Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Increased Tg" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

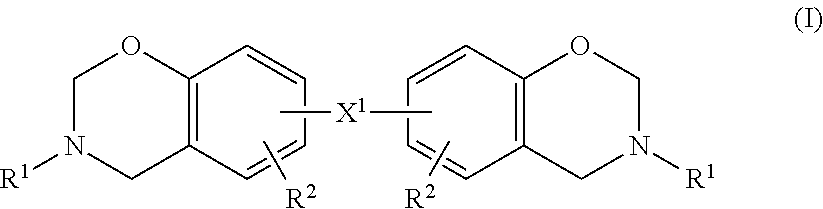

Ternary systems of benzoxazine, epoxy, and phenolic resins

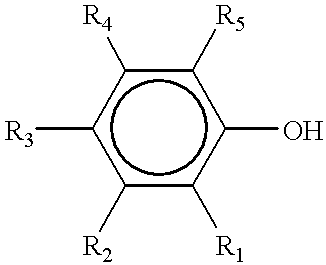

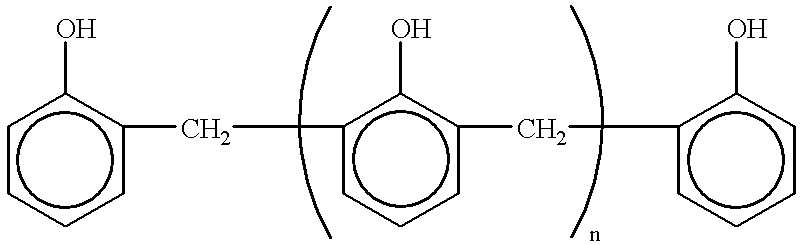

Low viscosity ternary mixtures of benzoxazine, epoxy and phenolic resins have been developed. The blends render homogeneous and void free cured specimen with a wide range of properties. Melt viscosity values as low as 0.3 Pa.s at 100° C. can be achieved. The phenolic resin acts as a cure accelerator to the system, besides its typical function as a hardener of epoxy resin. Glass transition temperatures Tg as high as 170° C. can also be obtained.

Owner:EDISON POLYMER INNOVATION EPIC

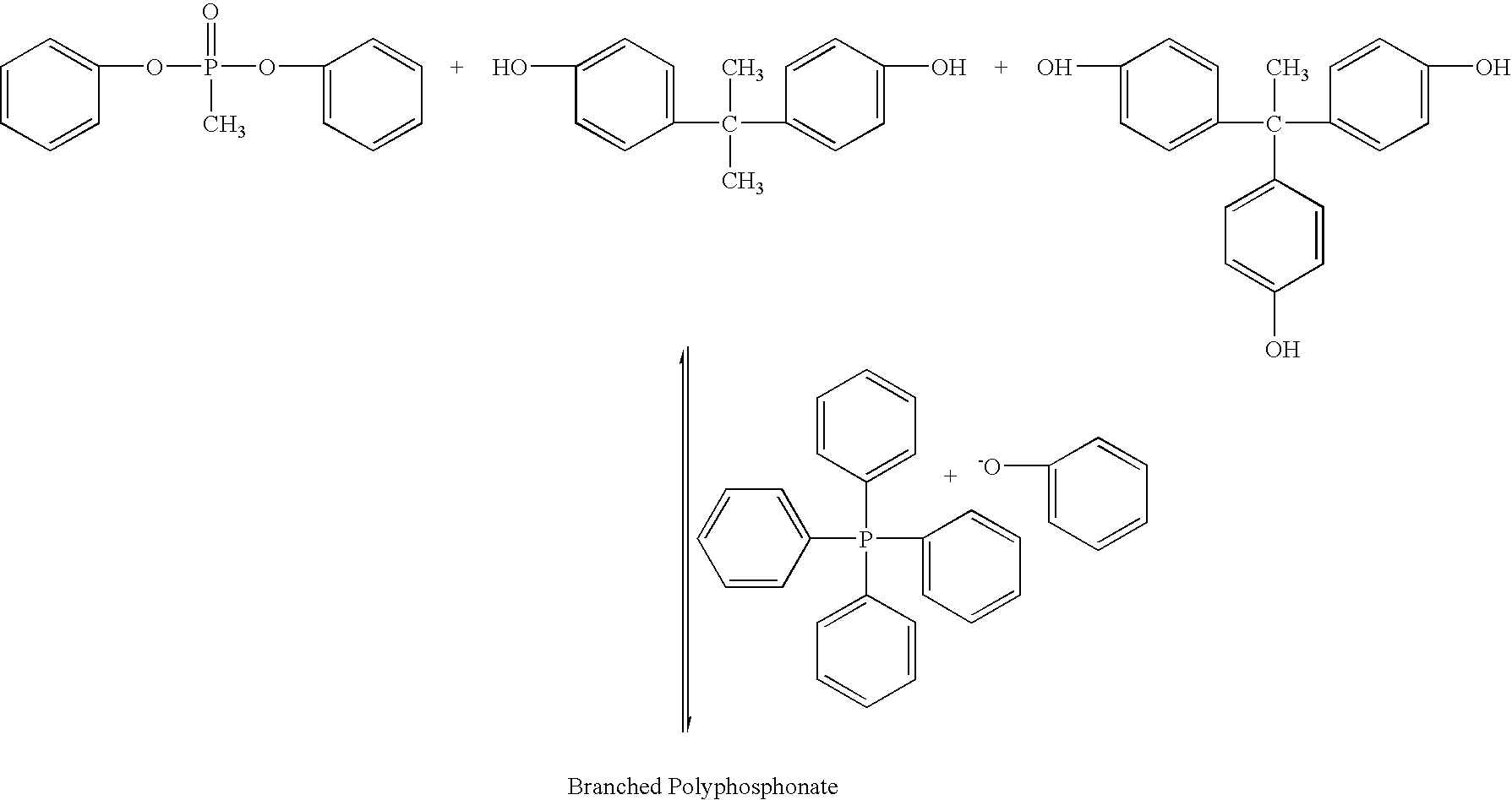

Branched polyphosphonates that exhibit an advantageous combination of properties, and methods related thereto

Disclosed are branched polyphosphonates produced via a superior transesterification process, and methods related thereto. These branched polyphosphonates exhibit a unique and advantageous combination of properties, such as outstanding fire resistance, improved heat stability, improved toughness, and superior processing characteristics. Also disclosed are polymer compositions that comprise these branched polyphosphonates and at least one other polymer, wherein the resulting polymer compositions exhibit flame retardant properties. Further disclosed are articles of manufacture produced from these polymers, such as fibers, films, coated substrates, moldings, foams, fiber-reinforced articles, or any combination thereof; these articles may be coated with a moisture barrier to enhance their moisture resistance properties.

Owner:FRX POLYMERS LLC

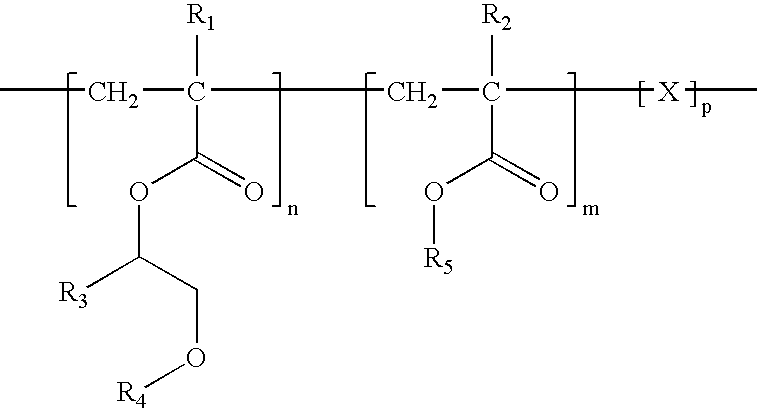

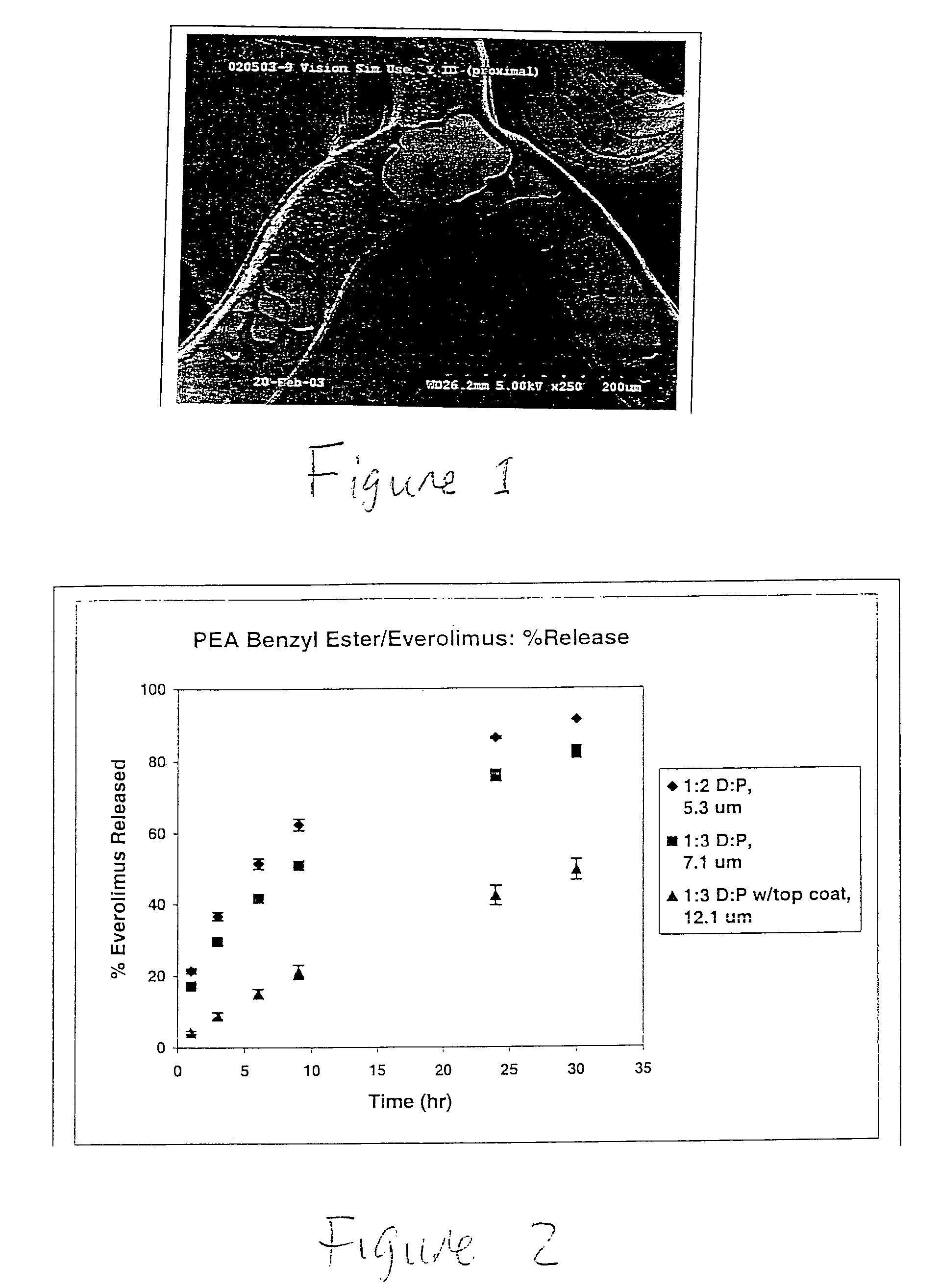

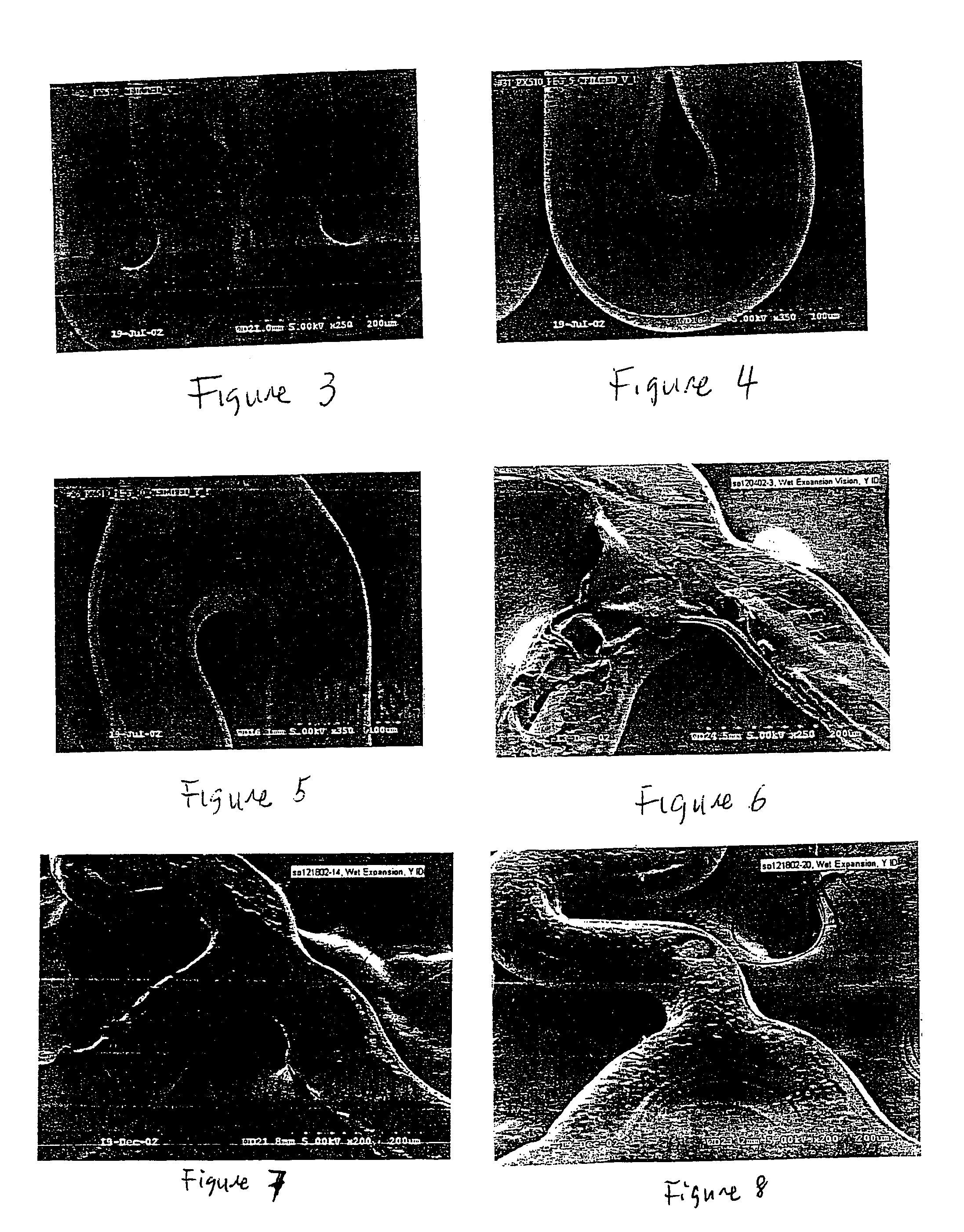

Coating on a balloon comprising a polymer and a drug

ActiveUS20100063570A1Rapid drug releaseGood mechanical integrityBiocidePeptide/protein ingredientsMedicineMedical device

Owner:ABBOTT CARDIOVASCULAR

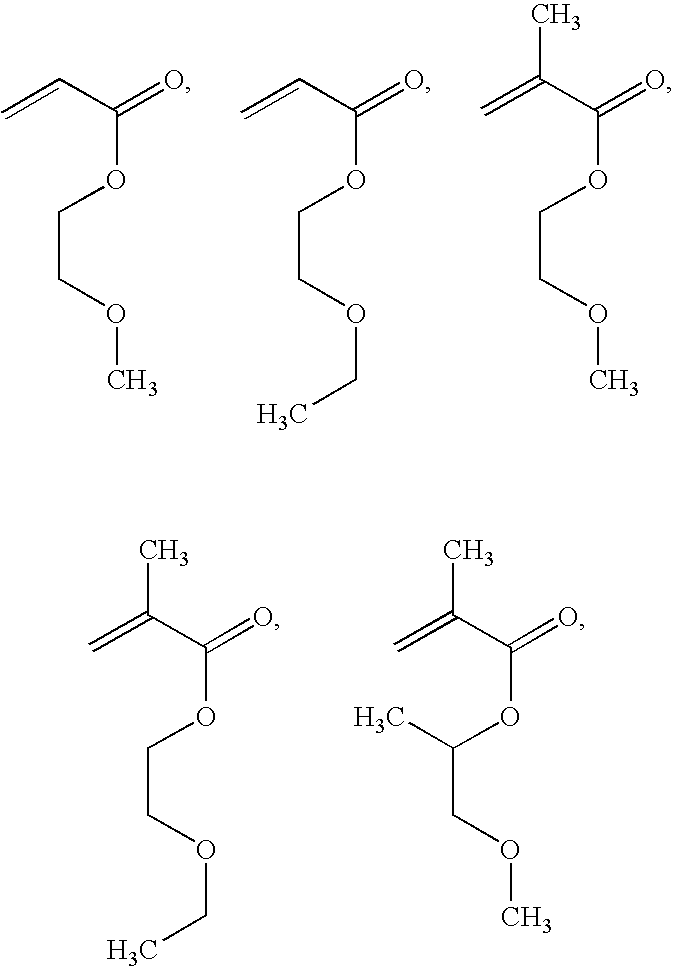

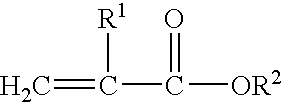

Wet surface adhesives

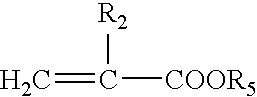

InactiveUS6855386B1Overcome environmentalOvercome safety undesirabilityEnvelopes/bags making machineryFilm/foil adhesivesMeth-Solvent

A wet stick pressure sensitive adhesive comprising the solventless polymerization product of: a) about 30 to about 70 parts by weight of an (meth)acrylate ester monomer wherein the (meth)acrylate ester monomer, when homopolymerized, has a Tg of less than about 10° C.; b) about 70 to about 30 parts by weight of a hydrophilic acidic comonomer; and c) about 10 to 100 parts based on 100 parts of the sum of components (a+b) of a non-reactive plasticizing agent, wherein the pressure sensitive adhesive adheres to wet substrate surfaces and a method of making.

