Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Long-term effective protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of cement-based material having deep self-repairing function

ActiveCN104261736AGood repairing effectAccelerated carbonate mineralization depositionC constantNondestructive testing

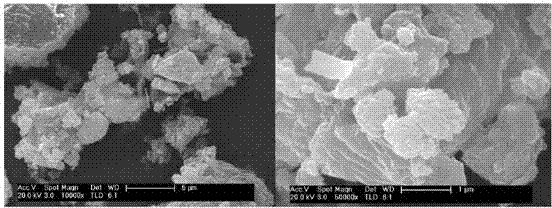

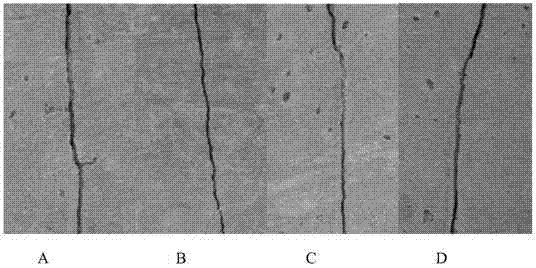

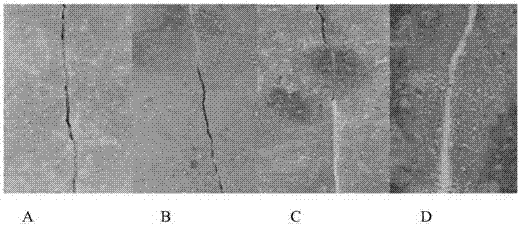

The invention provides a preparation method of a cement-based material having a deep self-repairing function. The preparation method disclosed by the invention comprises the following steps of: mixing concentrated solution of carbonic anhydrase generating bacteria with saccharomycete powder according to the mass ratio of (50-60) to 1, and immobilizing on a same carrier; mixing a substrate with a nutritional substance according to the mass ratio of (30-40) to 1, and fixing on another carrier; adding cement, sand and water by taking the carriers as lightweight aggregates, wherein the mass of the carriers is 17-23% of the total mass of mortar; uniformly stirring, and forming a test piece; and manufacturing a crack of the test piece after standard curing, and introducing air to maintain and repair under 25-30 DEG C constant-temperature water bath conditions. The repairing process of the test piece is monitored by utilizing a concrete nondestructive detection technology (ultrasonic sound); the repairing result is detected through a water permeability test; the result shows that the crack is completely repaired after repairing for 21 d; in addition, compared with other microbiological methods for repairing cracks of the cement-based material, the crack repairing speed and repairing depth are greatly improved.

Owner:SOUTHEAST UNIV

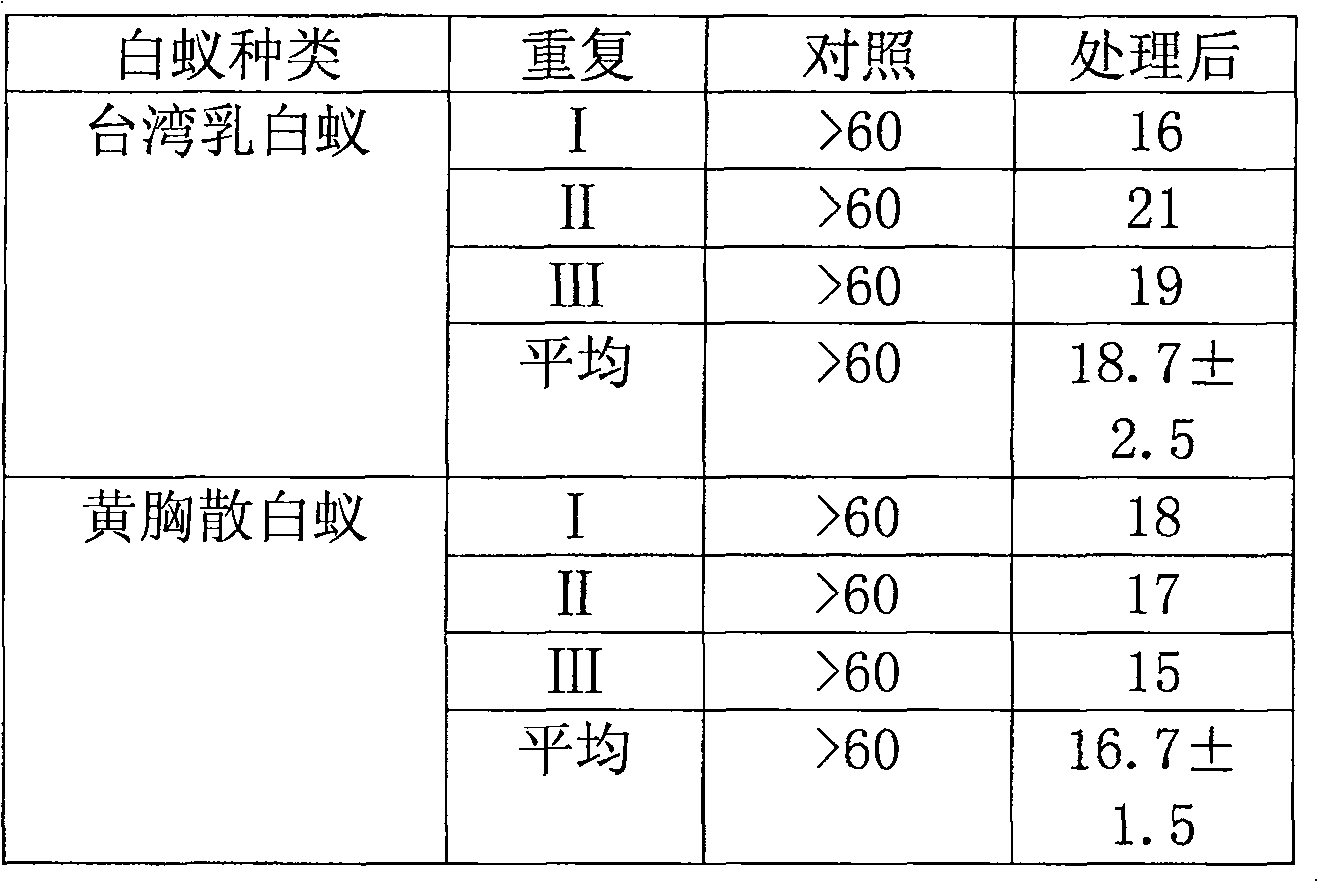

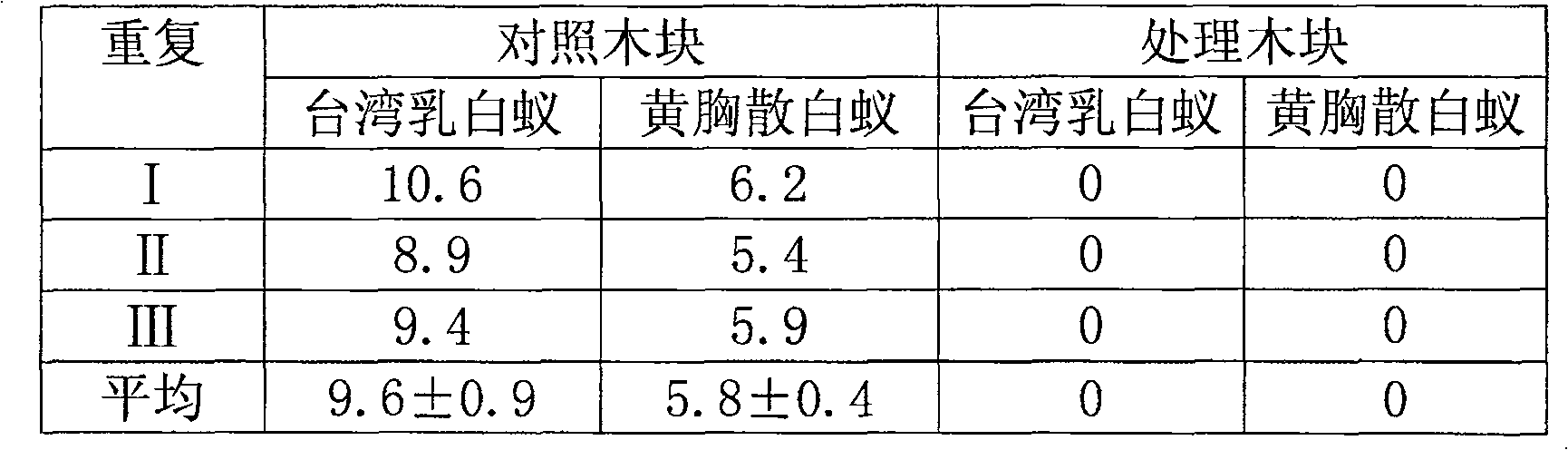

Vermin-proof mould inhibitor for lumber and method for producing the same

InactiveCN101219548AFacilitated DiffusionImprove permeabilityWood impregnation detailsSolubilityVermin

The invention relates to a lumber protection technique, in particular to a lumber insert-resistant mildew-proof agent and a preparation method thereof. The lumber insert-resistant mildew-proof agent comprises an insert resistant agent, a mildew-proof agent, a solvent, a cosolvent, an auxiliary infiltration agent and a stabilizer, and the weight proportions of the components are respectively 0.1-70 percent, 0.1-50 percent, 1-40 percent, 1-30 percent, 1-20 percent and 1-40 percent. The invention is characterized by high efficiency, wide application, environment friendliness, good water solubility and fixity. By dissolving the insert-resistant mildew-proof agent into the solution, the protection treatment is easy. The invention also provides the preparation method of the lumber insert-resistant mildew-proof agent.

Owner:蔡文根 +1

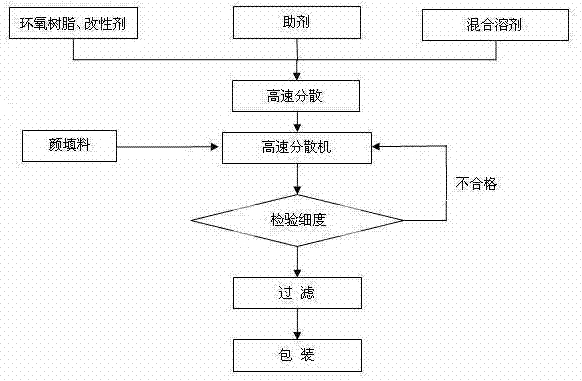

High-performance high-solid general modified epoxy antirust paint and preparation method thereof

ActiveCN102363690AHas acid and alkali resistanceNo acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsLife ProlongationSlurry

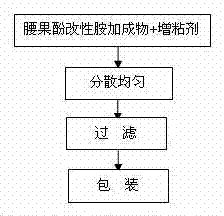

The invention discloses a general modified epoxy antirust paint with high performances and high solids and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises 10-20 parts of an E44 epoxy resin, 10-20 parts of an NPPN-631 epoxy resin, 5-15 parts of a terpene resin, 4-18 parts of a cumarone resin, 0.1-1.0 parts of a BYK antifoaming agent, 0.1-1.0 part of an HX leveling agent, 0.1-1.5 parts of a rheological assistant, 5-20 parts of active silica, 10-20 parts of a mixed solvent and 10-30 parts of a pigment-filler; and the component B comprises 10-40 parts of cardanol modified amine and 0.5-3 parts of a modified silane coupling agent. The antirust paint of the invention has the advantages of compact coating, low viscosity, good compatibility and fast curing of a curing agent, high tough strength and strong adhesion of the coating, coating number reduction during the thick slurry curing, construction efficiency improvement, construction cost reduction, and anticorrosion life prolongation.

