Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Low varistor voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Voltage dependent resistor dielectric material of zinc oxide and method of manufacturing electrical resistor

InactiveCN101367649ALow varistor voltageHigh nonlinear coefficientVaristor coresResistive material coatingVaristorElectronic materials

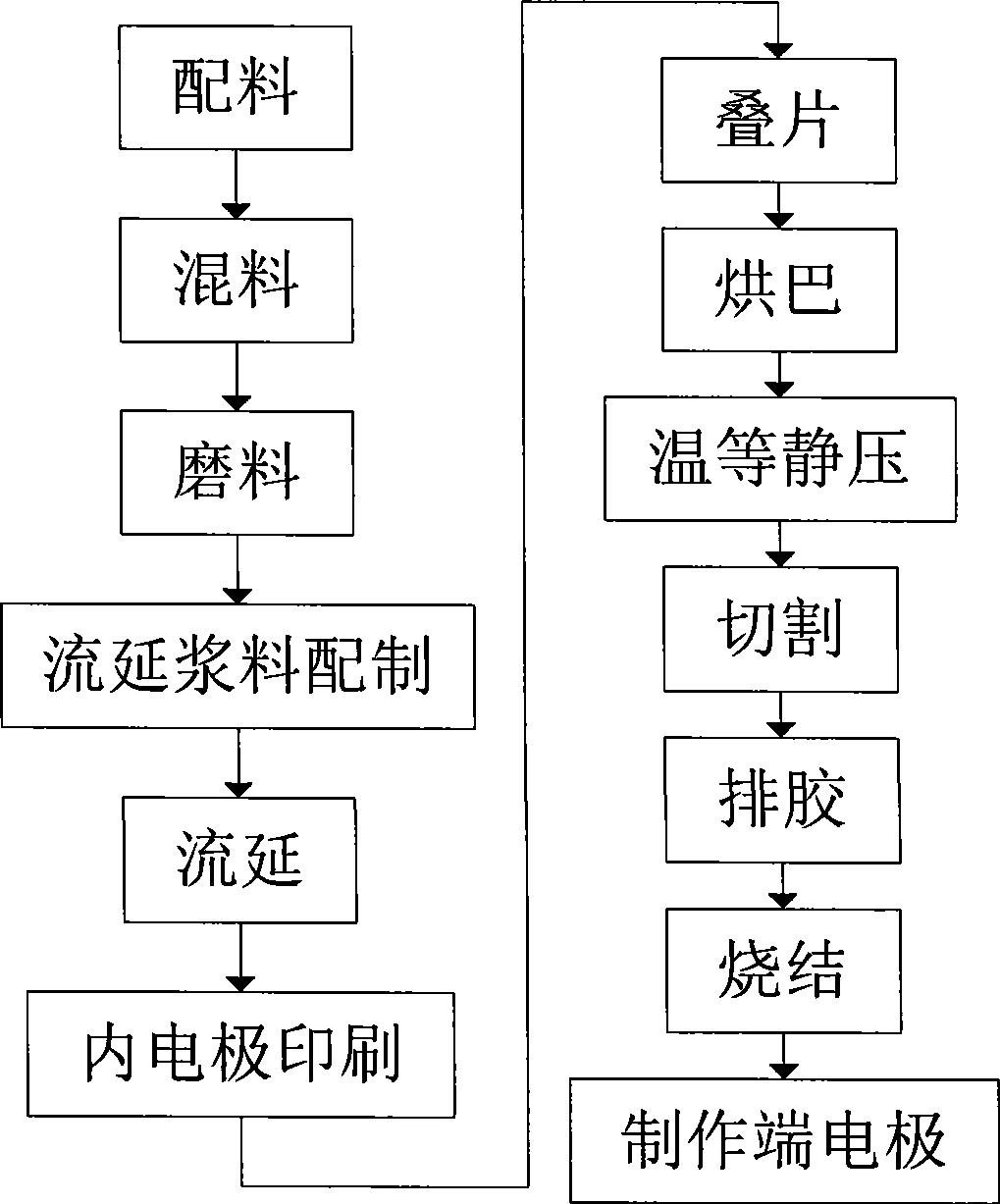

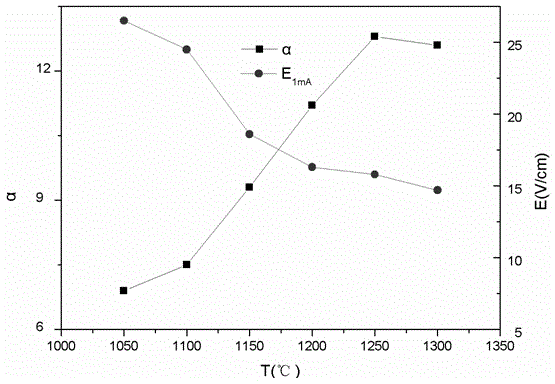

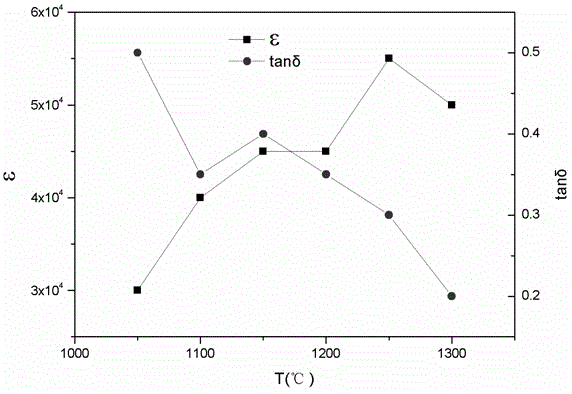

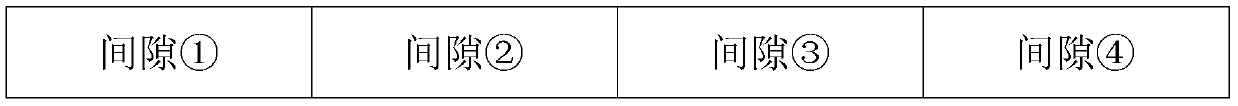

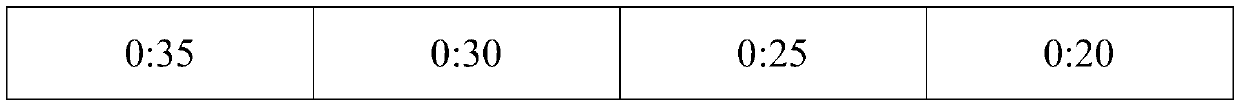

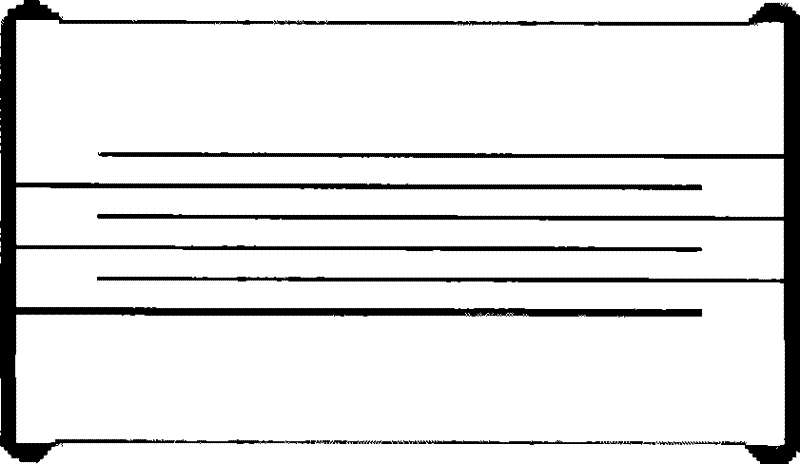

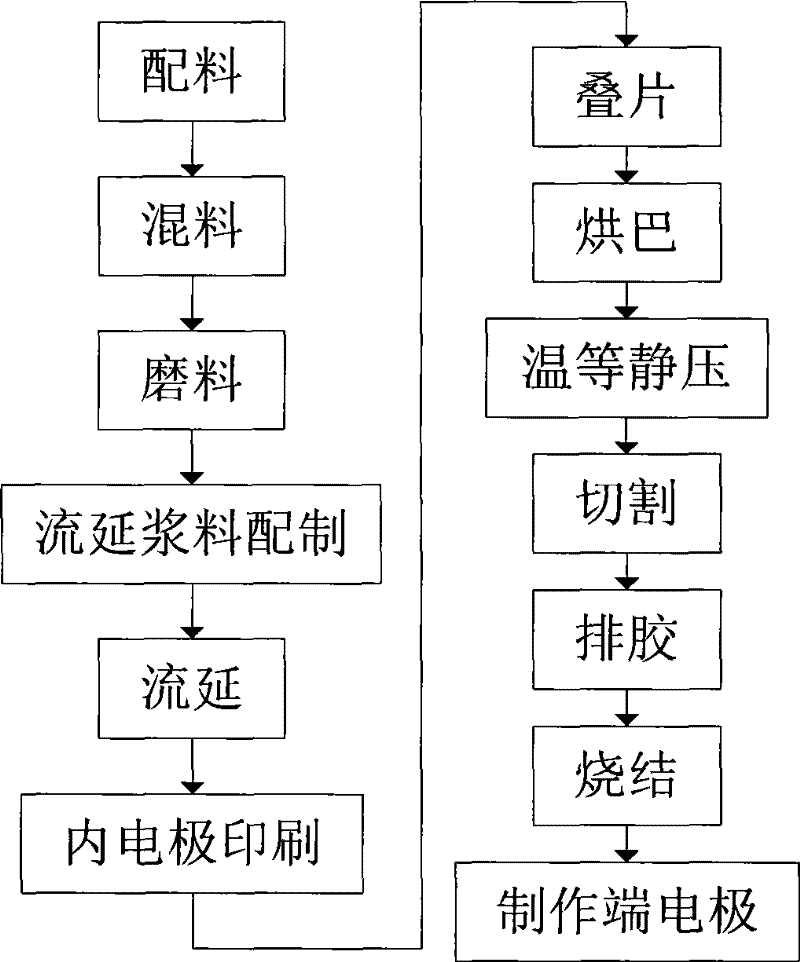

The invention relates to a zinc oxide voltage dependent resistor medium material and a resistor preparation method, which belongs to the technology field of electronic material. The components of the zinc oxide voltage dependent resistor medium material comprises 85 percent to 95 percent of ZnO, 2 percent to 6 percent of Bi2O3, 1 percent to 5 percent of TiO2, 1 percent to 3.5 percent of Sb2O3, 1 percent to 4 percent of MnCO3, 1.2 percent to 5 percent of Co2O3, 0.2 percent to 1 percent of Cr2O3, 0.1 percent to 1 percent of ZrO2, 0.2 percent to 1 percent of Ni2O3 and 1.2 percent to 3 percent of SiO2. The chip type zinc oxide resistor preparation method comprises the steps of dosing according to a zinc oxide resistor medium material medium material, material mixing, material grinding, casting sizing agent making, casting, inner electrode printing, laminating, baking, temperature isostatic pressing, cutting, gule discharging, sintering, end electrode making, and the like. The zinc oxide voltage dependent resistor medium material of the invention is suitable for making chip type voltage dependent resistor; the prepared chip type voltage dependent resistor has the characteristics of low voltage-dependent voltage, high nonlinear coefficient and stable voltage-dependent characteristic, the sintering temperature is moderate, preparation technology is simple and is easy to control, and cost is low.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Multilayer ceramic electronic component