Owner:3M INNOVATIVE PROPERTIES CO

Electrically insulative powder coatings and compositions and methods for making them

InactiveUS20050065294A1Increased TgImprove adhesionPlastic/resin/waxes insulatorsInsulated cablesEpoxyAcrylic resin

The present invention provides powder compositions comprising from 20 to 90 phr of one or more than one silicone resin having a glass transition temperature (Tg) of at least 40° C., from 10 to 80 phr of one or more than one resin chosen from glycidyl functional acrylic resin, mixtures of aromatic epoxy resin or novolac resin with carboxyl functional acrylic resin carboxyl functional polyester resin or glycidyl functional acrylic resin, and one or more than one filler, such as wollastonite, barium sulfate, mica, talc, alumina, layered silicates like montmorillonite, and mixtures thereof. The one or more than one silicone resin may or may not be flaked and may or may not contain silanol groups. The compositions of the present invention provide single layer or multilayer powder coatings that are free of voids larger than 30 μm in diameter, and which may meet the UL Class H (180° C.) certification for electrical insulation applications. Further, the compositions may be used to provide powder coatings, films, moldings, electrical potting compounds and electrical encapsulation compounds.

Owner:CRAMER MICHELE LE +2

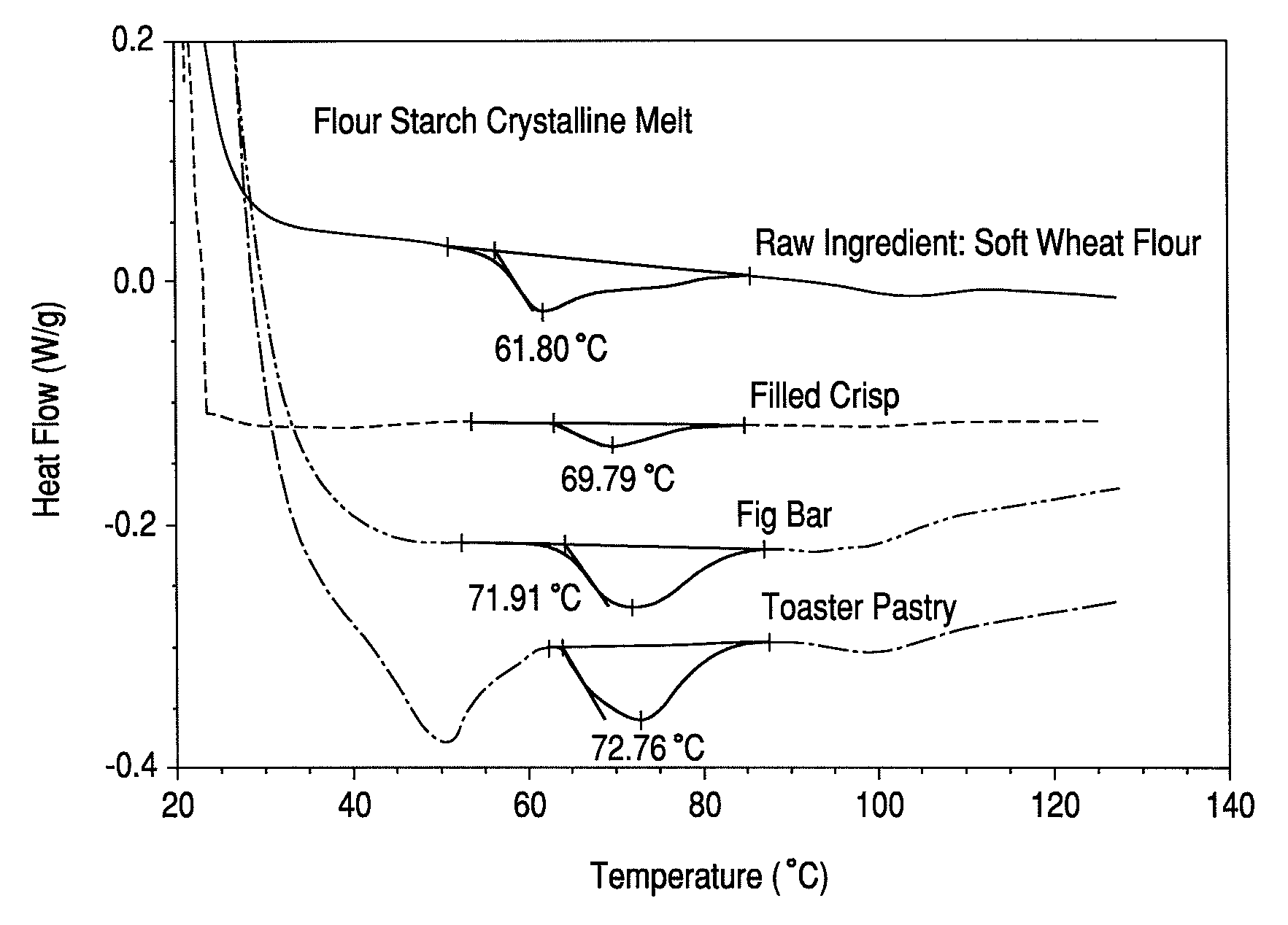

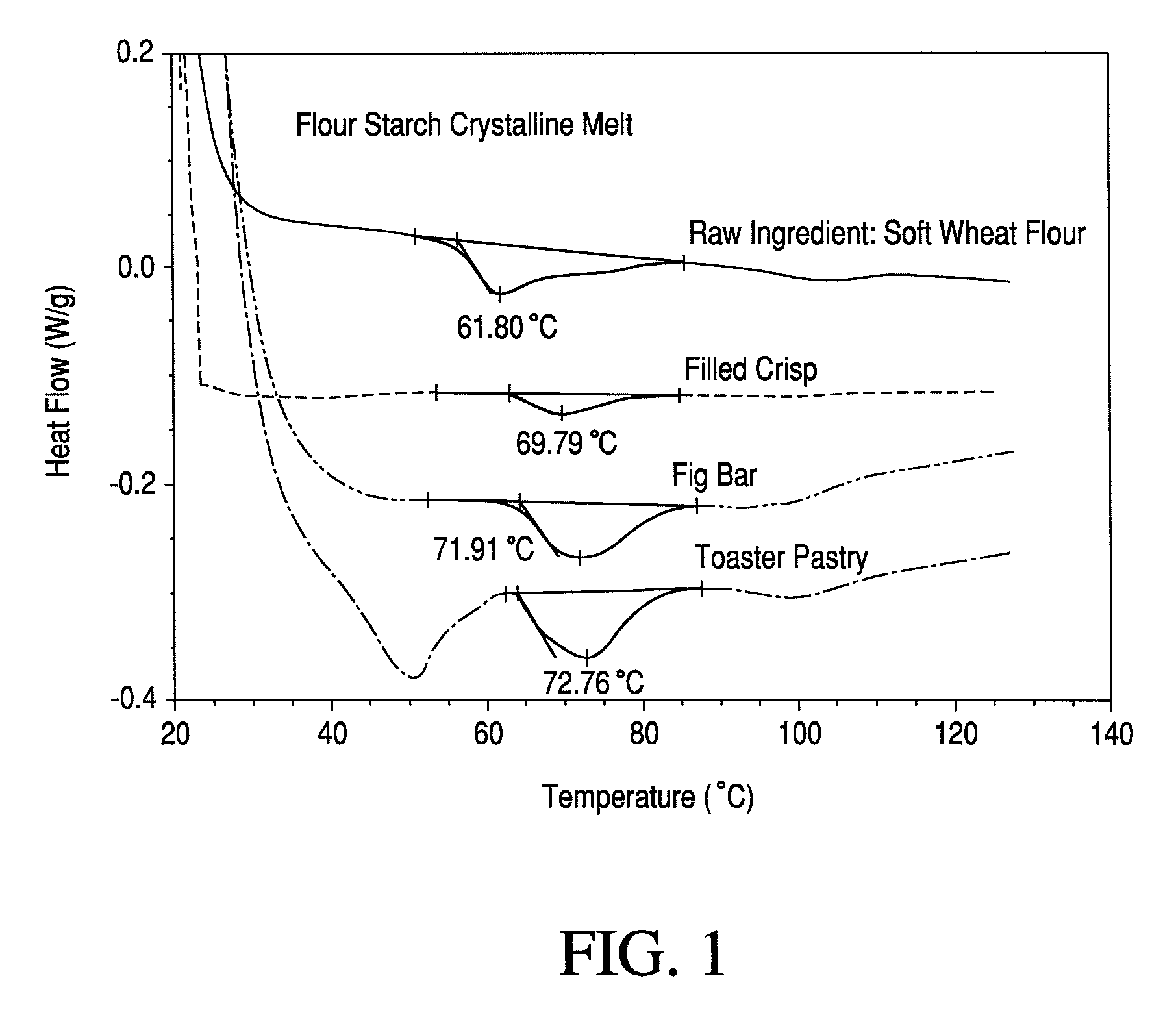

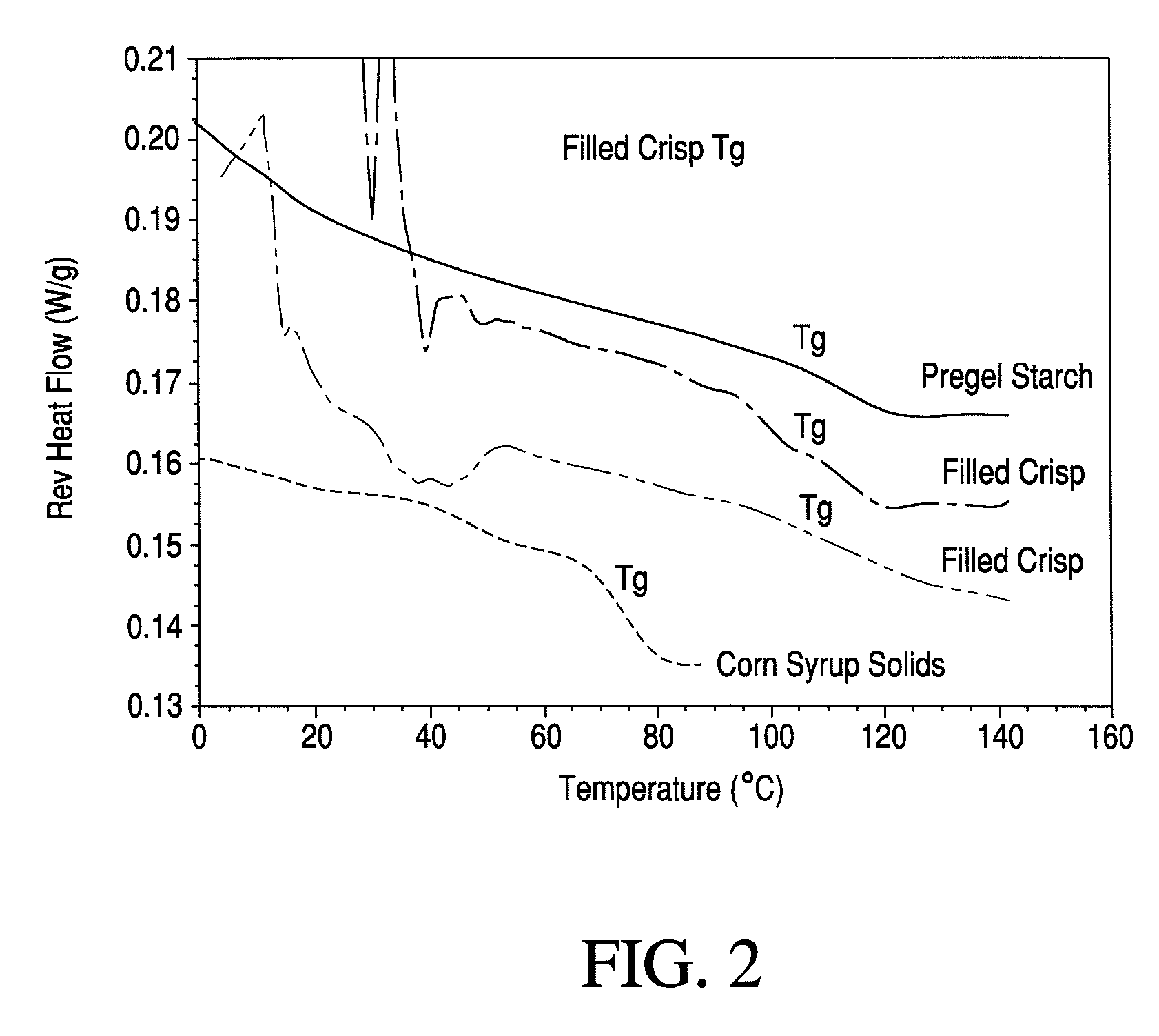

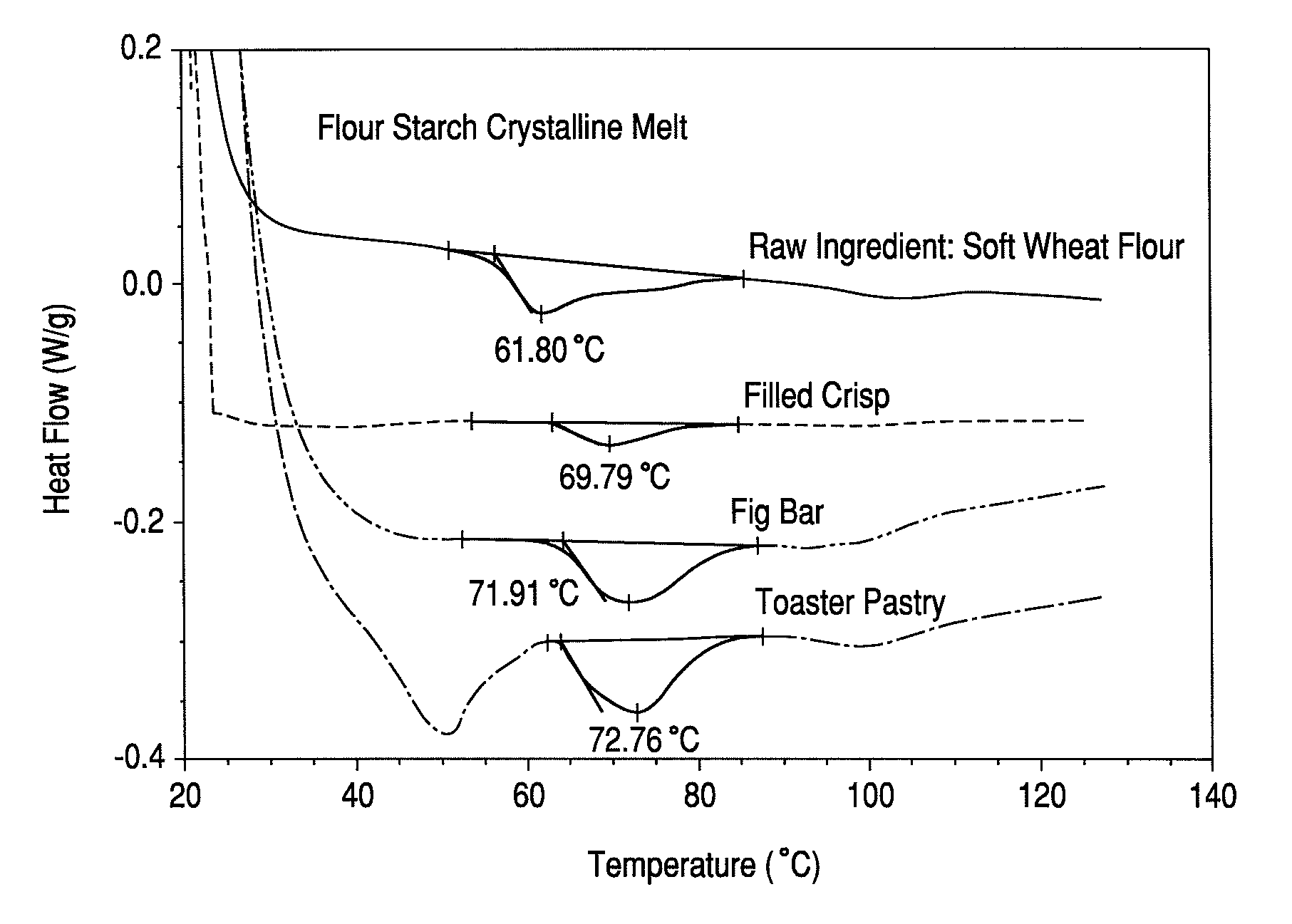

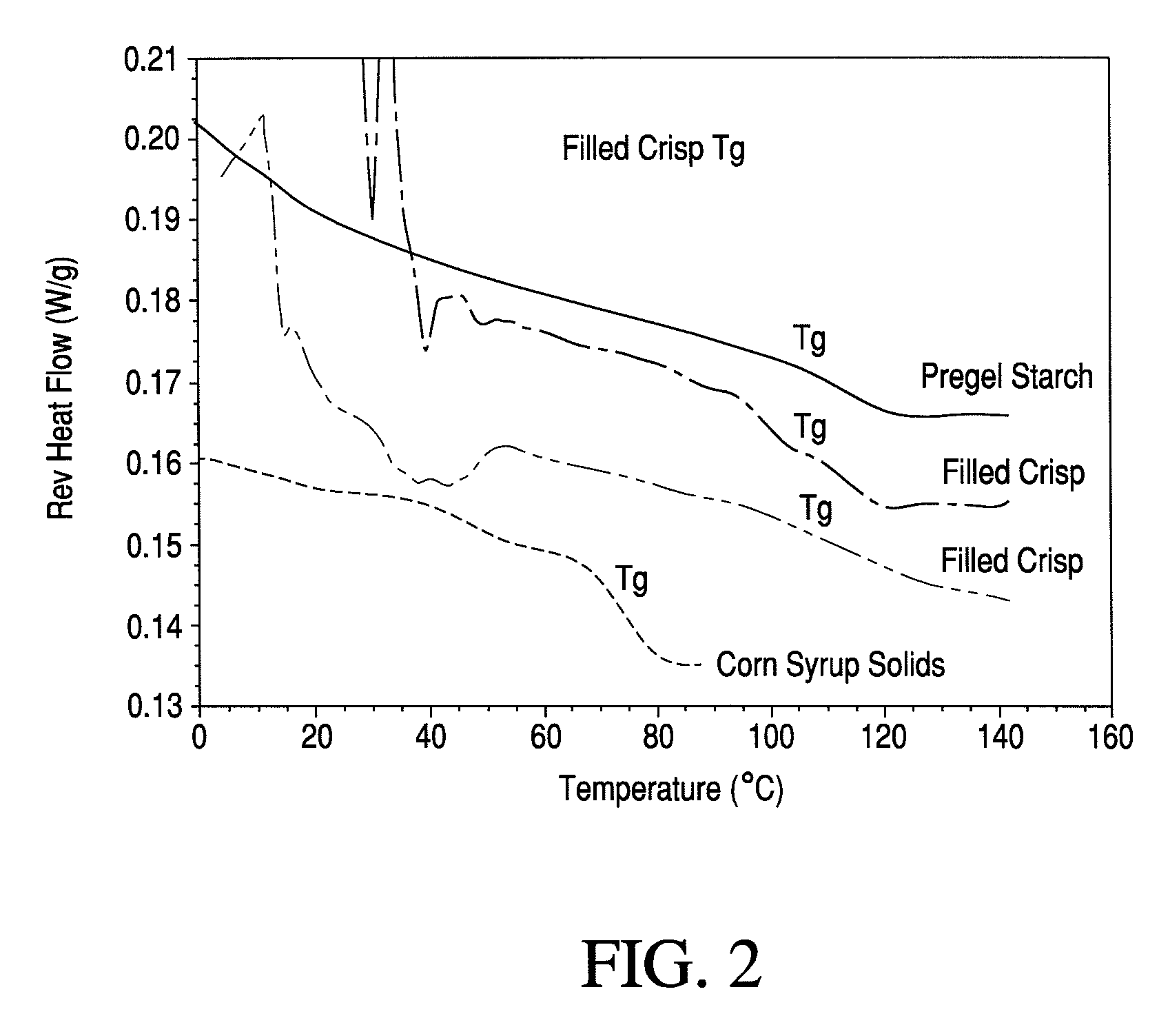

Filled, baked crispy snack having a high moisture content

ActiveUS20090220654A1Improve gelatinizationIncreased TgDough treatmentConfectioneryHigh resistanceReady to eat

A shelf-stable, filled, baked crispy snack which possesses a crispy textured casing and a moist, soft textured filling over a prolonged period of time is obtained by formulating a casing which when baked has a high glass temperature (Tg) at a high moisture content. Increasing the degree of starch gelatinization to increase the Tg may be achieved during baking and by the addition of a pregelatinized starch. The high Tg baked casing permits the use of a high moisture content filler in high amounts to provide a shelf-stable substantial textural dichotomy in the filled, baked, crispy snack. The filled, baked snack exhibits an unexpectedly high resistance to deformation or peak force at high baked casing moisture contents. The baked snack is ready-to-eat out of the packaging and does not have to be toasted, microwaved or further baked, cooked, or heated for consumption, or to achieve a crisp textured casing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

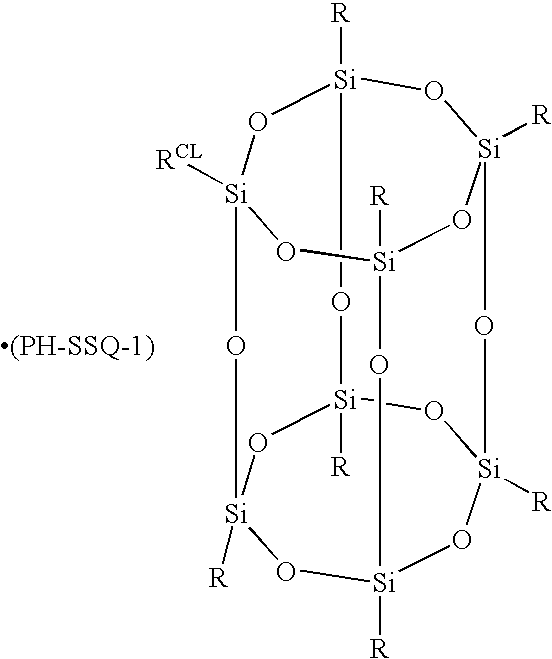

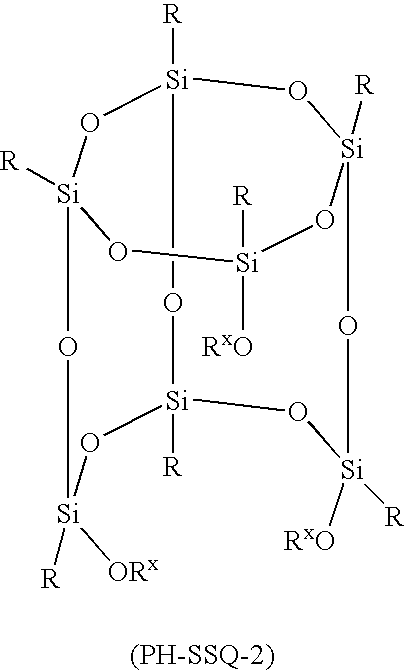

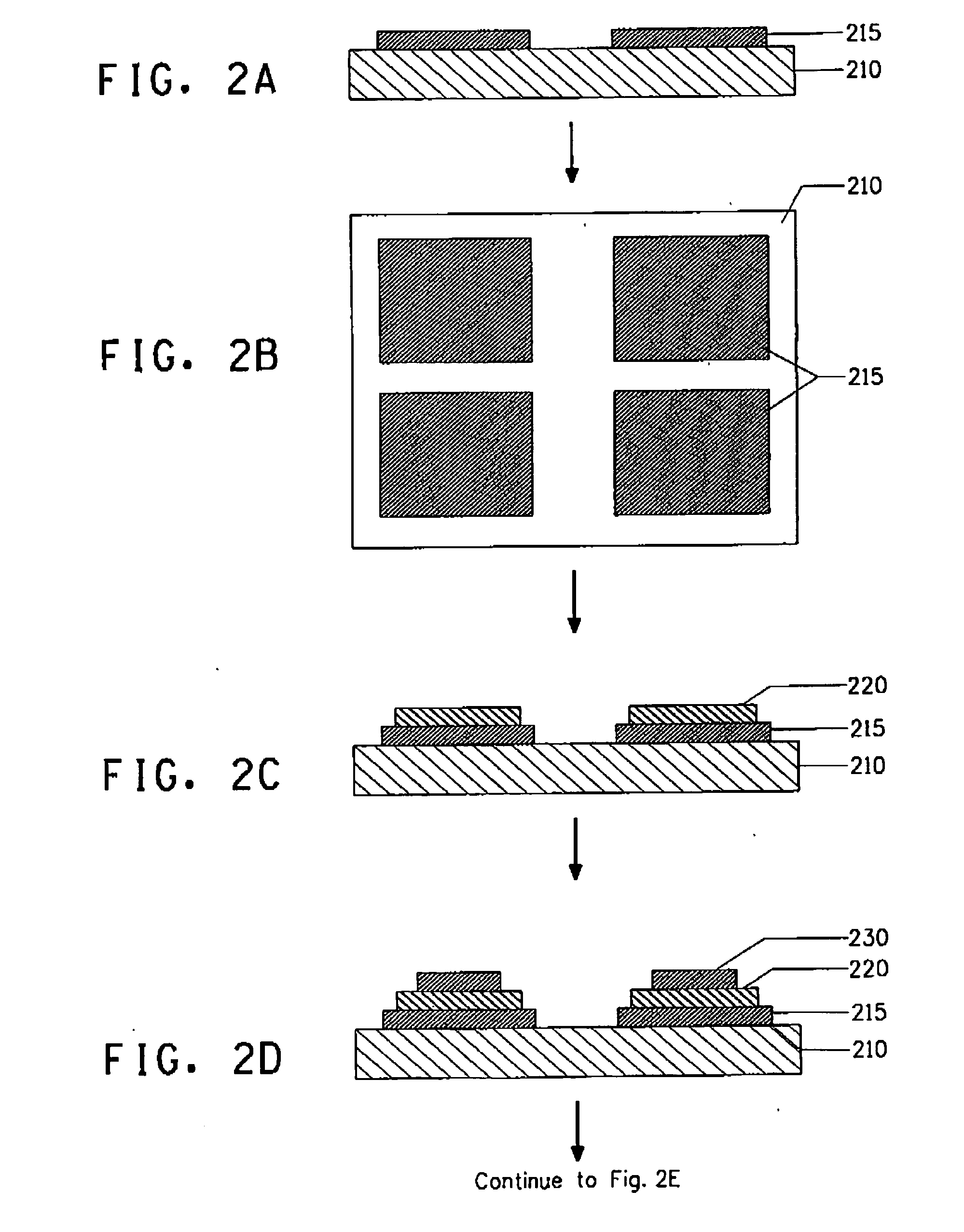

Molecular photoresists containing nonpolymeric silsesquioxanes

