Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "No change in liquidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

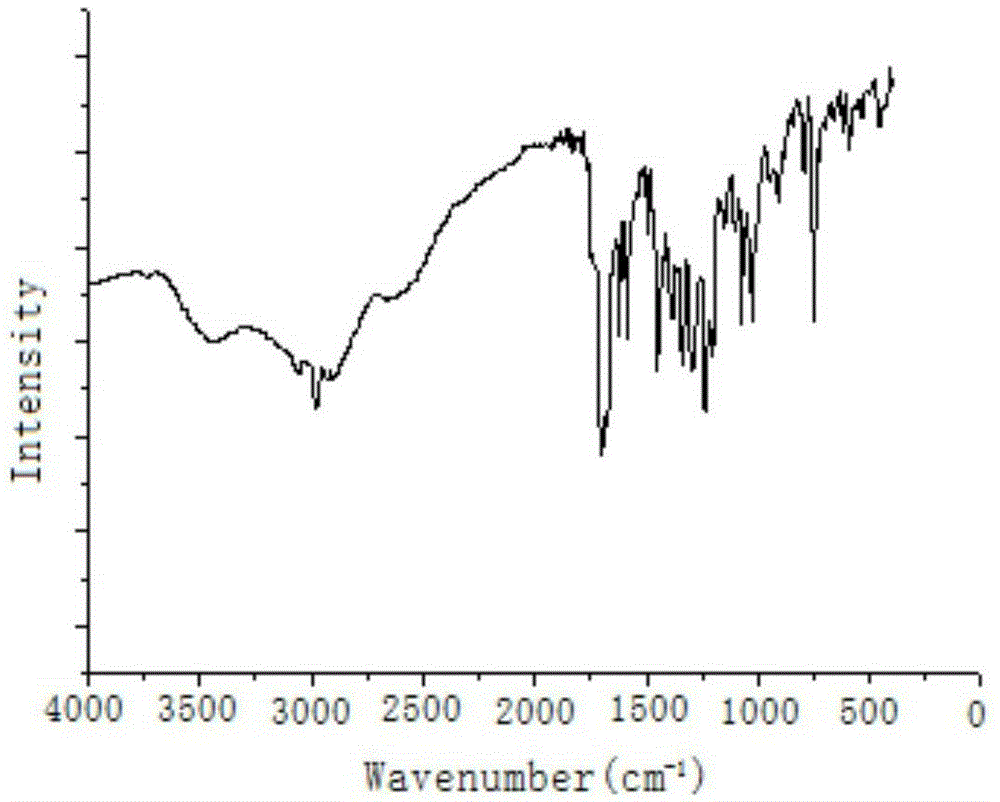

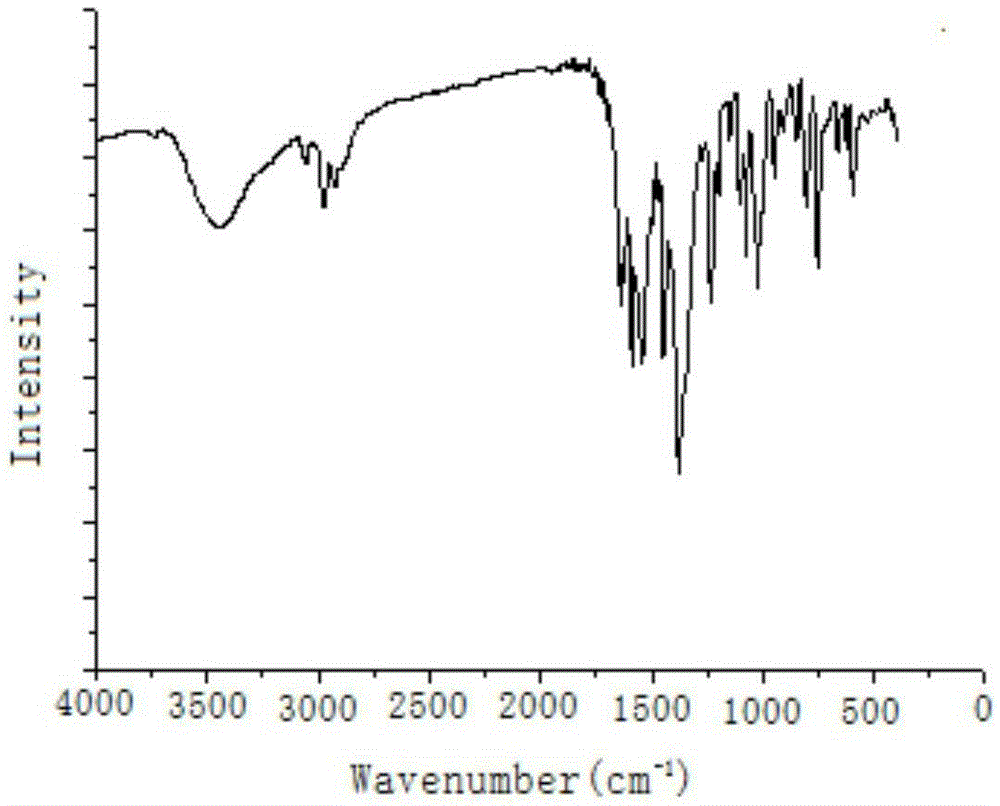

Preparation method for perfluor polyether oil-based magnetic liquid

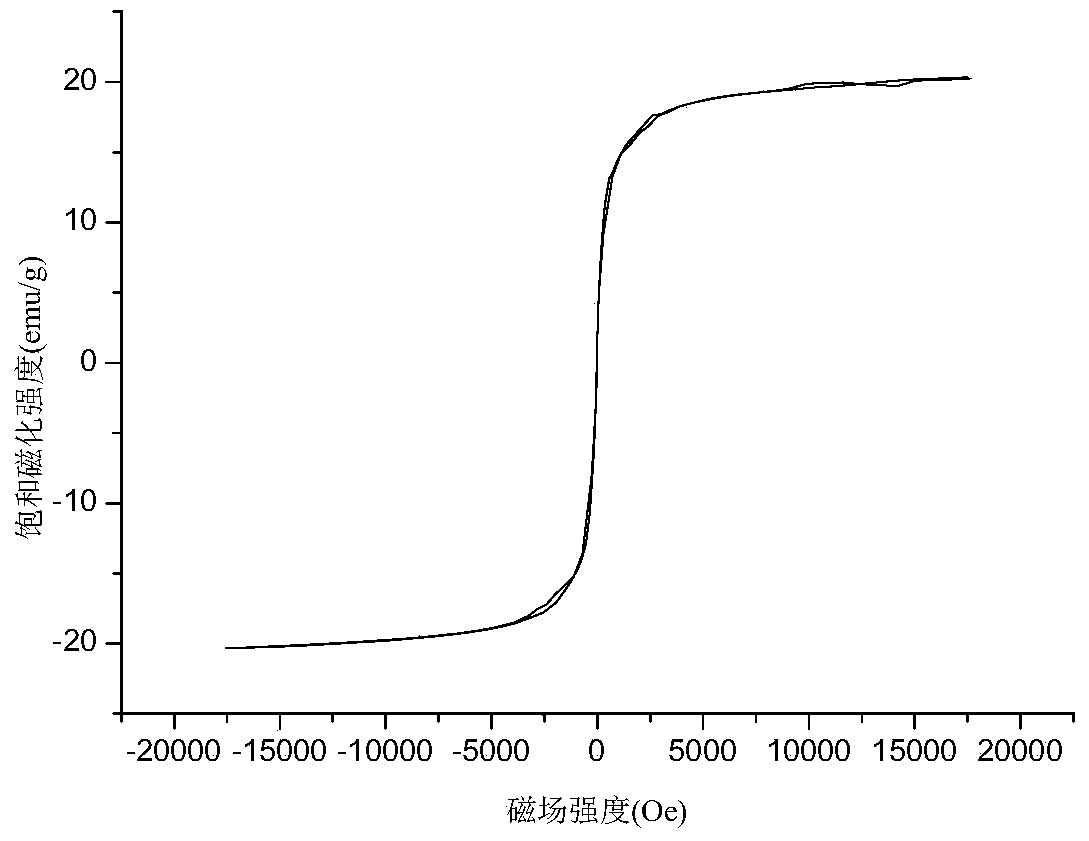

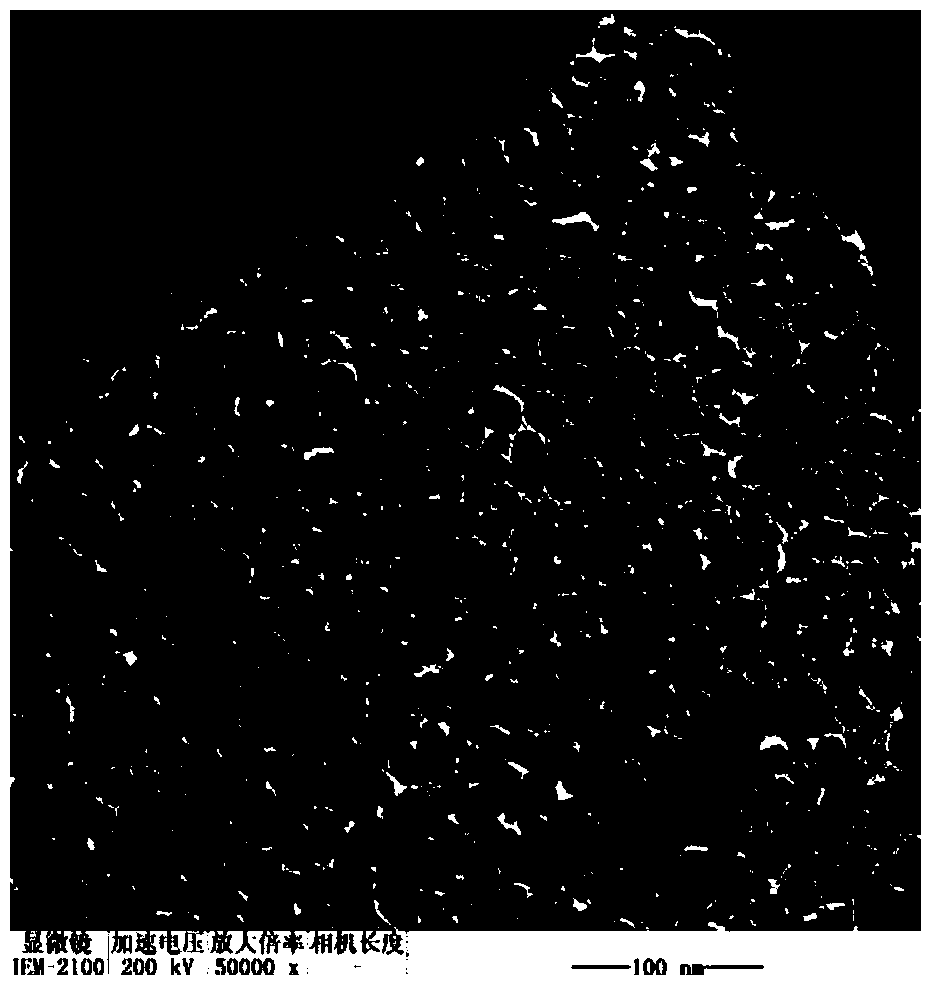

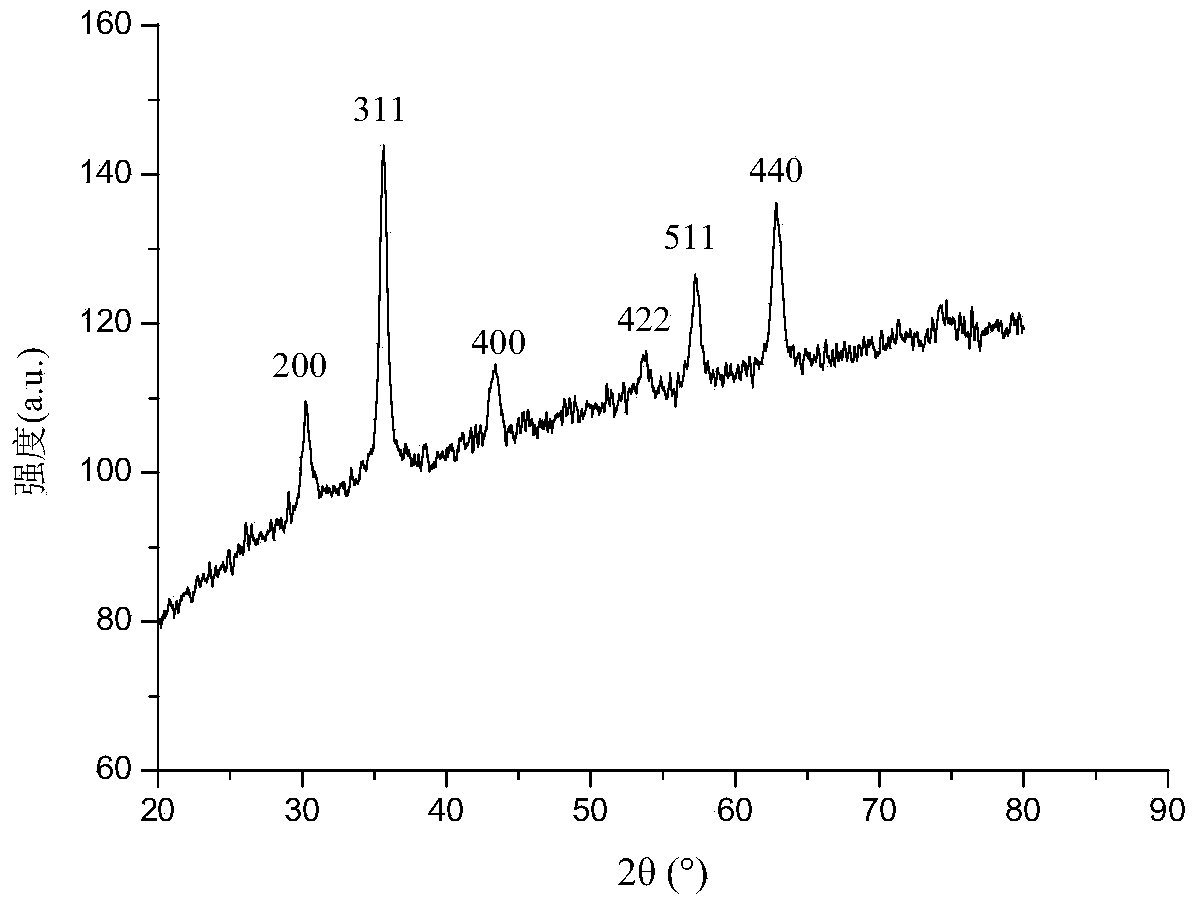

InactiveCN103680798AExtended application environmentEasy to useMagnetic liquidsOrganic/organic-metallic materials magnetismHigh energyMagnetization

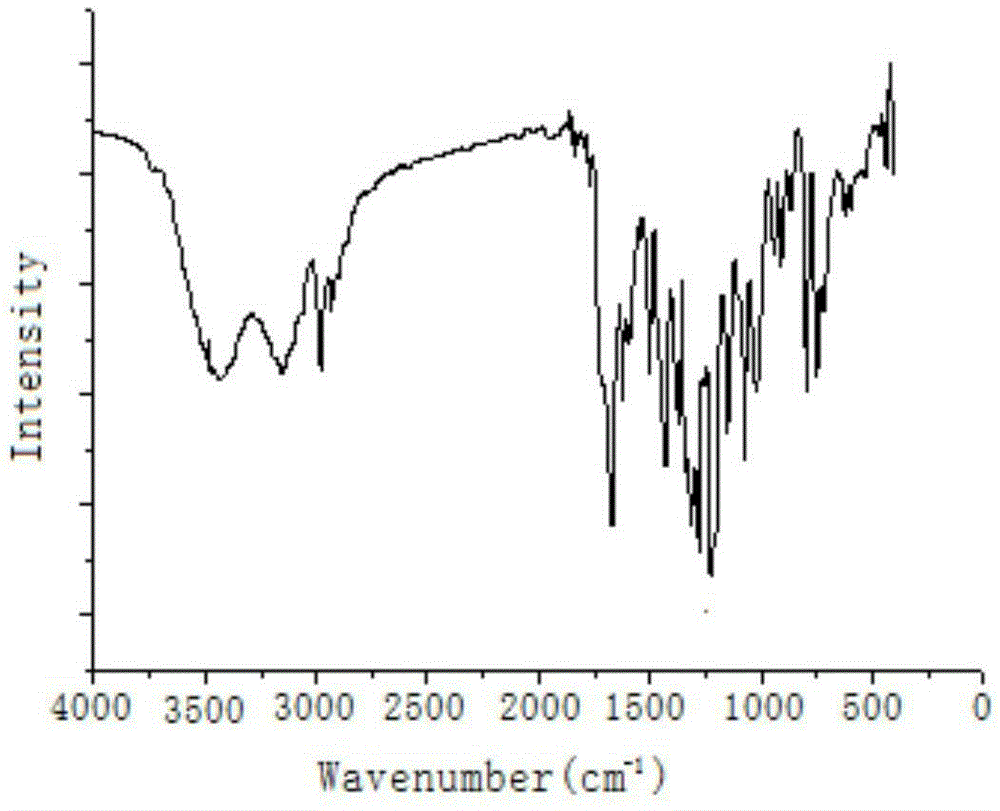

The invention discloses a preparation method for a perfluor polyether oil-based magnetic liquid. The magnetic liquid is formed by bare Fe[3]O[4] magnetic nano-particles, a perfluor polyether carboxylic acid surface active agent and a perfluor polyether oil-based carrier liquid in a prepared mode. The bare Fe[3]O[4] nano-particles with the average particle diameter of 10 nanometers are firstly prepared by the adoption of a chemical coprecipitation method; the perfluor polyether carboxylic acid surface active agent is then adopted for modifying the bare Fe[3]O[4] nano-particles; finally, the modified Fe[3]O[4] magnetic nano-particles and the perfluor polyether oil-based carrier liquid are blended through a high-energy ball milling or ultrasonic shaking method to form the uniform and stable perfluor polyether oil-based magnetic liquid, and the saturation magnetization of the perfluor polyether oil-based magnetic liquid is 14-600 Gs. The magnetic liquid has the excellent special performance of resisting to chemical corrosion, high temperature, low temperature resistance and radiation and never burning, can work stably for a long time at the temperature of 40 DEG C below zero-200 DEG C at the pH value of 1-14, and is particularly suitable for space stations, aeronautics and astronautics and other military industry fields.