Owner:XIAMEN SUNRUI SHIP COATING

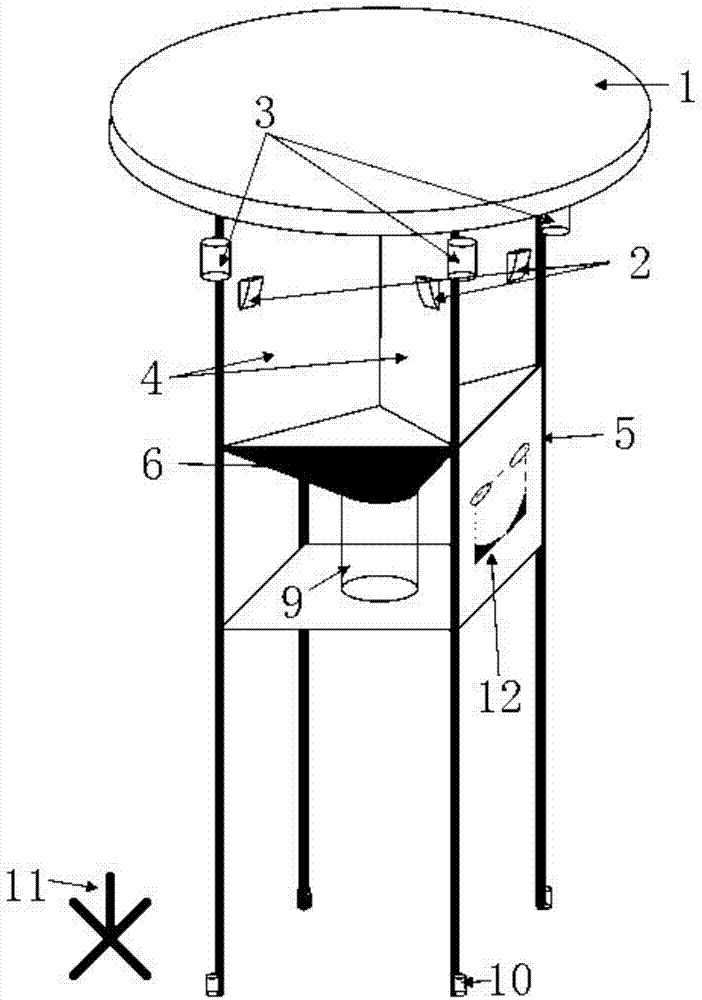

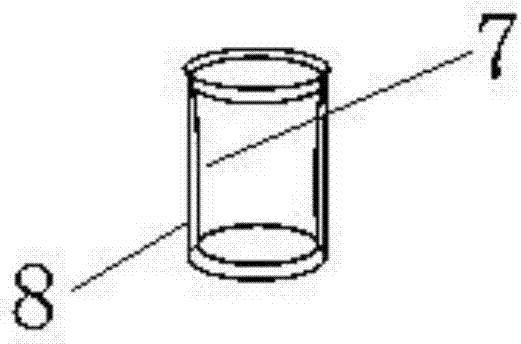

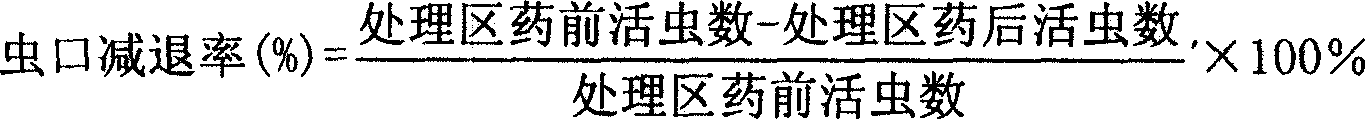

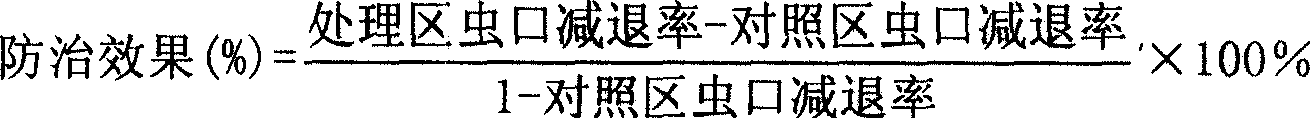

Garden pest monitoring method and large vertical garden pest monitoring device

The invention discloses a garden pest monitoring method and a large vertical garden pest monitoring device. A transparent intercepting plate with a hole is elevated through a bracket, and pests are attracted by means of a slow-release attractant, so that the insects fall into an insect collecting funnel at the bottom after colliding with the transparent intercepting plate; a pest collecting cup containing a specimen preservation solution is arranged below the insect collecting funnel to collect the fallen pests, so that garden pest monitoring can be achieved by counting the pests in the pest collecting cup; meanwhile, the garden pests are subjected to centralized trapping and killing, and the number of the garden pests can be effectively controlled.

Owner:SOUTHWEST FORESTRY UNIVERSITY +2

Bamboo and wood protecting agent

InactiveCN1436465ABroad-spectrumImprove mildew resistanceBiocideWood treatment detailsSolubilityEmulsion

The bamboo and wood protecting agent is prepared with zinc acid in 1.8-2.2 wt%, boric acid in 0.8-1.2 wt% and borate in 2.4-3.6 wt% as main material and through adding one or two of fluoride, quaternary ammonium salt, chlorothalonil, phenol sodium pentammine and phoxim emulsion in 2-3 wt%. It has high-efficiency and wide-spectrum motherproof, moldproof and anticorrosive effect, high water solubility, high fixity, low cost, no harm to environment and no dyeing effect on bamboo and wood.

Owner:王文久 +2

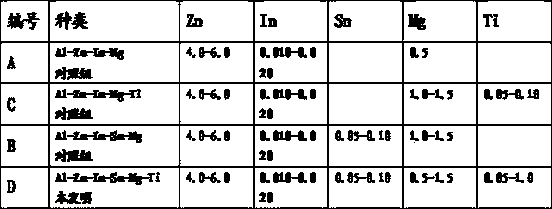

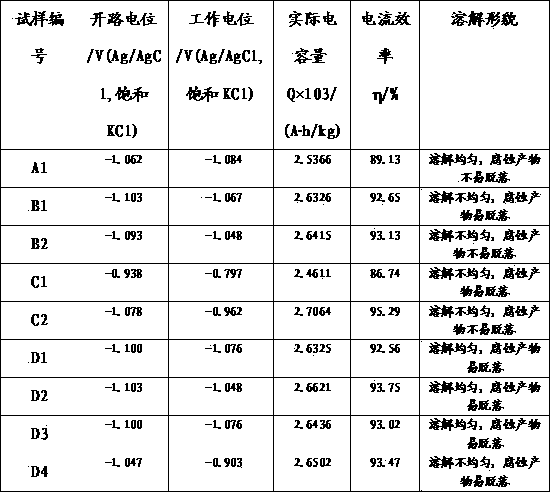

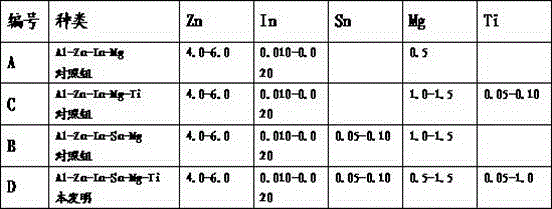

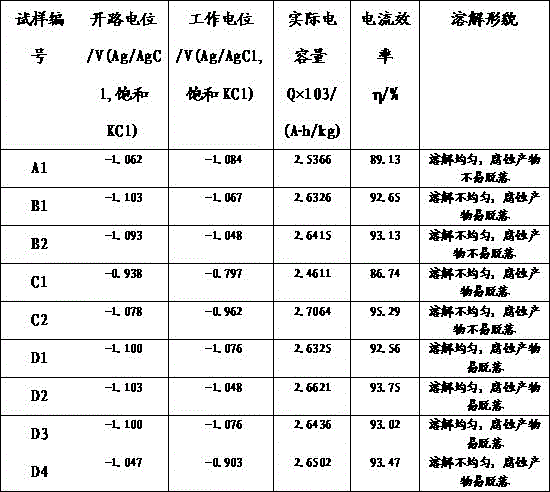

Aluminum alloy sacrificial anode suitable for deep sea environment and high in current efficiency

The invention belongs to the technical field of corrosion prevention, and particularly relates to an aluminum alloy sacrificial anode suitable for the deep sea environment and high in current efficiency. According to the sacrificial anode, with aluminum as the matrix, 4.0-6.0wt% of zinc, 0.020-0.030wt% of indium, 0.05-0.10wt% of tin, 0.5-1.0wt% of magnesium and 0.05-1.0wt% of titanium are added, wherein the weight percentage of iron impurities is smaller than 0.050wt%, the weight percentage of copper is smaller than 0.010wt%, and the balance is the aluminum. The sacrificial anode is manufactured in a vacuum melting mode. As is shown in tests carried out in a simulated deep sea environment, the current efficiency of the sacrificial anode is larger than 92%, the open circuit potential of the sacrificial anode ranges from -1.05 to -1.20, the activation performance is good, dissolution is uniform, and corrosion products can fall off easily. The sacrificial anode can be applied to cathode protection for metal components used in the deep sea environment.

Owner:UNIV OF SCI & TECH BEIJING

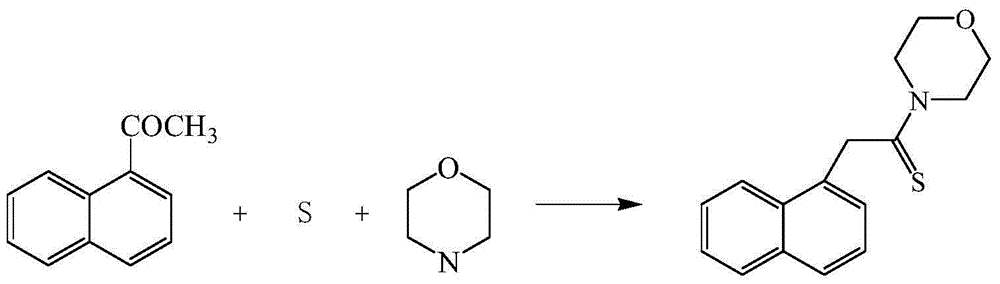

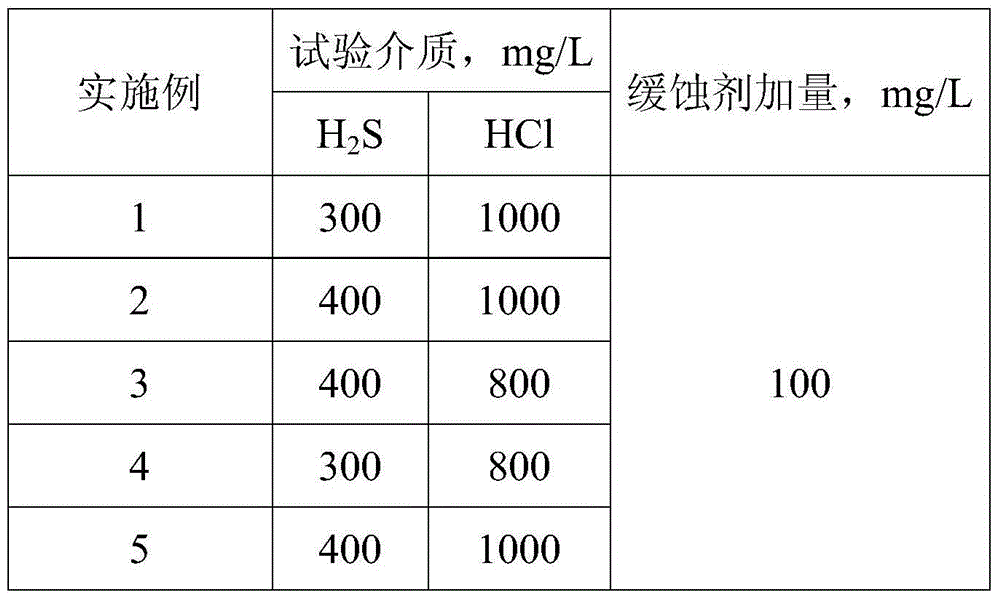

High-temperature corrosion inhibitor for H2S-HCl-H2O system and preparation method of high-temperature corrosion inhibitor

