Ceramic metal powder as well as preparation method and application thereof

A ceramic metal and metal powder technology, applied in the field of 3D printing, can solve the problems of low oxygen content, high sphericity, and high cost, and achieve the effect of stress concentration without segregation, high sphericity, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present application proposes a preparation method of ceramic metal powder, which includes the following steps: mixing nano-ceramic powder suspension and metal powder suspension so that the nano-ceramic powder evenly adheres to the surface of the metal powder.

[0057] By setting the nano-ceramic powder and metal powder in the form of a suspension and then mixing them, the nano-phase can be effectively adhered to the surface of the metal powder evenly, without changing the shape, particle size and fluidity of the metal powder. In the process of selective laser fusion forming, the nano phase is uniformly distributed, cracks are reduced, stress concentration is not segregated, etc.

[0058] In an optional embodiment, the preparation of the nano-ceramic powder suspension may include, for example: mixing the nano-ceramic powder with a first organic solvent.

[0059] The raw material of the above-mentioned nano-ceramic powder may include at least one of oxide ceramics and n...

Embodiment 1

[0089] Mix nano-TiB with a volume ratio of 1:100 2 (with a particle size of 3 nm) was placed in an aqueous ethanol solution, and ultrasonically dispersed for 15 minutes to obtain a nano ceramic powder suspension.

