a tio 2 Preparation method of low-voltage varistor ceramic material

A varistor ceramic, low-voltage technology, applied in the direction of varistors, varistor cores, etc., can solve the problems of difficult integrated circuits, high varistor voltage, etc., to reduce the barrier height, reduce the varistor voltage, and increase the number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

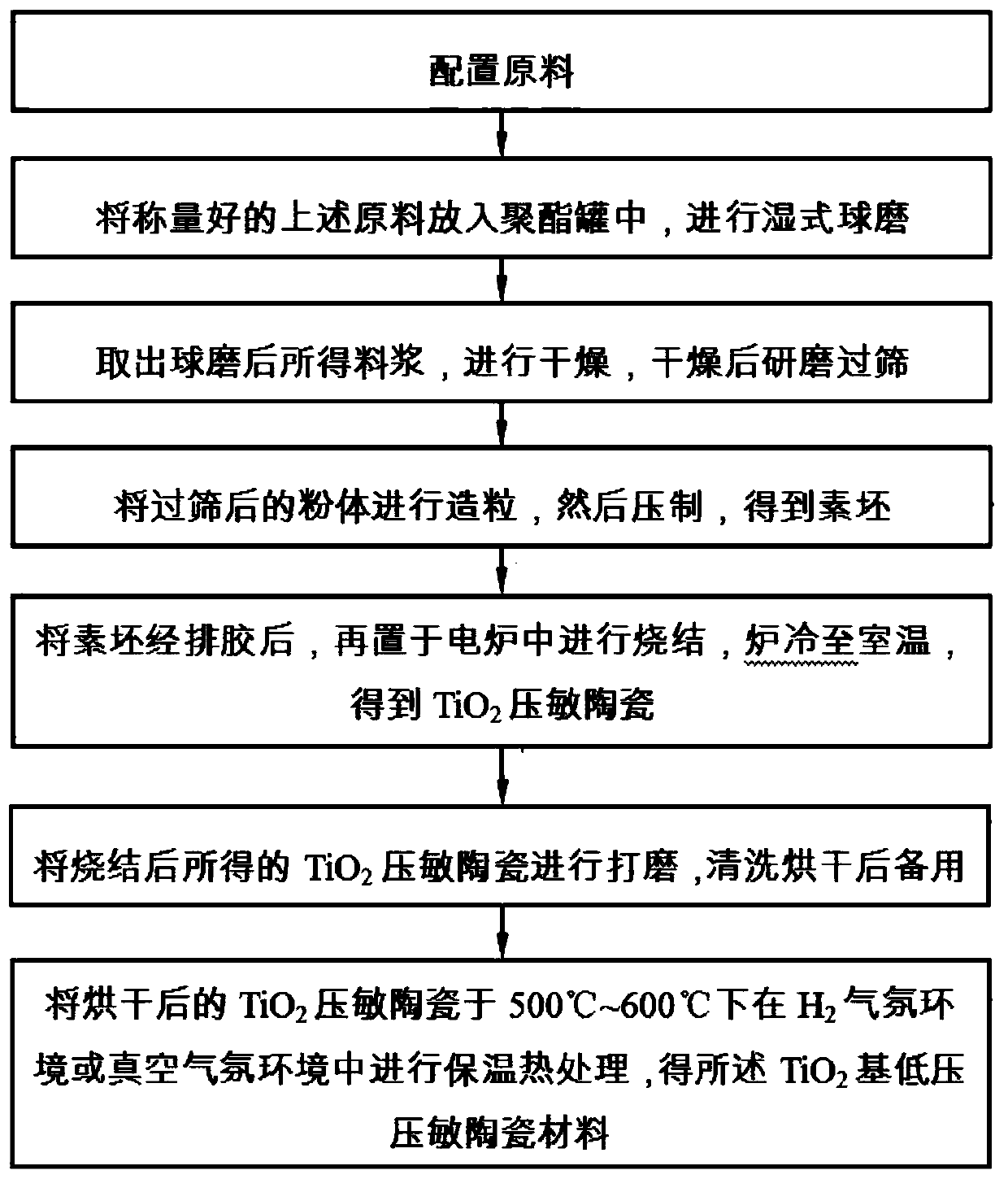

[0027] TiO of the present invention 2 The preparation method of low-voltage varistor ceramic material, such as figure 1 shown, including the following steps:

[0028] Step 1, follow the TiO 2 , Nb 2 o 5 , Bi 2 o 3 The mass ratio of TiO is 120~301:1:1.75~3.5, respectively weigh TiO 2 , Nb 2 o 5 , Bi 2 o 3 , where TiO 2 The particle size is 200nm~300nm;

[0029] Step 2, the TiO 2 , Nb 2 o 5 and Bi 2 o 3 After mixing with zirconia balls and absolute ethanol, place them in a polyester tank at a mass ratio of 1:1:1.5, ball mill at a speed of 350r / min to 450r / min for 8 to 12 hours, and then grind at 60°C to 70°C Dry at ℃ for 10h~14h, grind to obtain mixed powder;

[0030] Step 3, adding PVA solution with a mass fraction of 5% to the mixed powder obtained in step 2 dropwise, passing through a 20-mesh sieve to granulate, then sealing it with a plastic bag for 24 hours, and then pressing and molding to obtain a green body;

[0031] Step 4, debinding the green body ob...

