Silicone-free gel-like thermally conductive composition

A composition and silicone technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of reducing the dielectric strength, failure, and flow of thermally conductive grease of thermally conductive materials, and achieve excellent insulation performance and dielectric strength. Effects of excellent shape retention, excellent long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation method of silicone-free gel-like thermally conductive composition

[0031] The composition described above can be made into a gel-like thermally conductive composition by, for example, mixing all the ingredients. Suitable mixing equipment such as twin planetary mixers, extruders such as twin screw extruders and the like can be used to prepare the compositions described herein. Usually, components (a), (c), (d), and (e) can be mixed uniformly in a double planetary mixer, and then component (b) can be added under the protection of an inert gas such as nitrogen, and after mixing, store in an anaerobic conditioned (e.g. in an airtight container) until ready to use. For example, the obtained gel-like thermally conductive composition is filled into containers suitable for automatic dispensing and mounting of electronic components, such as dispensing tubes or syringes.

[0032] According to the technical scheme provided by the present invention, the thermal condu...

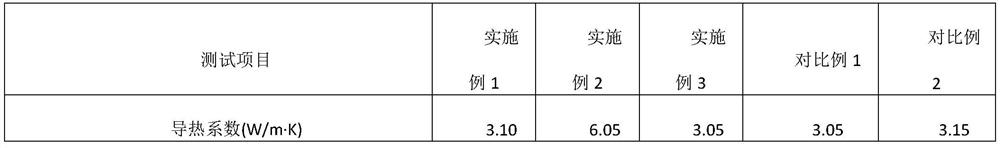

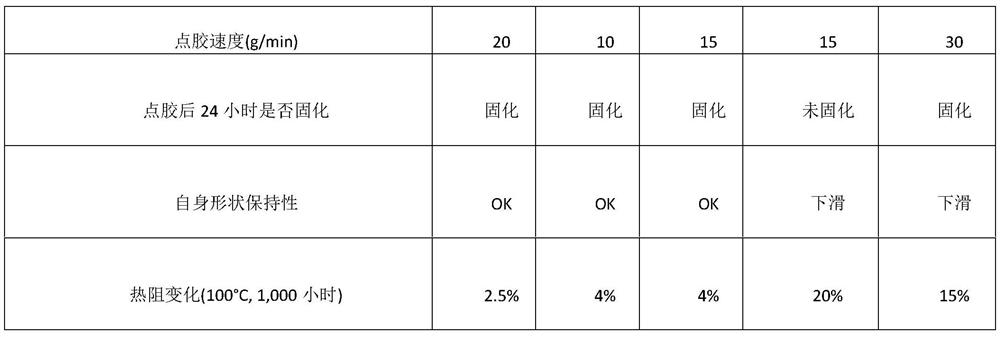

Embodiment 1

[0046] Use polyalphaolefin with a kinematic viscosity of 1,240cSt at 40°C, such as SpectraSyn100 manufactured by ExxonMobil, use linseed oil as a reactive and curable component, and use 45 micron and 5 micron spherical alumina as a thermal conductive filler, such as Japan Denka Manufactured DAM-45 and DAW-05, adding nano-alumina, thixotropic agent fumed silica, such as Aerosil 200 manufactured by Evonik, antioxidant is Irganox 1010. The weight percentage of each component in the composition is as follows Table 1 shows.

[0047] component Example 1 Example 2 Example 3 Comparative Example 1 Comparative Example 2 SpectraSyn 100 5.5% 4.5% 8.5% SpectraSyn 40 5.5% Ketjenlube-165 5% Linseed oil 3% 2% 3.5% 3% DAM-45 55% 33% 55% 55% 55% DAM-90 26% DAW-05 31.5% 32.6% 31.5% 31.5% 31.5% Nano alumina 4% 1.5% 4% 4% 4% Aerosil 200 0.8% 0.2% 0.8% 0.8% 0.8% Irganox 10...

Embodiment 2

[0051] A silicone-free gel-like heat-conducting composition, the weight percentage of each component in the composition is shown in Table 1. The preparation method is also the same as that of Example 1. Firstly, the components other than the linseed oil are mixed uniformly, and then the linseed oil is added under the protection of nitrogen, and mixed uniformly under vacuum. Press it into the dispensing syringe under the protection of nitrogen, and store it in a sealed and low temperature (<5°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com