Colloidal gold immunoassay paper for detecting bacillus in bee larvae and its preparation and application

A technology for bacillus and bee larvae, applied in the direction of measuring devices, instruments, and biological material analysis, can solve the problems of high operational technical requirements, long detection methods, unfavorable rapid detection, etc., and achieve good detection repeatability and easy promotion and use , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

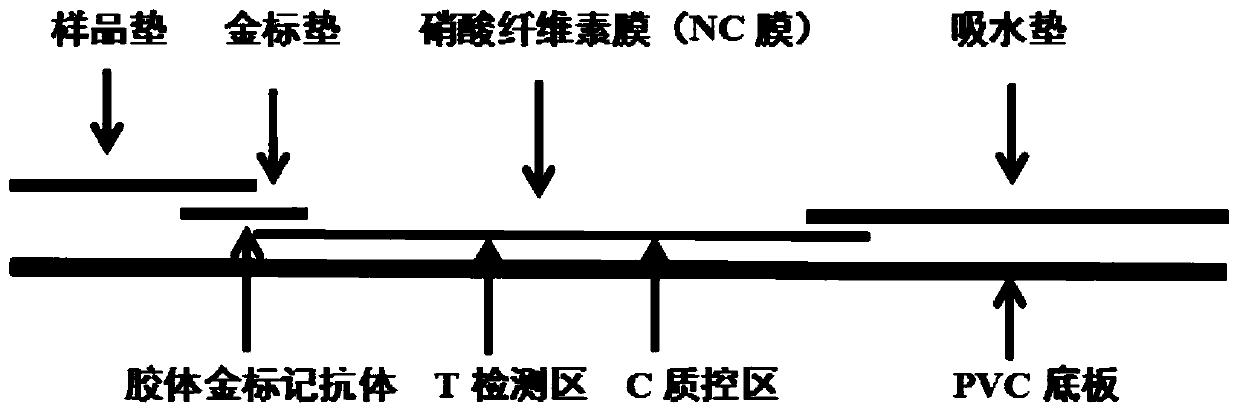

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Purification of PLMP polyclonal antibody

[0037] 1. Serum pretreatment

[0038] Draw 6 mL of rabbit serum with a clean syringe and filter it with a 0.45 μm filter membrane.

[0039] 2. Caprylic acid precipitates non-IgG proteins

[0040] Take a 50 mL autoclaved centrifuge tube, add 24 mL of acetic acid buffer and 6 mL of rabbit serum filtered through a 0.45 μm filter membrane, shake and mix well, and adjust the pH to 4.5 with 1 mol / L NaOH. Add 2.25 mL of n-octanoic acid, stir at room temperature for 30 min, centrifuge at 10,000 rpm for 20 min, and discard the precipitate. Draw up the remaining liquid with a syringe, filter it with a 0.45 μm filter membrane, add 1 / 10 volume of 0.01mol / L PBS solution (PH=7.4), then adjust the pH to 7.4 with 1mol / L NaOH, and put it in an ice bath follow-up experiment.

[0041] 3. Ammonium sulfate precipitation of IgG

[0042] In an ice-bath environment, an equal volume of saturated ammonium sulfate was added to the above sol...

Embodiment 2

[0043] Embodiment two: the preparation of gold label pad

[0044] 1. Determination of the optimum pH value of colloidal gold

[0045] In this test, 0.2mol / L K was added 2 CO 3 The amount is standard. Take 10 1.5mL centrifuge tubes and mark the numbers, and add 1mL of colloidal gold solution to each centrifuge tube. Add a certain amount of 0.2mol / L K to each centrifuge tube 2 CO 3 Mix thoroughly (as shown in Table 3-2), then add 30 μg of purified polyclonal antibody to each tube, mix again, and let stand at room temperature for 30 minutes. Slowly add 20 μL of 10% NaCl solution to each centrifuge tube, mix well and let stand at room temperature for 2 hours. Observe the color change of the 10 centrifuge tubes and whether there are black particles of sedimentation and aggregation. Select the K for the tube that starts with no aggregation 2 CO 3 The addition amount of solution, then is the optimum 0.2mol / L K of colloidal gold in this test. 2 CO 3 The amount of addition, ...

