Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Little warpage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

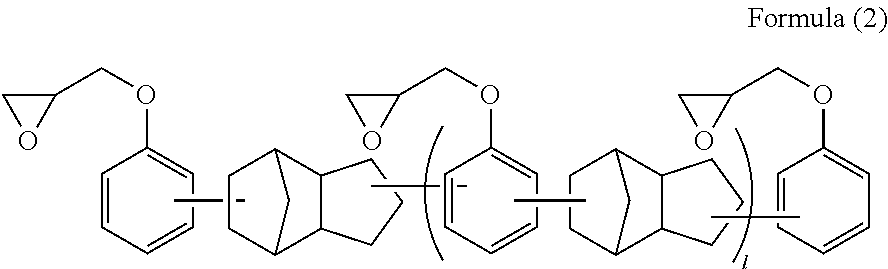

Photosensitive resin composition, dry film thereof, and printed wiring board using them

ActiveUS20120250268A1Reduce warpageLittle on environmentPhotosensitive materialsPrinted circuit aspectsResistCyclic ether

An alkali-developable photosensitive resin composition comprises a carboxyl group-containing urethane resin having a biphenyl novolak structure, a photopolymerization initiator, and aluminum hydroxide and / or a phosphorus-containing compound. The composition may be formulated as a photocurable and thermosetting resin composition by further incorporating therein a thermosetting component having a plurality of cyclic ether groups and / or cyclic thioether groups in the molecule, besides the components described above. The photosensitive resin composition may further contain a colorant. By using the photosensitive resin composition or a dry film thereof, a printed wiring board having a flame-retardant cured film, such as a solder resist, formed from the halogen-free composition can be provided while imposing little burden on the environment, the cured film being flame-retardant and reduced in warpage and having various excellent properties including bending characteristics, resistance to soldering heat, and resistance to gold plating.

Owner:TAIYO HLDG CO LTD

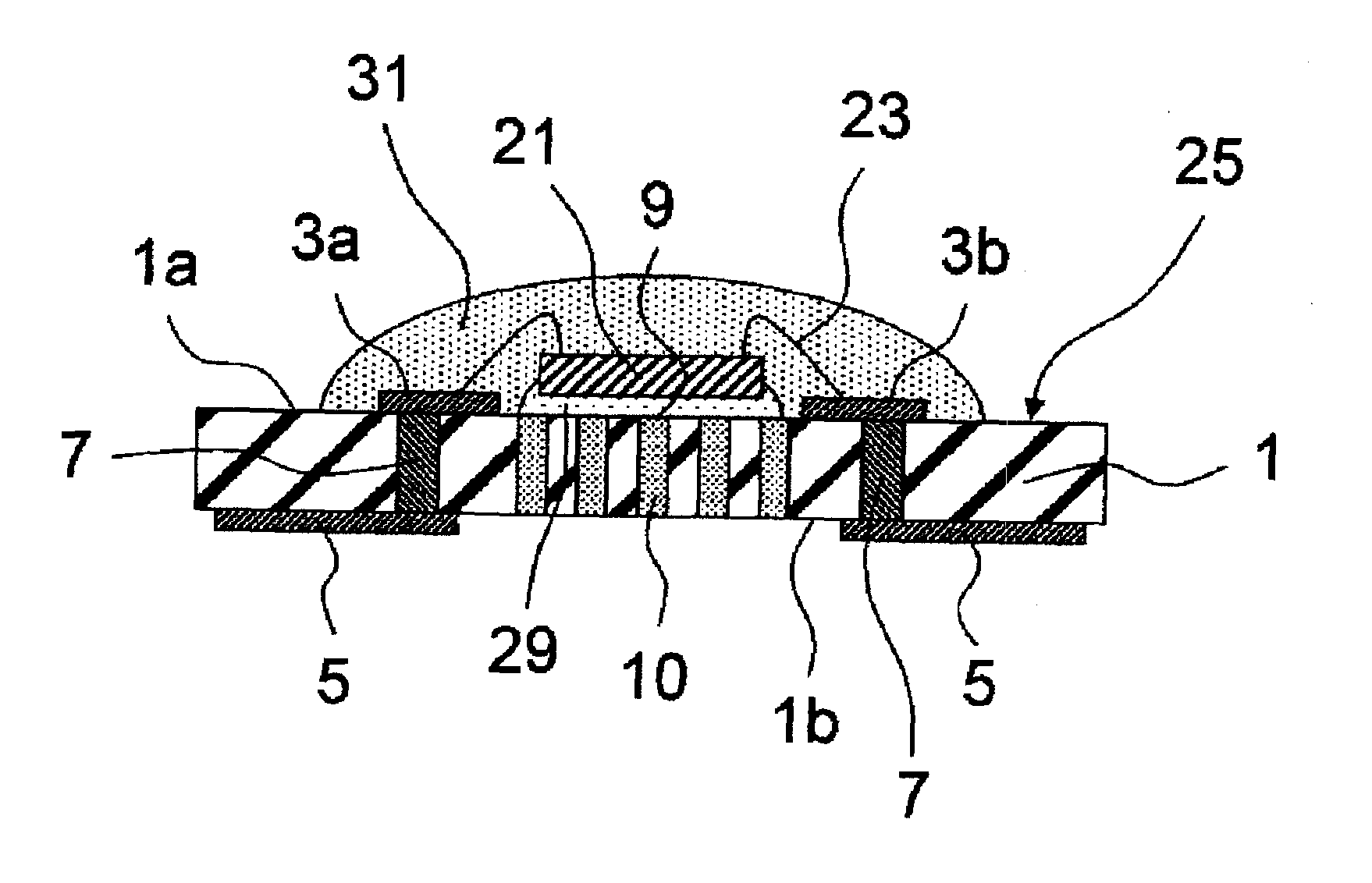

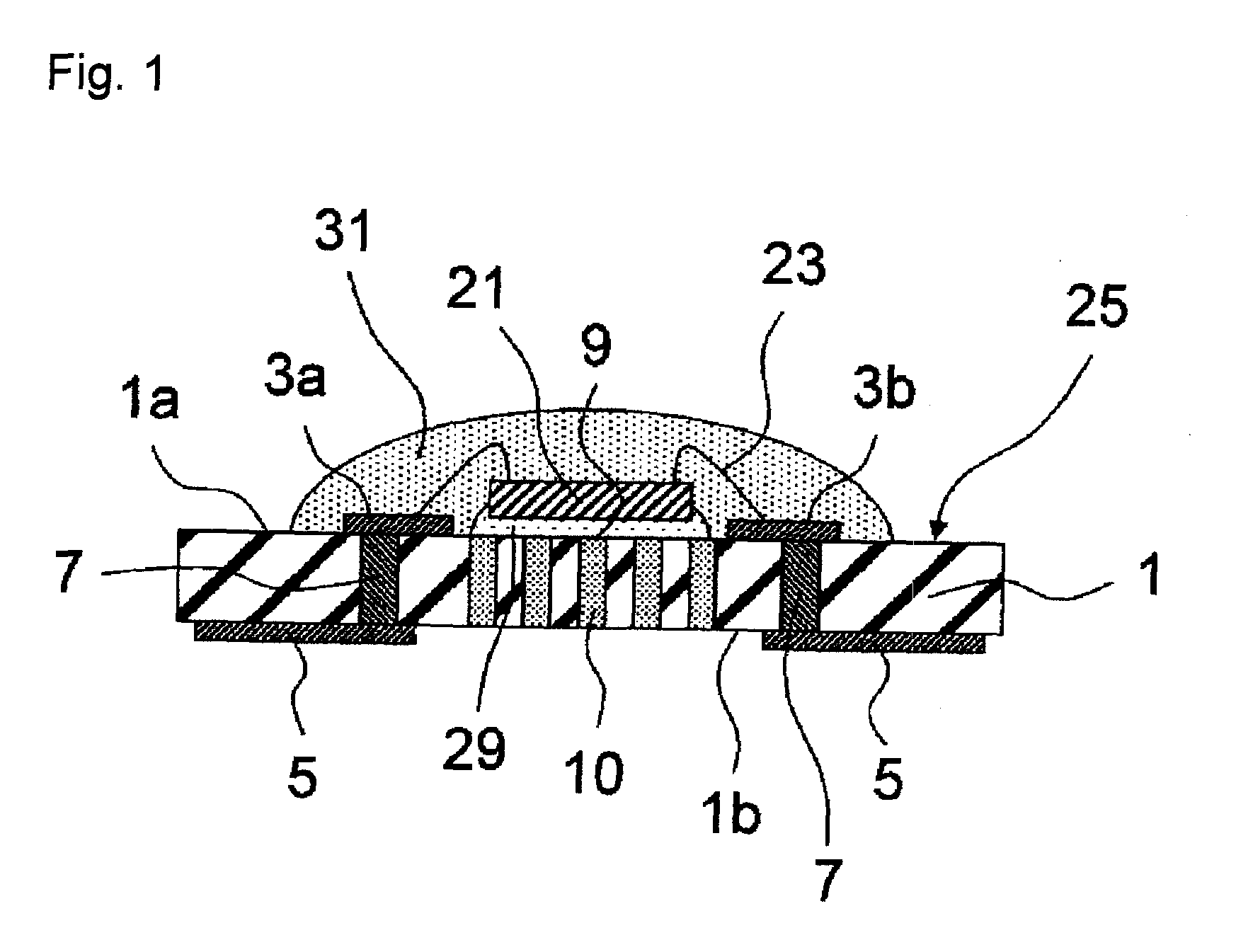

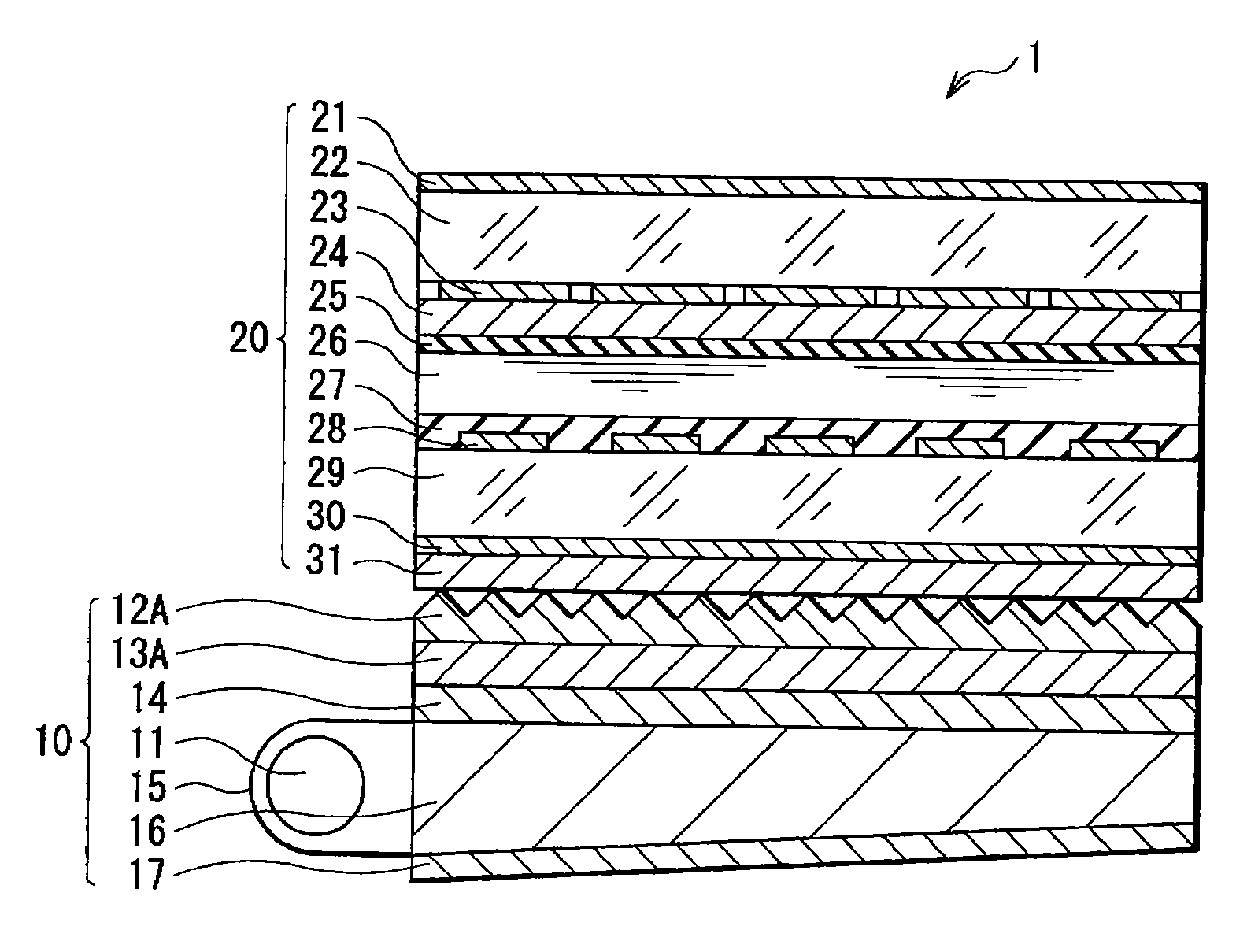

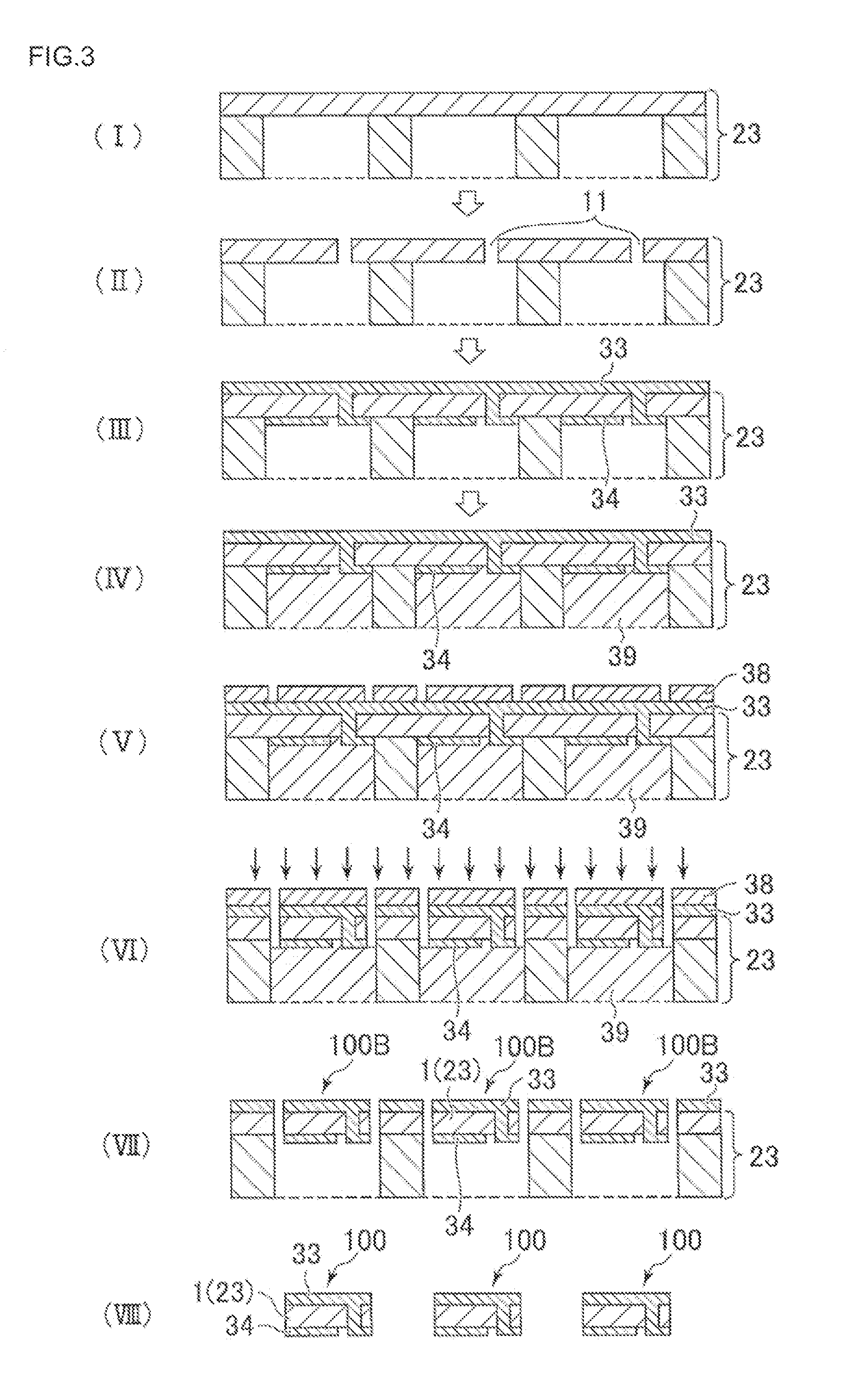

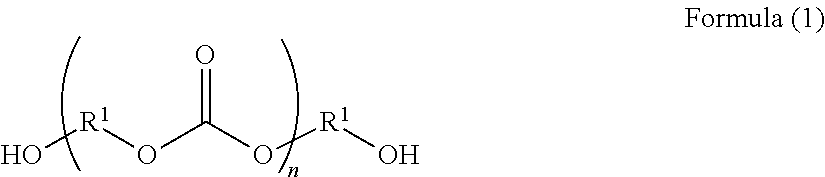

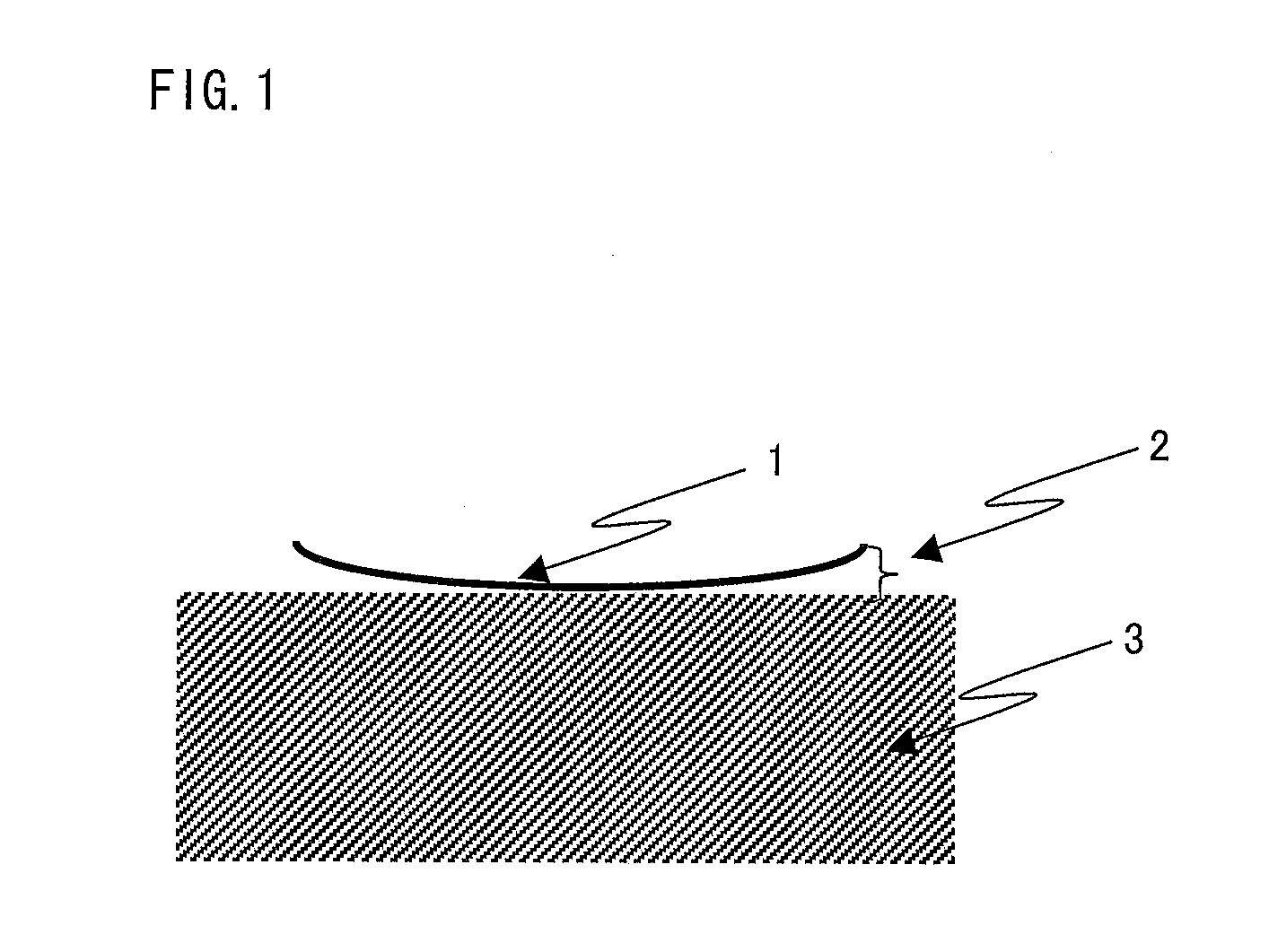

Light emitting diode package

ActiveUS20110001162A1High strengthExcellent in heat dissipation propertySemiconductor/solid-state device detailsSolid-state devicesFlexural strengthLight-emitting diode

To provide a light emitting diode package of which the height of protrusion of a thermal via is decreased without decreasing the flexural strength of an insulating substrate.A light emitting diode package comprising a light emitting diode element mounted on a substrate, wherein the substrate is obtained by firing a glass ceramic composition containing a powder of glass containing, as represented by mole percentage, from 57 to 65% of SiO2, from 13 to 18% of B2O3, from 9 to 23% of CaO, from 3 to 8% of Al2O3 and from 0.5 to 6% of at least one of K2O and Na2O in total, and a ceramic filler.