The invention relates to a high-temperature corrosion inhibitor for an H2S-HCl-H2O system and a preparation method of the high-temperature corrosion inhibitor. According to the preparation method, methyl-alpha-naphthyl ketone, morpholine and sulfur are taken as main raw materials and are subjected to a Willgerodt-Kindler method to generate naphthylethyl thioacylmorpholine. The high-temperature corrosion inhibitor comprises the following components in percentage by weight: 30%-50% of ethyl thioacylmorpholine, 5%-15% of hexadecyl pyridine, 10%-15% of alcohol amine compounds, 1%-3% of potassium molybdate or potassium tungstate and 29%-57% of a solvent. The high-temperature corrosion inhibitor belongs to strong-adsorption mixed type corrosion inhibitors, is capable of forming a layer of compact protecting film on the surface of metal and particularly applicable to the corrosion prevention of the H2S-HCl-H2O system and can be generalized and used for the prevention of sulfuretted hydrogen corrosion in the industries of oil fields, boilers and steel mills. The use temperature of the high-temperature corrosion inhibitor during the use can reach 120 DEG C; the high-temperature corrosion inhibitor has the characteristics of low consumption, high efficiency, wide use temperature range, good dispersity and low environmental pollution and is simple and convenient to produce.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

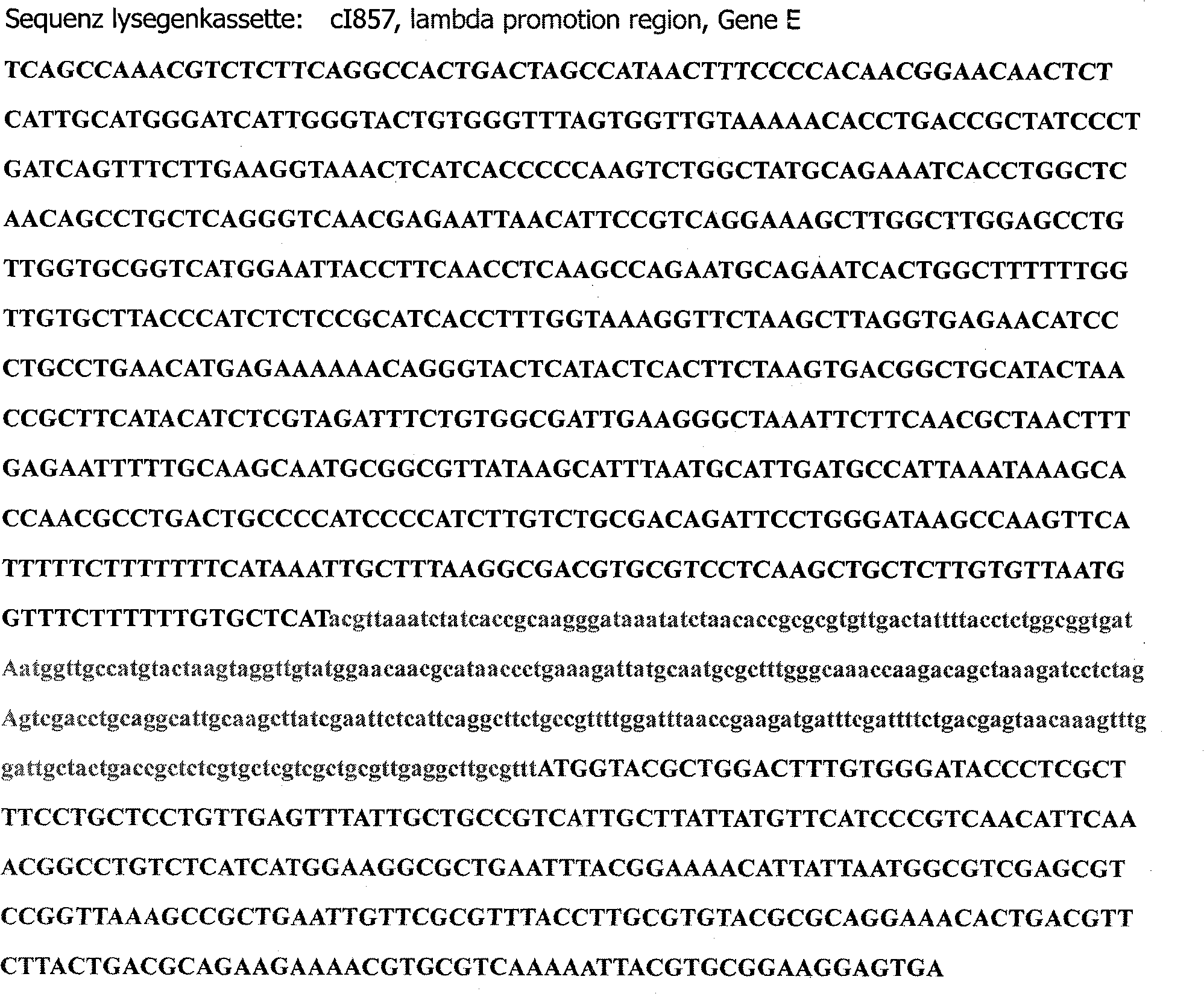

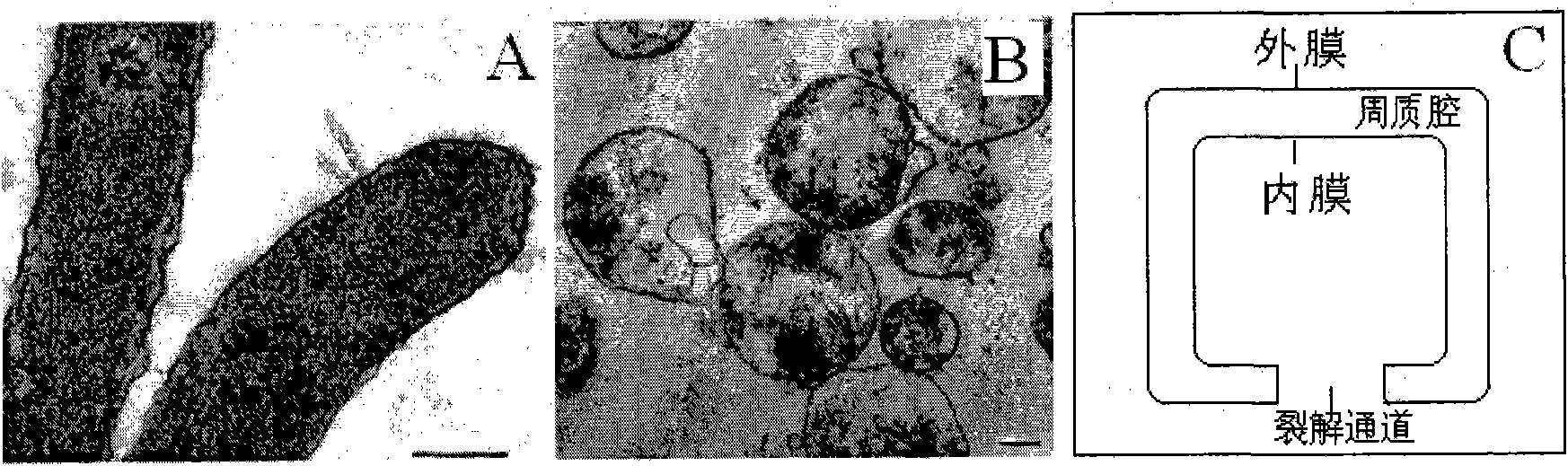

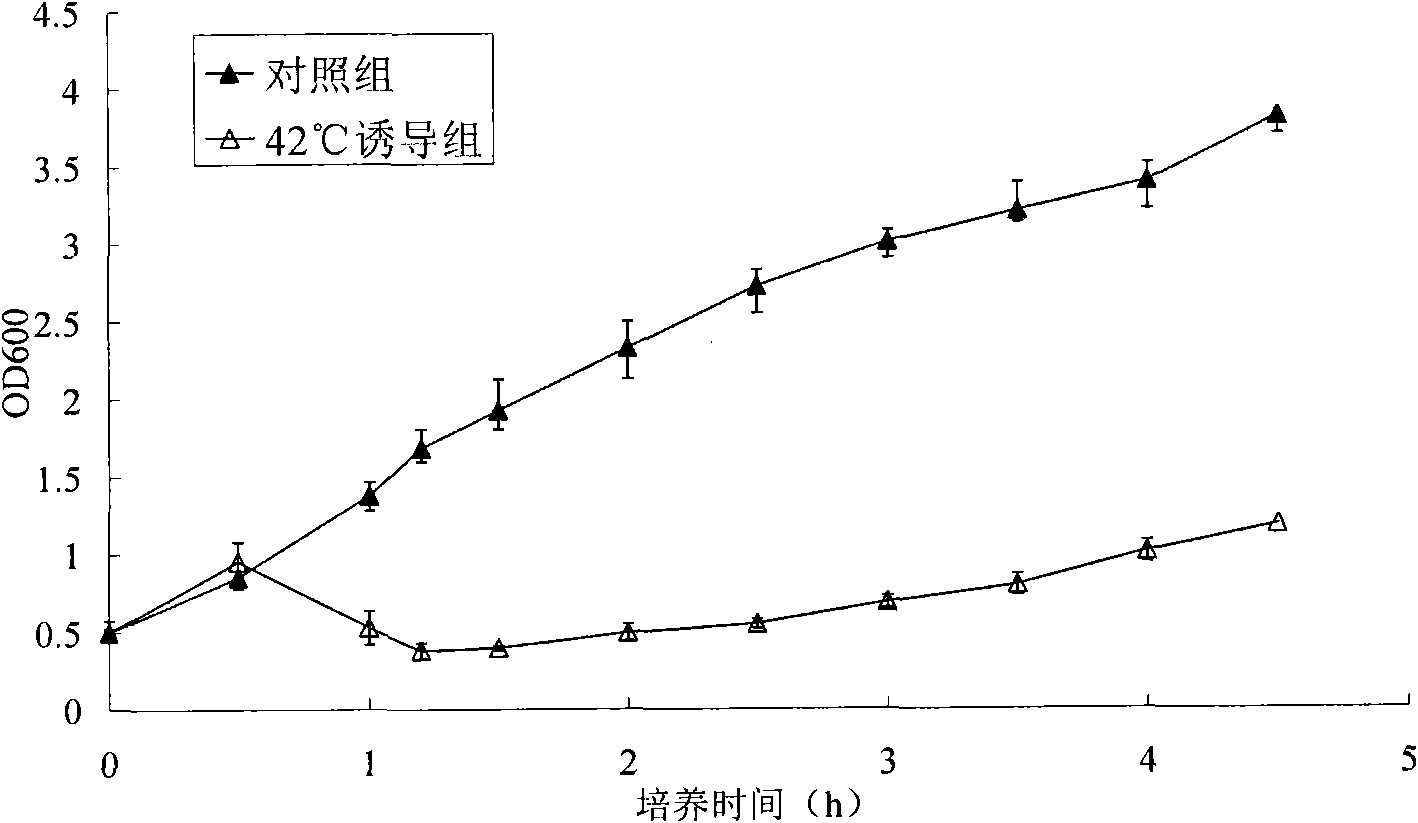

Double-target DNA vaccine and constructing method thereof

InactiveCN101991863AStimulation of immune propertiesStimulate immune response levelViral antigen ingredientsGenetic material ingredientsDiseaseAntigen

The invention discloses a double-target DNA vaccine and a constructing method thereof. The vaccine uses BG (Butylene Glycol) as a DNA conveying carrier, and the DNA carries a DNA vaccine of a molecular chaperone constant chain Ii gene of MHC-II. The vaccine can prevent the degradation of the DNA vaccine and increase the expression level of a DNA coding sequence of the vaccine in an antigen presenting cell and can be used for further presenting the expressed antigen to an immunize effect cell efficiently, thereby greatly improving the immunocompetence of the DNA vaccine. The invention plays an important role in the research (of improving the immunocompetence of the traditional DNA vaccine and the future DNA vaccine) of the novel vaccine and the control of future diseases, and has wide application prospect.

