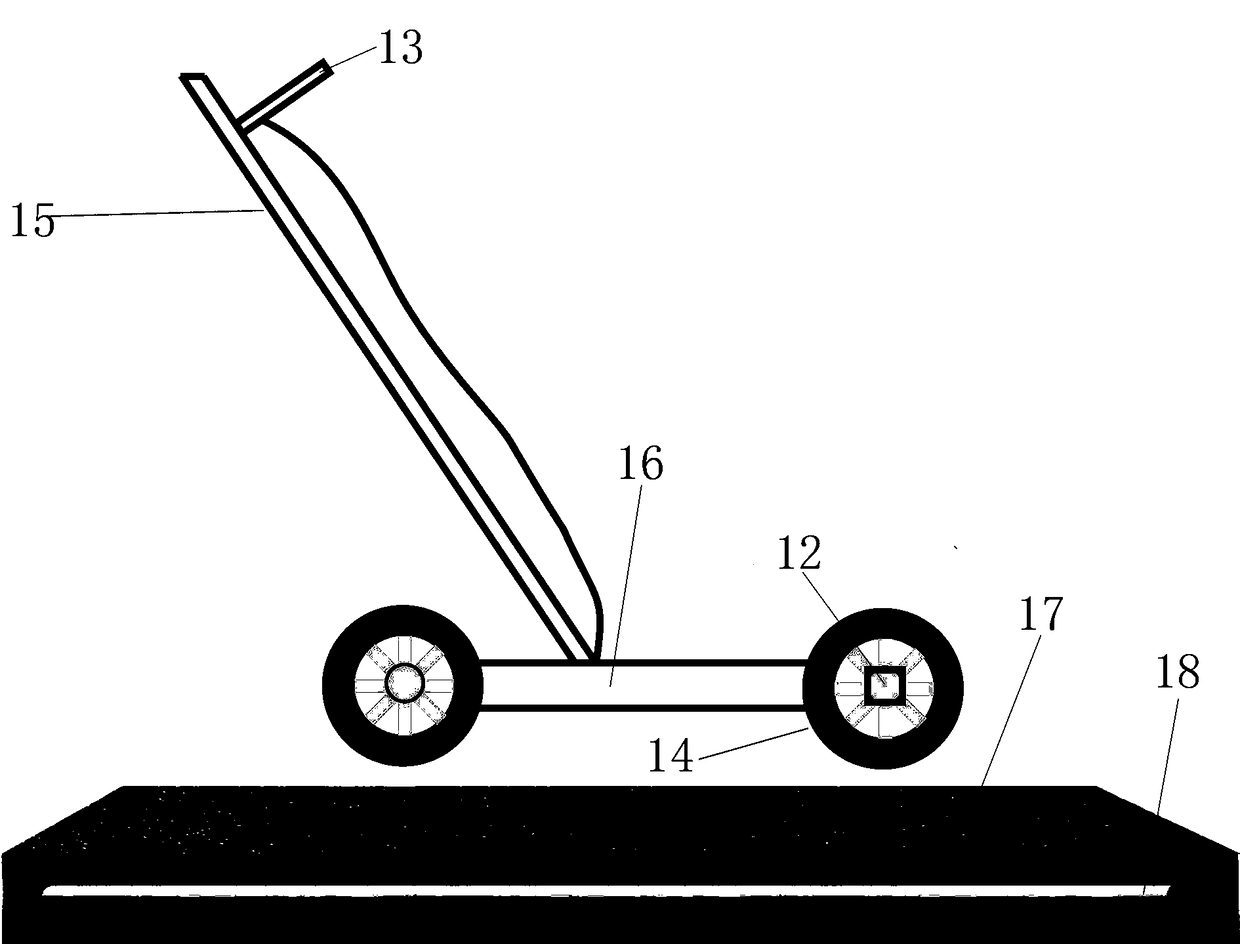

A device and method for locating underground pipelines based on complementary gray codes

ActiveCN107390276BHas noise-like propertiesImprove anti-interference abilityRadio wave reradiation/reflectionElectric/magnetic detection for transportMeasurement pointDisplay device

The present invention relates to the geophysical exploration field, specially to a device and method of underground pipeline positioning device based on complementation Gray codes. The device comprises an encoding converter, a complementation Gray code generation device, a power divider, a first amplifier, an emission antenna, a receiving antenna, a second amplifier, an adjustable electric delay line, an photoelectric signal collection device, a speed sensor, a triggering control device, a GPS device, a signal processing storage device and a display device. A complementation Gray code A and a complementation Gray codes used at the same measurement point are taken as detection signals, the related information obtained through twice detection is added so as to substantially improve the signal to noise ratio of the system.

Owner:山西润泽丰科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com