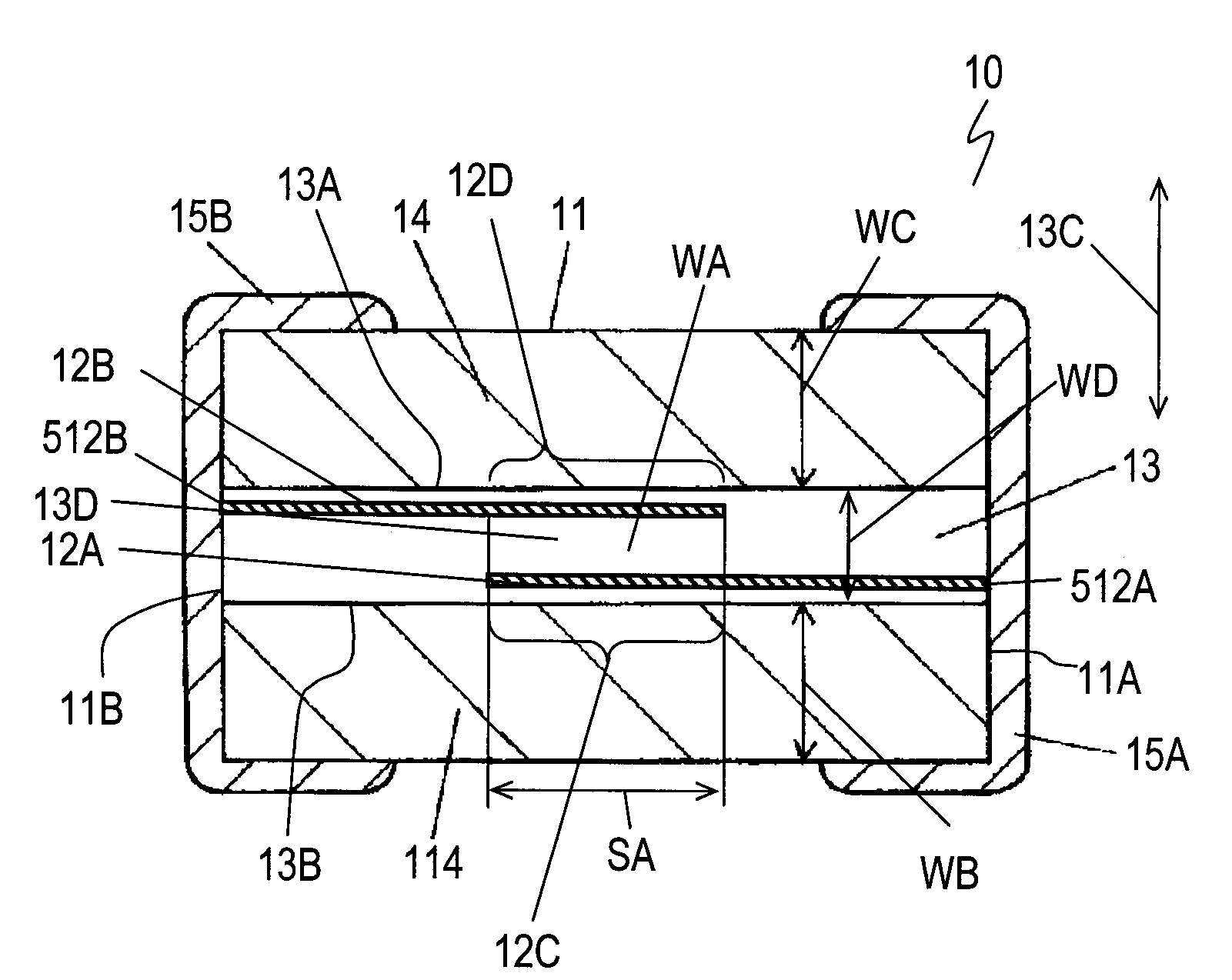

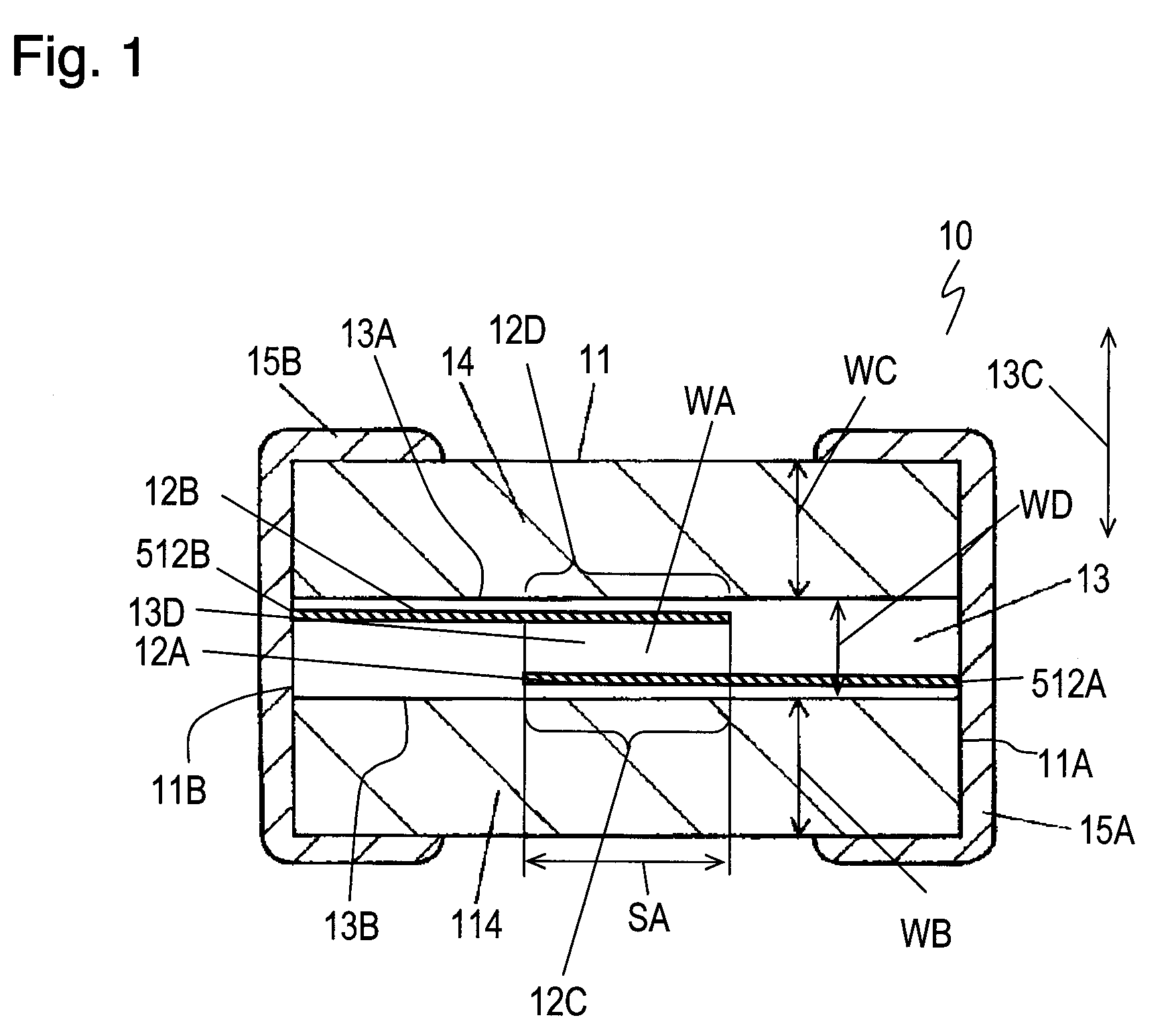

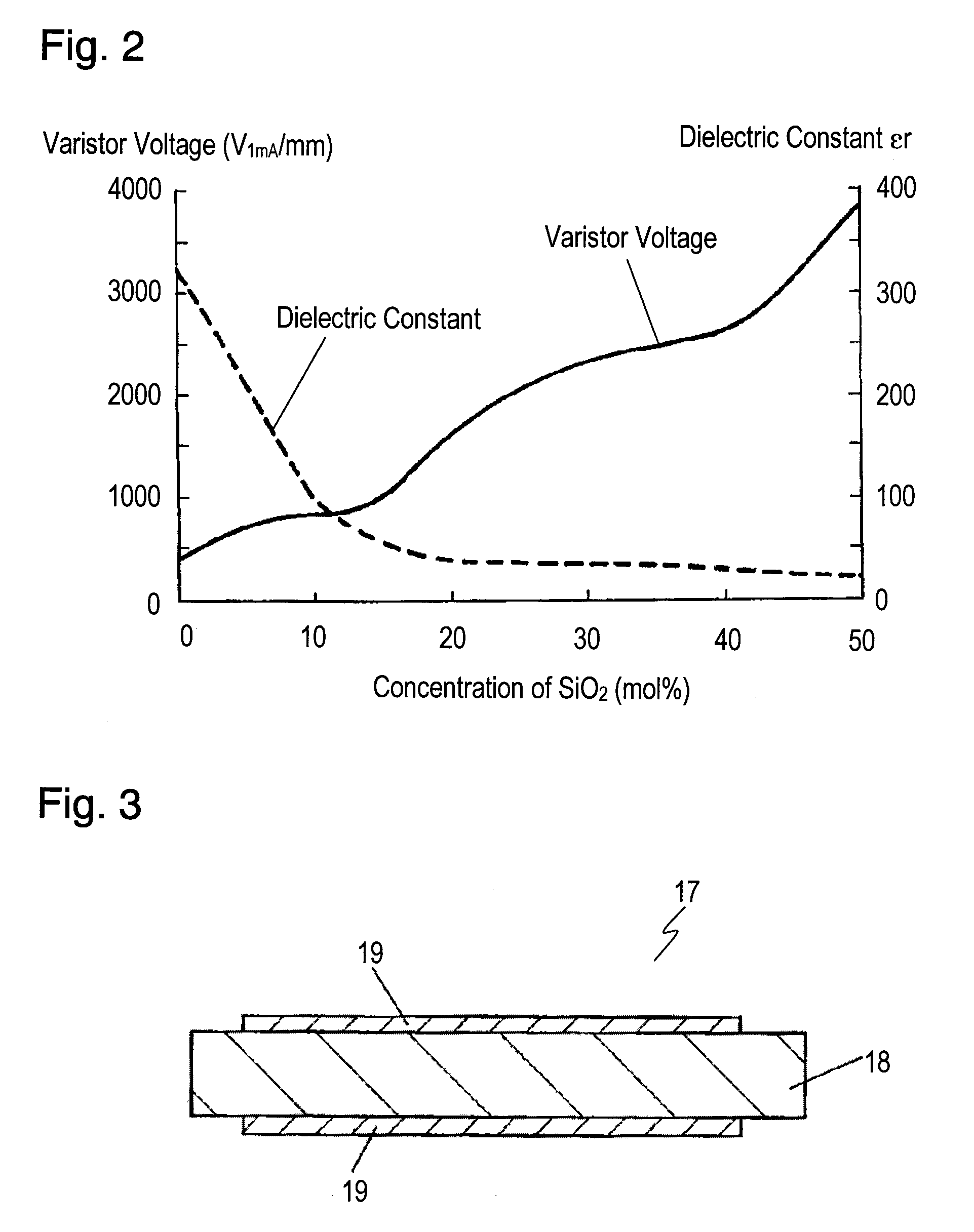

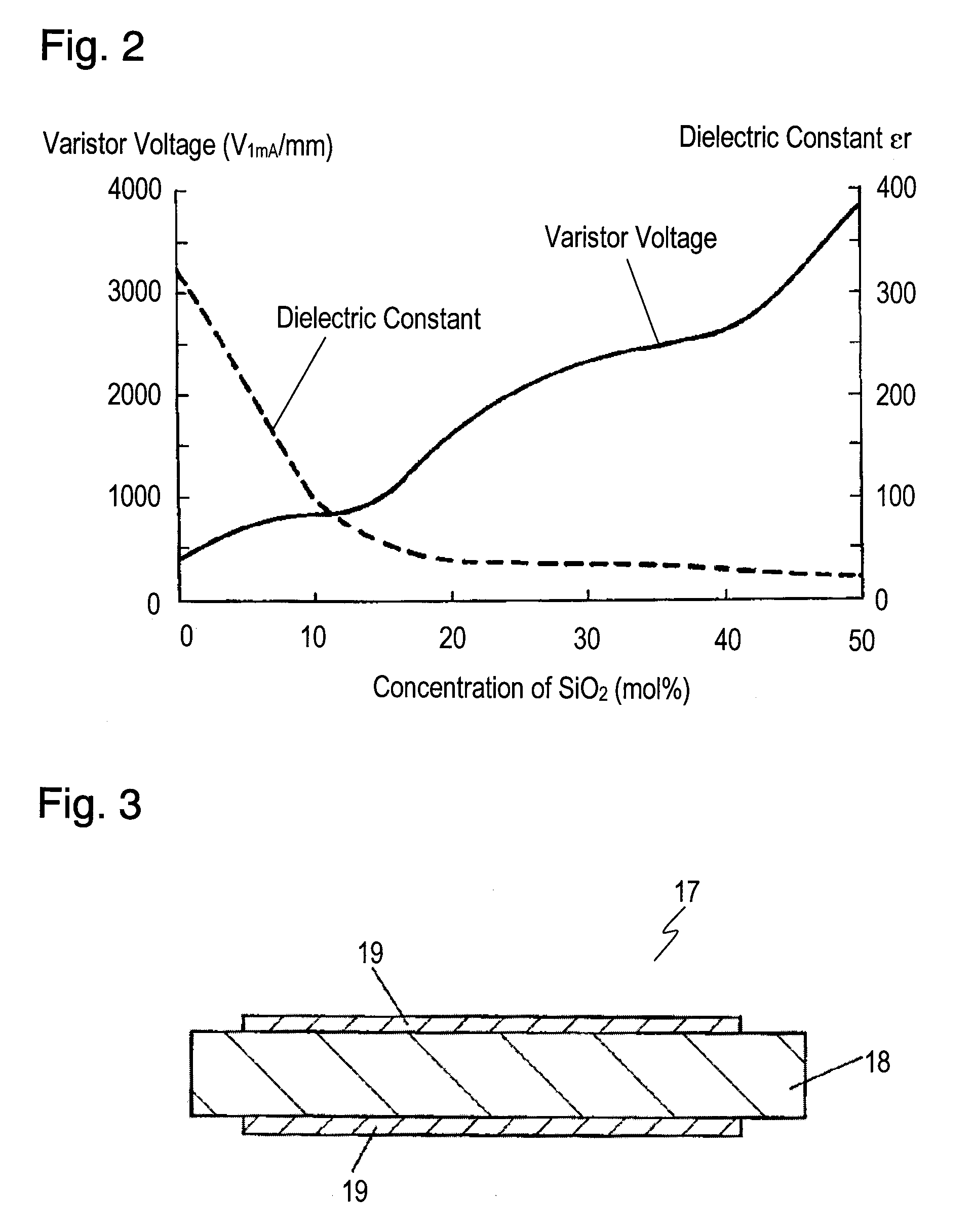

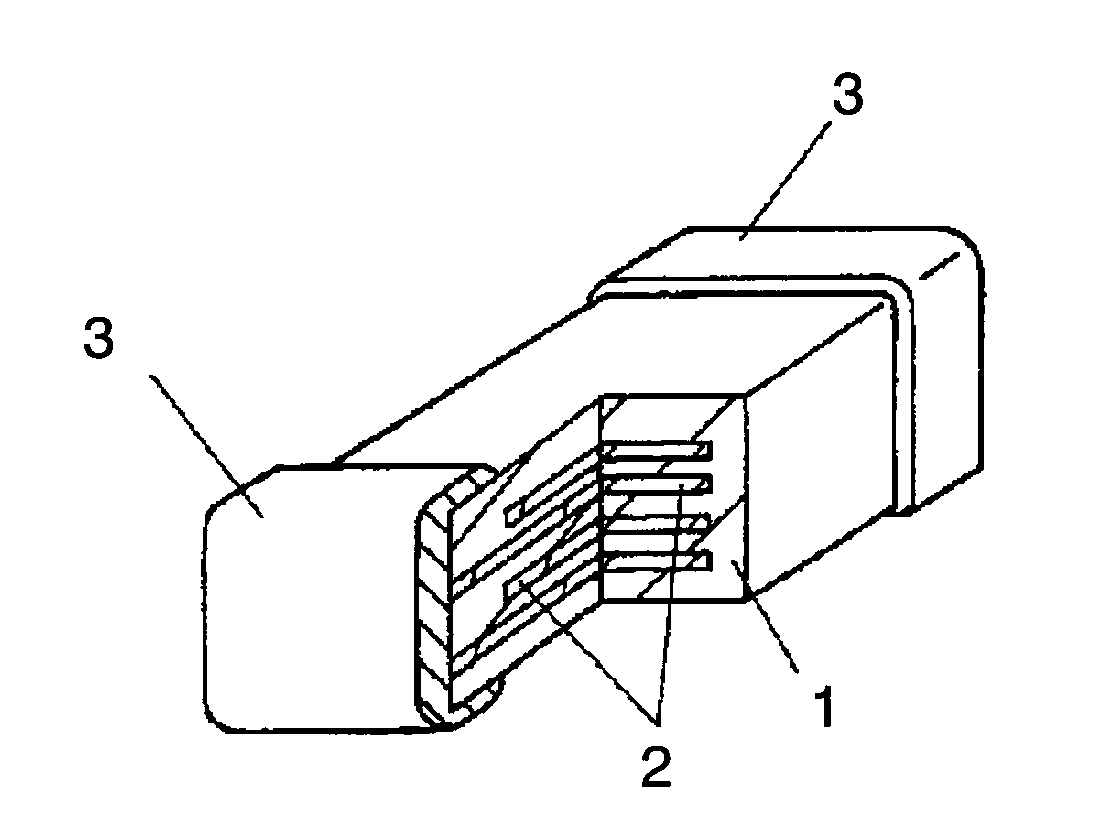

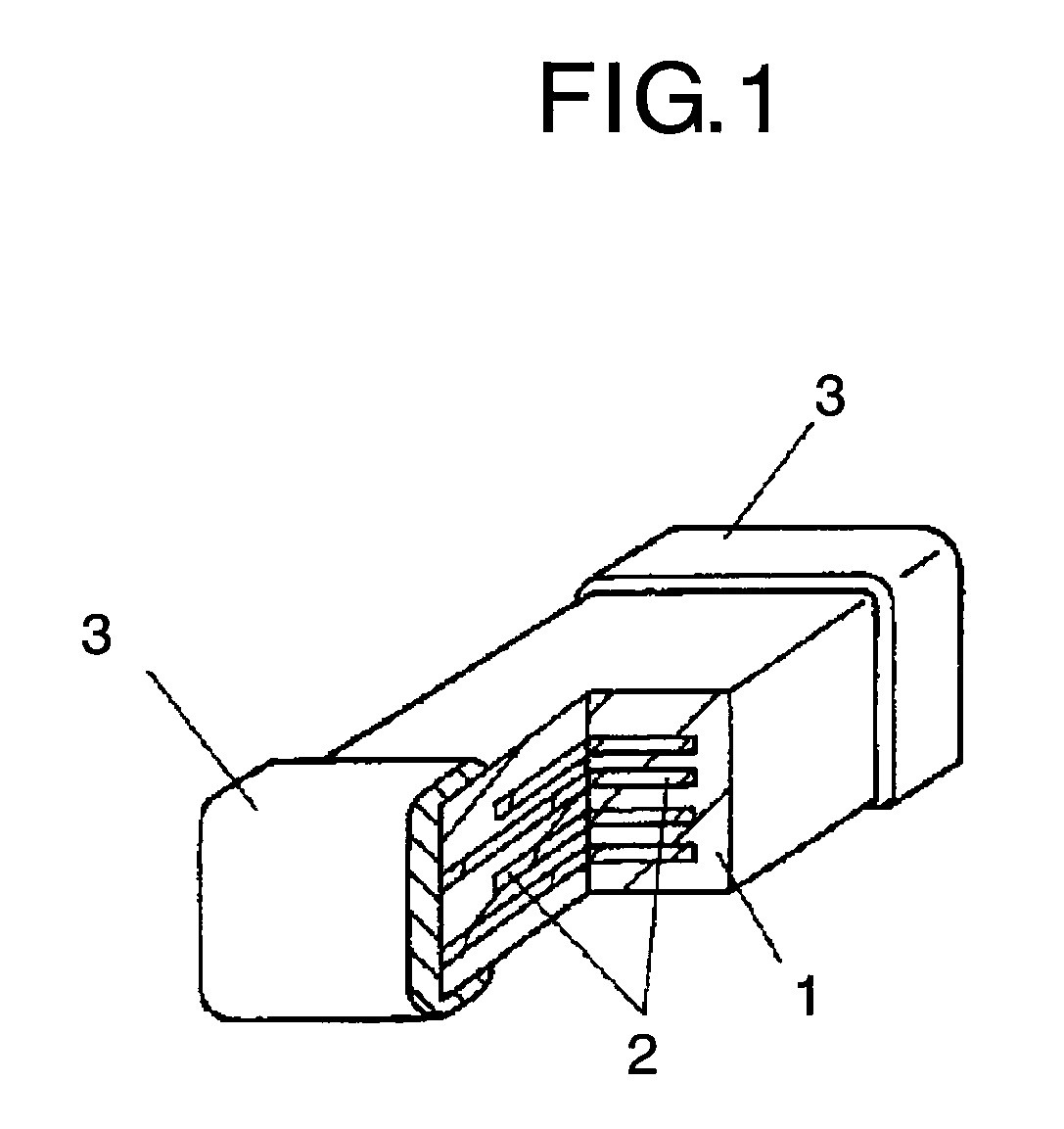

ActiveUS20090021340A1Low varistor voltageSmall capacitanceCurrent responsive resistorsFixed capacitor terminalsCapacitanceMetallurgy

