Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Moderate curing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

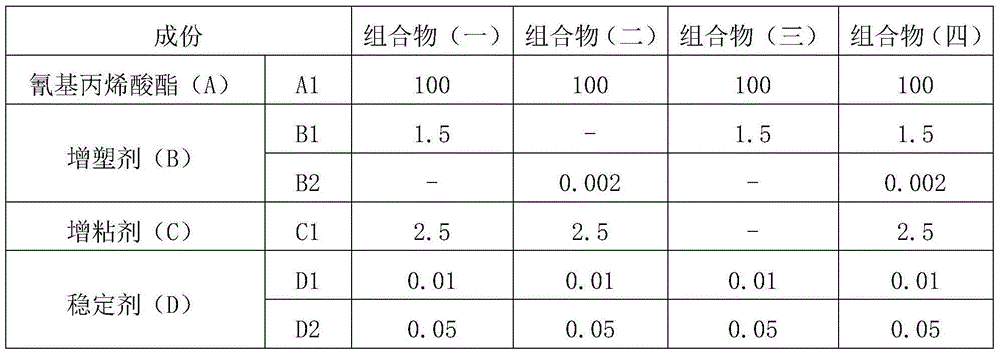

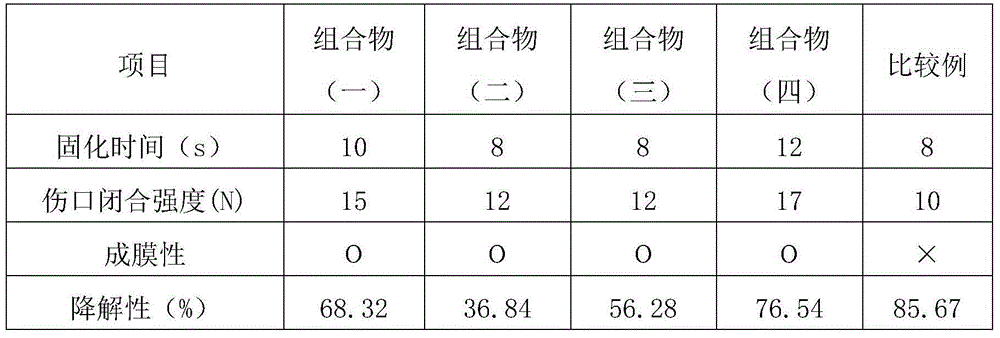

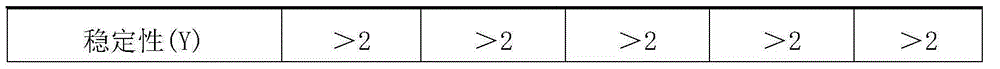

Chemical medical adhesive composition and preparation method thereof

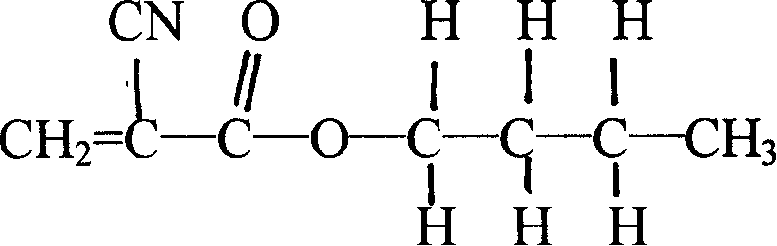

InactiveCN104958781AOvercome not easily flawedEasy to manufactureSurgical adhesivesCyanoacrylatePlasticizer

The invention relates to a chemical medical adhesive composition and a preparation method thereof. The composition is composed of cyanoacrylate, plasticizer, tackifier, stabilizer and other aids. The chemical medical adhesive composition can be quickly polymerized under the initiation of negative ions and produce the adhesive capacity, has high adhesive strength, releases low heat during adhering and has good environment-friendly performance, and adhesive membranes can be degraded and completely excreted out of the body. Therefore, the biodegradable medical adhesive can be used for various wound adhesion, large-area wound hemostasis, closure of internal organ and soft tissue wounds, and is convenient to use.