Owner:FIELD OPERATION BLOOD TRANSFUSION INST OF PLA SCI ACAD OF MILITARY

An aluminum alloy sacrificial anode with high current efficiency for deep-sea environments

ActiveCN104060280BLong-term effective protectionStable Current EfficiencyIndiumBiological activation

Owner:UNIV OF SCI & TECH BEIJING

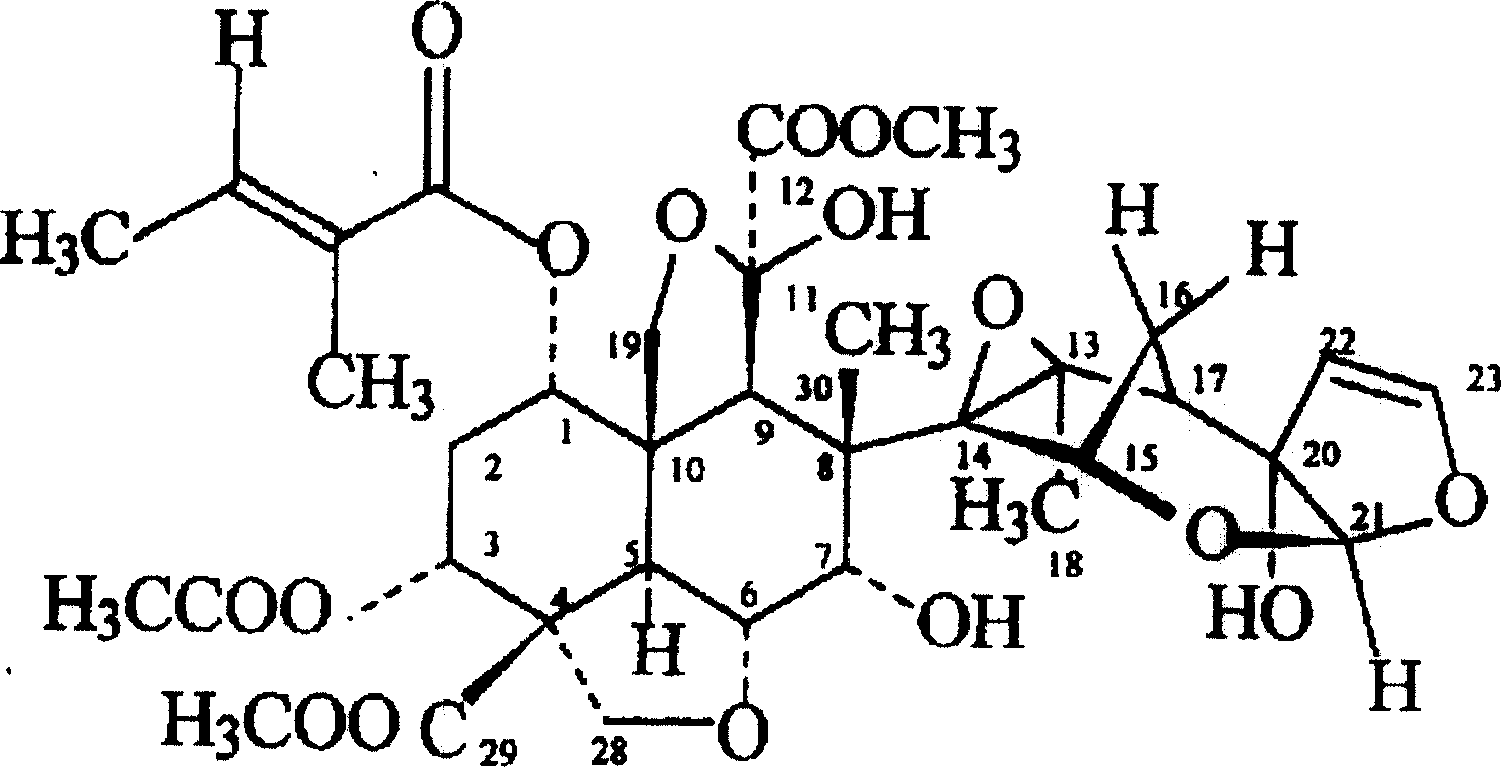

Nimbin-containing injection formulation for tree trunk and application of nimbin in field of injection for tree trunk

The present invention discloses a truck injection agent with nimbin, which consists of nimbin, latent solvent, osmotic agent, mixing agent and diluent, at the same time, the invention discloses the application of the truck injection agent with nimbin in the truck injection field, namely that the truck injection agent is injected into the truck directly. The injecting part is positioned on the truck with more than 10 cm from the ground, and the injecting depth reaches the xylem. By the method of direct injection, the medicine enters directly into the plant tissue, which reduces the influence of environmental factor to the nimbin, ensures a good suction rate of the plant to the nimbin and reduces correspondingly the relative usage of the nimbin, moreover, the nimbin after entering the plant tissue is able to be conducted primely so as to have longer lasting performance, thus protecting the target plant in a better manner.

Owner:FUJIAN INST OF APPLIED ECOLOGICAL OF AGRI & FORESTRY UNIV

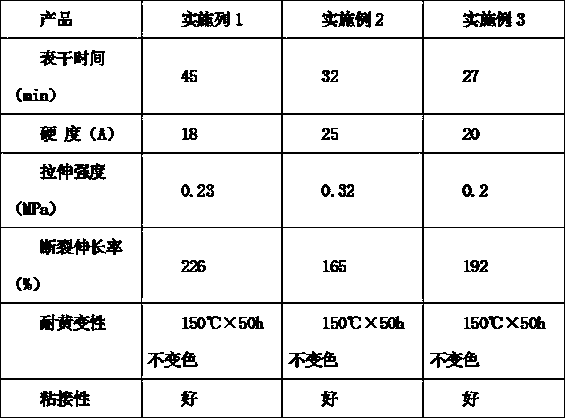

Preparation of two-component transparent LED silicone coating adhesive

InactiveCN109749698ANot corrosiveIncrease elasticityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAdhesive

The invention discloses preparation of a two-component transparent LED silicone coating adhesive. The two-component transparent LED silicone coating adhesive comprises a component A and a component B,wherein the component A is formed by mixing alpha-omega-dihydroxypolydimethylsiloxane and a diluent according to the weight ratio of (50.0-75.0): (25.0-50.0); the component B is formed by mixing a cross-linking agent, a diluent, a tackifier, a catalyst and an anti-yellowing agent according to the weight ratio of (35.0-50.0): (20.0-40.0): (15.0-30.0): (0.0-0.3): (0.5-1.5); and the component A andthe component B are mixed and used according to the weight ratio of 10: 1. The preparation of the two-component transparent LED silicone coating adhesive has the advantages of low viscosity, good transparency, good elasticity, good adhesion property, good yellowing resistance, good weather resistance, no corrosion and environmental friendliness. Meanwhile, the two-component transparent LED silicone coating adhesive can adapt to alternate change of the temperature when an LED display screen is used, and cannot crack, the circumstance that the light transmittance of an LED lamp is reduced due toyellowing of an adhesive layer is avoided, and a display screen module can be effectively protected for a long time.

Owner:FUJIAN CHANGDE PLASTIC IND

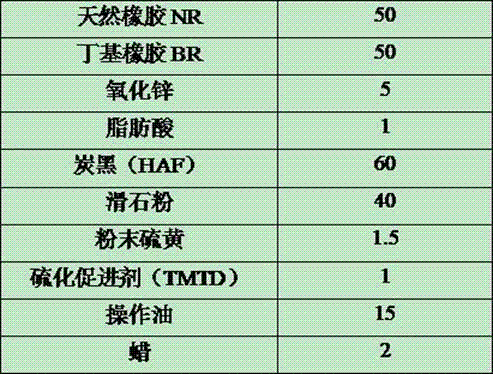

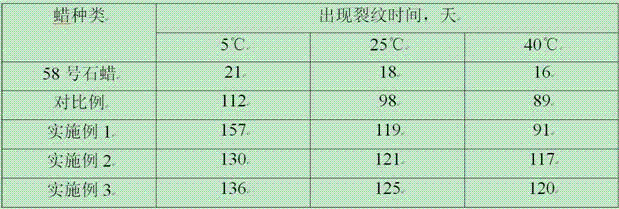

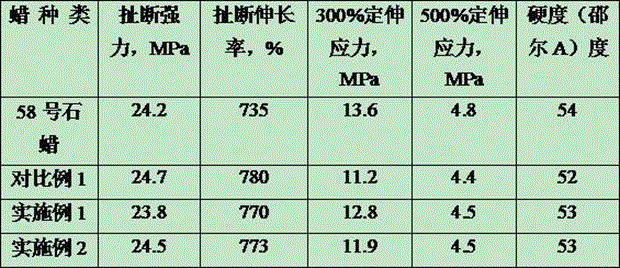

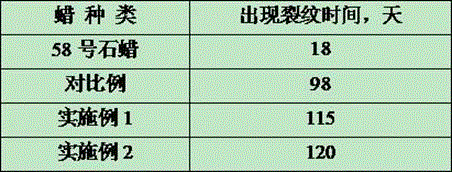

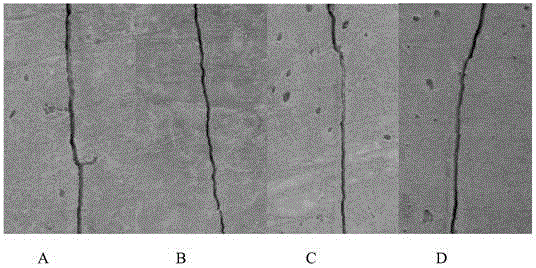

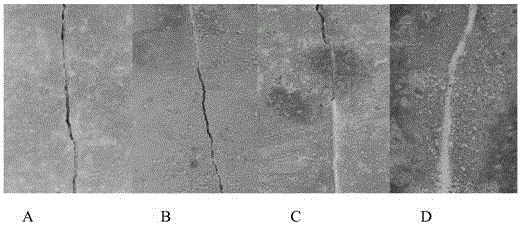

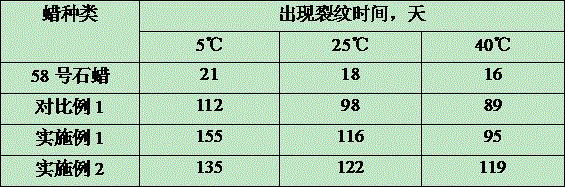

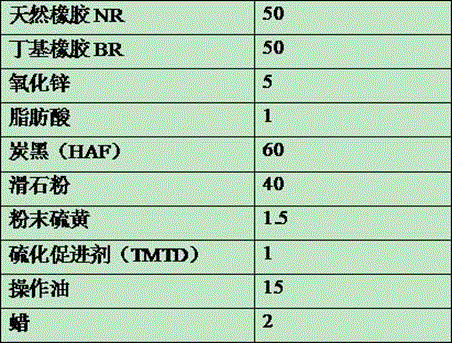

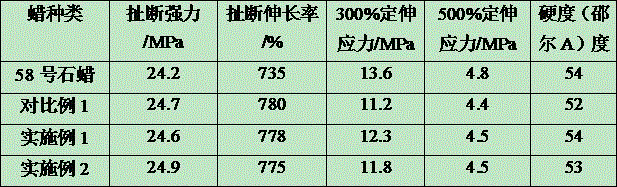

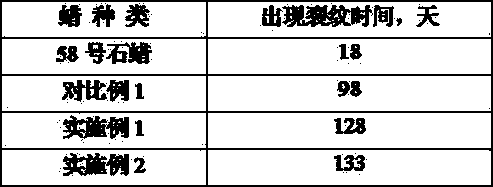

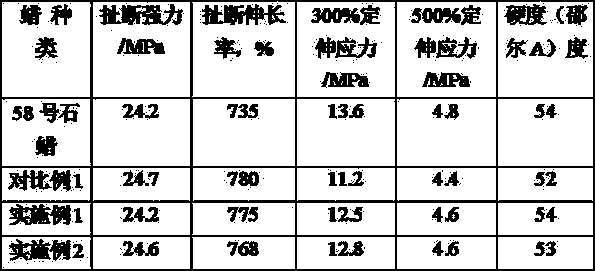

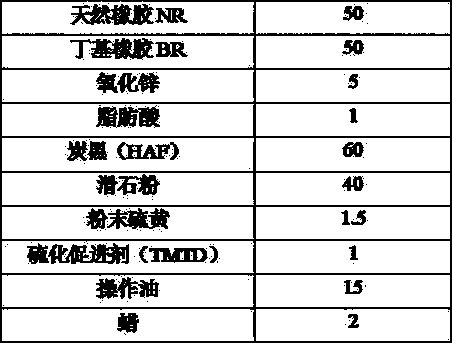

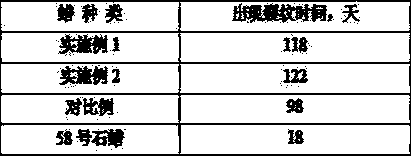

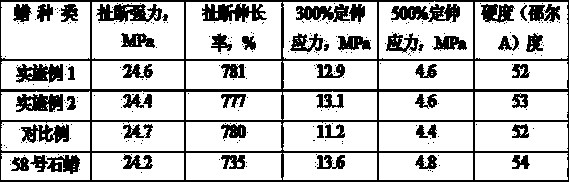

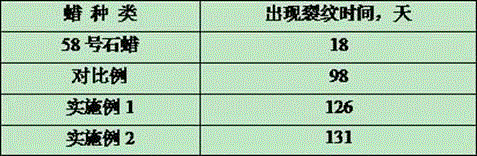

Method for producing rubber protection wax

ActiveCN107513423AIncrease contentExtended service lifeWax physical treatmentPetroleum wax refiningSolid componentCarbon number