ActiveUS20050112382A1Lower activation energyImprove imaging resolutionSilicon organic compoundsPhotosensitive materialsResistVitrification

A nonpolymeric silsesquioxane is provided wherein at least one silicon atom of the silsesquioxane is directly or indirectly bound to an acid-cleavable substituent RCL. The silsesquioxane has a glass transition temperature Tg of greater than 50° C, and the RCL substituent can be cleaved from the silsesquioxane at a temperature below Tg, generally at least 5° C. below Tg. The remainder of the silicon atoms within the silsesquioxane structure may be bound to additional acid-cleavable groups, acid-inert polar groups RP, and / or acid-inert nonpolar groups RNP. The nonpolymeric silsesquioxane can be a polyhedral silsesquioxane optionally having one to three open vertices, such that the polyhedron appears to be a “partial cage” structure, or a macromer of two to four such polyhedral silsesquioxanes. Photoresist compositions containing the novel nonpolymeric silsesquioxanes are also provided, as is a method for using the compositions in preparing a patterned substrate.

Owner:IBM CORP

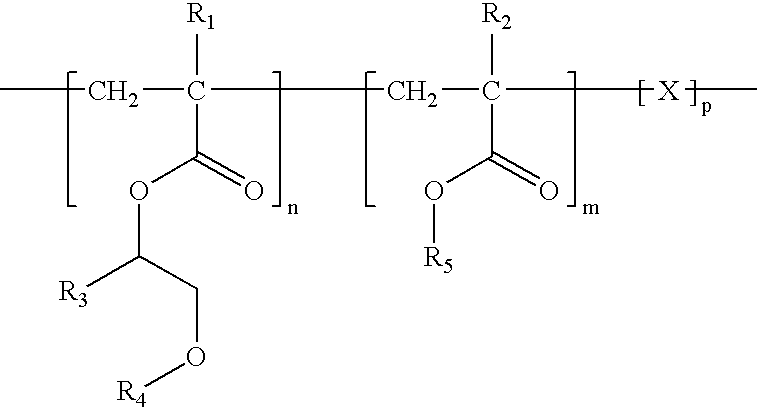

Methods for modulating thermal and mechanical properties of coatings on implantable devices

InactiveUS7820732B2High molecular weightNarrow molecular weight distributionStentsSurgical adhesivesVulnerable plaqueImplanted device

Methods for modulating and enhancing thermal and mechanical properties and biocompatibilities of coatings on implantable devices are disclosed. Implantable devices containing the enhanced thermal and mechanical properties and biocompatibilities are also described. The implantable devices can be used to treat a medical condition such as vulnerable plaque or restenosis.

Owner:ABBOTT CARDIOVASCULAR

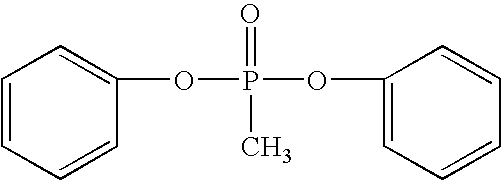

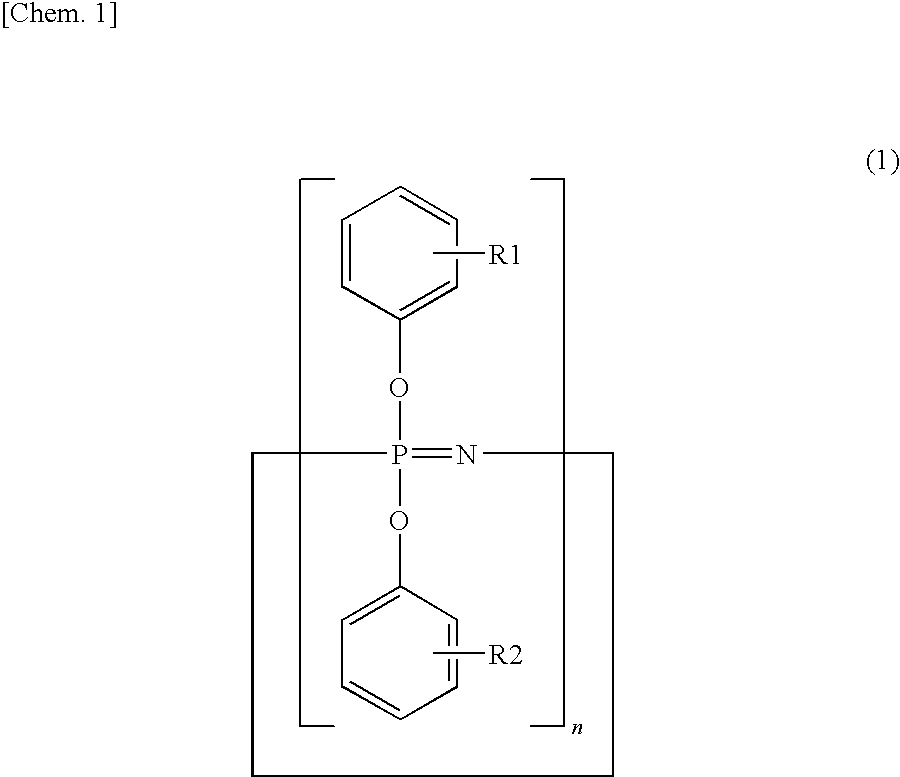

Flame-retardant resin composition, and prepreg, resin sheet and molded article using the same

InactiveUS20100233486A1Maintain heat resistanceLow dielectric constantSynthetic resin layered productsPrinted circuit aspectsEpoxyHalogen

There is provided a flame-retardant resin composition which can maintain heat resistance at a high level and simultaneously provide low dielectric constant and low dielectric loss tangent while ensuring flame-retardancy without containing any halogen compound causing the generation of harmful substances. This flame-retardant resin composition comprises 0.1 to 200 parts by mass of a cyclophosphazene compound represented by the following formula (1):wherein n=3 to 25; and one of R1 and R2 is CN and the other is H, or both of R1 and R2 are CN, based on 100 parts by mass of a resin component containing a polyfunctional epoxy resin having a biphenyl aralkyl structure, wherein the ratio of cyanophenoxy groups in the compound is 2 to 98% of the total number of phenoxy groups and cyanophenoxy groups in the compound.

