Insulating Substrate and Manufacturing Method Therefor, and Multilayer Wiring Board and Manufacturing Method Therefor

a technology of insulation substrate and manufacturing method, which is applied in the direction of printed circuit, thin material processing, electrical equipment, etc., can solve the problems of method paying attention, multi-layer wiring boards of related art, and inability to meet such a demand, so as to reduce shrinkage variations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

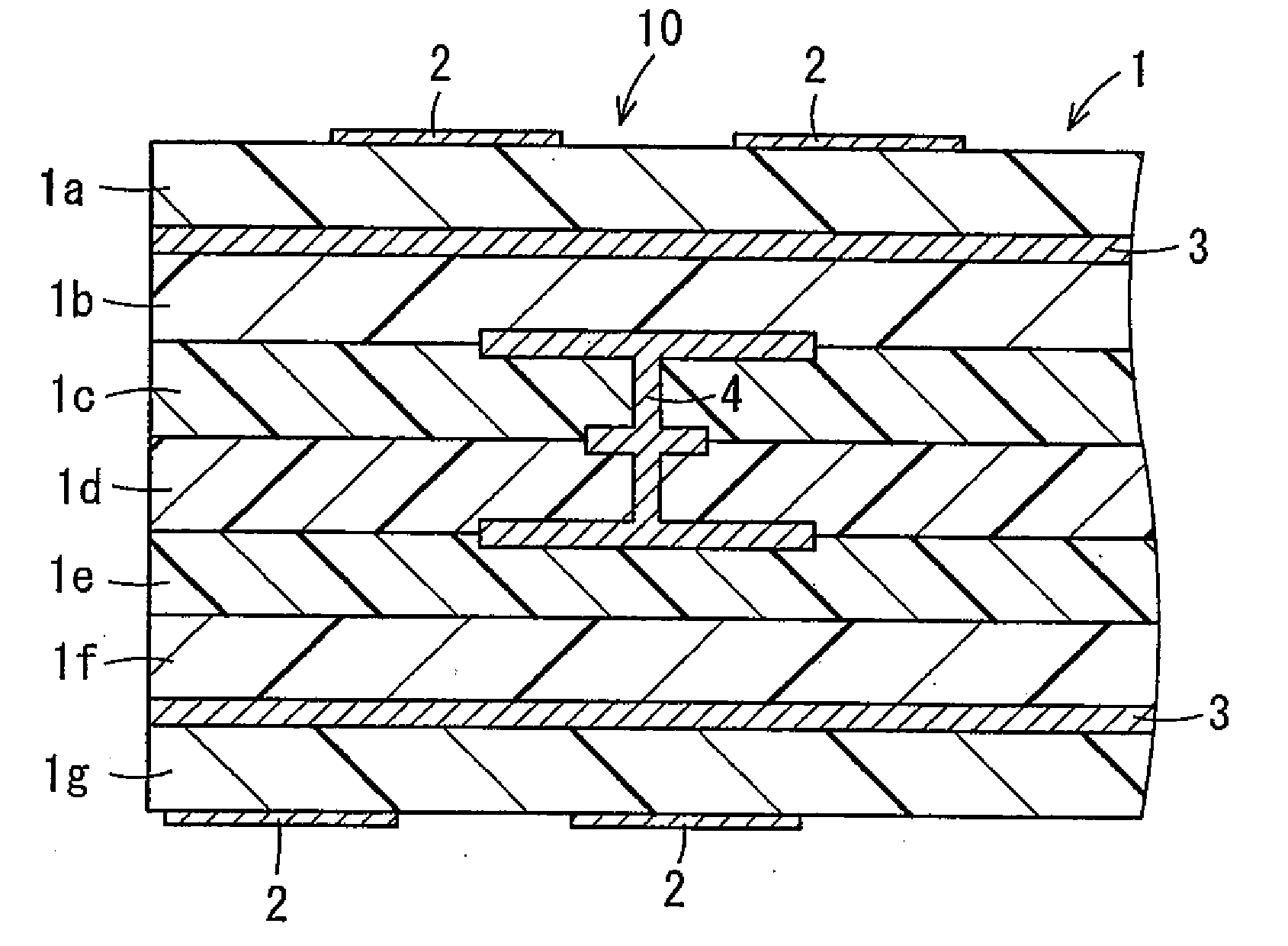

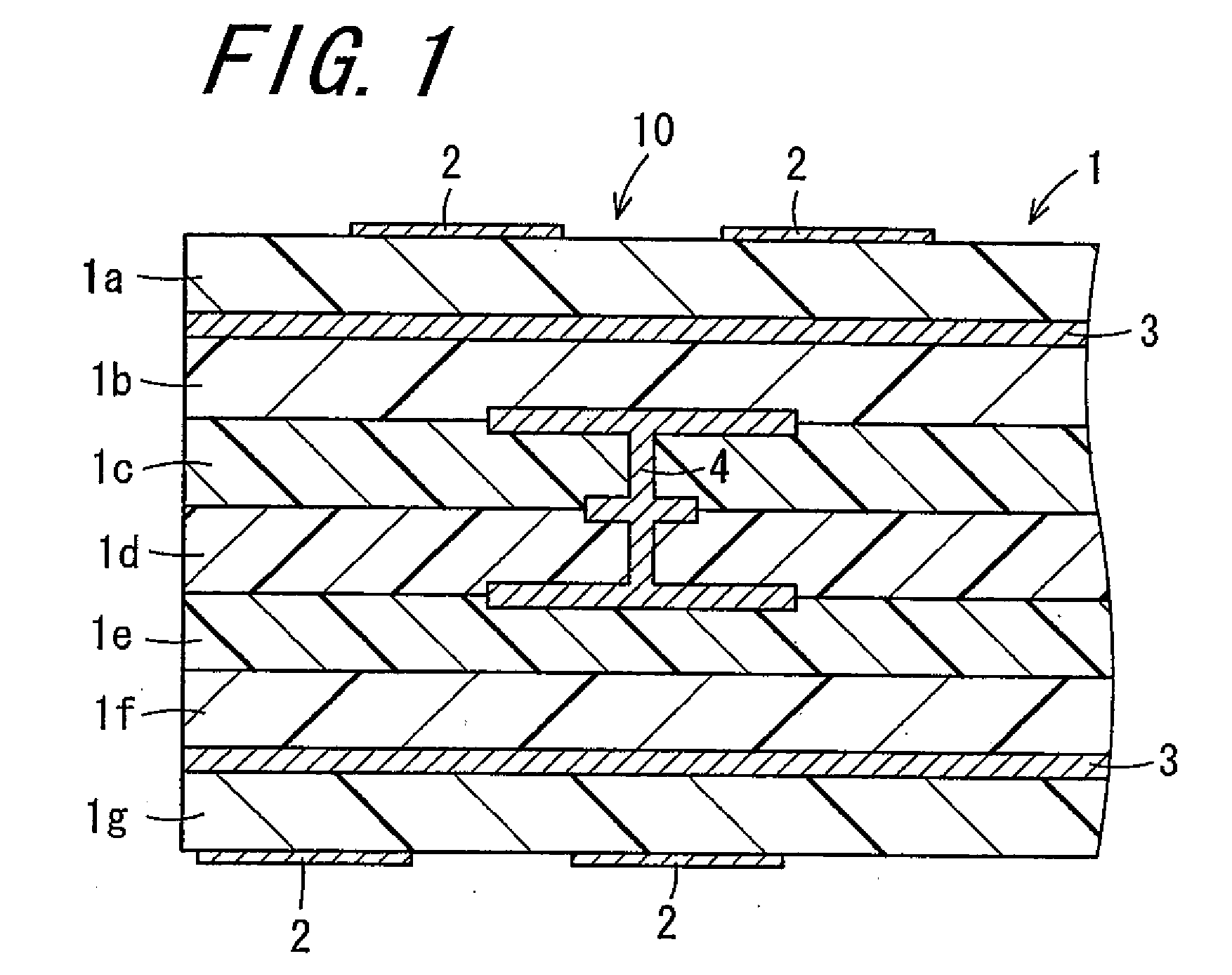

[0064]FIG. 1 is a schematic sectional view showing a multilayer wiring board according to a first embodiment of the invention. In FIG. 1, the multilayer wiring board 10 is composed of: an insulating substrate 1 composed of a laminated body constituted by stacking together insulating layers 1a through 1g; surface conductor layers 2 formed on the top and back surfaces of the insulating substrate 1; inner conductor layers 3 formed within the insulating substrate 1; and a via-hole conductor 4 for providing connection among the conductor layers.

[0065]In more detail, in the multilayer wiring board 10 of the invention having such a constitution, the insulating substrate 1 is formed by stacking a plurality of insulating layers 1a through 1g on top of one another thereby to assume a lamination structure. The inner conductor layer 3 is interposed between the adjacent insulating layers. The via-hole conductor 4 is so formed as to extend penetratingly through at least one of the insulating laye...