Owner:ASAHI GLASS CO LTD

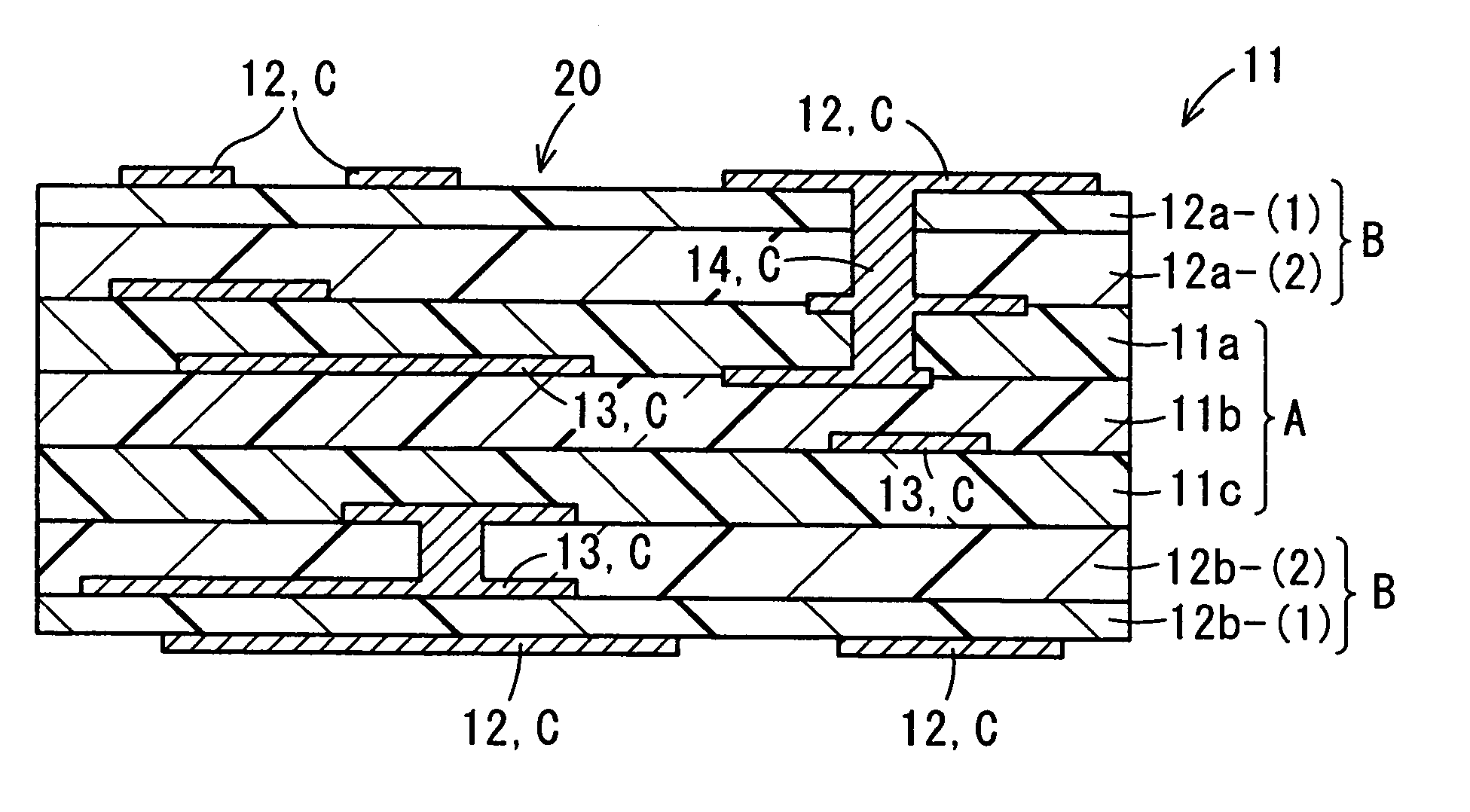

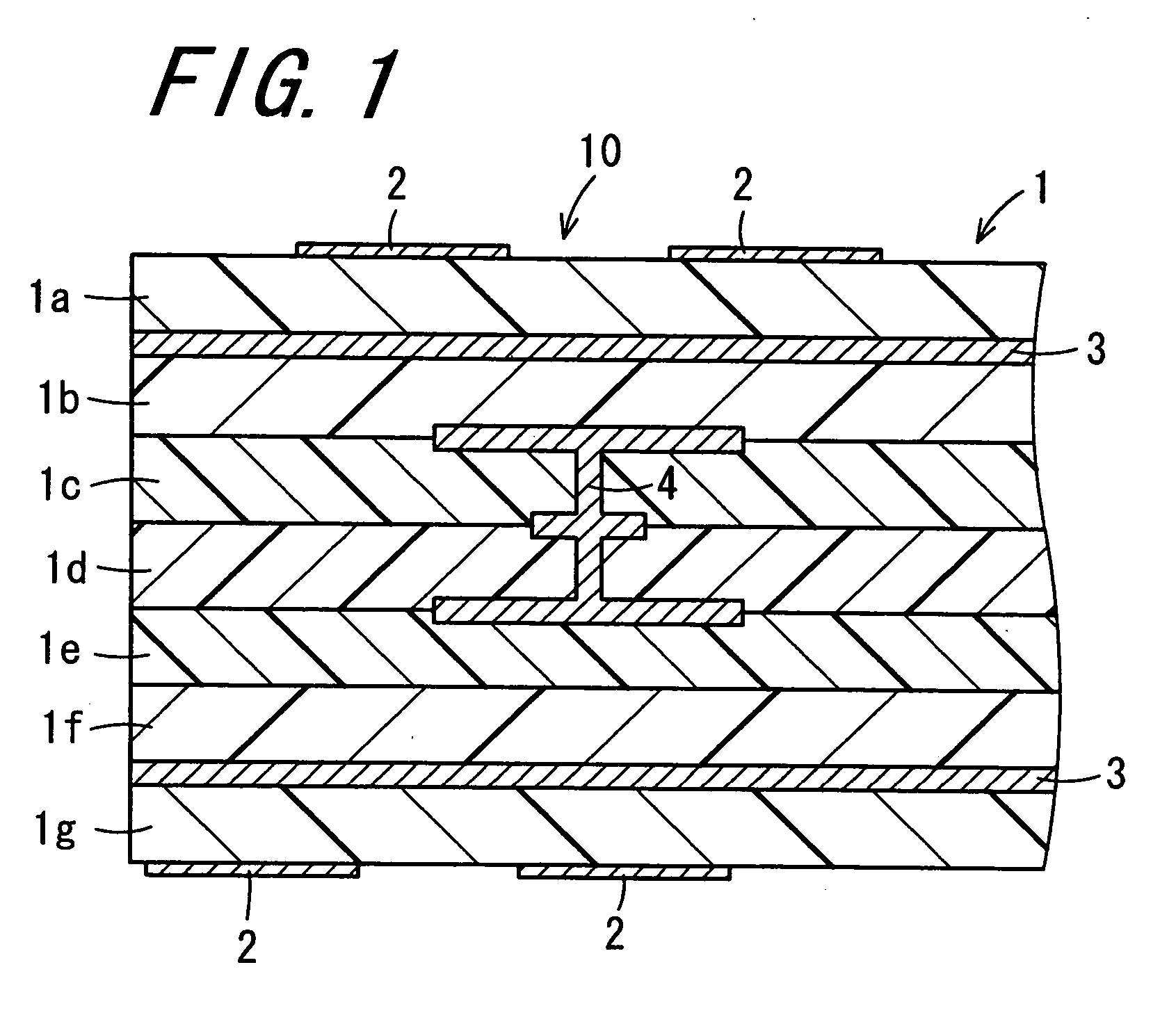

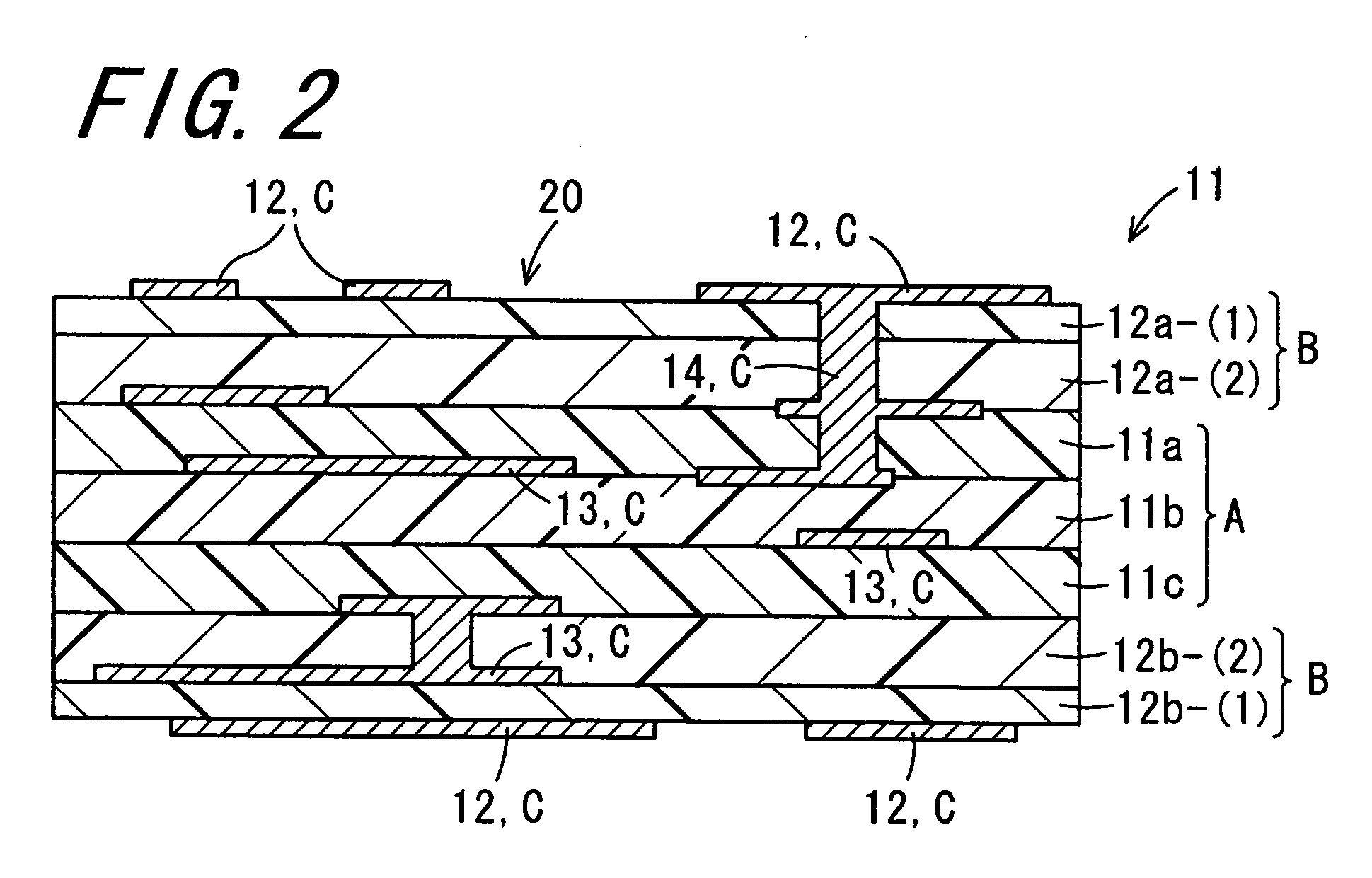

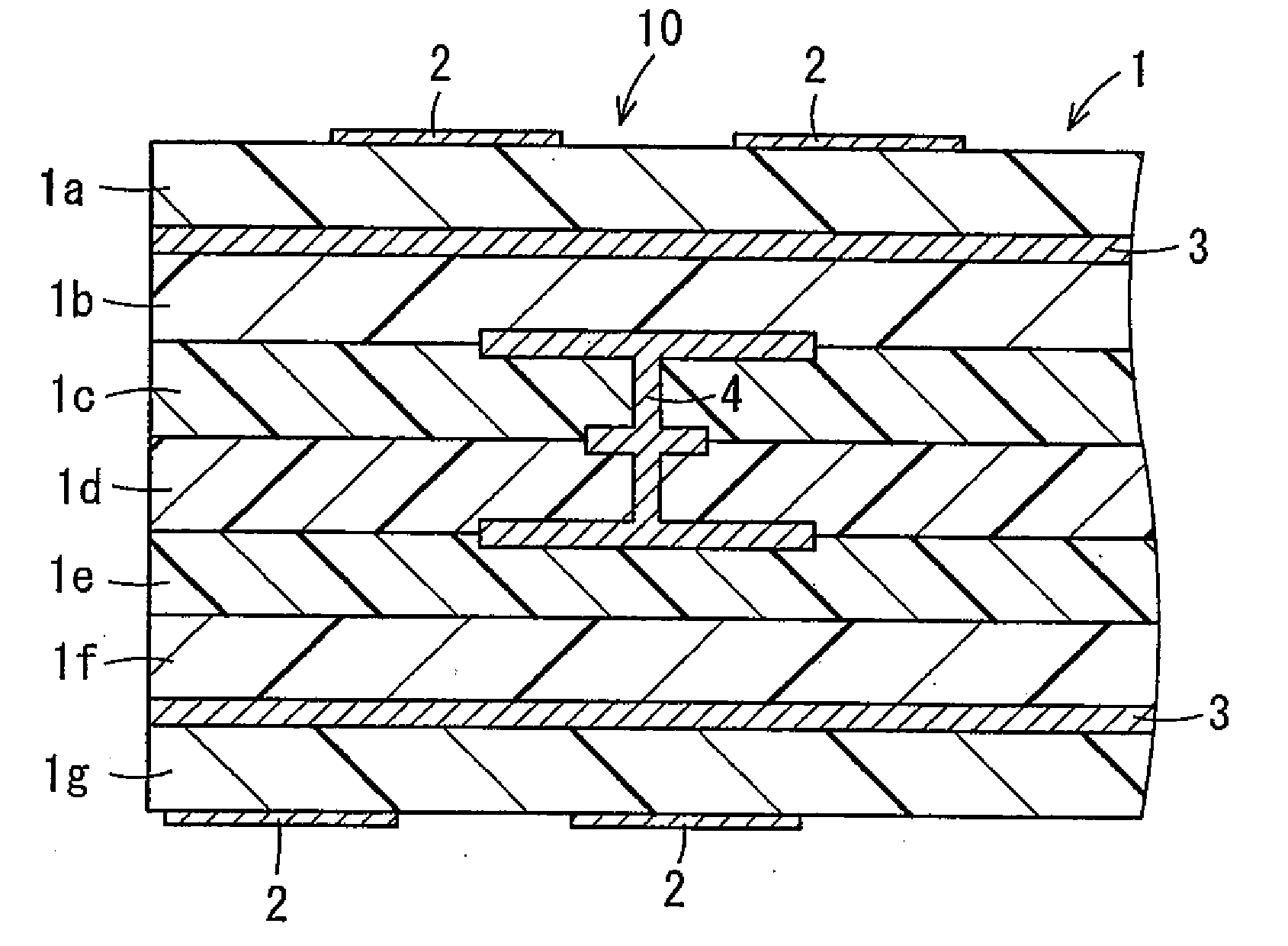

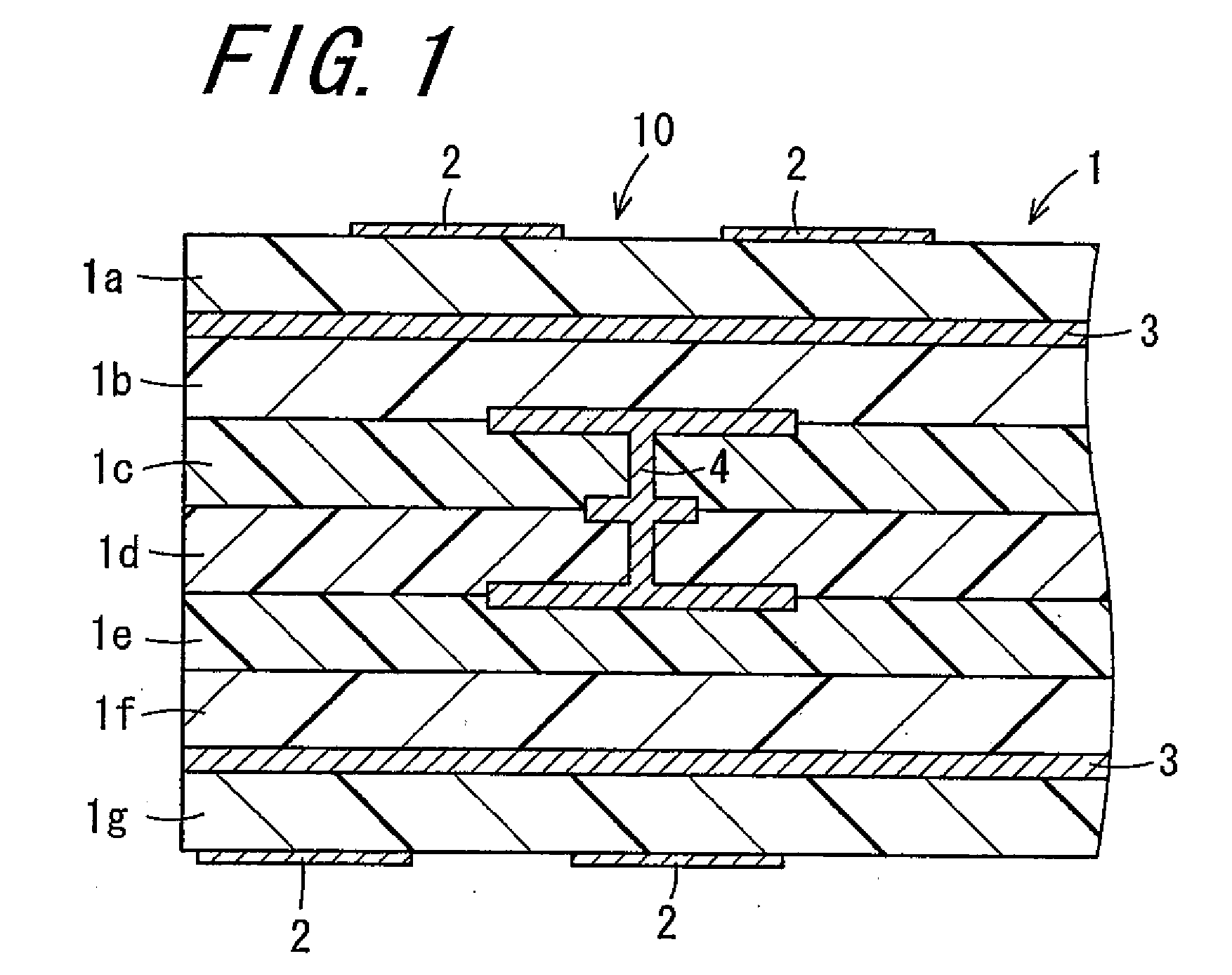

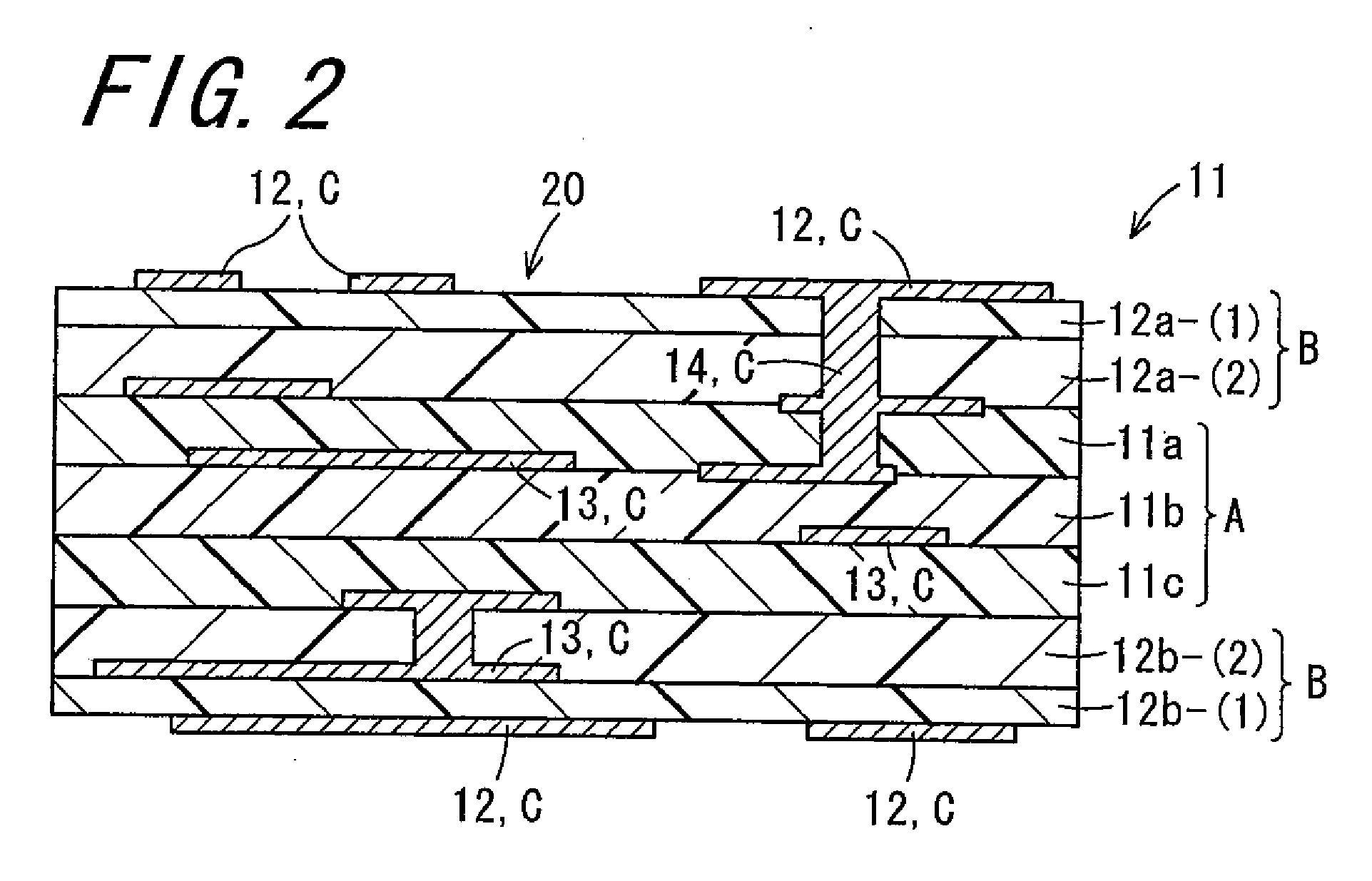

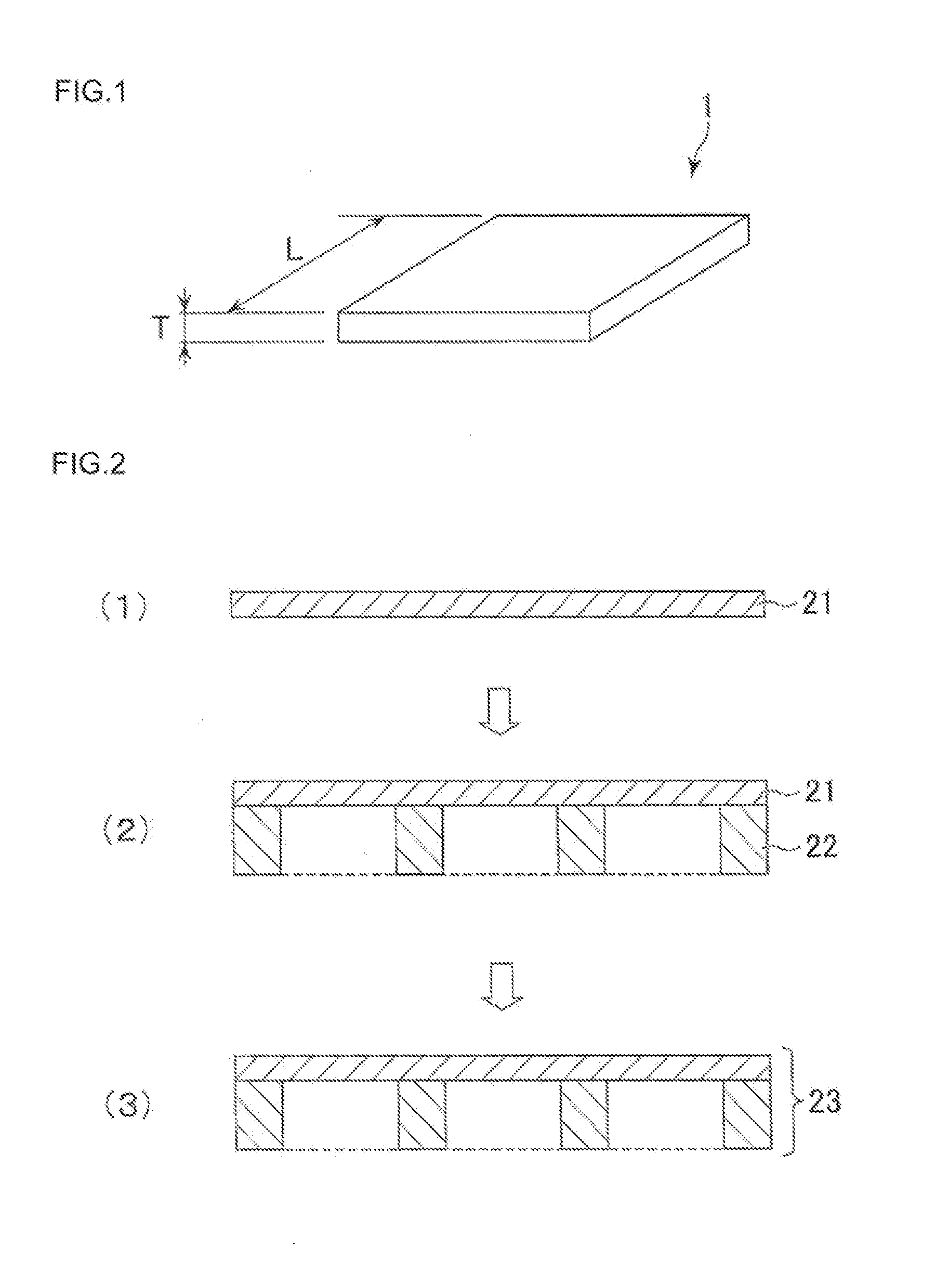

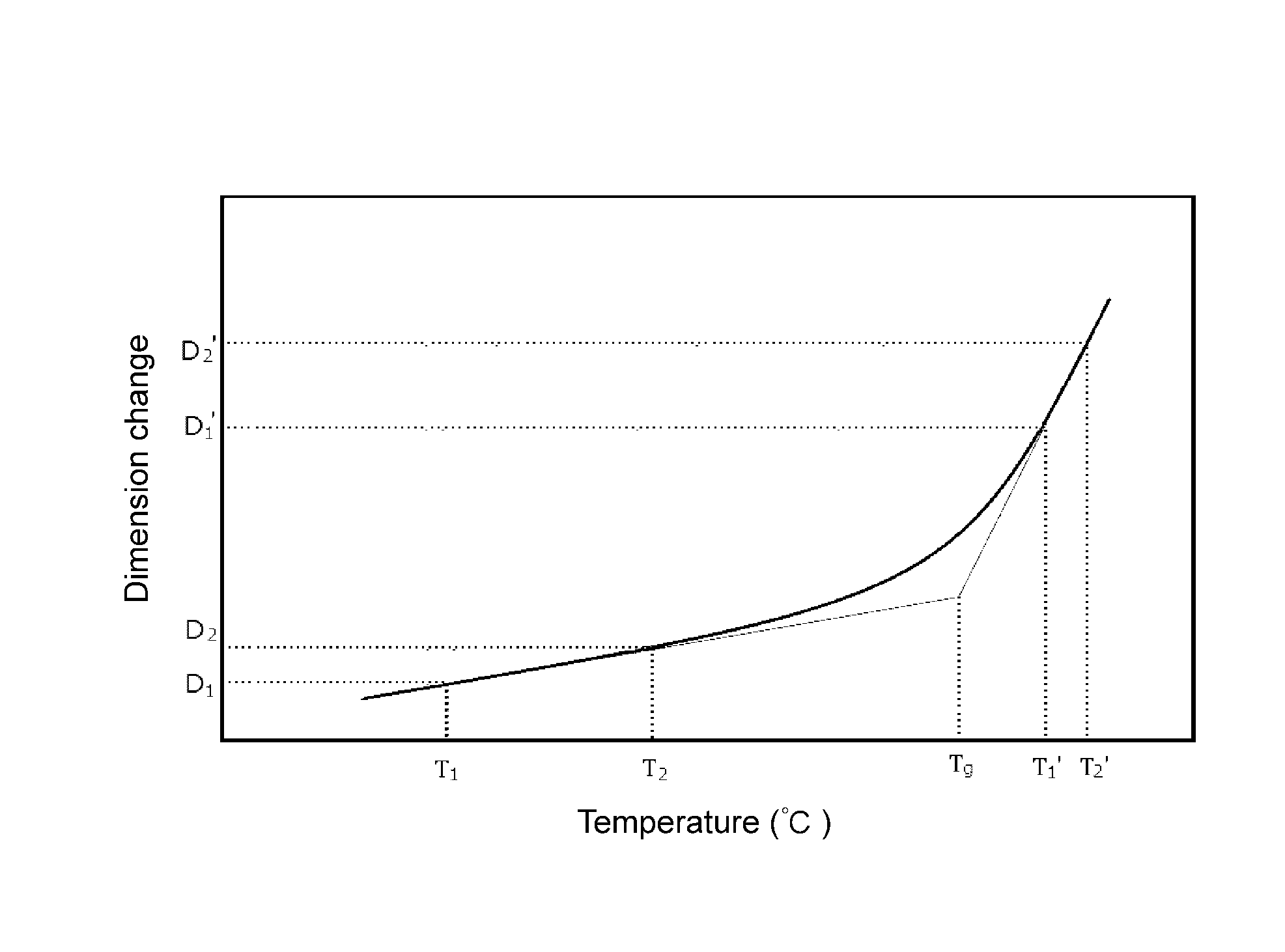

Insulating substrate and manufacturing method therefor, and multilayer wiring board and manufacturing method therefor

ActiveUS20060194032A1Reduce variationExcellent electrical propertiesCeramic layered productsPrinted circuit manufactureThermal expansionCrystallization temperature

There is provided a dimensionally accurate insulating substrate in which plane direction-wise shrinkage is practically zero and shrinkage variations are small. The insulating substrate includes a laminated body composed of at least two kinds of insulating layers made of crystallizable glass ceramics. The crystallization temperature of crystallizable glass contained in the first insulating layer is lower than the softening point of crystallizable glass contained in the second insulating layer. The difference in thermal expansion coefficient between the first and second insulating layers is preferably 2×10−6 / ° C. or below.