The invention discloses a method for producing rubber protection wax. On the basis of the ordinary sweating process, airflows pass through a wax layer and carry away a liquid component in the sweating process so that a solid component and the liquid component are forcibly separated and gas produced from a decomposable substance dissolved in the raw material forms tiny bubbles in the wax layer and thus raw material components unsuitable for rubber protection wax are fast removed, and then the rubber protection wax product is prepared through adjusting carbon number distribution. The method has the advantages of low equipment investment, simple production process, low operation cost, safety, energy saving and no solvent pollution. The product can effectively protect rubber and its products for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Jasminum sambac hand cream

InactiveCN107638344AHigh in essential oilsIncrease elasticityCosmetic preparationsToilet preparationsGlycerolCold injury

The invention discloses jasminum sambac hand cream. The jasminum sambac hand cream is prepared from the following raw materials in percent by weight: 6 to 12 percent of a jasminum sambac extractive, 0.5 to 5 percent of wheatgerm oil, 0.1 to 5 percent of a shaddock peel extractive, 5 to 15 percent of glycerinum, 0.1 to 5 percent of a zingiber officinale roscoe extractive, 0.1 to 2 percent of a folium artemisiae argyi extractive, and bamboo juice for the surplus. The bamboo juice is put into a stirrer to be heated to 75 to 80 DEG C, and is cooled down to 40 to 50 DEG C after half an hour of heatpreservation; the glycerinum is added and uniformly stirred; the jasminum sambac extractive, the wheatgerm oil, the shaddock peel extractive, the zingiber officinale roscoe extractive and the foliumartemisiae argyi extractive are added and uniformly stirred; homogenizing is performed for 30 to 40min at 8 to 12MPa and 40 to 50 DEG C; the raw materials are heated to 90 DEG C; sterilization and cooling are performed, so that the hand cream is obtained. The hand cream adopts natural components as the raw materials, is safe and reliable in the processing process, and has the efficacies of moisturizing, preventing cold injury, repairing damaged skin, promoting skin metabolism and improving the skin elasticity.

Owner:广西巧恩茶业有限公司

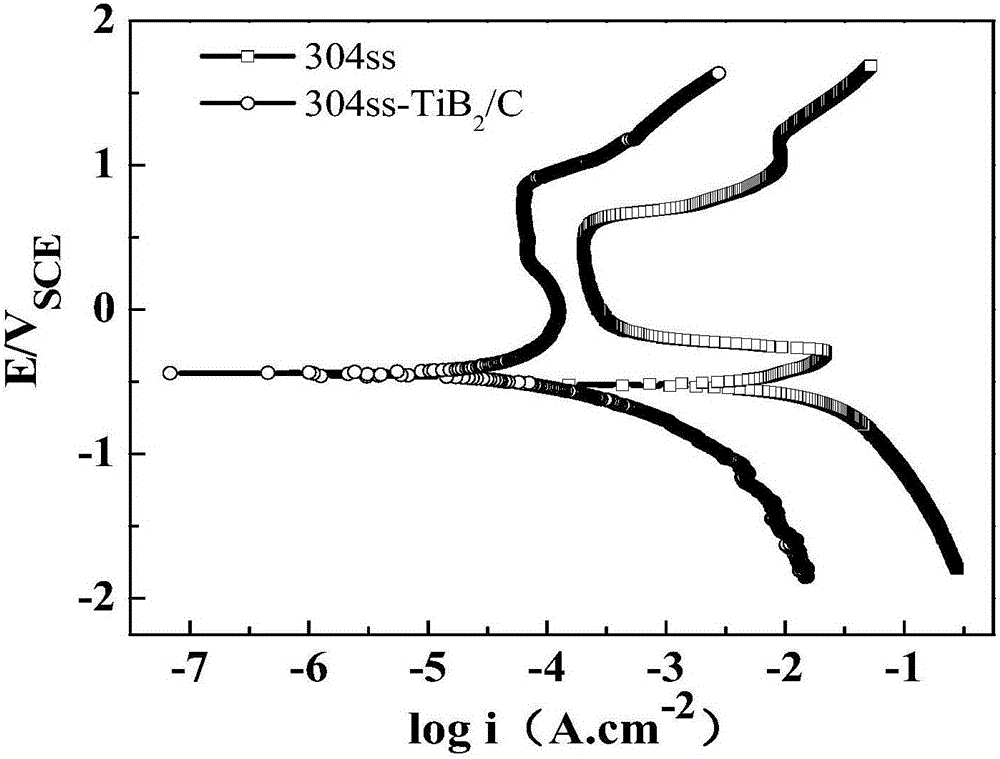

Method for preparing boride coating on stainless steel surface

ActiveCN105821459AReduce brittlenessImprove densification performanceElectrolytic coatingsElectrodesBorideHigh energy

The invention belongs to the technical field of modified treatment of stainless steel surfaces and particularly relates to a preparation process of a TiB2 / C anti-corrosion coating. A stainless steel substrate is taken as the cathode of high-energy micro-arc alloying equipment, a depositing electrode is taken as the anode of the high-energy micro-arc alloying equipment, high-energy micro-arc alloying deposition is performed under the protection of argon, and a coating is obtained on the substrate surface. The TiB2 / C coating prepared after doping TiB2 powder with carbon powder is improved in compactness; and the high-energy micro-arc alloying process promotes metallurgical bonding of the coating and the substrate, so that the fragility is reduced, no obvious defect exists on the surface, and under such severe conditions as high temperature and acidity, the substrate can be effectively protected for a long term.

Owner:上海韵申新能源科技有限公司

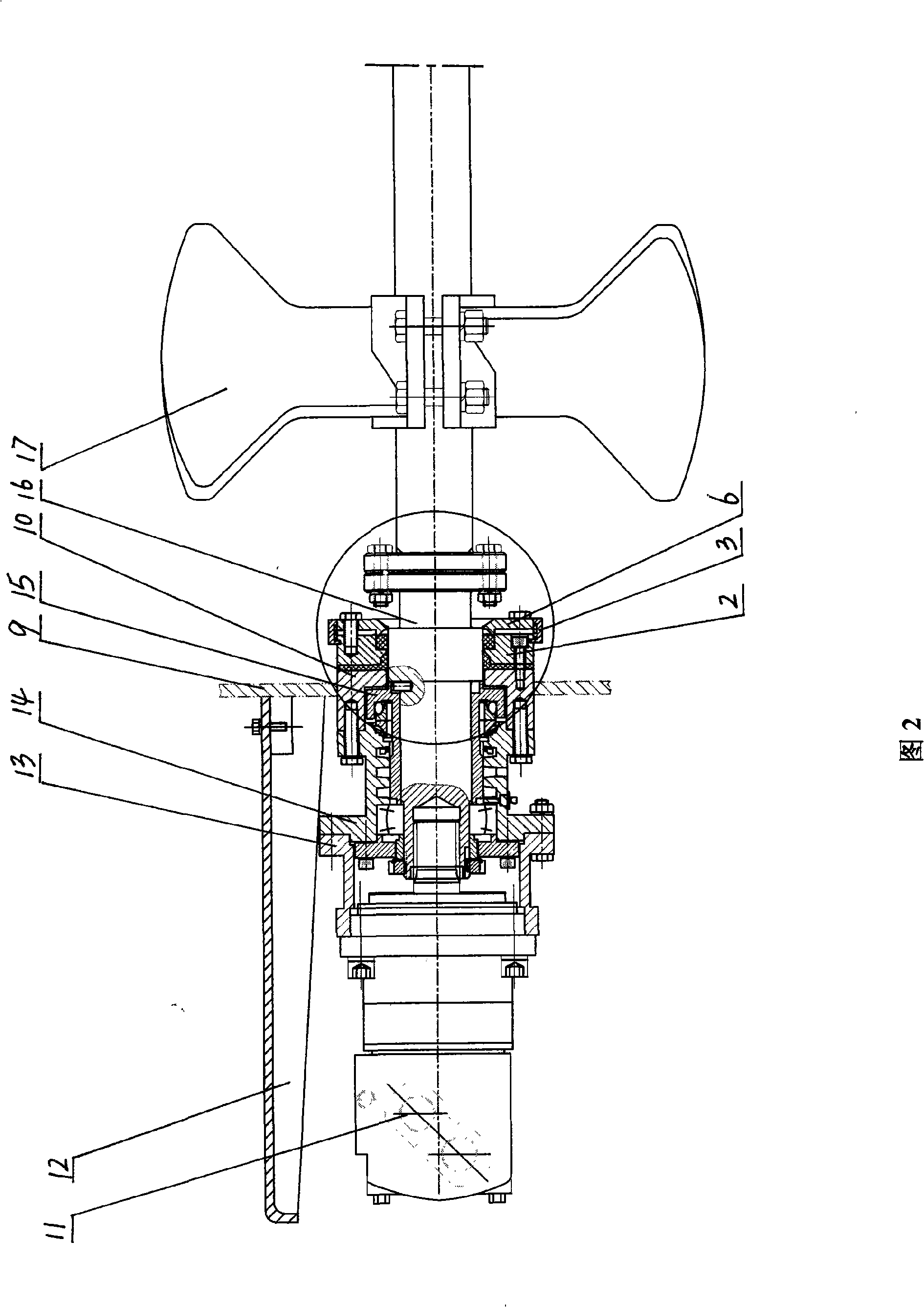

Concrete delivery pump adjustable double-layer seal assembly

InactiveCN101349265APrevent leakageAvoid cloggingEngine sealsPositive displacement pump componentsEngineeringMechanical engineering

The invention discloses an adjustable double-layer sealing assembly of a concrete conveying pump, which has a double-layer sealing of a sealing sleeve and a sealing ring, the sealing ring is located between a fixing sleeve and a stirring shaft of the concrete conveying pump, the sealing sleeve is located between the fixing sleeve and a hopper stirring seat and between the fixing sleeve and the stirring shaft, the inner circular face of the fixing sleeve is contacted with the oblique face of the sealing sleeve, an adjustable plate is provided with an oblique face which is contacted with the sealing ring, the adjustable plate is fixed on the fixing sleeve via an adjusting screw bolt, a gap is arranged between the adjustable plate and the fixing sleeve, and a sealing hoop is arranged outside the gap. The adjustable double-layer sealing assembly of the concrete conveying pump can efficiently prevent concrete grout leaking in an operating system of the stirring shaft, thereby avoiding blocking a lubricating oil passage, prolonging the service life of the operating system of the stirring shaft, and bringing convenience and fastness for maintenance and repair.