Owner:PANASONIC CORP

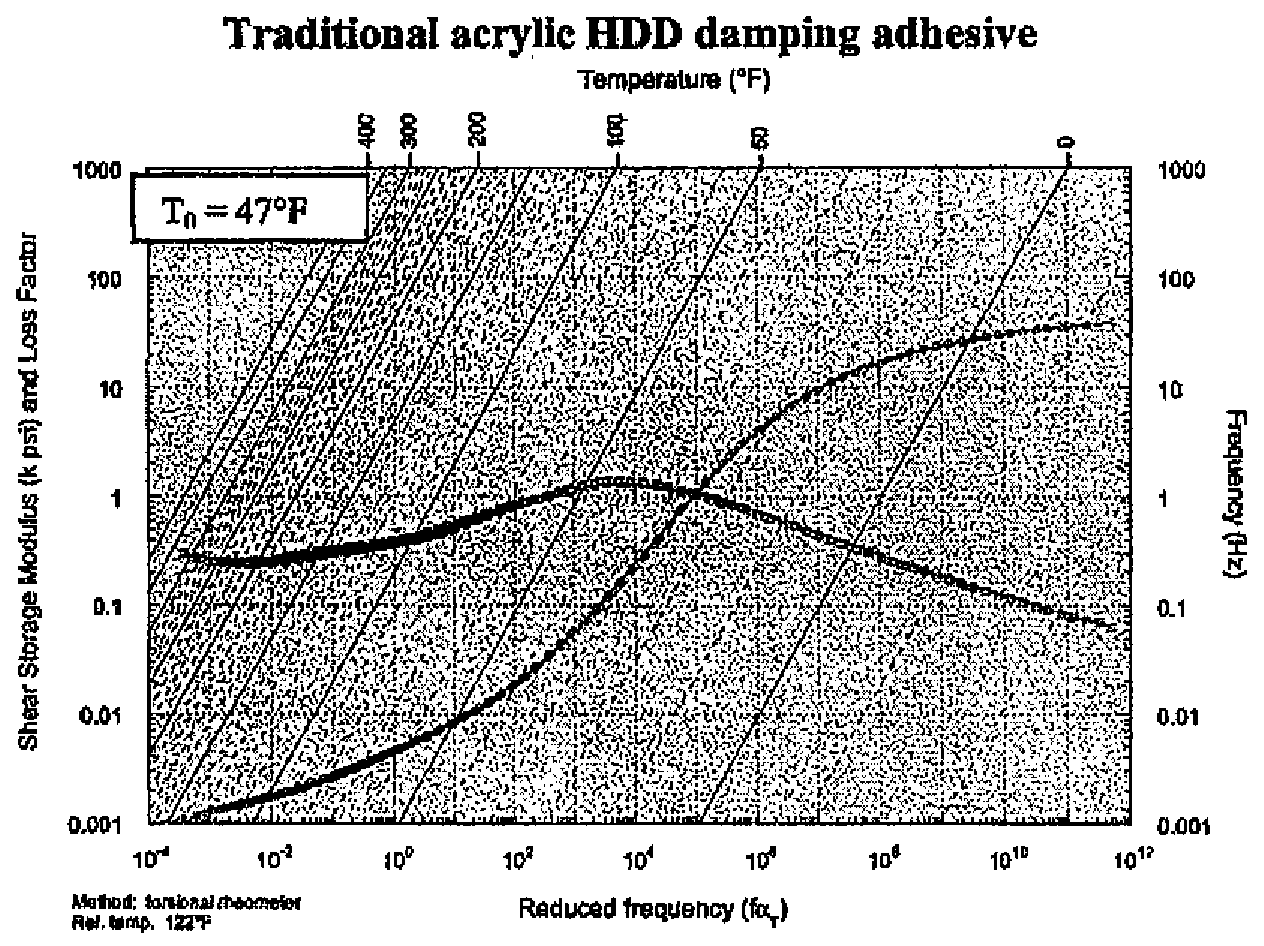

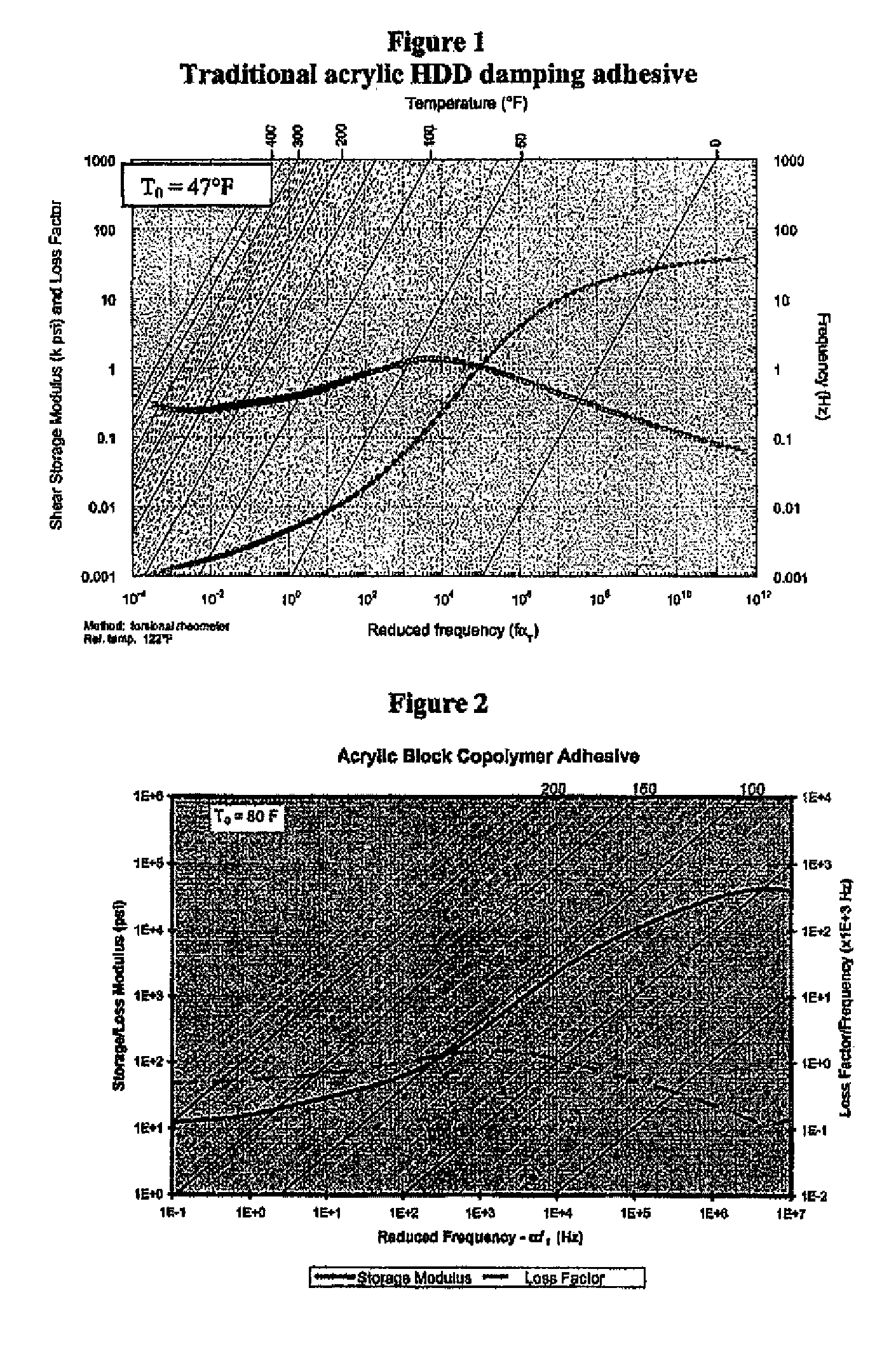

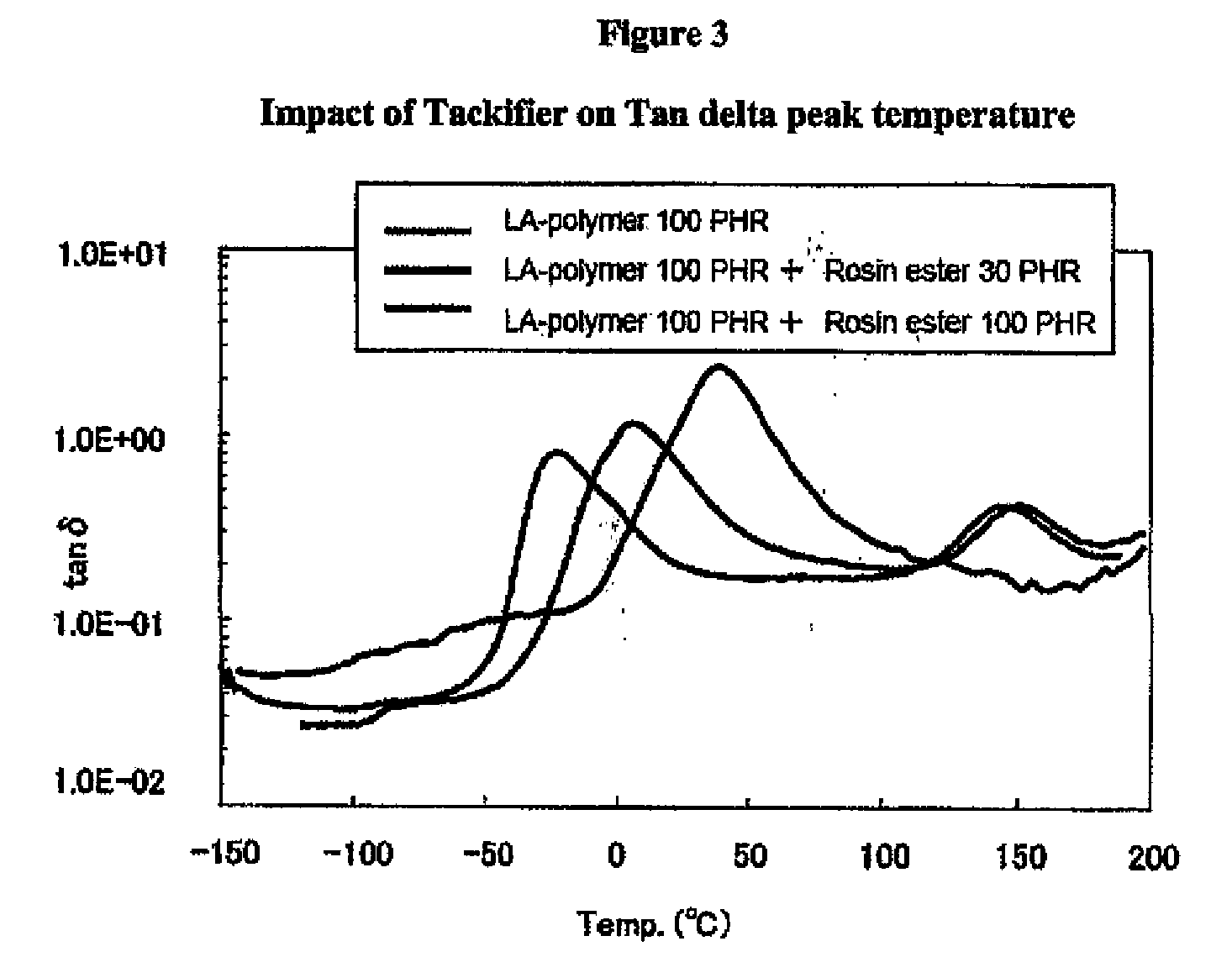

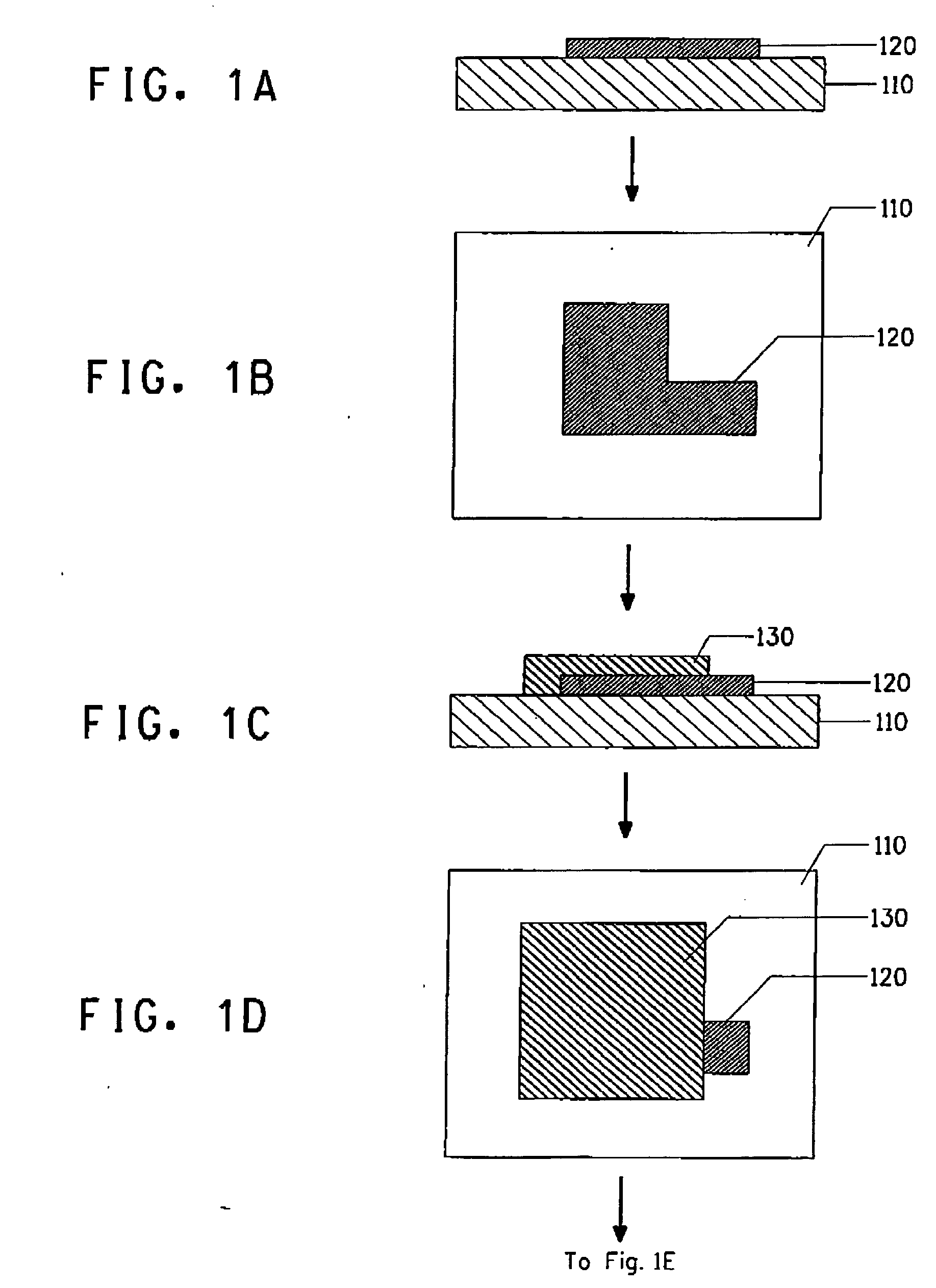

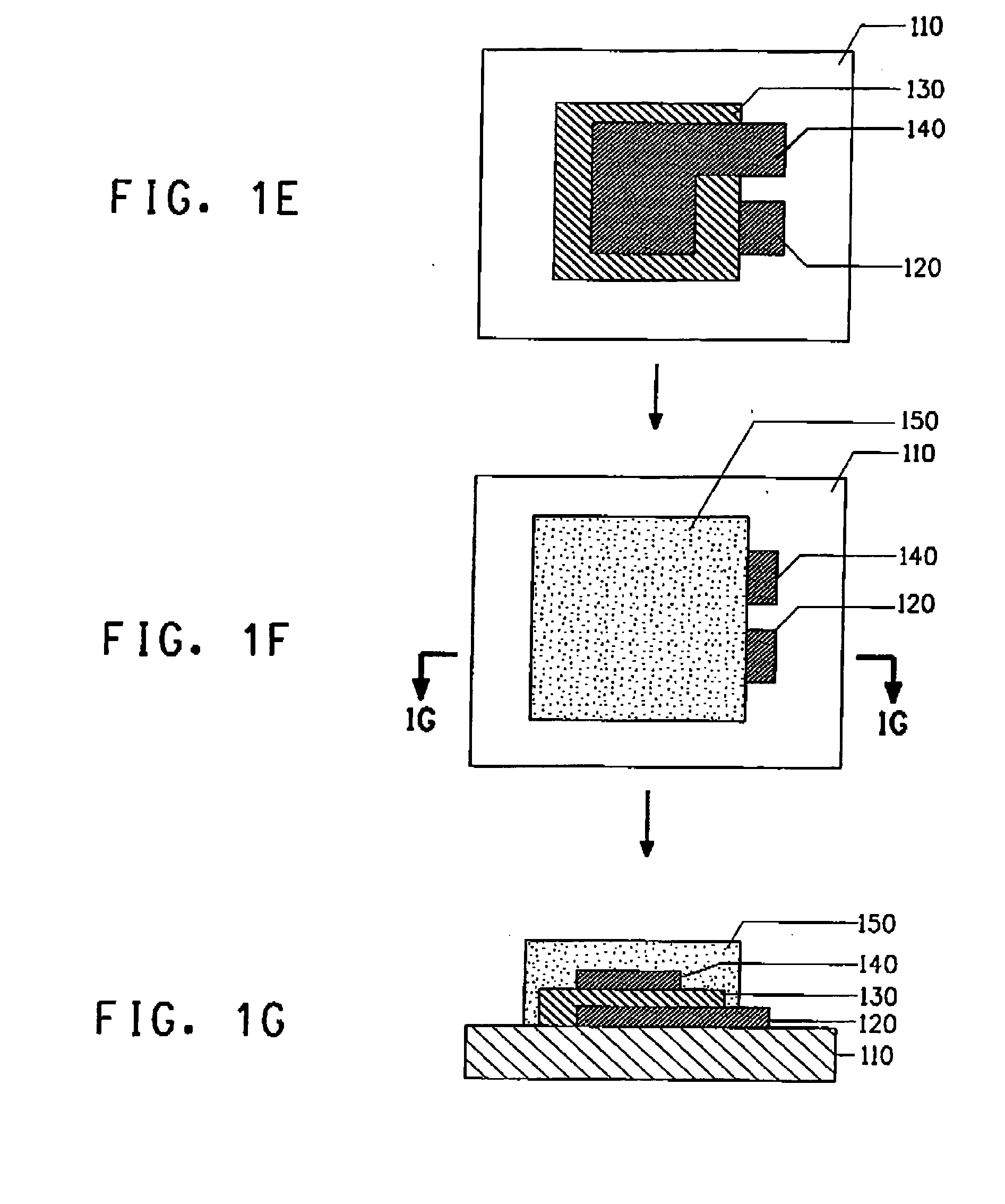

Acrylic Block Copolymers as Acoustical and Vibrational Dampening Material for Use in Electronic Devices

InactiveUS20080194759A1Improve adhesion performanceImproved acoustical and vibrational damping performanceEmulsion paintsAdhesivesPolymer scienceMeth-

An electronic device comprises a pressure sensitive adhesive comprising a block copolymer comprising at least one block of a poly(alkyl(meth)acrylate), e.g., poly(methyl(meth)acrylate), and at least one block of a poly(alkylacrylate), e.g., poly(butylacrylate). The adhesive can further comprise a tackifier, e.g., a rosin ester.

Owner:BRADY WORLDWIDE INC

Hydrophobic crosslinkable compositions for electronic applications

InactiveUS20070244267A1Increased TgImprove thermal stabilityPrinted circuit aspectsPrinted capacitor incorporationEpoxyOrganic solvent

Compositions comprising: an epoxy containing cyclic olefin resin with a water absorption of 2% or less; one or more phenolic resins with water absorption of less than 2% or less; an epoxy catalyst; optionally one or more of an electrically insulated filler, a defoamer and a colorant and one or more organic solvents. The compositions are useful as encapsulants and have a cure temperature of 190° C. or less.

