Preparation of two-component transparent LED silicone coating adhesive

A silicone, two-component technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve unfavorable environmental protection, unfavorable cost saving, insufficient adhesion and yellowing resistance, etc. problems, to achieve good elasticity, prolong product life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

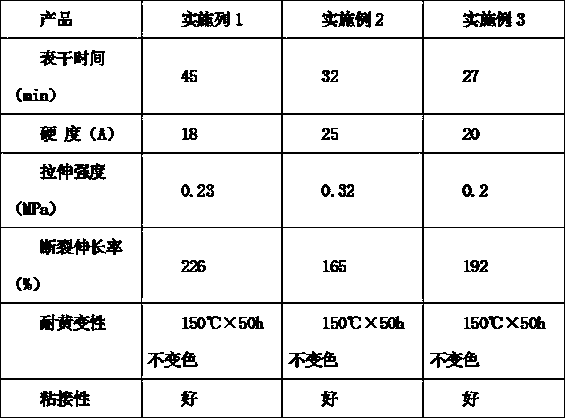

Examples

Embodiment 1

[0027] A two-component transparent LED silicone coating adhesive, including component A and component B, component A is composed of α-ω-dihydroxy polydimethylsiloxane and diluent in a weight ratio: (50.0-75.0 ): (25.0-50.0) mixed composition, component B consists of crosslinking agent, diluent, tackifier, catalyst and anti-yellowing agent in a weight ratio: (35.0-50.0): (20.0-40.0): (15.0- 30.0): (0.0-0.3): (0.5-1.5) mixed composition, and the A component and the B component are mixed at a weight ratio of 10:1.

[0028] Preferably, the α-ω-dihydroxy polydimethylsiloxane is one or a mixture of 107 silicone rubbers with a viscosity of 750 to 80,000 cps.

[0029] Preferably, the diluent is one or a mixture of simethicone with a viscosity of 50-100 cps.

[0030] Preferably, the crosslinking agent is one of propyl orthosilicate and ethyl orthosilicate or a mixture thereof, and the diluent is one or a mixture of dimethyl silicone oil of 50-100 cps.

[0031] Preferably, the tackifier is a s...

Embodiment 2

[0042] As in the preparation of a two-component transparent LED silicone coating of Example 1, the following process can also be used:

[0043] S1. Mix 107 silicone rubber with a viscosity of 750 cps and a viscosity of 1500 cps and a dimethyl silicone oil (201 silicone oil) with a viscosity of 100 cps at a weight ratio of 50.0:25.0:25.0. Mix and stir uniformly, and filter with an 80 mesh filter to obtain component A. Component A is a colorless and transparent liquid with a viscosity of 520 cps, and it is ready for use;

[0044] S2. Mix the modified silane coupling agent A-52: phenyltrimethoxysilane: modified silane coupling agent S-28= 25:10:65 (weight ratio), stir and mix well, seal well, and at room temperature After standing reaction, self-made thickener M is prepared;

[0045] S3. Combine propyl orthosilicate, dimethyl silicone oil (201 silicone oil) with a viscosity of 100 cps, thickener M obtained in S2, dibutyl tin dilaurate and anti-yellowing agent (Fisorb L-9322) in a weigh...

Embodiment 3

[0049] As in the preparation of a two-component transparent LED silicone coating of Example 1, the following process can also be used:

[0050] S1. Mix 107 silicone rubber with a viscosity of 1500 and a viscosity of 20000 cps and a dimethyl silicone oil with a viscosity of 50 cps (201 silicone oil) at a weight ratio of 35.0:25.0:40.0 and mix them to obtain component A by filtering with an 80 mesh filter. The A component is a colorless and transparent liquid with a viscosity of 1100cps, and it is ready for use;

[0051] S2. Mix the modified silane coupling agent A-52: phenyltrimethoxysilane: modified silane coupling agent S-28= 25:10:65 (weight ratio), stir and mix well, seal well, and at room temperature After standing reaction, self-made thickener M is prepared;

[0052] S3. Combine ethyl orthosilicate, dimethyl silicone oil (201 silicone oil) with a viscosity of 50cps, thickener M, dibutyltin diacetate and anti-yellowing agent (Fisorb L-9322) in a weight ratio of 45:28.8:25.3: 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com