Embodiment 1

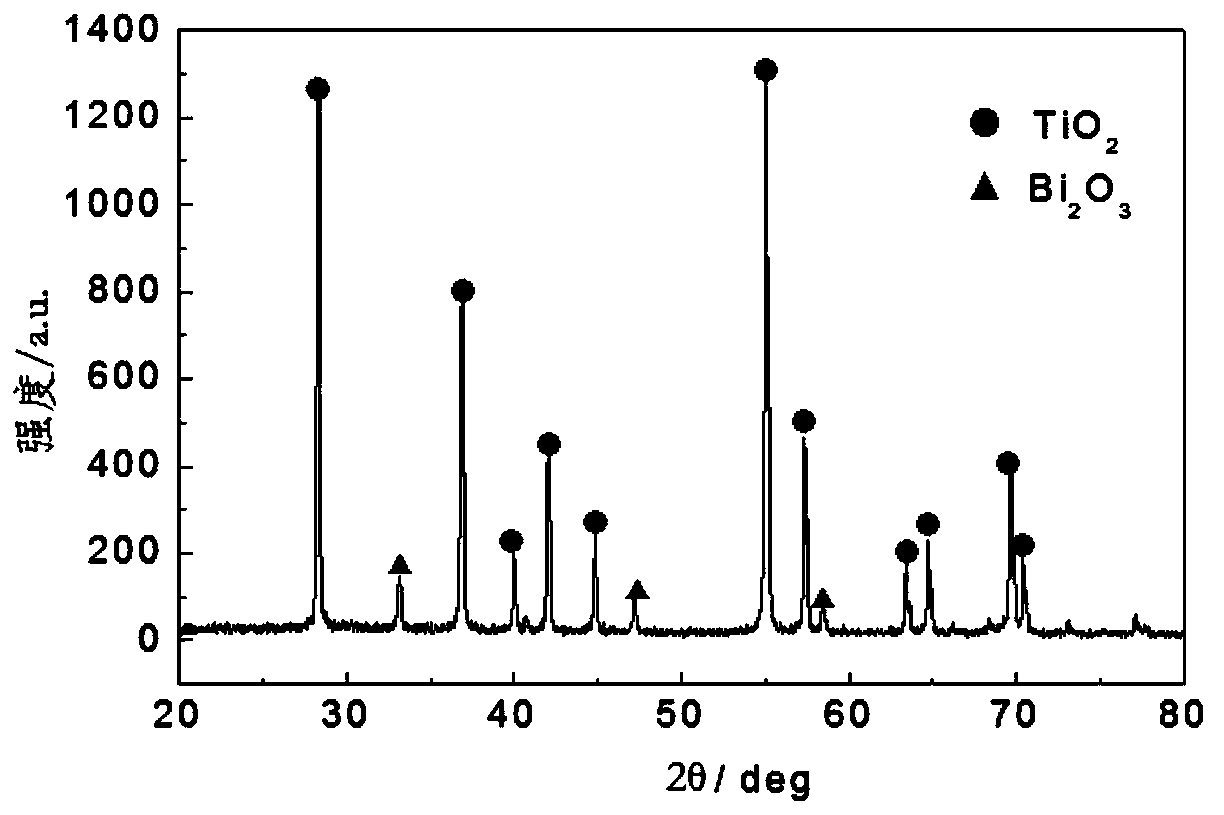

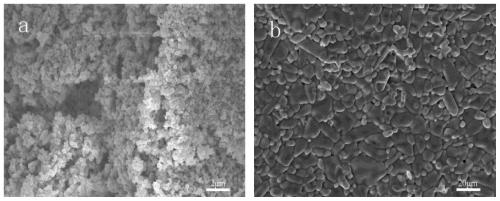

[0043] TiO with a particle size of 200nm to 300nm and a purity of 99.5% 2 As raw material (Degussa AG), with Nb 2 o 5 (AR, 99.99%) and Bi 2 o 3 (AR, 99.99%) is an additive, the TiO used 2 , Nb 2 o 5 、 Bi 2 o 3 All are commercially available products. According to the mass ratio of TiO 2 : Nb 2 o 5 : Bi 2 o 3 =301:2:5 Weigh the ingredients, then put the batch ingredients, zirconia balls and absolute ethanol in a polyester tank with a mass ratio of 1:1:1.5, ball mill at a speed of 400r / min for 10h, and ball mill After completion, take out the obtained slurry, then dry the slurry in an oven at 70°C for 12 hours to exclude absolute ethanol, then grind it through a 325 mesh sieve, and then add an appropriate amount of 5% of the mass fraction to the sieved powder dropwise. Mix the PVA solution into the powder evenly, pass through a 20-mesh sieve to granulate, seal it with a plastic bag and place it for 24 hours; press the powder into a disc with a diameter of about 15m...

Embodiment 2

[0054] TiO with a particle size of 200nm to 300nm and a purity of 99.5% 2 As raw material (Degussa AG), with Nb 2 o5 (AR, 99.99%) and Bi 2 o 3 (AR, 99.99%) is an additive, the TiO used 2 , Nb 2 o 5 、 Bi 2 o 3 All are commercially available products. According to the mass ratio of TiO 2 : Nb 2 o 5 : Bi 2 o 3 =301:2:5 Weigh the ingredients, then put the batch ingredients, zirconia balls and absolute ethanol in a polyester tank with a mass ratio of 1:1:1.5, ball mill at a speed of 350r / min for 12h, and ball mill After completion, take out the obtained slurry, then dry the slurry in an oven at 60°C for 14 hours to exclude absolute ethanol, then grind it through a 325 mesh sieve, and then add an appropriate amount of 5% of the mass fraction to the sieved powder dropwise. Mix the PVA solution into the powder evenly, pass through a 20-mesh sieve to granulate, seal it with a plastic bag and place it for 24 hours; press the powder into a disc with a diameter of about 15mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com