Owner:SHAANXI BOYU REGENERATIVE MEDICINE CO LTD

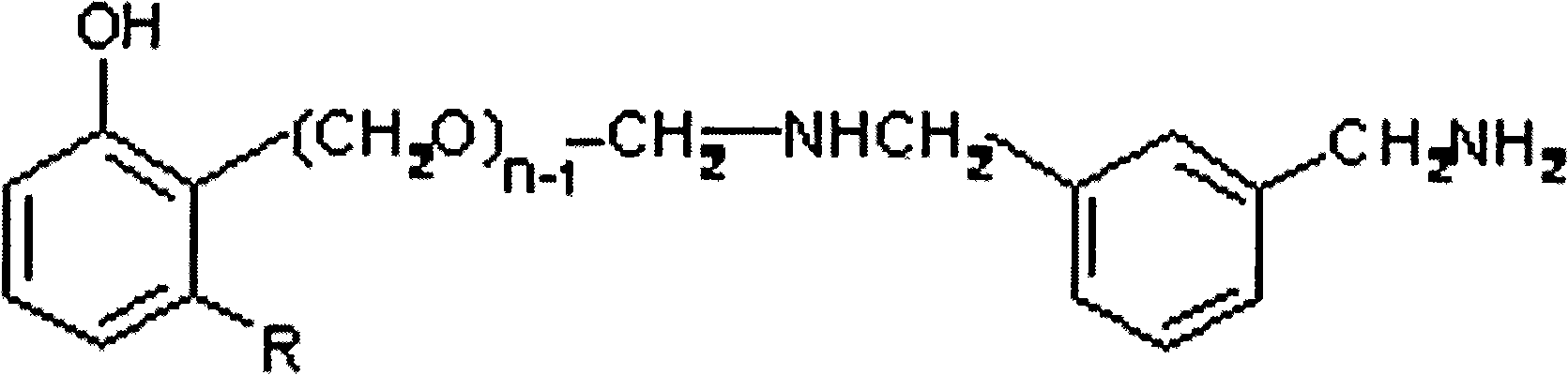

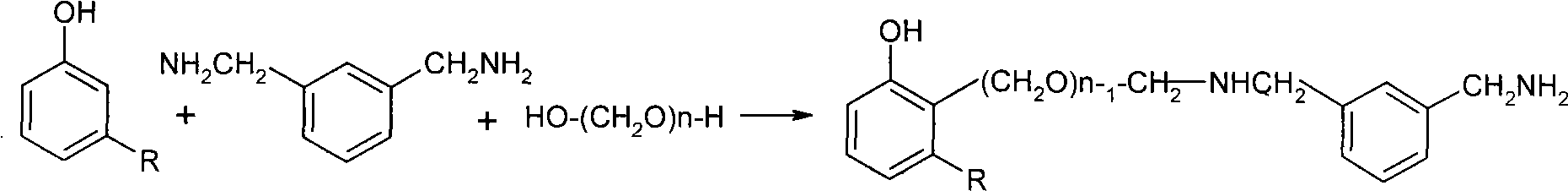

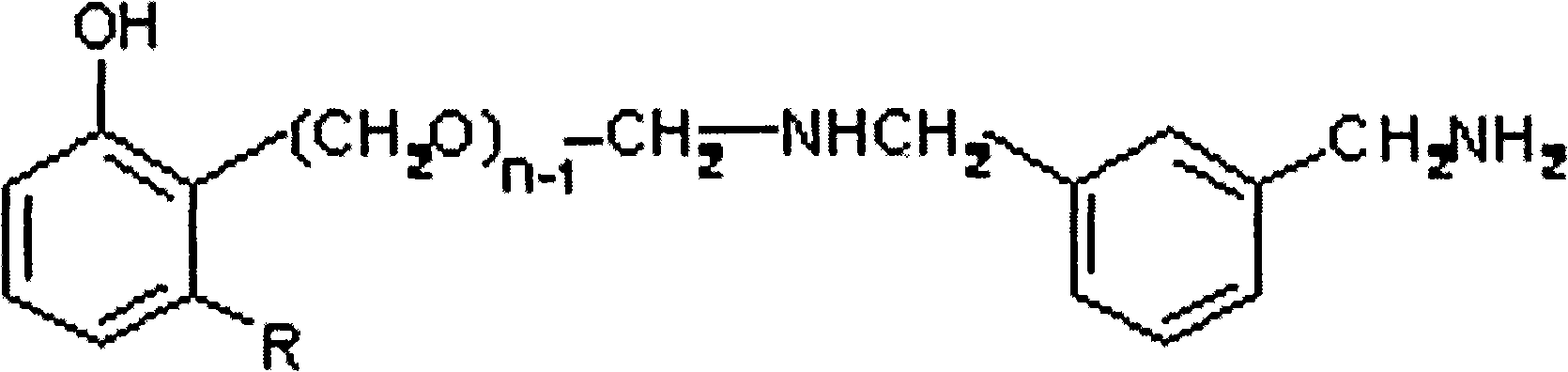

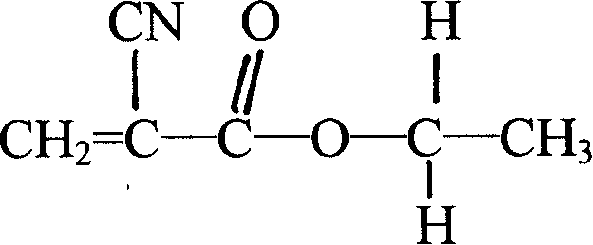

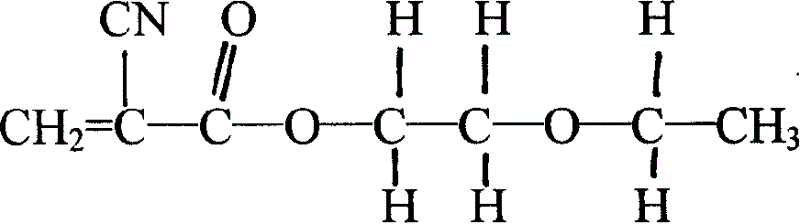

Low-viscosity cardanol solidifying agent of epoxy resin and preparation method thereof

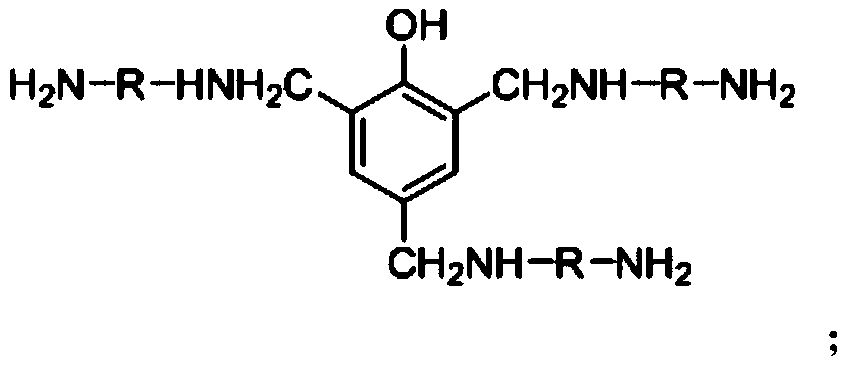

The invention relates to a low-viscosity cardanol epoxy resin curing agent which has a structural formula shown on the right. The method for preparing the low-viscosity cardanol epoxy resin curing agent utilizes reaction of cardanol, p / m-benzene dimethylamine and paraformaldehyde to prepare the low-viscosity cardanol epoxy resin curing agent. The low-viscosity cardanol epoxy resin curing agent has no solvent, has no irritation, is nontoxic and environment-friendly, is mild in heat release, low in color, low in viscosity, and moderate in curing speed, can be cured at a low temperature, and simultaneously has superior anti-corrosive and protective properties; and cured products have superior toughness, good strength, superior adhesion and invasive ability on substrates, and superior low surface construction performance, and are normally used on wet and rusty surfaces.