Owner:BEIJING JIAOTONG UNIV

C100 high-performance concrete and formulation method thereof

ActiveCN101121586AReduce manufacturing costLose weightSolid waste managementWork performancePolymer science

The present invention discloses a C100 high performance concrete, which is made of glue material, sand, stone, water and additive; the glue material comprises cement and mixture; the adding amount for the glue material is 500 to 600kg concrete per stere; thereinto, the cement is 42.5; the mixture comprises three components such as silicon powder, coal ash and scoria powder; the active SiO2, the mount of whch is 20 -40 percent of the total weight in the glue material, and the surface area of which is 1000-1200m2 / kg; is included in the glue material, the additive is polymer carboxyl acid with high-efficient dewater ability, the amount of which is 2 - 5 percent of the total glue material; The catalyzer is a mixture consisting of smoke ash and coal waste rock grain, the amount of which are 1-5 percent of the total weight in the glue material. The material does not need high-mark cement with simple produce process and low produce cost; the device can not only enhance the intension of the concrete, but also enhance the working performance and wear ability for the concrete.

Owner:北京新奥混凝土集团有限公司

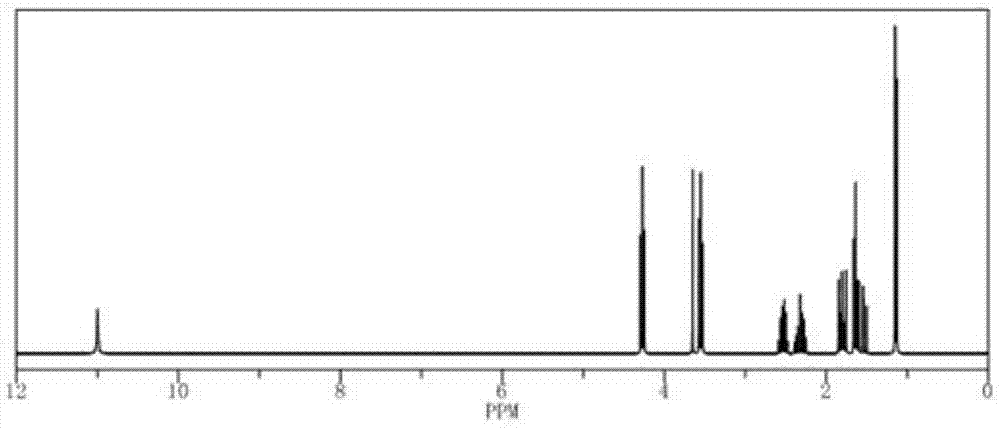

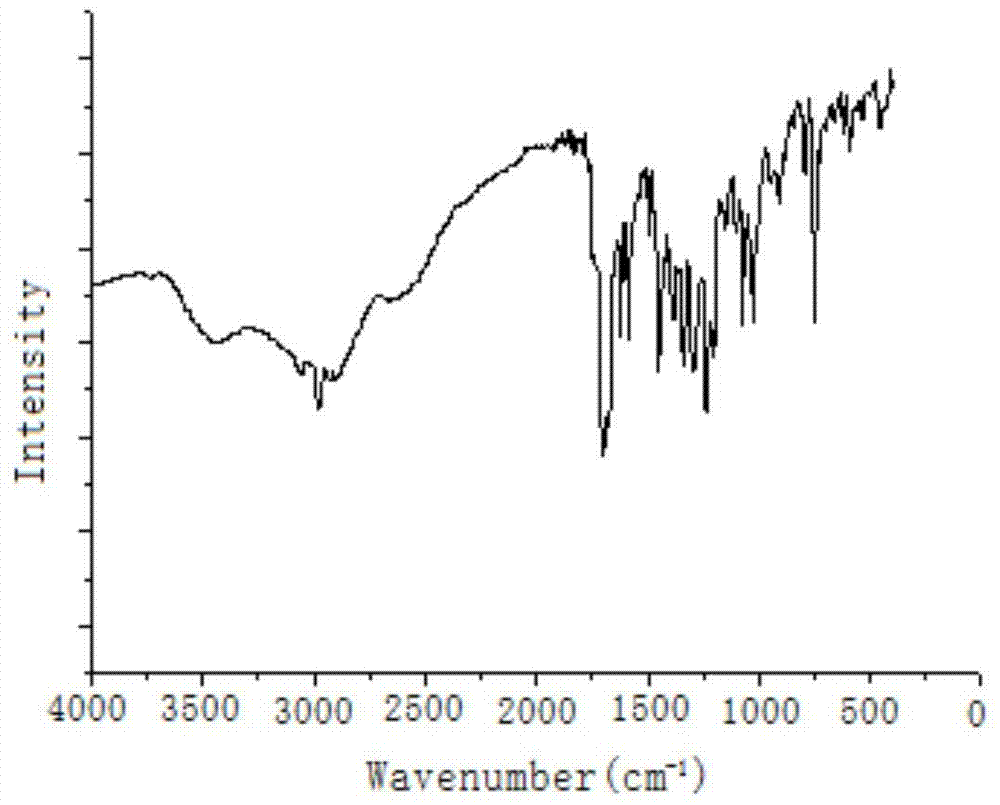

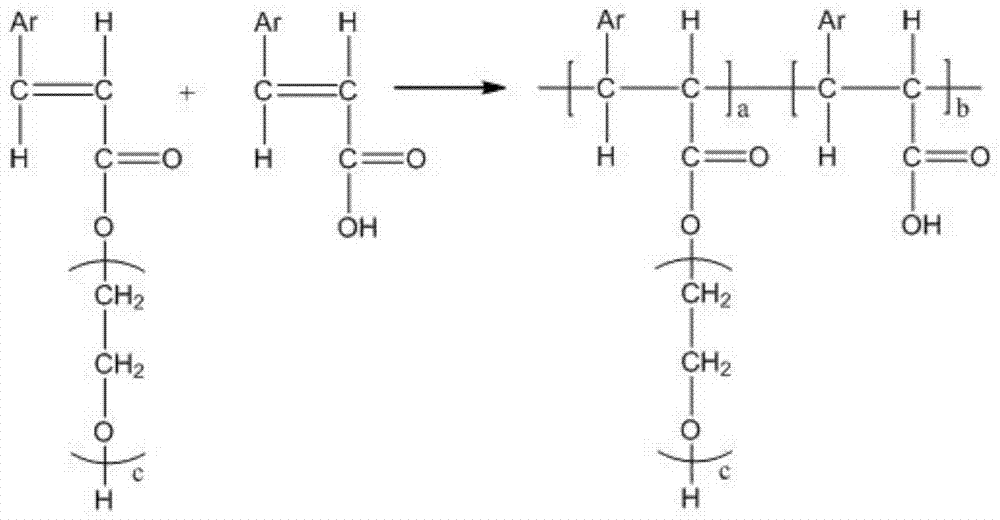

Acrylic acid grafted polyvinyl alcohol enhancer, and preparation method and application thereof

The invention discloses an acrylic acid grafted polyvinyl alcohol enhancer, and a preparation method and application thereof. The preparation method comprises the following steps: adding 0.1-1 part of polyvinyl alcohol into 4-10 parts of water, and heating at 60-90 DEG C for 1-5 hours to gelatinize the polyvinyl alcohol; and adding 1-5 parts of acrylic acid, adding alkali to regulate the pH value to 7-8, adding 0.01-0.1 part of initiator, and reacting at 60-90 DEG C for 2-6 hours to obtain the acrylic acid grafted polyvinyl alcohol enhancer. The polyvinyl alcohol chain used as the framework is grafted with the polyacrylic acid branched chain with certain flexibility to form the block macromolecular structure with branched chain, so that the prepared enhancer has better enhancement effect; and the nano glaze slip with the enhancer can not easily crack after being applied to the ceramic billet surface. The enhancer has small influence on the viscosity and flowability of the glaze slip, so the glaze thickness on the billet surface can not be influenced when the traditional glazing method is adopted.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Perfluor polyether oil-based magnetic liquid

InactiveCN103680799AEasy to useBreakthrough progress in promoting localizationMagnetic liquidsOrganic/organic-metallic materials magnetismPerfluoropolyetherNanoparticle

The invention discloses a perfluor polyether oil-based magnetic liquid. The magnetic liquid is composed of bare Fe[3]O[4] magnetic nano-particles, a perfluor polyether carboxylic acid surface active agent and a perfluor polyether oil-based carrier liquid, the ratio of the bare Fe[3]O[4] magnetic nano-particles (g) to the perfluor polyether carboxylic acid surface active agent (ml) is 40:1-1:1, and the ratio of the modified bare Fe[3]O[4] magnetic nano-particles (g) to the perfluor polyether carboxylic acid surface active agent (ml) is 1:20-2:1. The saturation magnetization of the perfluor polyether oil-based magnetic liquid is 14-600 Gs, the magnetic liquid has the excellent special performance of resisting to chemical corrosion, high temperature, low temperature resistance and radiation and never burning, and can work stably for a long time at the temperature of 40 DEG C below zero-200 DEG C at the pH value of 1-14, a magnetic liquid of a conventional type can not achieve the effect, and the perfluor polyether oil-based magnetic liquid is particularly suitable for space stations, aeronautics and astronautics and other military industry fields.

Owner:BEIJING JIAOTONG UNIV

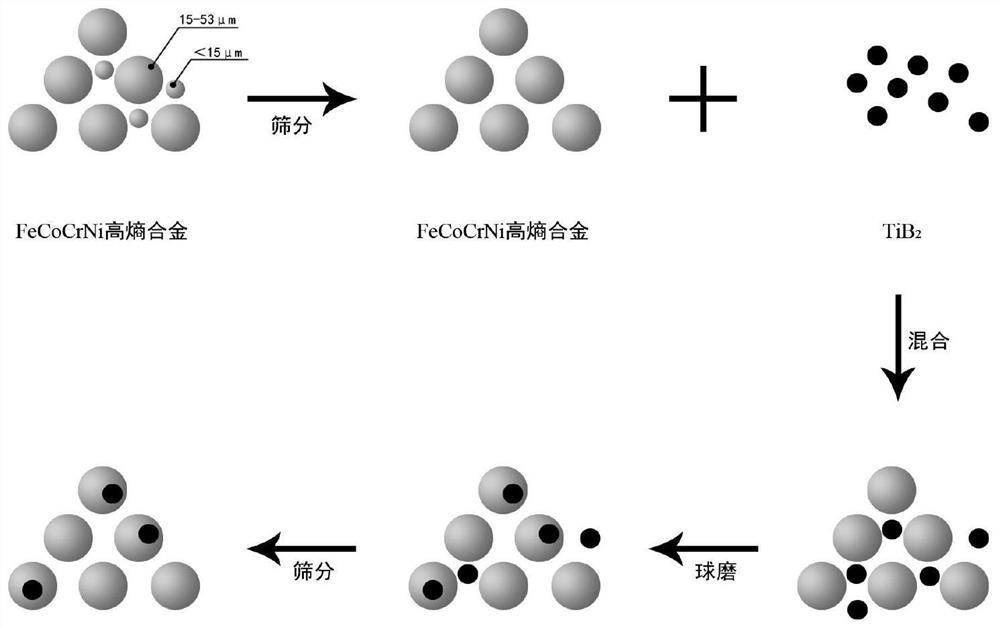

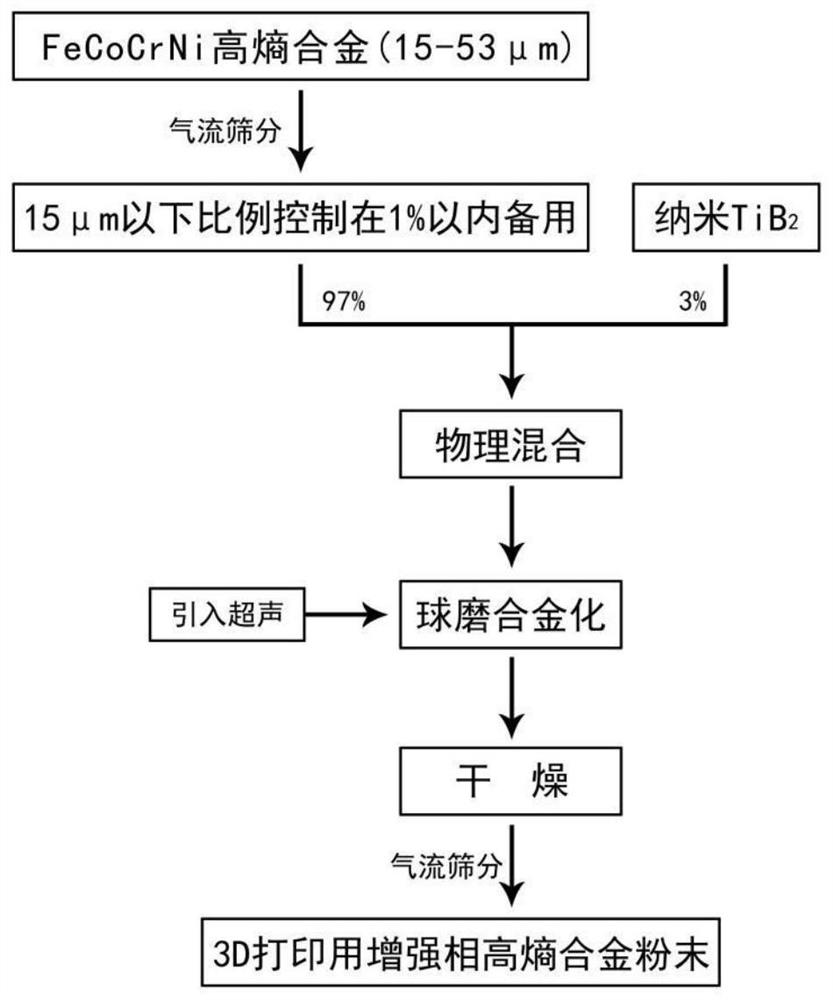

Preparation method of TiB2 enhanced high-entropy alloy powder for 3D printing

InactiveCN112792346AImprove mechanical propertiesDoes not affect the powder spreading effectAdditive manufacturing apparatusTransportation and packagingHigh entropy alloysDry box

The invention provides a preparation method of TiB2 enhanced high-entropy alloy powder for 3D printing, which is characterized by comprising the following steps: (1) performing airflow classification on FeCoNiCr high-entropy alloy with the specification of 15-53mu m, and controlling the weight ratio of powder with the specification of less than 15mu m in the powder within 1% for later use; (2) putting nano TiB2 and the screened high-entropy alloy powder of the first part into a mixer according to a mass fraction ratio of 3: 97, and fully and uniformly mixing the nano TiB2 and the screened high-entropy alloy powder of the first part; (3) placing the mixed metal powder on a ball mill to be subjected to ball milling, introducing ultrasonic waves into the periphery of the ball mill, and embedding the nano TiB2 into the high-entropy alloy powder in a mechanical alloying mode; (4) putting the ball-milled high-entropy alloy powder into a drying box to be dried; and (5) performing airflow classification on the dried ball-milled high-entropy alloy powder, and it is guaranteed that the weight ratio of powder with the specification of less than 15mu m is controlled within 1%.