Owner:泰安市前进机械制造有限公司

Production method of aluminum foil for candy wrapping

InactiveCN110356133AKeep the flavorKeep shapeDecorative surface effectsOther printing apparatusFine lineAluminum foil

The invention relates to a production method of aluminum foil for candy wrapping. The aluminum foil in the O state is included. The method sequentially comprises the following steps of printing, embossing and slitting. The method has the advantages that the production method of printing, embossing and slitting in sequence is adopted in the aluminum foil to prepare an aluminum foil coiled material,the aluminum foil surface is coated with an ink layer firstly, through an embossing machine, patterns with the fine lines and uniform thickness are pressed on the aluminum foil surface, softness of the aluminum foil with the horizontal surface without embossed patterns originally can be changed, the inherent forming property of the aluminum foil is kept, stable property of online high-speed packaging of an automatic packaging device can be achieved, and the attractive and efficient packaging effect is achieved; and finally, the aluminum foil is soft in texture, good in ductility, convenient to machine, light, attractive, easy to recycle, and beneficial to environment friendliness, and the energy-saving and emission-reducing functions are achieved.

Owner:GLODSTONE PACKAGING JIAXING

Method for producing rubber protecting wax

ActiveCN106883875AExtended service lifeNo pollution in the processPetroleum wax refiningPetroleum wax recoverySolventWax

The invention discloses a method for producing rubber protecting wax. In a sweating process, air-flow passes through a wax layer for carrying liquid state oil in order to compulsively separate wax and oil; at the same time, a solid weight is placed on the wax layer in order to exert pressure intensity on the wax layer for accelerating separating speed of wax and oil and ensuring passing of the air-flow through the wax layer, and method can be used for rapidly and effectively removing components which are not proper for the rubber protecting wax in paraffin, and producing the rubber protecting wax product by blending. The method has the advantages of low apparatus investment, simple production process, low operation cost without solvents for polluting environment, long-term and effective protection effects for rubber and products thereof, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cobalt-based coating on surface of cobalt-based alloy

ActiveCN109321785AImprove high temperature resistanceImprove corrosion resistanceTransportation and packagingMetal-working apparatusWear resistantHigh energy

The invention belongs to the technical field of alloy material surface modification treatment, in particular to a method for preparing a cobalt-based coating on the surface of a cobalt-based alloy. The method specifically comprises the following steps that firstly, wet grinding is carried out on cobalt powder, chromium powder, molybdenum powder and aluminum powder according to a ratio to obtain amixture powder, after dried, the mixed powder with appropriate granularity is selected to undergo vacuum hot-pressing sintering to prepare a cobalt-based alloy matrix, Y2O3 is mixed into the raw material powder for wet grinding, then vacuum hot-pressing sintering is carried out to prepare an electrode material, and finally a high-energy micro-arc alloying method is adopted to make the electrode material be deposited on the surface of the cobalt-based alloy matrix under the protection of argon so as to prepare the cobalt-based / Y2O3 coating. According to the method, the coating is in metallurgical bonding with the matrix, so that the compactness of the coating mixed with the Y2O3 is improved, and the surface of the coating is free of obvious defects. The method is good in process repeatability and feasible in process, and the obtained high-corrosion-resistance wear-resistant coating further widens the application range of the cobalt-based alloy.

Owner:CHANGZHOU UNIV

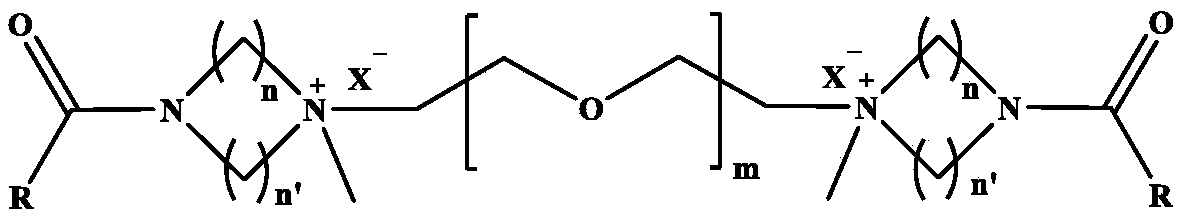

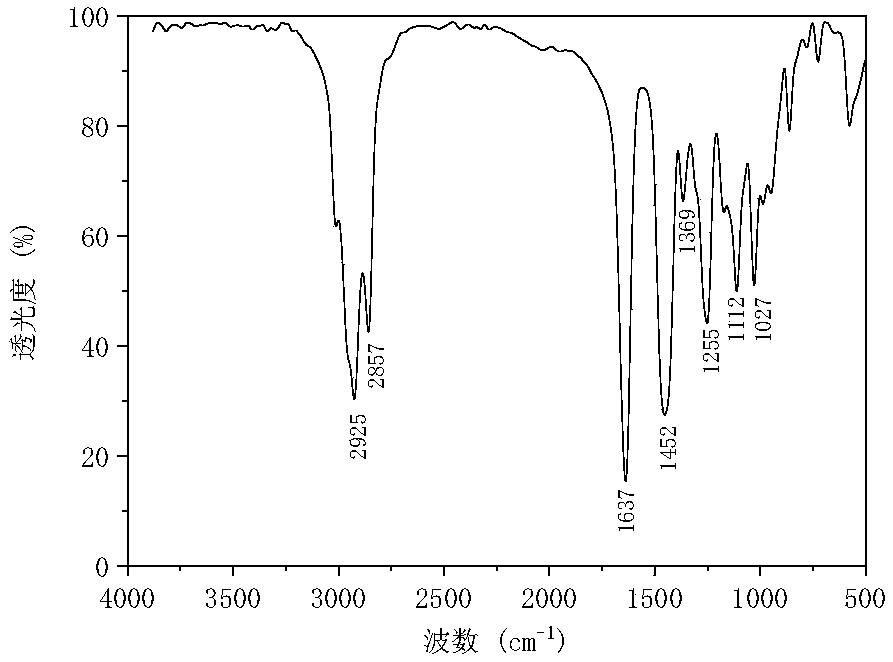

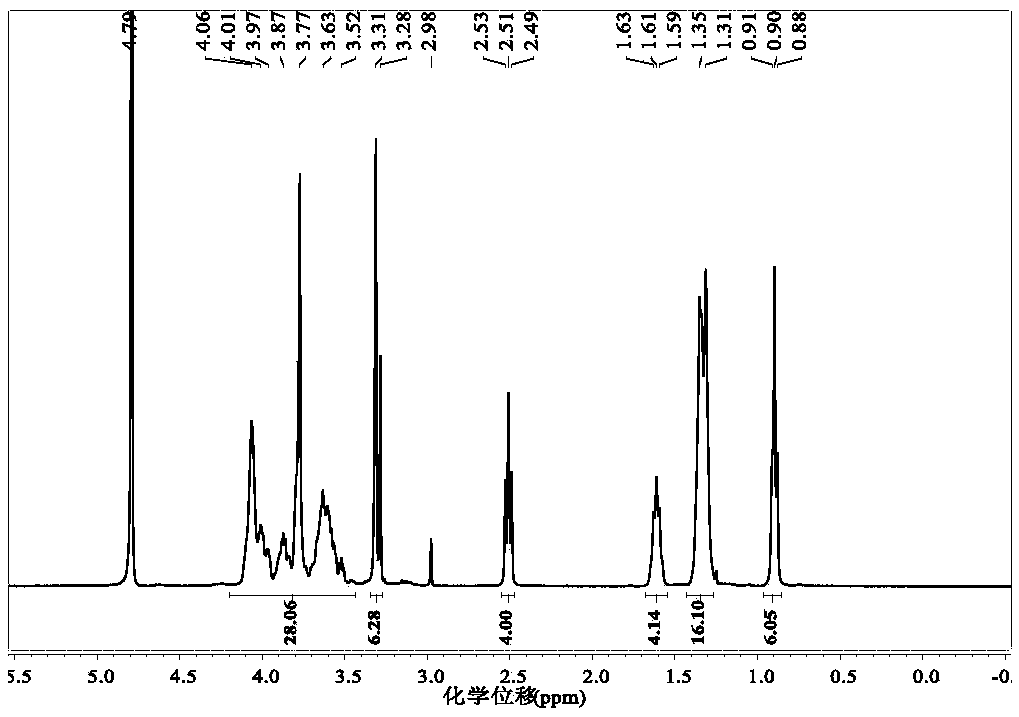

Polyethylene glycol diazacyclo compound, preparation method and application

ActiveCN108440450AImprove adsorption capacityImprove washing resistanceOrganic chemistryDrilling compositionNitrogenPolyethylene glycol

The invention provides a polyethylene glycol diazacyclo compound as shown in Figure 1. The invention further provides a preparation method of the compound, which comprises the following steps of: halogenating polyethylene glycol with a halogenation reagent to prepare polyethylene glycol dihalide, preparing long-chain diazacyclo amide via an amidation reaction of long-chain acyl halide and a diazacyclo compound, allowing polyethylene glycol dihalide and long-chain diazacyclo amide to give a quaternization reaction, and preparing the polyethylene glycol diazacyclo compound after purification, wherein the number of carbon atoms of long-chain acyl halide is 4-20; the polyethylene glycol diazacyclo compound has good swelling and washing resistance, and can effectively protect an oil reservoir;and the preparation method has the advantages of reliable method principles, easiness and simplicity in operation, higher productivity, greenness and environmental protection.

Owner:SOUTHWEST PETROLEUM UNIV

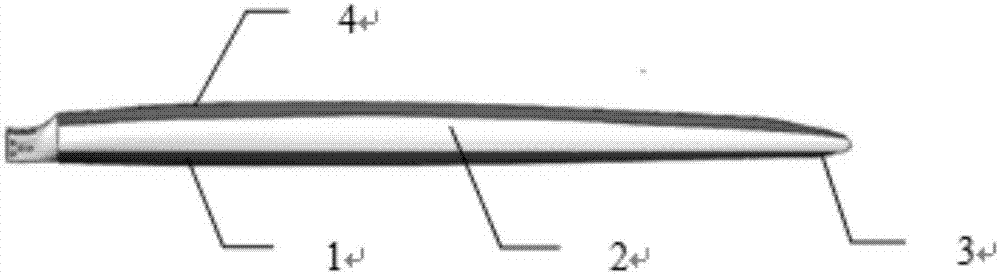

Polyurethane paint used on windward sides of wind power blade machines, and preparation method thereof

InactiveCN107446399AStrong service lifeSafe to useFireproof paintsAntifouling/underwater paintsCarvacryl acetateSilicon dioxide

The invention discloses a polyurethane paint used on windward sides of wind power blade machines, and a preparation method thereof. The polyurethane paint comprises modified phenolic resin reinforced polyurethane, urea-formaldehyde resin, ethylene-vinyl acetate copolymer, an anti-settling agent, rutile titanium dioxide, flake graphite powder, methyl methacrylate, coumarone, zinc oxide, kaolin, diethylene glycol, an aromatic hydrocarbon oil, a stabilizing agent, silicon dioxide, an antifoaming agent, a dispersant, a base material wetting agent, and a bactericide. The polyurethane paint is long in service life, and high in using safety, is capable of reducing blade production cost and maintenance cost in operation process. It is confirmed by a plurality of performance tests that the polyurethane paint is excellent in adhesive force, wear resistance, weatherability, salt spray resistance, damp heat resistance, and flexibility, can be used on wind driven generator blades, and is capable of protecting operation of wind driven generator blades for a long term.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