Owner:上海美东生物材料股份有限公司

Medical adhesive used for adhering skin and viscus hemostasis, and its prepn. method

A medical adhesive for adhering skin and hemostasis of viscera is prepared from at least two organic compounds chosen from alpha-ethyl cyanoacrylate, alpha-ethoxyethyl cyanoacrylate, alpha-butyl cyanoacrylate and alpha-octyl cyanoacrylate through proportional mixing.

Owner:石平安

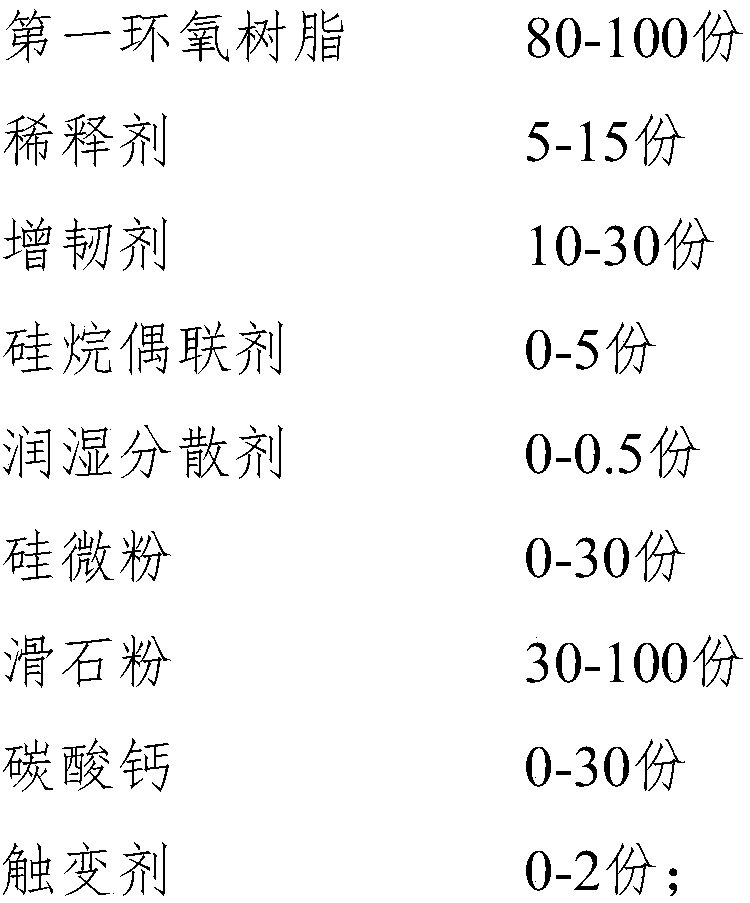

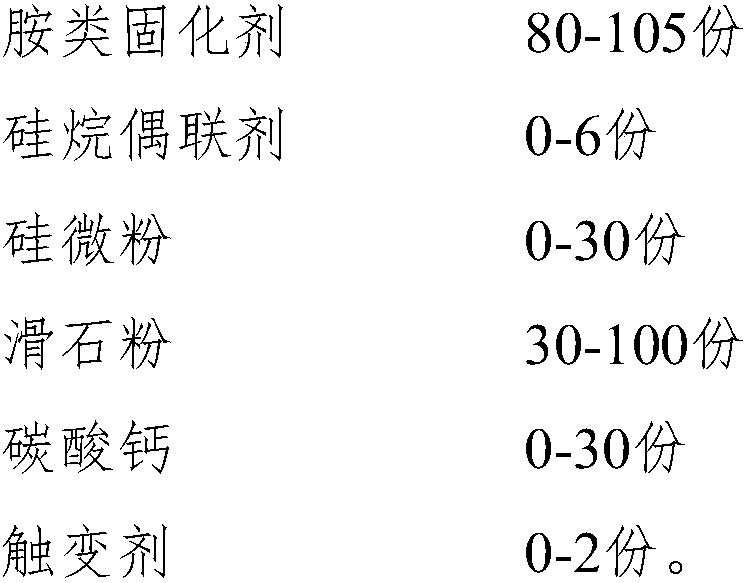

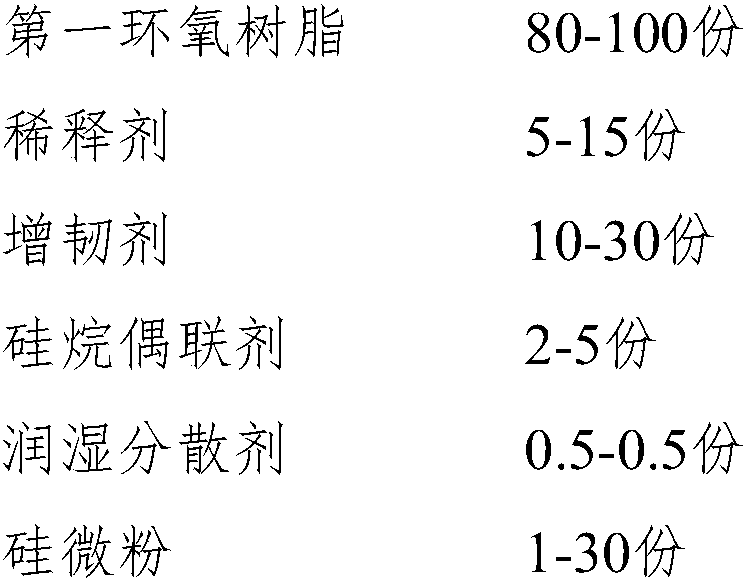

Epoxy adhesive and preparation method thereof

InactiveCN109777333AHigh bonding strengthHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesion strengthViscosity