Owner:NANTONG JINYUAN INTELLIGENT TECH CO LTD

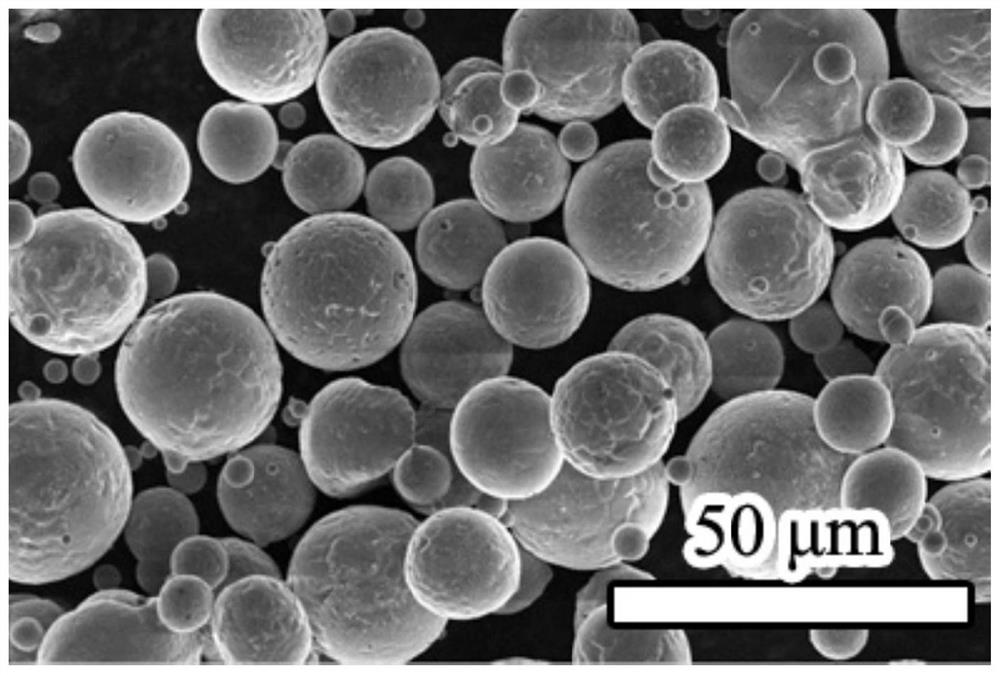

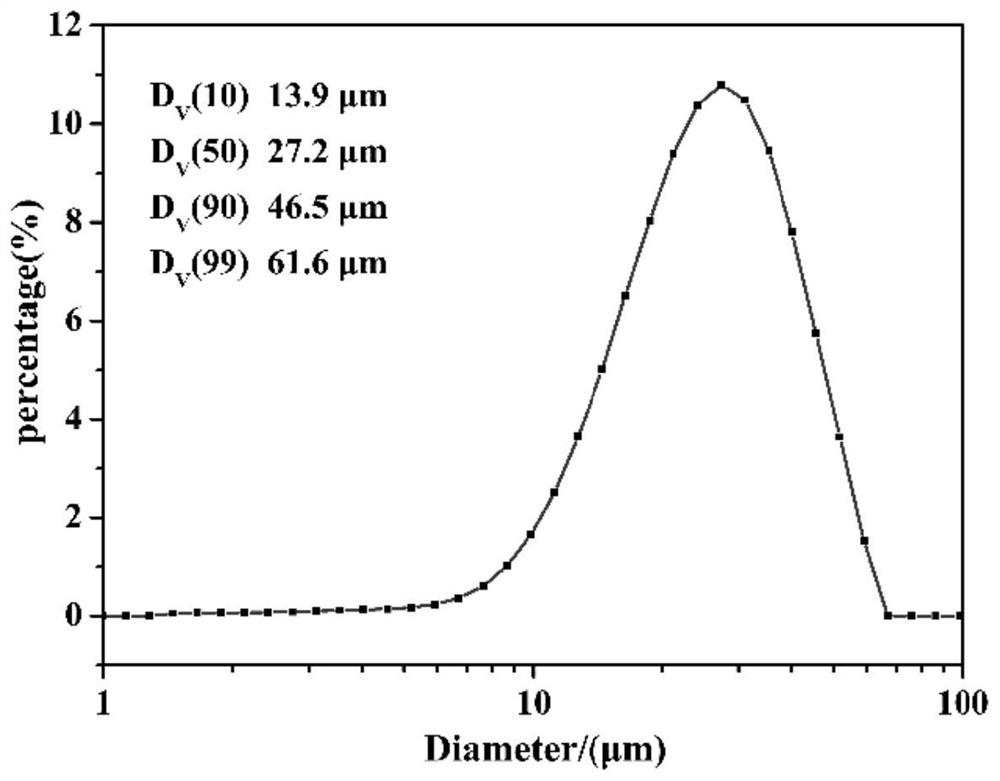

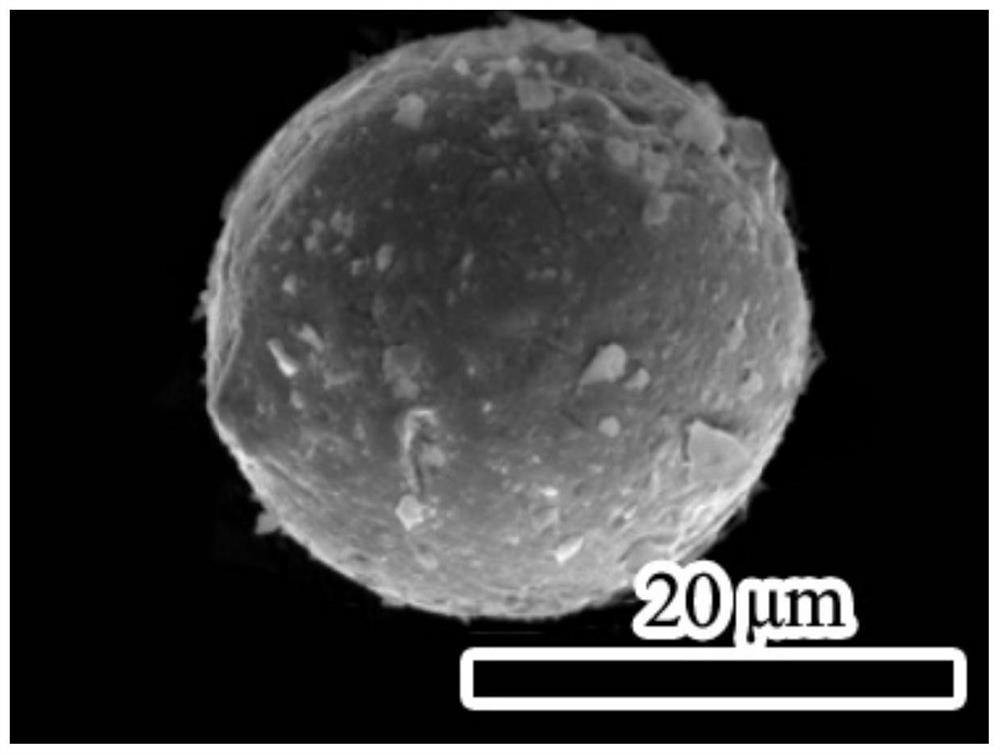

Ceramic metal powder as well as preparation method and application thereof

ActiveCN111872373ANo change in granularityNo change in liquidityAdditive manufacturing apparatusTransportation and packagingSelective laser meltingCrazing

The invention discloses ceramic metal powder and a preparation method and application thereof, and belongs to the technical field of 3D printing. The preparation method comprises the following steps:mixing a nano ceramic powder suspension and a metal powder suspension to enable nano ceramic powder to be uniformly adhered to the surface of metal powder. The nano ceramic powder and the metal powderare arranged in a suspension form and then mixed, so that a nano phase can be effectively and uniformly adhered to the surface of the metal powder, morphology, granularity and flowability of the metal powder are not changed, meanwhile, uniform distribution of the nano phase in the selective laser melting forming process is achieved, and cracks, stress concentration, segregation-free and the likeare reduced. Moreover, the method can overcome the defects of long period and high cost of developing new materials suitable for the SLM technology at present. The ceramic metal powder prepared through the method is good in fluidity, high in sphericity degree and particularly suitable for the selective laser melting technology.

Owner:GUANGDONG INST OF NEW MATERIALS

Titanium dioxide nano ink

The invention relates to a titanium dioxide nano ink which is prepared from the following raw materials in parts by weight: 0.5-2 parts of Al powder with the average particle size of 100nm, 3-5 parts of TiO2 powder with the average particle size of 500nm, 25-30 parts of pigment, 32-40 parts of polyamide resin, 13-17 parts of alkyd resin, 2-5 parts of 6# varnish and 0.1-0.5 part of polyalkyl ethylene glycol. The ink has the advantages of favorable stability, low pigment consumption, high covering power, full color, clear printed image and long service life, and is suitable for industrial production.

Owner:SUZHOU YIHENG PRINTING

Silver nano ink

InactiveCN103694778AStrong drying effectPrevents problems with longer drying timesInksArylPentaerythritol

The invention relates to a silver nano ink, which comprises the following active ingredients in parts by weight: 10-15 parts of pigments, 3-5 parts of Ag powder with average particle size of 100nm, 10-20 parts of carbon black, 30-45 parts of rosin pentaerythrityl ester, 1-2 parts of linseed oil, and 1-3 parts of sodium aryl sulfonate. The ink is good in stability, less in pigment consumption, high in hiding power, full in color, clear in printed images, long in service life, and applicable to industrial production.

