A kind of graphene anticorrosion coating and preparation method thereof

A technology of anti-corrosion coatings and graphene, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor anti-corrosion performance of coatings, no data on the mechanical properties and anti-corrosion performance of primers, etc., and achieve excellent adhesion , It is conducive to large-scale industrial production and solves the effect of easy reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

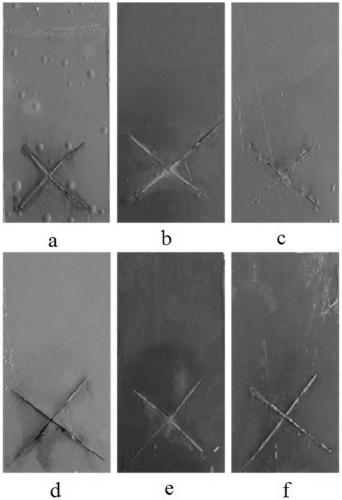

Image

Examples

Embodiment Construction

[0044] The graphene anticorrosive coating of the present invention will be further described below in conjunction with specific embodiments.

[0045] The coating material formulations of the comparative examples of the present invention and Examples 1-7 are listed in Table 1 and Table 2, respectively.

[0046] Table 1 Graphene anticorrosive coating formula in the comparative example

[0047]

[0048] Note: Unless otherwise specified, all percentage units in the present invention are mass percentages. The A component and B component are calculated at 100% content respectively.

[0049] The preparation method of the graphene anticorrosive coating in the comparative example, the specific steps are as follows:

[0050] 1) Preparation of component A

[0051] a. Add the epoxy resin of the A component formula into the mixing container, and stir at the speed of 1000-1500r / min;

[0052] b. Then add the solvent, zinc powder, graphene and filler of the A component formula in sequence, and continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com