Owner:KYOCERA CORP

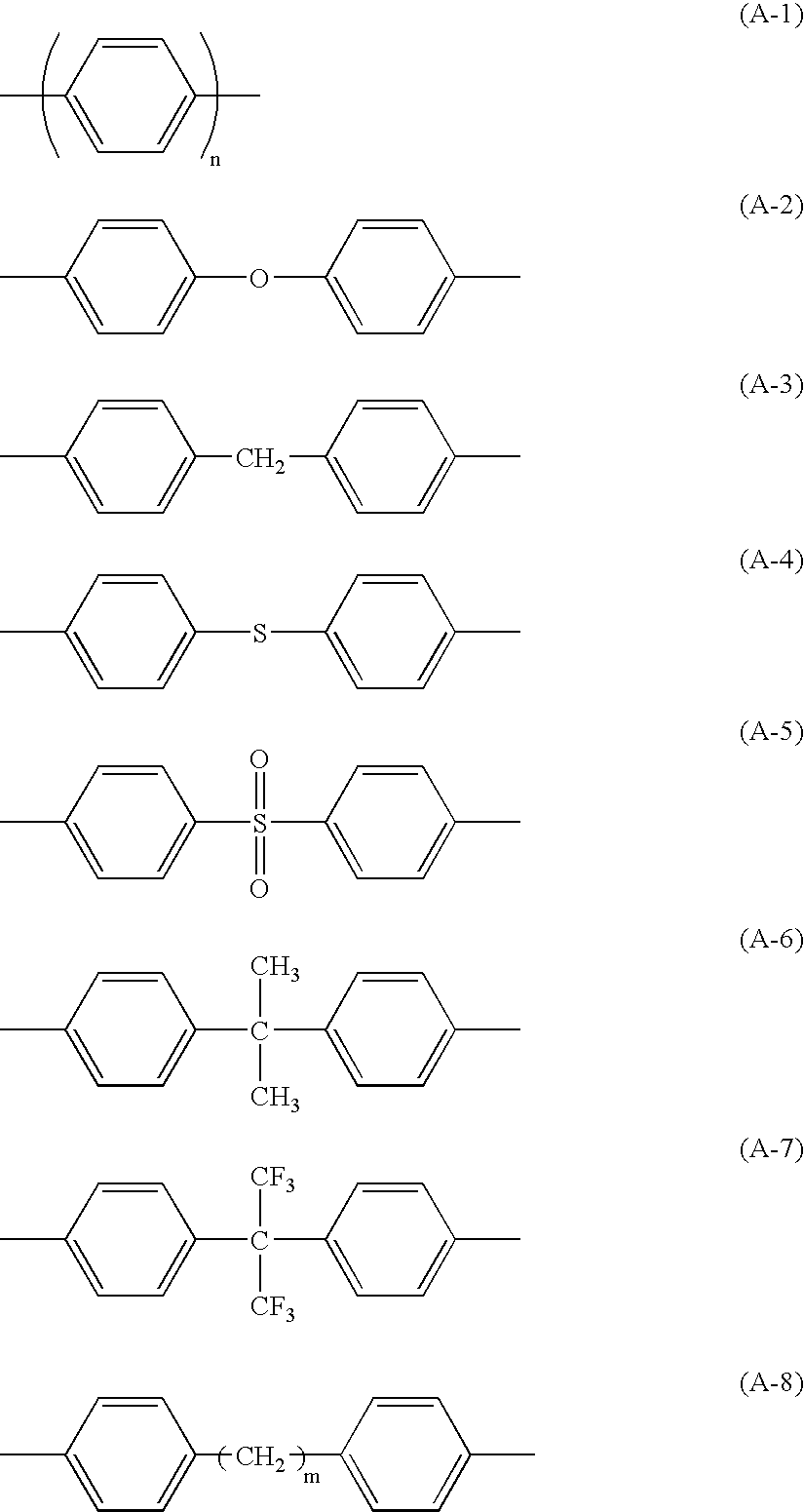

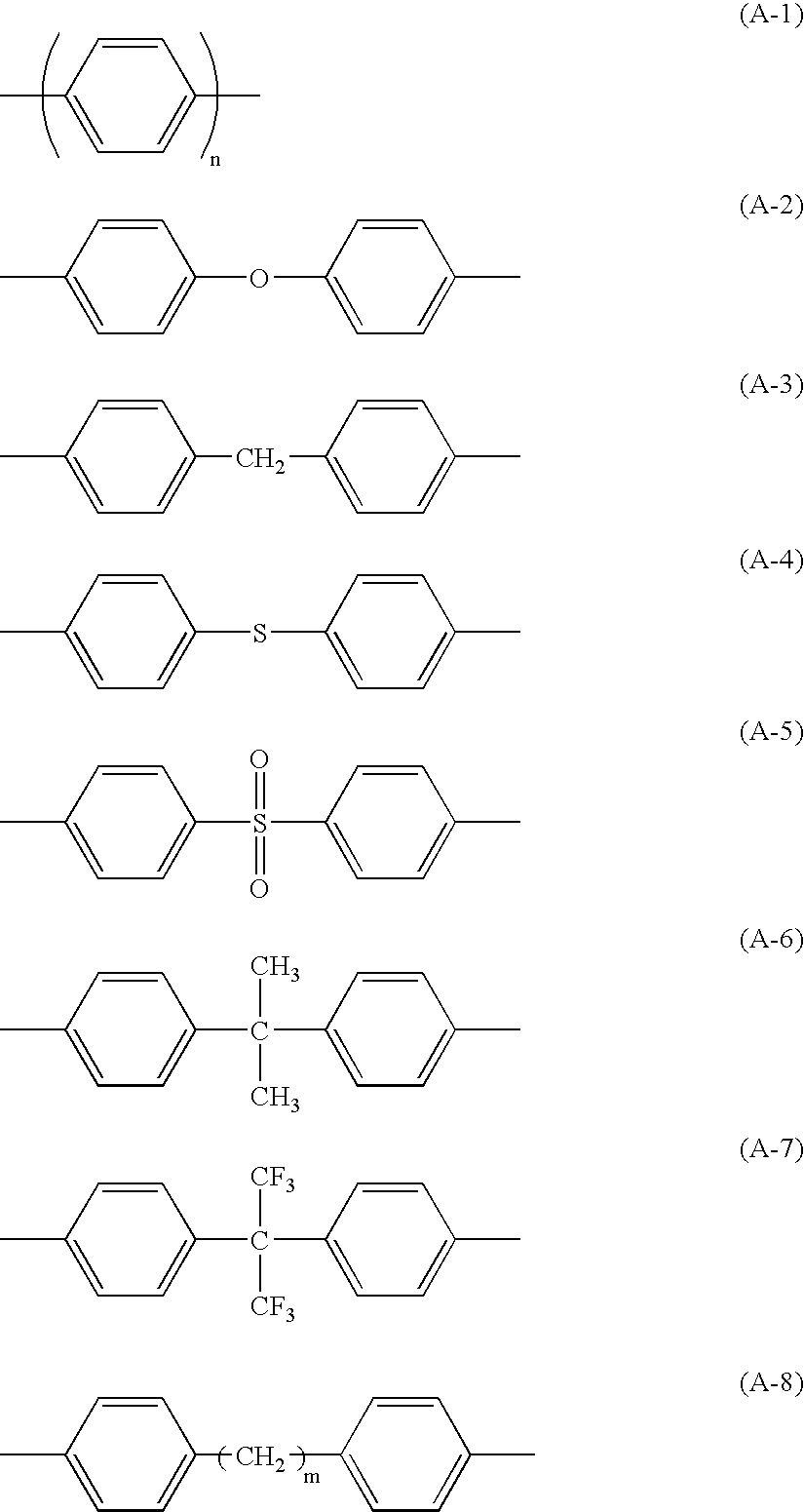

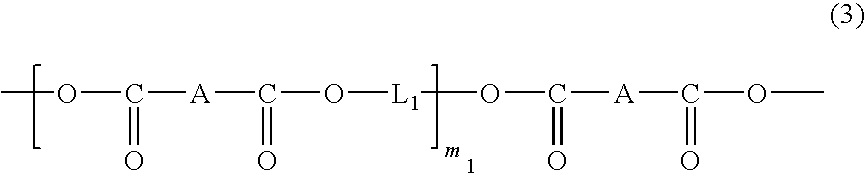

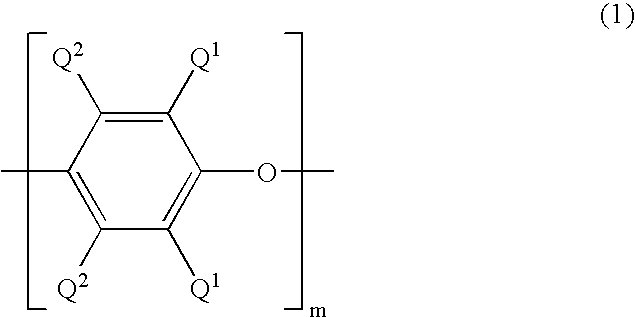

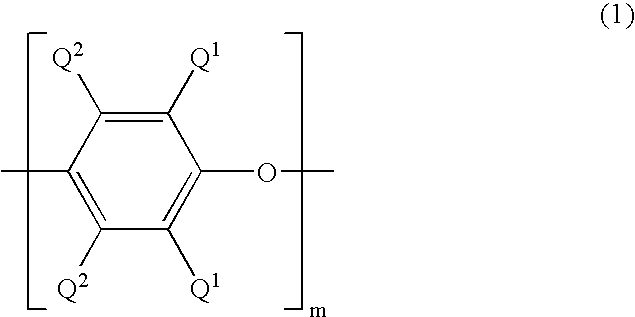

Liquid crystalline polymer cpmposition and use thereof

InactiveUS20070293633A1Little warpageSmall size changeLiquid crystal compositionsLiquid crystallinePolymer science

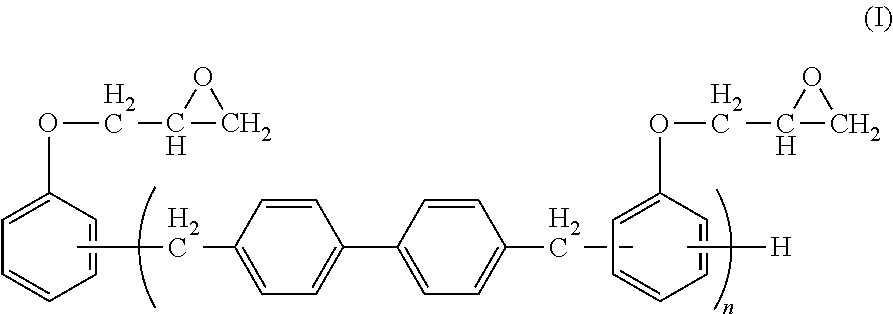

The present invention provides a liquid crystalline polymer composition comprising (A) a polymer including units of formula (I), and units of formula (II) and / or units of formula (III), the units of formula (I) being included in 15-80% by mol, based on the total units [(I)+(II)+(III)]; and (B) a polymer (B) including units of formula (IV), formula (V) and the formula (VI), each of units being included in 30-80% by mol, 10-35% by mol and 10-35% by mol, respectively, based on the total units [(IV)+(V)+(VI)], the component (B) being included in 5-80% by weight based on the total weight of the components (A) and (B); wherein (I) —(VI) are —OC—Ar1-0-, —O—Ar2—O—, —OC—Ar3—CO—, —OC—Ar4—O—, —O—Ar5—X— and —OC—Ar6—CO—, respectively.

Owner:SUMITOMO CHEM CO LTD

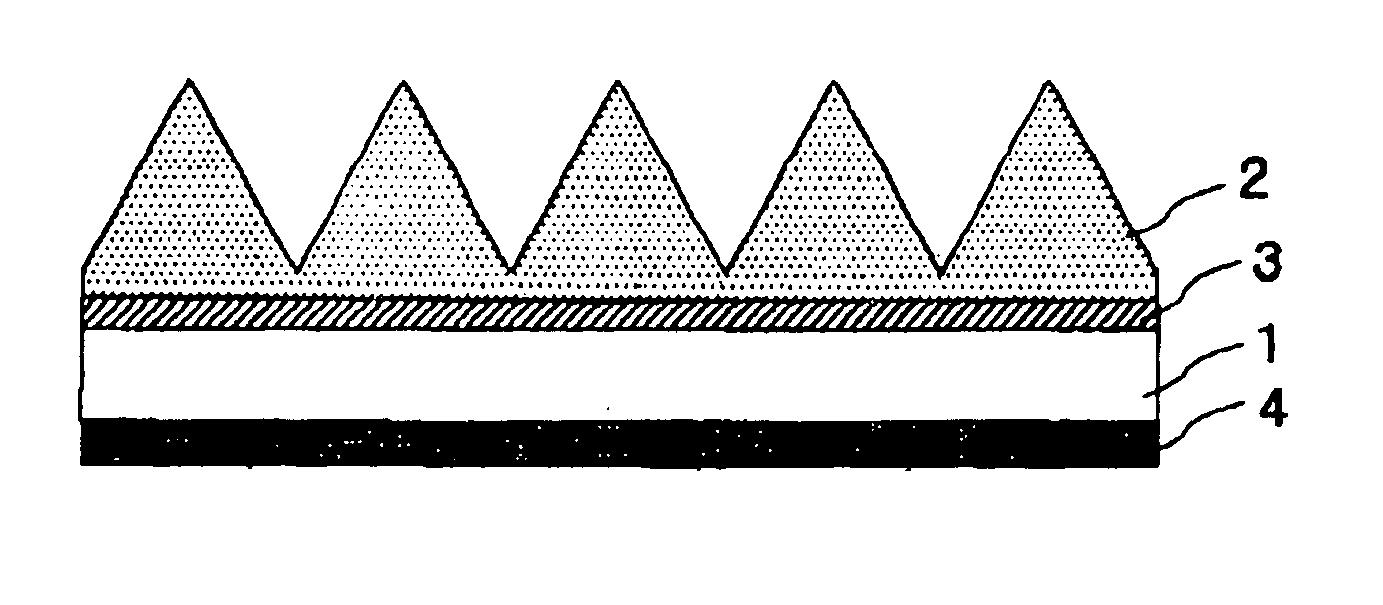

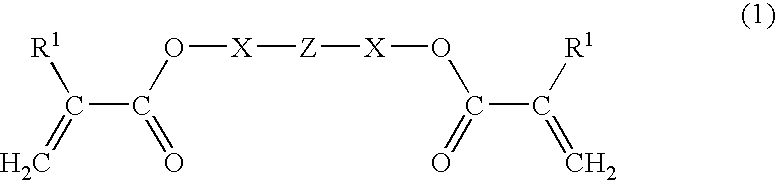

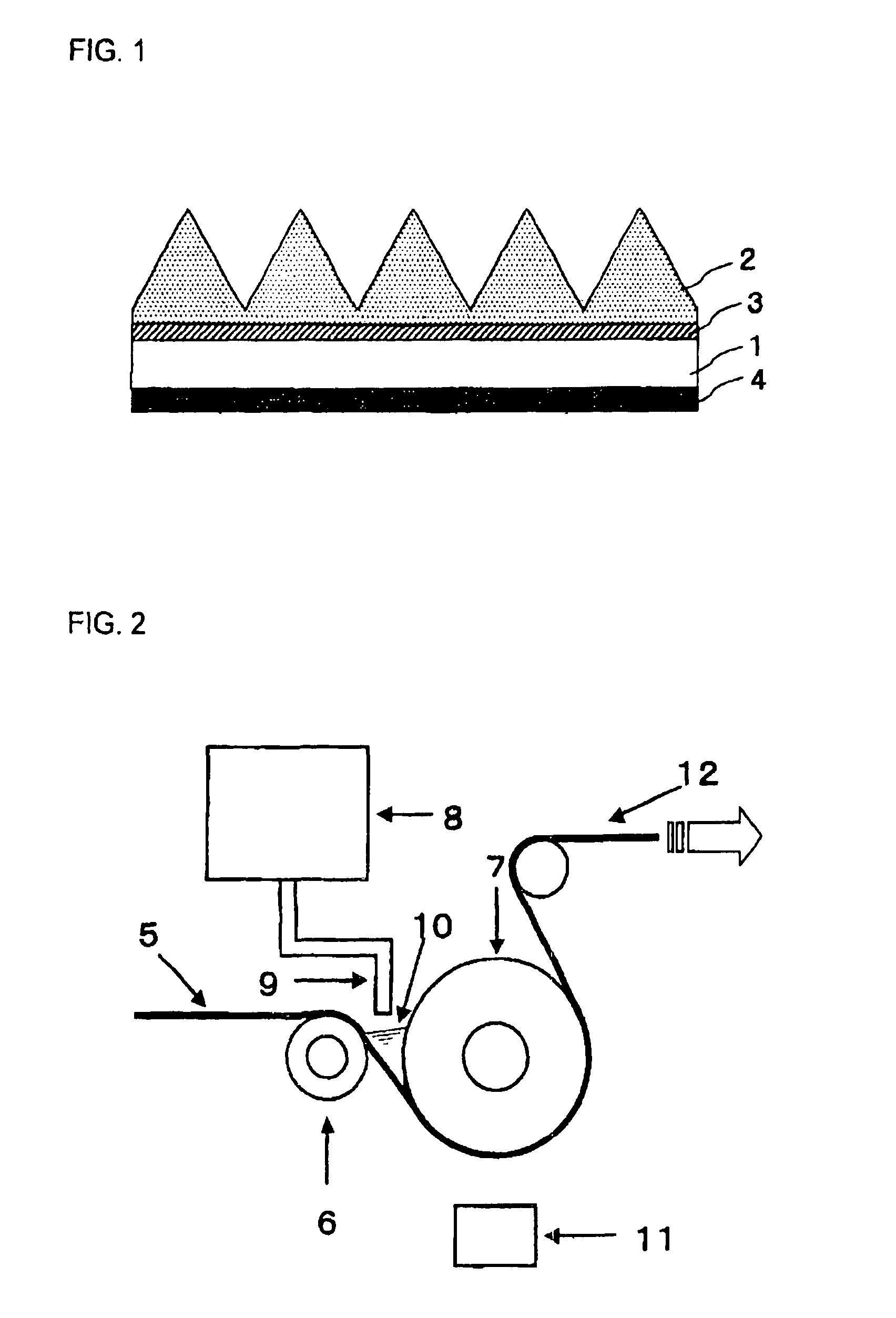

Active energy ray curable resin composition and sheet-like optical article

InactiveUS20090030104A1Reduce warpageImprove heat resistanceMixing methodsDiffusing elementsHeat resistancePrism

An active energy ray curable resin composition for a sheet-like optical article capable of providing a cured material having a dynamic elastic modulus at 25° C. of 950 MPa or less and a dynamic elastic modulus at 60° C. of 100 MPa or more and a sheet-like optical article prepared from the resin composition are disclosed. The sheet-like optical article (e.g., prism sheet) has good heat resistance and extremely small warpage.

Owner:MITSUBISHI CHEM CORP

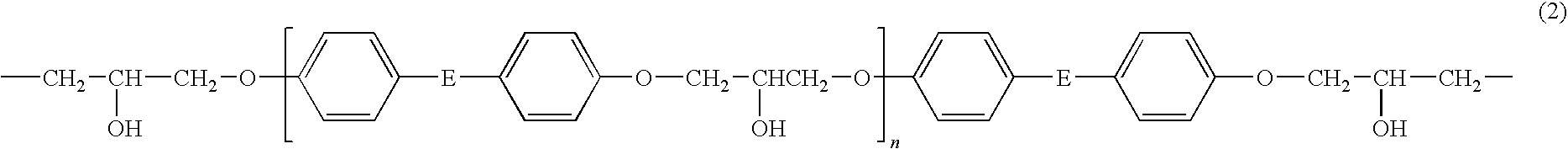

Utraviolet-curable composition for optical disk and optical disk

InactiveUS20090324870A1Reduce distortion problemsIncreased durabilityLayered productsRecord information storagePolyesterUV curing

By using an ultraviolet-curable composition, which contains a specific ultraviolet-curable compound obtained by modifying a bisphenol epoxy compound with a polyester having a flexible structure, as a light transmission layer. Accordingly, the present invention achieves an optical disk having excellent characteristics such as excellent durability, excellent light resistance and excellently reduced warp, while suppressing deterioration of the light reflection film due to environment of high temperature and high humidity or light exposure. Consequently the ultraviolet-curable composition of the present invention is most suitable for optical disks having a thick light-transmitting layer on which recording / reproduction is performed by using a blue laser.