second embodiment

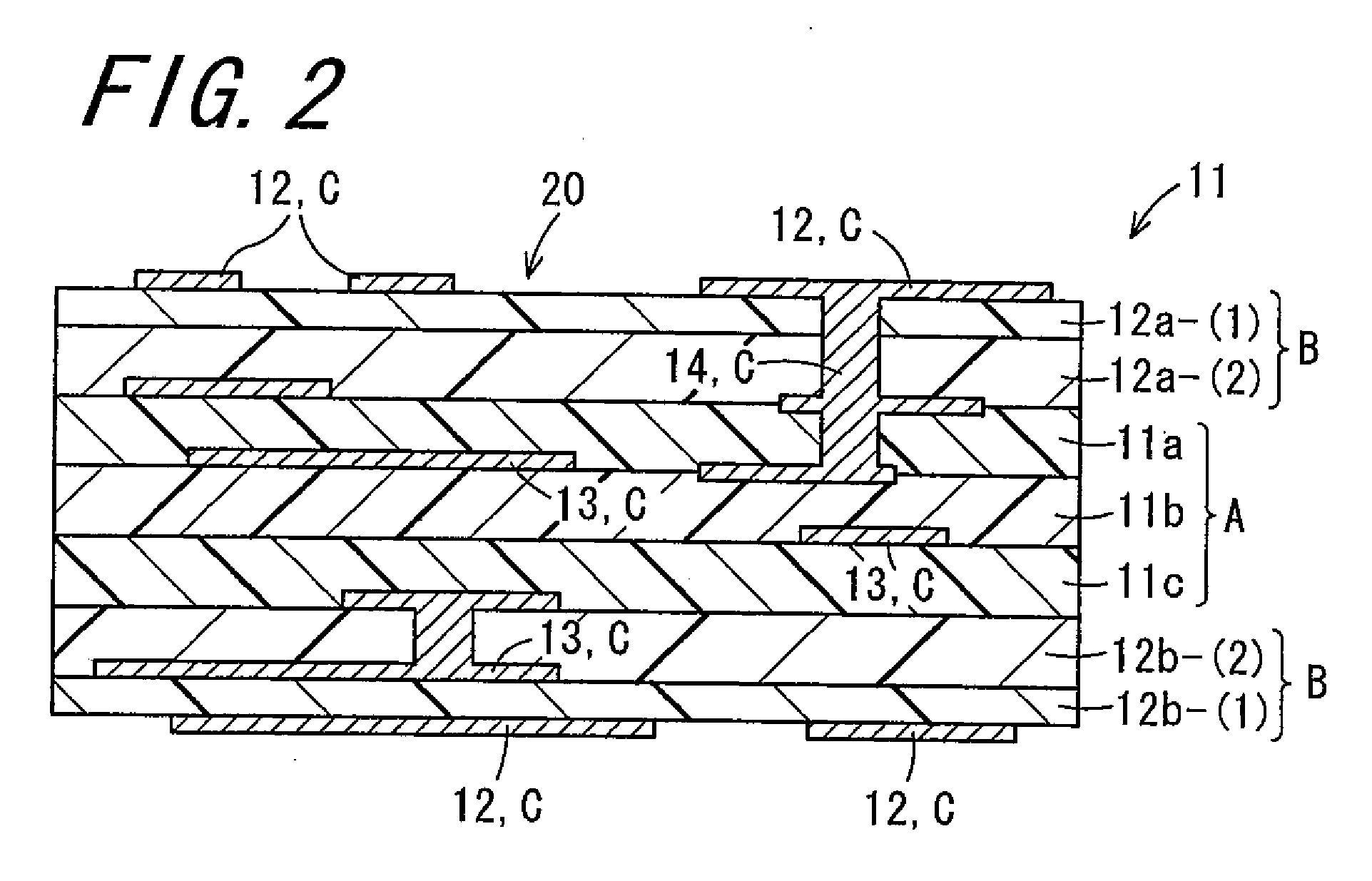

[0102]FIG. 2 is a schematic sectional view showing a multilayer wiring board according to a second embodiment of the invention. In FIG. 2, the multilayer wiring board 2 is composed of: an insulating substrate 11 constituted by stacking together second insulating sheets 11a through 11c which are ceramic green sheets and combined layers 12a and 12b; surface conductor layers 12 formed on the top and back surfaces of the insulating substrate 11; inner conductor layers 13 formed within the insulating substrate 11; and a via-hole conductor 14 for providing connection among the conductor layers.

[0103]The combined layers for constituting the insulating substrate 11 are composed of first and second insulating sheets which are ceramic green sheets having different shrinking starting temperatures. Specifically, the firing shrinking starting temperature of the insulating sheets 12a-(1) 12b-(1) is lower than those of the other insulating sheets 12a-(2), 12b-(2), and 11a through 11c. Meanwhile, t...

example 1

[0128]Referring to Table 1, glass powder and ceramic powder serving as filler were mixed together at the mixing ratio shown in Table 1. Then, ethylcellulose (organic binder) and 2-2-4 trimethyl pentadiol monoisobutyrate (organic solvent) are blended into the powder admixture to form a slurry. The slurry was molded into a thin-layer component by the doctor blade method to obtain green sheets. Whereupon, the insulating sheets for constituting a multilayer insulating substrate were prepared for use (sheets A through H). Note that the crystallization temperature Tc of the glass and the softening point Tg of the glass were determined, by means of DTA (Differential Thermal Analysis), in accordance with a curve obtained with a temperature rising speed kept at 10° C. / min.

[0129]Also listed in Table 1 are the firing shrinking starting temperatures, shrinking ending temperatures, thermal expansion coefficients, and dielectric constants of the individual insulating sheets. In carrying out data ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sheet resistance | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com