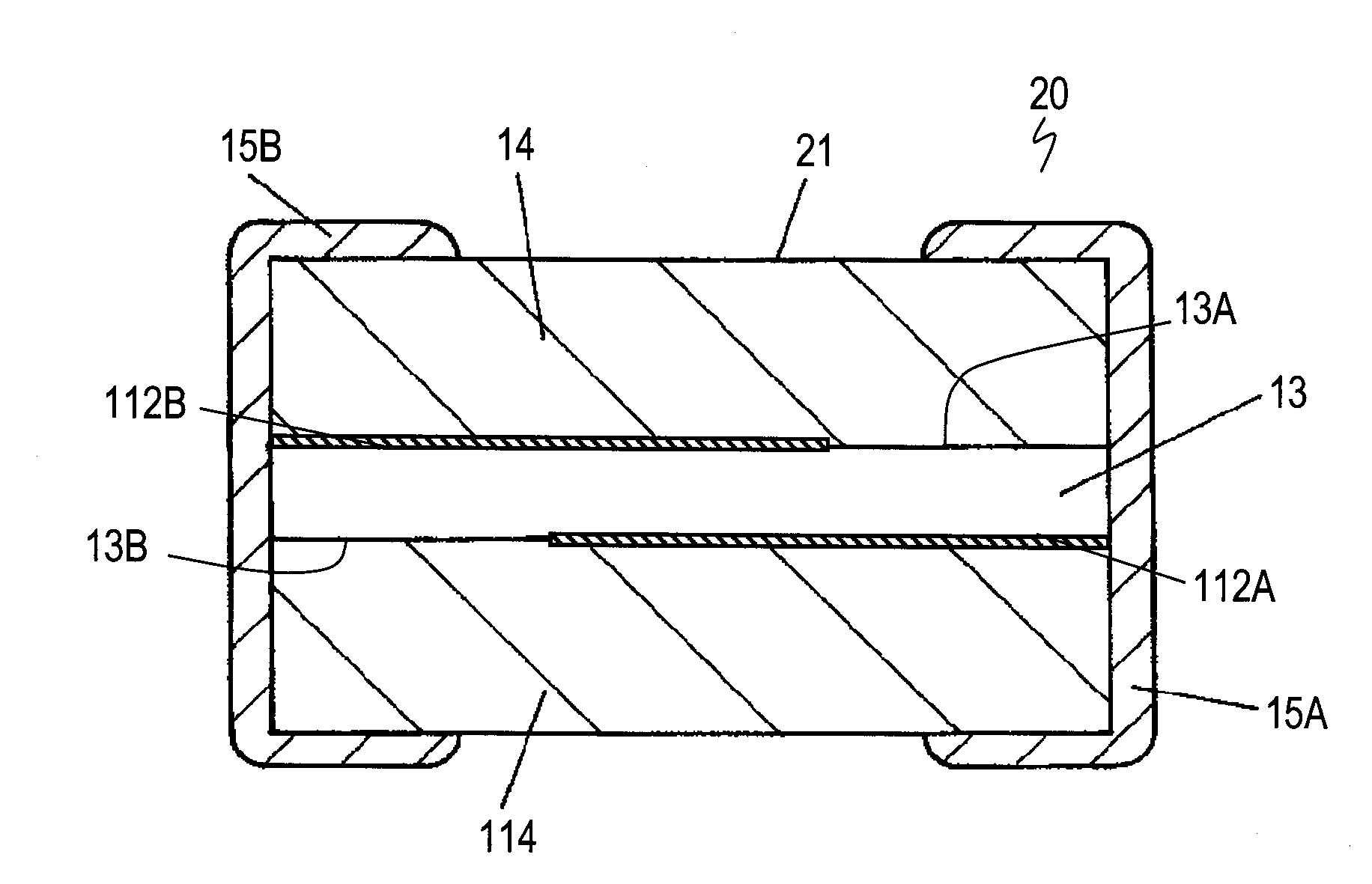

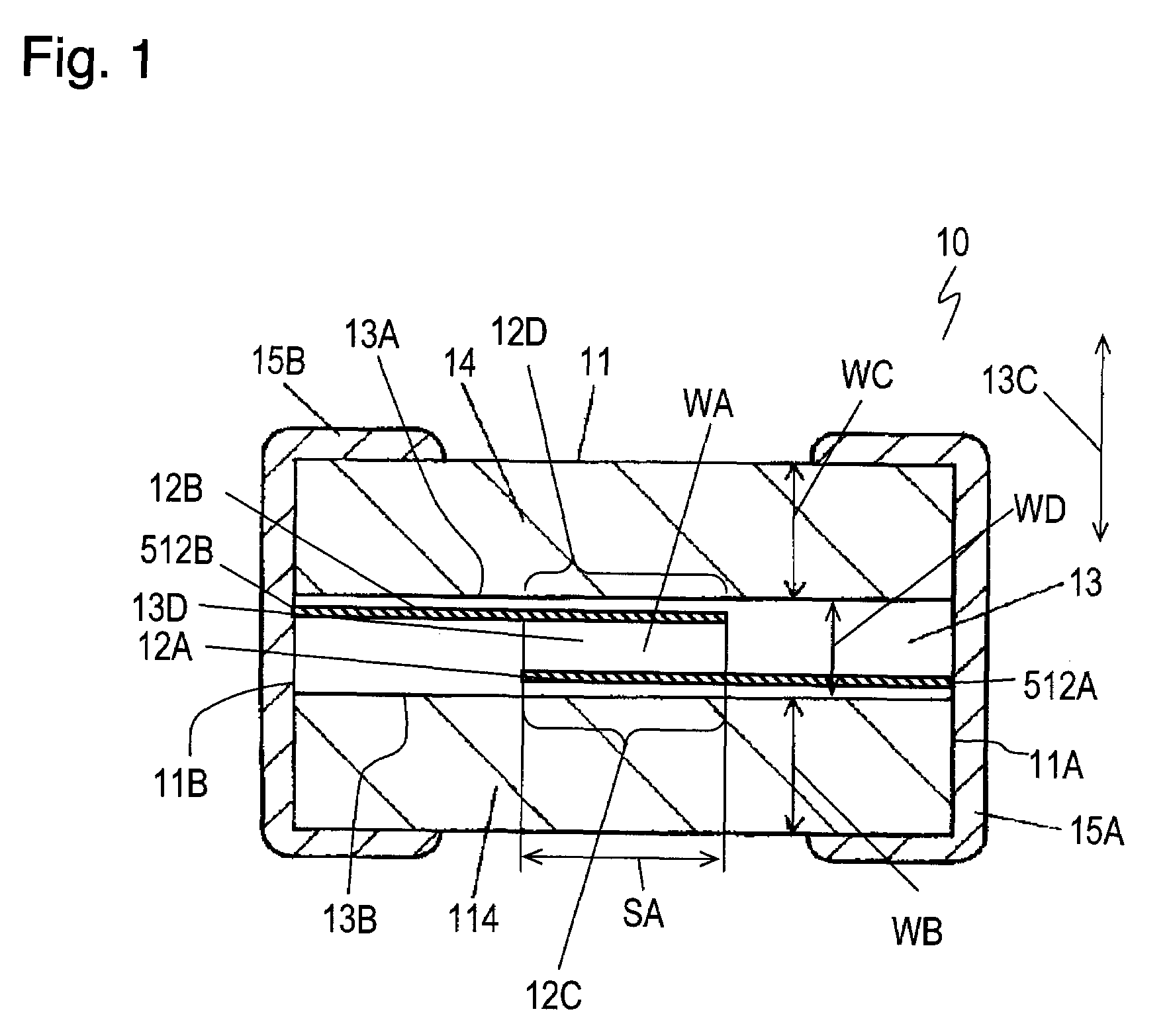

A multilayer ceramic electronic component includes a multilayer body, a first internal electrode provided in the multilayer body, and a second internal electrode provided in the multilayer body and facing the first internal electrode. The multilayer body includes a first ceramic layer, a second ceramic layer provided on a first surface of the first ceramic layer, and a third ceramic layer provided on a second surface of the first ceramic layer opposite to the first surface. The first and second internal electrodes are connected to the first ceramic layer. The first ceramic layer contains mainly ZnO and 0 to 15 mol % of SiO2. The second ceramic layer contains mainly ZnO and 15 to 50 mol % of SiO2. The third ceramic layer contains mainly ZnO and 15 to 50 mol % of SiO2; The multilayer ceramic component has a low varistor voltage and a small capacitance.

Owner:PANASONIC CORP

Method for improving electrical property of zinc-oxide-based low voltage varister ceramic film

InactiveCN102219499AHigh nonlinear coefficientLow varistor voltageLeakage current densityLow voltage

The invention relates to varistor ceramics, and specifically relates to a method for improving the electrical property of a zinc-oxide-based low voltage varister ceramic film. The method is characterized in that: an aluminum foil, which is used as an absorption layer, is attached to the surface of a zinc-oxide-based low voltage varister ceramic film sample; a confinement medium is painted, stuck or covered on the aluminum foil; the ceramic film sample is then embedded on a mold; and laser impact is applied to the ceramic film sample, such that the electrical property of the zinc-oxide-based low voltage varister ceramic film is improved. According to the present invention, a laser impact treatment technology is employed in the surface treatment upon the zinc-oxide-based low voltage varister ceramic film. With the liquid confinement medium, non-linear coefficient of the zinc-oxide-based ceramic film is raised by 24% or above comparing to that before the laser impact treatment, varister voltage of the zinc-oxide-based ceramic film is reduced by 30% or above comparing to that before the laser impact treatment, and leakage current density of the zinc-oxide-based ceramic film is reducedby 35% or above comparing to that before the laser impact treatment. The advantage of the method is that: non-linear coefficient of the film is improved while the leakage current density of the film is reduced.