Owner:DAINIPPON INK & CHEM INC

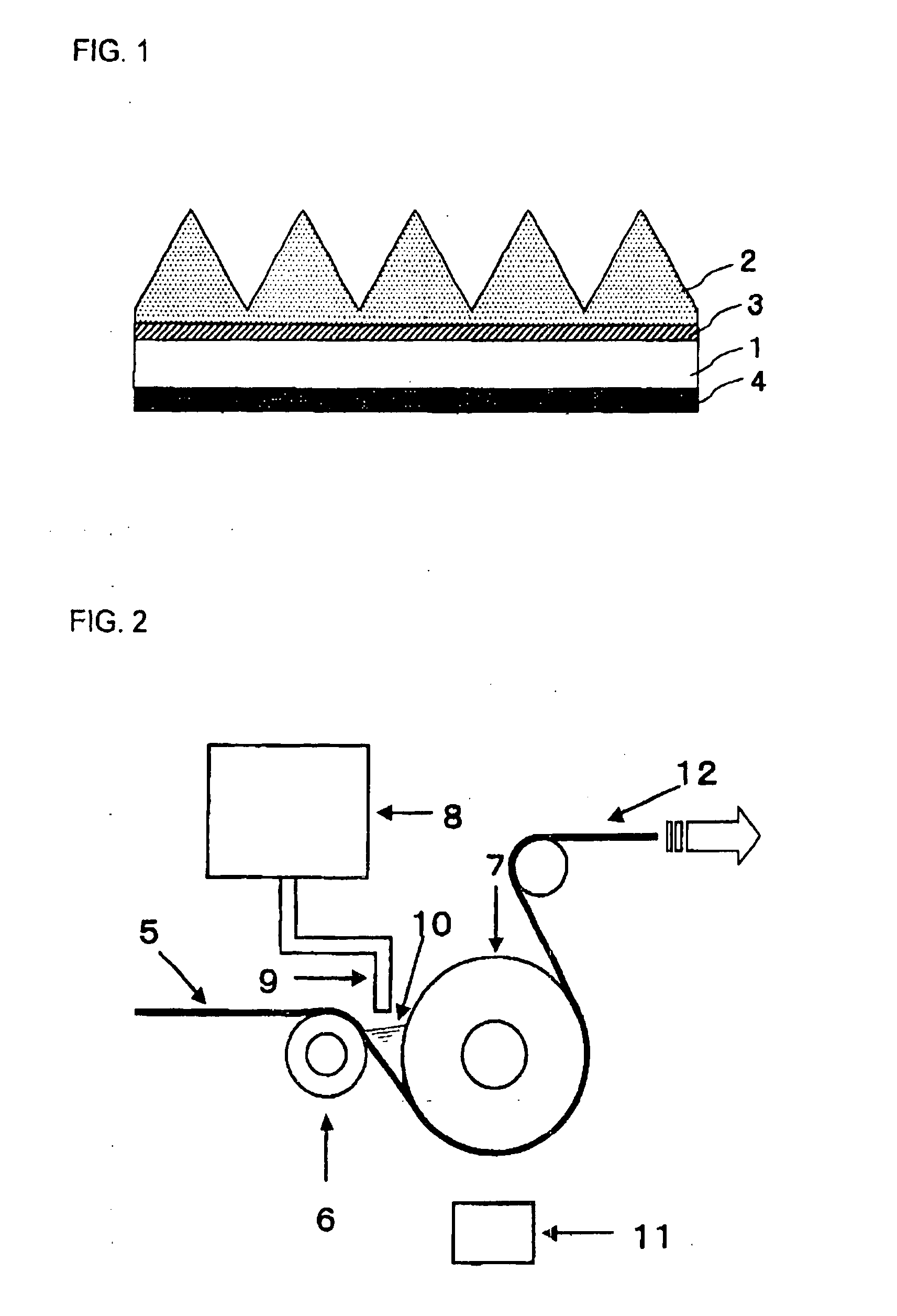

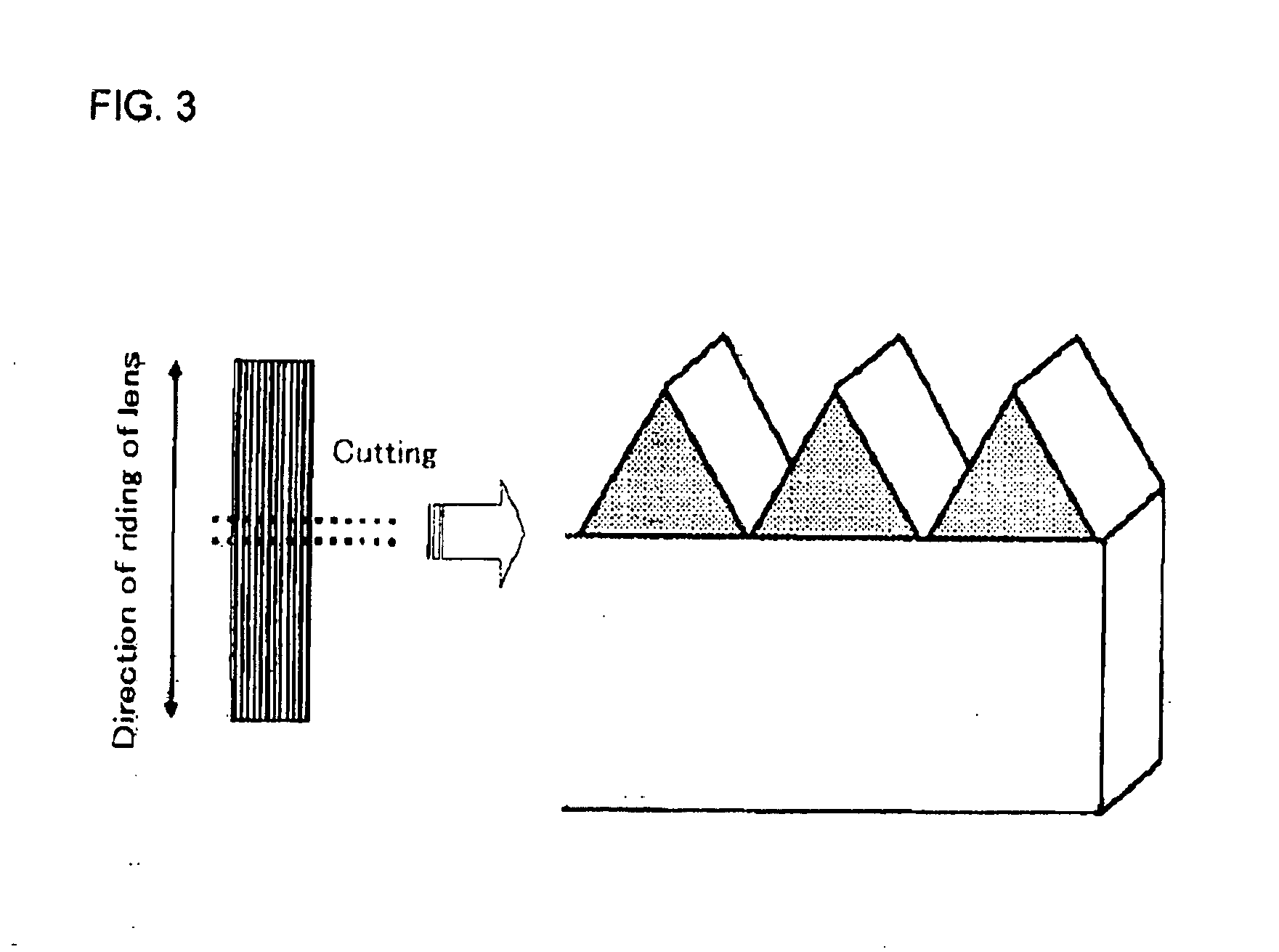

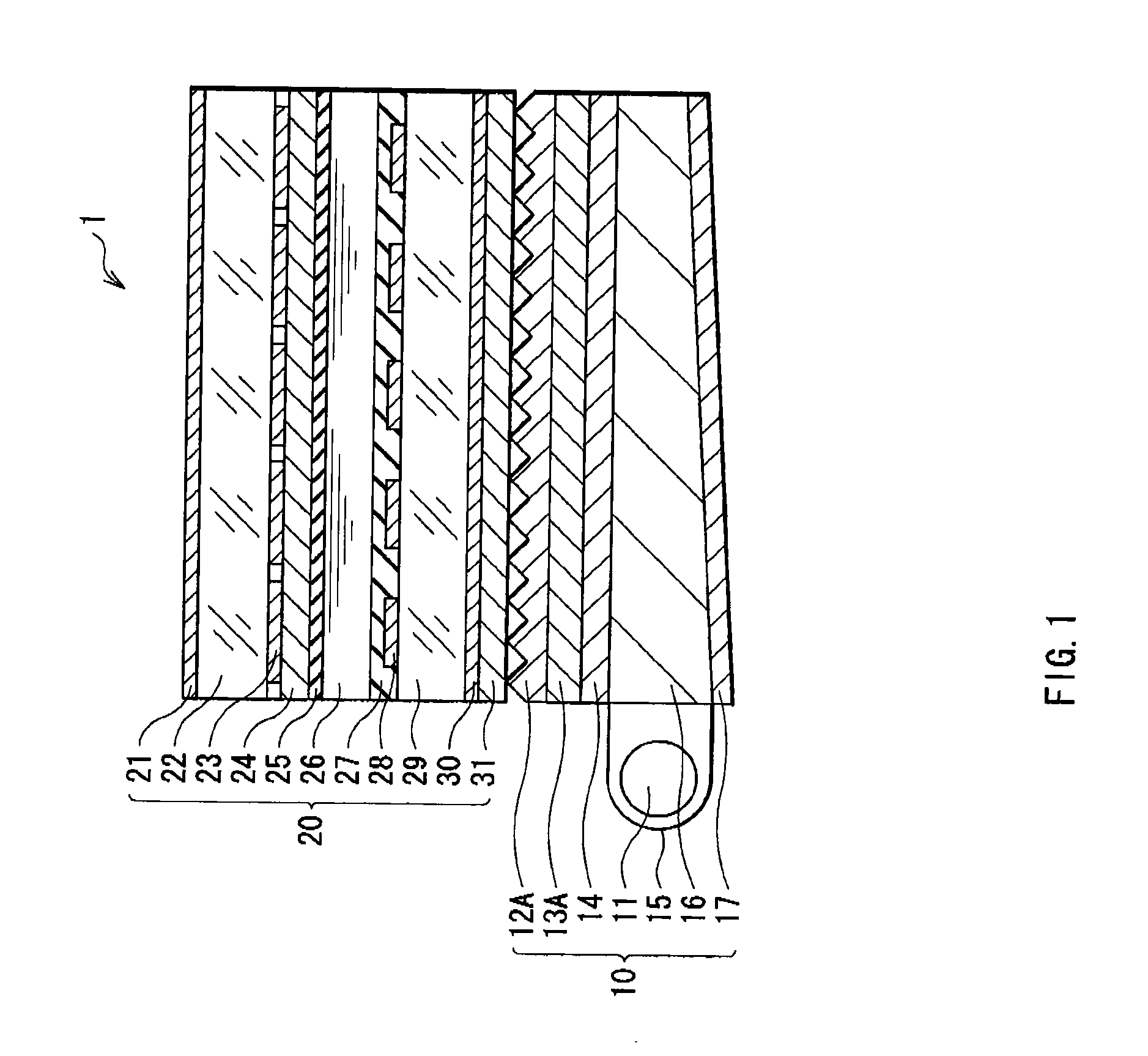

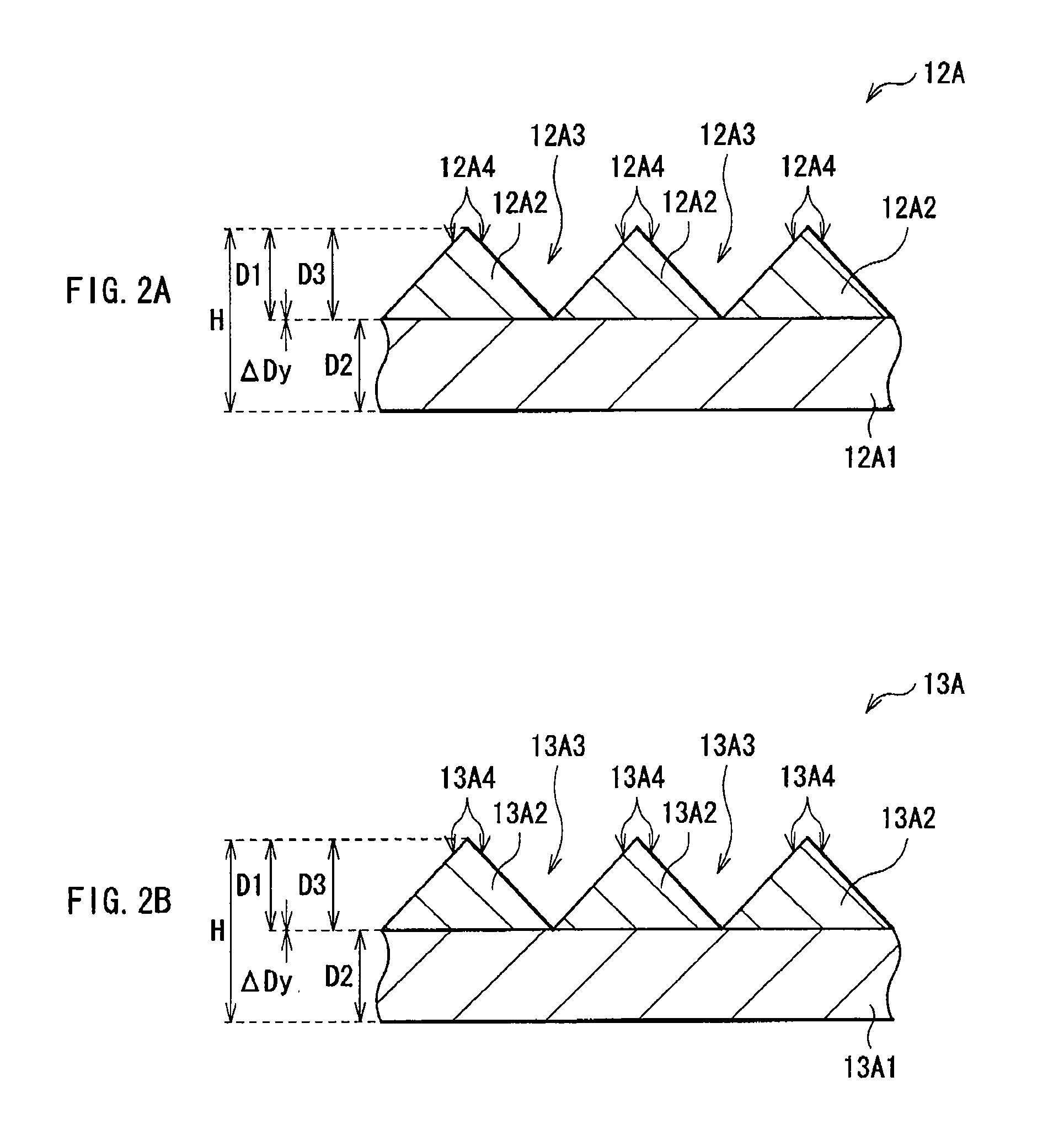

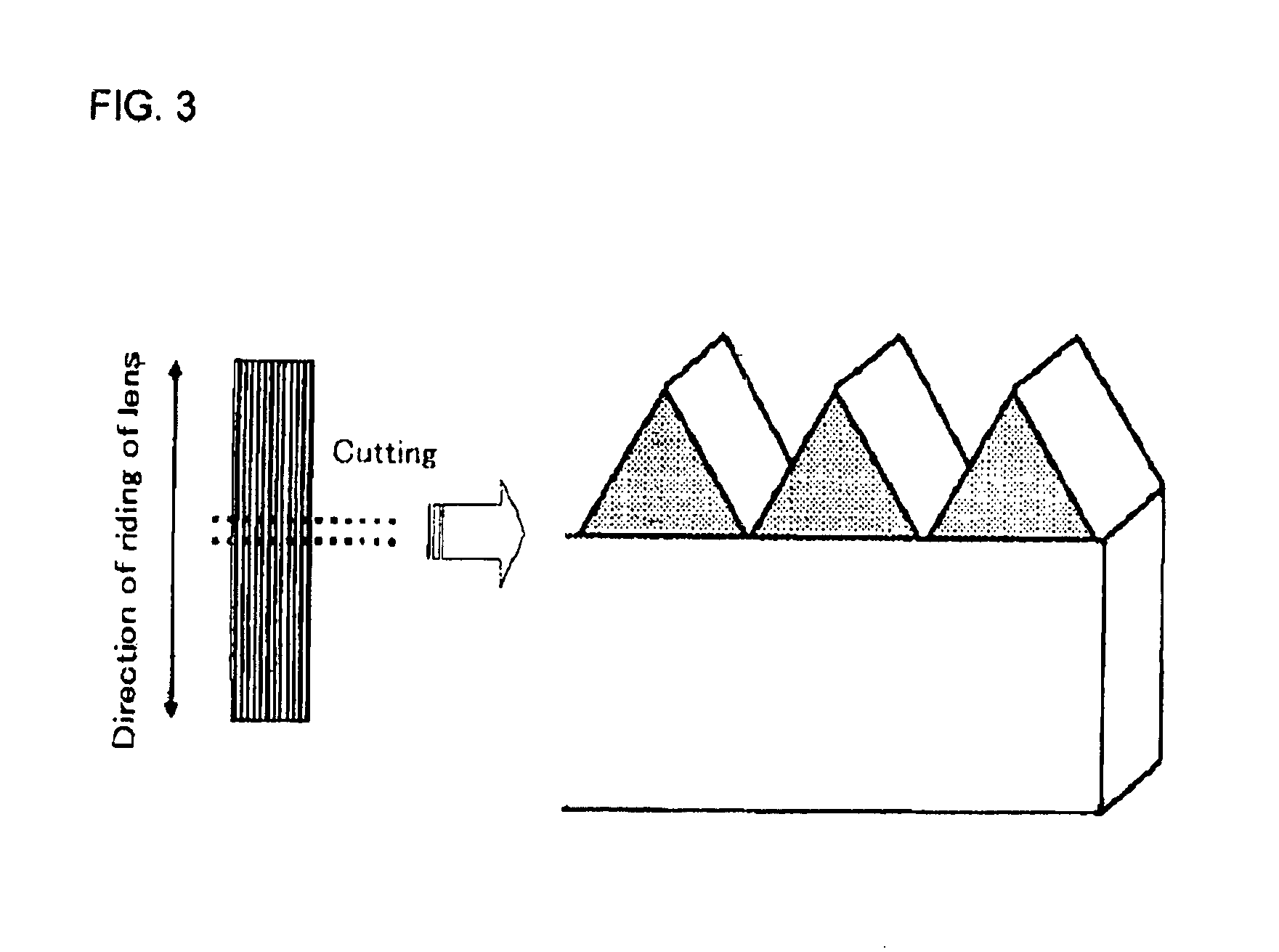

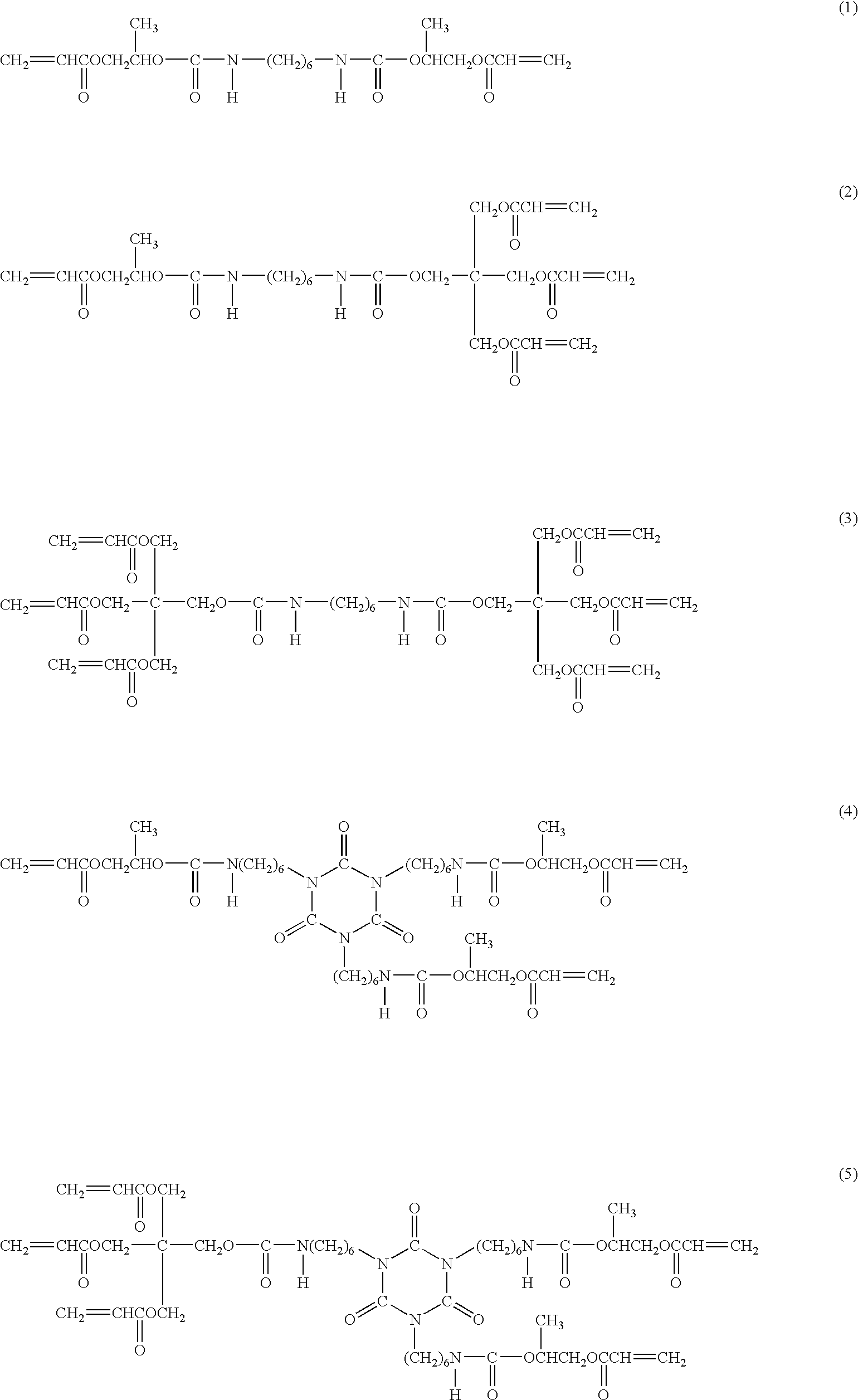

Optical sheet, method for producing the same and display apparatus

ActiveUS20070258030A1Reduced strengthImprove shrinkage ratioPrismsDiffusing elementsEngineeringPrism

A lens film with small warpage even when a transparent base is thin is provided. Pole prisms made of a hardening resin are arranged along the extending direction on a transparent base made of flexible material. The transparent base has a depression according to a valley between the pole prisms adjacent to each other. The pole prism has a sloping face extending to an inner wall of the he depression. The transparent base is in contact with the valley. A layer not functioning as a prism, that is, a so-called skirt layer does not exist between the transparent base and the pole prisms.