Owner:EI DU PONT DE NEMOURS & CO

Low dissipation factor resin composition and product made thereby

A low dissipation factor resin composition comprises: (A) 100 to 150 parts by weight of a vinyl-containing compound or a polymer thereof; (B) 0 to 75 parts by weight of styrene-butadiene-divinylbenzene terpolymer, styrene-butadiene-maleic anhydride terpolymer, vinyl functional polybutadiene urethane oligomer or a combination thereof; (C) 30 to 150 parts by weight of flame retardant; and (D) 0.1 to 10 parts by weight of peroxide. The resin composition and a product made thereby are applicable to a copper-clad laminate and a printed circuit board, characterized by having low dissipation factor at high frequency and satisfactory thermal resistance and thermal expansion.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Fusible reactive media

InactiveUS20060204684A1Improve stain resistanceImprove waterproof performanceCoatingsThermographyPorous layerRecord element

An inkjet recording element comprises a support having thereon in order, from top to bottom, a fusible, porous layer comprising fusible multifunctional polymer particles derived from an aqueous dispersion that comprise a thermoplastic polymer with at least two reactive functional groups capable of crosslinking with each other. Optionally, an ink-carrier-liquid receptive layer is present between the fusible, porous layer and the support. Also disclosed is a method of inkjet printing on the element.

Owner:EASTMAN KODAK CO

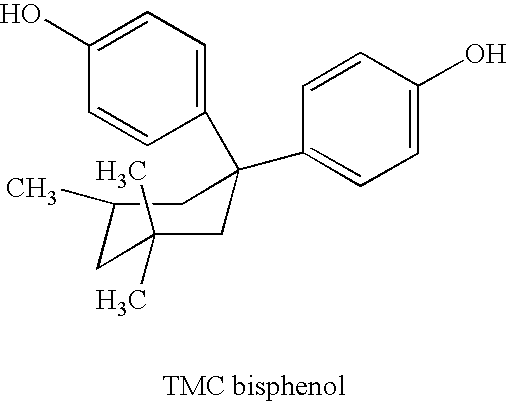

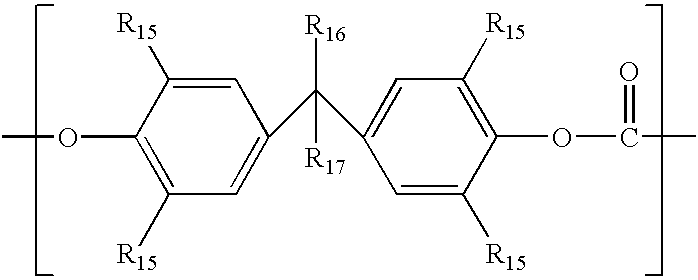

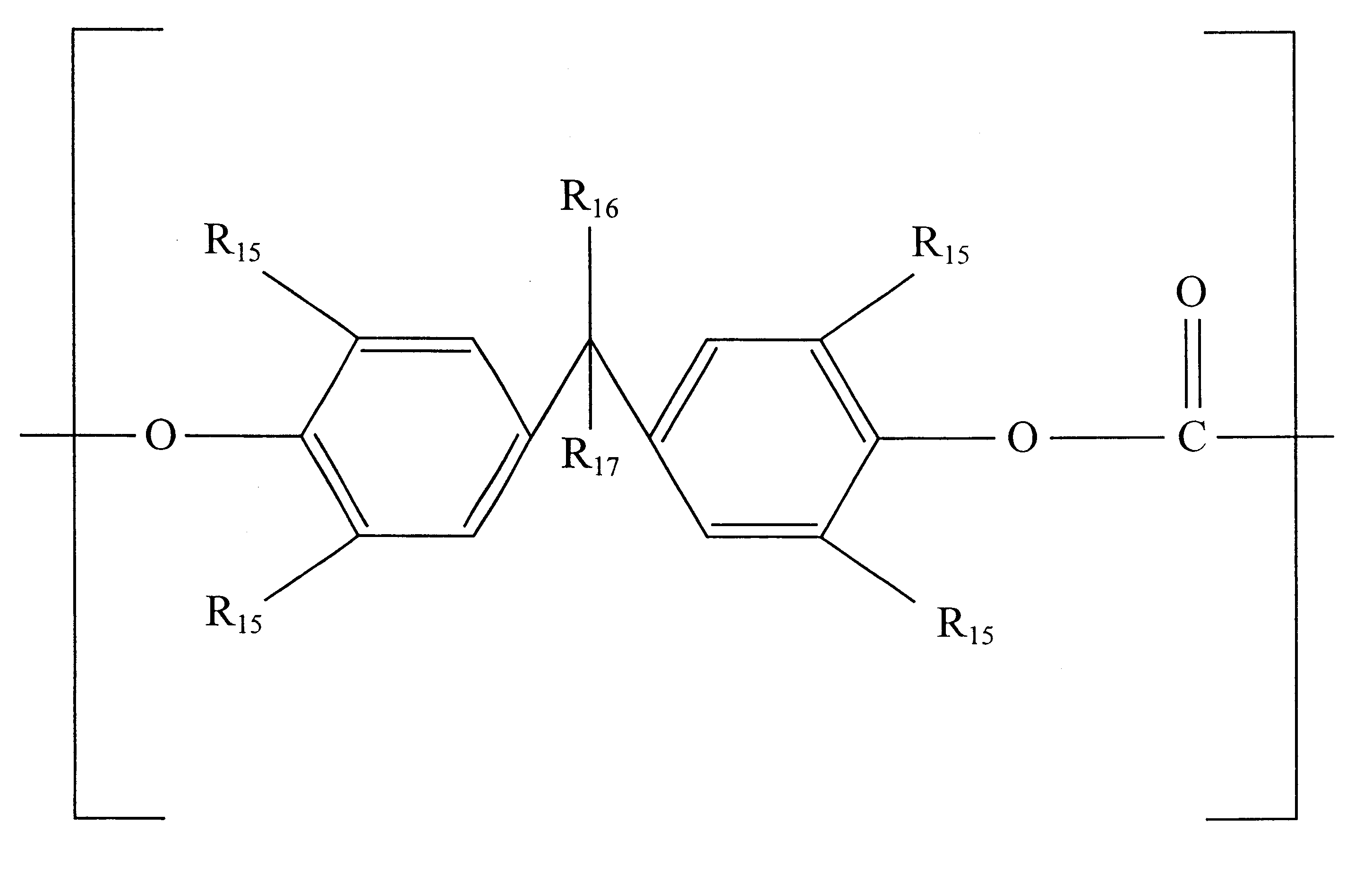

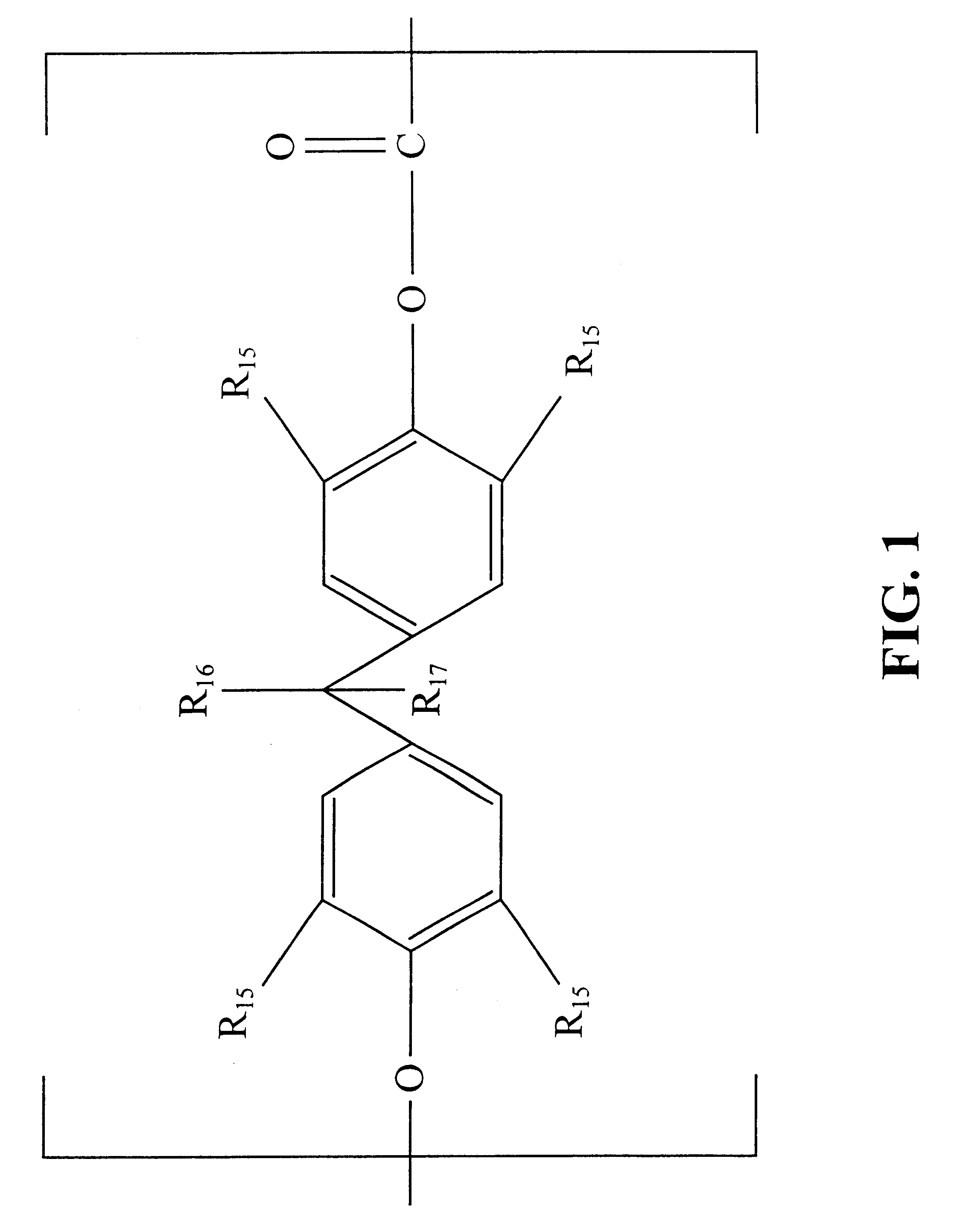

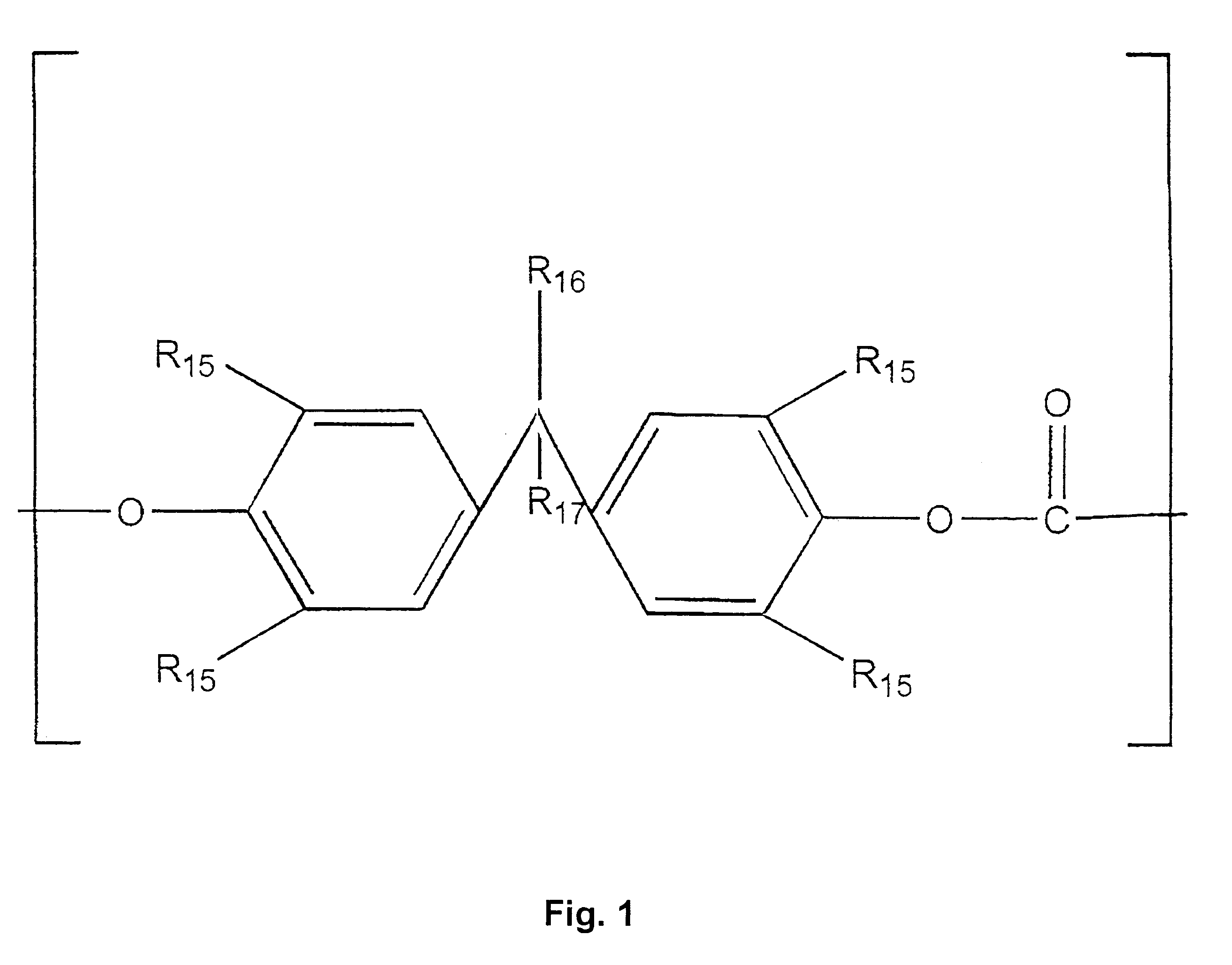

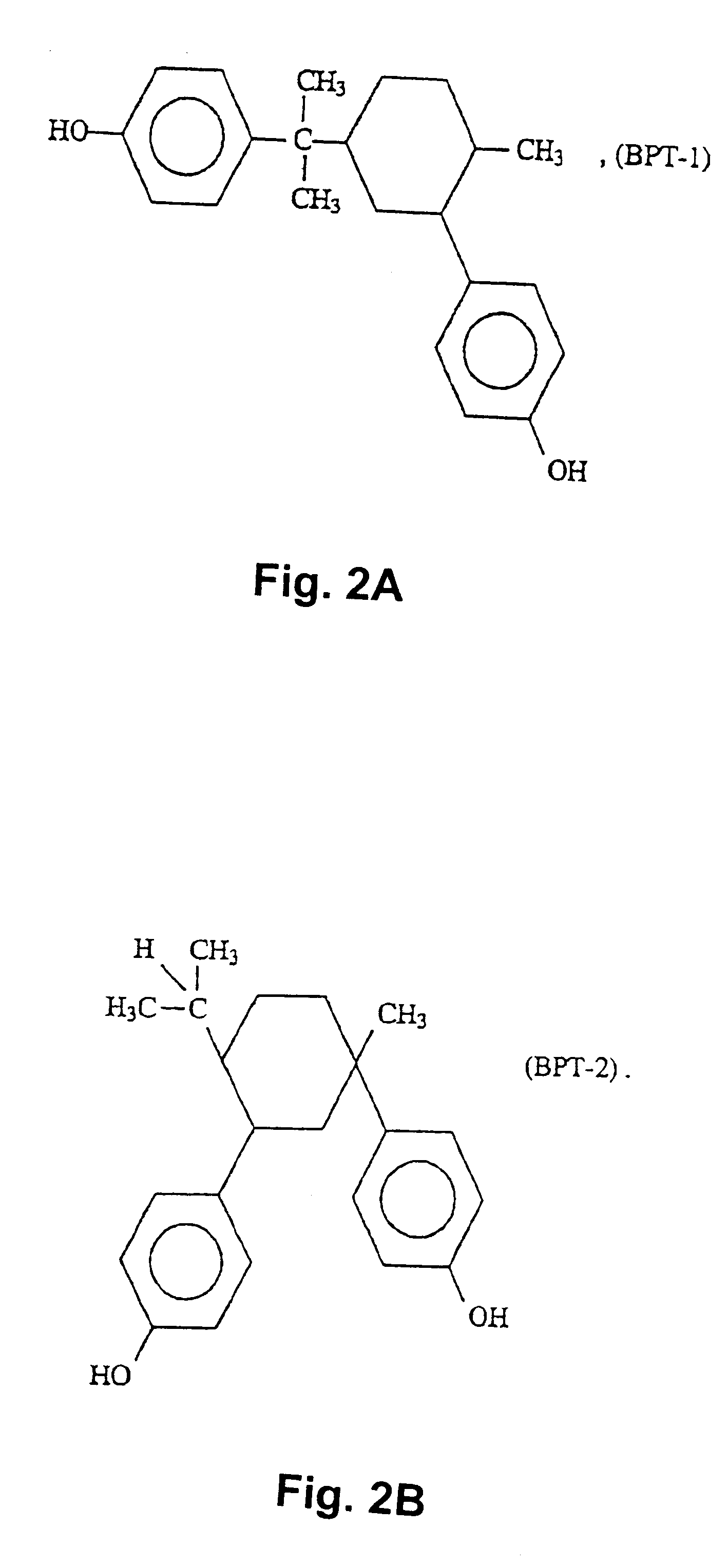

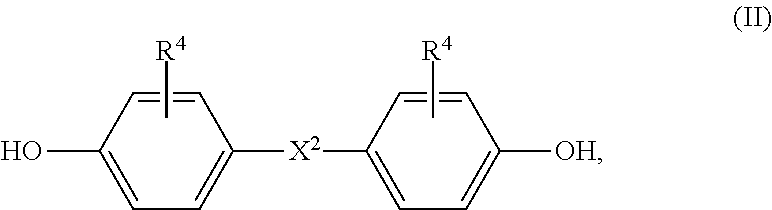

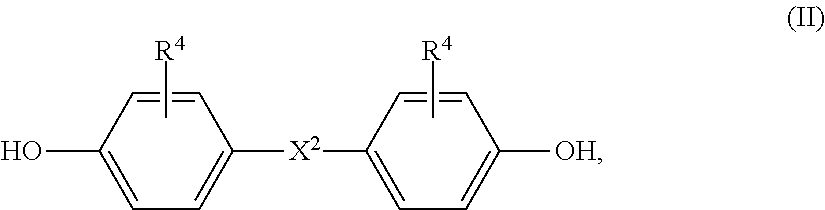

Method of making polycarbonates

Copolymers of BPA, BPT-1 and BPT-2, can be used as a modifier to enhance the thermal properties of a BPA polymer. A single copolymer modifier can be used in differing amounts to produce a product with desired thermal properties. Thus, polycarbonate can be made by combining a bisphenol A polycarbonate and a BPA / BPT-1 / BPT-2 copolymer modifier, and mixing the combined materials to form a blend. By adjusting the relative amounts and the properties of the bisphenol A polycarbonate and BPA / BPT-1 / BPT-2 copolymer, the glass transition temperature and the toughness of the blend can be selected. Suitable BPA / BPT-1 / BPT-2 copolymers contain BPT-1 and BPT-2 in a ratio, BPT-1 / BPT-2, in the range of 70 / 30 to 10 / 90, preferably less than or equal to 50 / 50, for example around 30 / 70.