Embodiment 3

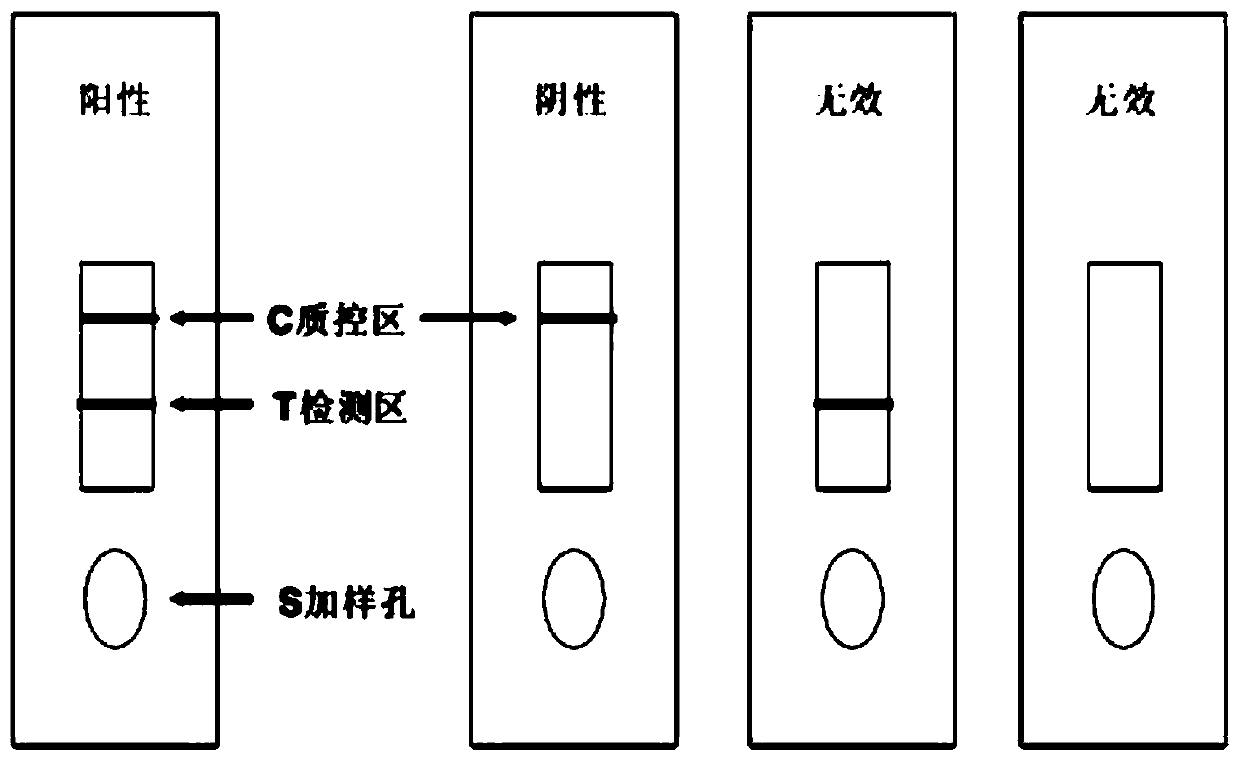

[0059] Example 3: Preparation of detection line and quality control line

[0060] 1. Determination of the detection line coating antibody concentration

[0061] On the NC membrane of the detection line, add dropwise the concentration of 0.4mg / mL, 0.6mg / mL, 0.8mg / mL, 1.0mg / mL, 1.2mg / mL, 1.4mg / mL, 1.6 mg / mL diluted with PBS, respectively. mL, 1.8 mg / mL 1 μL PLMP polyclonal antibody, on the NC membrane of the quality control line, drop 1.0 μL of goat anti-rabbit IgG antibody with a concentration of 1.0 mg / mL diluted with PBS. Use 10 μg / mL purified PLMP protein for detection, observe the color development of the detection line, and determine the optimal concentration of the coating antibody.

[0062] When the C line is coated with 1.5 μL of goat anti-rabbit IgG antibody with a concentration of 1 mg / mL, set 8 concentration gradients of the PLMP protein polyclonal antibody, and use PLMP protein for detection. It can be seen that when the concentration is diluted from 1.0 mg / mL to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com