Owner:SATURN LICENSING LLC

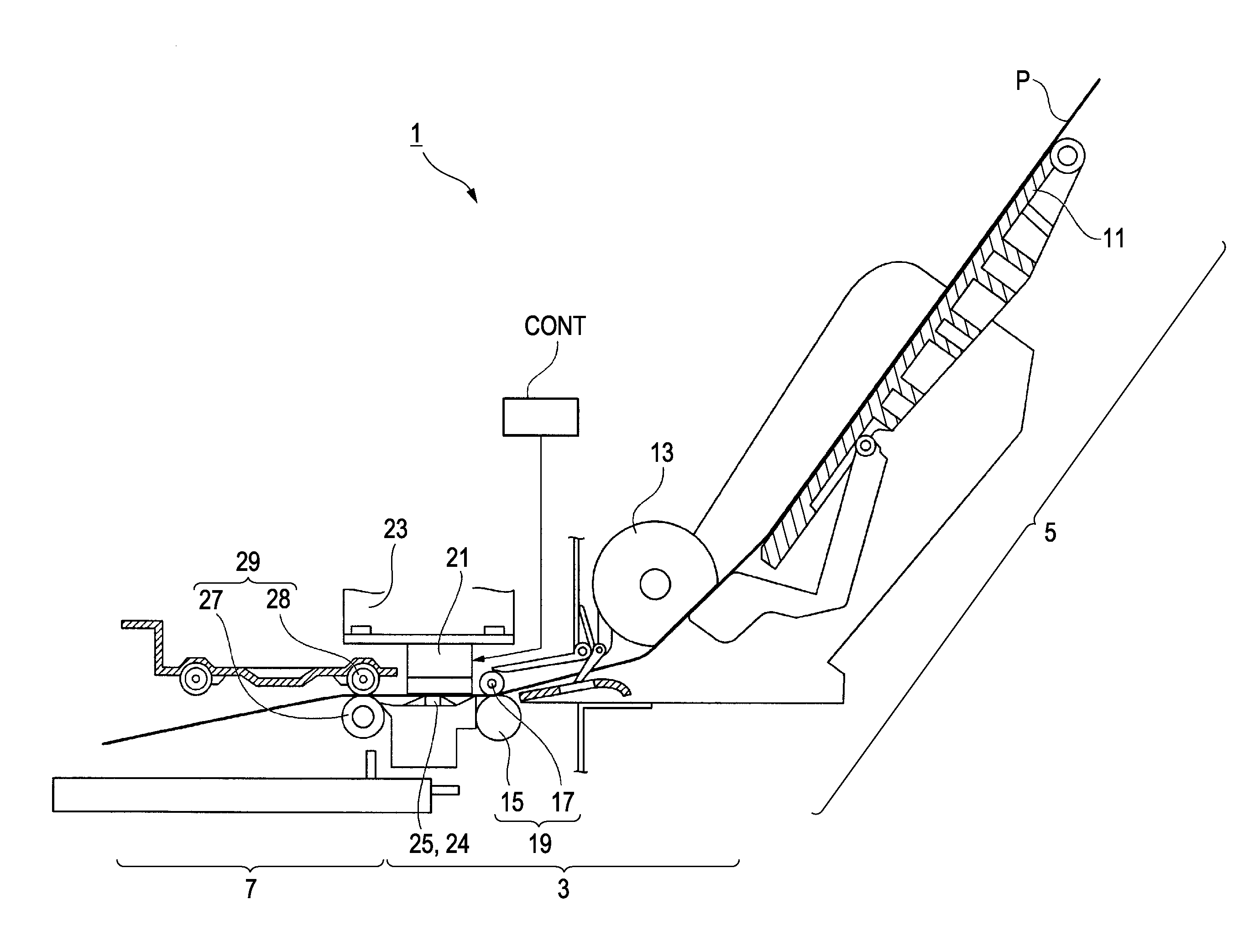

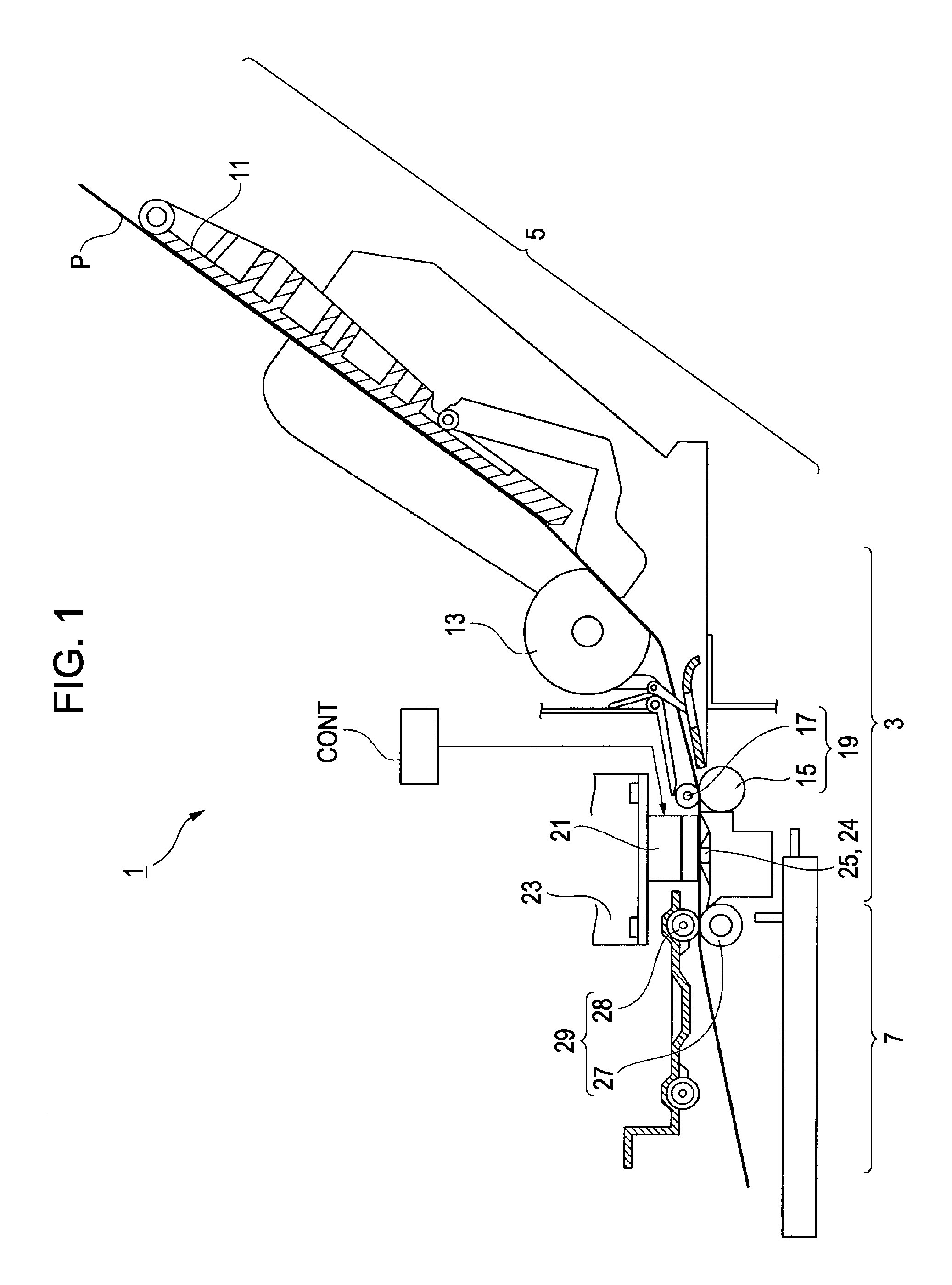

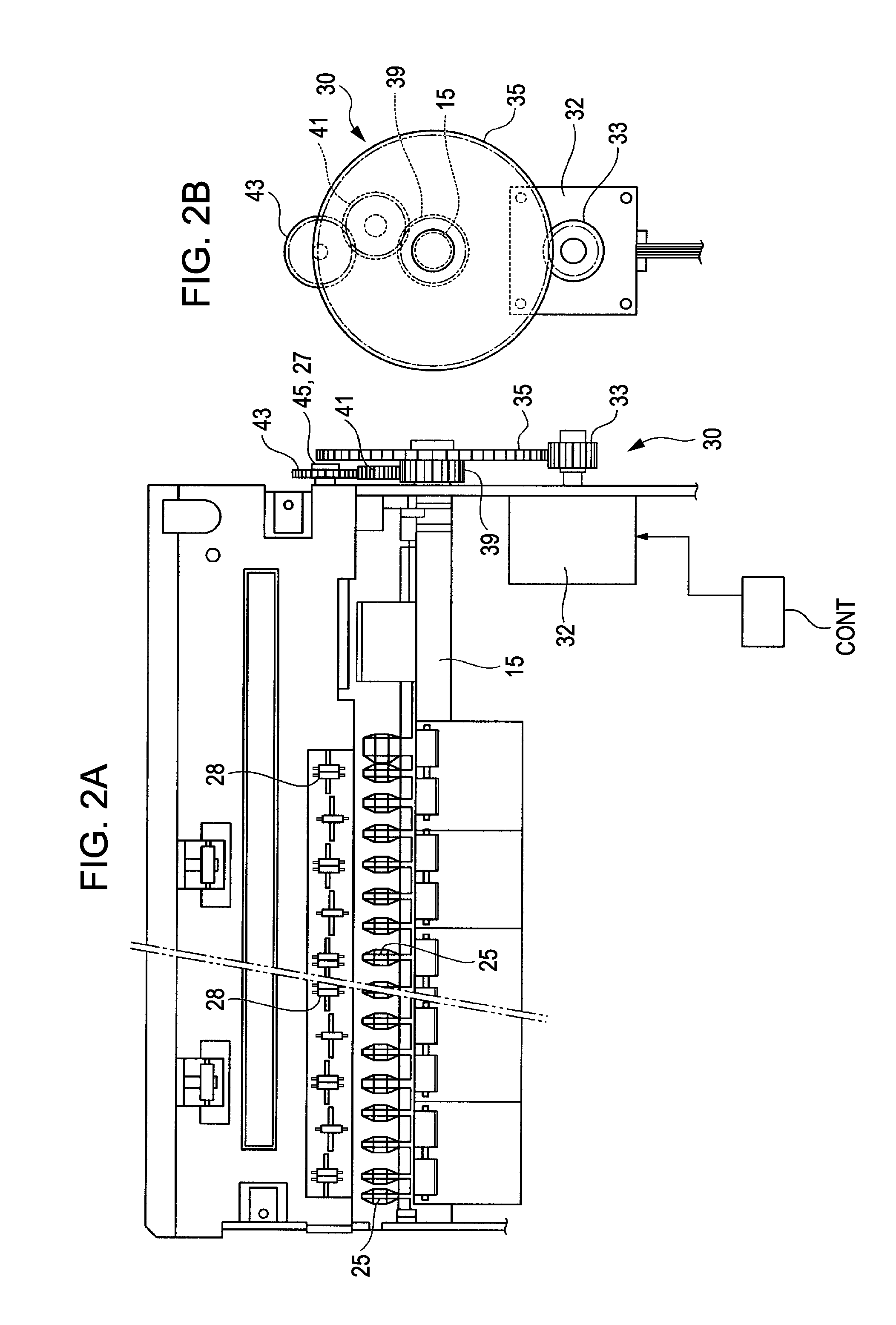

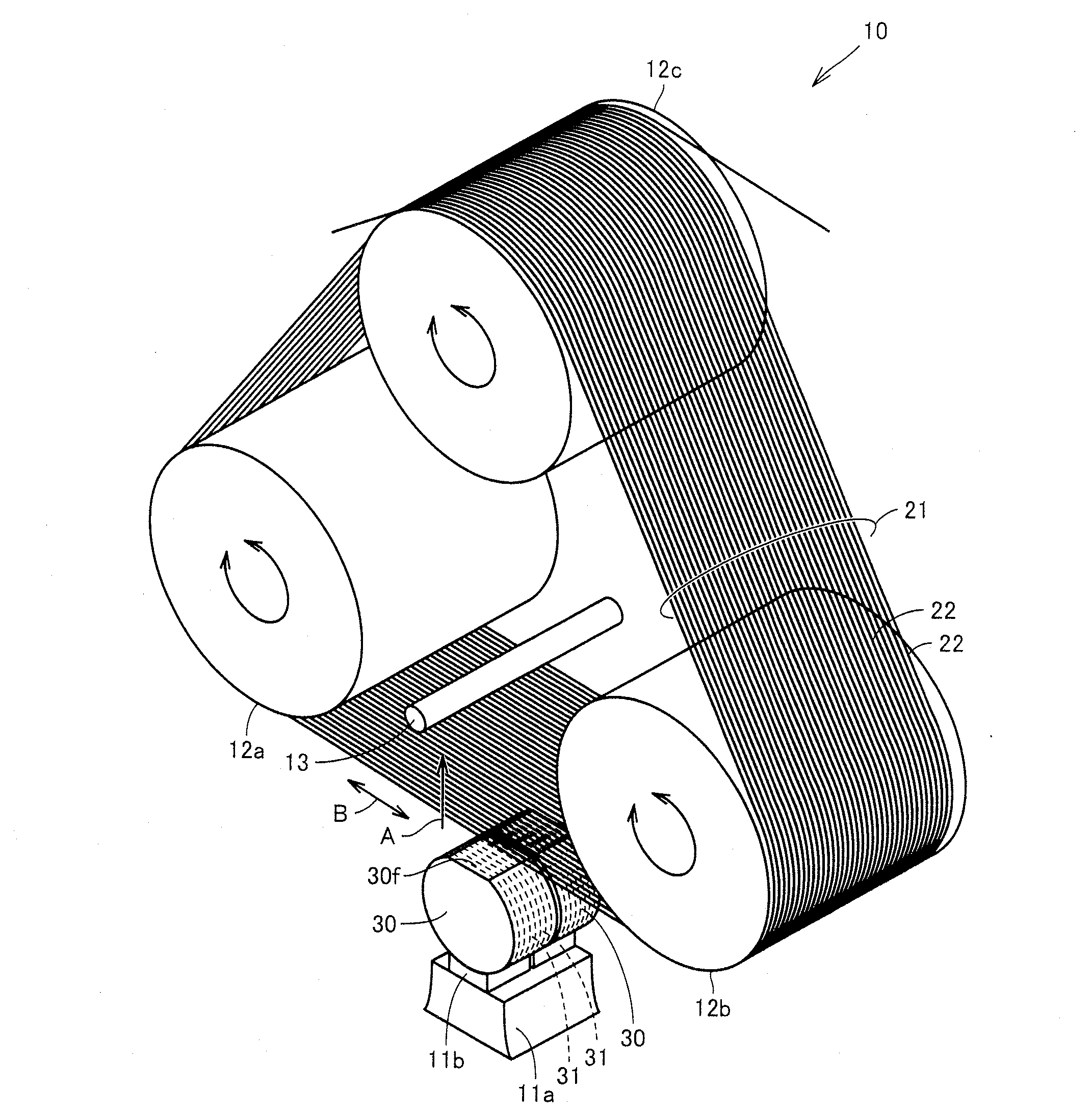

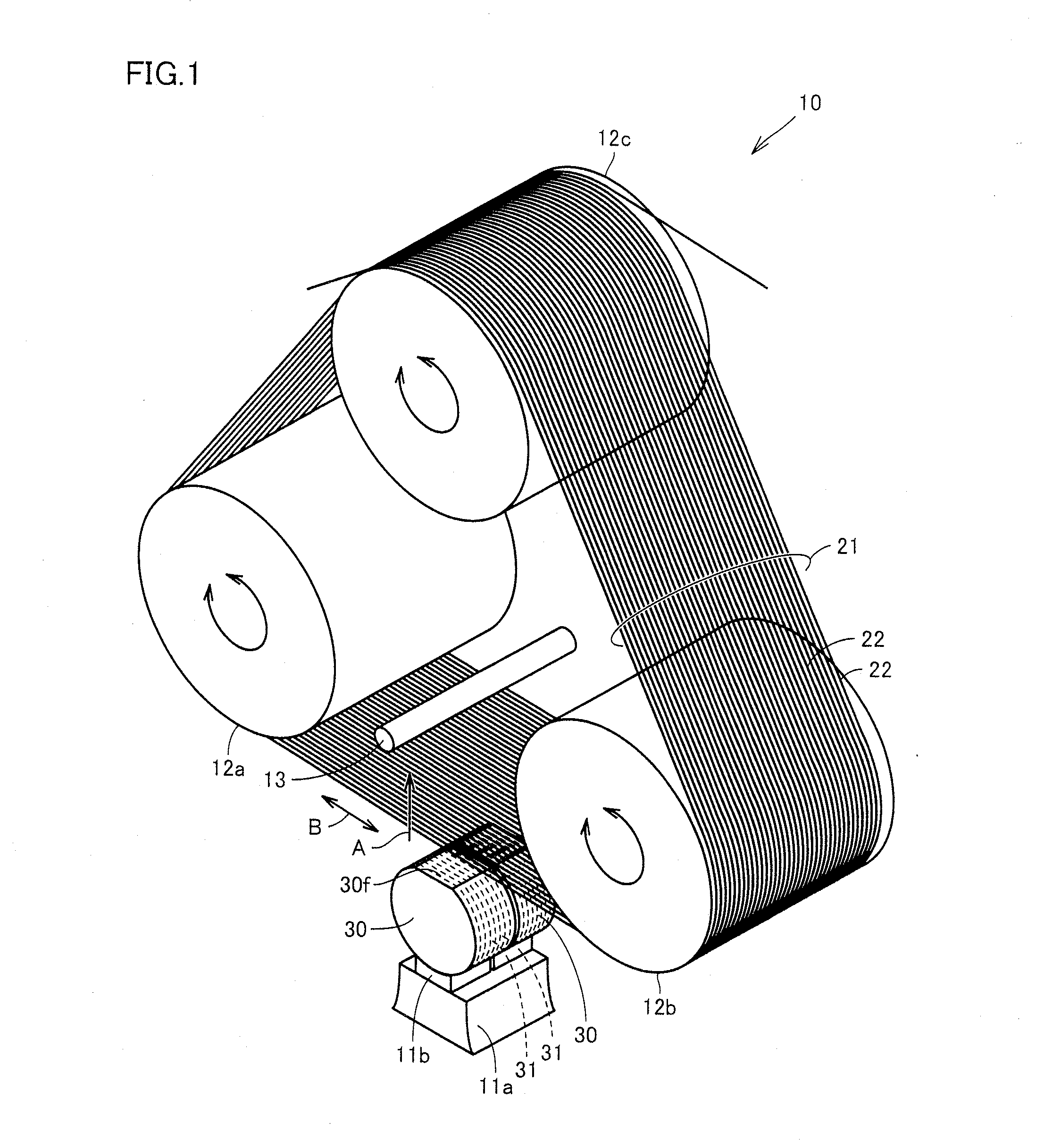

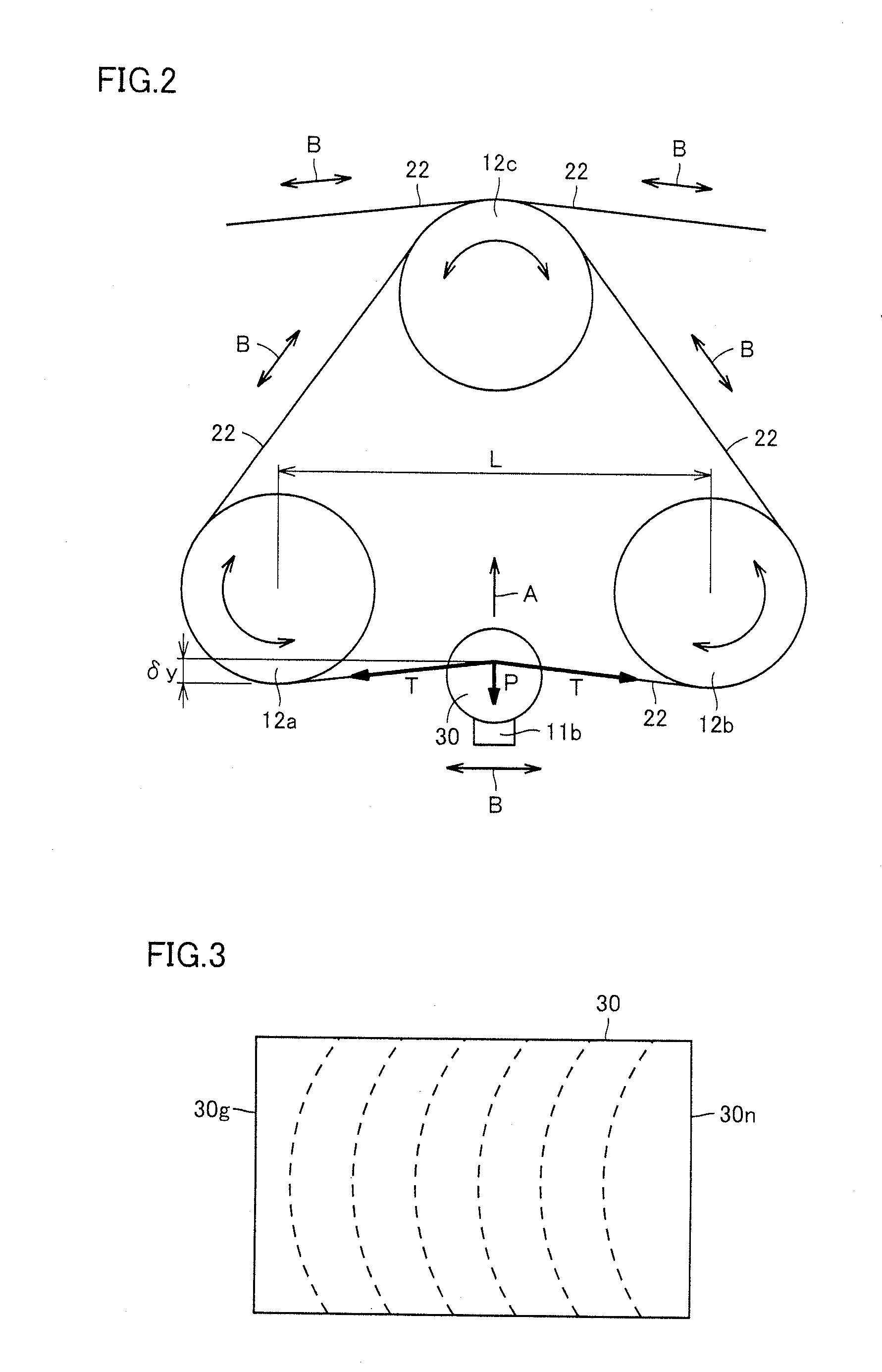

Transportation roller, transportation unit, printing apparatus, and method of manufacturing transportation roller

InactiveUS20110142524A1Large thicknessShorten the timeShaft and bearingsPortable power-driven toolsEngineeringMetal sheet

Provided is a transportation roller, a transportation unit, a printing apparatus, and a method of manufacturing a transportation roller capable of reducing warpage with the elapsing of time. A transportation roller includes: a roller body which is formed in a cylindrical shape by subjecting a metal sheet to a pressing process and allowing a pair of end portions thereof to face each other, and has a joint formed between the pair of end portions, wherein in a sectional shape perpendicular to the axis of the roller body, a thickness of a joint facing portion facing the joint with the axis interposed therebetween is larger than a thickness of a joint portion provided with the joint, and a thickness of the roller body connecting the joint facing portion and the joint portion is gradually changed as it goes from the joint facing portion to the joint portion.

Owner:SEIKO EPSON CORP

Saw wire and method of manufacturing group iii nitride crystal substrate using the same

InactiveUS20130061841A1High yieldHigh tensile strengthSemiconductor/solid-state device manufacturingMetal sawing toolsSulfurCopper

A method of manufacturing a group III nitride crystal substrate slices a group III nitride crystal body with a saw wire which includes a steel wire having a carbon concentration of 0.90-0.95 mass %, a silicon concentration of 0.12-0.32 mass %, a manganese concentration of 0.40-0.90 mass %, a phosphorus concentration of 0.025 mass % or less, a sulfur concentration of 0.025 mass % or less, and a copper concentration of 0.20 mass % or less, and has a diameter of not less than 0.07 mm and less than 0.16 mm, a tensile strength at break of higher than 4200 N / mm2, and a curl size of 400 mm or more, with a tension of not less than 50% and not more than 65% of the tension at break applied to the saw wire. Thus, group III nitride crystal substrates with small warpage can be manufactured.

Owner:SUMITOMO ELECTRIC IND LTD

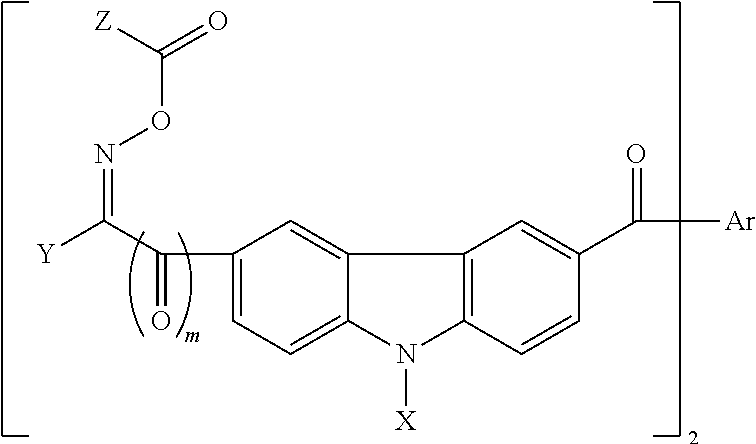

Novel photosensitive resin composition and use thereof

ActiveUS20130264099A1Good non-stickGood flexibilityPhotosensitive materialsPhotosensitive material processingCross-linkCrosslinked polymers

In order to provide (A) a photosensitive resin composition which (i) obtains an excellent tack-free property after being applied and dried, (ii) can be subjected to fine processing so as to have photosensitivity, (iii) prepares a cured film having excellent flexibility, flame retardancy, and electrical insulation reliability, and (iv) has small warpage after being cured, (B) a resin film, (C) an insulating film, and (D) an printed wiring board provided with an insulating film, the photosensitive resin composition containing at least (A) binder polymer; (B) cross-linked polymer particles, whose polymer has a urethane bond in its molecule; (C) thermosetting resin; and (D) photo-polymerization initiator is used.

Owner:KANEKA CORP

Reinforced thermoplastic resin composition and molded products thereof

ActiveUS7405253B2Reduce wearLittle warpagePlastic/resin/waxes insulatorsAlkaline-earth metal silicatesCalcium silicatePolymer science

The present invention relates to a reinforced thermoplastic resin composition comprising at least an amorphous thermoplastic resin (A), a flame retardant (B), fibrous calcium silicate (C) and an inorganic material (D) comprising talc and / or mica,the content of flame retardant (B) being 0.01 to 30 parts by weight based on 100 parts by weight of the amorphous thermoplastic resin (A);the content of fibrous calcium silicate (C) in said composition being 3 to 30% by weight, and the content of the inorganic material (D) comprising talc, mica or mixture thereof in said composition being 3 to 30% by weight.

Owner:MITSUBISHI ENG PLASTICS CORP

Insulating Substrate and Manufacturing Method Therefor, and Multilayer Wiring Board and Manufacturing Method Therefor

InactiveUS20090025855A1Reduce variationExcellent electrical propertiesCeramic layered productsPrinted circuit manufactureCrystallization temperatureThermal expansion

There is provided a dimensionally accurate insulating substrate in which plane direction-wise shrinkage is practically zero and shrinkage variations are small. The insulating substrate includes a laminated body composed of at least two kinds of insulating layers made of crystallizable glass ceramics. The crystallization temperature of crystallizable glass contained in the first insulating layer is lower than the softening point of crystallizable glass contained in the second insulating layer. The difference in thermal expansion coefficient between the first and second insulating layers is preferably 2×10−6 / ° C. or below.

Owner:KYOCERA CORP

Method for manufacturing piezoelectric element

InactiveUS20120117769A1Warpage is hardlyAvoid damagePiezoelectric/electrostrictive device manufacture/assemblyOperating means/releasing devices for valvesEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

Insulating layer forming material, insulating layer forming paste

An insulating layer forming material and an insulating layer forming paste capable of forming an insulating layer on a metallic substrate without the filler and glass reacting or warpage occurring even when repeatedly fired at 850° C. or higher are provided. The insulating layer forming material containing a lead-free glass composition and an α-quartz filler contains 17.0-40.0 wt. % of the α-quartz filler and 60.0-83.0 wt. % of the lead-free glass composition. The α-quartz filler has an average particle diameter (D50) of 1.0-3.5 μm and a specific surface area of 2.5-6.5 m2 / g. The lead-free glass composition includes no B2O3 and comprises a composition, in mol %, of 40.0-60.0% SiO2, 0.5-10.0% Al2O3, 20.0-45.0% MgO+CaO+SrO+BaO, 5.0-23.0% ZnO, and 0-10.0% Li2O+Na2O+K2O.

Owner:NIHON YAMAMURA GLASS CO LTD

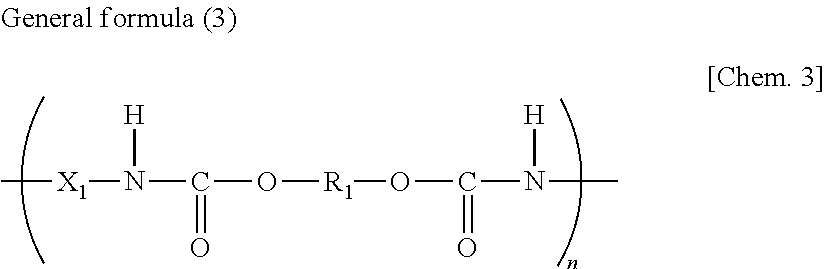

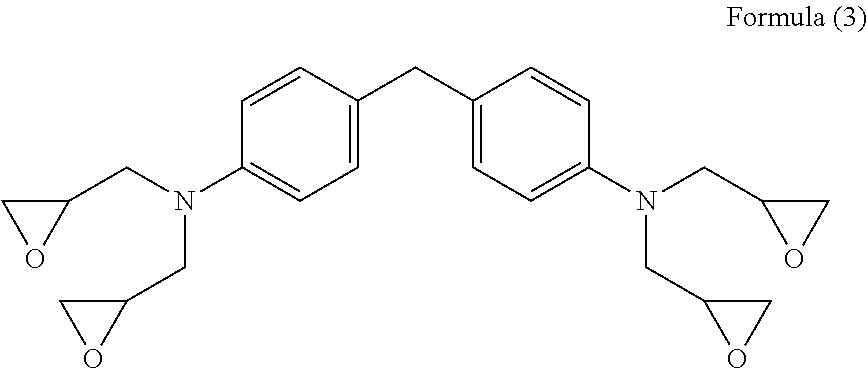

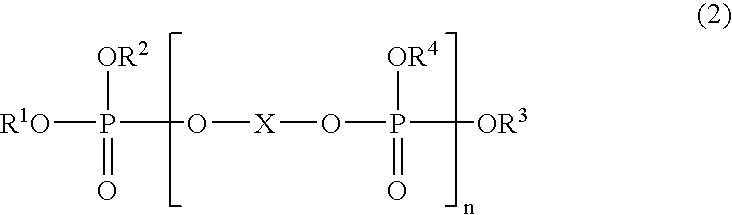

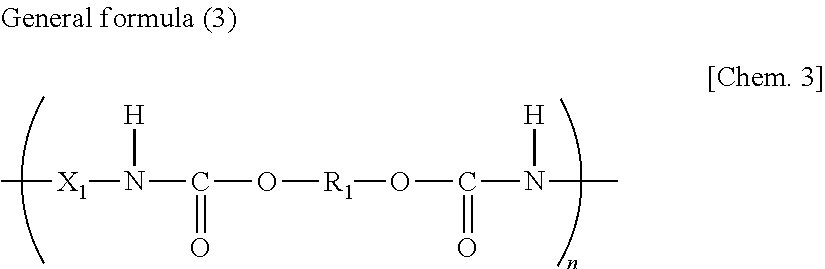

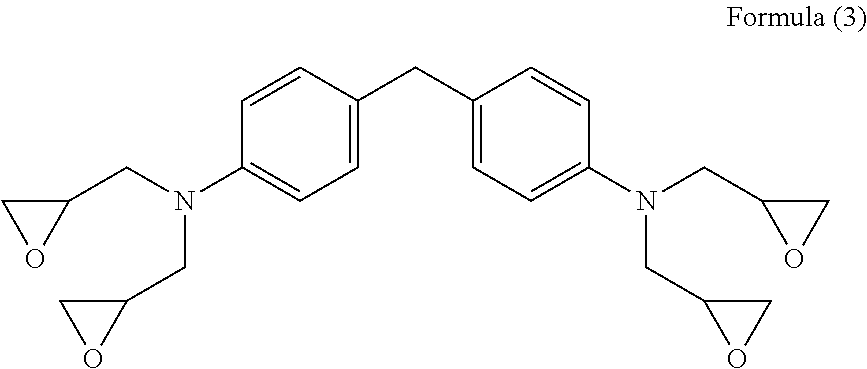

Curable composition

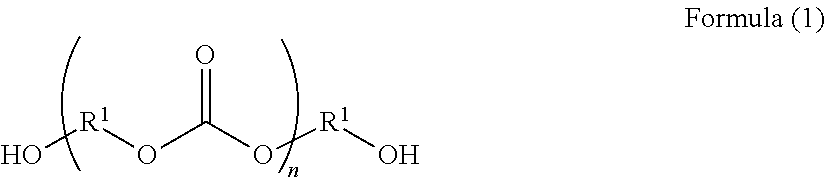

ActiveUS20110253426A1Increase flexibilityExcellent in long-term electrical insulation propertyPolyurea/polyurethane coatingsConductive pattern formationElectricityDiethylene glycol diethyl ether

It is an object of the present invention to provide a curable composition which provides a cured product excellent in low warpage properties and long-term electrical insulation reliability and causes little bleeding during screen printing. The present invention is a curable composition comprising the following components (a) to (e): a component (a): polyurethane having a functional group capable of curing reaction and a carbonate bond, a component (b): γ-butyrolactone, a component (c): diethylene glycol diethyl ether, a component (d): inorganic fine particles and / or organic fine particles, and a component (e): a compound having two or more epoxy groups in one molecule.