Owner:SHPP GLOBAL TECH BV

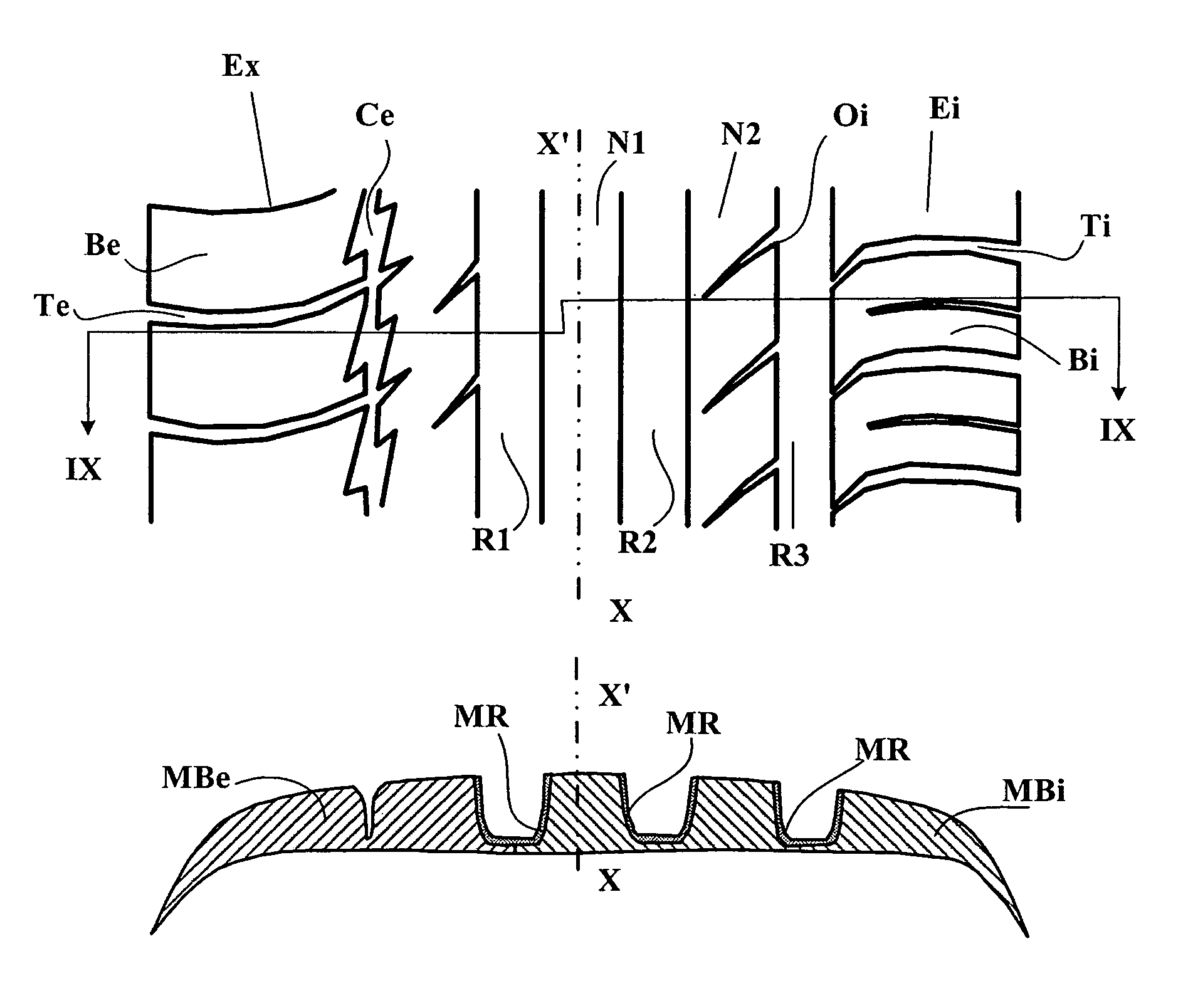

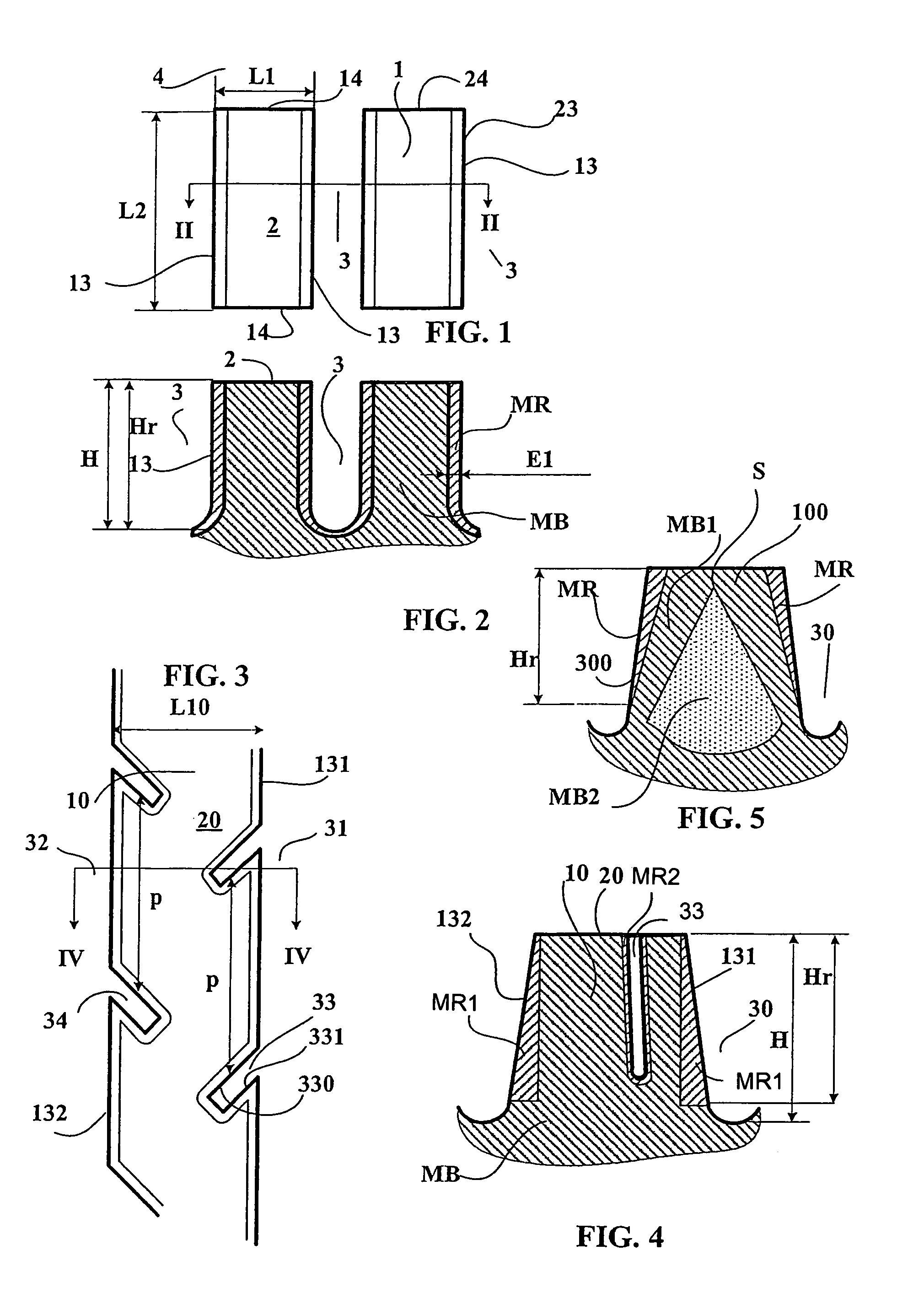

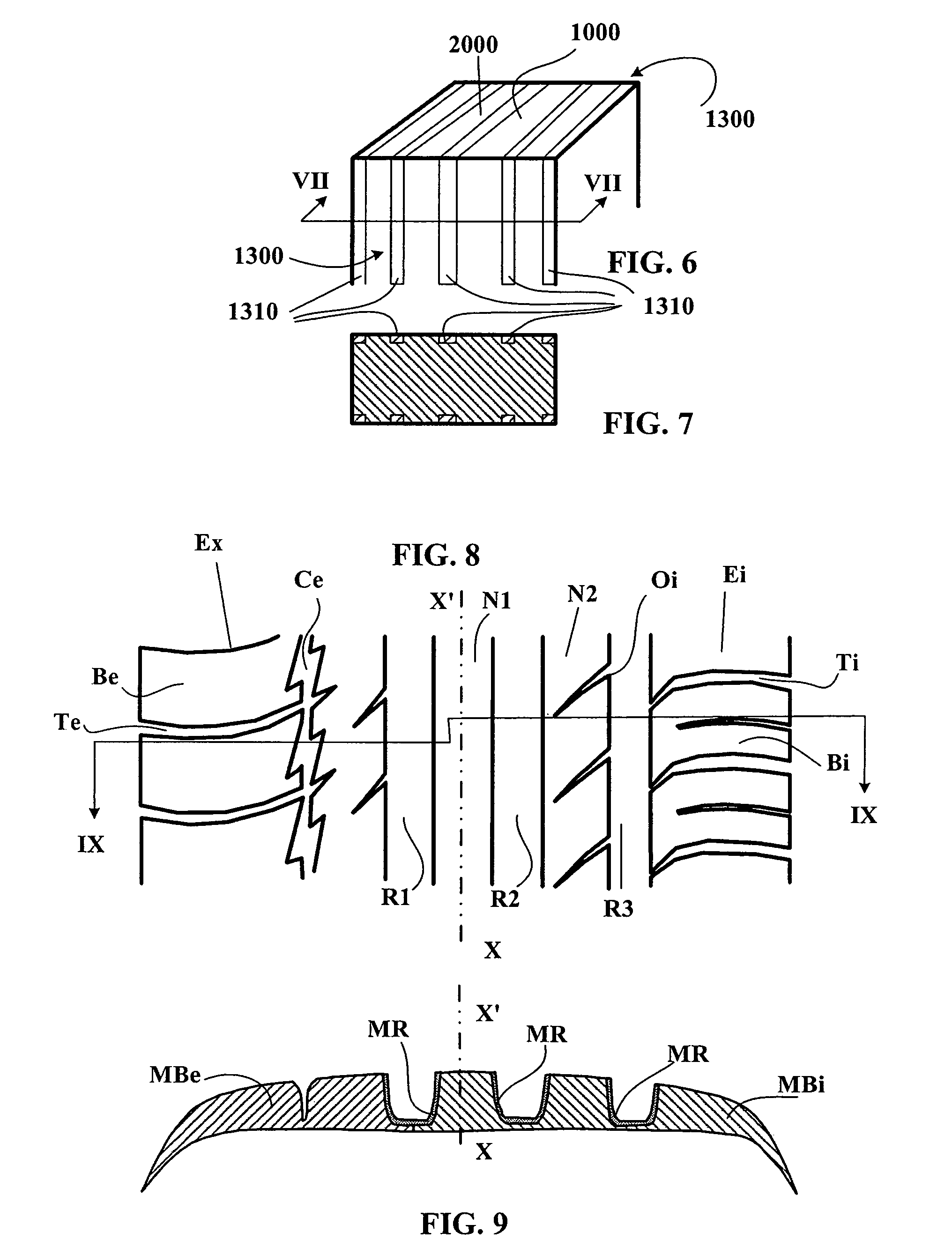

Tread having tread pattern elements formed of at least two rubber mixes

InactiveUS7311128B2Improve the mixing effectIncreased TgSpecial tyresInflatable tyresEngineeringTread

A tire tread includes a plurality of elements in relief (rib and / or block) having lateral faces, and a contact face intended to come into contact with the roadway during travel. The intersection of each lateral face with the contact face forms a ridge. The tread also includes a plurality of cutouts each defined by opposing main faces. Each tread pattern element is formed with at least one base mix. As viewed in section in a plane containing the thickness of this tread, at least one face defining at least one cutout is formed at least in part with a covering mix. The base mix exhibits a gripping action on wet ground which is lower than a gripping action of the covering mix on the same ground.

Owner:MICHELIN RECH & TECH SA

Polycarbonate blends and method of making same

Copolymers of BPA and menthane bisphenols such as BPT1 and BPT2 can be used as a compatabilizer to allow the formation of homogeneous blends of BPA with menthane bisphenol polycarbonates such as poly-BPT1 or poly-BPT2 or copolymers thereof. Thus, a compatible polycarbonate blend is made by combining a bisphenol A polycarbonate, a menthane bisphenol polycarbonate and a BPA / menthane bisphenol copolymer compatabilizer, and mixing the combined materials to form a blend. The compatabilizer may contain one or more species of menthane bisphenol. In a specific example, BPT1 and BPT2 are used in the compatabilizer in a ratio, BPT1 / BPT2, in the range of 70 / 30 to 10 / 90, preferably less than or equal to 1 / 1, for example around 30 / 70. By adjusting the relative amounts and the properties of the bisphenol A polycarbonate and the menthane bisphenol polycarbonate, the glass transition temperature and the toughness of the blend can be selected.