Owner:SUZHOU YIHENG PRINTING

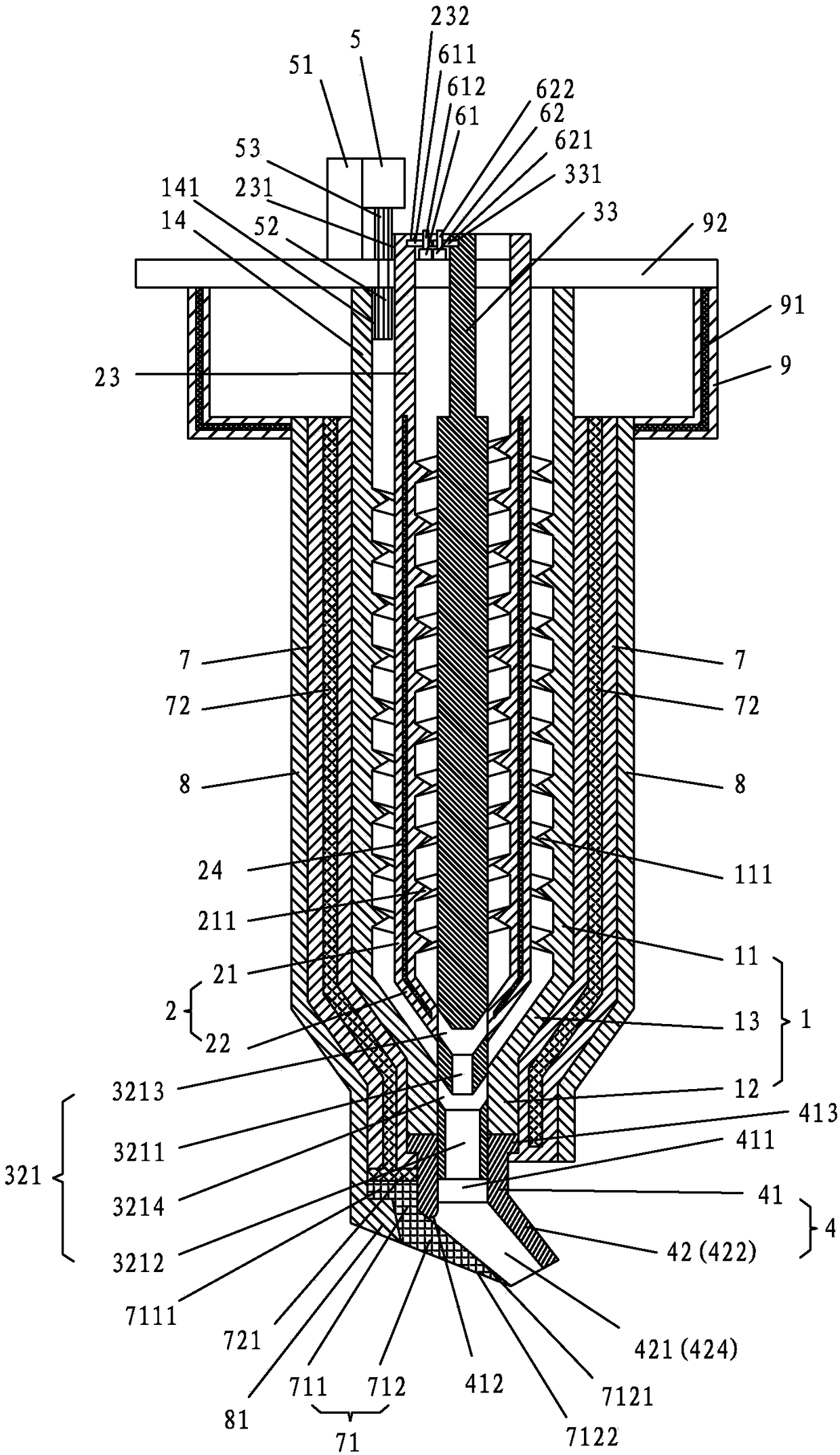

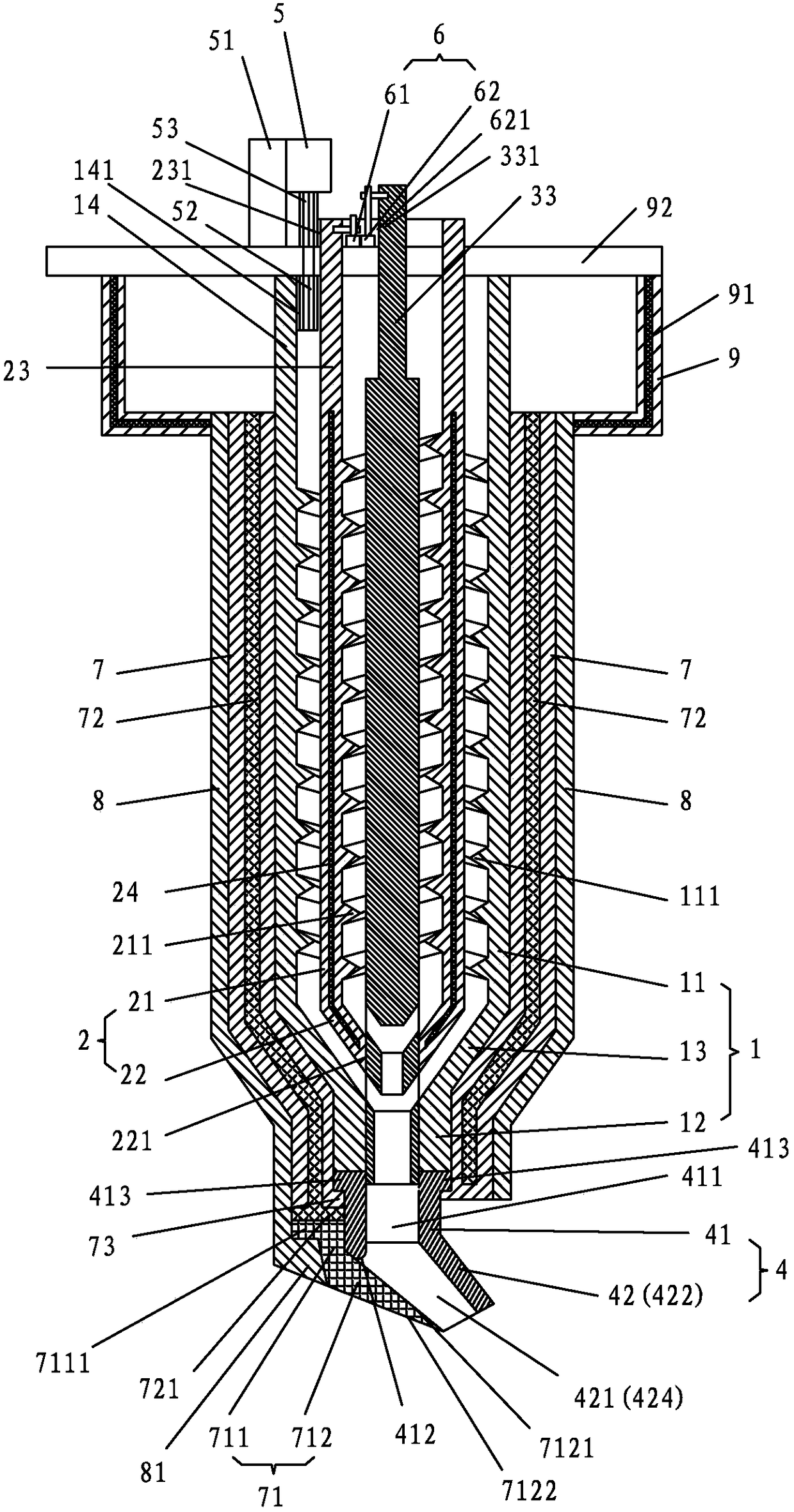

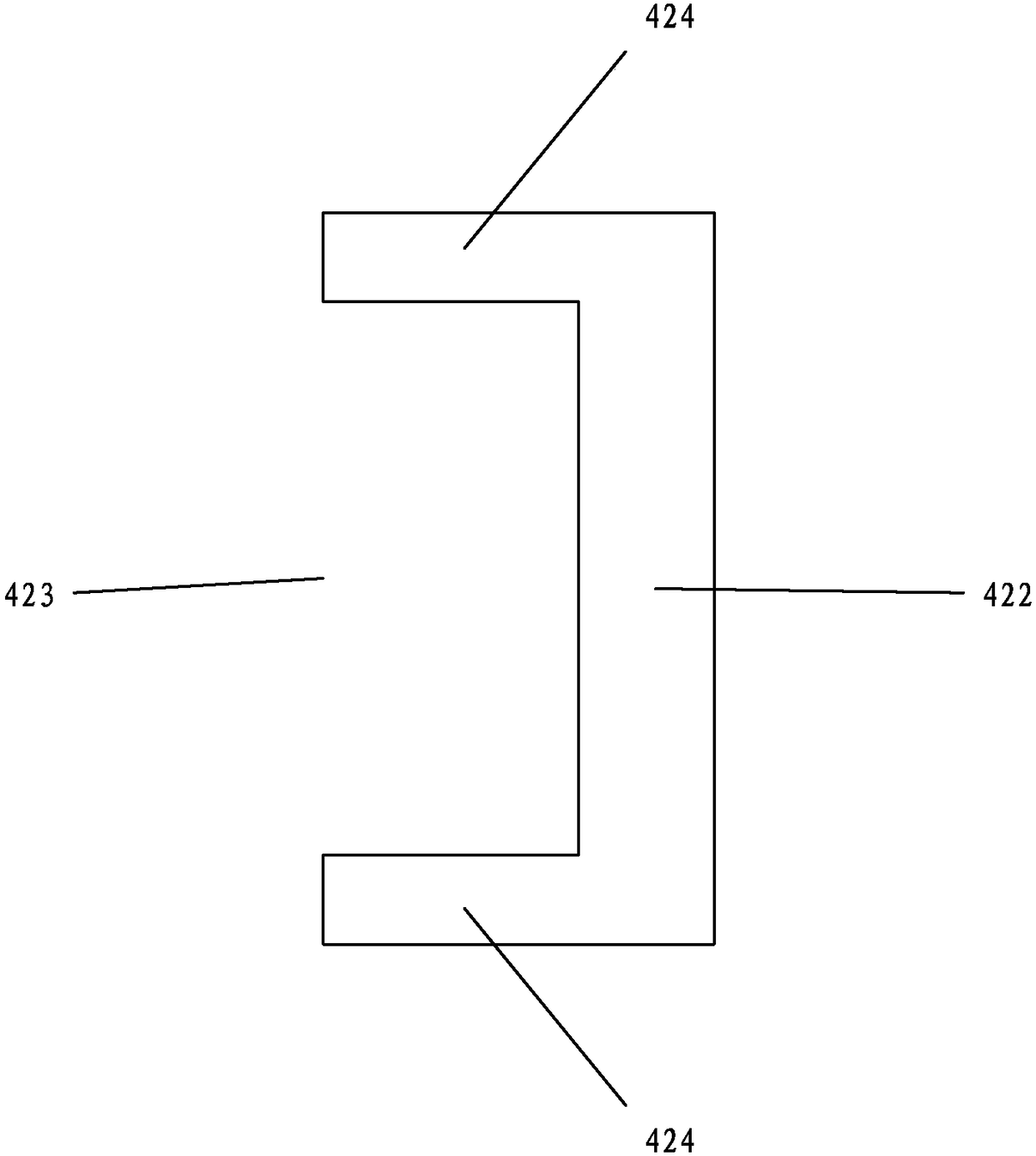

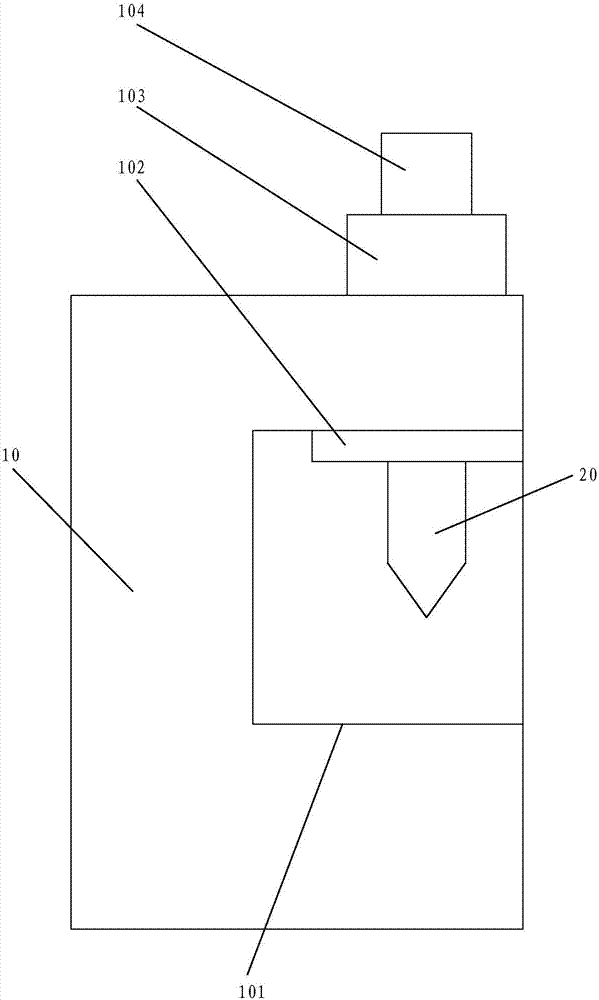

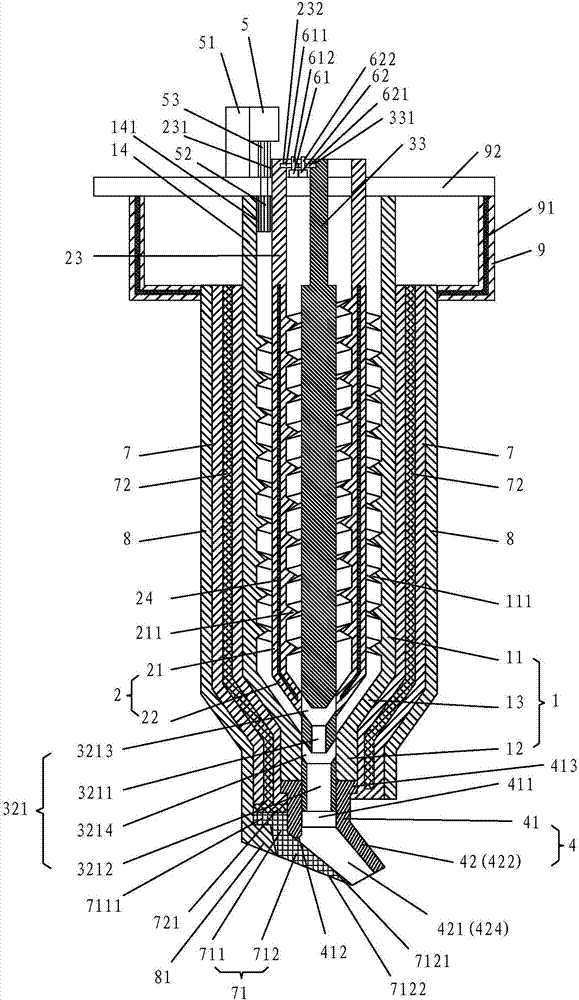

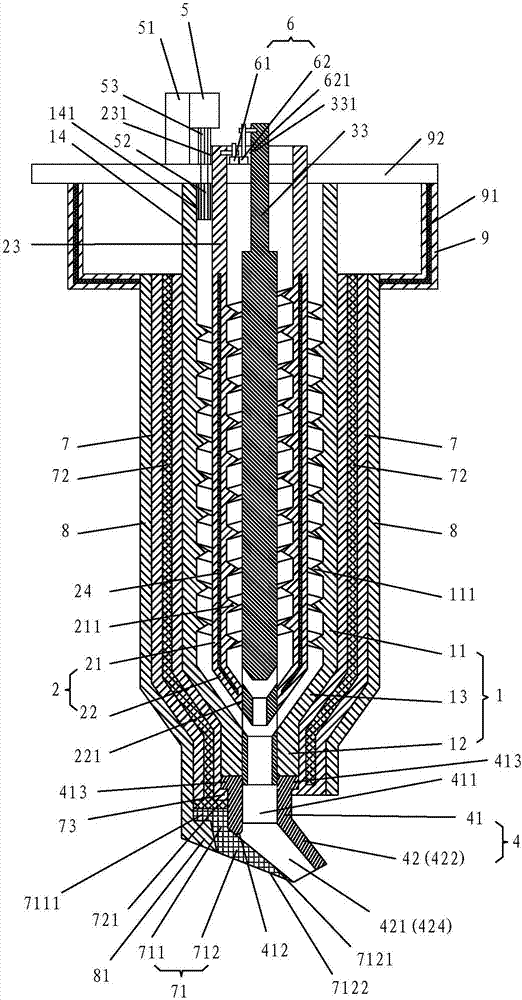

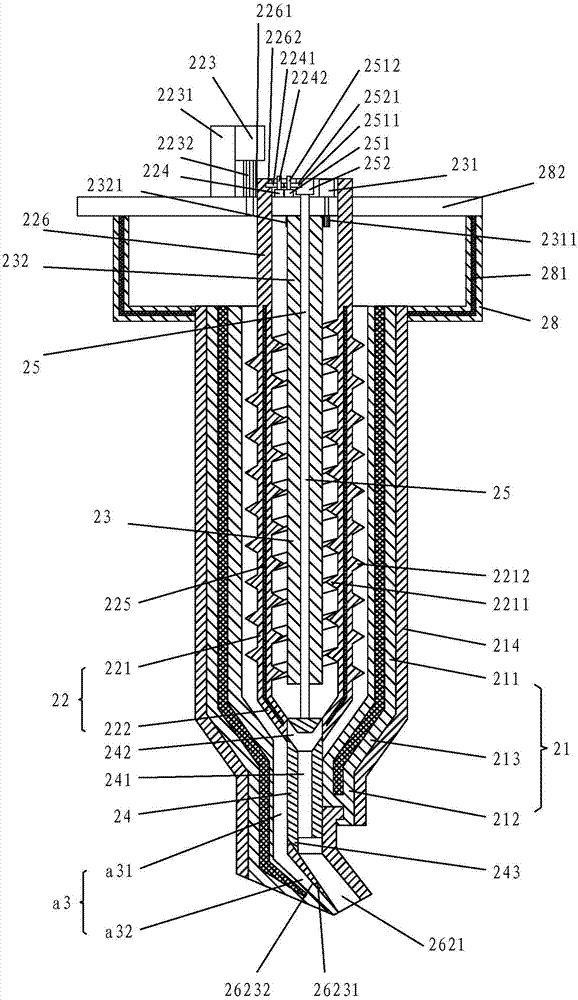

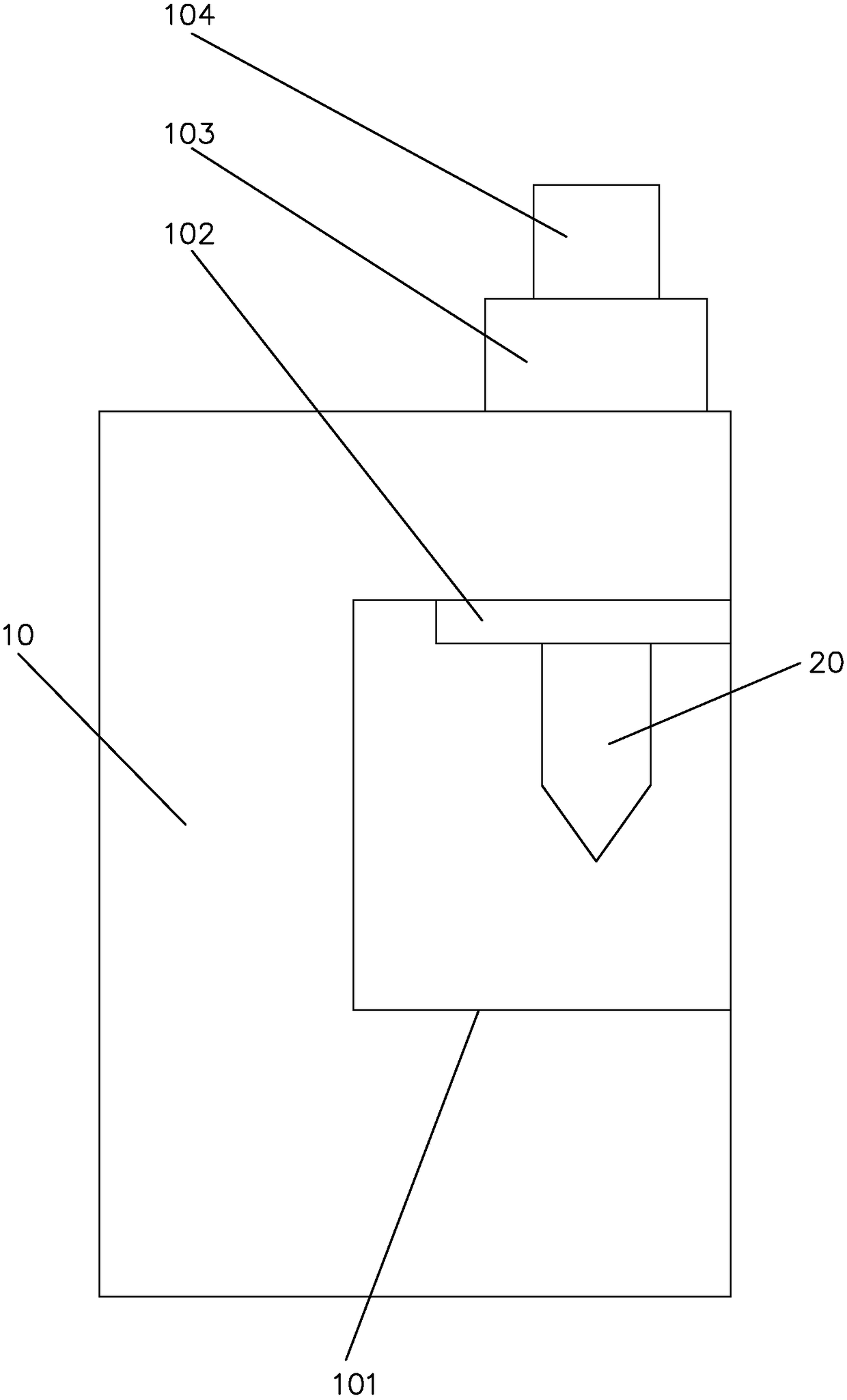

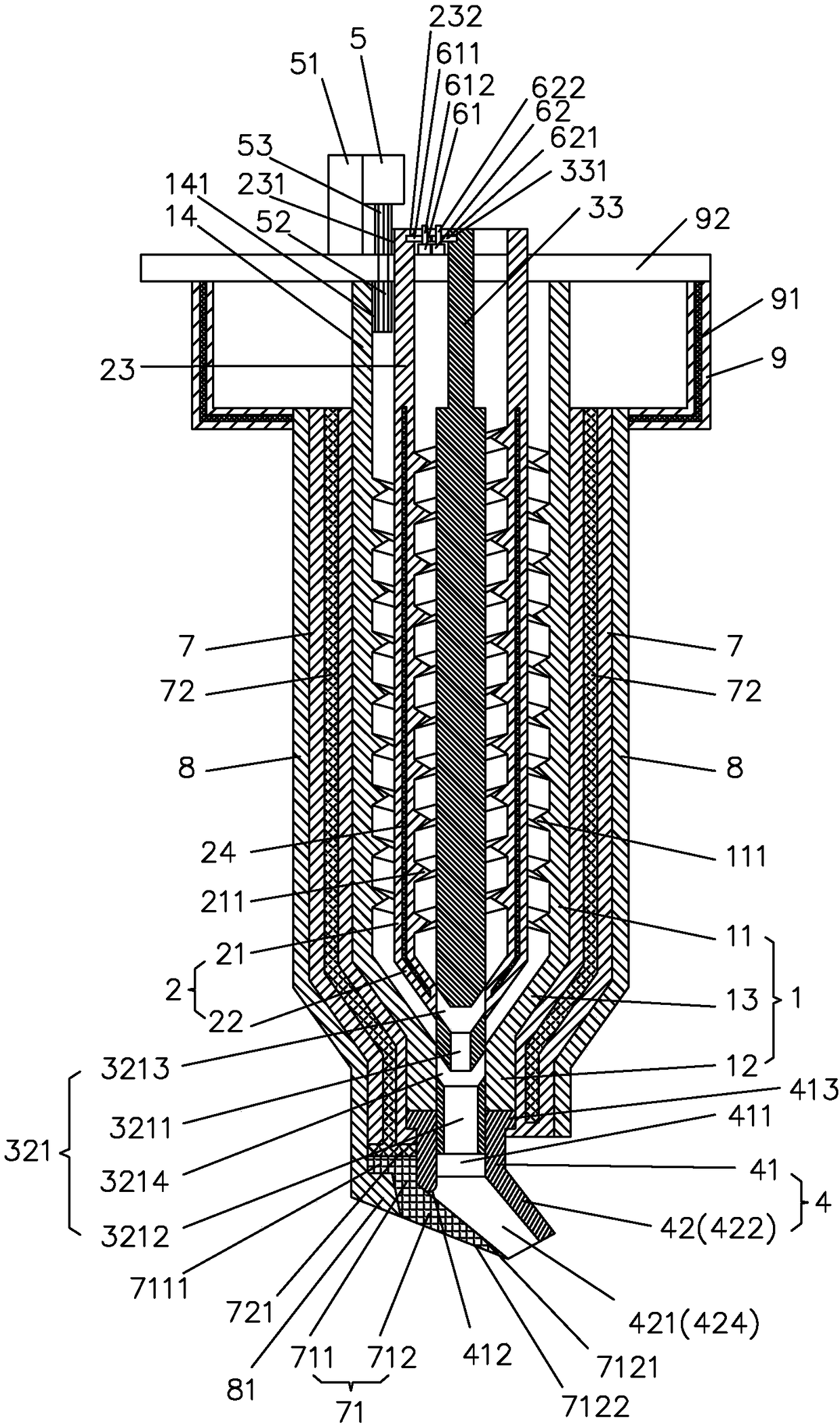

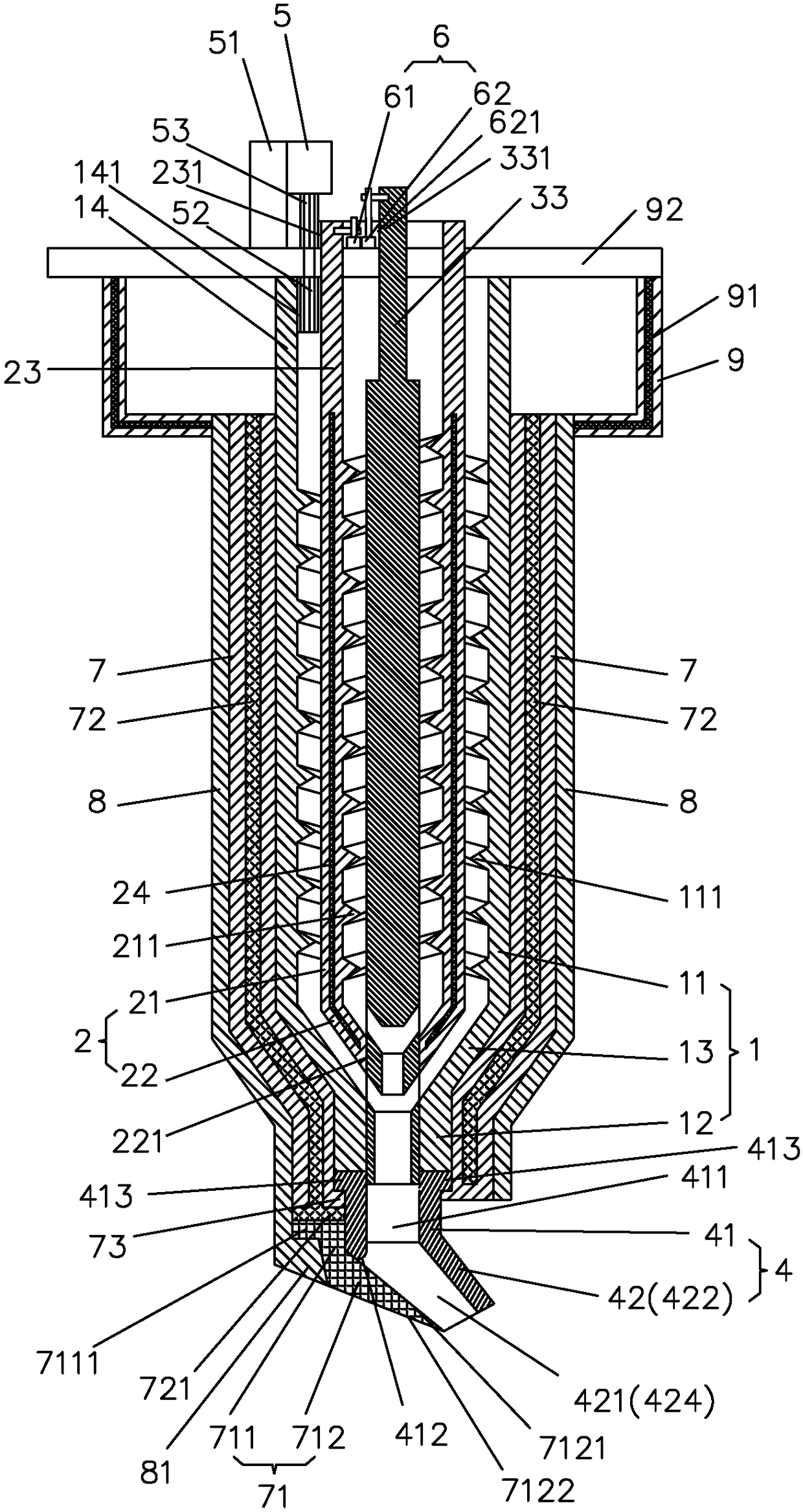

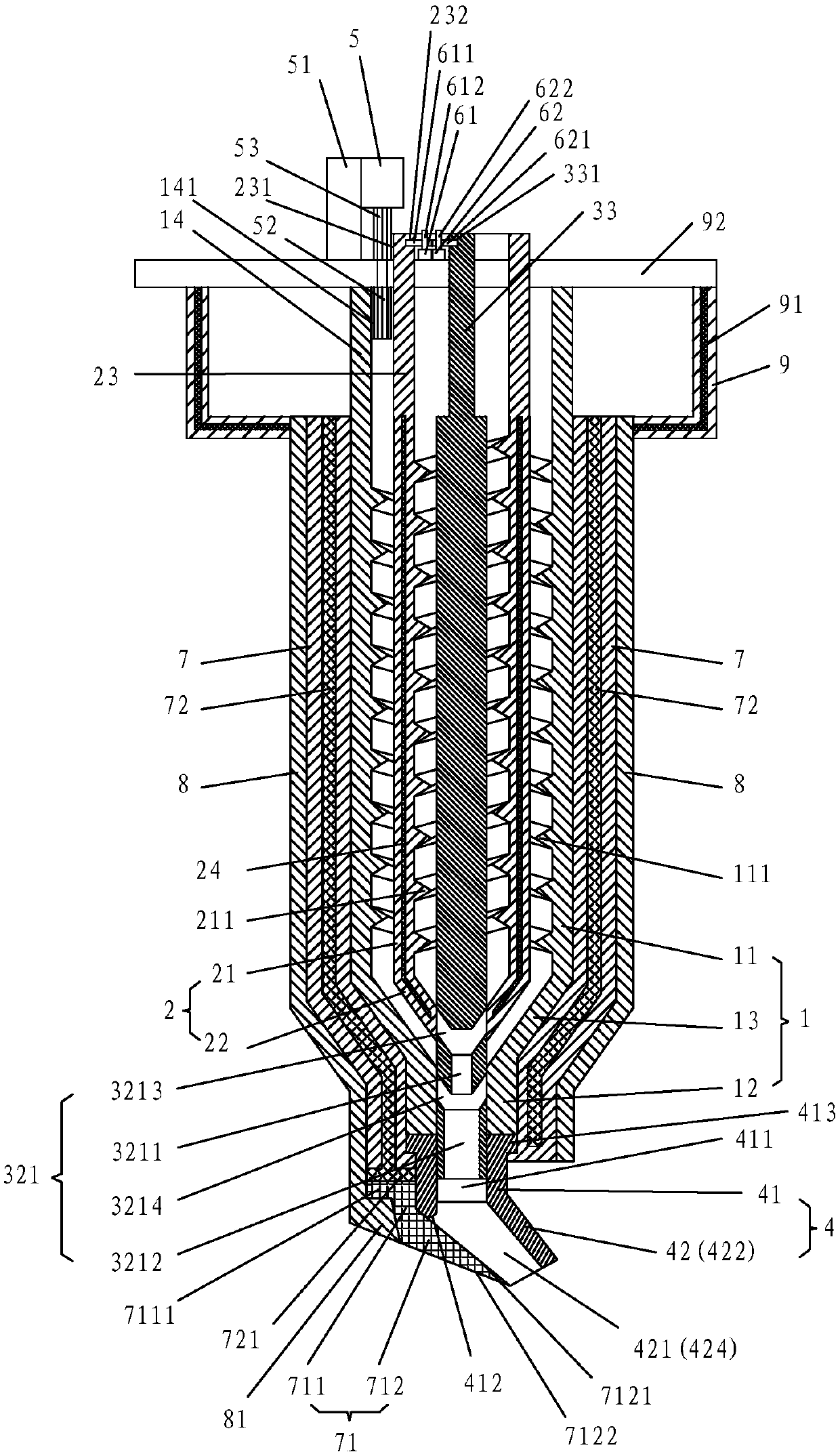

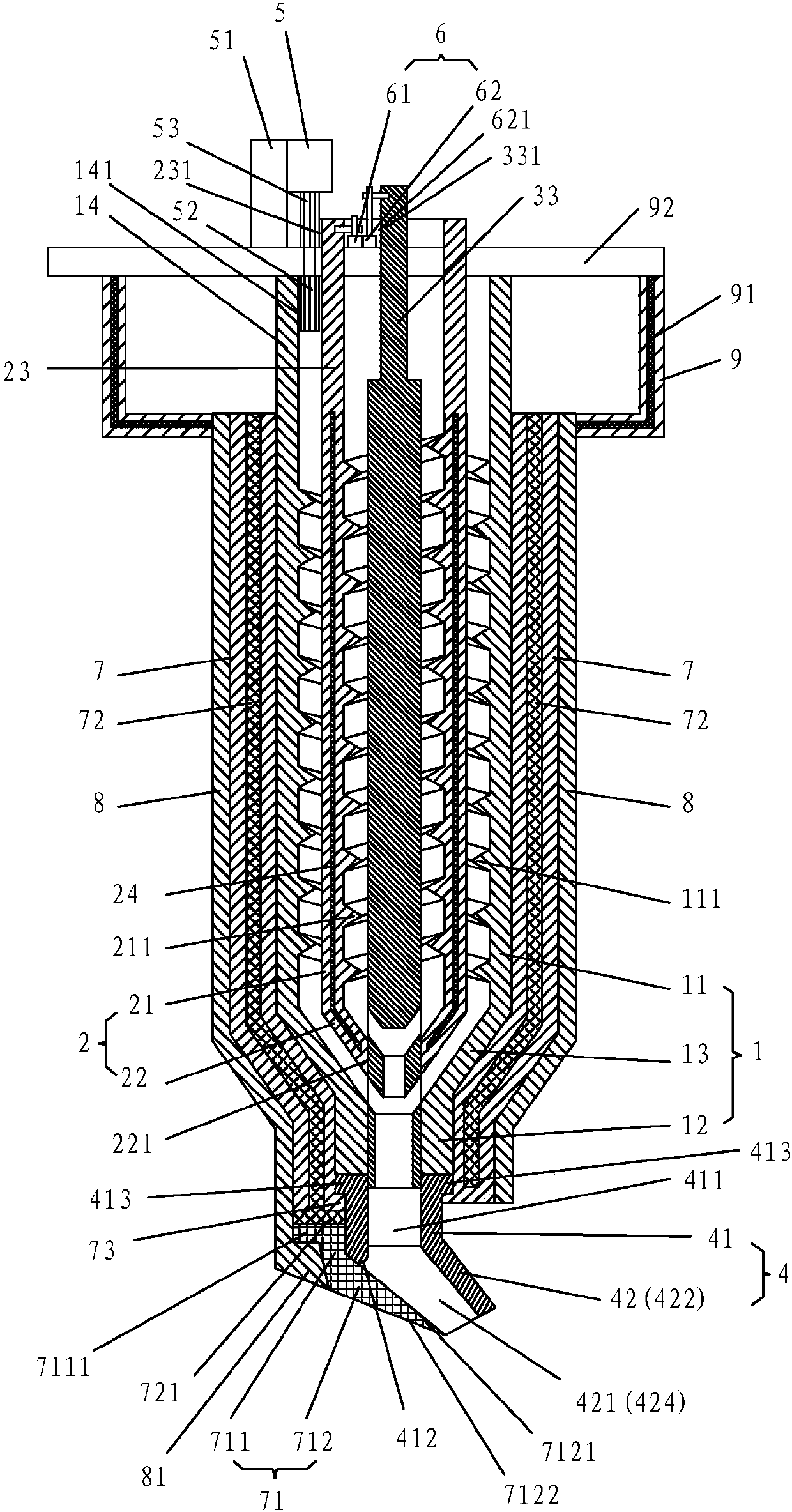

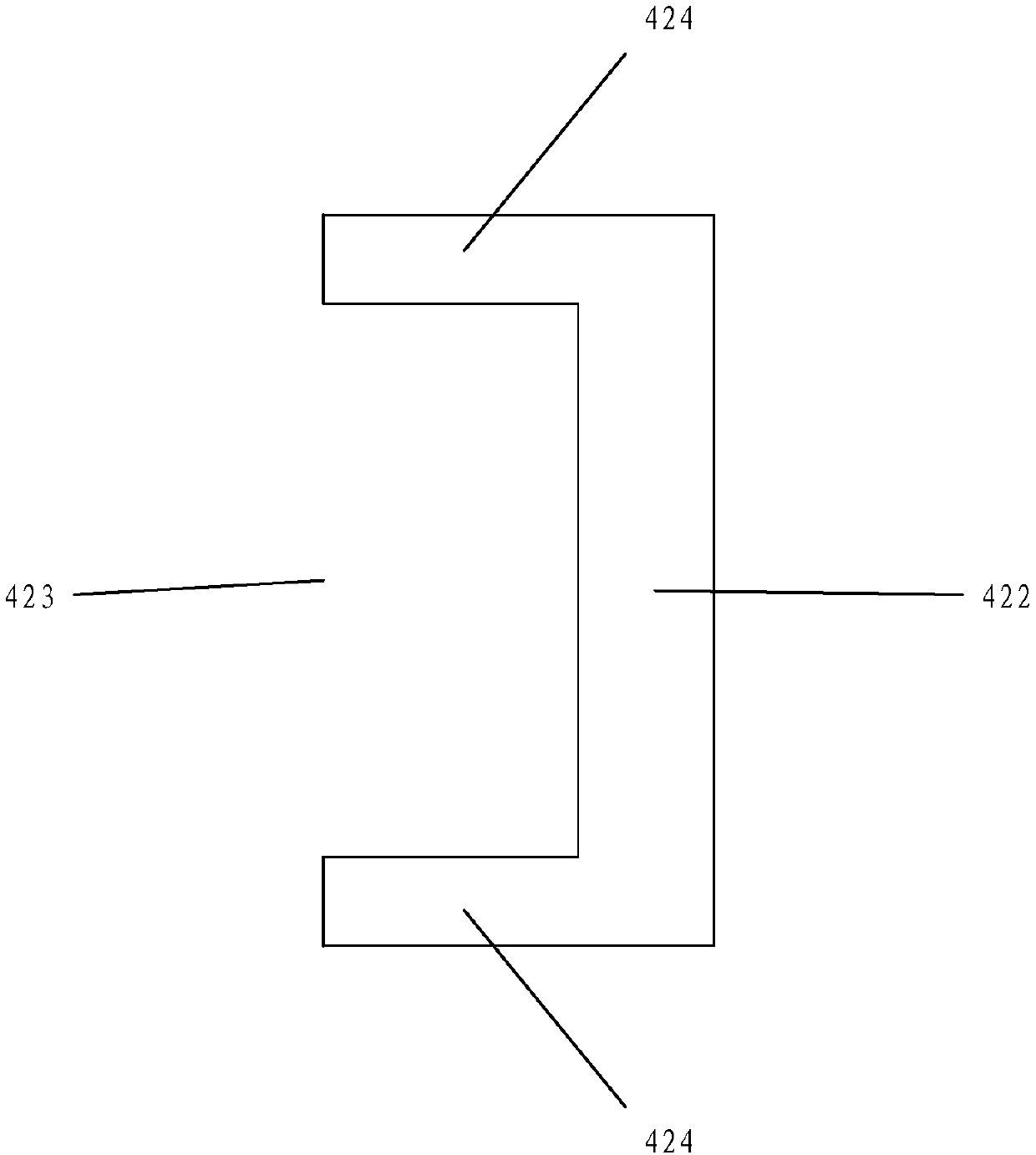

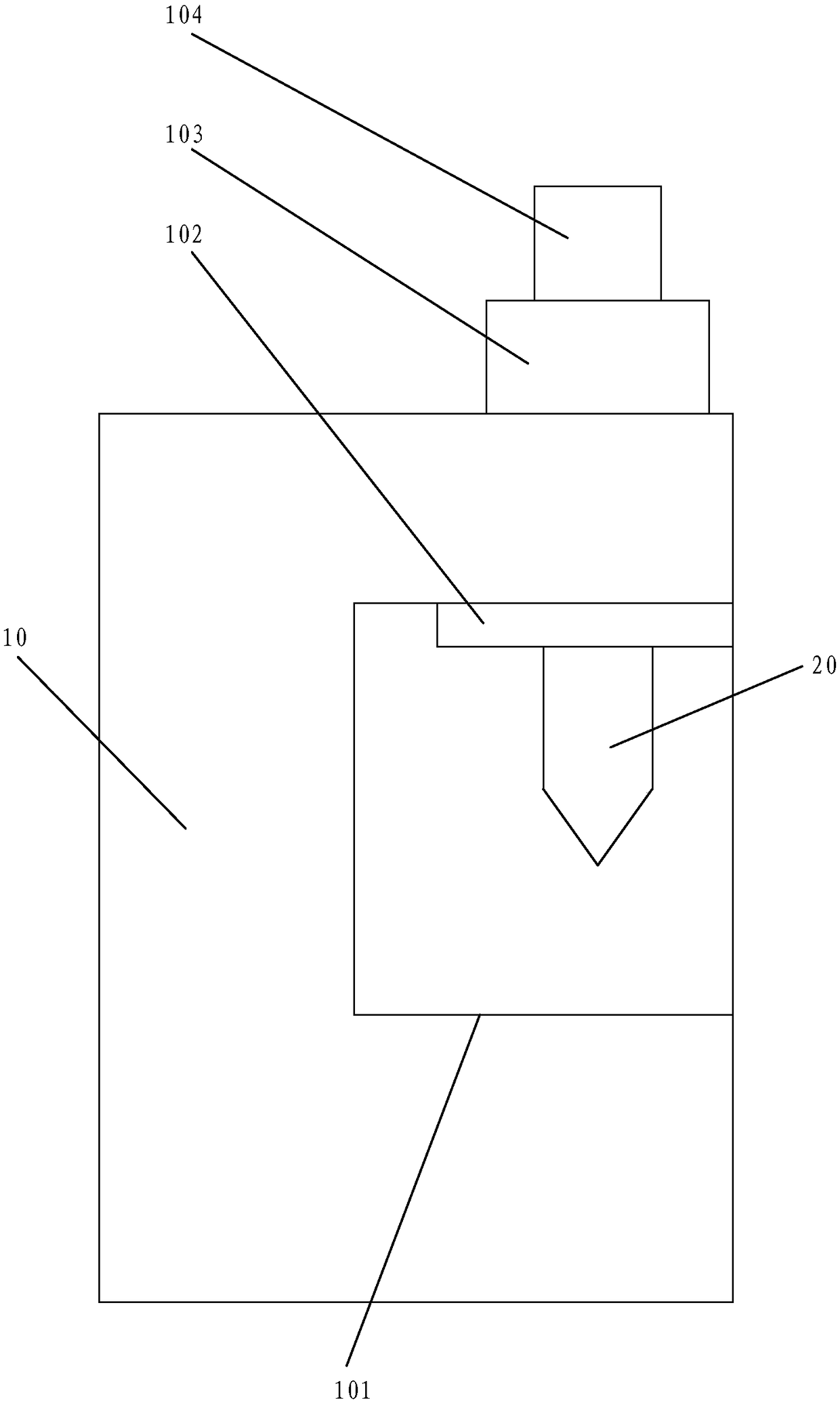

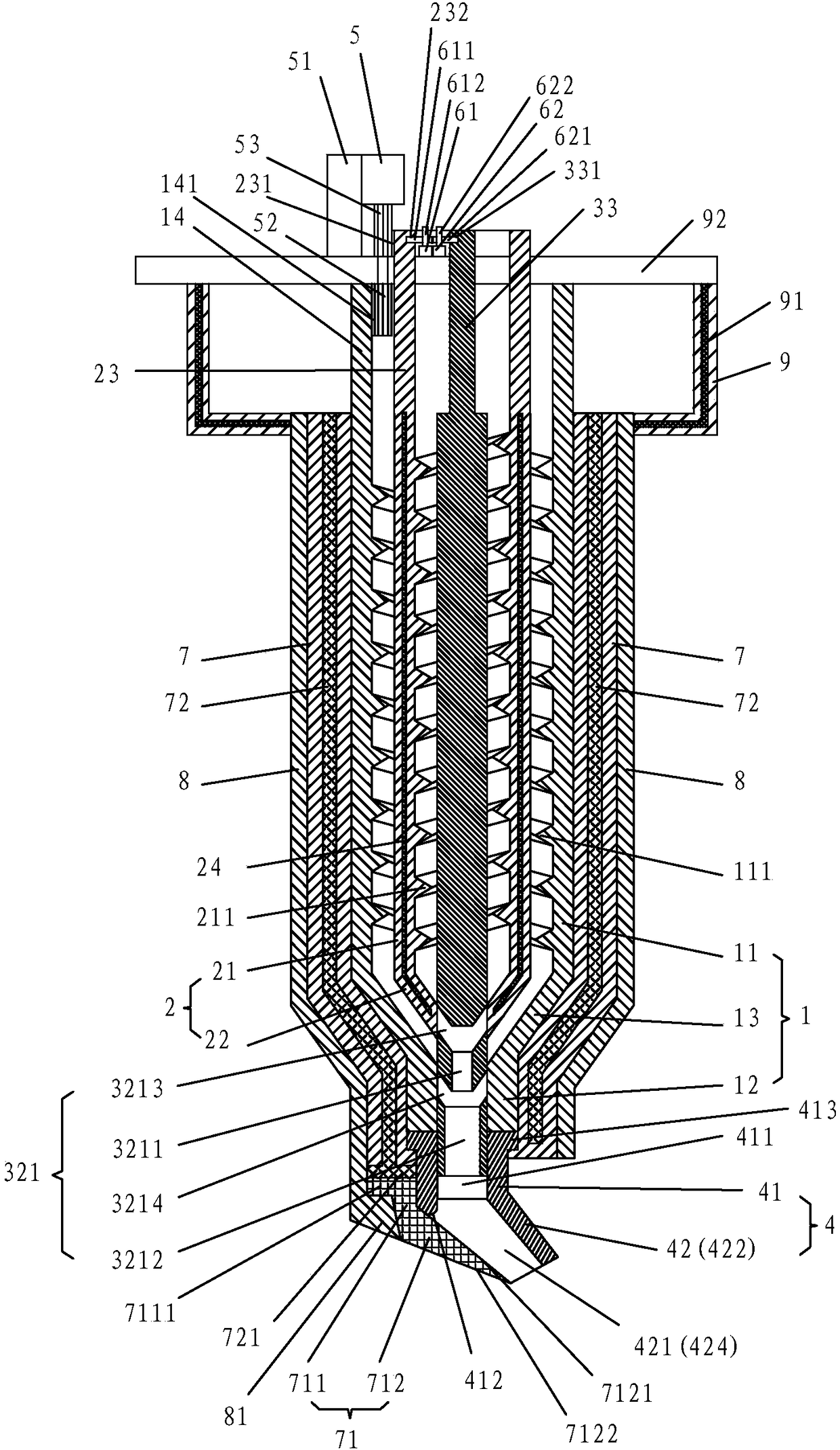

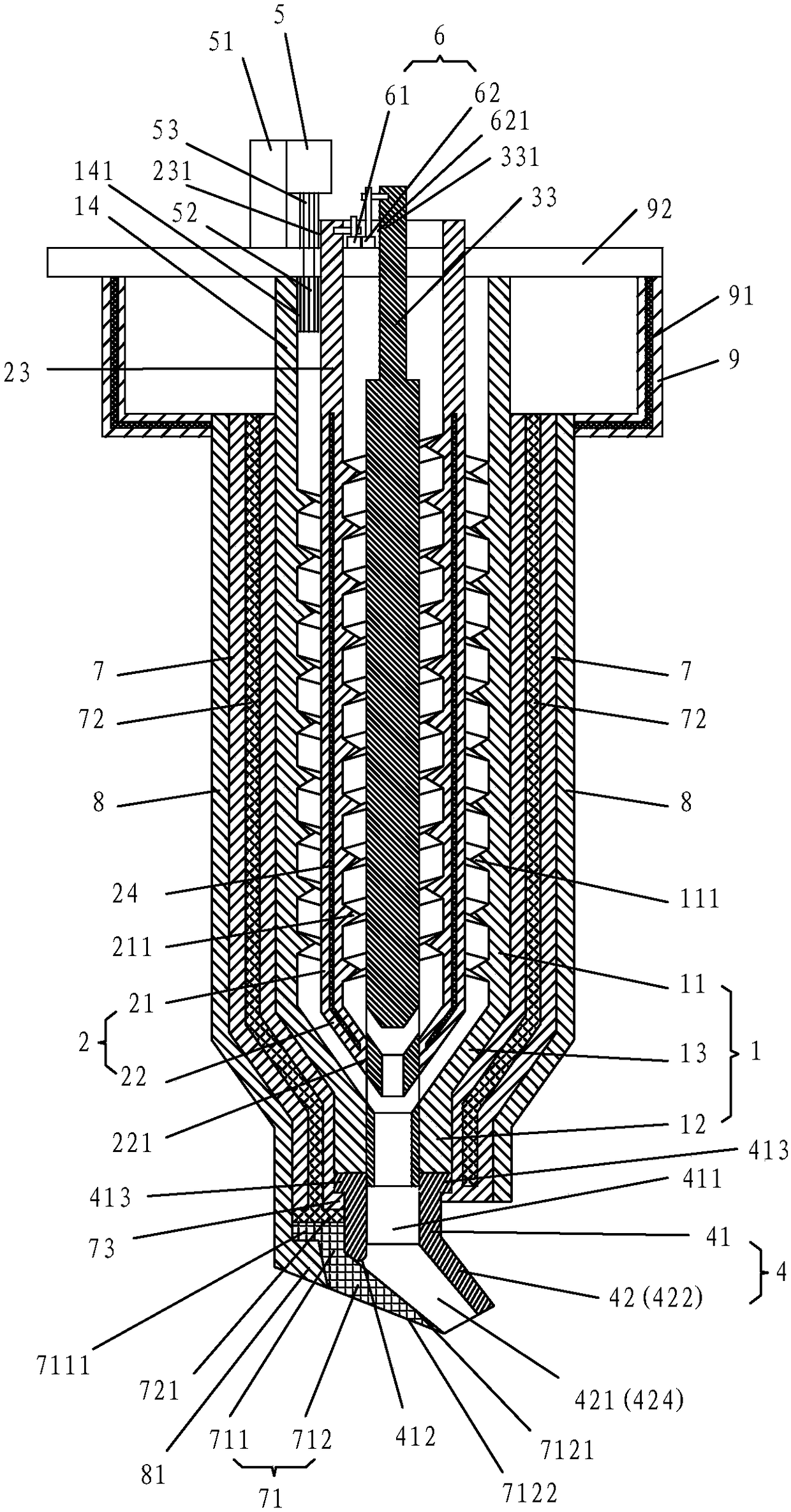

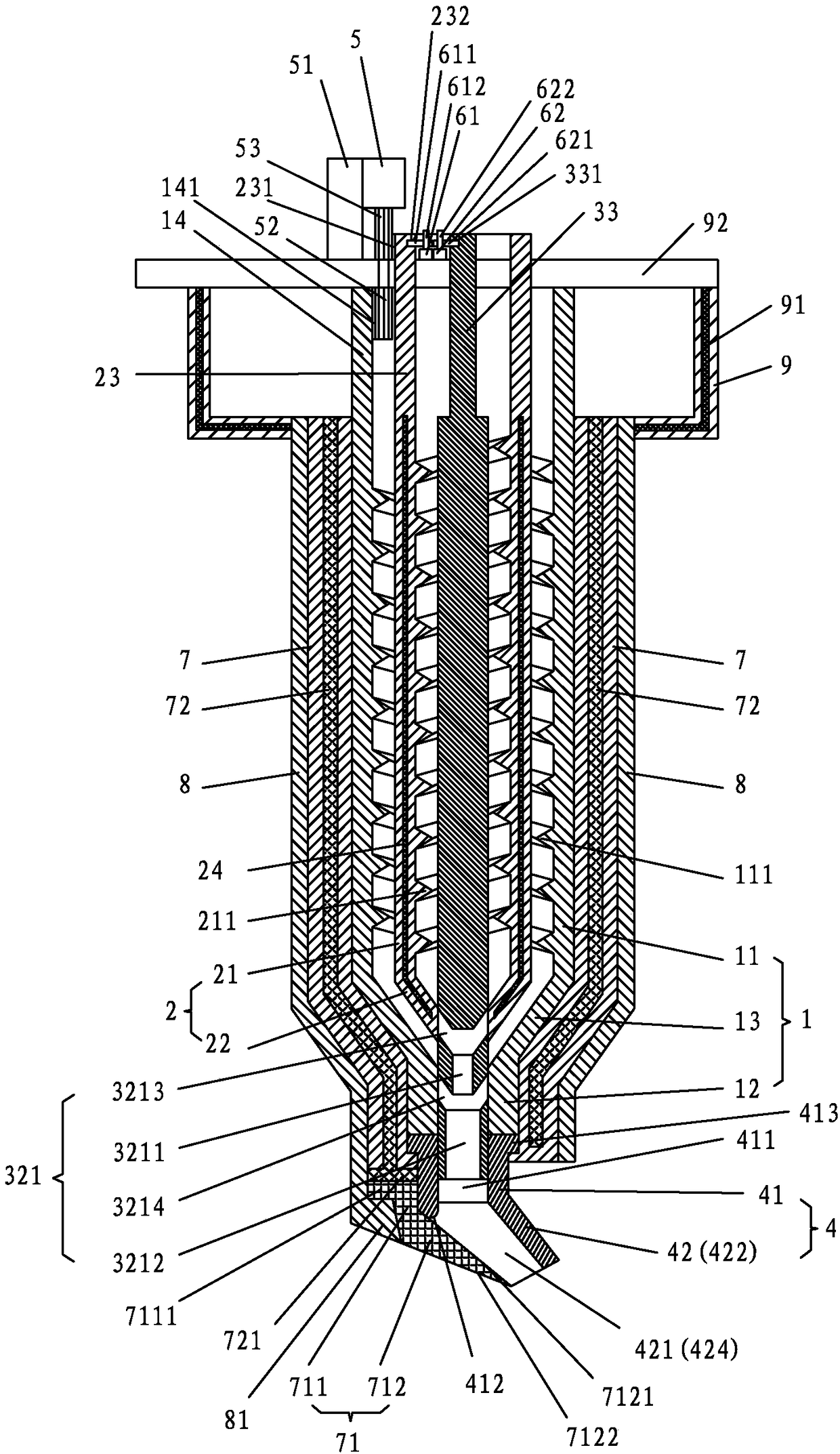

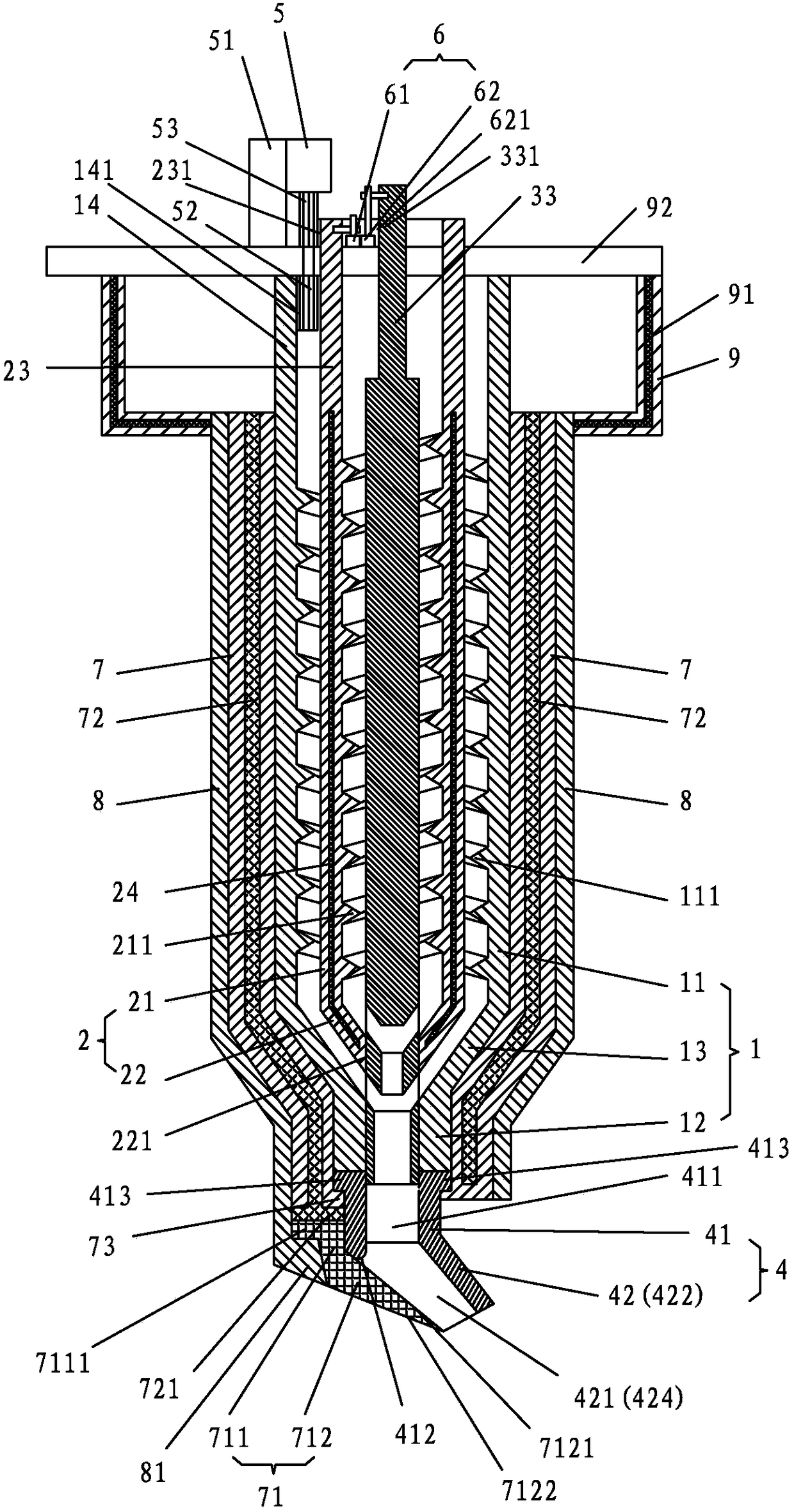

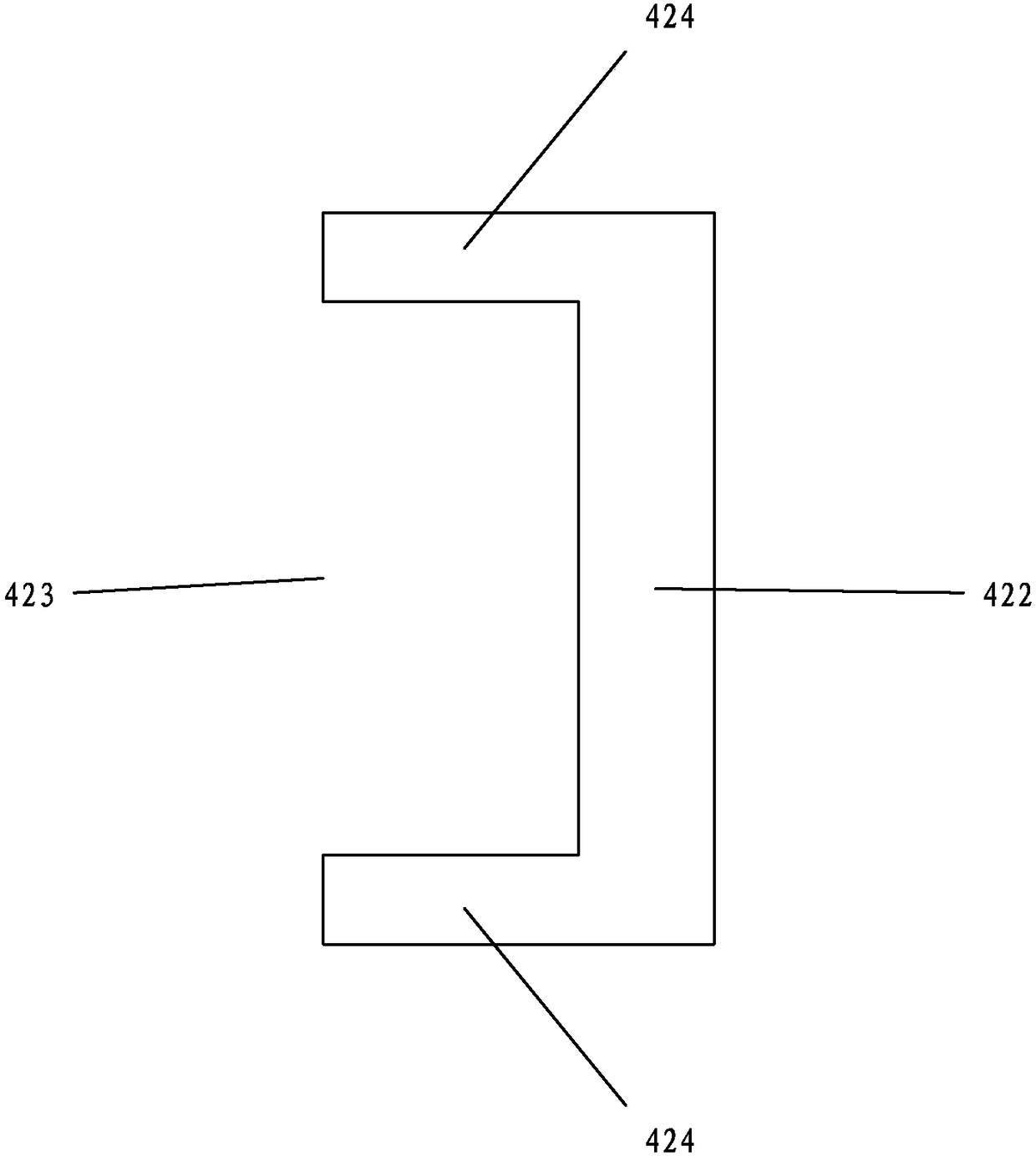

Finished-product integrally jointed type three-dimensional printing head

ActiveCN108312527AIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingWhole bodyJoints types

The invention provides a finished-product integrally jointed type three-dimensional printing head. The finished-product integrally jointed type three-dimensional printing head breaks through a construction form of a traditional three-dimensional printing head; a heating layer is used for carrying out further heating on raw materials in an outer conveying pipe, so that the temperature and flowability of the raw materials in the outer conveying pipe are higher than the temperature and flowability of raw materials in an inner conveying pipe; in a printing process, a lower inclined plane of a flexible heating block is in contact with a printing layer which is slightly cooled and condensed on a lower layer, so that the upper surface of the printing layer on the lower layer can be melted; meanwhile, the raw materials flowing out from an upper feeding hole and the raw materials flowing out from a lower feeding hole are gathered in a material discharging hole; the raw materials flowing out from the lower feeding hole are uniformly distributed at the periphery of the raw materials flowing out from the upper feeding hole to cover the periphery; then the raw materials flow out from a third channel and are in contact with the printing layer on the lower layer, so that the raw materials flowing out from the upper feeding hole and the printing layer on the lower layer are naturally fused toform a whole body, and an obvious jointing surface is not formed between a printing layer on an upper layer and the printing layer on the lower layer; the jointing between the adjacent printing layersis firmer.