Owner:NIPPON POLYTECH CORP

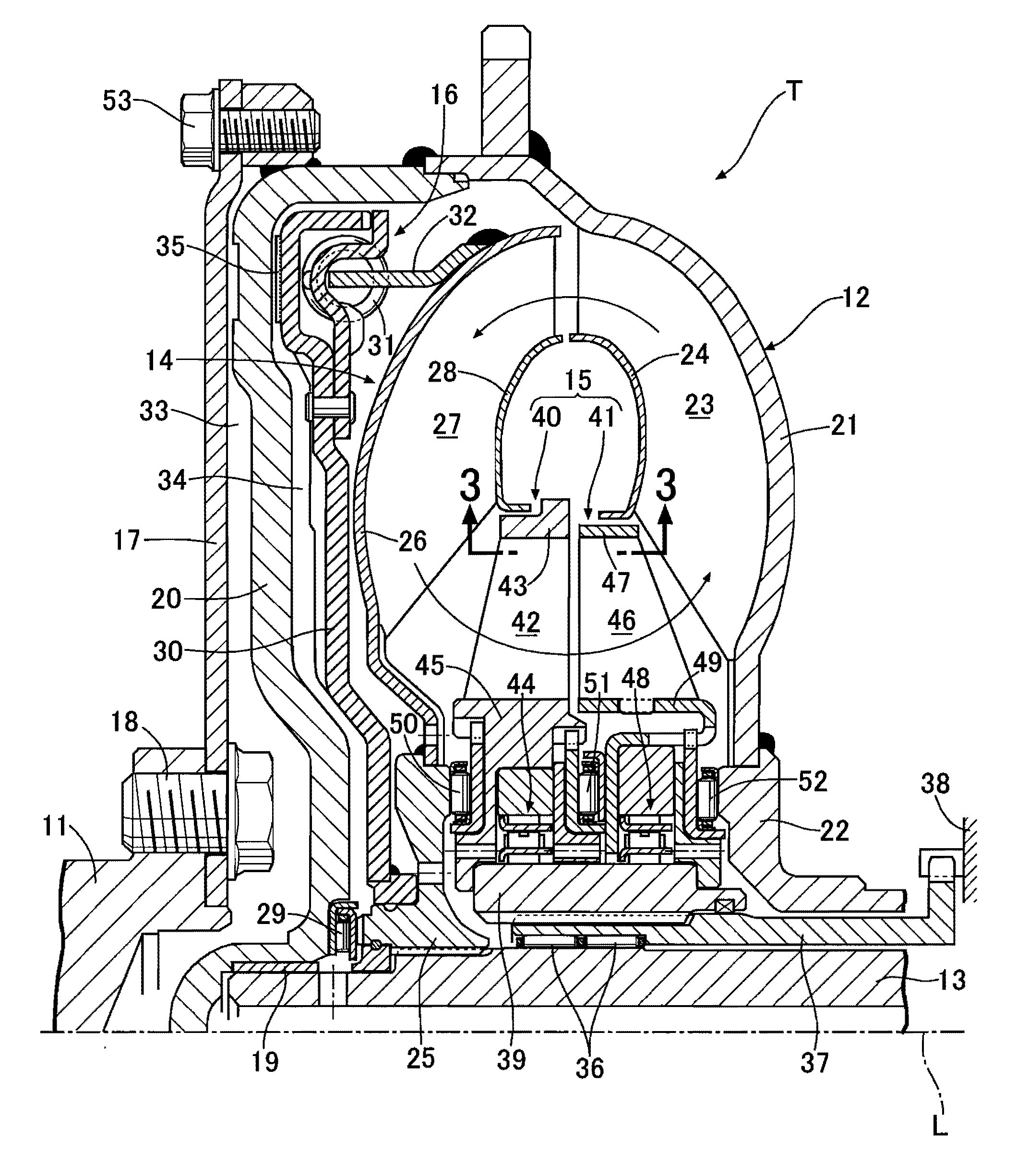

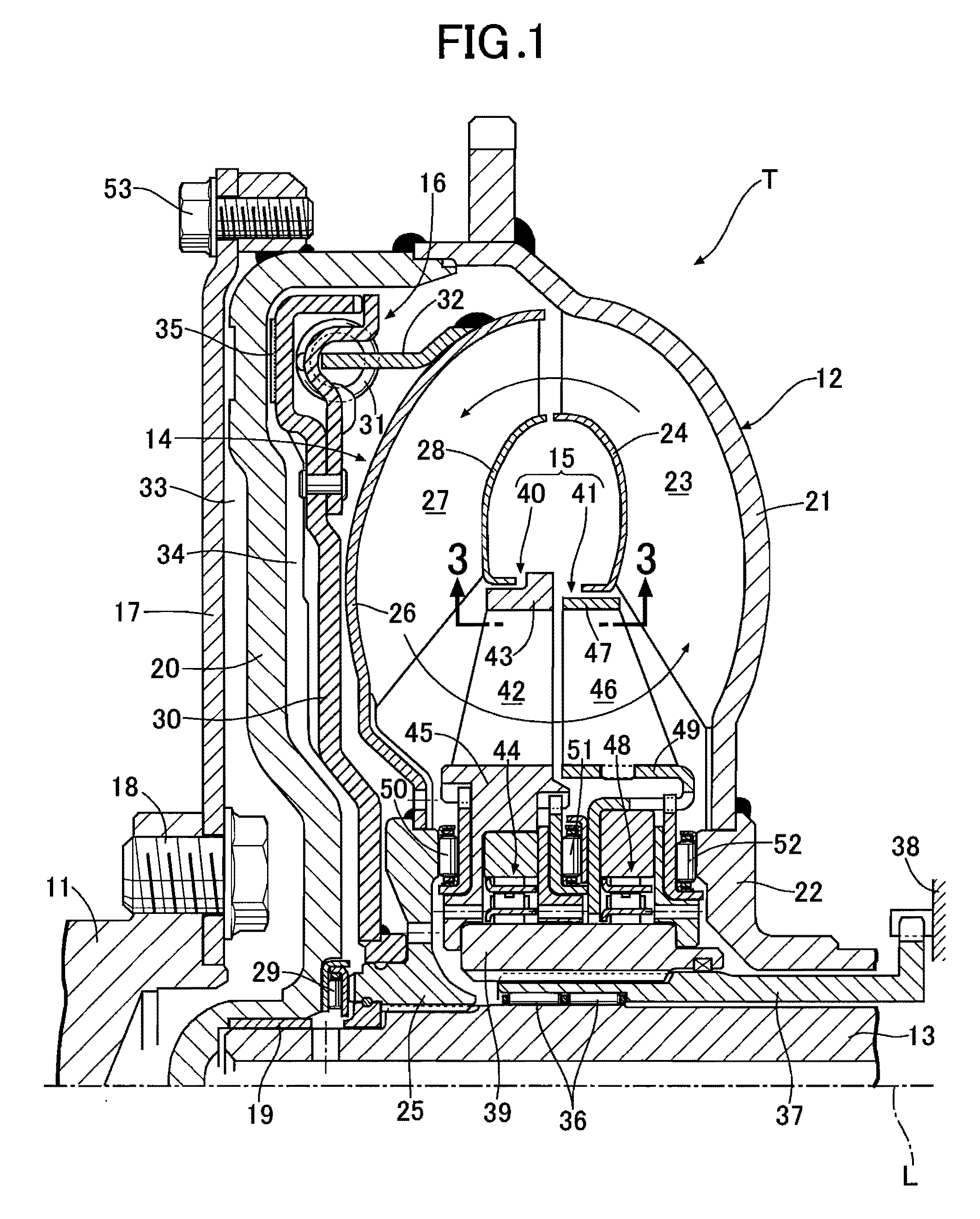

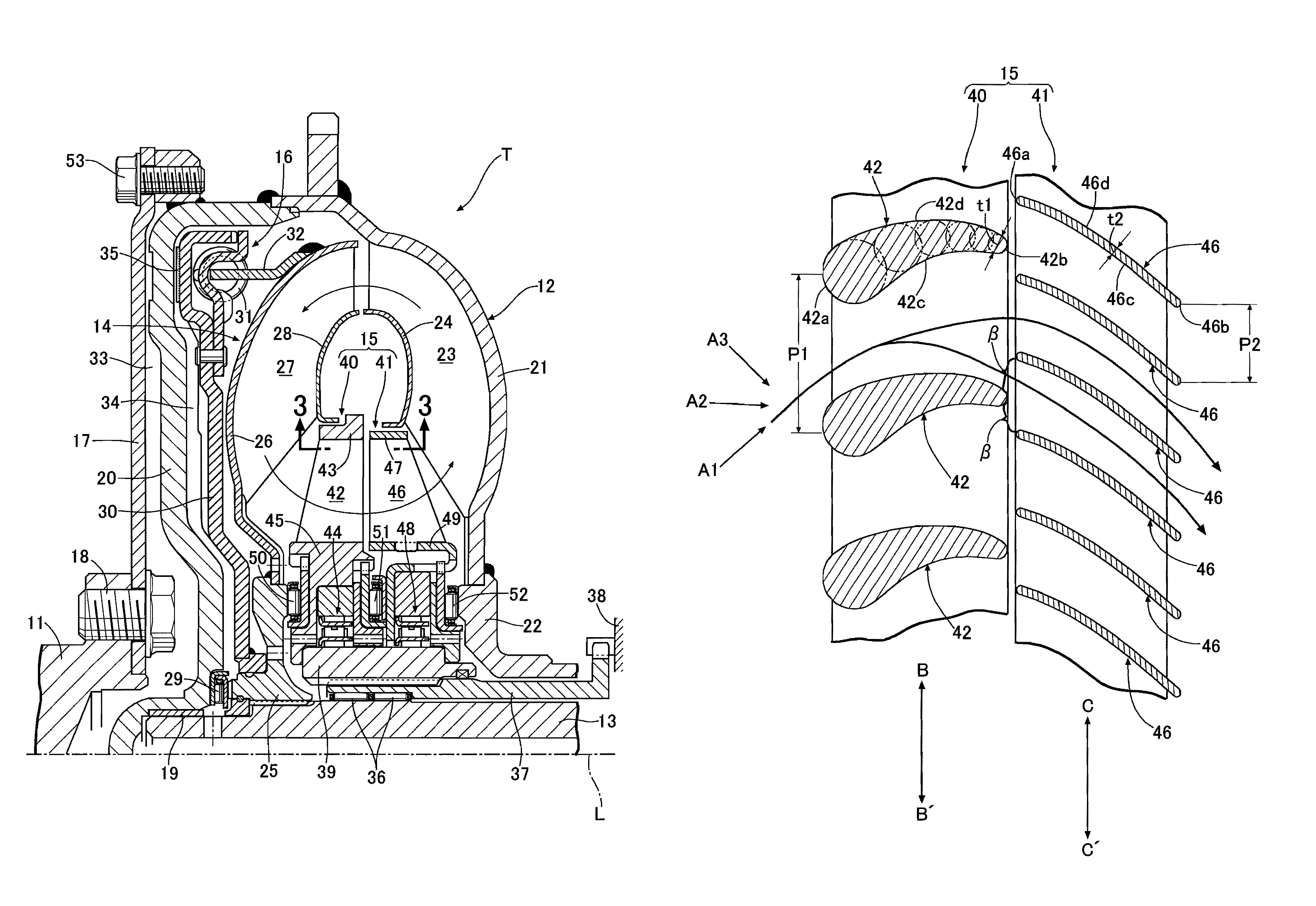

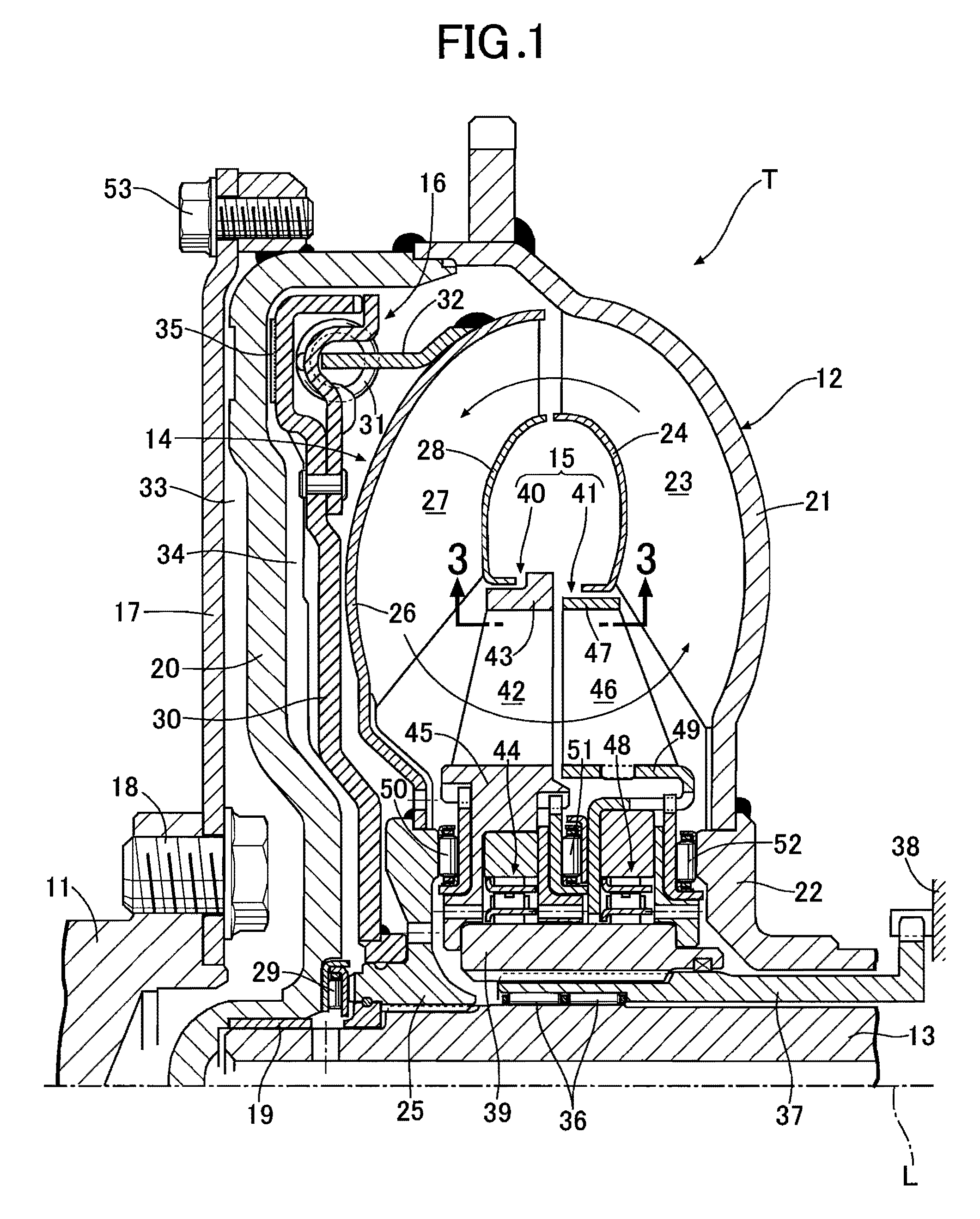

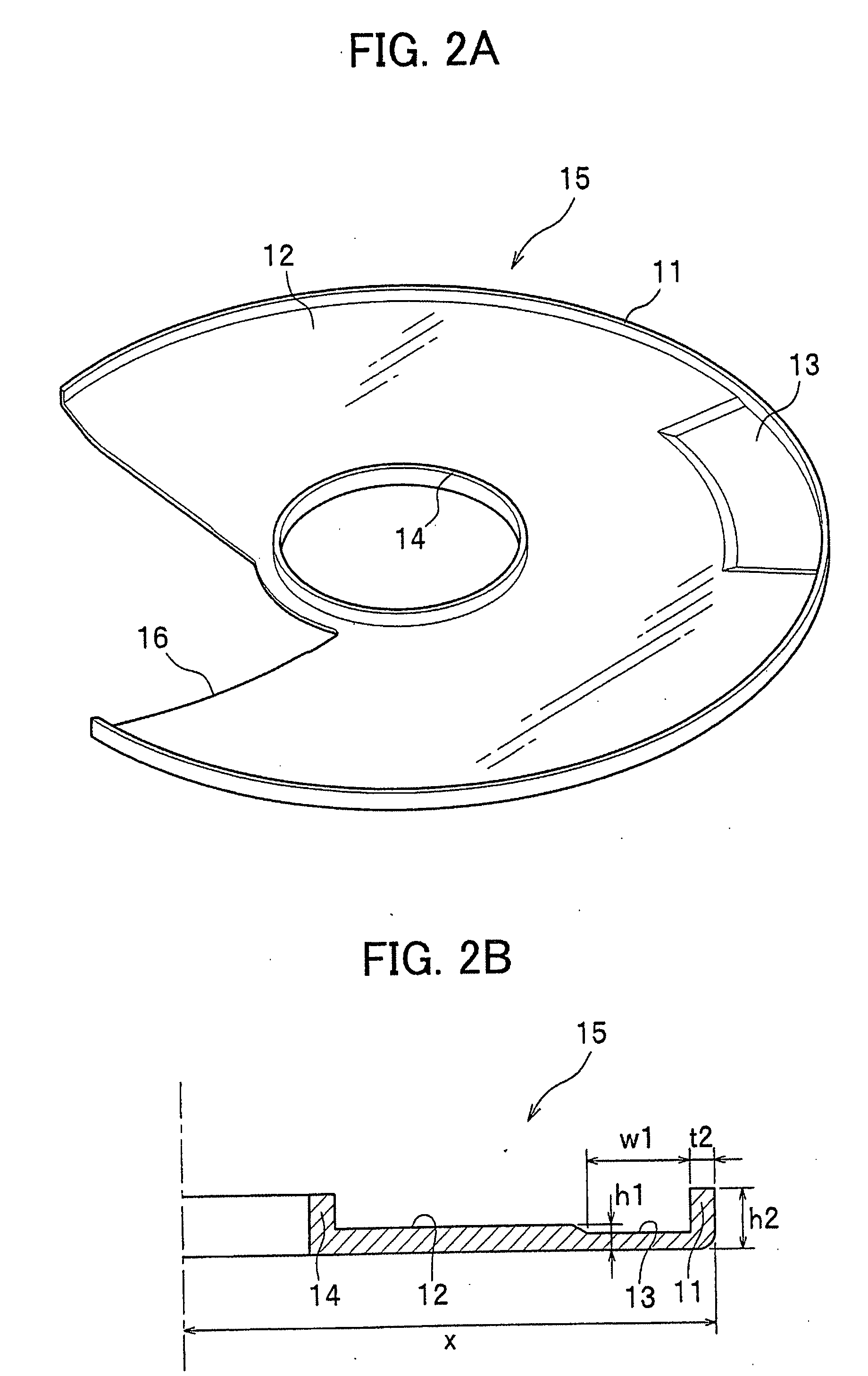

Torque converter stator structure

ActiveUS20140123637A1Effective alignmentAvoid flowRotary clutchesGearing controlLeading edgeTrailing edge

Among first and second stators of a torque converter supported on a fixed part by a one-way clutch corresponding to the stators, the number of second stator blades of the second stator on the downstream side in the direction of flow of oil is larger than the number of first blades of the first stator on the upstream side, and the maximum value t2 for blade thickness of the second stator blade is smaller than the minimum value t1 for blade thickness of the first stator blade. Therefore, it is possible to ensure that there is a sufficient gap (β) between a trailing edge of the first stator blade and a leading edge of the second stator blade, thus preventing the flow of oil from being stopped by the gap (β), and it is possible to align effectively the flow of oil by means of the second stator blades.

