Stratified structure low-voltage ZnO piezoresistor preparation method

A technology of piezoresistor and layered structure, applied in the direction of piezoresistor core, piezoresistor, etc., can solve the problems of large leakage current, no major development, complicated process, etc., and achieve the improvement of electrical parameter value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

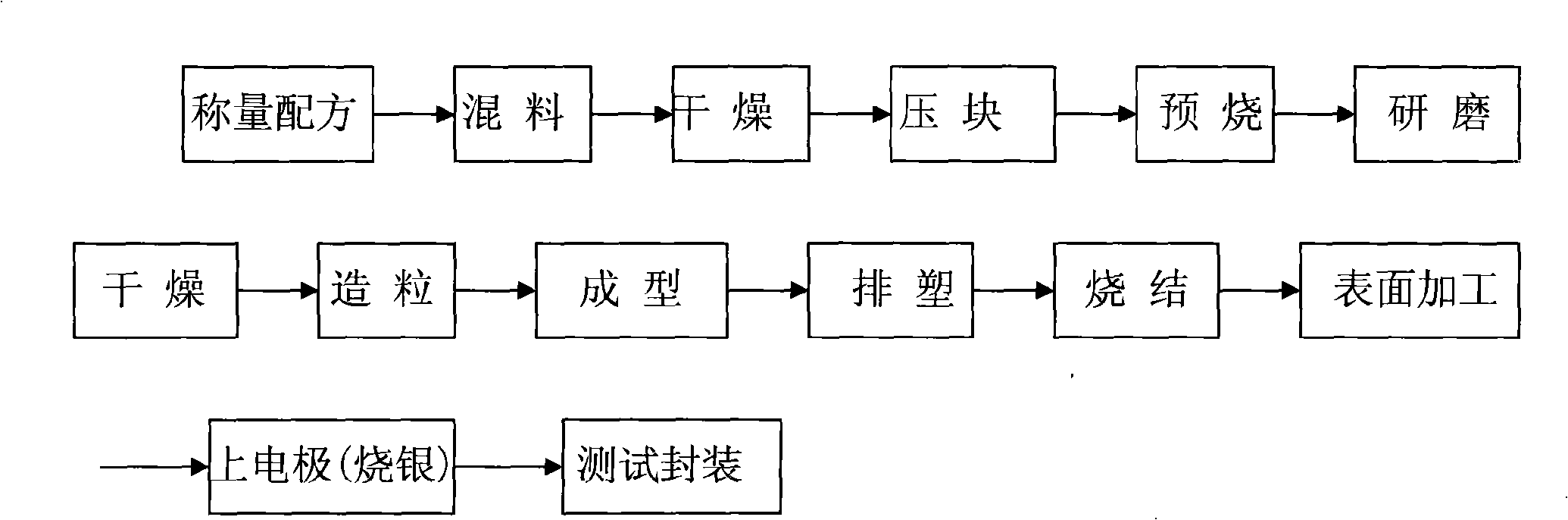

[0016] Embodiment 1: as figure 1 As shown, the manufacturing method of the layered structure low-voltage ZnO varistor ceramics is to use ZnO powder first, add 0.5% TiO by molar ratio 2 , 0.3% SiO 2 , 0.7% Cr 2 o 3 , 5% PbO, 2% B 2 o 3 , 5% nanometer ZnO powder forms mixed raw material 1, then this raw material is in planetary ball mill, adds water and alcohol and grinds and mixes for 3 hours; (dried, then passed through a 320-mesh standard sieve), pressed into blocks under a certain pressure, pre-fired at 600-750°C, ground again and put into a ball mill tank with water and alcohol to grind for 8-12 hours; the ball-milled material The slurry is dried and granulated (adding an appropriate amount of 7% PVA aqueous solution to the dried powder, the shape is like fish scales, which means that when the mixture is uniform, then pass through a 40-mesh standard sieve, pre-compress into blocks with a pressure of 50Mpa, and then break into pieces. Go through 45 mesh standard sieves...

Embodiment 2

[0019] Embodiment 2: as figure 1 As shown, the manufacturing method of the layered structure low-voltage ZnO varistor ceramics is to use ZnO powder first, add 0.5% TiO by molar ratio 2 , 0.4% SiO 2 , 0.5% Cr 2 o 3 , 5% PbO, 2% B 2 o 3, 8% nanometer ZnO powder forms mixed raw material 1, then this raw material is in planetary ball mill, adds water and alcohol and grinds and mixes for 3 hours; (dried, then passed through a 320-mesh standard sieve), pressed into blocks under a certain pressure, pre-fired at 600-750°C, ground again and put into a ball mill tank with water and alcohol to grind for 8-12 hours; the ball-milled material The slurry is dried and granulated (adding an appropriate amount of 7% PVA aqueous solution to the dried powder, the shape is like fish scales, which means that when the mixture is uniform, then pass through a 40-mesh standard sieve, pre-compress into blocks with a pressure of 50Mpa, and then break into pieces. Go through 45 mesh standard sieves ...

Embodiment 3

[0022] Embodiment 3: as figure 1 As shown, the manufacturing method of the layered structure low-voltage ZnO varistor ceramics is to use ZnO powder first, add 0.5% TiO by molar ratio 2 , 0.4% SiO 2 , 0.5% Cr 2 o 3 , 5% PbO, 2% B 2 o 3 , 8% nanometer ZnO powder forms mixed raw material 1, then this raw material is in planetary ball mill, adds water and alcohol and grinds and mixes for 3 hours; (dried, then passed through a 320-mesh standard sieve), pressed into blocks under a certain pressure, pre-fired at 600-750°C, ground again and put into a ball mill tank with water and alcohol to grind for 8-12 hours; the ball-milled material The slurry is dried and granulated (adding an appropriate amount of 7% PVA aqueous solution to the dried powder, the shape is like fish scales, which means that when the mixture is uniform, then pass through a 40-mesh standard sieve, pre-compress into blocks with a pressure of 50Mpa, and then break into pieces. Cross 45 mesh standard sieves agai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com