Owner:JIANGSU UNIV

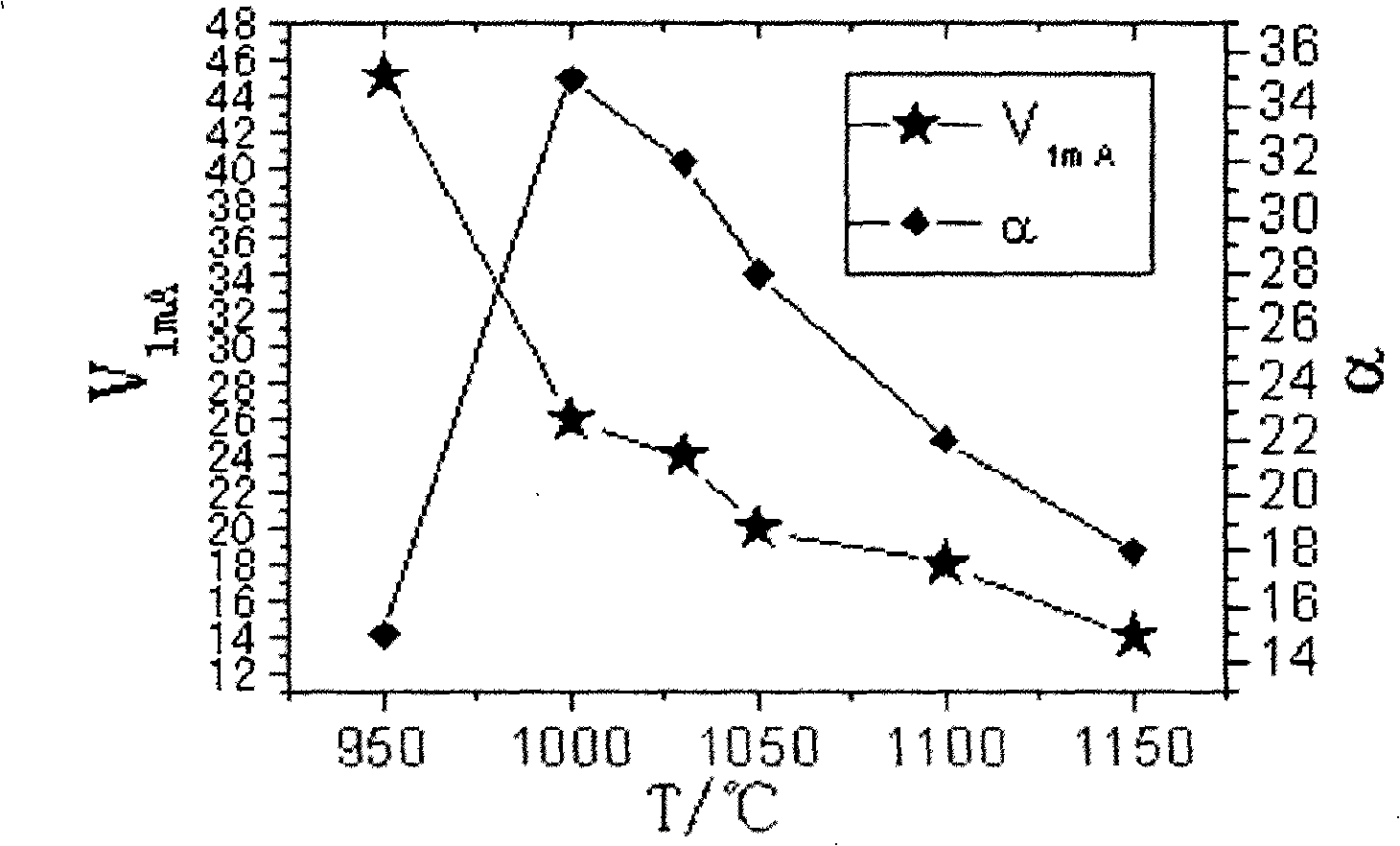

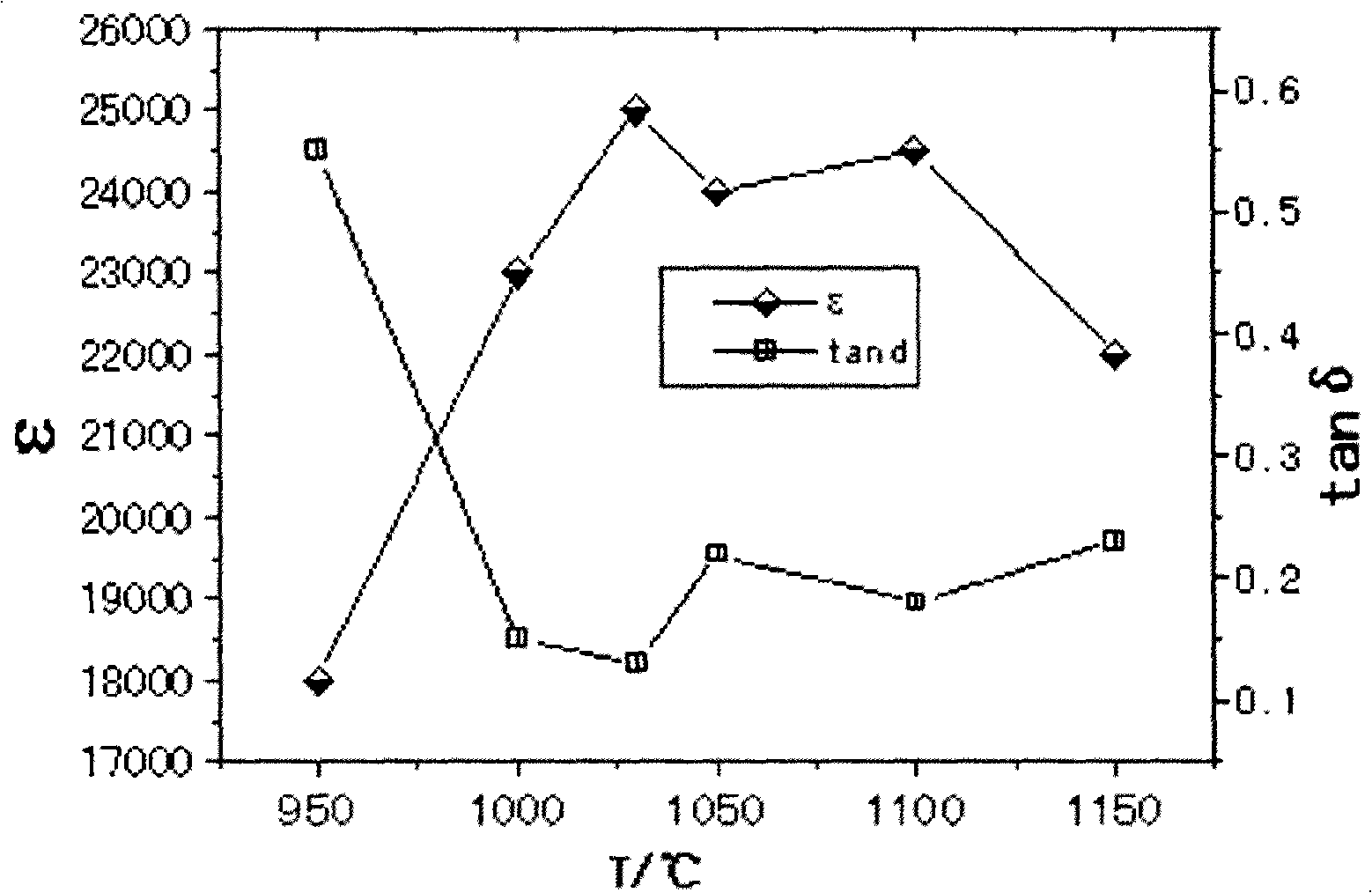

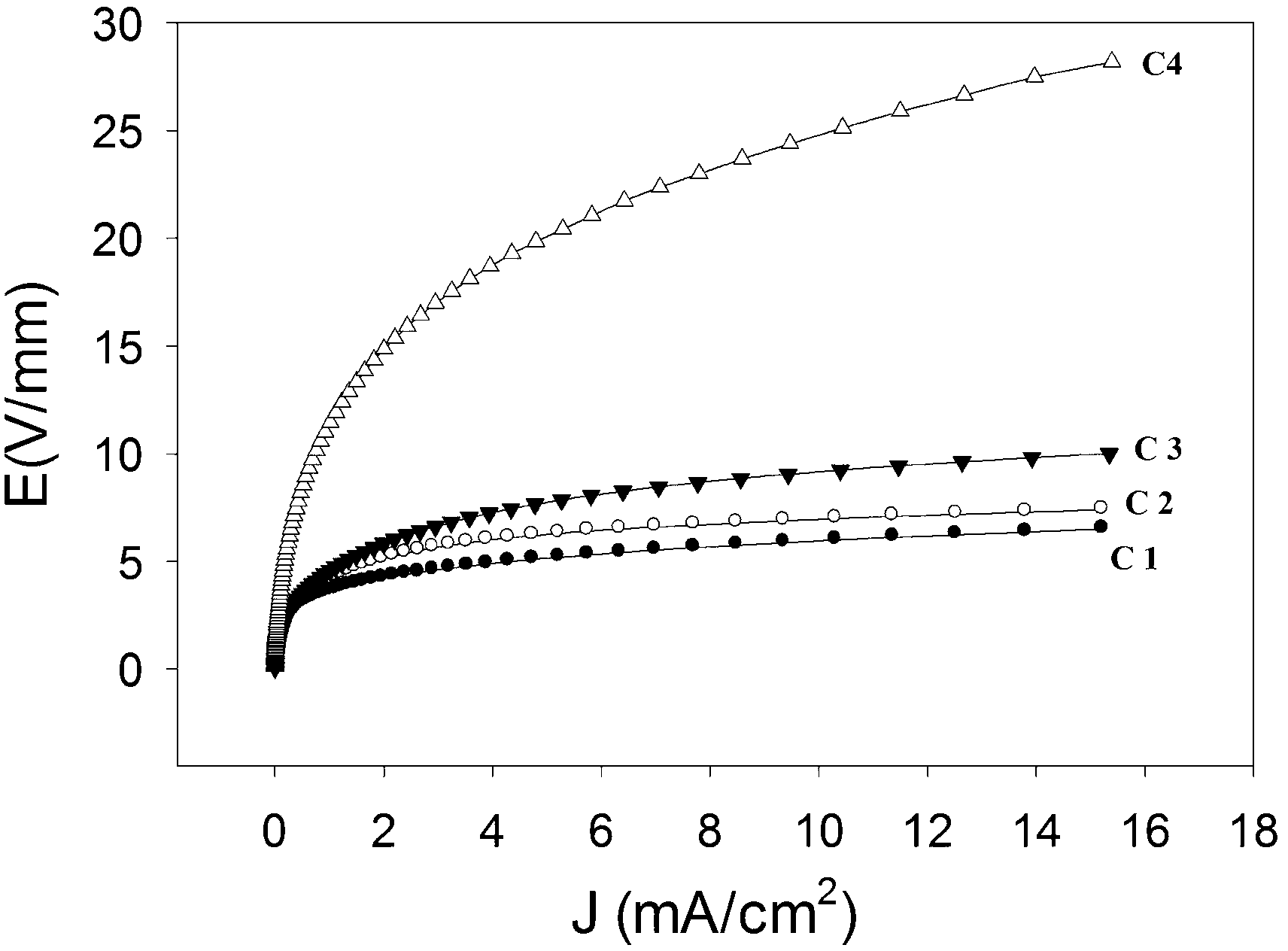

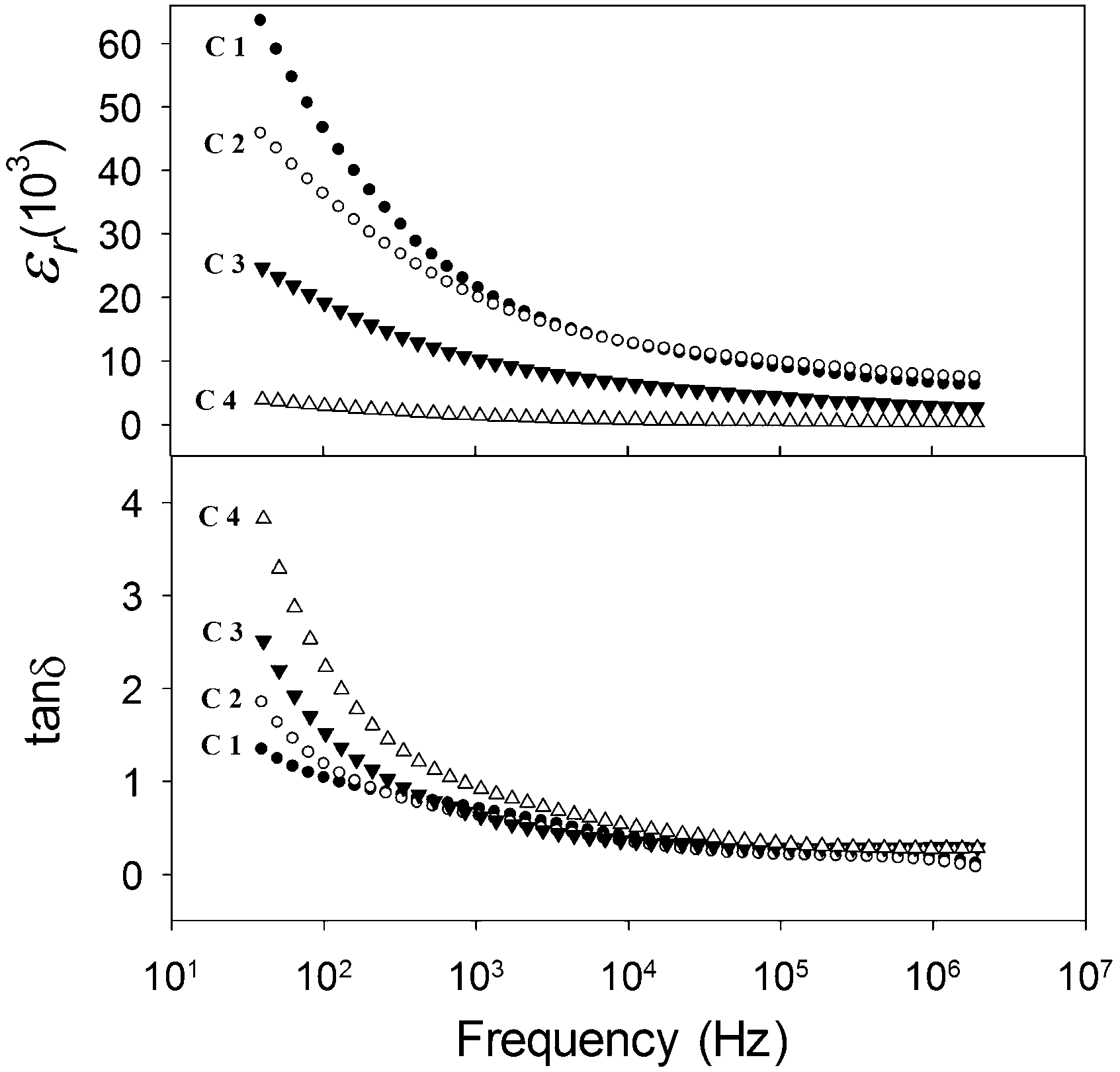

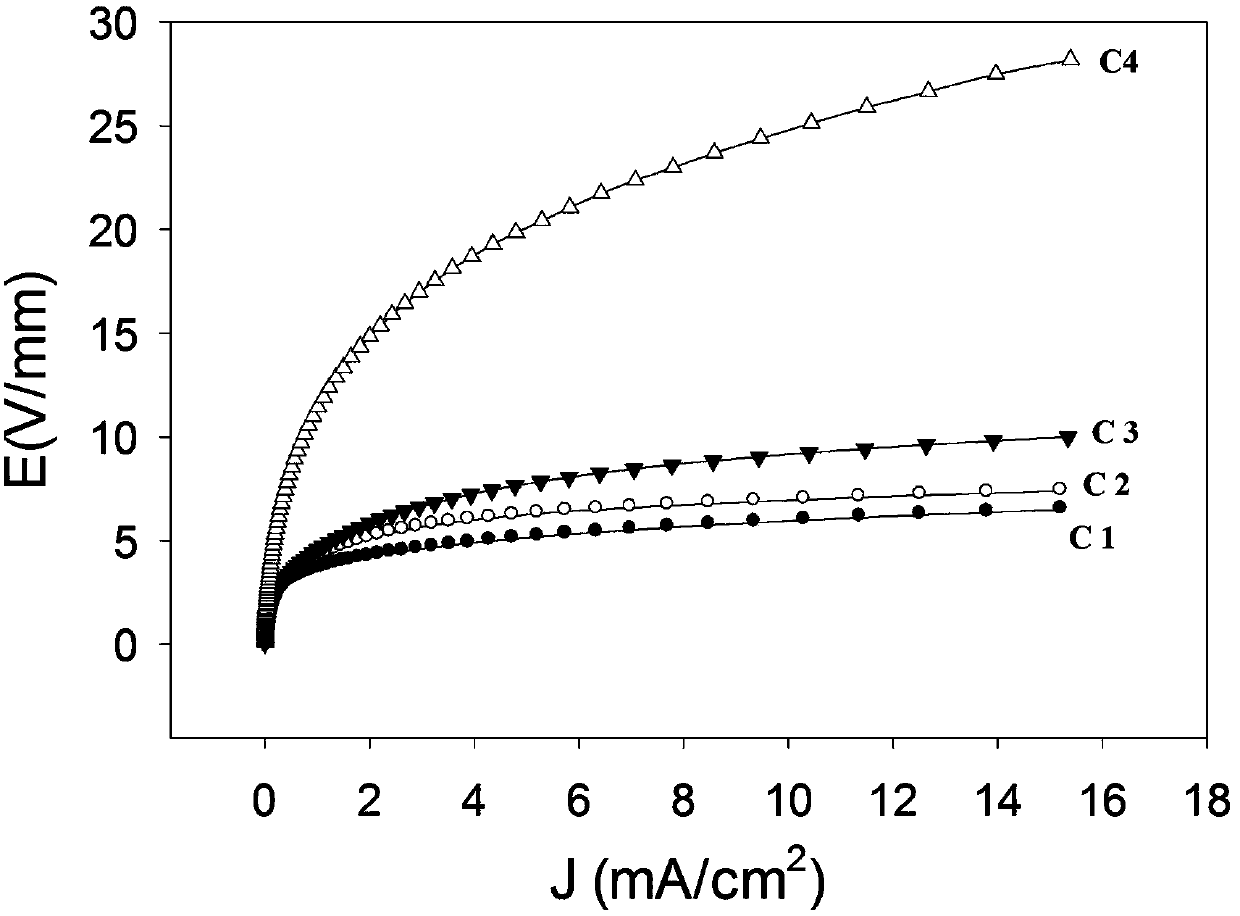

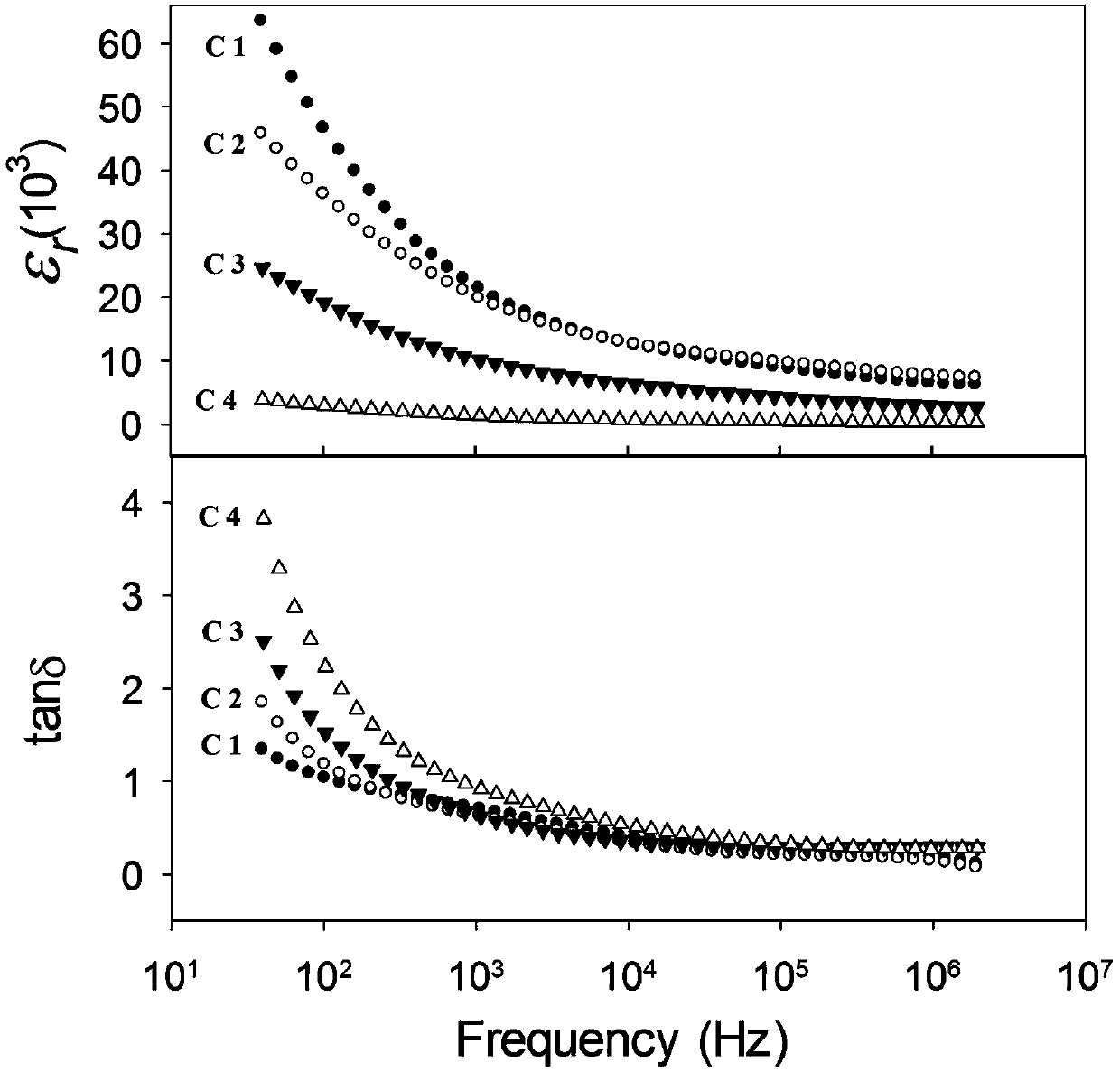

La2O3-SnO2-Zn2SnO4 varistor-capacitor bifunctional ceramic material and preparation method thereof

The invention relates to a La2O3-SnO2-Zn2SnO4 varistor-capacitor bifunctional ceramic material. The ceramic material is formed by mixing, pressing and sintering SnO2 powder, Zn2SnO4 powder and La2O3 powder, and the mol ratio of all the components (La2O3, SnO2 and Zn2SnO4) is X:85:15; X=0 / 1-2.5. The La2O3-SnO2-Zn2SnO4 composite ceramic material prepared by mixing, pressing and sintering the SnO2 powder, the Zn2SnO4 powder and the La2O3 powder has good varistor properties, superhigh dielectric constant and low varistor voltage.