Owner:HONDA MOTOR CO LTD +1

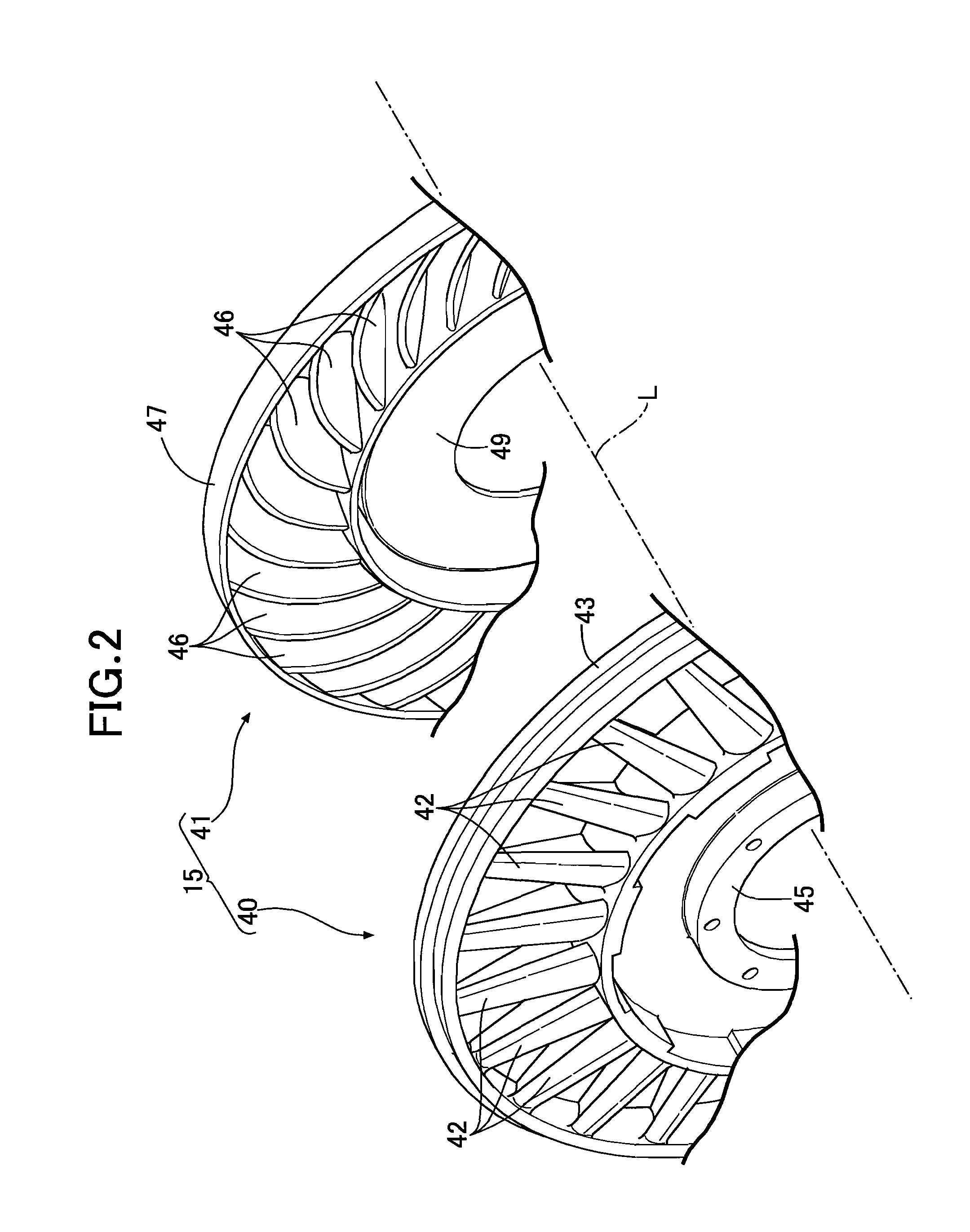

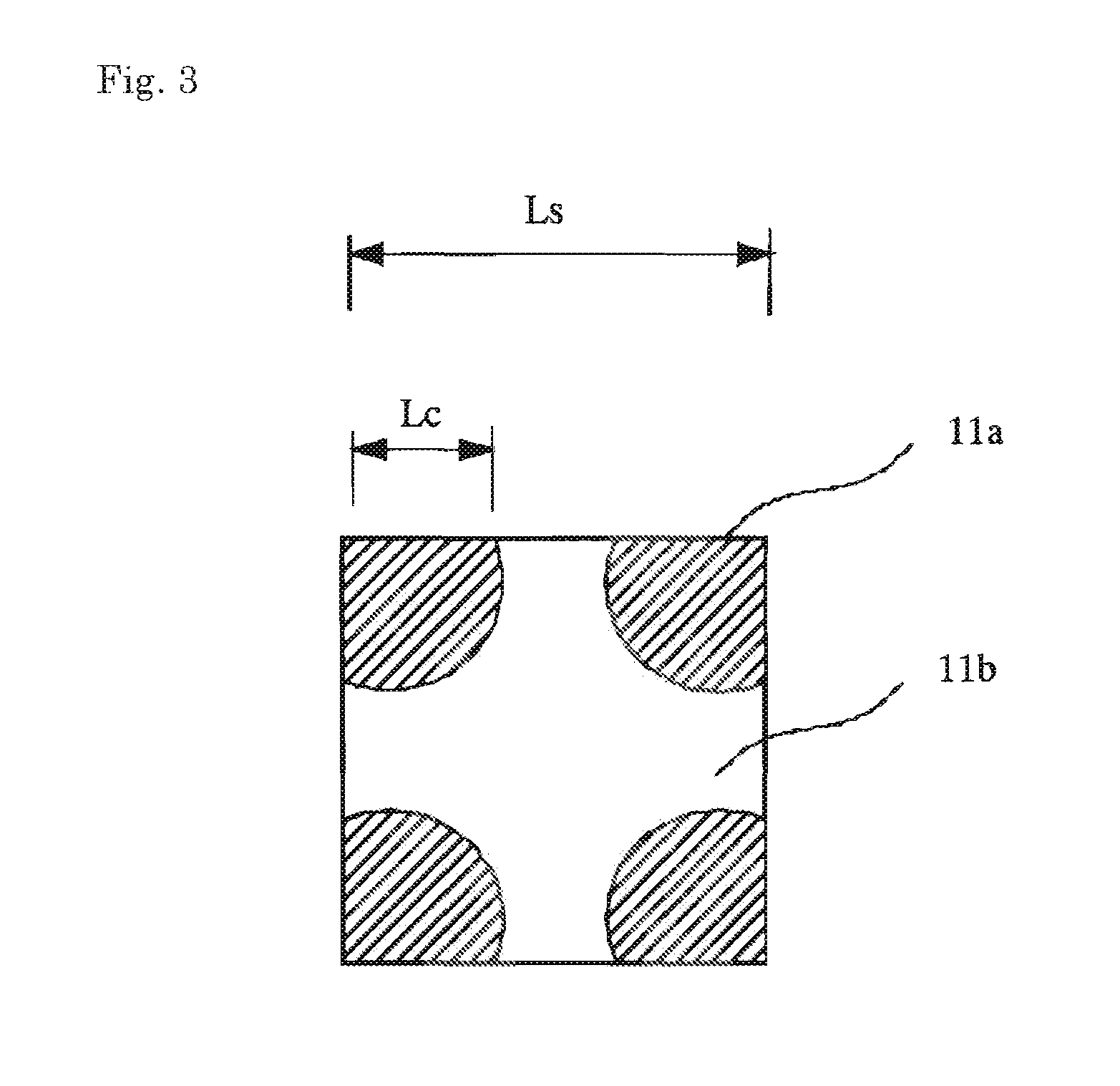

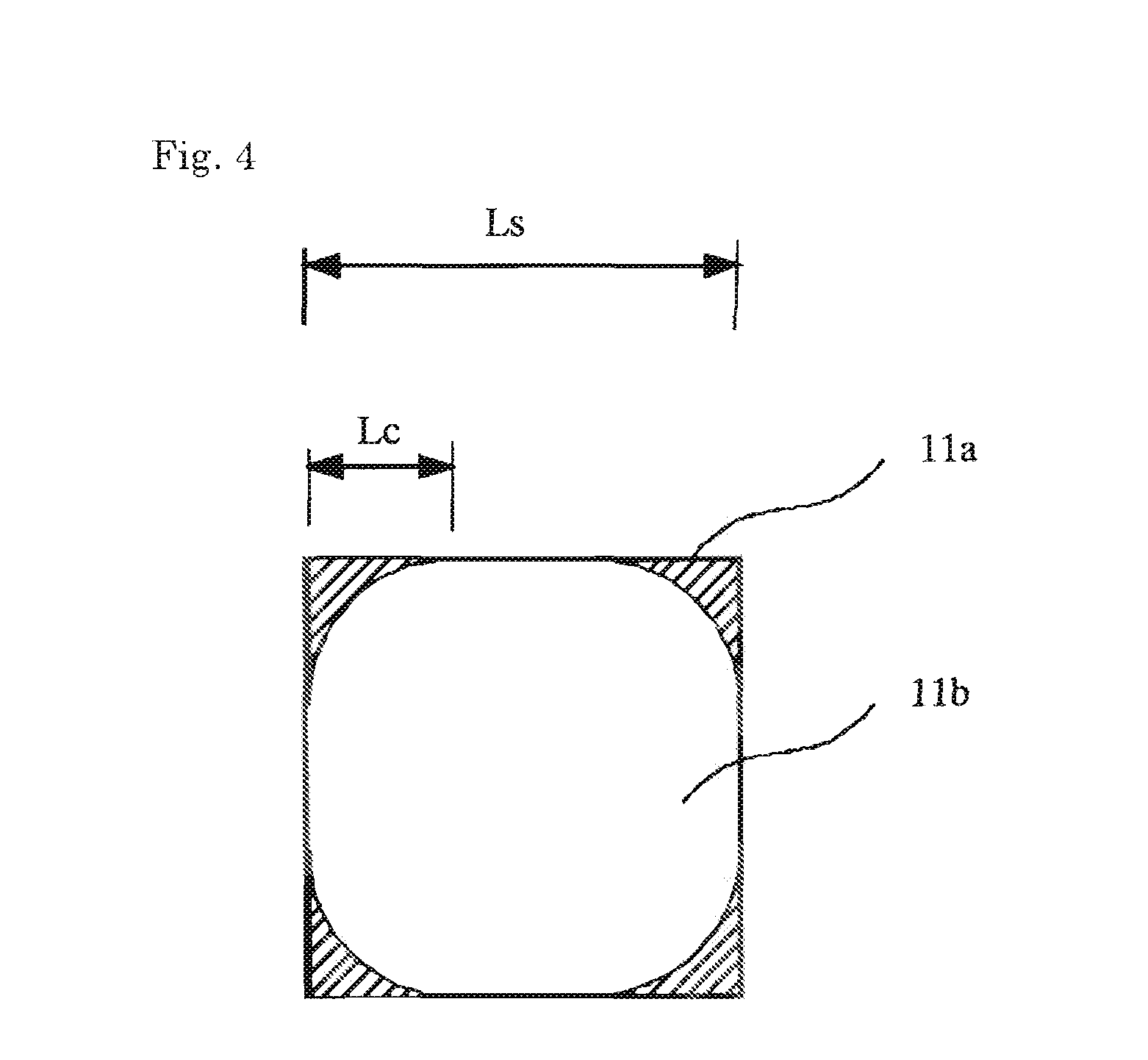

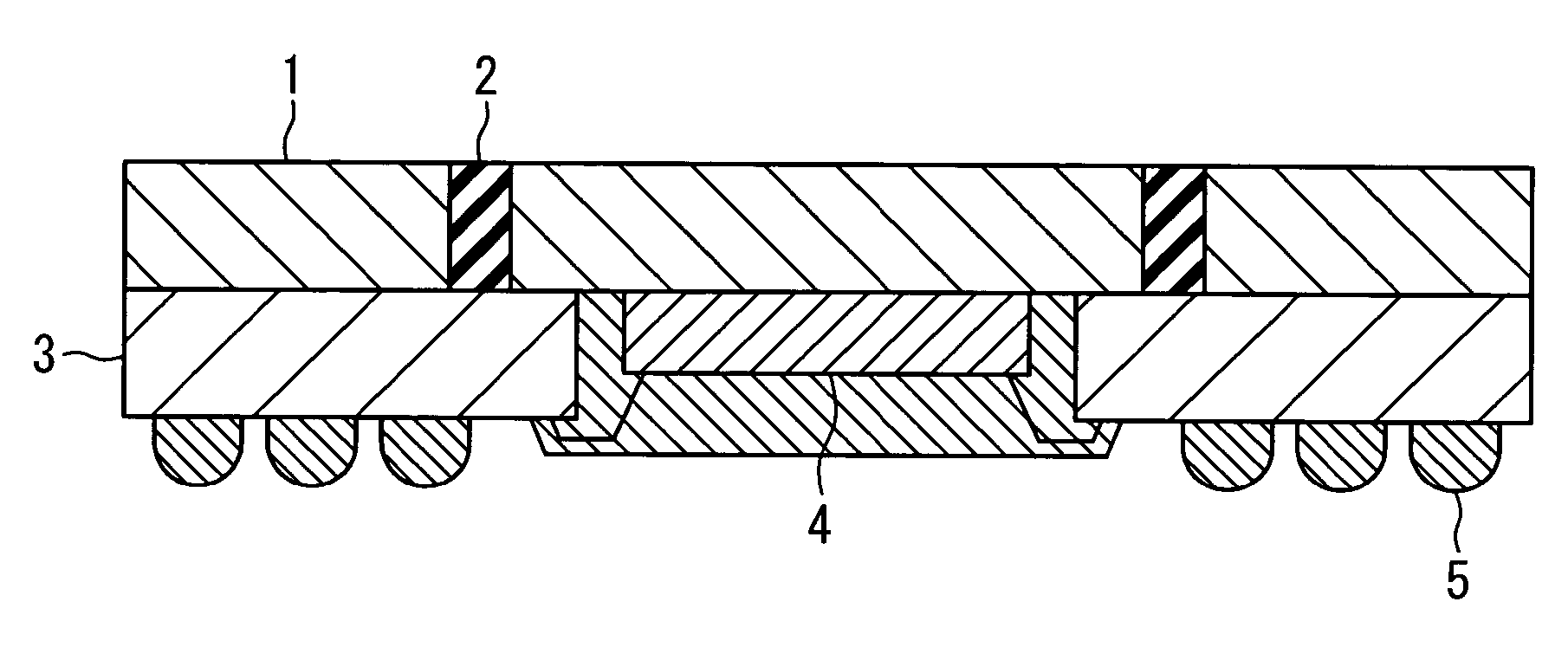

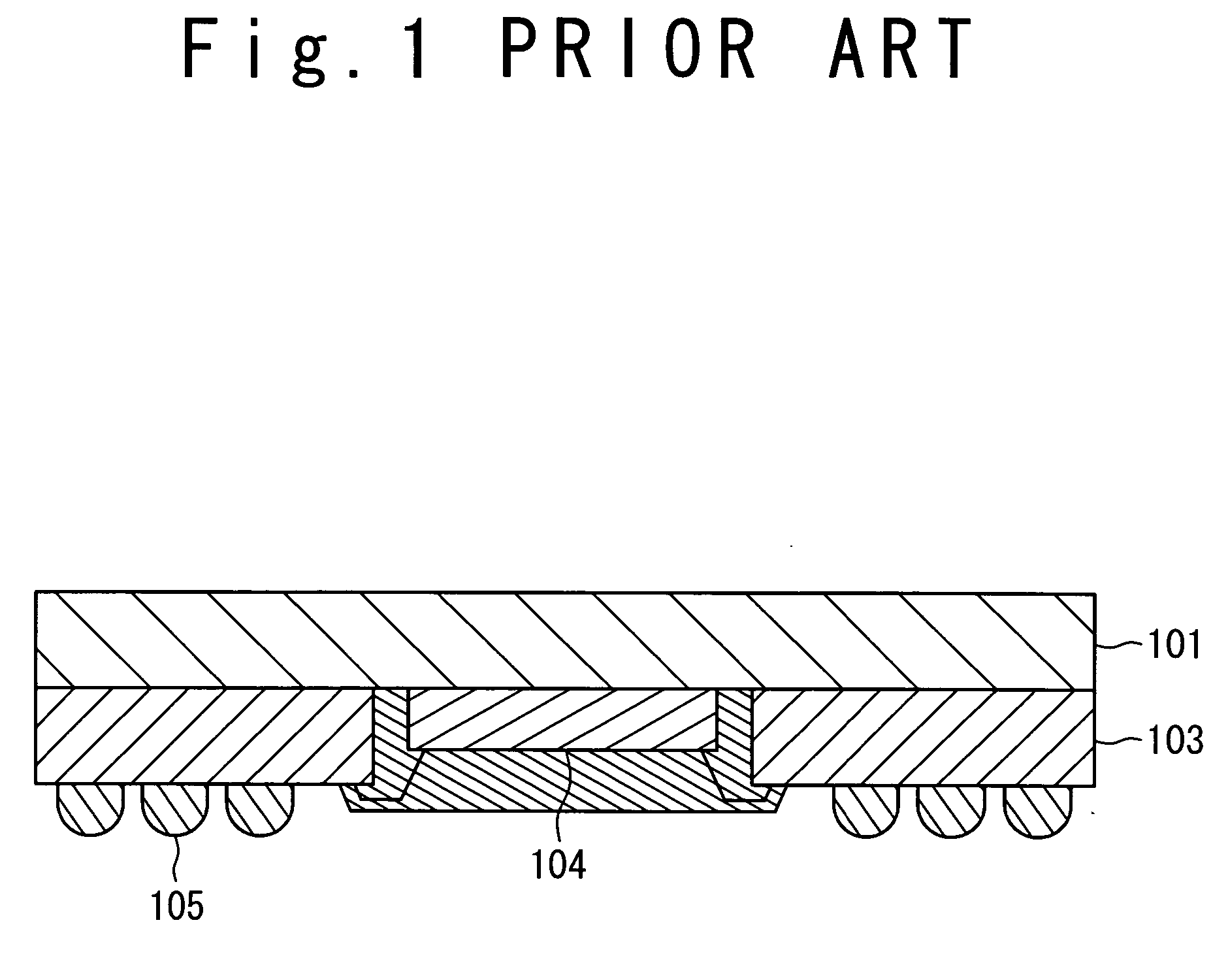

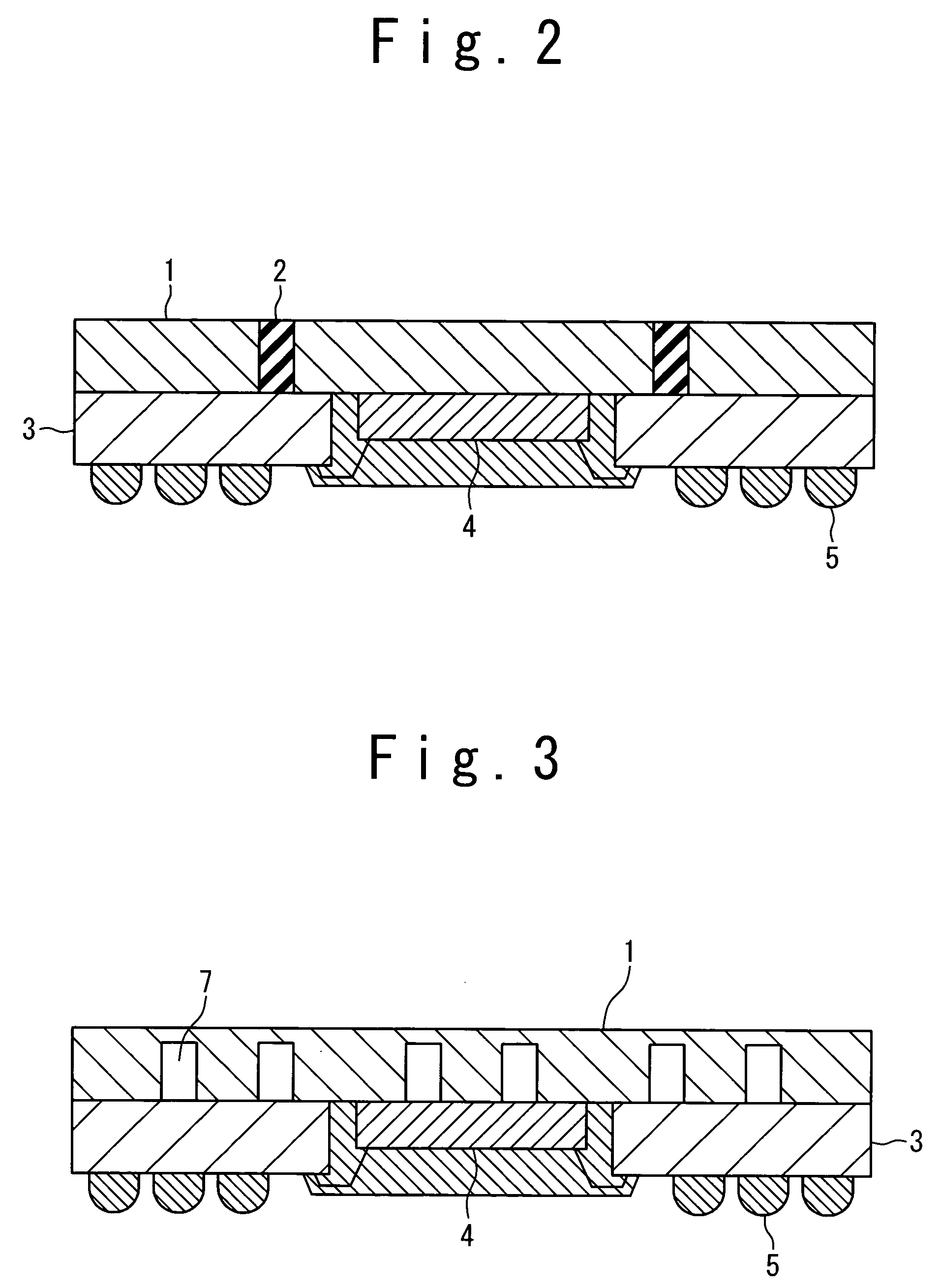

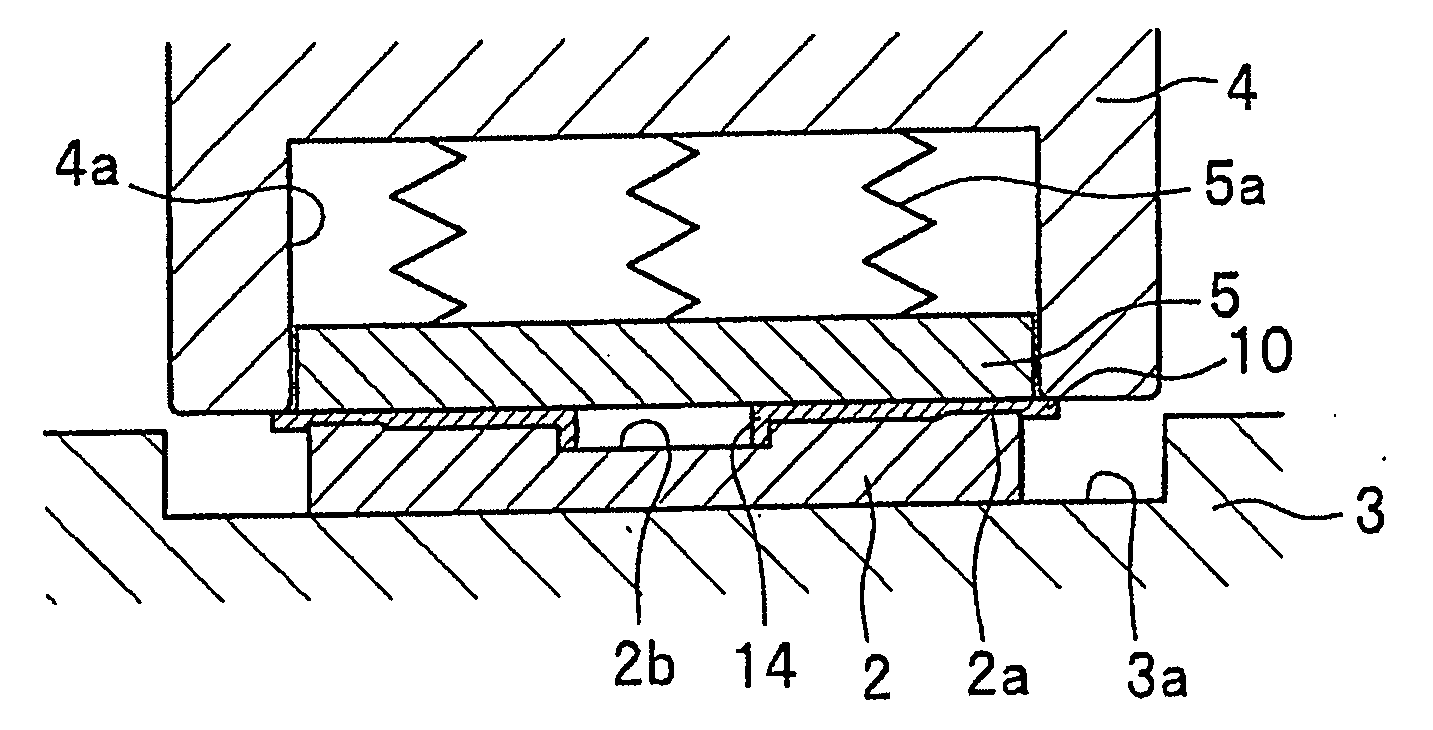

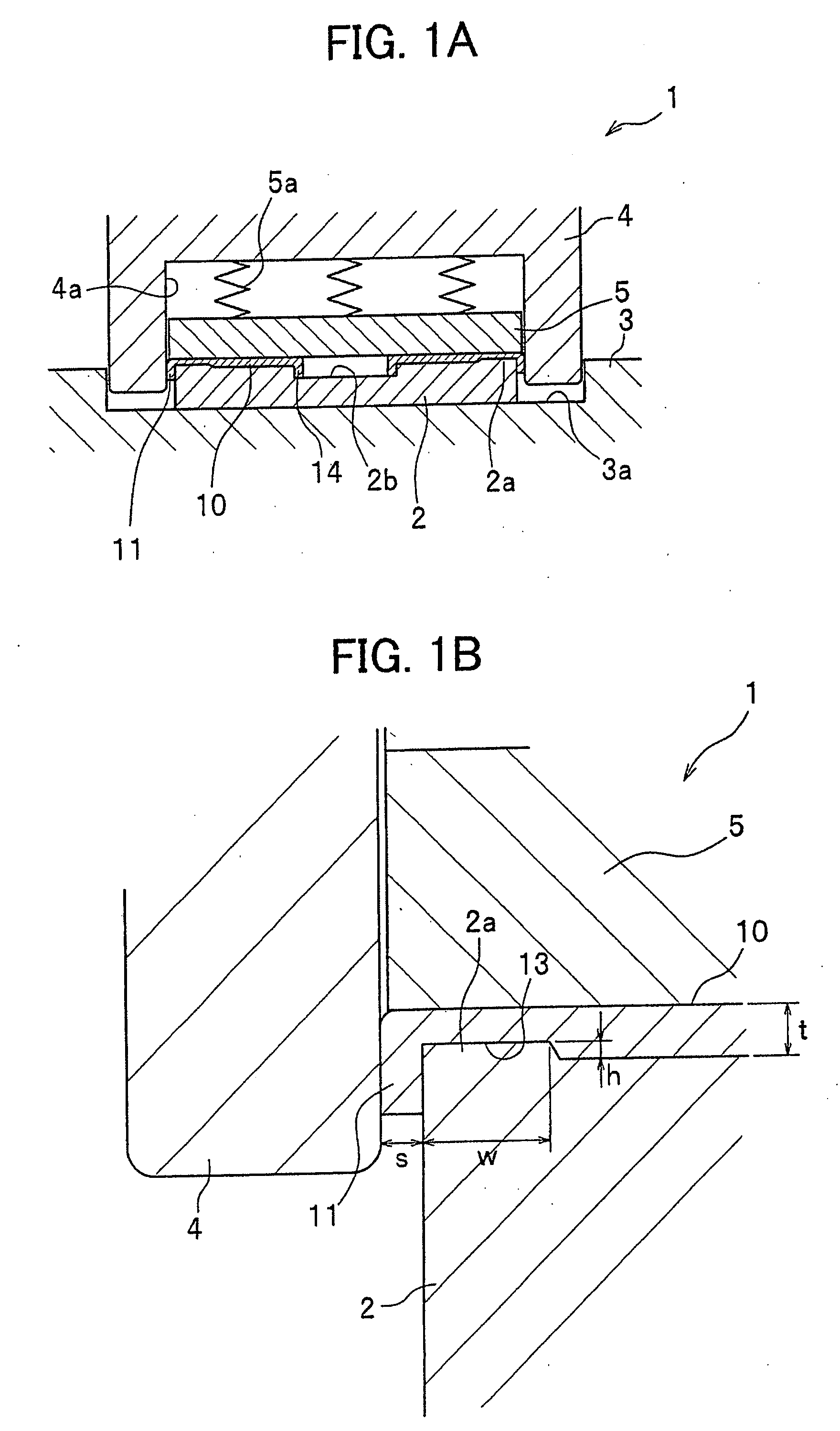

Electronic Component Mounting Structure

InactiveUS20070275504A1Little warpageSynthetic resin layered productsSolid-state devicesFlexural modulusEngineering

An object of the present invention is to provide an electronic component mounting structure having no degradation of bonding reliability and small warpage at the same time even when a die becomes more extensive in a mounting structure including a semiconductor device carrying a flip-chip mounting.Such electronic component mounting structure comprises a substrate and a quadrate electronic component mounted on the substrate, wherein a gap between the substrate and the electronic component is filled with a first cured resin filling at least a corner area of the electronic component and a second cured resin filling at least a center area of the electronic component, and a flexural modulus of the first cured resin is higher than a flexural modulus of the second cured resin.

