A low-cost low-temperature sintered varistor silver paste and its preparation method

A varistor, low-temperature sintering technology, applied in varistor, resistor, resistance manufacturing and other directions, can solve the problems of high sintering temperature, large amount of precious metal silver, etc., to achieve the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Accurately weigh various raw materials with a balance with an accuracy of 0.01g:

[0037] step one:

[0038] Weigh 30g of glass powder, 10g of titanium powder (surface treatment before use) and stir it evenly;

[0039] Step two:

[0040] Weigh 300g of silver micropowder A and 200g of silver micropowder B, 50g of silver micropowder C, pour the three kinds of silver powder into the mixer and halve it evenly;

[0041] Step three:

[0042] Weigh 350g of organic binder, 50g of diluent, and 10g of additive and add in the mixer together and mix with the silver powder obtained in step 2 for 30min again;

[0043] Step four:

[0044] Start the three-roller mill, and carry out rolling according to the following conditions:

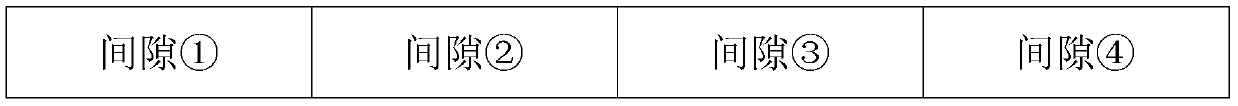

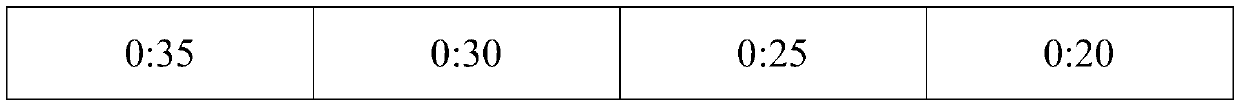

[0045] 1) The pressure of the three-roller machine is controlled at 20 bar, and the gap conditions are as follows, and the uniformly mixed materials are added to the three-roller machine for pre-mixing, and the time is 15 minutes;

[0046] Gap ①...

Embodiment 2

[0055] Accurately weigh various raw materials with a balance with an accuracy of 0.01g:

[0056] step one:

[0057] Weigh glass powder 35g, titanium powder 30g (surface treatment before use) and stir it evenly;

[0058] Step two:

[0059] Weigh 400g of silver micropowder A and 200g of silver micropowder B, 50g of silver micropowder C, pour the three kinds of silver powder into the mixer and halve it evenly;

[0060] Step three:

[0061] Weigh 300g of organic binder, 25g of diluent, and 25g of additives and add them together to the mixer and mix with the silver powder in step 2 for another 30min;

[0062] Step four:

[0063] Start the three-roller mill, and carry out rolling according to the following conditions:

[0064] 1) The pressure of the three-roll machine is controlled at 20 bar, and the gap conditions are as follows. Add the uniformly mixed materials to the three-roll machine for pre-mixing, and the time is about 15 minutes.

[0065] Gap ① Gap ② Gap ...

Embodiment 3

[0074] Accurately weigh various raw materials with a balance with an accuracy of 0.01g:

[0075] step one:

[0076] Weigh 40g of glass powder, 15g of titanium powder (surface treatment before use) and stir it evenly;

[0077] Step two:

[0078] Weigh 350g of silver micropowder A and 200g of silver micropowder B, 50g of silver micropowder C, pour the three kinds of silver powder into the mixer and halve it evenly;

[0079] Step three:

[0080] Weigh 300g of organic binder, 35g of diluent, and 10g of additives and add them into the mixer together with the silver powder in step 2 and mix for 30min again;

[0081] Step four:

[0082] Start the three-roller mill, and carry out rolling according to the following conditions:

[0083] 1) The pressure of the three-roll machine is controlled at 20 bar, and the gap conditions are as follows. Add the uniformly mixed materials to the three-roll machine for pre-mixing, and the time is about 10 minutes.

[0084] Gap ① Gap ② ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com