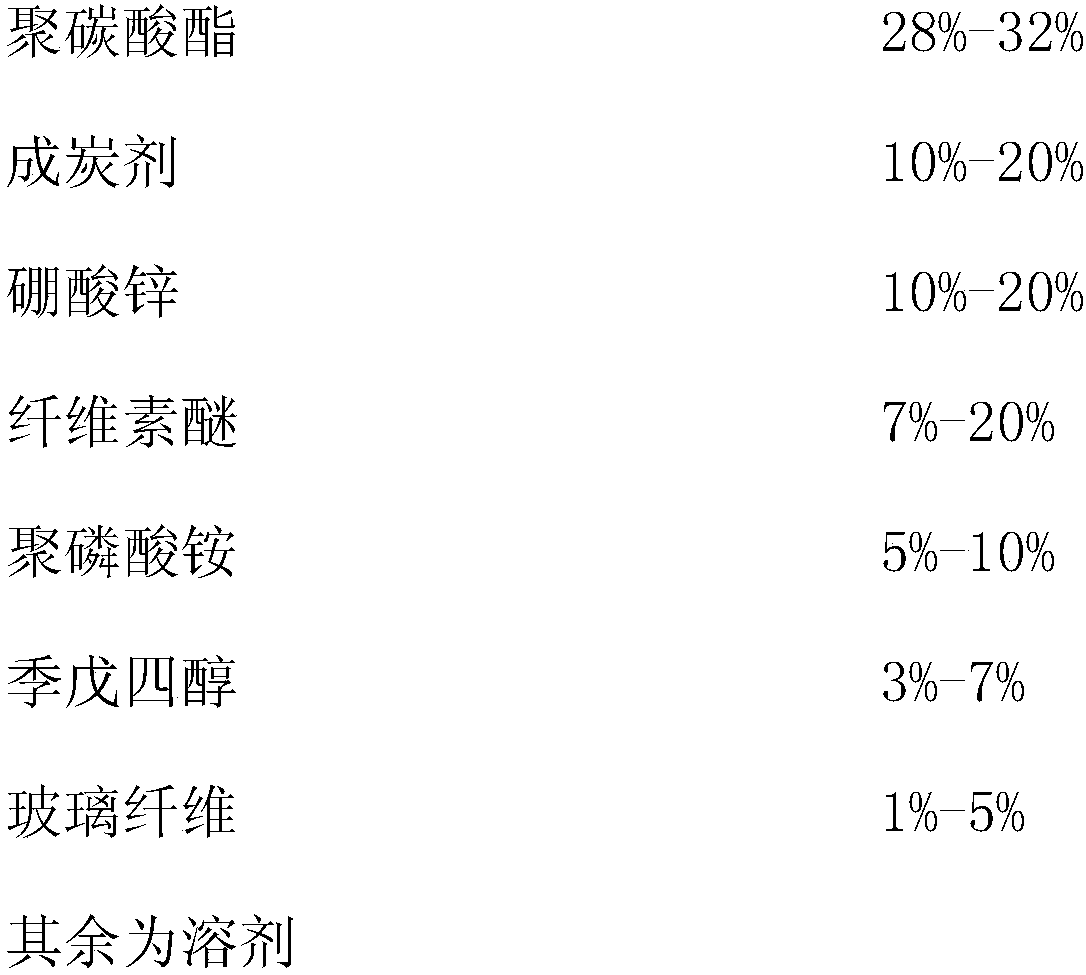

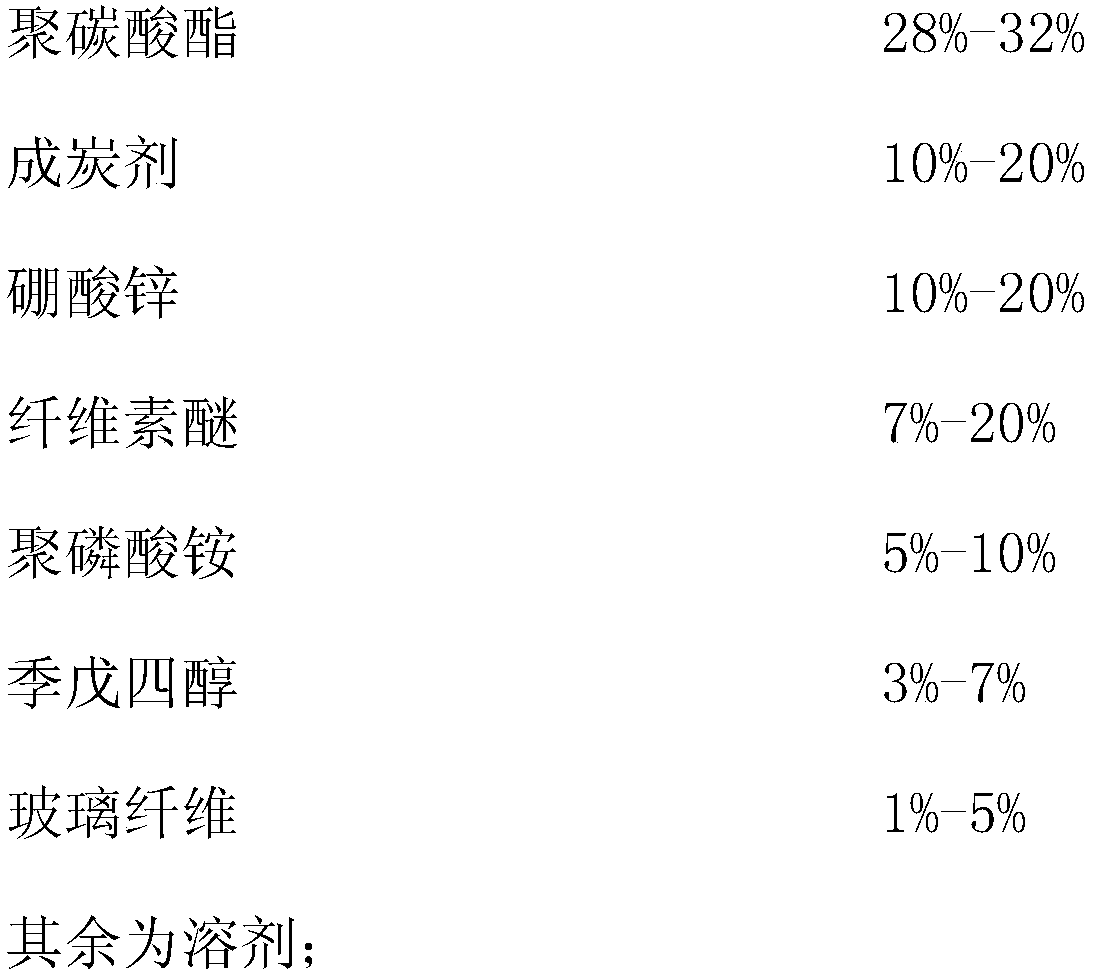

Fireproof paint and preparation method thereof

InactiveCN108059909ALong-term effective protectionImprove fire performanceFireproof paintsPolycarbonate coatingsCelluloseGlass fiber

The invention discloses a fireproof paint, which comprises following raw materials: polycarbonate, a charring agent, zinc borate, cellulose ether, pentaerythritol, glass fibers, a solvent, a curing agent, and a light stabilizer. The invention also discloses a preparation method of the fireproof paint. The preparation method comprises the following steps: step one, mixing polycarbonate, zinc borate, ammonium polyphosphate, glass fibers, a curing agent, and a solvent, evenly stirring, and grinding the mixture at a high speed to obtain color paste; and step two, mixing cellulose ether, a charringagent, pentaerythritol, and a light stabilizer, evenly mixing, adding the mixture into the color paste obtained in the step one, and carrying out high speed dispersion to obtain the fireproof paint.The fireproof performance is obviously improved, and moreover, the fireproof paint has an excellent performance on resisting coldness and freezing, is resisting to cracking and falling evenly under great temperature difference and long term light irradiation, is resisting to cracking and peeling under a dry or moisture condition, is chemically stable, can protect a flammable basic material for a long term, and has a wide application range.

Owner:惠水县凡趣创意科技有限公司

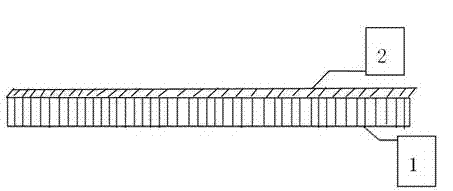

Book corner neatening patch

The invention discloses a book corner neatening patch, which is characterized by having a shape of a right angled isosceles triangle or a right angled sector, being made of a sheet-shaped material and having a double-layer structure, wherein two right-angle sides have an enclosed structure, and the other side is opened, so that a book corner is inserted into the other side; adhesive glue capable of gluing to the book corner is arranged in the book corner neatening patch; an anti-adhesive film is attached to the adhesive glue; when the book corner neatening patch is used, the anti-adhesive film is stripped, the book corner is sleeved into the book corner neatening patch after being flattened, and the adhesive glue is used for gluing and fixing so as to eliminate the phenomenon of tilting and wrinkling of the book corner; and the book corner neatening patch can protect the book corner for a long term and prolong the service life of books and is a good book care product.

Owner:NANTONG XINYING DESIGN SERVICE

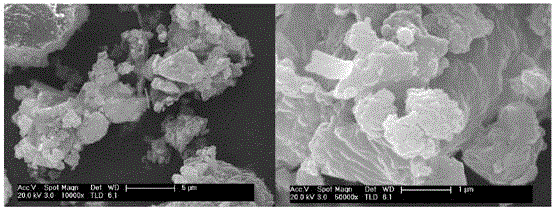

Vermin-proof mildew inhibitor for lumber and method for producing the same

InactiveCN100566955CFacilitated DiffusionImprove permeabilityWood impregnation detailsSolubilityVermin

The invention relates to wood protection technology, in particular to a wood insect-proof and mildew-proof agent and a preparation method thereof. A kind of insect-proof and anti-fungal agent for wood, comprising insect-repellent, anti-mold agent, solvent, co-solvent, permeation aid and stabilizer, wherein the weight percentage content of each component is respectively: insect repellent 0.1-70%, anti-mold agent 0.1% ~50%, solvent 1~40%, cosolvent 1~30%, penetration aid 1~20%, stabilizer 1~40%. The invention has the characteristics of high efficiency, broad spectrum, environmental protection, good water solubility and fixability, and the insect-proof and mildew-proof agent is made into a solution, so that the protection treatment is simple and easy. In addition, the present invention also provides a preparation method of the above wood insect-proof and mildew-proof agent.

Owner:蔡文根 +1

A preparation method of cement-based material with deep self-healing function

The invention provides a preparation method of a cement-based material having a deep self-repairing function. The preparation method disclosed by the invention comprises the following steps of: mixing concentrated solution of carbonic anhydrase generating bacteria with saccharomycete powder according to the mass ratio of (50-60) to 1, and immobilizing on a same carrier; mixing a substrate with a nutritional substance according to the mass ratio of (30-40) to 1, and fixing on another carrier; adding cement, sand and water by taking the carriers as lightweight aggregates, wherein the mass of the carriers is 17-23% of the total mass of mortar; uniformly stirring, and forming a test piece; and manufacturing a crack of the test piece after standard curing, and introducing air to maintain and repair under 25-30 DEG C constant-temperature water bath conditions. The repairing process of the test piece is monitored by utilizing a concrete nondestructive detection technology (ultrasonic sound); the repairing result is detected through a water permeability test; the result shows that the crack is completely repaired after repairing for 21 d; in addition, compared with other microbiological methods for repairing cracks of the cement-based material, the crack repairing speed and repairing depth are greatly improved.

Owner:SOUTHEAST UNIV

Bamboo and wood protecting agent

InactiveCN1209024CBroad-spectrumImprove mildew resistanceBiocideWood treatment detailsPentachlorophenolChlorothalonil

The invention is a bamboo wood protective agent. It is characterized in that based on zinc salt, boric acid and borate, one or two of fluoride, quaternary ammonium salt, chlorothalonil, sodium pentachlorophenate and phoxim emulsion are added, and the weight ratio of each component is : zinc salt: boric acid: borate: one or both of fluoride, quaternary ammonium salt, chlorothalonil, sodium pentachlorophenate, phoxim emulsion = 1.8~2.2: 0.8~1.2: 2.4~3.6: 2~3. The present invention has high efficiency, anti-insect, anti-mildew and anti-corrosion effects, has broad spectrum, good water solubility and fixability (i.e. leaching resistance), low cost, low toxicity, basically harmless to the environment, and has no effect on the treated materials. Dyeing effect, can maintain natural color.