Owner:QUANZHOU BILINED TECH CO LTD

Plastic colored sand and processing technique thereof

InactiveCN104530540AChemically stableImprove the uniformity of dispersionTitanium dioxideCarbon black

The invention discloses a plastic colored sand and a processing technique thereof. The plastic colored sand is prepared from 20-30 parts of color master batch pigment, 20-30 parts of low-molecular weight polyethylene, 10-20 parts of nano BaSO4 and 30-50 parts of titanium dioxide. The processing technique comprises the following steps: by using the titanium dioxide and carbon black as base materials, adding the low-molecular weight polyethylene to perform dispersion function, adding the nano BaSO4 to improve the dispersity, banburying, cooling, pulverizing and milling to obtain the product. The plastic colored sand has the advantages of favorable coloring power, favorable dispersity, no pollution and the like, is convenient for measurement, does not change the physical properties of the plastic, and can be widely used in plastics, rubber, chemical fibers, wire cables and other industries.

Owner:孙恩昌

High performance concrete prepared from wastes

InactiveCN105384400AAvoid Engineering Disaster AccelerationReduce dosageSolid waste managementScrapHigh performance concrete

The invention discloses a high performance concrete prepared from wastes. The high performance concrete is prepared from, by mass, 150-300 parts of cement, 100-200 parts of fly ash, 100-200 parts of mineral powder, 700-1000 parts of waste sands, 700-1000 parts of waste stones, 5-15 parts of an additive, and 150-200 parts of water, wherein the waste sands are second area medium sands, the fineness modulus is 2.3-2.5, and the average particle size is 0.5-0.35mm; and the average particle size of the waste stones is 5.5-25mm. The high performance concrete is made by adopting the waste sands and the waste stones, so economy and environmental protection are realized, and the construction cracking problem is solved.

Owner:BEIJING ZHENGFU CONCRETE CO LTD

Three-dimensional printer (3DP) capable of producing firm finished products

ActiveCN107139452AIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingEngineeringRaw material

The invention provides a three-dimensional printer (3DP) capable of producing firm finished products. Structural forms of traditional 3DPs are broken through, a heating layer is used for further heating raw materials in an outer conveying tube, and the temperature and fluidity of the raw materials in the outer conveying tube are made higher than those of raw materials in an inner conveying tube; in the printing process, the lower bevel of a flexible heating block makes contact with a lower printed layer which is slightly cooled and solidified, and the upper surface of the lower printed layer can be melted; meanwhile, raw materials flowing out of an upper feeding hole and raw materials flowing out of a lower feeding hole are converged in a discharging hole, the raw materials flowing out of the lower feeding hole are distributed uniformly on the peripheries of the raw materials flowing out of the upper feeding hole for a wrapping purpose, and then the raw materials flow out of a third channel to make contact with the lower printed layer, so that the raw materials flowing out of the upper feeding hole, and the lower printed layer are naturally fused into a whole; and an obvious junction surface between an upper printed layer and the lower printed layer does not exist, and junction between the adjacent printed layers are firmer.

Owner:QUANZHOU BILINED TECH CO LTD

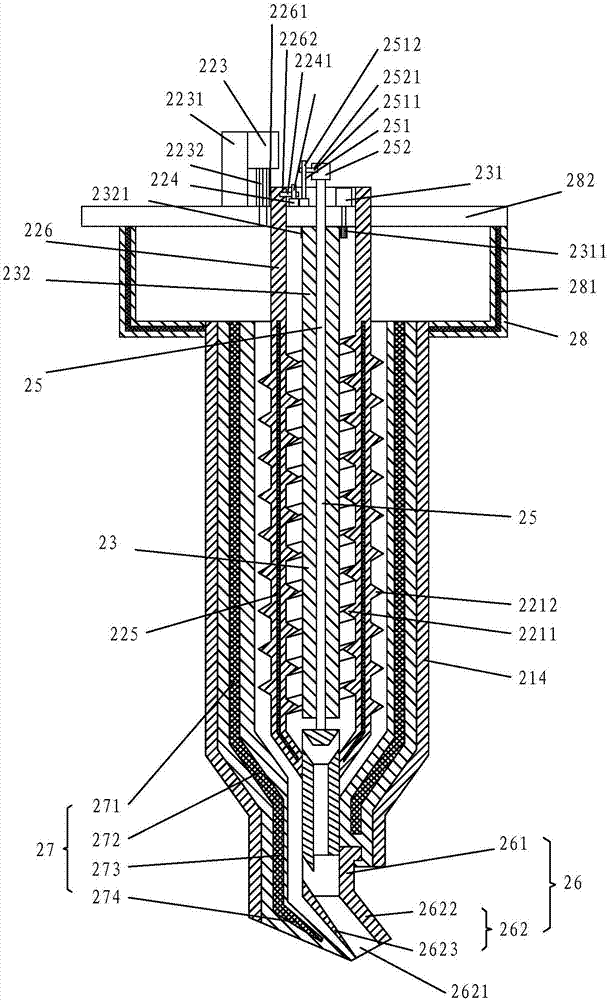

Three-dimensional printer with high practicability

ActiveCN107020742APracticalIncrease temperatureManufacturing heating elements3D object support structuresWhole bodyEngineering

The invention provides a three-dimensional printer with high practicability. The three-dimensional printer breaks through the structure mode of the traditional three-dimensional printer; meanwhile a heating component further heats a raw material between a conveying casing and a conveying pipe, so that the temperature and the flowability of a raw material on the outer side of the conveying pipe are higher than that of a raw material on the inner side of the conveying pipe, that is, the temperature and the flowability of a raw material flowing out from a lower discharging channel are greater than that of a raw material flowing out from a third channel; during printing, a heating inclined plane is in contact with a printing layer in the lower layer, which is slightly cooled and solidified, and the upper surface of the lower layer printing layer is molten; then the raw material flowing out from the lower discharging channel is underlaid between the raw material flowing out from the third channel and the lower layer printing layer with the surface being molten; the raw material flowing out from the lower discharging channel achieves gluing effect to fuse the raw material flowing out from the third channel and the lower layer printing layer into a whole body, so that an obvious connection plane cannot occur between an upper layer printing layer and the lower layer printing layer, and the connection between adjacent printing layers is firmer.

Owner:QUANZHOU BILINED TECH CO LTD

Nano-particle-size ink

The invention relates to a nano-particle-size ink which is composed of the following raw materials in parts by weight: 1-3 parts of Ag powder with the average particle size of 120-150nm, 1-3 parts of Al powder with the average particle size of 60-80nm, 1-3 parts of Cu powder with the average particle size of 200-230nm, 50-70 parts of pigment, 10-15 parts of pentaerythritol rosin ester, 18-22 parts of flaxseed oil, 12-20 parts of polyamide resin, 10-15 parts of alkyd resin, 1-2 parts of polyalkyl ethanediol and 1-2 parts of sodium arylsulfonate. The ink has the advantages of favorable stability, low pigment consumption, high covering power, full color, clear printing image and long service life, and is suitable for industrial production.

Owner:WUXI BENNIU BIOTECH CO LTD

Environment-friendly energy-saving agent

InactiveCN107619691AColor unchangedNo change in liquidityLiquid carbonaceous fuelsEngineeringAmmonia

The invention relates to an environment-friendly energy-saving agent. The environment-friendly energy-saving agent is prepared from the following components of 3 to 10 parts of Span 20, 70 to 85 partsof naphthenic acid, and 10 to 25 parts of ammonia water in a mixing way. The environment-friendly energy-saving agent has the advantages that after mixing with diesel and water, the original color and the original flowing property of diesel are not changed, the oil and water are not separated, and the quality warranty period of original mixing is extended from dozens of days to half of one year.

Owner:都江堰惠农生物技术有限责任公司

Preparation method for efficient and environment-friendly metal injection molding feed

InactiveCN112276074AReduce consumptionReduce pollutionTransportation and packagingMetal-working apparatusParaffin waxAdhesive

The invention relates to the technical field of metal injection molding, in particular to a preparation method for an efficient environment-friendly metal injection molding feed. The preparation method comprises the following step I of preparing adhesive comprising the following components by weight: 65-85 parts of PEG, 15-25 parts of paraffin, 1-5 parts of propping agents and 2-10 parts of toughening agents; the step II of performing vacuum drying for different processing aids, such as the PEG and the paraffin, and drying in a constant-temperature vacuum drying oven at 60 DEG C for 3-6 hours;and the step III of adding the dried raw materials to a constant-temperature mixing mill, starting stirring at the speed of 10-15 revolutions per minute, starting heating at the same time, and setting the temperature to be 180 DEG C-190 DEG C. The method for preparing the metal injection molding feed is safer, more environmentally friendly and more efficient; on the premise of ensuring that the fluidity and the molding performance of the metal feed are not changed, the degreasing time and the sintering time are shortened, and the energy consumption is reduced; and the environmental pollutionis reduced.

Owner:苏州炻展新材料科技有限公司

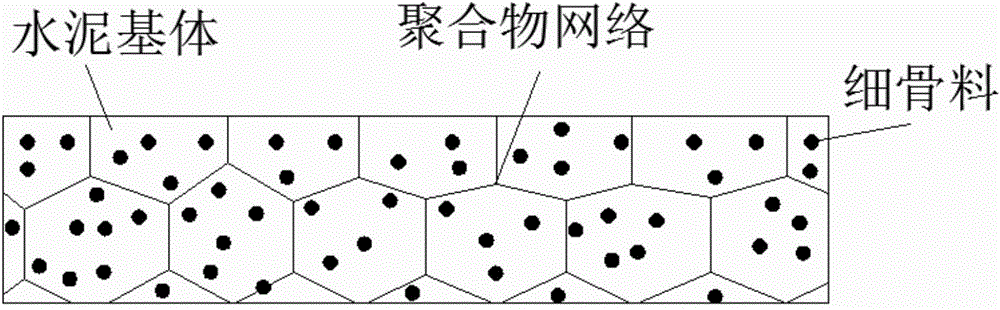

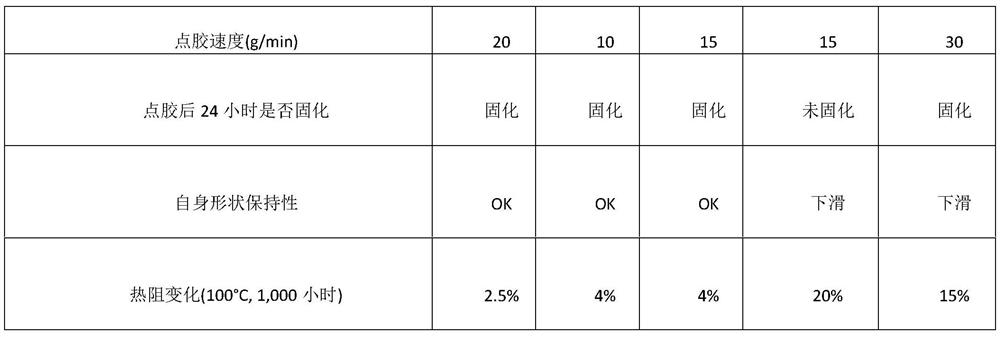

Preparation method of special-shaped polymer structure reinforcing composite light-weight cement

InactiveCN104016642AIncrease usage intensityRealize integrated formingCement compositesCement slurry

The invention relates to a preparation method of special-shaped polymer structure reinforcing composite light-weight cement, relating to a preparation method of composite light-weight cement and aiming at obtaining a light-weight high-strength cement building material. The preparation method comprises the following steps of 1, preparing a special-shaped polymer structure; 2, preparing cement slurry; 3, forming a light-weight cement composite material. The preparation method disclosed by the invention improves the reinforcing mechanism of the cement-based composite material from the independent reinforcement of a discontinuous reinforcement phase into the synergetic enhancement of a continuous reinforcement phase by substituting a continuous polymer special-shaped structure network for a discontinuous polymer fiber, thereby effectively enhancing the usage property of the cement-based composite material. The preparation method disclosed by the invention effectively reduces the weight of the material by 40%-50%, does not change the flowing property of the cement slurry, can be used for freely designing the structure of the reinforcement phases and integrally forming the composite material and a prefabricated structure, has the advantages of simple preparation process, low cost, high designability of a technical process, abundance in used raw material and the like and can effectively reduce the weight of the cement building material.

Owner:HARBIN INST OF TECH

Three-dimensional printer for strong finished product integrity

ActiveCN108515692AIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingRaw material3D printing

The invention provides a three-dimensional printer for a strong finished product integrity. A heating layer makes the temperature and the fluidity of a raw material in an outer conveying tube higher than the temperature and the fluidity of a raw material in an inner conveying tube, the lower slope of a flexible heating block is in contact with a slightly cooled and solidified lower printed layer in the printing process to make the upper surface of the lower printed layer melted, the raw material flowing out of an upper feeding hole and a raw material flowing out of a lower feeding hole meet ina discharging hole, and the raw material flowing out of the lower feeding hole is uniformly distributed surrounding the raw material flowing out of the upper feeding hole to wrap the raw material flowing out of the upper feeding hole, then flows out of a third channel and is in contact with the lower printed layer to make the raw material flowing out of the upper feeding hole and the lower printed layer naturally melted integrally. A first heat insulating layer avoids the heating layer and heat of the raw material in the outer conveying tube from being delivered to the raw material in the inner conveying tube in order to avoid the normally designed fluidity of the raw material in the inner conveying tube from being affected. A second heat insulating layer ensures the integral heat insulating effect of a whole printing head.

Owner:QUANZHOU BILINED TECH CO LTD

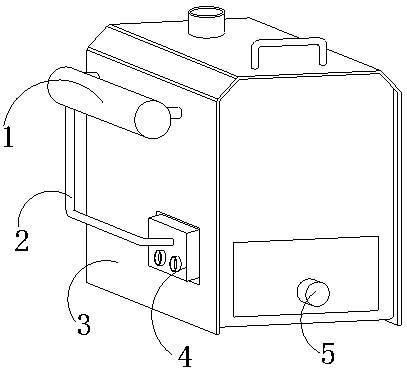

High efficiency liquid-permeable and gas-barrier fluid composite membrane system

InactiveCN110559860APuncture aidNo change in liquidityMembranesSemi-permeable membranesEmbedmentEngineering

The invention discloses a high efficiency liquid-permeable and gas-barrier fluid composite membrane system, which consists of an outer pipe, a connecting pipe, a membrane separation device, a communicating block and an output pipe. The outer pipe is connected to the membrane separation device, the output pipe is arranged at the bottom of the membrane separation device, and runs through the membrane separation device, the outer pipe and the communicating block are connected together by the connecting pipe, and the communicating block is connected to the membrane separation device. The inventionhas the beneficial effects that: an external mechanical force is utilized to control the rotation switch of a central shaft between a clockwise state and an anticlockwise state, thus reaching the purpose of controlling the separation and embedment of stab rods on puncture heads and holes on an outer ring layer, circulating motion of the stab rods is utilized to puncture bubbles accumulated on a separation membrane, embedment block bulges are arranged on the outer ring layer, and along with the rotation of a central shaft, bubbles at the edge can be punctured all the time, thus guaranteeing constant circulation performance of the separation membrane in the filtering process of liquid-permeable and gas-barrier fluid.