Owner:HENAN UNIV OF SCI & TECH

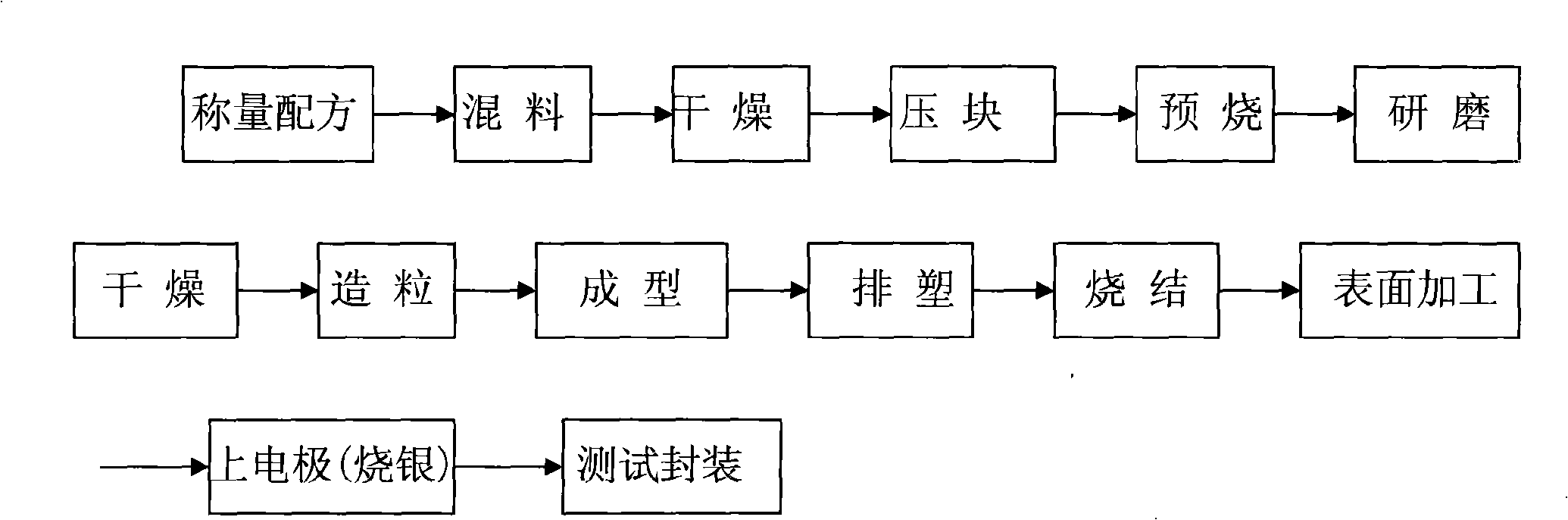

Stratified structure low-voltage ZnO piezoresistor preparation method

InactiveCN101286393ALow varistor voltageReduce leakage currentVaristor coresLow voltageMixed materials

The invention relates to a production method of a low-voltage and voltage-sensitive ZnO ceramic material with a laminar structure and a resistance that is produced by the ZnO ceramic material, and the invention belongs to the technical field of the production of electrical apparatus elements and materials. One group of raw materials is the mixed material that consists of ZnO and any oxide powder that is added into ZnO and selected from the oxides nano ZnO and doping elements of Bi, Al, Fe, Eu, Pr, La, Ce, Nd, B, Si, Mn, Cr, Co, Pb and Ti; the other group of raw materials is the mixed material that does not have addition elements or comprises ZnO that is blended with part of the oxides that are selected from the oxides of Al, Ti, Mn, Cr and Co; the two groups of powder materials are placed into a mold according to a certain proportion, then pressed, molded and gradually heated, and heat-preserved colloid discharge and heated agglomeration are implemented, thus obtaining the low-voltage and voltage-sensitive ZnO ceramic material with the laminar structure; the surface processing of the ZnO ceramic material is implemented, silver is burned on the surface of the ZnO ceramic material by electrodes, and the ZnO ceramic material is tested and encapsulated, thus obtaining the product. The low-voltage and voltage-sensitive ZnO ceramic material with the laminar structure has the advantages of simple technique, lower cost, good performance and wide application range, and the resistance that is produced by the ZnO ceramic material has good repeatability, stability and consistency, as well as remarkably improved electric parameter values.

Owner:KUNMING UNIV OF SCI & TECH

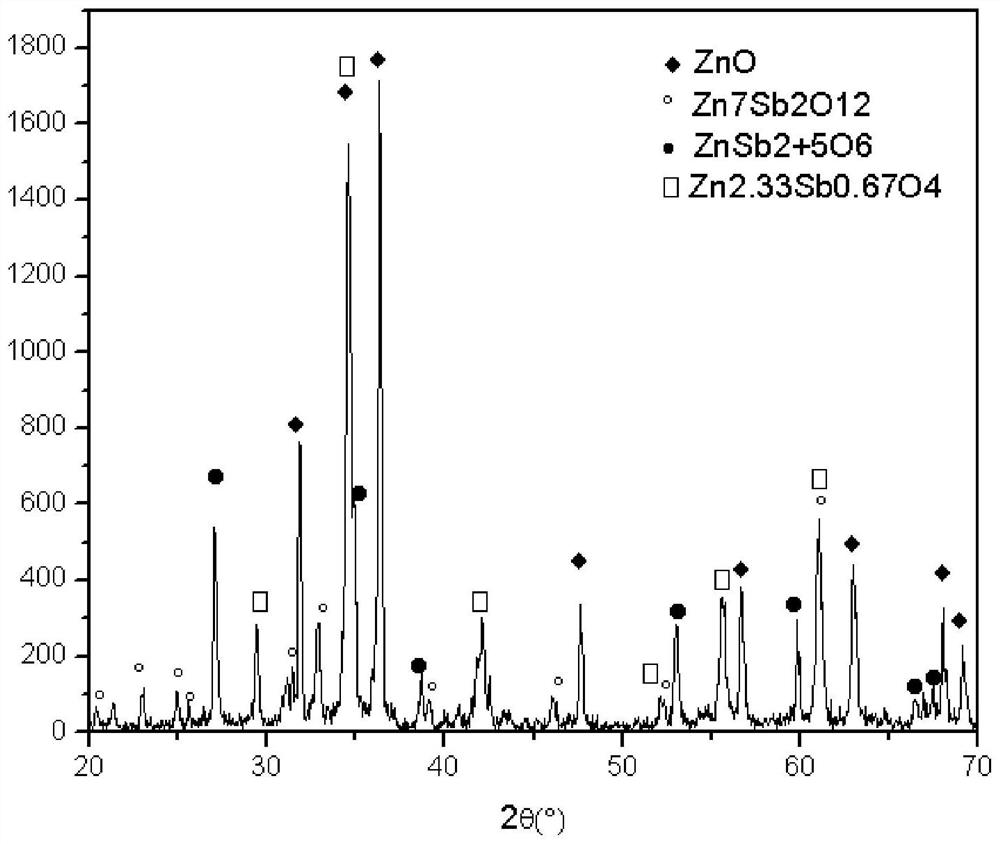

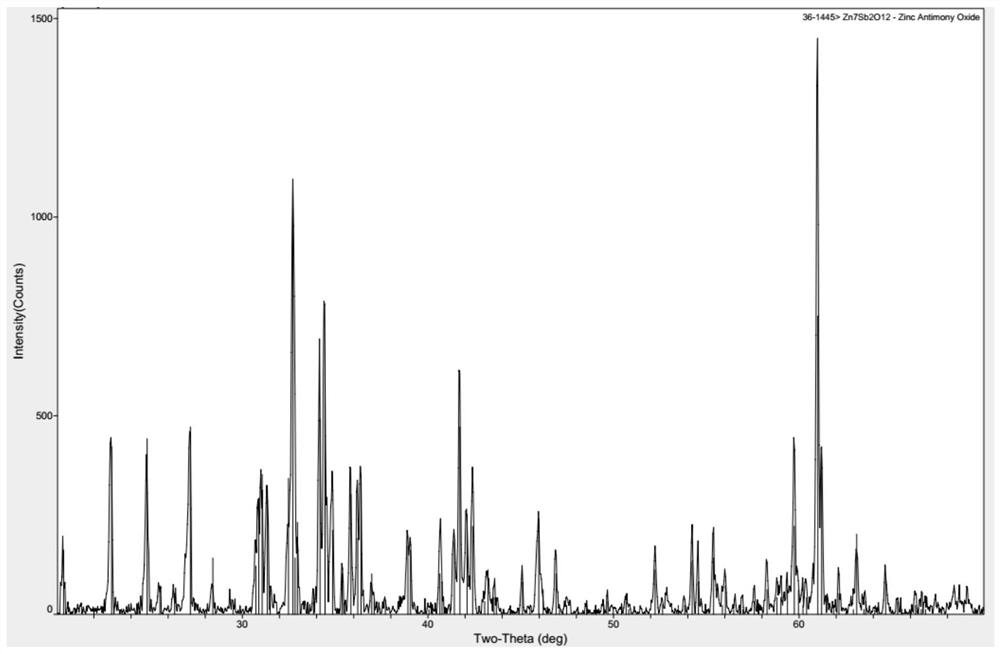

ZnO varistor ceramic additive as well as preparation method and application thereof

The invention belongs to the field of varistor materials, and provides a ZnO varistor ceramic additive as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) carrying out ball milling on ZnO and Sb2O3 by taking a solvent as a medium to obtain slurry, wherein a molar ratio of the ZnO to the Sb2O3 is equal to 1-(14 to 1); (2) drying and calcining the slurry obtained in the step (1) to obtain the ZnO varistor ceramic additive. The invention also provides the ZnO varistor ceramic additive and application thereof. After the ZnO varistor ceramic additive is added into raw materials for preparing ZnO varistor ceramics, ZnO grain growth is promoted, the varistor voltage is reduced, the low temperature sintering of a varistor is maintained, and the nonlinear coefficient of the varistor ceramics can be increased; the sintering temperature of the ZnO varistor ceramics is reduced to 850-900DEG C, the nonlinear coefficient alpha value of the material can reach 91, and the varistor field strength is as low as 500-760V / mm.

Owner:LIAOCHENG UNIV

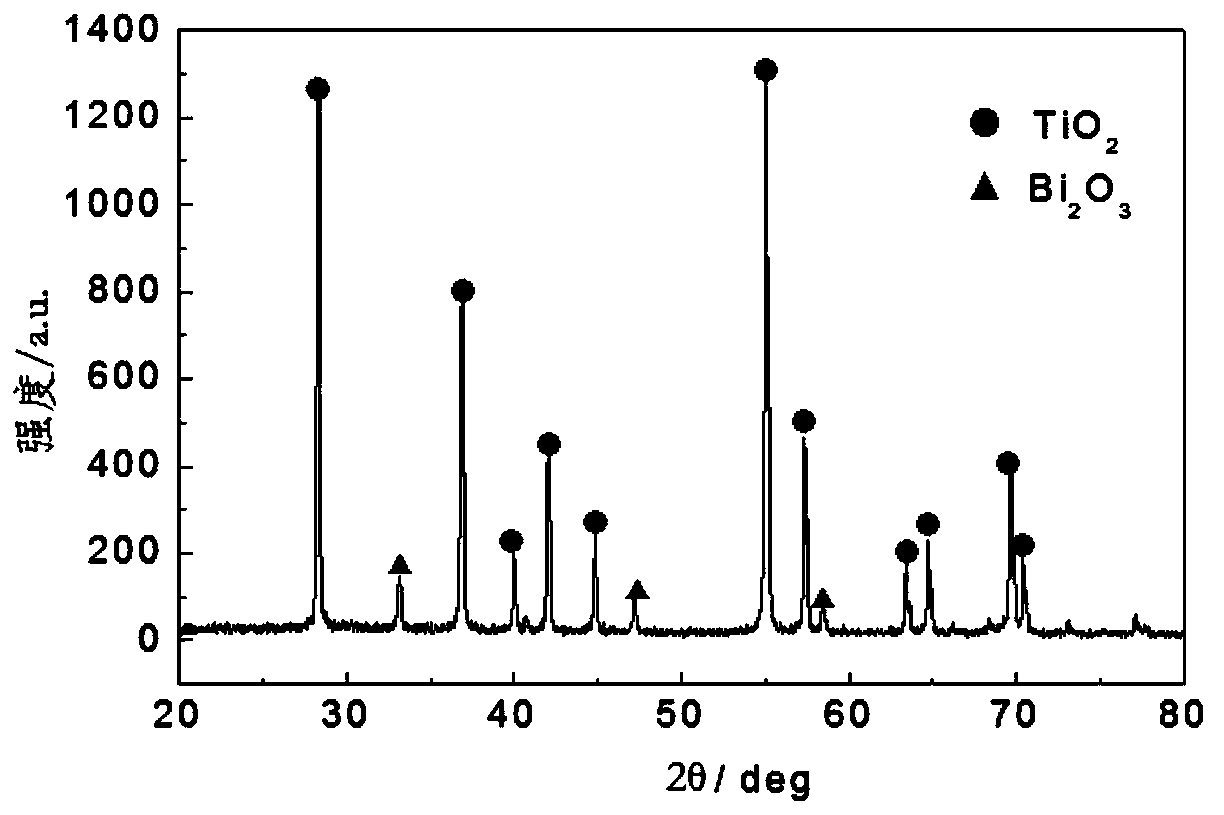

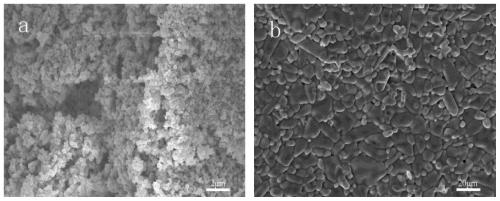

Preparation method for pressure-sensitive material applied to ceramic resistor body

InactiveCN107935585ASimple manufacturing processImprove performanceResistor manufactureVaristor coresSilver electrodeRoom temperature

The invention discloses a method for preparing a pressure-sensitive material used for ceramic resistors. In the method of the invention, TiO2 powder, SnO2 powder, Bi2O3 powder, MnO2 powder and SiO2 powder are uniformly mixed to obtain a mixed material, and then the mixed material is Wet grinding, drying, sieving, adding binder and grinding, continue sieving, and then granulate, and then press the powder into block material; heat the block material to remove glue, reheat sintering and cool to room temperature, and then grind , cleaning, drying, silver-plated electrodes and packaging to obtain (SnO2, Bi2O3, MnO2 and SiO2) co-doped TiO2 varistors. The invention improves the performance of TiO2 series varistor ceramic resistors and simplifies the production process.

Owner:SICHUAN QIXING ELECTRONICS

Preparation method and application of voltage-sensitive ceramic material

ActiveCN104844192ASimple manufacturing processImprove performanceVaristor coresElectrical resistance and conductanceSilver electrode

The invention relates to a preparation method and application of a voltage-sensitive ceramic material and belongs to the technical fields of electrical apparatus elements and material manufacture of the electrical apparatus elements. The preparation method comprises the steps of firstly adding Ge, Nb2O5 and Y2O3 into TiO2 to obtain a mixed material, then conducting wet grinding, drying, screening and pelleting on the mixed material, continuing to perform screening after pelleting, producing powder into small round pieces, conducting heating and glue discharging on the small round pieces, preheating, sintering and cooling the small round pieces to be at room temperature to obtain (Ge, Nb2O5 and Y2O3) co-doped TiO2 voltage-sensitive ceramic, conducting voltage-sensitive ceramic surface processing, electrode adding, silver electrode firing and package to obtain a (Ge, Nb2O5 and Y2O3) co-doped TiO2 voltage-sensitive resistor. The performance of the TiO2 voltage-sensitive resistor is improved.

Owner:KUNMING UNIV OF SCI & TECH

Method for codoping TiO2 voltage-sensitive ceramic, codoped TiO2 piezoresistor and preparation method of TiO2 voltage-sensitive ceramic

The invention relates to a method for codoping TiO2 voltage-sensitive ceramic, a codoped TiO2 piezoresistor and a preparation method of the TiO2 voltage-sensitive ceramic, and belongs to the technical fields of electrical elements and material manufacturing of the electrical elements. The method comprises the following steps: firstly, adding Ge, GeO2, V2O5 and Y2O3 to TiO2 to obtain a mixture; carrying out wet-milling, drying, sieving and pelletizing the mixture, further sieving, and pressing powder into small disks; and heating the small disks, discharging glue, thermally sintering and cooling to a room temperature to prepare (Ge, GeO2, V2O5 and Y2O3) codoped TiO2 voltage-sensitive ceramic. The voltage-sensitive ceramic surface is processed, is subjected to silver electrode firing by an electrode, and then is encapsulated to obtain the (Ge, GeO2, V2O5 and Y2O3) codoped TiO2 piezoresistor. The performance of a TiO2-based voltage-sensitive ceramic resistor is improved.