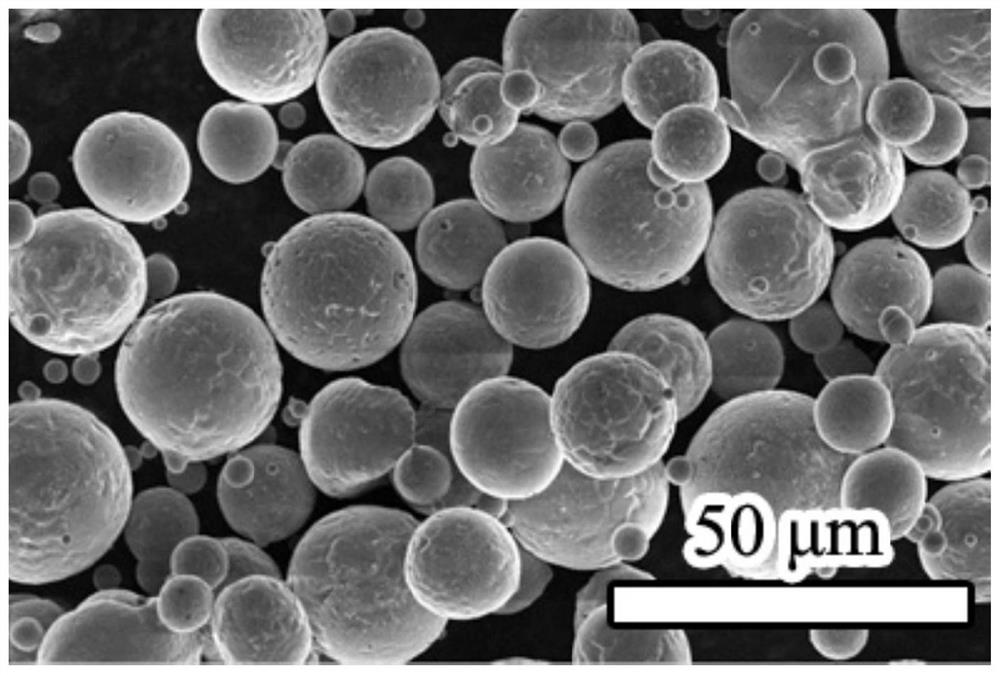

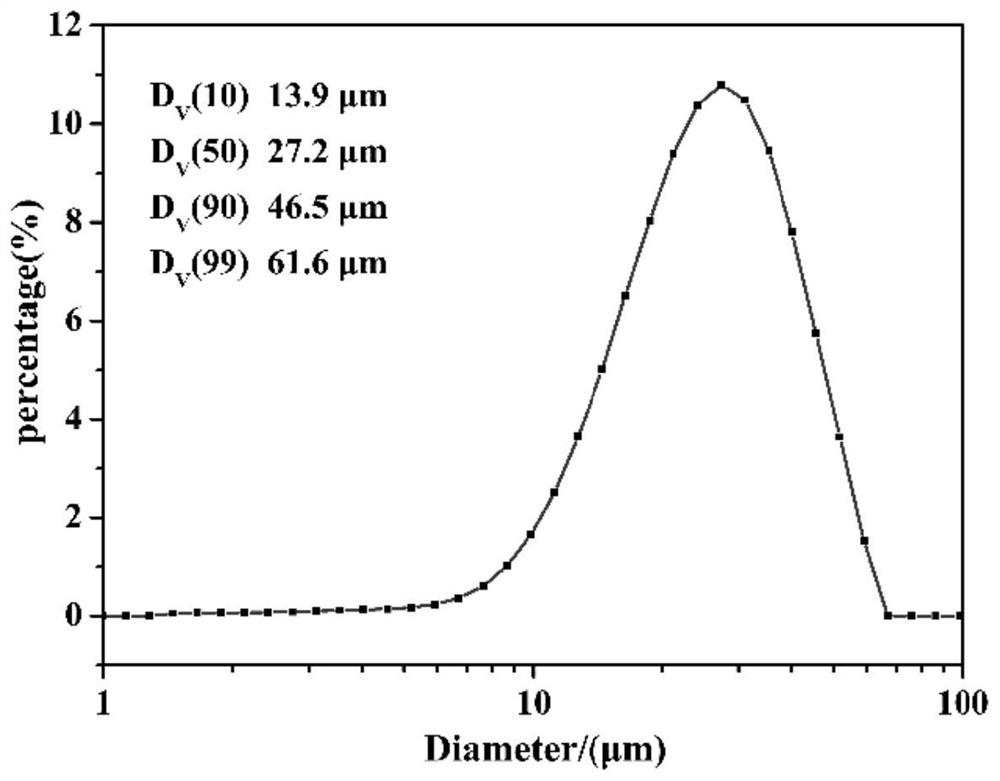

[0090] With a volume ratio of 20:100, nickel 625 powder (fluidity 23.94s / 50g, morphology and particle size distribution are as follows figure 1 and figure 2 shown) was dispersed in another aqueous ethanol solution, and 1 wt% sodium dodecylsulfonate was added, and stirred to obtain a metal powder suspension.

[0091] Pour the above-mentioned metal powder suspension into the nano-ceramic powder suspension, then add 0.5wt% polyvinyl alcohol (PVA) to the above-mentioned mixed suspension, centrifuge at a high speed for 10min at a speed of 100rpm, and then undergo rotary evaporation , drying, and sieving to obtain ceramic metal powder suitable for SLM technology, that is, TiB 2 / Ni625 composite powder.

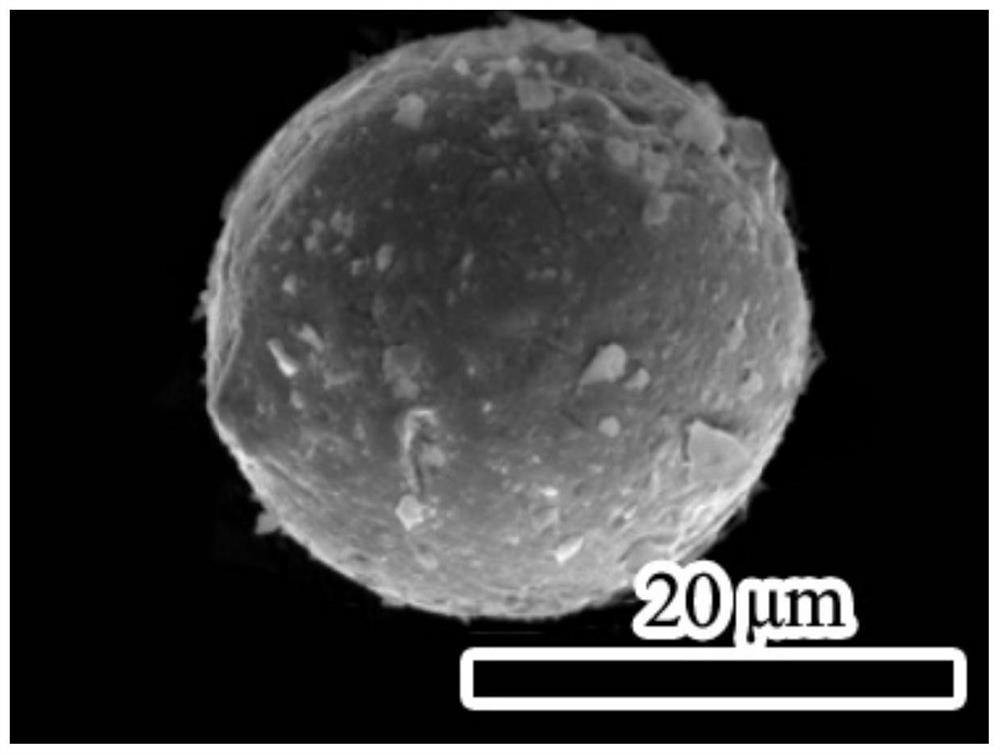

[0092] The TiB 2 The fluidity of the / Ni625 composite powder i...

Embodiment 2

[0100] Nano-TiC (particle size: 30nm) was placed in ethanol aqueous solution at a volume ratio of 5:100, and ultrasonically dispersed for 20 minutes to obtain nano-ceramic powder suspension.

[0101] Disperse nickel 718 powder (with a particle size of 5-50 μm) in another aqueous ethanol solution at a volume ratio of 30:100, add 1 wt% polyethylene glycol (PEG) 20000, and stir to obtain a metal powder suspension.

[0102]Pour the above-mentioned metal powder suspension into the nano-ceramic powder suspension, then add 1wt% polyvinyl alcohol (PVA) to the above-mentioned mixed suspension, and centrifuge at a high speed for 6 minutes at a speed of 300 rpm to obtain a suspension C. Then, through rotary evaporation, drying and sieving, ceramic metal powder suitable for SLM technology is obtained, that is, TiC / Ni718 composite powder, and its fluidity is 25-32s / 50g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com