Owner:白海山

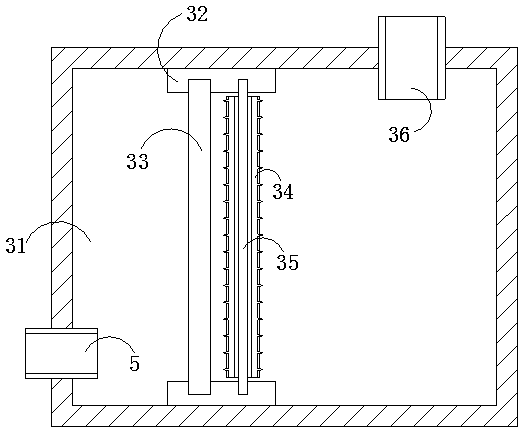

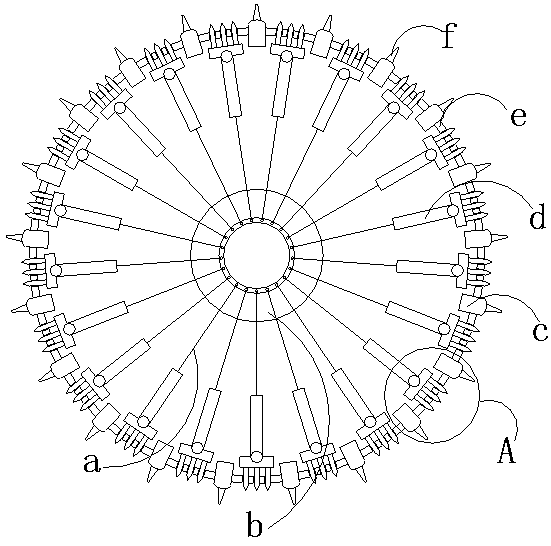

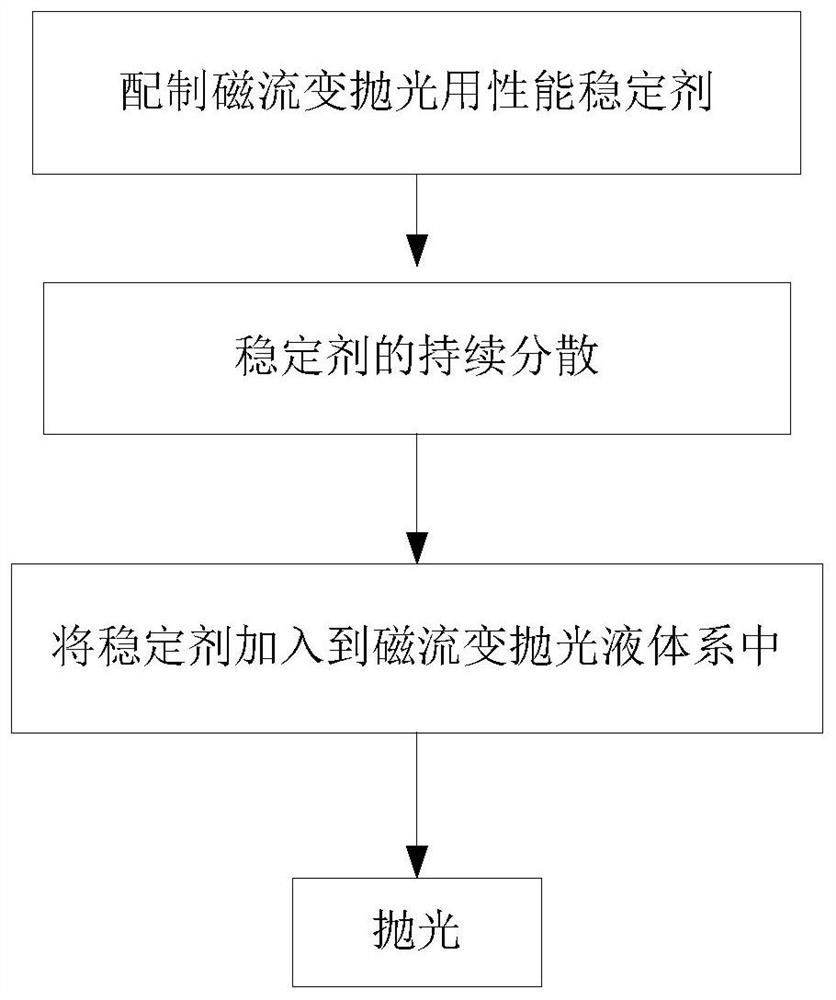

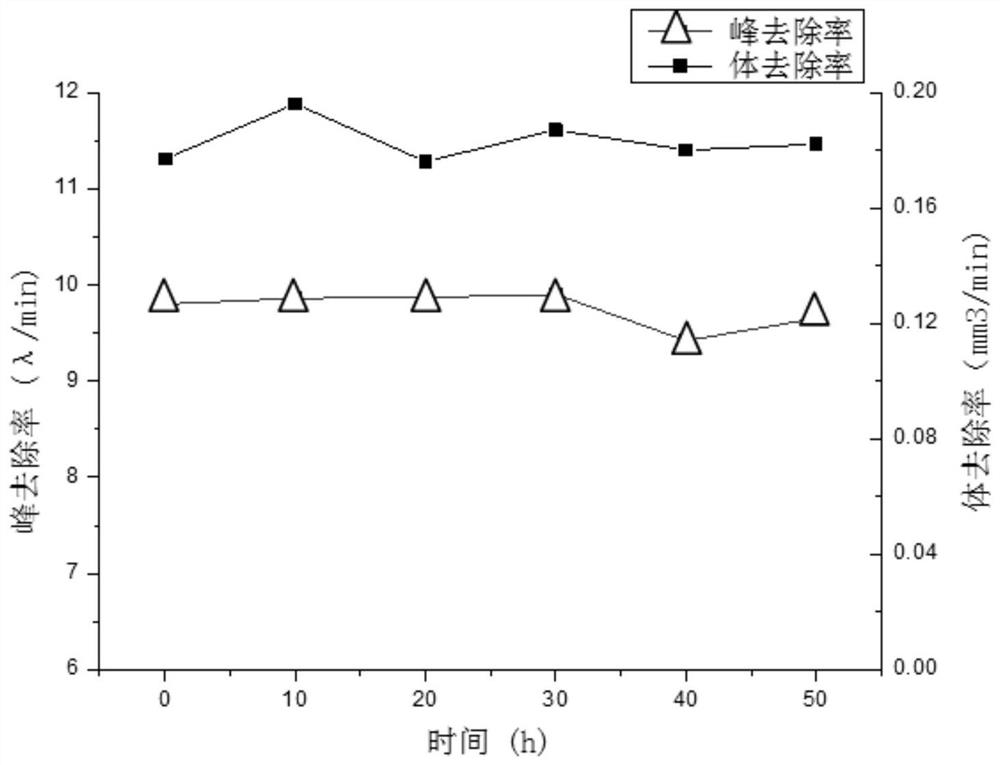

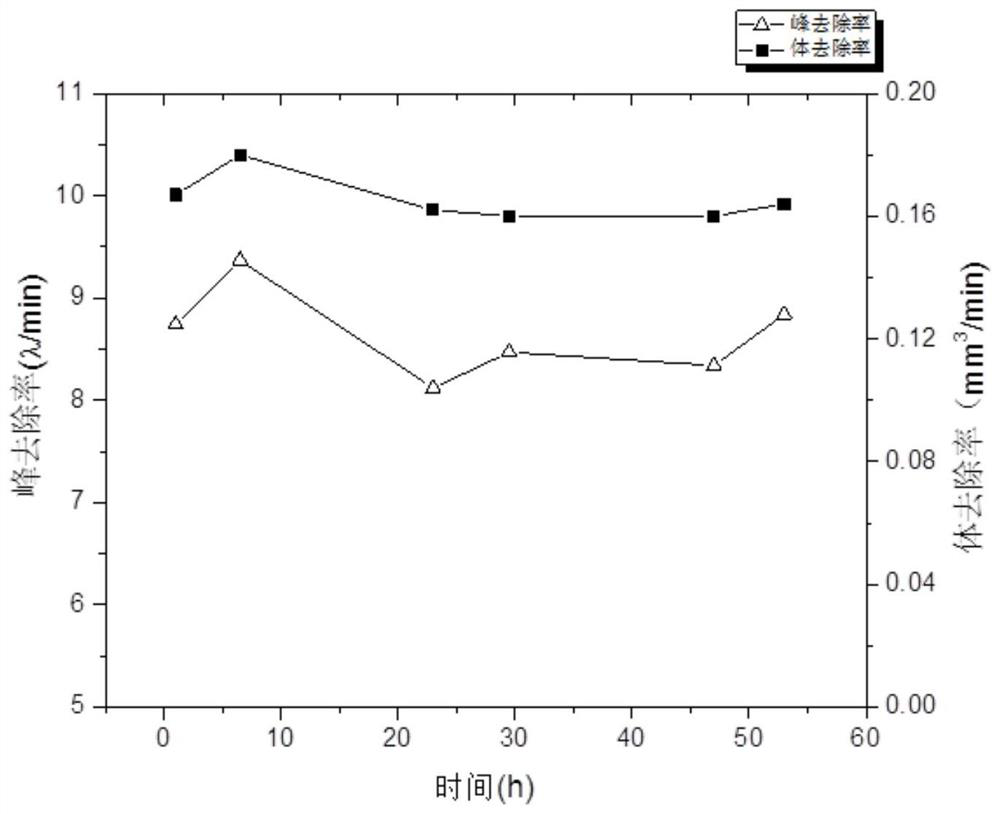

Method for maintaining polishing efficiency of magnetorheological polishing liquid, stabilizer and preparation method of stabilizer

PendingCN112980333ASimple compositionEasy to operatePolishing compositions with abrasivesWettingOxidizing agent

The invention discloses a method for maintaining the polishing efficiency of a magnetorheological polishing liquid, a stabilizer and a preparation method of the stabilizer, and solves the technical problems that the polishing efficiency stability of an existing magnetorheological polishing solution is poor, and the long-time use requirement cannot be met. The stabilizer comprises the following components in percentage by mass: 12%-30% of abrasive particles, 0.5%-5% of a wetting agent, 0.05%-5% of a dispersing agent, 0.2%-3% of an antioxidant and the balance of water. The magnetorheological polishing liquid has the advantages that the polishing efficiency is stable after the stabilizer is added, and long-time use is met.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

A 3D printing head with smooth feeding

ActiveCN107139467BIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingEngineeringJoint surface

The invention proposes a three-dimensional printing head with smooth feeding, which breaks through the structural form of the traditional three-dimensional printing head. The heating layer further heats the raw materials in the outer conveying pipe, so that the temperature and fluidity of the raw materials in the outer conveying pipe are higher than those in the inner conveying pipe. The temperature and fluidity of the raw material in the tube. During the printing process, the lower inclined surface of the flexible heating block contacts the slightly cooled and solidified printing layer of the lower layer, which can melt the upper surface of the lower printing layer. At the same time, the raw material flowing out of the upper feeding hole and the The raw materials flowing out of the lower feeding hole meet in the lower feeding hole, and the raw materials flowing out of the lower feeding hole will be evenly distributed around the raw materials flowing out of the upper feeding hole for wrapping, and then flow out from the third channel to contact the lower printing layer, making the upper printing layer The raw materials flowing out of the feed hole and the lower printing layer are naturally integrated into one, so that there is no obvious joint surface between the upper printing layer and the lower printing layer, and the joint between adjacent printing layers is stronger.

Owner:QUANZHOU BILINED TECH CO LTD

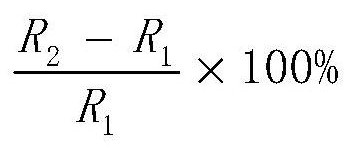

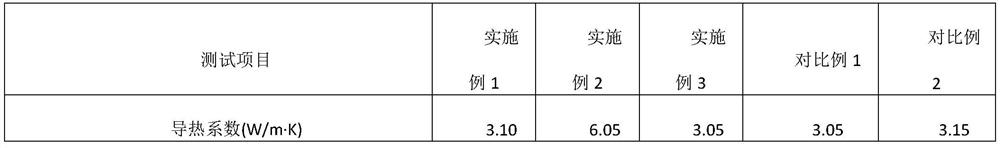

Silicone-free gel-like thermally conductive composition

ActiveCN107828105BImprove insulation performanceHigh dielectric strengthHeat-exchange elementsPhysical chemistryHeat sink

The invention provides an organosilicone-free gel-like thermal conduction composition, and relates to the field of thermal conduction interface materials. The invention in particular relates to organosilicone-free thermal conduction gel which is applied in electronic products and communication equipment and is used for heat conduction of contact interfaces of heating elements and cooling fins. Thethermal conduction gel is prepared from organosilicone-free base oil, dry oil, heat conduction filler, a thixotropic agent and additives. The thermal conduction gel has the advantages of extrudable dispensing, high thermal conductivity, excellent shape retention capability and no organic silicon contamination, and can significantly improve the long-term reliability performance of the electronic products at the same time.

Owner:BEIJING BEIHUAXINXIANG SPECIAL MATERIAL TECH

Wet granulation process of electric jade powder

Owner:温州炫邦新材料有限公司

Preparation method of composite lightweight cement reinforced by special-shaped polymer structure

InactiveCN104016642BIncrease usage intensityRealize integrated formingCement compositesCement slurry

The invention relates to a preparation method of special-shaped polymer structure reinforcing composite light-weight cement, relating to a preparation method of composite light-weight cement and aiming at obtaining a light-weight high-strength cement building material. The preparation method comprises the following steps of 1, preparing a special-shaped polymer structure; 2, preparing cement slurry; 3, forming a light-weight cement composite material. The preparation method disclosed by the invention improves the reinforcing mechanism of the cement-based composite material from the independent reinforcement of a discontinuous reinforcement phase into the synergetic enhancement of a continuous reinforcement phase by substituting a continuous polymer special-shaped structure network for a discontinuous polymer fiber, thereby effectively enhancing the usage property of the cement-based composite material. The preparation method disclosed by the invention effectively reduces the weight of the material by 40%-50%, does not change the flowing property of the cement slurry, can be used for freely designing the structure of the reinforcement phases and integrally forming the composite material and a prefabricated structure, has the advantages of simple preparation process, low cost, high designability of a technical process, abundance in used raw material and the like and can effectively reduce the weight of the cement building material.

Owner:HARBIN INST OF TECH

C100 high-performance concrete and formulation method thereof

A C100 high-performance concrete, which is formed by mixing and gelling cementitious materials, sand, stone, water and admixtures. The cementitious materials include cement and admixtures. The amount of cementitious materials added per cubic meter of concrete 500-600kg, of which the cement is 42.5; the admixture has three components of silica fume, fly ash and slag powder, and contains active SiO2 in an amount of 20%-40% of the total weight of the cementitious material, and its specific surface area 1000-1200m2 / kg; the admixture is polycarboxylate high-efficiency water reducer with a dosage of 2% to 5% of the total weight of the cementitious material; the activator is soot and coal with a dosage of 1 to 5% of the total weight of the cementitious material A mixture of gangue fine powder. No special raw materials such as high-grade cement are needed, the production process is simple, and the manufacturing cost is low. While greatly improving the strength of concrete, it also improves the workability and durability of concrete.

Owner:北京新奥混凝土集团有限公司

High-performance concrete prepared from waste materials

InactiveCN105384400BReduce dosageReduce manufacturing costSolid waste managementFineness modulusFly ash

The invention discloses a high performance concrete prepared from wastes. The high performance concrete is prepared from, by mass, 150-300 parts of cement, 100-200 parts of fly ash, 100-200 parts of mineral powder, 700-1000 parts of waste sands, 700-1000 parts of waste stones, 5-15 parts of an additive, and 150-200 parts of water, wherein the waste sands are second area medium sands, the fineness modulus is 2.3-2.5, and the average particle size is 0.5-0.35mm; and the average particle size of the waste stones is 5.5-25mm. The high performance concrete is made by adopting the waste sands and the waste stones, so economy and environmental protection are realized, and the construction cracking problem is solved.

Owner:BEIJING ZHENGFU CONCRETE CO LTD

A three-dimensional printer with a solid finished product

ActiveCN107139452BIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingEngineering3d printer

Owner:QUANZHOU BILINED TECH CO LTD

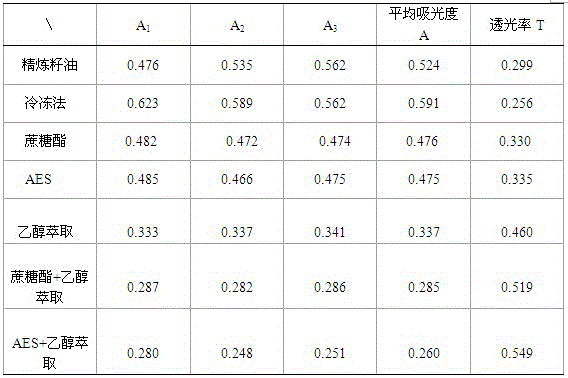

A method for dewaxing by combining surface crystal copolymerization and alcohol extraction of peony seed oil

InactiveCN104017645BHigh removal rateEasy to separateFatty-oils/fats refiningActive agentAlcohol ethyl

The invention discloses a method for dewaxing the peony seed oil by combining surface crystal copolymerization and alcohol extraction. The specific steps are as follows: heating the peony seed oil to 70-90°C until the waxy crystals precipitated at normal temperature are completely dissolved in the peony After soaking in the seed oil, cool down to 50-65°C, then add 0.08-0.15% surfactant by weight of peony seed oil, then slowly lower the temperature under stirring conditions, stop stirring when it reaches 5-8°C, grow crystals, and centrifuge. Take the supernatant oil and set it aside; add absolute ethanol solution to the supernatant oil, transfer it to a separatory funnel and let it stand, separate the liquids, remove the lower layer of oil, repeat the extraction once, remove the lower layer of oil, and finally remove the ethanol solution. The invention combines surfactant with ethanol extraction to obtain dewaxed oil with low viscosity, good fluidity and clear color, which improves the poor dewaxing effect of the traditional dewaxing process and the wax esters in the oil cannot be effectively removed. The incoming grease becomes viscous or even waxy prematurely.

Owner:HENAN UNIV OF SCI & TECH

A perfluoropolyether oil-based magnetic liquid

InactiveCN103680799BEasy to useBreakthrough progress in promoting localizationMagnetic liquidsOrganic/organic-metallic materials magnetismPerfluoropolyetherNanoparticle

The invention discloses a perfluor polyether oil-based magnetic liquid. The magnetic liquid is composed of bare Fe[3]O[4] magnetic nano-particles, a perfluor polyether carboxylic acid surface active agent and a perfluor polyether oil-based carrier liquid, the ratio of the bare Fe[3]O[4] magnetic nano-particles (g) to the perfluor polyether carboxylic acid surface active agent (ml) is 40:1-1:1, and the ratio of the modified bare Fe[3]O[4] magnetic nano-particles (g) to the perfluor polyether carboxylic acid surface active agent (ml) is 1:20-2:1. The saturation magnetization of the perfluor polyether oil-based magnetic liquid is 14-600 Gs, the magnetic liquid has the excellent special performance of resisting to chemical corrosion, high temperature, low temperature resistance and radiation and never burning, and can work stably for a long time at the temperature of 40 DEG C below zero-200 DEG C at the pH value of 1-14, a magnetic liquid of a conventional type can not achieve the effect, and the perfluor polyether oil-based magnetic liquid is particularly suitable for space stations, aeronautics and astronautics and other military industry fields.

Owner:BEIJING JIAOTONG UNIV

Three-dimensional printing head with high product integrity

ActiveCN108381923AIncrease temperatureImprove liquidityManufacturing heating elementsManufacturing material handlingRaw material3D printing

The invention provides a three-dimensional printing head with high product integrity, and aims at breaking the structure form of a traditional three-dimensional printing head. The three-dimensional printing head with the high product integrity is characterized in that raw materials in an outer conveying pipe are further heated through a heating layer, so that the temperature and the mobility of the raw materials in the outer conveying pipe are more than those of the raw materials in an inner conveying pipe; during printing, a lower inclined surface of a flexible heating block is in contact with a lower printing layer which is slightly cooled and solidified, so that the upper surface of the lower printing layer can be molten; and meanwhile, the raw materials flowing from an upper feeding hole are combined with the raw materials flowing from a lower feeding hole through a discharging hole; the raw materials flowing from the lower feeding hole can be uniformly distributed at the surroundings of the raw materials flowing from the upper feeding hole in order to coat the raw materials flowing from the upper feeding hole and then the raw materials flowing from the lower feeding hole flowout from a third channel and are in contact with the lower printing layer, and thus the raw materials flowing from the upper feeding hole are naturally integrated with the lower printing layer; an integrating surface between the upper printing layer and the lower printing layer is not obvious; the adjacent printing layers can be firmly integrated.

Owner:QUANZHOU BILINED TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com