Owner:KUNMING UNIV OF SCI & TECH

Multilayer ceramic electronic component

ActiveUS7623020B2Low varistor voltageSmall capacitanceCurrent responsive resistorsFixed capacitor terminalsCapacitanceMetallurgy

A multilayer ceramic electronic component includes a multilayer body, a first internal electrode provided in the multilayer body, and a second internal electrode provided in the multilayer body and facing the first internal electrode. The multilayer body includes a first ceramic layer, a second ceramic layer provided on a first surface of the first ceramic layer, and a third ceramic layer provided on a second surface of the first ceramic layer opposite to the first surface. The first and second internal electrodes are connected to the first ceramic layer. The first ceramic layer contains mainly ZnO and 0 to 15 mol % of SiO2. The second ceramic layer contains mainly ZnO and 15 to 50 mol % of SiO2. The third ceramic layer contains mainly ZnO and 15 to 50 mol % of SiO2; The multilayer ceramic component has a low varistor voltage and a small capacitance.

Owner:PANASONIC CORP

Low-cost and low-temperature sintered piezoelectric resistor silver paste and preparation method thereof

ActiveCN107799199ALow softening pointLower transition temperatureNon-conductive material with dispersed conductive materialResistor manufactureSilver pasteTitanium powder

The invention relates to low-cost and low-temperature sintered piezoelectric resistor silver paste and a preparation method thereof. The preparation method comprises the steps of accurately weighing various materials such as 30-70 parts of silver micro powder A, 20-30 parts of silver micro powder B, 5-20 parts of silver micro powder, 2-6 parts of glass powder, 1-3 parts of titanium powder, 1-3 parts of additive, 1-5 parts of organic diluent and 1-5 parts of organic binding agents, and performing uniform stirring; and performing rolling. The preparation method has the characteristics that the application performance of the paste is improved and the device production cost is greatly reduced.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

Voltage non-linear resistor ceramic composition and multilayer varistor using the same

ActiveUS7973638B2Improve reliabilitySmall capacitanceCurrent responsive resistorsThick film varistorsMaterials scienceResistor

A voltage non-linear resistor ceramic composition has ZnO as a main component and is represented by the general formula (1−x)ZnO+x[Sr1−yMy]1−a[Co1−zAz]1+aO3. Here, M is at least one of Ca and Ba, and A is Mn or Cr. x, y, z and a indicate molar ratios, and 0.0005≦x≦0.10, 0≦y≦0.8, 0≦z≦0.8, and −0.1≦a≦0.2 are satisfied.

Owner:PANASONIC CORP

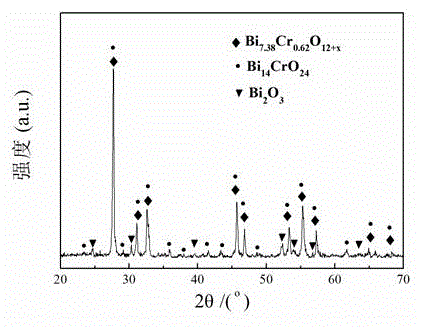

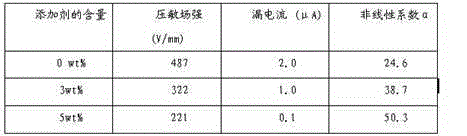

Low-voltage additive for ZnO varistor and preparation method thereof

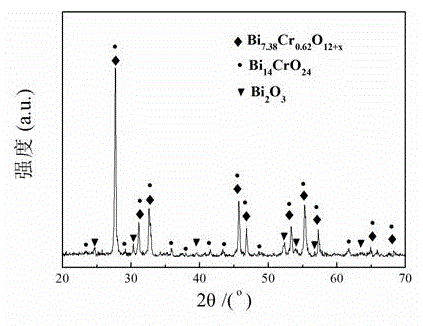

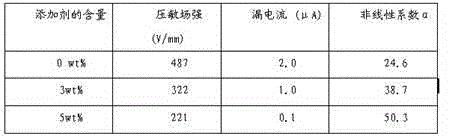

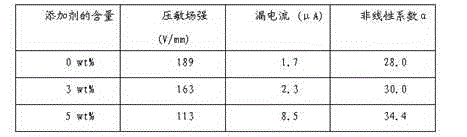

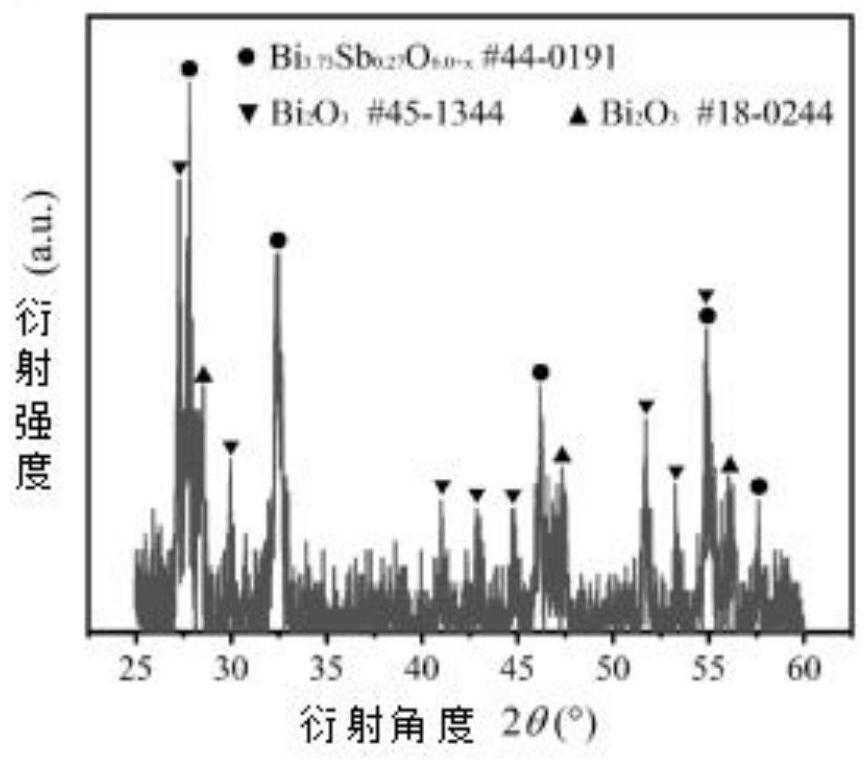

The invention discloses a low-voltage additive for a ZnO varistor and a preparation method thereof. The low-voltage additive comprises the chemical elements of Bi, Cr and O and the phase structure components of Bi2O3, Bi7.38Cr0.62O(12+x) and Bi14CrO24 and is prepared by calcining mixed powder of the Bi2O3 and Cr2O3. The mole ratio of the Bi2O3 and the Cr2O3 which are included in initial raw materials is 18:1, the calcination temperature is 750 DEG C, and the heat preserving time is 2-4 hours. The doped quantity of the additive is regulated between 3 percent by weight and 5 percent by weight according to different formulas of a ZnO varistor base body in a using process. The low-voltage additive disclosed by the invention has simple preparation process and can promote the crystal grain growth, reduce the varistor voltage of the ZnO varistor and enhance the nonlinear coefficient of the ZnO varistor to a certain degree in a sintering process.

Owner:LIAOCHENG UNIV

Preparation method of TiO2 voltage-sensitive ceramic material

InactiveCN106747409ASimple manufacturing processImprove performanceVaristor coresManufacturing technologyRoom temperature

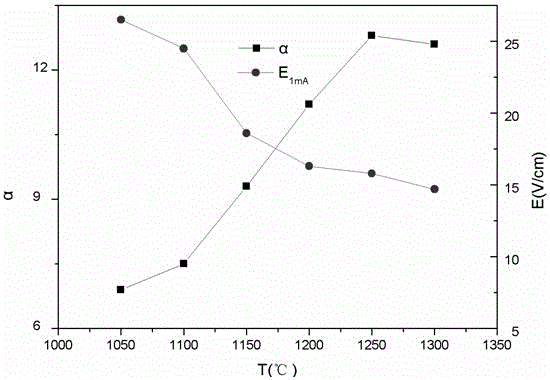

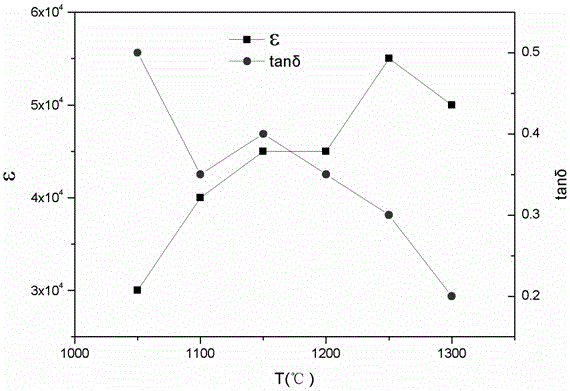

The invention discloses a preparation method of a TiO2 (titanium dioxide) voltage-sensitive ceramic material, and belongs to the technical field of functional ceramic. The preparation method comprises the following steps of adding Ge powder, Sb2O5 powder and MnO2 powder into TiO2 powder, and uniformly mixing, so as to obtain a mixture; performing ball milling on the obtained mixture, drying, screening by a 300 to 350-mesh standard sieve, granulating, and pressing the powder into a block material at the pressure of 100 to 150MPa; discharging rubber out of the block material, heating at the temperature of 1100 to 1350 DEG C, sintering, and warming for 1.5 to 3h; finally, cooling the sintered block material to room temperature, so as to obtain the TiO2 voltage-sensitive ceramic material. The preparation method has the advantage that Ge, Sb2O5 and MnO2 are blended with TiO2 to prepare a voltage-sensitive ceramic and a voltage-sensitive resistor, so that the manufacturing technology of the voltage-sensitive ceramic resistor is simplified, and the property of the TiO2 voltage-sensitive ceramic resistor is improved.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

Method for improving electrical properties of zinc oxide-based low voltage-sensitive ceramic film

The invention relates to voltage-sensitive ceramic, and specially discloses a method for improving electrical properties of a zinc oxide-based low voltage-sensitive ceramic film. The method is characterized in that an aluminum foil as an absorption layer is coated on the surface of a zinc oxide-based low voltage-sensitive ceramic film sample; a liquid restraint layer is coated, pasted or covered on the surface of the aluminum foil; and the zinc oxide-based low voltage-sensitive ceramic film sample with the aluminum foil and the restraint layer is embedded in a mold and then is subjected to laser shock so that electrical properties of the zinc oxide-based low voltage-sensitive ceramic film sample are improved. Through a laser shock treatment technology, the method provided by the invention realizes surface treatment on a zinc oxide-based low voltage-sensitive ceramic film. Through the liquid restraint layer, the zinc oxide-based low voltage-sensitive ceramic film obtained by the method has a non-linear coefficient which is higher than a non-linear coefficient of the unshocked zinc oxide-based low-voltage voltage-sensitive ceramic film by above 24%, has breakdown voltage which is lower than breakdown voltage of the unshocked zinc oxide-based low-voltage voltage-sensitive ceramic film by above 30%, and has leakage current density which is lower than leakage current density of the unshocked zinc oxide-based low-voltage voltage-sensitive ceramic film by above 35%. The method provided by the invention can reduce film breakdown voltage and simultaneously improve a film non-linear coefficient.