Owner:王文久 +2

Method for preparing rubber protecting wax

ActiveCN106883885AEfficient removalExtended service lifePetroleum wax refiningPetroleum wax recoveryWaxSolvent

The invention discloses a method for preparing rubber protecting wax. In a sweating process, air-flow passes through a wax layer for carrying liquid state oil in order to compulsively separate wax and oil; at the same time, a solid weight is placed on the wax layer in order to exert pressure intensity on the wax layer for accelerating separating speed of wax and oil as well as ensuring passing of the air-flow through the wax layer, and method can be used for rapidly and effectively removing components which are not proper for the rubber protecting wax in raw materials, and preparing the rubber protecting wax product by adjusting carbon number distribution with blending. The method has the advantages of low apparatus investment, simple preparation process, low operation cost without solvents for polluting environment, long-term and effective protection effects for rubber and products thereof, simplified formula determination process, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of production method of novel rubber protective wax

ActiveCN106883881BExtended service lifeNo pollution in the processPetroleum wax refiningPetroleum wax recoveryParaffin waxPolymer science

The invention discloses a method for producing novel rubber protecting wax. In a sweating process, air-flow passes through a wax layer for carrying liquid state oil in order to compulsively separate wax and oil; at the same time, a solid weight is placed on the wax layer in order to exert pressure intensity on the wax layer for accelerating separating speed of wax and oil and ensuring passing of the air-flow through the wax layer, and method can be used for rapidly and effectively removing components which are not proper for the rubber protecting wax in goods paraffin; components obtained by sweating and alpha-olefin are blended in order to produce the rubber protecting wax product. The method has the advantages of simple production process, low operation cost, long-term and effective protection effects for rubber and products thereof, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for producing rubber protective wax by sweating

ActiveCN107523354BEasy dischargeImprove stabilityPetroleum wax refiningPetroleum wax recoveryWaxPolymer science

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing novel rubber protecting wax

ActiveCN106883874AEasy dischargeExtended service lifePetroleum wax refiningPetroleum wax recoveryInorganic saltsParaffin wax

The invention discloses a method for producing novel rubber protecting wax. The method is based on common sweating and de-oiling processes, in a sweating process, air-flow passes through a wax layer for carrying liquid state oil in order to compulsively separate wax and oil; at the same time, gas generated by decomposition of inorganic salt forms micro spaces in the wax layer, so that components which are not suitable for the rubber protecting wax in goods paraffin are rapidly and effectively removed; components obtained by sweating and alpha-olefin are blended in order to produce the rubber protecting wax product. The method has the advantages of simple production process, low operation cost, long-term and effective protection effects for rubber and products thereof, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

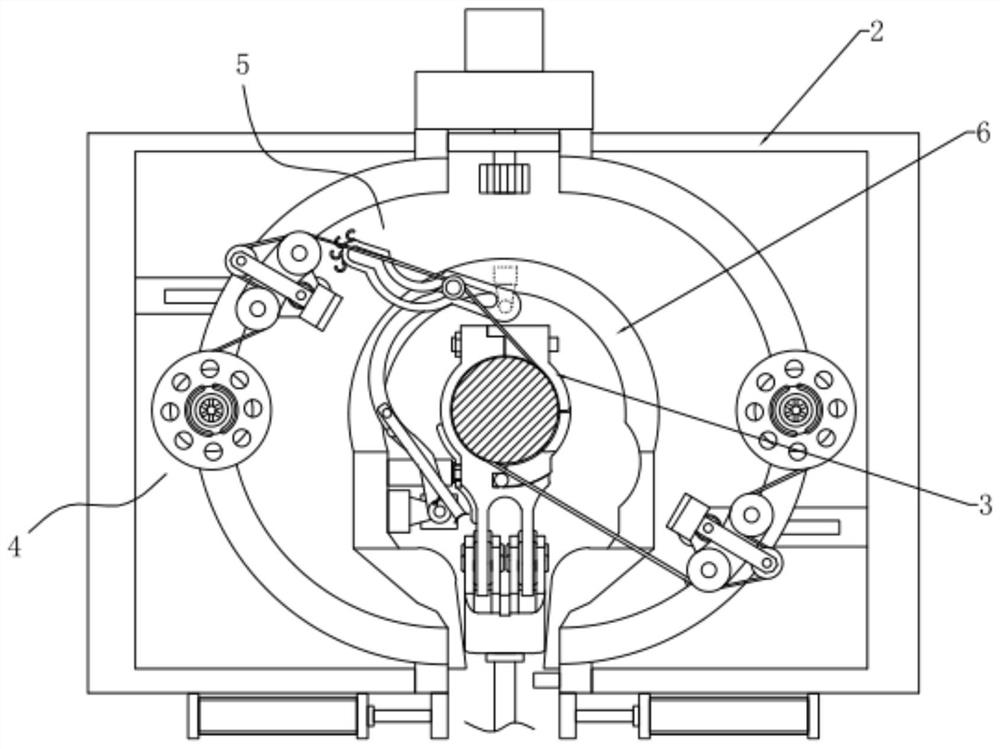

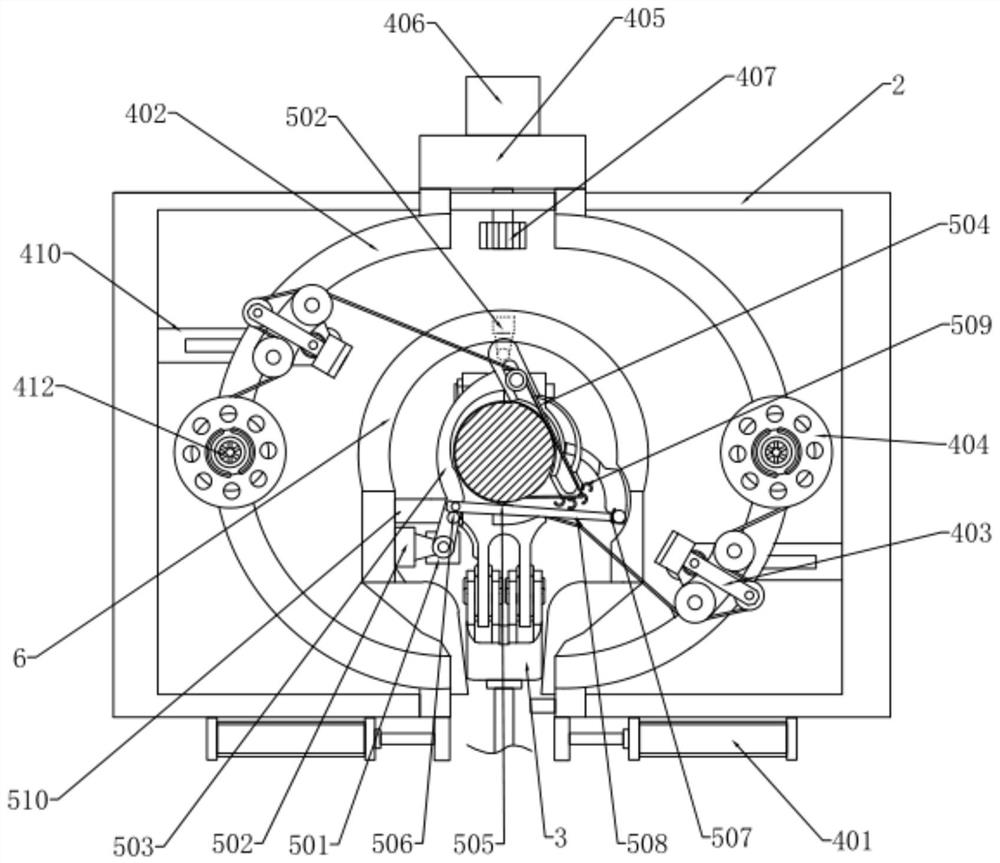

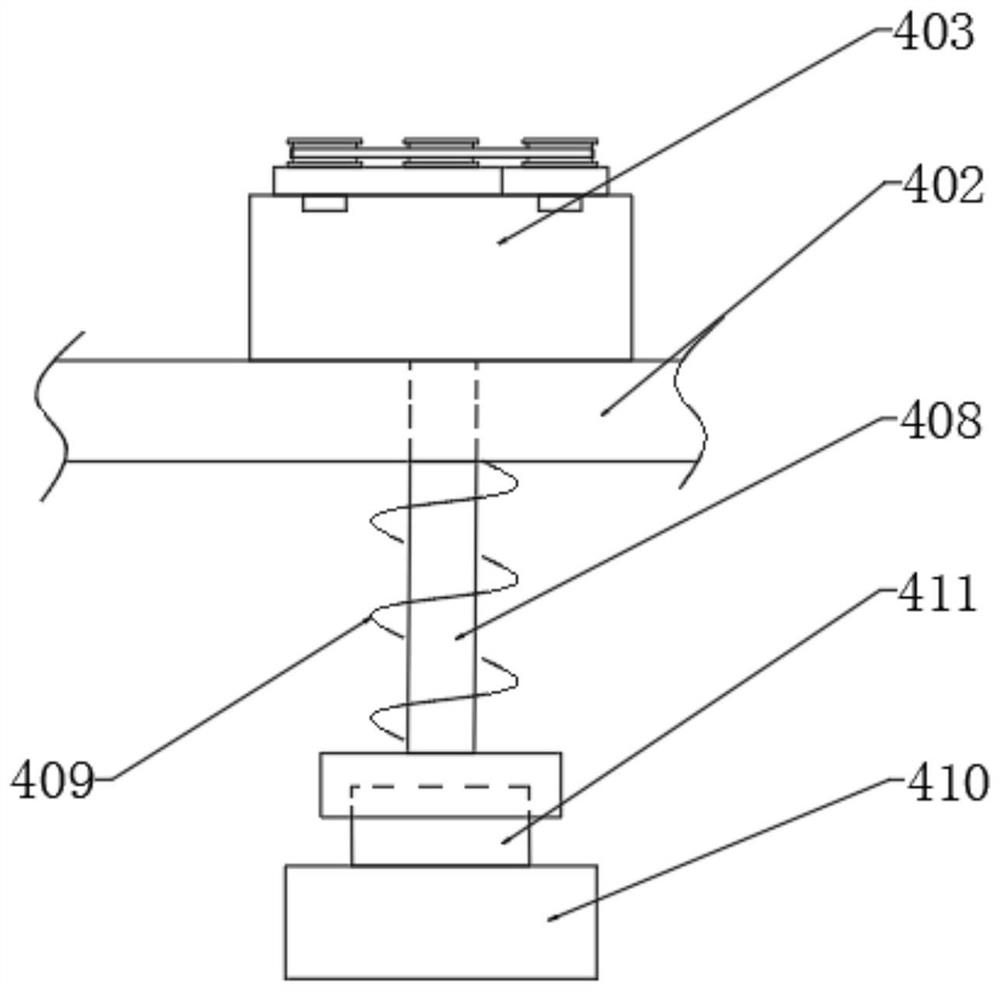

A protective device for the main cable of a steel suspension cable

ActiveCN112391955BLong-term effective protectionHigh degree of automationFilament handlingBridge structural detailsEngineeringStructural engineering

The invention discloses a protection device for a main cable of a steel suspension cable, which relates to the technical field of bridge protection equipment and includes a main body, a frame, a cable clamp, a wire winding mechanism and a wire pushing mechanism, and the main body is installed on the main cable of the suspension cable through a transmission device. superior. By setting the wire pushing mechanism and the new type of cable clamp, the present invention eliminates the need for a series of operations such as trimming the end of the wire winding section between the cable clamps, manual winding and welding, etc., thereby improving the degree of automation and the quality of the wire winding. Welding can only be done during the process of replacing the wire storage wheel after the wire wrap is used up, reducing a large number of welded joints and ensuring the long-term effective protection of the main cable by the wire wrap; Finally, in the process of closing the movable part, fill the inside of the storage chamber with coating paint, press the wrapped wire tightly in the wire slot and fill up the inside of the cable clamp, and then completely close the movable part by tightening the wrapped wire at both ends to seal the cable. Openings on both sides of the clip realize further sealing and protection of the inside of the cable clip.

Owner:振林建设集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com