Owner:HENKEL JAPAN

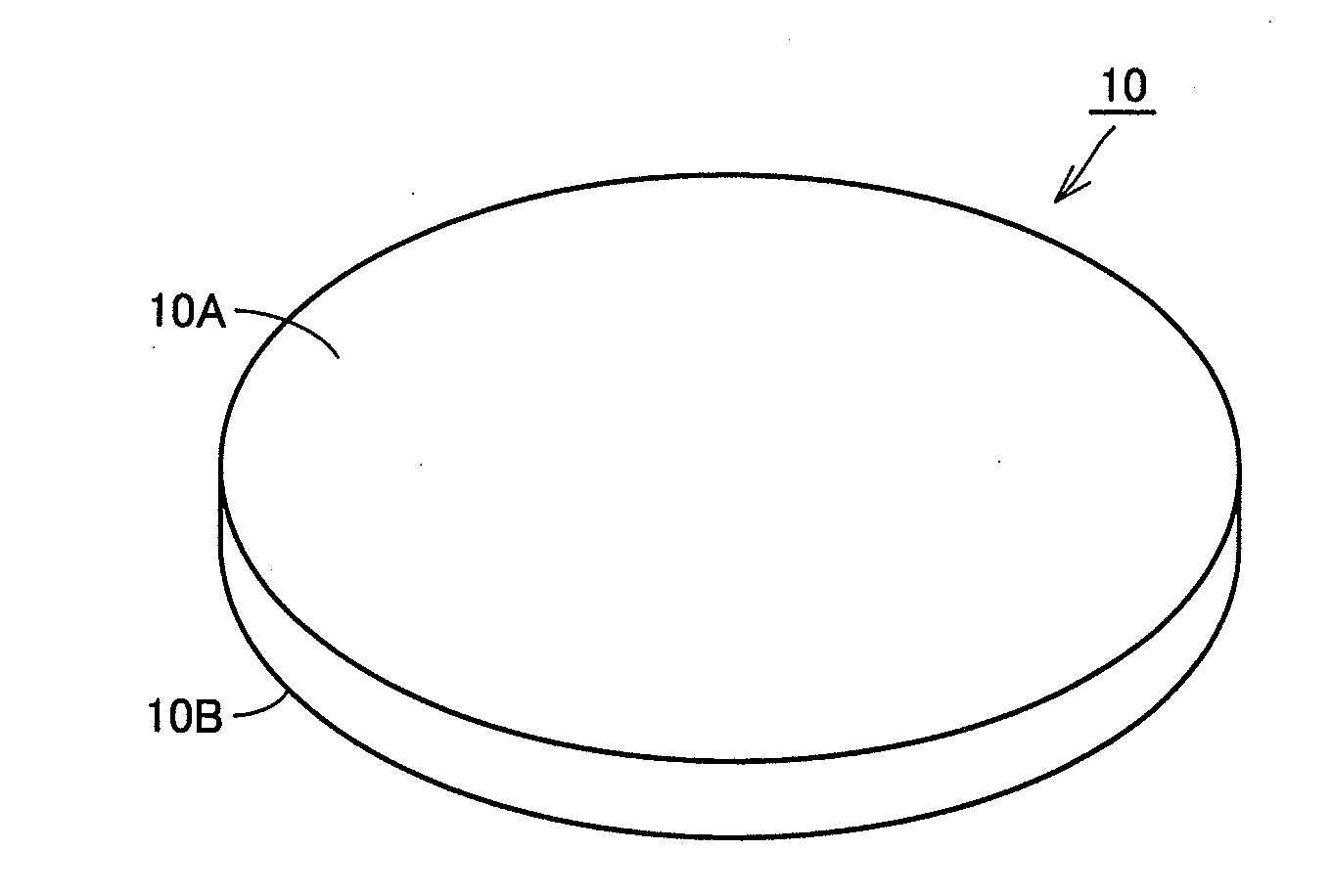

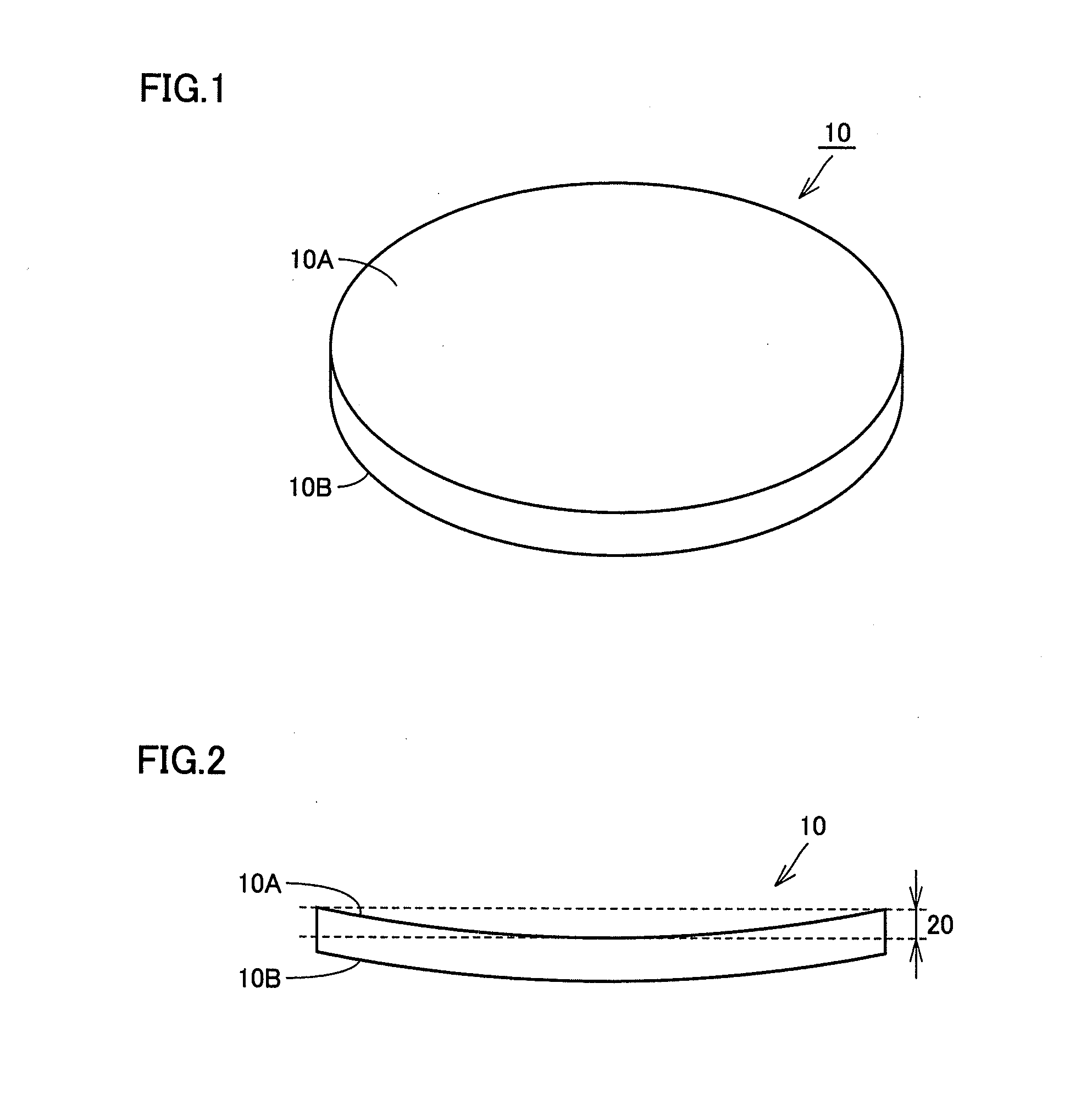

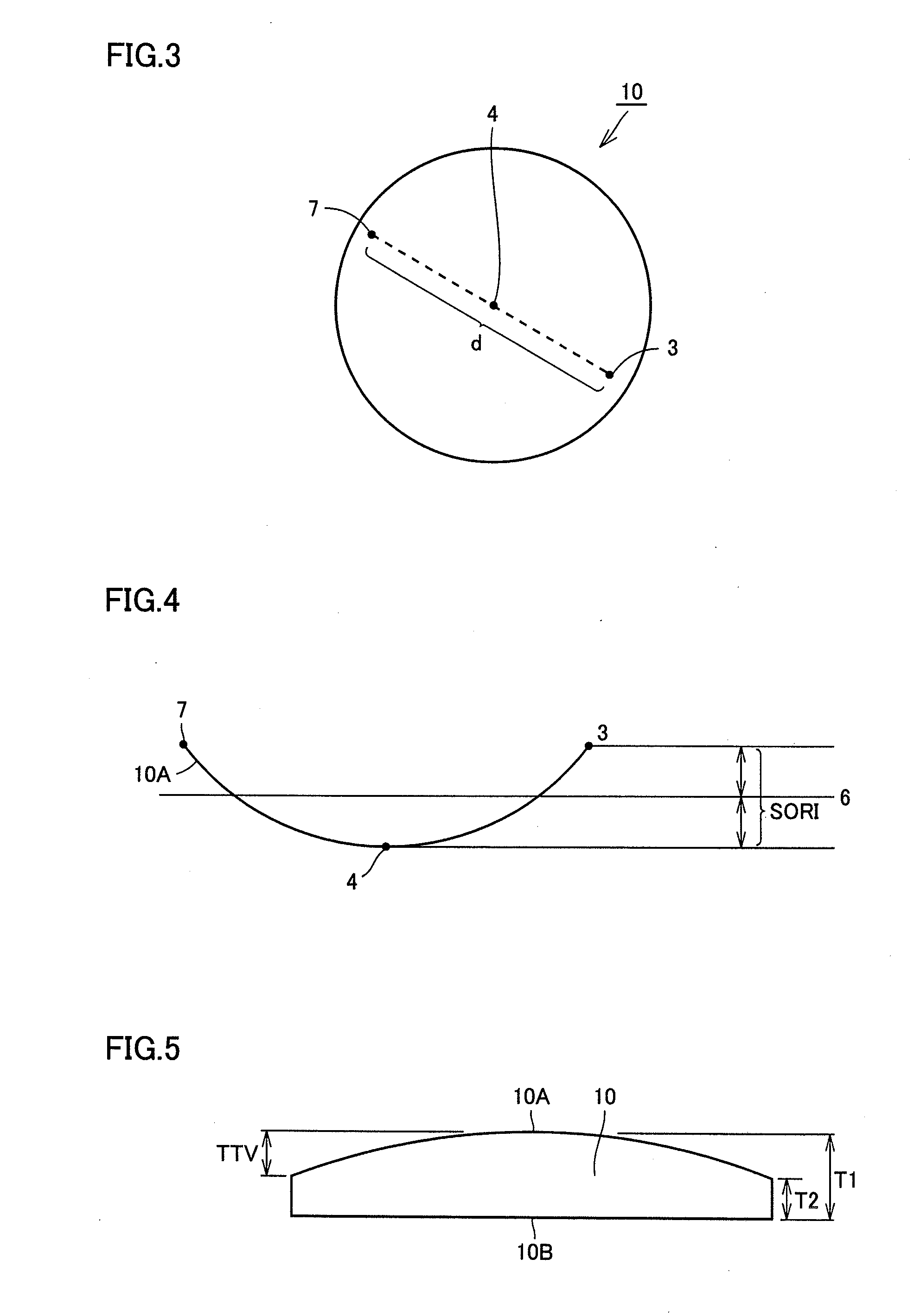

Silicon carbide substrate and fabrication method thereof

InactiveUS20150170928A1Little warpageDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon carbideIngot

A fabrication method of a silicon carbide substrate includes the following steps. By slicing a silicon carbide ingot, a first intermediate substrate having a first main surface and second main surface opposite to each other and a first SORI value, is formed. By etching at least one of the first main surface and the second main surface of the first intermediate substrate, a second intermediate substrate having a second SORI value smaller than the first SORI value is formed. By grinding at least one of the first main surface and the second main surface of the second intermediate substrate, a third intermediate substrate having a third SORI value greater than the second SORI value is formed. Accordingly, a silicon carbide substrate with small warpage is provided.

Owner:SUMITOMO ELECTRIC IND LTD

Conductor device and method of manufacturing thereof

InactiveUS20050269689A1Warpage suppressionLittle warpageSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A semiconductor device has a package substrate, and a heat spreader having a first surface attached to the package substrate. The heat spreader has a lattice-shaped slit opening on at least the first surface.

Owner:NEC ELECTRONICS CORP

Active energy ray curable resin composition and sheet-like optical article

InactiveUS7786184B2Improve heat resistanceLittle warpageMixing methodsDiffusing elementsHeat resistancePrism

An active energy ray curable resin composition for a sheet-like optical article capable of providing a cured material having a dynamic elastic modulus at 25° C. of 950 MPa or less and a dynamic elastic modulus at 60° C. of 100 MPa or more and a sheet-like optical article prepared from the resin composition are disclosed. The sheet-like optical article (e.g., prism sheet) has good heat resistance and extremely small warpage.

Owner:MITSUBISHI CHEM CORP

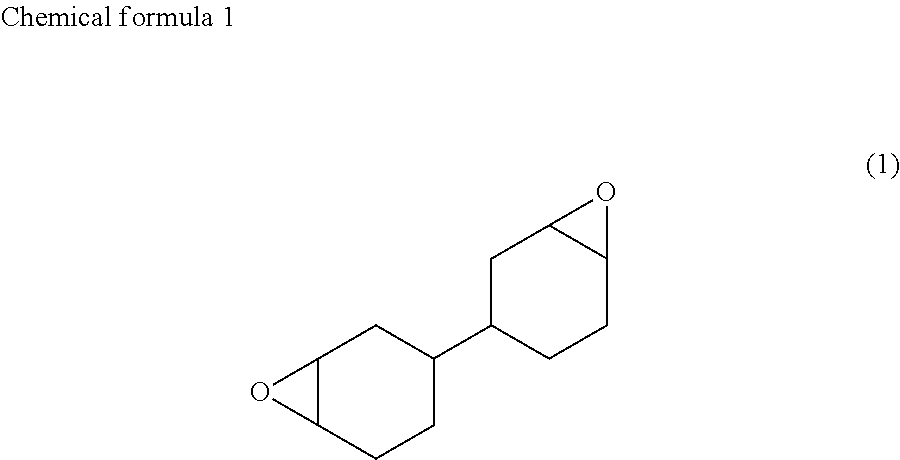

Resin composition for semiconductor encapsulation and semiconductor encapsulation method using same

InactiveUS20160152821A1Low viscosityLittle warpageSemiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor package

Provided are a resin composition for semiconductor encapsulation being fluid and exhibiting a low viscosity at a room temperature; and a semiconductor encapsulation method resulting in a small warpage even after performing molding through resin encapsulation i.e. a wafer level package-encapsulation method.The resin composition includes:(A) an alicyclic epoxy compound represented by formula 1:(B) an epoxy resin being liquid at a room temperature and an epoxy resin other than the alicyclic epoxy compound represented by formula 1;(C) an acid anhydride curing agent;(D) a curing accelerator; and(E) an inorganic filler, whereinthe component (A) is in an amount of 30 to 95 parts by mass with respect to 100 parts by mass of all the epoxy resins in the total amount of the resin composition, and the component (E) is contained in the total amount of the resin composition by 80 to 95% by mass.

Owner:SHIN ETSU CHEM IND CO LTD

Reinforced thermoplastic resin composition and molded products thereof

ActiveUS20050182166A1Reduce wearExcels in rigidityPlastic/resin/waxes insulatorsAlkaline-earth metal silicatesCalcium silicatePolymer science

The present invention relates to a reinforced thermoplastic resin composition comprising at least an amorphous thermoplastic resin (A), a flame retardant (B), fibrous calcium silicate (C) and an inorganic material (D) comprising talc and / or mica, the content of flame retardant (B) being 0.01 to 30 parts by weight based on 100 parts by weight of the amorphous thermoplastic resin (A); the content of fibrous calcium silicate (C) in said composition being 3 to 30% by weight, and the content of the inorganic material (D) comprising talc, mica or mixture thereof in said composition being 3 to 30% by weight.

Owner:MITSUBISHI ENG PLASTICS CORP

Novel resin composition for insulating film, and use thereof

ActiveUS20140363639A1Maintain good propertiesIncrease flexibilityLayered productsPolyurea/polyurethane coatingsCross-linkCrosslinked polymers

The present invention provides a resin composition for an insulating film which resin composition is excellent in tack property after drying and allows a resultant insulating film to be excellent in flexibility and electrical insulation reliability and to be small in warpage after curing, a resin film for an insulating film, an insulating film, and a printed wiring board provided with an insulating film. The resin composition for an insulating film contains at least: a (A) binder polymer; and (B) cross-linked polymer particles, whose polymer has a urethane bond and a carbonate skeleton in its molecule.

Owner:KANEKA CORP

Resin composition and semiconductor device produced using resin composition

InactiveUS8754178B2Improve reliabilityLittle warpageSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

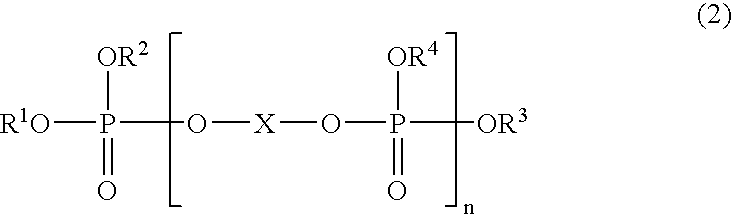

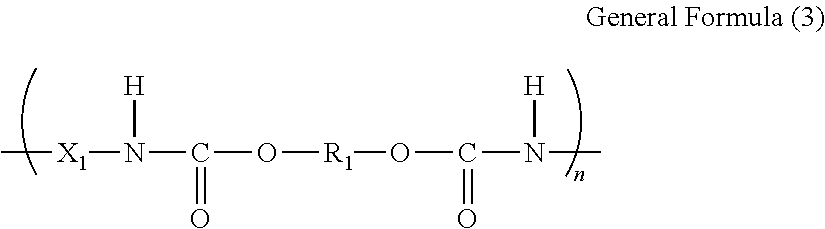

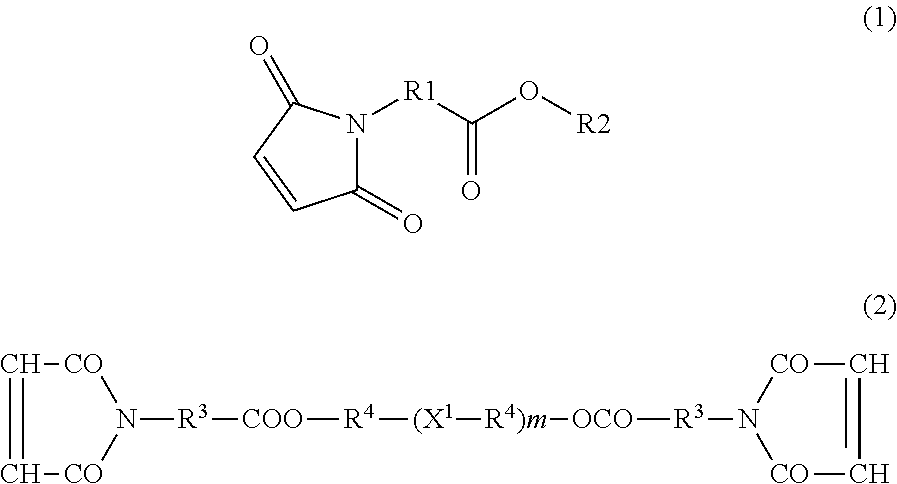

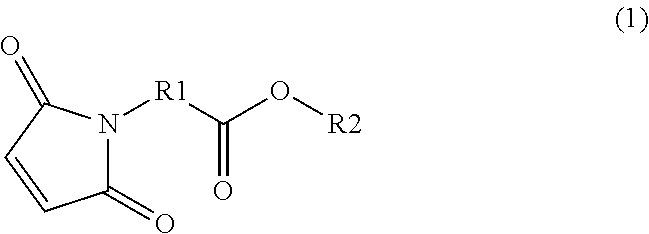

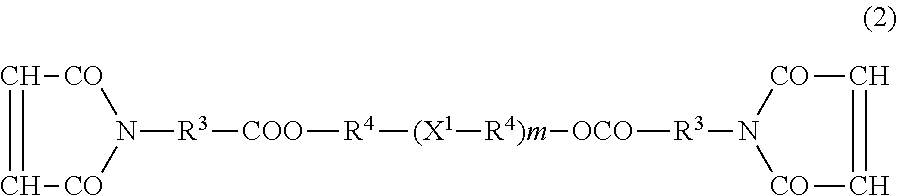

A resin composition of the present invention includes a maleimide derivative (A) represented by a general formula (1) and a bis-maleimide compound (B) represented by a general formula (2). In the general formula (1), R1 represents a straight chain or branched alkylene group having 1 or more carbon atoms, R2 represents a straight chain or branched alkyl group having 5 or more carbon atoms, and the sum of carbon atoms of R1 and R2 is 10 or less. In the general formula (2), X1 represents —O—, —COO—, or —OCOO—, R3 represents a straight chain or branched alkylene group having 1 to 5 carbon atoms, R4 represents a straight chain or branched alkylene group having 3 to 6 carbon atoms, and m is an integer of 1 or more and 50 or less.

Owner:SUMITOMO BAKELITE CO LTD

Torque converter stator structure

ActiveUS9267591B2Avoid flowEffective alignmentGearing controlFluid gearingsLeading edgeTrailing edge

Among first and second stators of a torque converter supported on a fixed part by a one-way clutch corresponding to the stators, the number of second stator blades of the second stator on the downstream side in the direction of flow of oils larger than the number of first blades of the first stator on the upstream side, and the maximum value t2 for blade thickness of the second stator blade is smaller than the minimum value t1 for blade thickness of the first stator blade. Therefore, it is possible to ensure that there is a sufficient gap (β) between a trailing edge of the first stator blade and a leading of the second stator blade, thus preventing the flow of oil from being stopped by the gap (β), and it is possible to align effectively the flow of oil by means of the second stator blades.

Owner:HONDA MOTOR CO LTD +1

Photosensitive resin composition and use thereof

ActiveUS9835942B2Good non-stickGood flexibilityPhotosensitive materialsPhotosensitive material processingCross-linkCrosslinked polymers

In order to provide (A) a photosensitive resin composition which (i) obtains an excellent tack-free property after being applied and dried, (ii) can be subjected to fine processing so as to have photosensitivity, (iii) prepares a cured film having excellent flexibility, flame retardancy, and electrical insulation reliability, and (iv) has small warpage after being cured, (B) a resin film, (C) an insulating film, and (D) an printed wiring board provided with an insulating film, the photosensitive resin composition containing at least (A) binder polymer; (B) cross-linked polymer particles, whose polymer has a urethane bond in its molecule; (C) thermosetting resin; and (D) photo-polymerization initiator is used.

Owner:KANEKA CORP

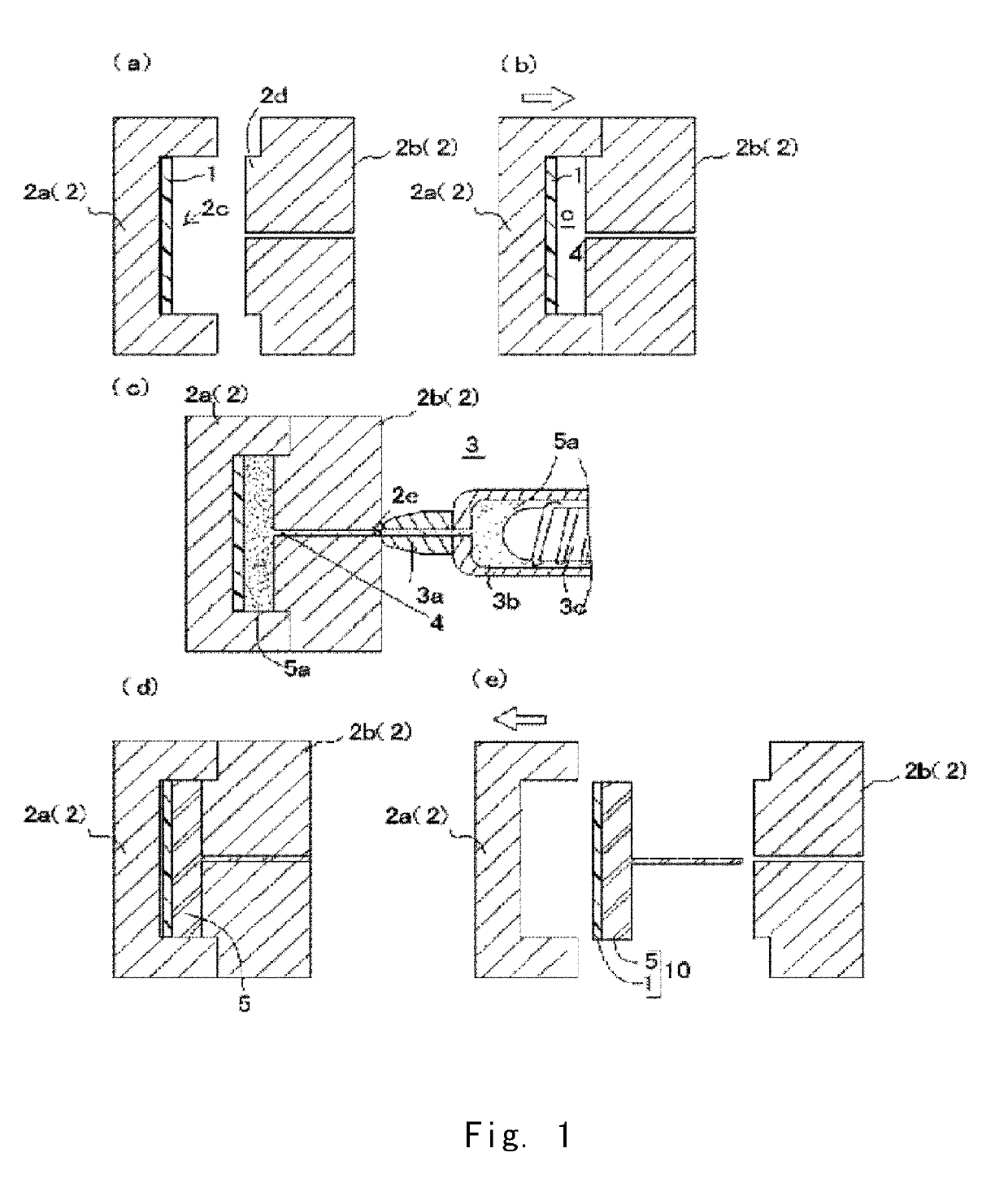

Press die, drawing method, and pressed product

A press die for molding an edge wall at a peripheral edge of a workpiece includes a die convexly formed along a shape of one surface of the edge wall, a punch formed with a concave portion along the other surface of the edge wall, and a stripper for holding the workpiece with the die therebetween, wherein a clearance between the die and the punch is in a range of not less than 70% and not more than 95% of a thickness of the workpiece before forming.

Owner:FUJIFILM CORP

Insulating layer forming material, insulating layer forming paste

An insulating layer forming material and an insulating layer forming paste capable of forming an insulating layer on a metallic substrate without the filler and glass reacting or warpage occurring even when repeatedly fired at 850° C. or higher are provided. The insulating layer forming material containing a lead-free glass composition and an α-quartz filler contains 17.0-40.0 wt. % of the α-quartz filler and 60.0-83.0 wt. % of the lead-free glass composition. The α-quartz filler has an average particle diameter (D50) of 1.0-3.5 μm and a specific surface area of 2.5-6.5 m2 / g. The lead-free glass composition includes no B2O3 and comprises a composition, in mol %, of 40.0-60.0% SiO2, 0.5-10.0% Al2O3, 20.0-45.0% MgO+CaO+SrO+BaO, 5.0-23.0% ZnO, and 0-10.0% Li2O+Na2O+K2O.

Owner:NIHON YAMAMURA GLASS CO LTD

Multilayer film

InactiveUS20190217586A1Little warpageSatisfactory in coextrusion film formabilityOptical articlesFurniture partsPolymer scienceWeather resistance

A multilayer film having a structure consisting of at least three layers: a polypropylene resin layer (X), an intermediate layer (Y) formed of a thermoplastic polymer composition containing 100 parts by mass of a thermoplastic elastomer (A), which is a block copolymer containing a polymer block (a1) formed of an aromatic vinyl compound unit and a polymer block (a2) formed of a conjugate diene compound unit or a hydrogenated product thereof, and 1 to 50 parts by mass a polypropylene resin (B) and a decorative layer (Z), in which the layers (X) (Y) and (Z) are stacked in this order, is excellent in preform moldability, successfully and firmly adhering to an adherend to decorate, small in warpage during thermal lamination and satisfactory in coextrusion film formability and weather resistance.

Owner:KURARAY CO LTD

Curable composition

ActiveUS8669306B2Excellent in flexibility and long-term electrical insulation propertyAvoid bleedingSpecial tyresPolyurea/polyurethane coatingsDiethylene glycol diethyl etherScreen printing

It is an object of the present invention to provide a curable composition which provides a cured product excellent in low warpage properties and long-term electrical insulation reliability and causes little bleeding during screen printing. The present invention is a curable composition comprising the following components (a) to (e): a component (a): polyurethane having a functional group capable of curing reaction and a carbonate bond, a component (b): γ-butyrolactone, a component (c): diethylene glycol diethyl ether, a component (d): inorganic fine particles and / or organic fine particles, and a component (e): a compound having two or more epoxy groups in one molecule.

Owner:NIPPON POLYTECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com