Owner:JIANGSU UNIV

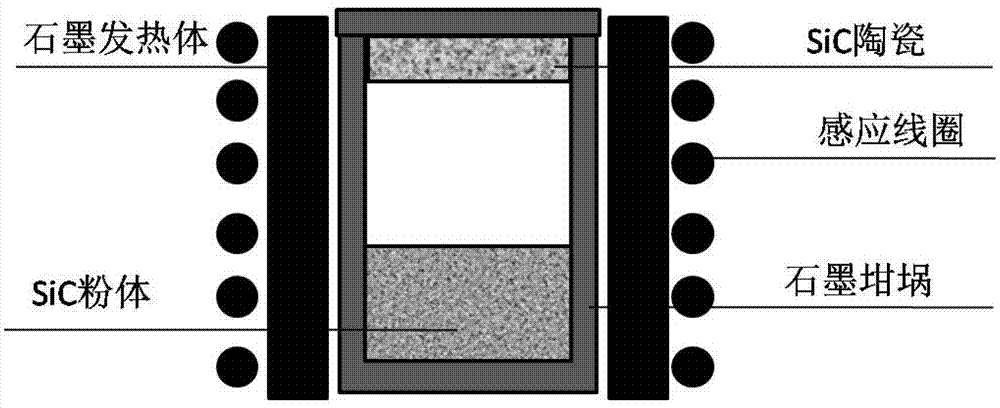

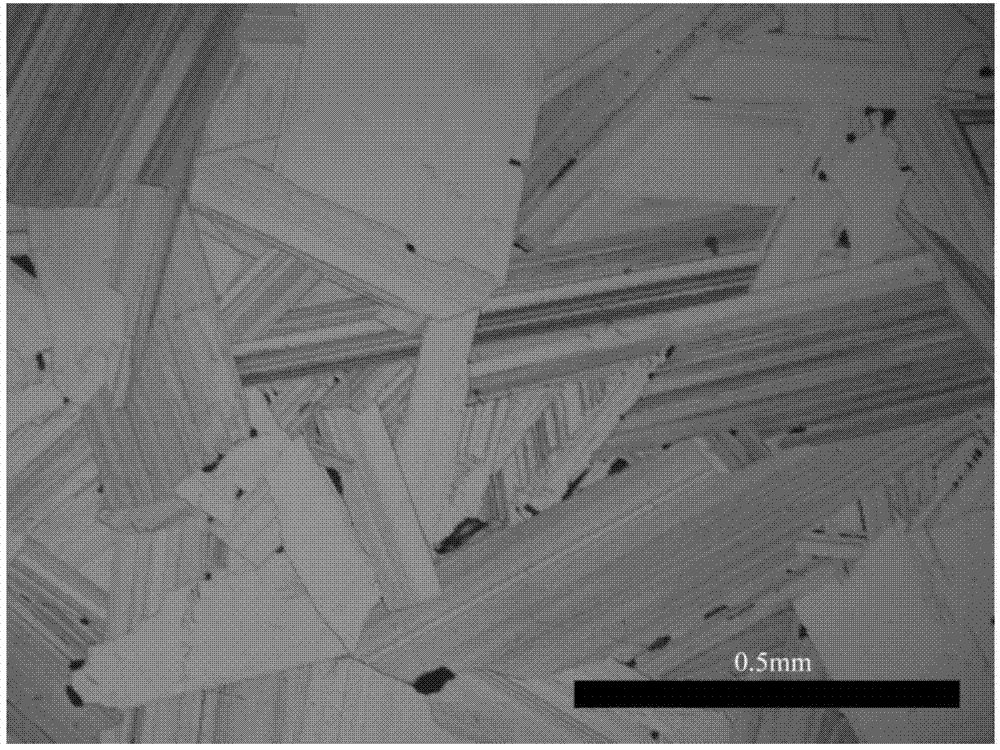

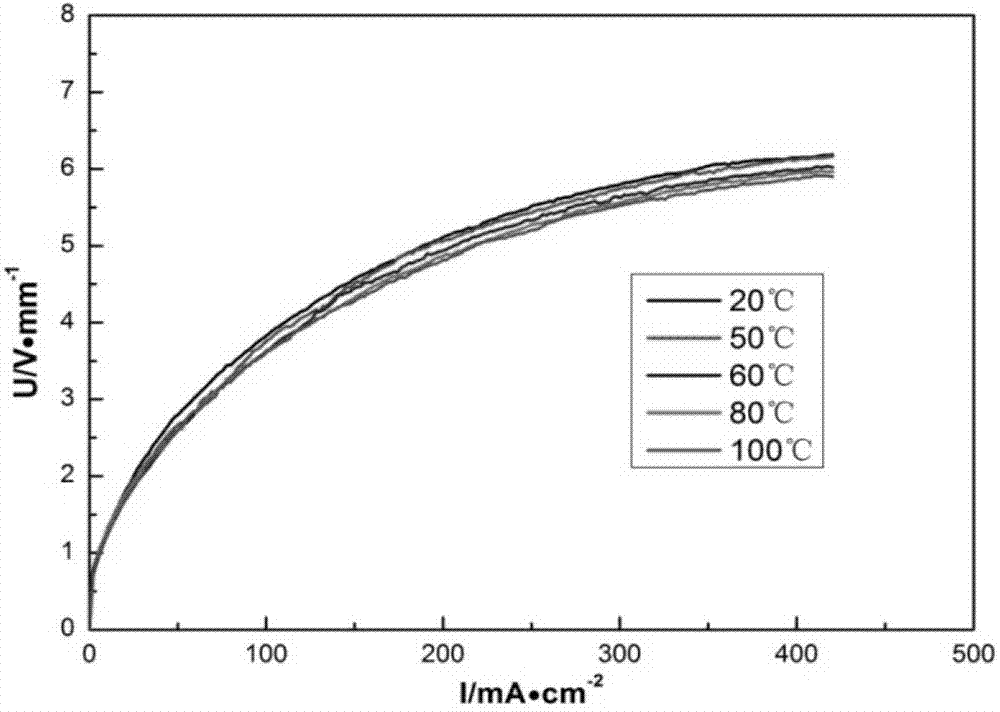

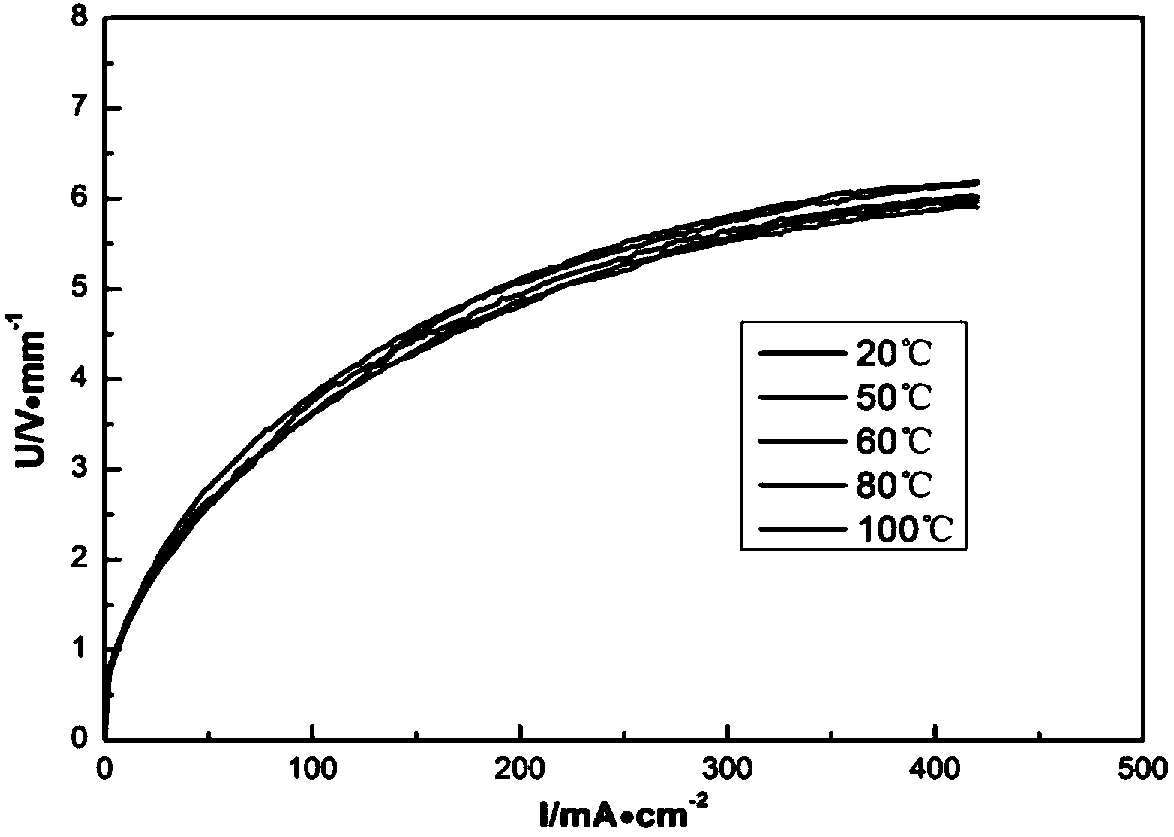

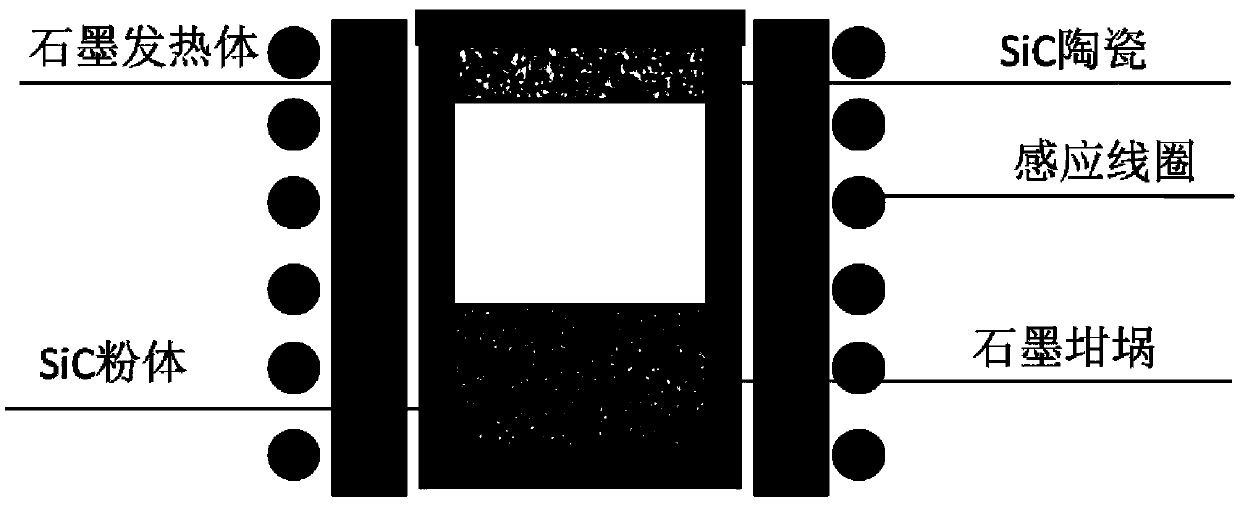

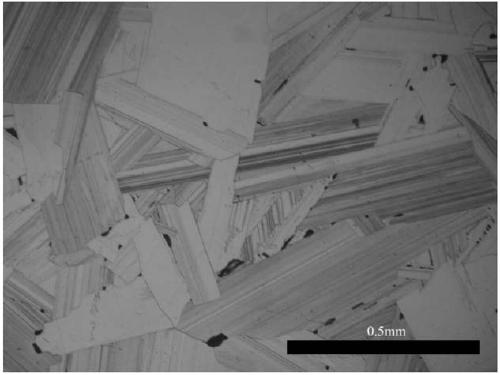

High-purity SiC voltage-sensitive ceramic

The invention relates to a high-purity SiC voltage-sensitive ceramic. The density of the SiC voltage-sensitive ceramic is 3.21+ / -0.01gcm<-3> and the volt-ampere characteristics are kept unchanged at 20-100 DEG C. A preparation method for the SiC voltage-sensitive ceramic comprises the following steps: placing SiC powder into the bottom of a graphite crucible and controlling the powder porosity within 50-70%; increasing the temperature to 1200-1400 DEG C in vacuum, thereby eliminating the impurities absorbed by the SiC powder; introducing inert atmosphere and continuously increasing temperature to 2100-2300 DEG C, controlling the pressure within 103-105Pa, controlling the temperature gradient along the height direction of the graphite crucible within 2.5-4 DEG C / cm, keeping the temperature for 30-120 minutes and adopting a physical gas phase transmission method for growing the SiC voltage-sensitive ceramic on an inner surface of a top cover of the graphite crucible.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Low-voltage ZnO voltage-sensitive resistance ceramic and preparation method thereof

The invention discloses low-voltage ZnO voltage-sensitive resistance ceramic. The low-voltage ZnO voltage-sensitive resistance ceramic is prepared from the following raw materials in parts by weight: 80 to 90 parts of ZnO, 1 to 10 parts of Bi2O3, 0.6 to 1.2 parts of MnO2, 0.1 to 0.8 part of BaCO3, 0.7 to 1.1 parts of Sb2O3, 0.8 to 1.2 parts of Co2O3, 0.9 to 1.5 parts of SiO2, and 0.8 to 1.2 parts of Cr2O3. The invention also discloses a preparation method of the low-voltage ZnO voltage-sensitive resistance ceramic. The preparation method comprises the following steps of using BaCO3 and one part of ZnO to prepare a seed crystal; then, putting the raw materials into a stirring ball mill to perform ball milling, so as to obtain viscous paste; utilizing a spraying and drying technique to spray the viscous paste onto the alloy substrate material, calcining, and demolding, so as to obtain the low-voltage ZnO voltage-sensitive resistance ceramic. The low-voltage ZnO voltage-sensitive resistance ceramic has the advantages that the comprehensive property is excellent, the voltage-sensitive voltage is decreased to 10 to 12V / mm, the residual voltage ratio is 1.190 to 1.20, and the leakage current is less than 1muA / cm<2>.

Owner:ANHUI TUOJITAI NOVEL CERAMIC TECH

La2O3-SnO2-Zn2SnO4 pressure-sensitive and capacitance difunctional ceramic material and preparation method thereof

The invention discloses a La2O3-SnO2-Zn2SnO4 pressure-sensitive and capacitance difunctional ceramic material, which is mixed, pressed and sintered by SnO2 powder, Zn2SnO4 powder and La2O3 powder according to a mole ratio of 85:15:X, wherein X ranges from 0.1 to 2.5. The composite ceramic has the advantages of good pressure-sensitive property, super-high dielectric constant and low breakdown voltage.

Owner:HENAN UNIV OF SCI & TECH

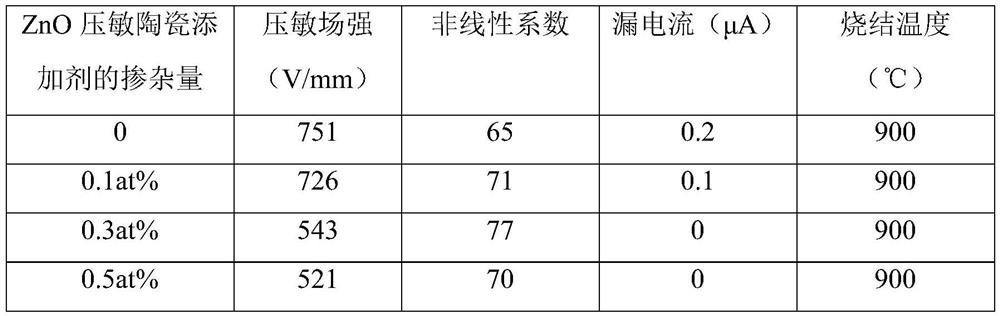

A kind of ZNO pressure-sensitive ceramic additive and its preparation method and application

ActiveCN108863405BHigh nonlinear coefficientLower sintering temperatureCeramic sinteringVaristor ceramics

The invention belongs to the field of pressure-sensitive materials, and provides a ZnO pressure-sensitive ceramic additive and its preparation method and application. The preparation method includes the following steps: 1) combining ZnO and Sb 2 o 3 Ball milling with solvent as medium to obtain slurry, in which ZnO and Sb 2 o 3 The molar ratio is 1-14:1; 2) drying and calcining the slurry obtained in step 1) to obtain the ZnO pressure-sensitive ceramic additive. The invention further provides the ZnO pressure-sensitive ceramic additive and its application. The ZnO varistor ceramic additive is added to the raw materials for preparing ZnO varistor ceramics to promote the growth of ZnO crystal grains, reduce the varistor voltage, keep the varistor sintered at low temperature, and increase the nonlinear coefficient of the varistor ceramics, ZnO The sintering temperature of the varistor ceramics is reduced to 850-900°C, the nonlinear coefficient α value of the material can reach 91, and the varistor field strength is as low as 500-760V / mm.

Owner:LIAOCHENG UNIV

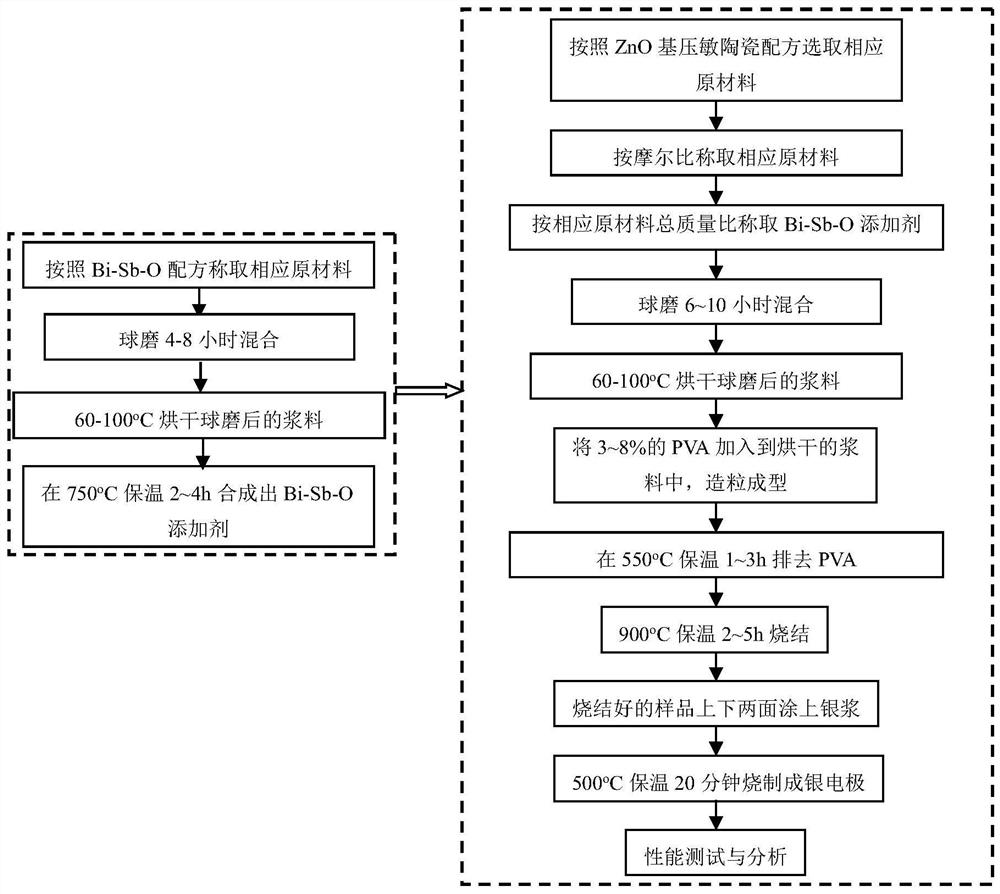

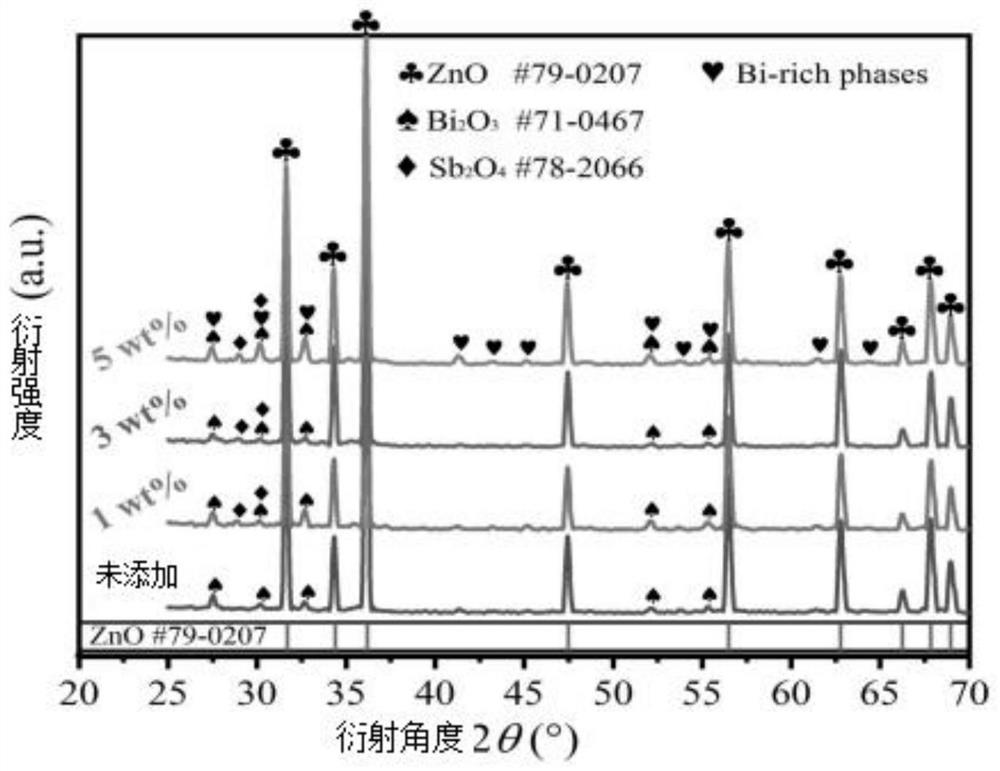

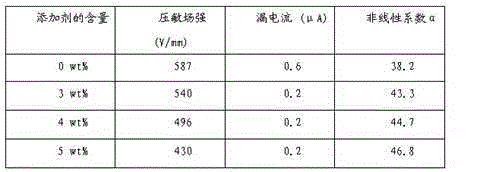

ZnO-based low-voltage high-nonlinearity voltage-sensitive ceramic co-fired with pure silver inner electrode and preparation method thereof