The invention relates to the technical field of polymers, in particular to an epoxy adhesive and a preparation method thereof. The epoxy adhesive comprises a component A and a component B, wherein thecomponent A comprises the following substances in parts by weight: 80 to 100 parts of epoxy resin, 5 to 15 parts of a diluting agent, 10 to 30 parts of a toughening agent, 0 to 5 parts of a silane coupling agent, 0 to 0.5 part of a wetting dispersing agent, 0 to 30 parts of silica powder, 30 to 100 parts of talcum powder, 0 to 30 parts of calcium carbonate, and 0 to 2 parts of a thixotropic agent; the component B comprises the following substances in parts by weight: 80 to 100 parts of an amine curing agent, 0 to 6 parts of a silane coupling agent, 0 to 30 parts of silica powder, 30 to 100 parts of talcum powder, 0 to 30 parts of calcium carbonate, and 0 to 2 parts of a thixotropic agent . Compared with the epoxy adhesive with same viscosity, the epoxy adhesive of the invention is higherin adhesion strength and stripping strength, moderate in curing speed, not only capable of satisfying the large-area coating, but also capable of being used for small-area adhesion, and not only capable of being cured at the normal temperature, but also capable of being rapidly cured in a heating manner, thereby meeting the requirements of different working conditions.

Owner:TONSAN ADHESIVES INC

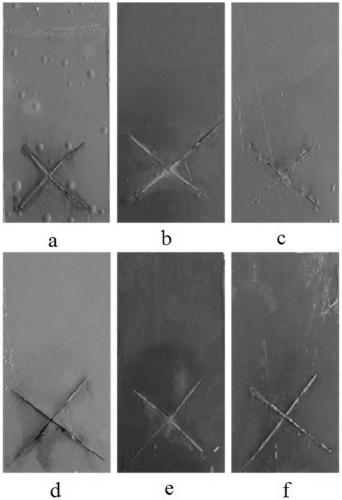

Polyaspartatepolyurea coating with moderate surface drying time and adaptability to environmental change and preparation method and use method and application thereof

ActiveCN109354987AAccelerated agingImprove photostabilityAntifouling/underwater paintsPaints with biocidesPolymer sciencePolyol

The invention belongs to the technical field of spraying polyurea elastic materials, and discloses a polyaspartatepolyurea coating witha moderate surface drying time and adaptability to environmentalchanges, which is prepared from a A material and a B material. The mole ratio of NCO in the A material to NH in the B material is 1.05:1.1. The A material is mainly prepared from,by weight,25-44% of polyether polyol, 55-74% of aliphatic polyisocyanate and 1-5% of nanographene oxide; the B material is mainly prepared from, by weight,70-80% of polyaspartate, 10-15% of nano metal oxide filler, 5-10%of pigment and filler, 1-3% of defoaming agent, 1-3% of leveling agent and 2-5% of adhesion promoter. The invention further provides a preparation method and use method and application of the polyaspartatepolyurea coating. The polyaspartatepolyurea coating has the advantages of being easy to brush, moderate in the surface drying time, and capable of adapting to the environmental changes.

Owner:四川嘉宝莉涂料有限公司

Graphene powder coating for radiator and preparation technology of graphene powder coating

InactiveCN106867360AFully curableSlow down the curing speedFireproof paintsPowdery paintsShock resistanceTitanium oxide

The invention relates to a graphene powder coating for a radiator and a preparation technology of the graphene powder coating. The graphene powder coating is prepared from the following components: phenolic aldehyde modified epoxy resin, hydroxyl saturated polyester resin, a solidification accelerator, rutile titanium oxide, butyl polyacrylate, yellowing resisting benzoin, a polysiloxane defoamer, a crosslinking agent, aminated graphene, carboxylic nanometer polytetrafluoroethylene and hydrogenated castor oil. As for the powder coating provided by the invention, the hydroxyl saturated polyester resin can enable the coating to ensure optimal leveling while the solidification speed is slowed down; combined use of the graphene and polytetrafluoroethylene can enable the whole coating to have better hardness, wear resistance and lubricating effect, be suitable for coating the surfaces of radiator type household appliances and be better in weatherability and yellowing resistance; the color of a coating film cannot change under the solidification condition with the temperature being 195-205 DEG C, and the solidified coating film cannot yellow permanently under the high-temperature working environment of the radiator after being solidified, is good in salt fog resistance, light fastness and shock resistance and is suitable for being further popularized and applied.

Owner:JIANGSU HUAGUANG POWDER

Two-component solvent-free plant oil-based adhesive

ActiveCN105969293AImprove initial tack performanceHigh strengthMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesAdhesiveHeat resistance

The invention provides a two-component solvent-free plant oil-based adhesive, which comprises components A and B, wherein component A comprises modified plant oil, tackifying resin, a coupling agent, a filler, microencapsulated microspheres and a chain extender; component B comprises isocyanate or a mixture of isocyanate and modified plant oil. The two-component solvent-free plant oil-based adhesive with high comprehensive performance is safe in use, economical, moderate in curing speed, adjustable in hardness, high in initial cohesiveness, water resistance and heat resistance, strong in adhesive strength, wide in application range, green and environment-friendly.