Owner:SABIC INNOVATIVE PLASTICS IP BV

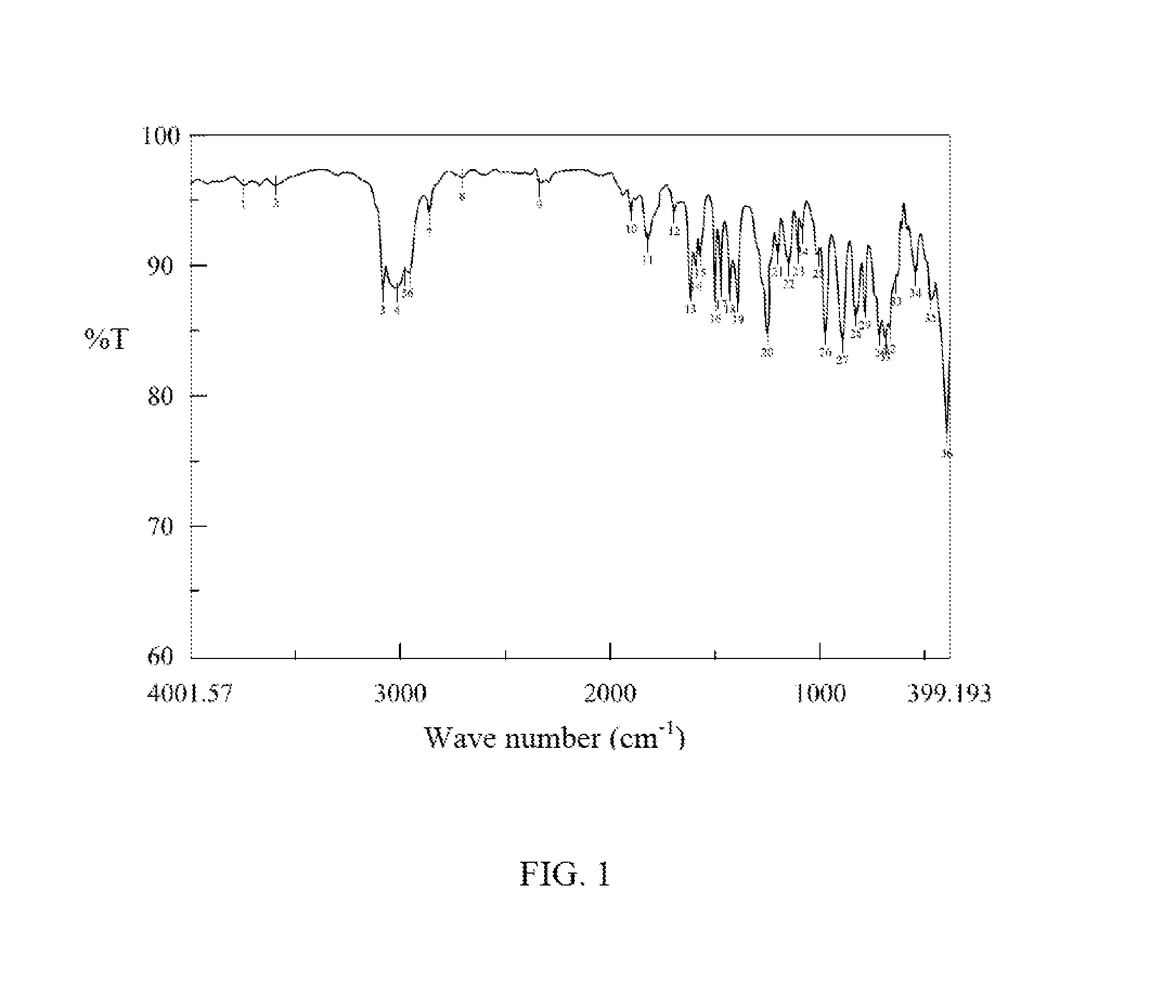

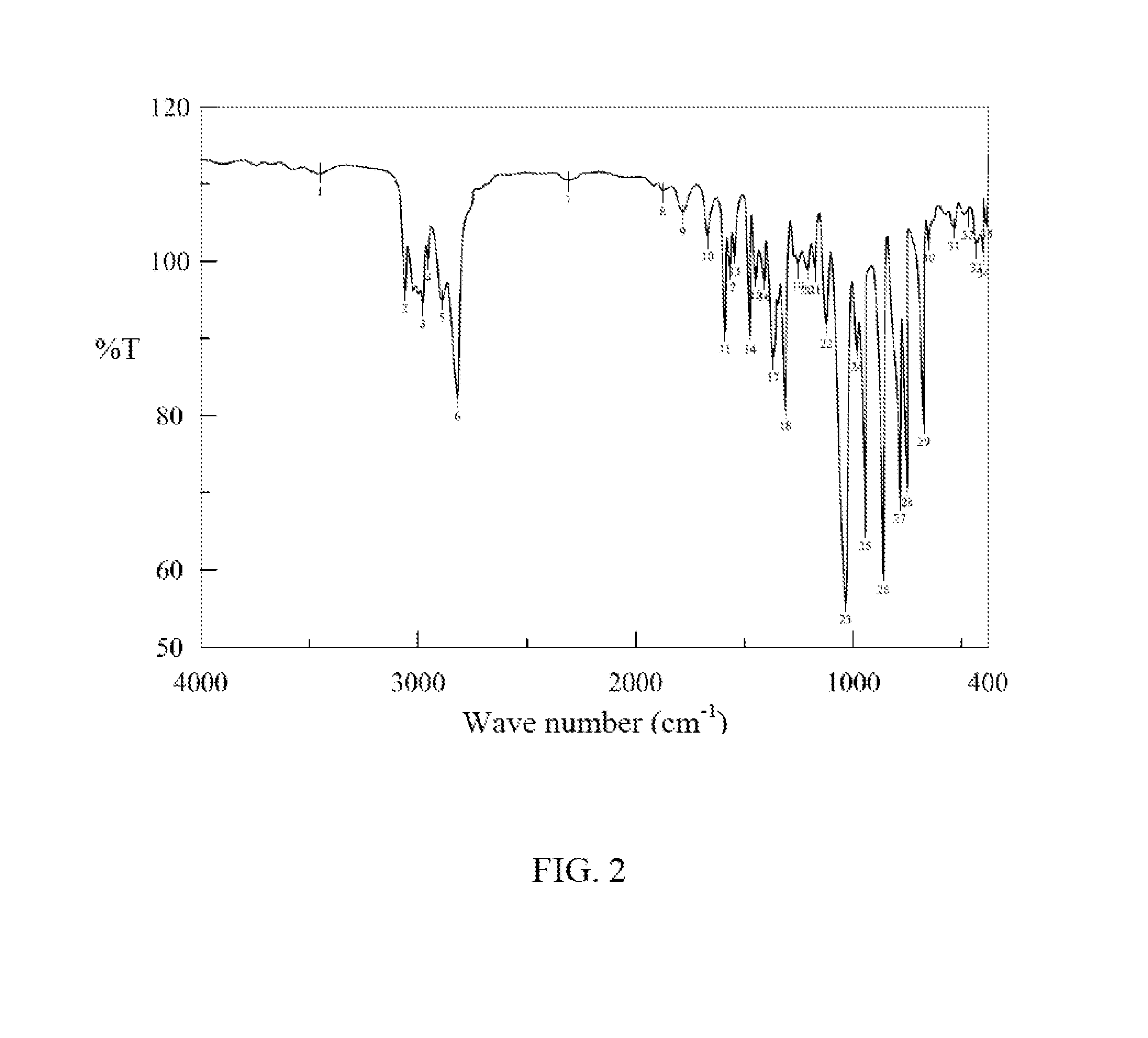

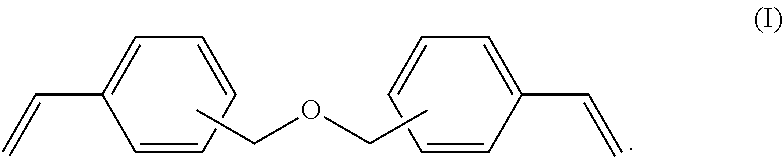

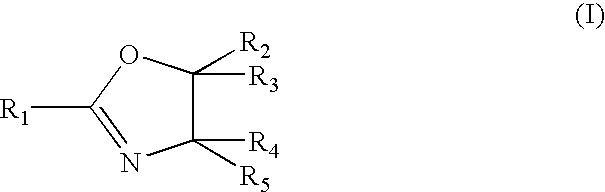

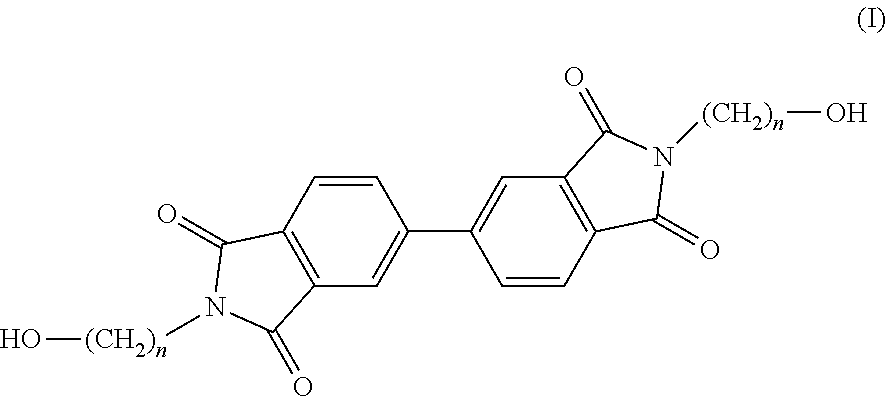

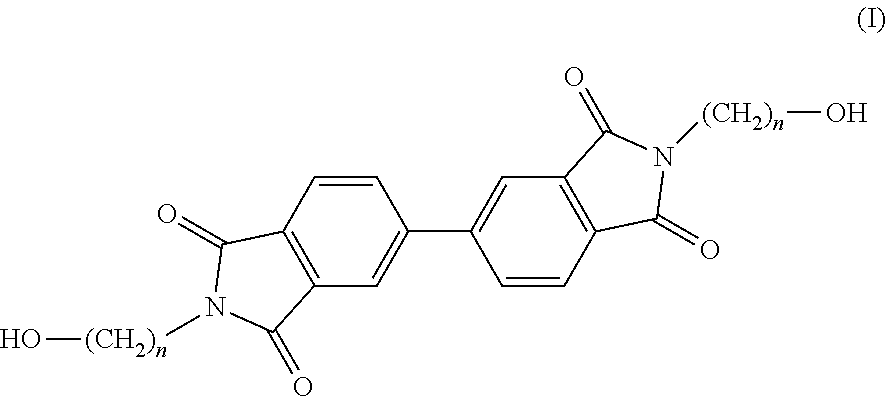

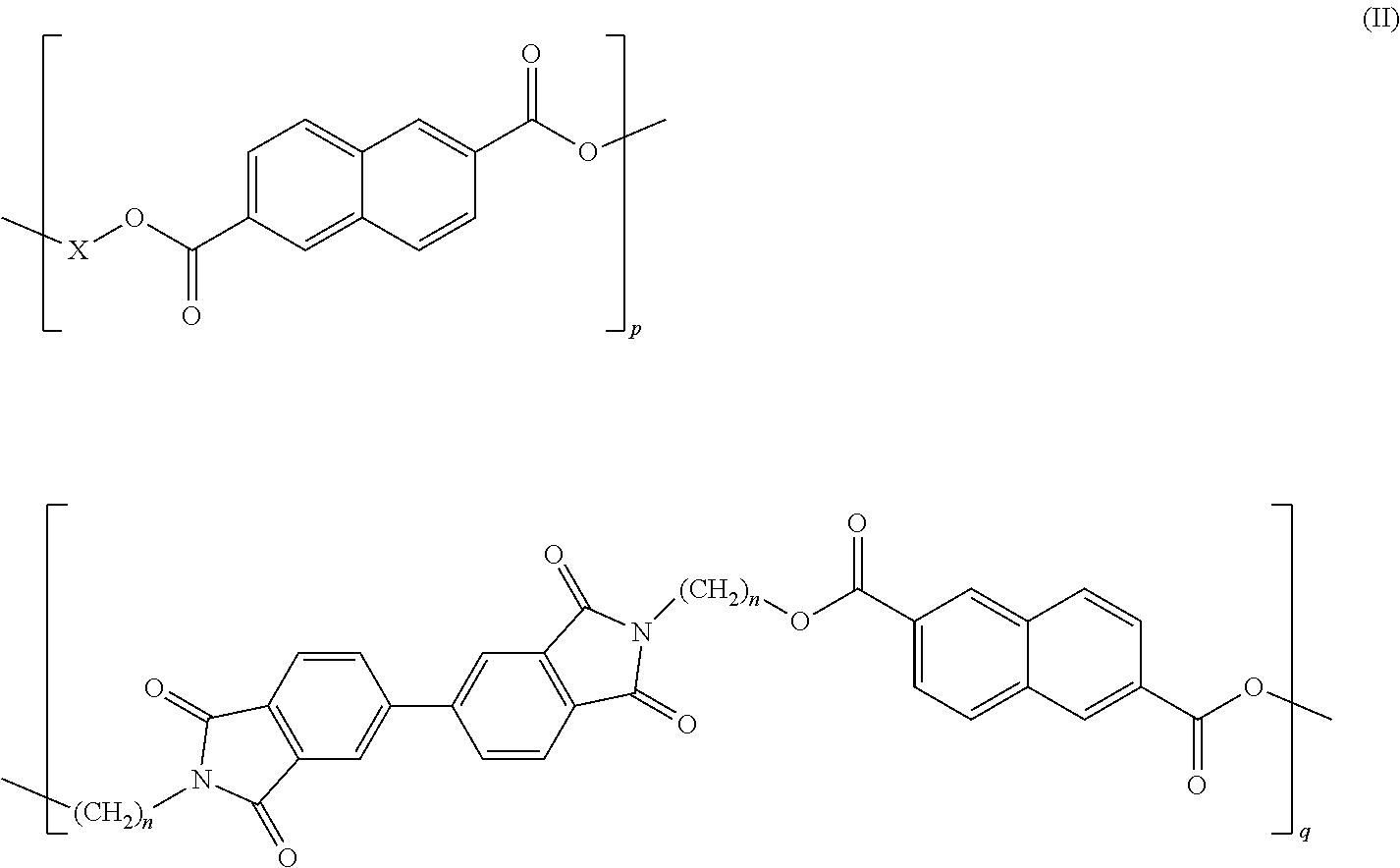

Copolyesterimides of poly(alkylene naphthalate)s having high glass transition temperature and film made therefrom

ActiveUS9096724B2Improved heat-resistanceImproved thermo-mechanical stabilityVitrificationPolymer science

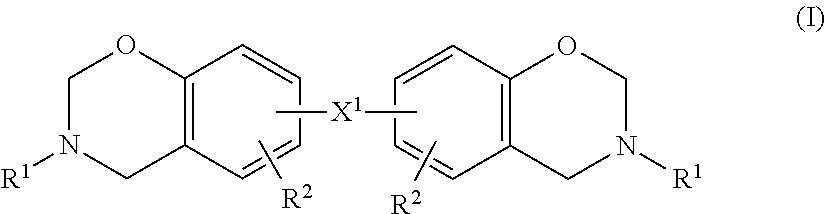

A copolyester comprising repeating units derived from an aliphatic glycol, naphthalene-dicarboxylic acid, and the monomer of formula (I) wherein n=2, 3 or 4, and films, fibres, moulding compositions and moulded articles made therefrom.

Owner:DUPONT TEIJIN FILMS U S LLP

Lowly heat-expandable laminate

InactiveUS6815053B2Tg of an unsaturated polyester resin can be loweredLow densityRecord information storageLight beam reproducingHeat resistanceThermal expansion

A low thermal expansion laminated plate which has excellent heat resistance, water resistance and toughness and whose average linear expansion coefficient within the temperature ranging from 40 to 150° C. is not higher than 20x10<-6> / ° C. can be obtained by laminating and curing fiber-reinforced layers impregnated with a resin composition consisting of a radically polymerizable resin, radically polymerizable monomer and inorganic filler combined with a specific amount of a thermoplastic resin.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

Filled, baked crispy snack having a high moisture content

ActiveUS9119410B2Improve gelatinizationIncreased TgDough treatmentConfectioneryHigh resistanceReady to eat

A shelf-stable, filled, baked crispy snack which possesses a crispy textured casing and a moist, soft textured filling over a prolonged period of time is obtained by formulating a casing which when baked has a high glass temperature (Tg) at a high moisture content. Increasing the degree of starch gelatinization to increase the Tg may be achieved during baking and by the addition of a pregelatinized starch. The high Tg baked casing permits the use of a high moisture content filler in high amounts to provide a shelf-stable substantial textural dichotomy in the filled, baked, crispy snack. The filled, baked snack exhibits an unexpectedly high resistance to deformation or peak force at high baked casing moisture contents. The baked snack is ready-to-eat out of the packaging and does not have to be toasted, microwaved or further baked, cooked, or heated for consumption, or to achieve a crisp textured casing.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

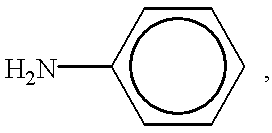

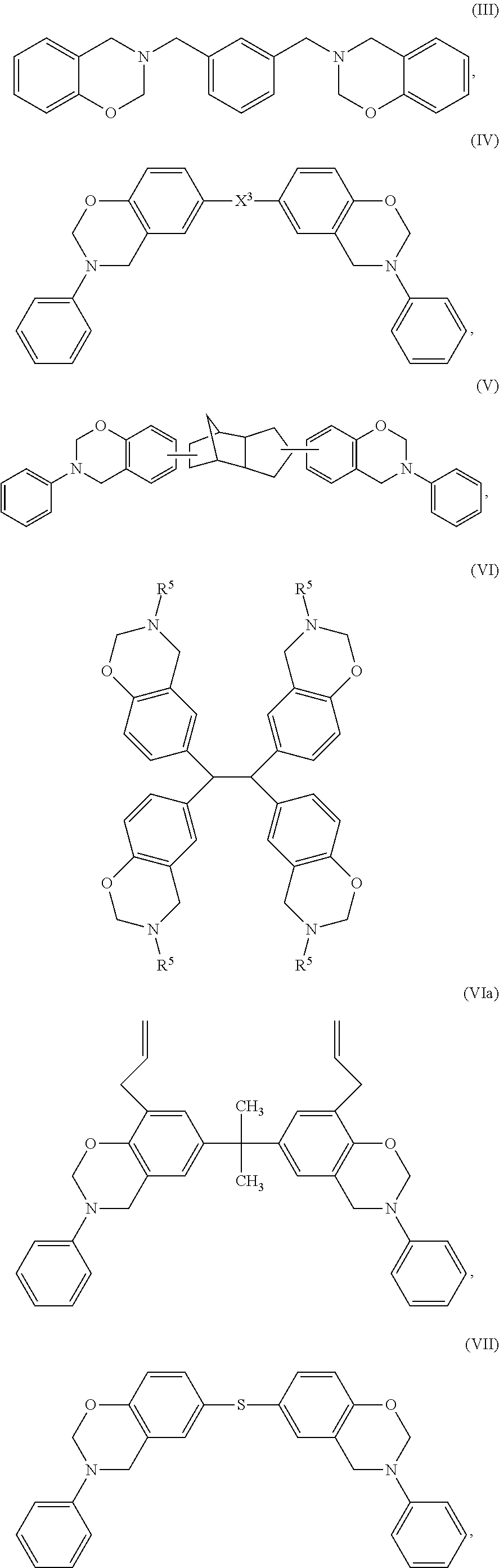

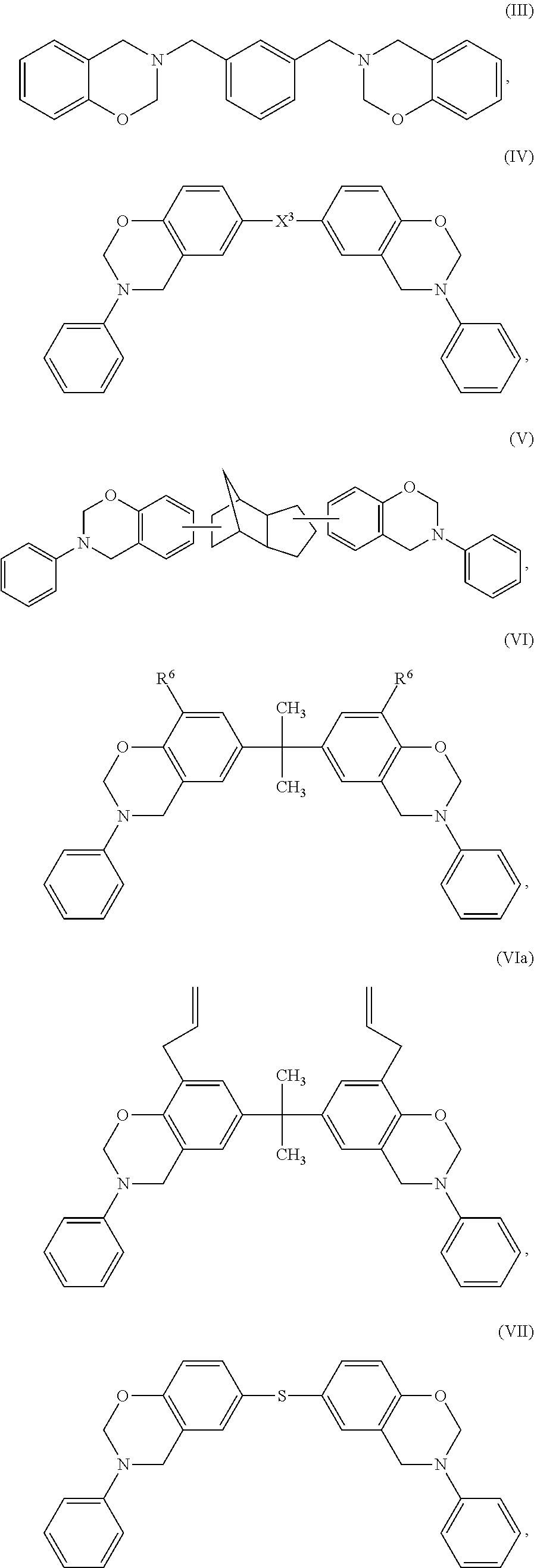

Thermosetting Composition

ActiveUS20120237753A1Improve balanceIncrease temperatureSynthetic resin layered productsPretreated surfacesPolymer scienceBis epoxide

A thermosetting composition comprising (a) at least one phosphorous-free dihydrobenzoxazine component; (b) at least a quaternary ammonium salt and (c) optionally a compound comprising at least an epoxy group is disclosed. Cured products made from these compositions have valuable chemical, physical and mechanical properties.