The invention discloses a ZnO-based low-voltage high-nonlinearity voltage-sensitive ceramic material which is high in nonlinearity and can be co-fired with a pure silver inner electrode and a preparation method thereof. The preparation method comprises the following steps: 1) keeping the temperature at 750 DEG C for 2 hours according to a molar ratio of Bi2O3 to Sb2O3 of 13.8, and synthesizing a Bi-Sb-O additive in advance; 2) selecting ZnO, Bi2O3, Co2O3, MnO2, Sb2O3 and Bi-Sb-O as raw materials, weighing corresponding raw materials according to a formula of 98 mol% ZnO (99.0%) + 0.5 mol% Bi2O3 (99%) + 1 mol% MnO2 (98.8%) + 0.5 mol% Co2O3 (99.0%) + x wt% Bi-Sb-O (0 < x < = 5); and (3) molding the uniformly ball-milled and mixed mixture by using a solid-phase sintering method, removing plastic, and sintering at the temperature of 900 DEG C for 2-5 hours to obtain the ZnO-based voltage-sensitive ceramic material. The comprehensive performance of the ZnO-based piezoresistor material obtained by the invention is as follows: the voltage-sensitive field intensity is as low as 235V / mm, the nonlinear coefficient alpha is as high as 53.0, and the leakage current IL is as low as 0.005 mu A.In addition, the preparation method has the advantages of being simple in process, low in energy consumption, environmentally friendly, capable of being co-fired with a pure silver inner electrode andthe like.

Owner:YANTAI UNIV

A kind of ZNO varistor low pressure additive and preparation method thereof

The invention discloses a low-voltage additive for a ZnO varistor and a preparation method thereof. The low-voltage additive comprises the chemical elements of Bi, Cr and O and the phase structure components of Bi2O3, Bi7.38Cr0.62O(12+x) and Bi14CrO24 and is prepared by calcining mixed powder of the Bi2O3 and Cr2O3. The mole ratio of the Bi2O3 and the Cr2O3 which are included in initial raw materials is 18:1, the calcination temperature is 750 DEG C, and the heat preserving time is 2-4 hours. The doped quantity of the additive is regulated between 3 percent by weight and 5 percent by weight according to different formulas of a ZnO varistor base body in a using process. The low-voltage additive disclosed by the invention has simple preparation process and can promote the crystal grain growth, reduce the varistor voltage of the ZnO varistor and enhance the nonlinear coefficient of the ZnO varistor to a certain degree in a sintering process.

Owner:LIAOCHENG UNIV

A high-purity sic varistor ceramic

ActiveCN107235729BLow varistor voltageImproved pressure stabilityVaristor coresVaristor ceramicsCeramic

The invention relates to a high-purity SiC voltage-sensitive ceramic. The density of the SiC voltage-sensitive ceramic is 3.21+ / -0.01gcm<-3> and the volt-ampere characteristics are kept unchanged at 20-100 DEG C. A preparation method for the SiC voltage-sensitive ceramic comprises the following steps: placing SiC powder into the bottom of a graphite crucible and controlling the powder porosity within 50-70%; increasing the temperature to 1200-1400 DEG C in vacuum, thereby eliminating the impurities absorbed by the SiC powder; introducing inert atmosphere and continuously increasing temperature to 2100-2300 DEG C, controlling the pressure within 103-105Pa, controlling the temperature gradient along the height direction of the graphite crucible within 2.5-4 DEG C / cm, keeping the temperature for 30-120 minutes and adopting a physical gas phase transmission method for growing the SiC voltage-sensitive ceramic on an inner surface of a top cover of the graphite crucible.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of low-temperature-sintering chip-type voltage dependent resistor material

InactiveCN106554199ALow varistor voltageHigh nonlinear coefficientElectrical resistance and conductanceNano sio2

A preparation method of a low-temperature-sintering chip-type voltage dependent resistor material includes the following steps: (1) raw material preparation: preparing the raw materials including, on the basis of 100 parts by weight, 1-3 parts of ZrO2, 2-5 parts of FeCl2, 1-2 parts of Fe3O4, 1-2 parts of Fe2O3, 1-3 parts of AlCl3, 1-4 parts of nano Cr2O3, 2-5 parts of nano SiO2, 2-5 parts of Mn2O3, and the balanced being ZnO; (2) mixing the raw materials and adding deionized water, performing wet-milling for 48-50 h and drying the mixture at 140-160 DEG C; (3) under the pressure of 5-8 MPa, shaping the mixture into small round chips being 20 mm in diameter [Phi] and being 1.4-1.8 mm in thickness, and sintering the chips in air and naturally cooling the chips to room temperature; and (4) sinter-coating the two surfaces of the sintered ceramic body with silver. The chip-type voltage dependent resistor has low varistor voltage, high non-linear coefficient and stable voltage-dependent characters, is moderated in sintering temperature, has simple and controllable produce technology, and is low in cost.

Owner:蒋宏伟

A low-cost low-temperature sintered varistor silver paste and its preparation method

ActiveCN107799199BLow softening pointLower transition temperatureNon-conductive material with dispersed conductive materialResistor manufactureSilver pasteDiluent

The invention relates to low-cost and low-temperature sintered piezoelectric resistor silver paste and a preparation method thereof. The preparation method comprises the steps of accurately weighing various materials such as 30-70 parts of silver micro powder A, 20-30 parts of silver micro powder B, 5-20 parts of silver micro powder, 2-6 parts of glass powder, 1-3 parts of titanium powder, 1-3 parts of additive, 1-5 parts of organic diluent and 1-5 parts of organic binding agents, and performing uniform stirring; and performing rolling. The preparation method has the characteristics that the application performance of the paste is improved and the device production cost is greatly reduced.

Owner:CAIHONG GRP ELECTRONICS CO LTD +1

Preparation method and application of a pressure-sensitive ceramic material

ActiveCN104844192BSimple manufacturing processImprove performanceVaristor coresElectrical resistance and conductanceSilver electrode

The invention relates to a preparation method and application of a voltage-sensitive ceramic material and belongs to the technical fields of electrical apparatus elements and material manufacture of the electrical apparatus elements. The preparation method comprises the steps of firstly adding Ge, Nb2O5 and Y2O3 into TiO2 to obtain a mixed material, then conducting wet grinding, drying, screening and pelleting on the mixed material, continuing to perform screening after pelleting, producing powder into small round pieces, conducting heating and glue discharging on the small round pieces, preheating, sintering and cooling the small round pieces to be at room temperature to obtain (Ge, Nb2O5 and Y2O3) co-doped TiO2 voltage-sensitive ceramic, conducting voltage-sensitive ceramic surface processing, electrode adding, silver electrode firing and package to obtain a (Ge, Nb2O5 and Y2O3) co-doped TiO2 voltage-sensitive resistor. The performance of the TiO2 voltage-sensitive resistor is improved.

Owner:KUNMING UNIV OF SCI & TECH

Voltage dependent resistor dielectric material of zinc oxide and method of manufacturing electrical resistor

InactiveCN101367649BLow varistor voltageHigh nonlinear coefficientVaristor coresResistive material coatingCooking & bakingDielectric

The invention relates to a zinc oxide voltage dependent resistor medium material and a resistor preparation method, which belongs to the technology field of electronic material. The components of the zinc oxide voltage dependent resistor medium material comprises 85 percent to 95 percent of ZnO, 2 percent to 6 percent of Bi2O3, 1 percent to 5 percent of TiO2, 1 percent to 3.5 percent of Sb2O3, 1 percent to 4 percent of MnCO3, 1.2 percent to 5 percent of Co2O3, 0.2 percent to 1 percent of Cr2O3, 0.1 percent to 1 percent of ZrO2, 0.2 percent to 1 percent of Ni2O3 and 1.2 percent to 3 percent ofSiO2. The chip type zinc oxide resistor preparation method comprises the steps of dosing according to a zinc oxide resistor medium material medium material, material mixing, material grinding, casting sizing agent making, casting, inner electrode printing, laminating, baking, temperature isostatic pressing, cutting, gule discharging, sintering, end electrode making, and the like. The zinc oxide voltage dependent resistor medium material of the invention is suitable for making chip type voltage dependent resistor; the prepared chip type voltage dependent resistor has the characteristics of low voltage-dependent voltage, high nonlinear coefficient and stable voltage-dependent characteristic, the sintering temperature is moderate, preparation technology is simple and is easy to control, and cost is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A co-doped tio 2 Methods of varistor ceramics, co-doped tio 2 Varistor and its preparation method

InactiveCN104649661BHelp semiconductorImprove completenessVaristor coresSilver electrodeVaristor ceramics

Owner:KUNMING UNIV OF SCI & TECH

a tio 2 Preparation method of low-voltage varistor ceramic material

ActiveCN106747408BIncrease the number ofIncreased concentration of oxygen vacanciesVaristor coresPolyesterLattice oxygen

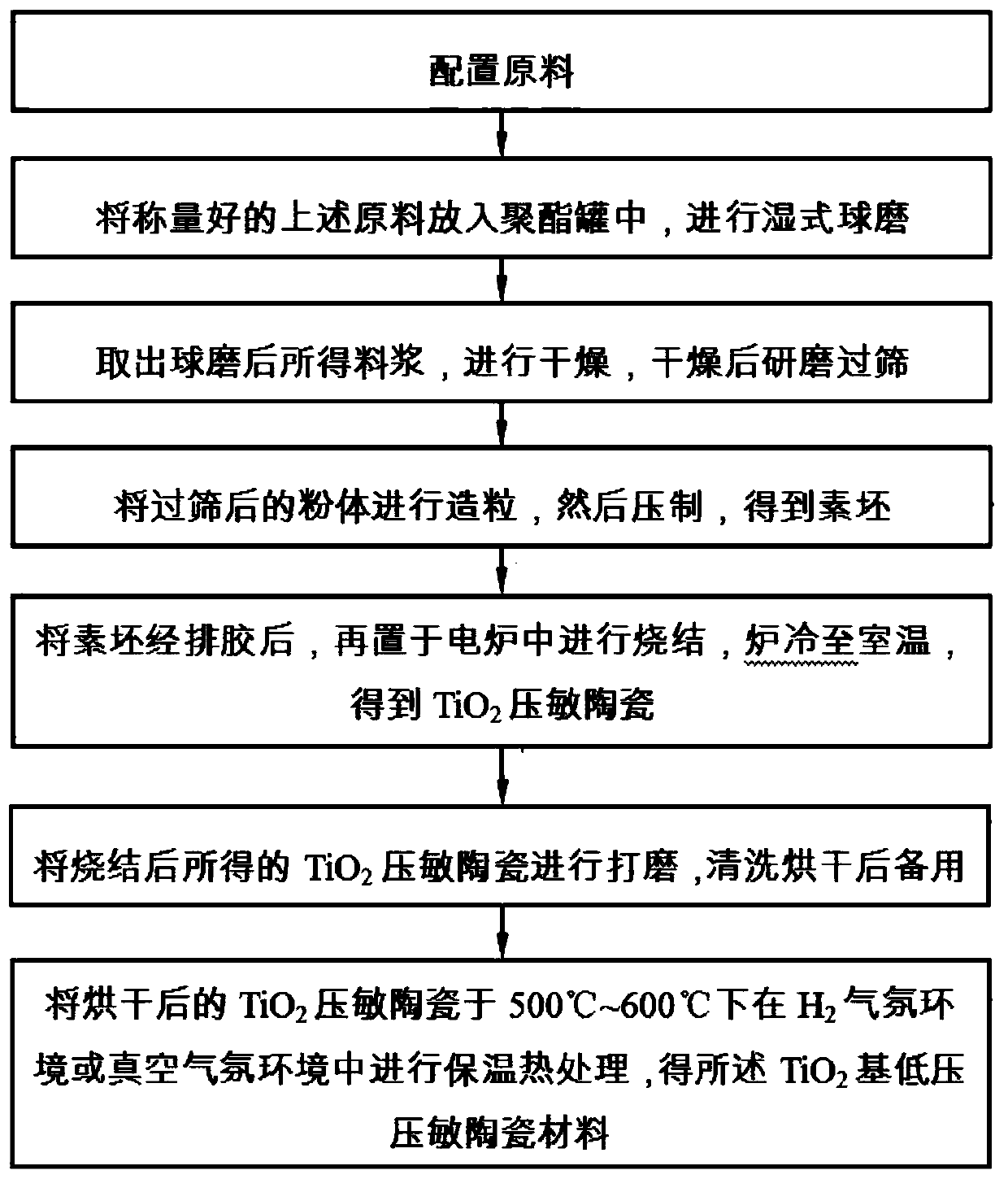

The invention discloses a preparation method of a TiO2 (titanium dioxide)-based low-voltage voltage-sensitive ceramic material. The preparation method comprises the following steps of mixing TiO2, Nb2O5 (niobium pentoxide) and Bi2O3 (bismuth trioxide), putting into a polyester tank, performing wet type ball milling, drying, and grinding, so as to obtain a mixed powder; granulating the mixed powder, and pressing, so as to obtain a plain blank; discharging glue out of the plain blank, sintering, and cooling a furnace to room temperature, so as to obtain TiO2 voltage-sensitive ceramic; grinding the TiO2 voltage-sensitive ceramic, cleaning, drying, and performing heat treatment, so as to obtain the TiO2-based low-voltage voltage-sensitive ceramic material. The preparation method of the TiO2-based low-voltage voltage-sensitive ceramic material has the advantages that by using the TiO2 as the raw material, and adding the Nb2O5 and Bi2O3, the TiO2 voltage-sensitive ceramic is prepared by the simple preparation technology; then, a sample is performed with heat treatment under H2 (hydrogen) or vacuum low-oxygen and differential-voltage atmosphere, the lattice oxygen of the TiO2 is volatized, the vacancy concentration of oxygen is increased, the number of semiconducting crystal grains is increased, the barrier height is reduced, the width is reduced, and the breakdown voltage is obviously reduced.

Owner:XIAN UNIV OF TECH

Method for improving electrical property of zinc-oxide-based low voltage varister ceramic film

InactiveCN102219499BHigh nonlinear coefficientLow varistor voltageLeakage current densityLow voltage

The invention relates to pressure-sensitive ceramics, in particular to a method for improving the electrical properties of a zinc oxide-based low-voltage pressure-sensitive ceramic film, which is characterized in that: an aluminum foil is pasted on the surface of a zinc oxide-based low-voltage pressure-sensitive ceramic film sample as an absorbing layer, After coating, pasting or covering the constrained layer on the surface of the aluminum foil, the ceramic film sample is embedded on the mold, and the ceramic film sample is subjected to laser shock to improve the electrical properties of the zinc oxide-based low-voltage varistor ceramic film. In the present invention, the surface treatment of the zinc oxide-based ceramic film is carried out by adopting the laser shock treatment technology, and the zinc oxide-based ceramic film obtained by using the above-mentioned liquid confinement layer has a non-linear coefficient increased by more than 24% compared with that before shock; The leakage current density is reduced by more than 30% before the impact; the advantage of the present invention is that the non-linear coefficient of the film is improved while reducing the varistor voltage of the film.

Owner:JIANGSU UNIV

La2O3-SnO2-Zn2SnO4 varistor-capacitor bifunctional ceramic material and preparation method thereof

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com