Owner:福建省南平星源辉生物科技有限公司

Cardanol modified amine epoxy resin curing agent as well as preparation method and application thereof

InactiveCN111793195AImprove hydrophobicityGood flexibilityOrganic compound preparationAmino-hyroxy compound preparationPolymer sciencePtru catalyst

The invention belongs to the technical field of epoxy resin curing agents, and discloses a cardanol modified amine epoxy resin curing agent as well as a preparation method and application thereof. Thecuring agent is prepared by the following steps: mixing cardanol and phenols, heating to 30-40 DEG C, stirring, adding alkali, heating to 60-70 DEG C, adding an acid catalyst, stirring to dissolve, heating to 80-90 DEG C, reacting, standing, separating liquid, and vacuumizing to obtain an intermediate product; and heating the intermediate product to 30-40 DEG C, stirring, adding aldehyde, controlling the temperature to be less than 50 DEG C, dropwise adding amine at 30-40 DEG C after the aldehyde is added, stirring, heating to 115-175 DEG C, cooling to 90-95 DEG C after the reaction is finished, and carrying out vacuum dehydration under reduced pressure. The curing agent has good hydrophobicity, flexibility and protective function, mild heat release and moderate curing speed, avoids degradation of the toughness of epoxy resin in the fast curing process, and is applied to the field of quick curing or toughening of epoxy resin.

Owner:SOUTH CHINA AGRI UNIV

Cashew nut oil modified solid aromatic amine epoxy curing agent

InactiveCN101851327AObvious oily smellAmbient temperature requirements are lowChemical industrySynthetic substanceSolvent

The invention relates to a cashew nut oil modified solid aromatic amine epoxy curing agent, belonging to epoxy curing agent. The cashew nut oil modified solid aromatic amine epoxy curing agent comprises the raw materials: 55-75% of cashew nut oil, 20-35% of diamino diphenyl methane and 5-15% of paraformaldehyde, and is prepared by the steps of: first, weighing the raw materials according to the mass ratio; adding the cashew nut oil into a reaction kettle, raising the temperature to 40 DEG C, and adding the paraformaldehyde; maintaining the temperature to be below 65 DEG C, adding the paraformaldehyde for 0.5-1h until the paraformaldehyde is completely dissolved; after the paraformaldehyde is completely dissolved, raising the temperature to 90-95 DEG C, adding the diamino diphenyl methane, and maintaining at the constant temperature for 3-4h; evenly stirring and mixing after the diamino diphenyl methane is dissolved; putting the evenly mixed synthetic substance into a vacuum furnace for vacuum dehydration, and generating water by separation reaction; and finally, detecting after cooling, and packaging. The cashew nut oil modified solid aromatic amine epoxy curing agent has the advantages that the cashew nut oil is natural plant and is not needed to be purified into cardanol, thus avoiding secondary pollution, protecting the environment and saving energy; and the curing agent contains no solvent, has no irritation, and is mild in heat emission and moderate in curing speed.

Owner:徐州中研科技工业有限公司

Polyurethane compound suitable for grouting and preparation method thereof

The invention discloses a polyurethane compound suitable for grouting. The polyurethane compound comprises the following raw materials by weight: 30-60 parts of polyether, 3-12 parts of methyl silicone oil, 3-15 parts of a plasticizer, 10-25 parts of a flame retardant, 25-50 parts of polypropylene glycol, 1-7 parts of dihydromethyl propionic acid, 2-10 parts of a chain extender, 2-10 parts of a catalyst, 20-35 parts of polyisocyanate, 10-25 parts of polyether polyol, 20-60 parts of isophorone diisocyanate, 10-25 parts of glycerol, 2-15 parts of pentaerythritol, 2-8 parts of a defoaming agent, and 3-7 parts of a diluents. The preparation method provided by the invention is simple, and the prepared grouting composition can be used in a high-pressure environment, and can maintain the high strength characteristic for a long time, thus being suitable for popularization.

Owner:江苏卓美聚氨酯科技有限公司

Silane modified polyether two-component sealing glue and preparation method thereof

InactiveCN110734730AHigh tensile strengthHigh elongationNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a silane modified polyether two-component sealing glue, which comprises a component A and a component B according to a weight ratio of 10-16:1, wherein the component A comprises the following raw materials by weight: 10-80 parts of a silane modified polymer, 0-40 parts of a plasticizer, 0-80 parts of a reinforcing filler, 0-20 parts of an additive A and 0-2 parts of a waterremoval agent, and the component B comprises the following raw materials by weight: 0-30 parts of toner, 0-70 parts of a plasticizer, 0-30 parts of an additive B, 0-10 parts of a catalyst and 0-20 parts of a coupling agent. The invention further discloses a preparation method of the silane modified polyether two-component sealing glue. According to the invention, the mechanical property of the product can be effectively improved; the stability of the system can be improved, the extrusion performance of the product is improved, and the deep curing speed after the two component mixing can be increased.

Owner:东莞市博君来胶粘材料科技有限公司

Preparation method for epoxy resin curing agent

InactiveCN103483225AGood flexibilityGood adhesionCarbamic acid derivatives preparationOrganic compound preparationEpoxyWater baths

The invention discloses a preparation method for an epoxy resin curing agent, and belongs to the technical field of curing agents. The preparation method comprises the following steps: (1) adding aliphatic polyamine or cycloaliphatic polyamine into a three-necked reaction flask; (2) performing water-bath heating on the three-necked reaction flask, and dropping propylene carbonate into the three-necked reaction flask for reaction when the temperature inside the three-necked reaction flask is 40-50 DEG C, wherein the molar ratio of aliphatic polyamine or cycloaliphatic polyamine to propylene carbonate is (1:1)-(2:1); (3) dropping propylene carbonate for 30-40 min, and preserving heat for 2.5-3.5 h when the dropping is completed, so that the epoxy resin curing agent is obtained. The method has a simple technology, the reaction condition is moderate, the material is non-toxic and easy to get, and the curing speed is moderate.

Owner:JIANGHAN UNIVERSITY

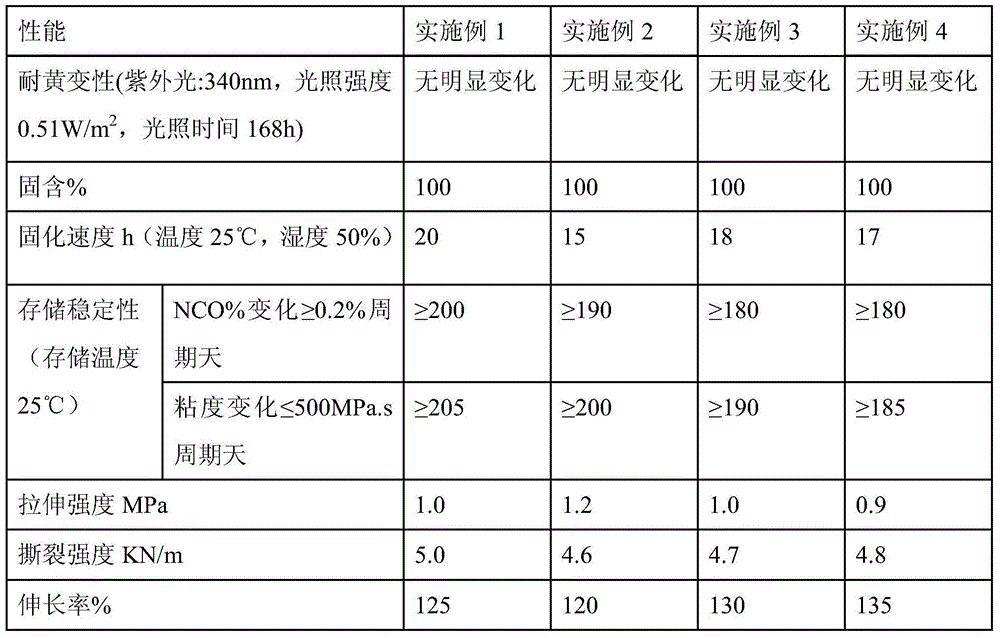

Solvent-free non-yellowing type polyurethane adhesive for sport field

ActiveCN103642449AModerate curing speedGood storage stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveSolvent

The invention belongs to the field of polyurethane adhesives, and relates to a solvent-free non-yellowing type polyurethane adhesive for a sport field and a preparation method thereof. The solvent-free non-yellowing type polyurethane adhesive is prepared from isocyanate, polyolefine polyalcohol, castor oil, an antioxidant, a light stabilizer and a catalyst in a mass ratio of (25-35):(30-40):(20-30):(1-4):(1-4):(1-2). The invention relates to the solvent-free non-yellowing type polyurethane adhesive for the sport field and the preparation method thereof. The solvent-free non-yellowing type polyurethane adhesive disclosed by the invention has the characteristics of odorlessness, no yellowing, environmental friendliness, moderation in curing speed, no deformation, good storage stability and excellent mechanical property.

Owner:SHANDONG INOV POLYURETHANE

Phenolic aldehyde modified polyether amine type epoxy resin curing agent and preparation method thereof

The invention relates to a phenolic aldehyde modified polyether amine type epoxy resin curing agent and a preparation method thereof, and belongs to the technical field of epoxy resin preparation. Thepreparation method comprises the steps: adding polyether amine and phenols into a reaction kettle, and stirring while heating; gradually dropwise adding an aldehyde aqueous solution when the temperature rises to a certain degree, and carrying out reflux reaction after dropwise adding is finished; and then carrying out vacuum dehydration, connecting the reaction kettle to a vacuum distillation device for distillation, and distilling to obtain the polyether amine type epoxy resin curing agent. The prepared phenolic aldehyde modified polyether amine is used as an epoxy resin curing agent, and anepoxy resin adhesive system obtained by compounding has excellent bonding performance and mechanical properties. In the aspect of mechanism, phenolic hydroxyl and amine active hydrogen are introducedinto the modifier, so that the reaction activity is enhanced to a great extent, the curing speed of amino and epoxy groups is increased, and the heat resistance and the corrosion resistance are improved.

Owner:WUXI ACRYL TECH

Epoxy elastic putty for surface of concrete

InactiveCN104497681AImprove toughnessReduced cured crosslink densityFilling pastesAnatase titanium dioxideChemistry

The invention relates to epoxy elastic putty for the surface of concrete. The epoxy elastic putty is composed of a componend a component B; the component A is prepared from the following ingredients in percentage by weight: 5-20% of liquid epoxy resin, 5-20% of flexible epoxy resin, 3-10% of anatase titanium dioxide, 10-30% of talcum powder, 30-60% of heavy calcium carbonate, and 5-15% of a mixed thinner; the component B is prepared from the following ingredients in percentage by weight: 10-20% of polyamide resin, 10-25% of polyether modified amine, 40-60% of heavy calcium carbonate, 15-35% of talcum powder, 5-15% of a mixed thinner and 0.5-2% of an anti-sagging agent, and the mass ratio of the component A and the component B is 10 to (3-4). According to the epoxy elastic putty, the advantages of epoxy putty and pure acrylic emulsion elastic putty are combined, the epoxy elastic putty has excellent adhesive force with a concrete base material, has good reelability and toughness, and has the good anti-crack property in a high-low temperature environment.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Polyurethane pouring sealant for water treatment curtain type membrane assembly and preparation method thereof

InactiveCN107629753AImprove curing hardnessSuitable mixing viscositySemi-permeable membranesPolyureas/polyurethane adhesivesEnvironmental resistanceWeather resistance

The invention provides a two-component high-hardness polyurethane pouring sealant suitable for fixing a water treatment curtain type membrane assembly, wherein the pouring sealant is prepared by mixing a component A of hydroxyl compound-modified isocyanate and a component B composed of a polymerized MDI modified hydroxyl compound according to the weight ratio of (50-90):100. The polyurethane pouring sealant has the advantages of high curing hardness, proper mixing viscosity, convenient construction, moderate curing speed, low heat release peak value, no bubbling, good bonding effect, environmental protection, no pollution, and excellent acid and alkali resistance and weather resistance. The process is simple, the condition is easy to control, and automatic production is easy to realize. The polyurethane pouring sealant is fully satisfied with technical requirements of the water treatment curtain type membrane assembly on the application process and product performance of the pouring sealant.

Owner:山东奥卓新材料有限公司

Low ratio rtv compositions and methods for making same

ActiveUS20100006224A1Cure speedModerate curing speedFilm/foil adhesivesFibre treatmentSilanesMoisture

A two-part moisture-curing composition having as a first part water and an hydroxy-terminated diorganosiloxane; and a second part which includes a reactive silicone, at least one end-capping silane which includes one or more enoxy groups, at least one end-capping catalyst and at least one moisture cure catalyst. Enhanced and controlled cure speed is obtained by these compositions.

Owner:HENKEL KGAA

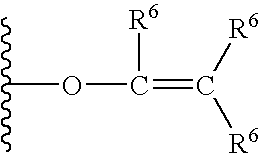

Wear-resisting and high-rigidity polycarbonate lens

The invention discloses a wear-resisting and high-rigidity polycarbonate lens. The wear-resisting and high-rigidity polycarbonate lens comprises a polycarbonate substrate and a coating which covers the surface of the polycarbonate substrate, wherein the coating is prepared from the following raw materials: a silicon resin pre-polymer, polyurethane, epoxy resin, hydroxyethyl methylacrylate, polyester polyol, aluminum acetylacetonate, dibutyltin dilaurate, tetrabutylammonium hydroxide, methylhexahydrophthalic anhydride, 2-methylimidazole, bicyclic amidine, a solvent, a silane coupling agent andan auxiliary agent. The wear-resisting and high-rigidity polycarbonate lens provided by the invention has good wear resistance, high surface rigidity, excellent heat-resisting performance and long service life.

Owner:望江县天长光学仪器有限公司

Material for ring-pull can body

The invention discloses a material of a ring-pull can body. The material comprises an aluminum alloy board and a protection coating coated on the surface of the aluminum alloy board. The aluminum alloy board is made of the material prepared from chemical components including, by weight, 1.0-1.5% of Mg, 0.8-1.2% of Mn, 0.20-0.30% of Cu, 0.25-0.60% of Fe, 0.20-0.40% of Si, 0.01-0.03% of Ni, 0.03-0.05% of Zn, 0.01-0.03% of Re, and the balance Al and inevitable impurities. The aluminum alloy board is obtained by conducting homogenization, hot rough rolling and hot finish rolling on an aluminum alloy cast ingot. The protection coating is formed by smearing epoxy resin paint onto the surface of the aluminum alloy board uniformly. The thickness of the coating is 3-5 micrometers.

Owner:天津国科医疗科技发展有限公司

A kind of graphene anticorrosion coating and preparation method thereof

ActiveCN106189719BModerate curing speedTight cross-linked structureAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

Injectable bioactive artificial bone material and preparation method and application thereof

The invention discloses an injectable bioactive artificial bone material and a preparation method and application thereof, belonging to the field of medicinal technology. The injectable bioactive artificial bone material is prepared by a solid phase and a liquid phase according to the solid-liquid ratio of (0.8-1.2)g:1ml, wherein the solid phase comprises a phosphate mixture and carbodiimide, the mass ratio of the phosphate mixture to a condensing agent is 10:1, and the phosphate mixture comprises tetracalcium phosphate and calcium hydrophosphate according to the molar ratio of 1:2; the liquid phase comprises water, chitosan and citric acid, and the mass ratio of water to chitosan to citric acid is 100:(1-2):(4-5). Covalent coupling of a bioactive molecule and a chitosan derivative is realized through the carbodiimide condensing agent. The injectable bioactive artificial bone material is widely used in preparation of artificial bones.

Owner:JINAN UNIVERSITY

Synthesis process of nitrile rubber modified phenolic resin for aramid honeycomb,

ActiveCN108192055AMeet the requirements of the preparation processImprove toughnessNitrile rubberOrganic solvent

The invention relates to a synthesis process of nitrile rubber modified phenolic resin for an aramid honeycomb. Adopted raw materials comprise phenol, formaldehyde, a catalyst, carbamide, nitrile rubber and an organic solvent. The synthetic process comprises the following steps: carrying out heating to dissolve the phenol and adding the nitrile rubber, then adding the formaldehyde and the catalyst, carrying out heating for a reaction, carrying out cooling when the reaction is carried out to a certain degree and adding the carbamide, carrying out vacuum dewatering, then adding a part of the organic solvent, carrying out cooling, adding a part of the organic solvent, then continuing to carrying out cooling, finally adding the remaining organic solvent, and then carrying out cooling rapidly to room temperature to obtain the nitrile rubber modified phenolic resin for the aramid honeycomb. Compared with the prior art, the flexibility of the phenolic resin is greatly improved, and the strength of the honeycomb core material made of the phenolic resin impregnated aramid honeycomb paper prepared through the method is greatly improved.

Owner:安徽复材科技有限公司

Filling and binding material composition

InactiveCN101844899BGood physical and chemical affinityGood weather resistanceSolid waste managementBuilding repairsFiberBrick

The invention relates to a filling and binding material composition, which comprises the following components in percentage by weight: 20-55% of natural hydraulic setting lime, 40-78% of aggregate, 0.01-2% of polymer emulsion powder, 0.01-2% of thixotropic lubricant, 0-2% of water-retentive thickening agent and 0-2% of wood fiber. The components are mixed in proportion to obtain powder, and 10-40kg of water is evenly mixed with every 100 kg of powder. The invention can satisfy the special requirements for filling, binding and reinforcing bricks and stone materials in historical buildings. When being used for binding cracked positions, the filling and binding material composition has the performance similar to that of the bricks or stone at the constructed position. The invention has the advantages of environmental protection, high safety after curing, favorable reinforcing force for sealing and binding, good weatherability and good self-recovery property.

Owner:中国文化遗产研究院 +1

Solvent-free, non-yellowing polyurethane adhesive for sports fields

ActiveCN103642449BNo smellNo deformationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveAntioxidant

The invention belongs to the field of polyurethane adhesives, and relates to a solvent-free non-yellowing type polyurethane adhesive for a sport field and a preparation method thereof. The solvent-free non-yellowing type polyurethane adhesive is prepared from isocyanate, polyolefine polyalcohol, castor oil, an antioxidant, a light stabilizer and a catalyst in a mass ratio of (25-35):(30-40):(20-30):(1-4):(1-4):(1-2). The invention relates to the solvent-free non-yellowing type polyurethane adhesive for the sport field and the preparation method thereof. The solvent-free non-yellowing type polyurethane adhesive disclosed by the invention has the characteristics of odorlessness, no yellowing, environmental friendliness, moderation in curing speed, no deformation, good storage stability and excellent mechanical property.

Owner:SHANDONG INOV POLYURETHANE

Radiopaque polymer and preparation method and application thereof

ActiveCN114805644ADisadvantages of improving developmentAvoid harmSurgical adhesivesTissue regenerationEpoxyPolymer science

The invention discloses an opaque polymer as well as a preparation method and application thereof. The opaque polymer provided by the invention contains a polyvinyl alcohol main chain and a developing side group grafted to the polyvinyl alcohol main chain, and the developing side group is formed by grafting an iodobenzyl alcohol compound to activated polyvinyl alcohol through an etherification reaction; the activated polyvinyl alcohol refers to that epoxy chloropropane is grafted to polyvinyl alcohol under the condition of a basic catalyst, so that chlorine atoms are introduced to the polyvinyl alcohol; the chemical structural formula of the developing side group is-OCH2CH (OH) CH2OR, R is iodobenzyl, and the polymer is soluble in a non-physiological solution and insoluble under physiological conditions, can be used as a liquid embolism material in medical treatment, and has high stability and excellent developing effect.

Owner:苏州美创医疗科技有限公司

A kind of medical adhesive and preparation method thereof

ActiveCN104368030BLess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideDIETHYL SEBACATE

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

Low ratio RTV compositions and methods for making same

A two-part moisture-curing composition having as a first part water and an hydroxy-terminated diorganosiloxane; and a second part which includes a reactive silicone, at least one end-capping silane which includes one or more enoxy groups, at least one end-capping catalyst and at least one moisture cure catalyst. Enhanced and controlled cure speed is obtained by these compositions.

Owner:HENKEL KGAA

Flame-retardant reinforced polyurethane grouting material and preparation method thereof

InactiveCN106589278APlay the function of fire retardantConvenient groutingOther chemical processesPolyesterPolyol

The invention discloses a flame-retardant reinforced polyurethane grouting material comprising the following raw materials in parts by weight: 15-30 parts of polyether glycol, 20-35 parts of polyurethane reactive monomers, 15-30 parts of polyester, 2-10 parts of a compatilizer, 1-2.5 parts of an amine catalyst, 0-2 parts of a tin catalyst, 2-5 parts of a flame retardant, 15-30 parts of isocyanate, 1-5 parts of a plasticizer, 10-25 parts of an organic solvent, 15-30 parts of flame-retardant polyalcohol, 15-30 parts of halogenated phosphate and 1-4 parts of antimony trioxide. A preparation method of the flame-retardant reinforced polyurethane grouting material is simple, and the prepared grouting composition can be flame-retardant and is suitable for popularization.

Owner:江苏卓美聚氨酯科技有限公司

Novel preparation method of epoxy tooling board

The invention relates to a novel preparation method of an epoxy tooling board. The novel preparation method comprises the following steps in sequence: feeding each material of a component A into a stirrer based on the fixed ratio; stirring and mixing for 40 to 80 minutes; feeding each material of a component B into the stirrer based on the fixed ratio; stirring and mixing for 40 to 80 minutes; respectively conveying the uniformly-mixed components A and B into a vacuum gapped tank through an automatic metering device based on the ratio of A to B of (4:1) to (1:1); stirring for 40 to 80 minutes; conveying the qualified materials of the uniformly-mixed components A and B into a vacuum tank by the automatic metering device; filling under the vacuum condition; curing the filled material for 1.5 to 3 hours at normal temperature; and curing at high temperature of 90 to 100 DEG C, thus obtaining the epoxy tooling board. The novel preparation method of the epoxy tooling board is high in automatic control degree, low in labor cost, high in production efficiency, stable in quality, low in density, high in strength and low in deformation rate.

Owner:江苏恒隆通新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com