Owner:HUNTSMAN ADVANCED MATERIALS LICENSING SWITZERLAND GMBH +1

Thermosetting resin for expediting a thermosetting process

ActiveUS20100317785A1Avoid changeEnhanced inhibitory effectPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsEpoxyTetrabromobisphenol A

The present invention discloses a thermosetting resin for expediting a thermosetting process. The thermosetting resin is composed of 100 parts of primary resin formed by mixing a brominized epoxy resin, a tetrafunctional epoxy resin and an epoxy resin with a high bromine content, and other materials including 35 parts of phenolic resin curing agent, 30 parts of tetrabromobisphenol A curing agent, 0.1 part of 2-ethyl-4-methylimidazole, 0.8 part Lewis acid, and 50˜70 parts of solvent, calculated based on every 100 parts of the primary resin by weight. The invention can expedite a thermosetting process and enhance the Tg of prepregs and clad laminates.

Owner:ITEQ WUXIELECTRONICS TECH +1

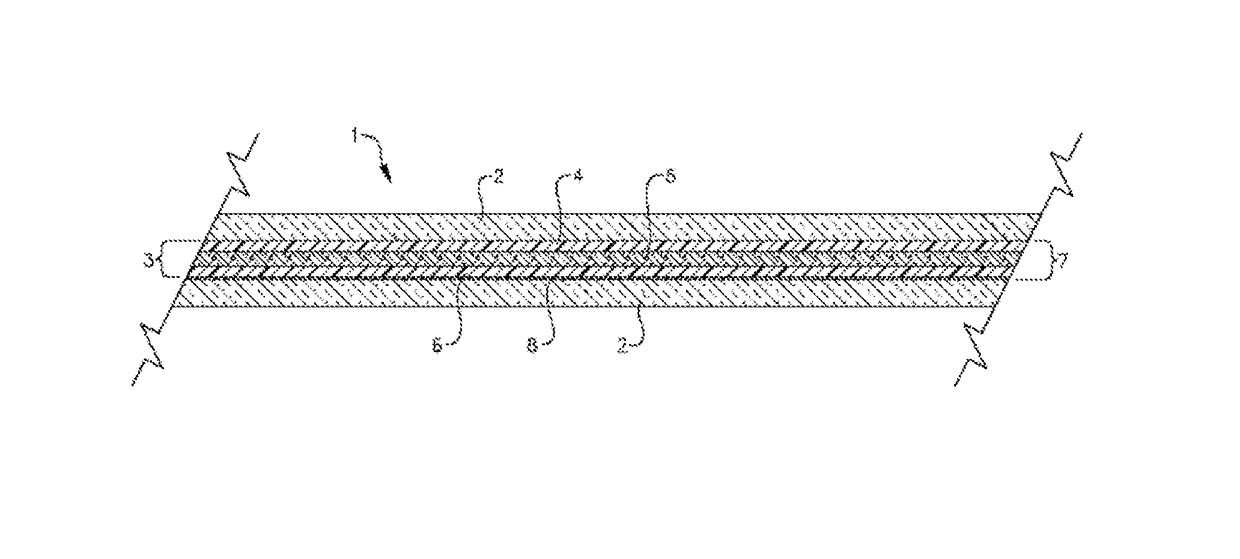

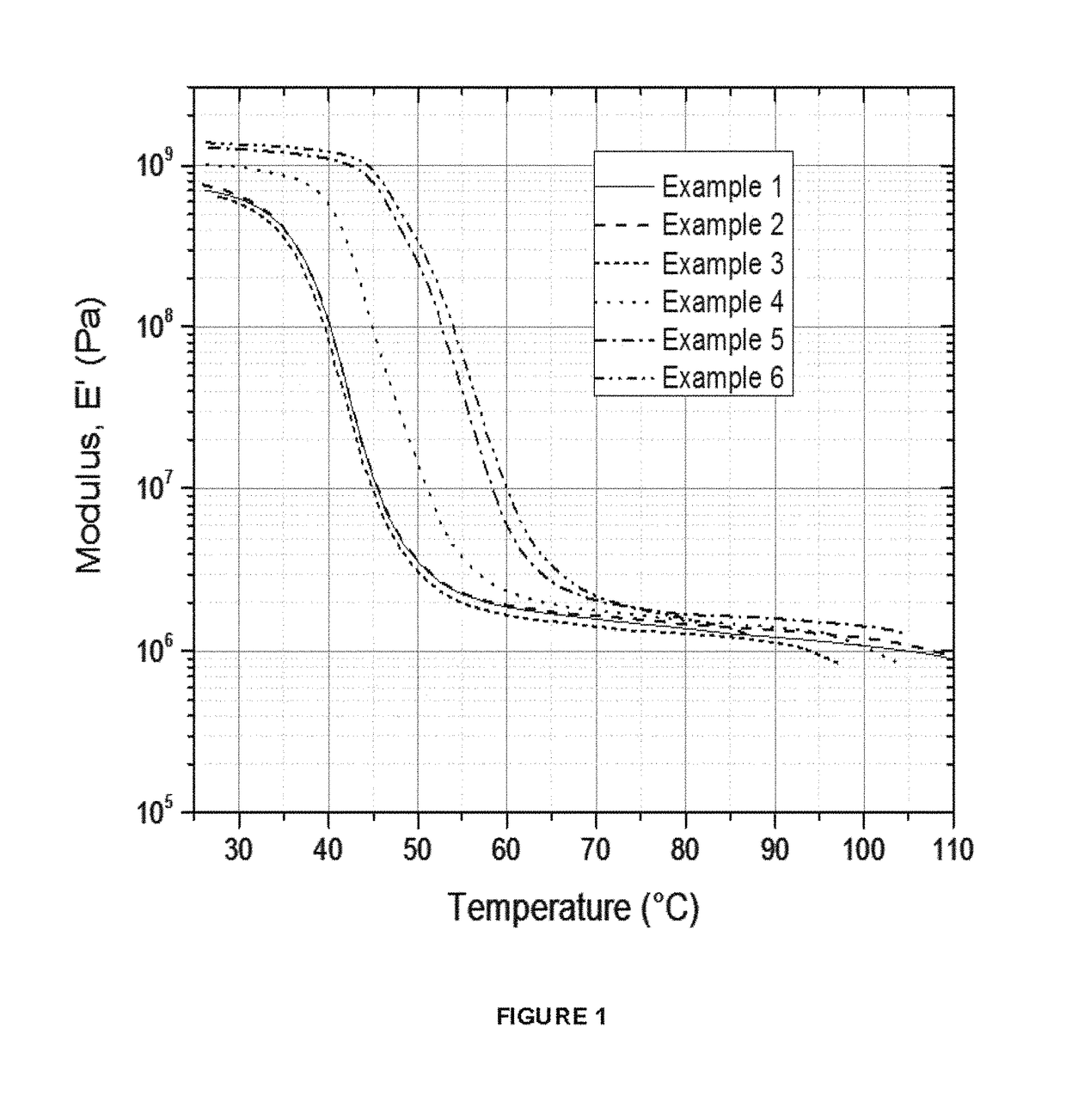

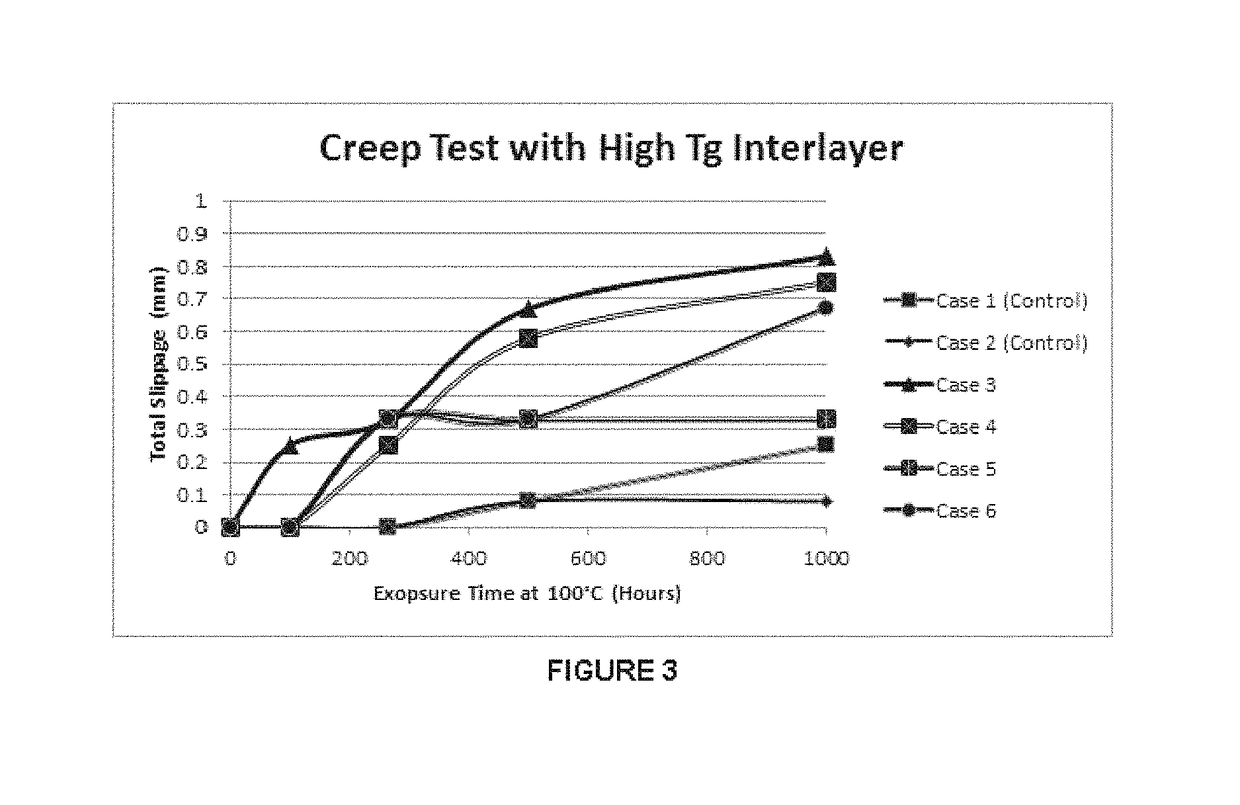

Multilayer interlayers having high Tg and high modulus

ActiveUS10000039B2Increased TgHigh melt flow indexSynthetic resin layered productsOptical articlesOutdoor temperaturePolymer chemistry

Owner:SOLUTIA INC

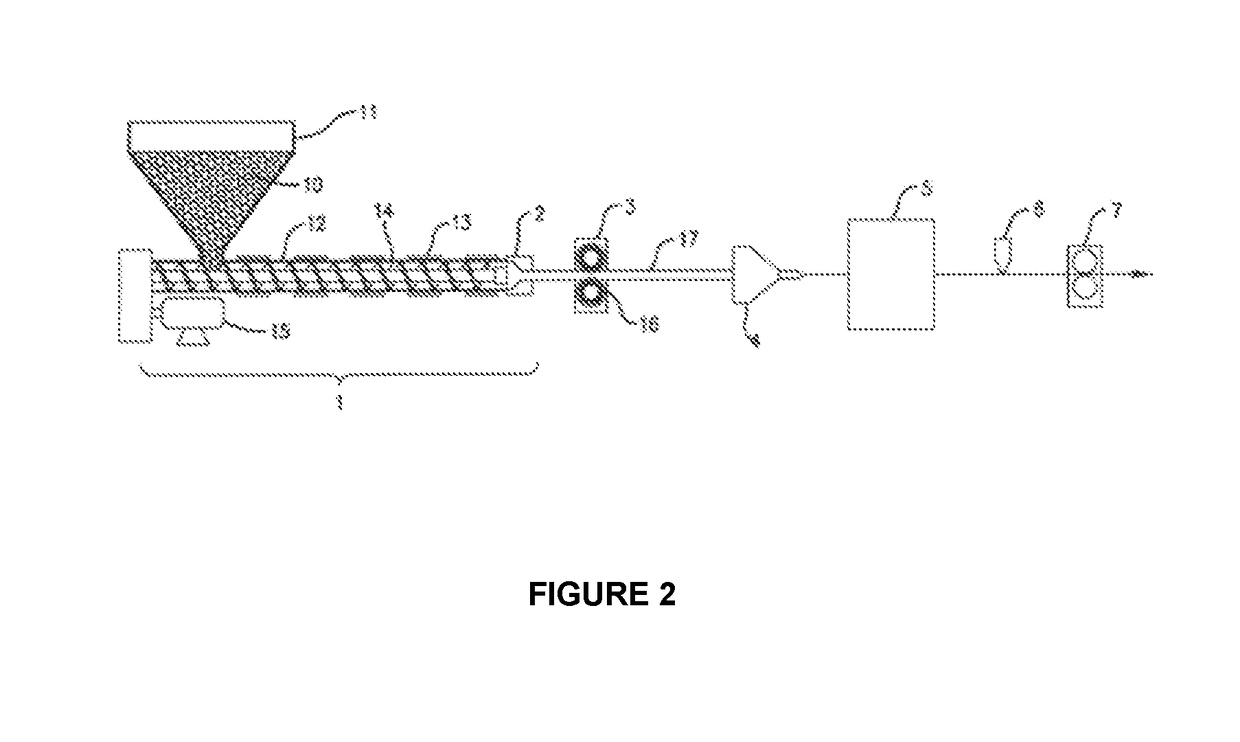

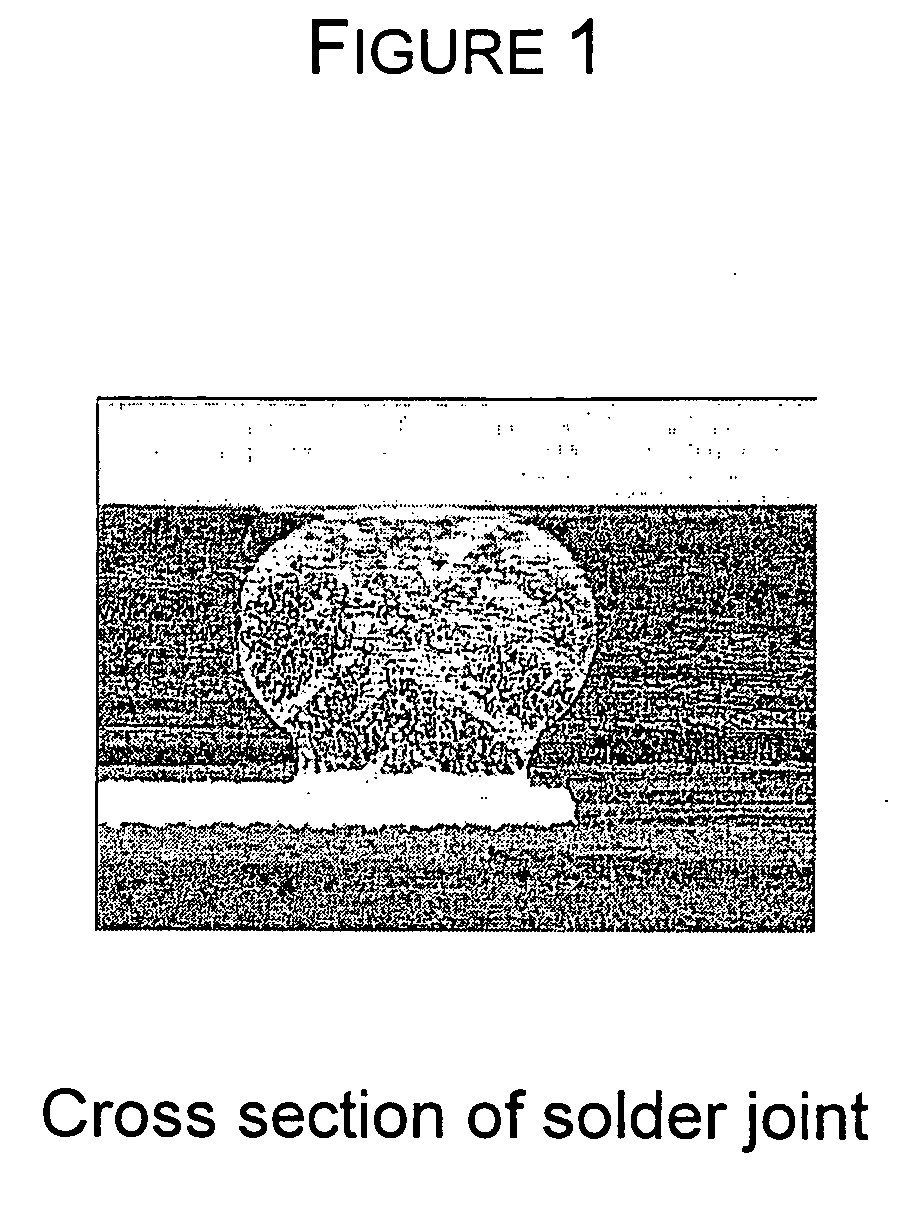

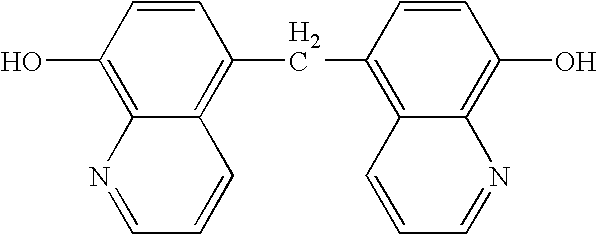

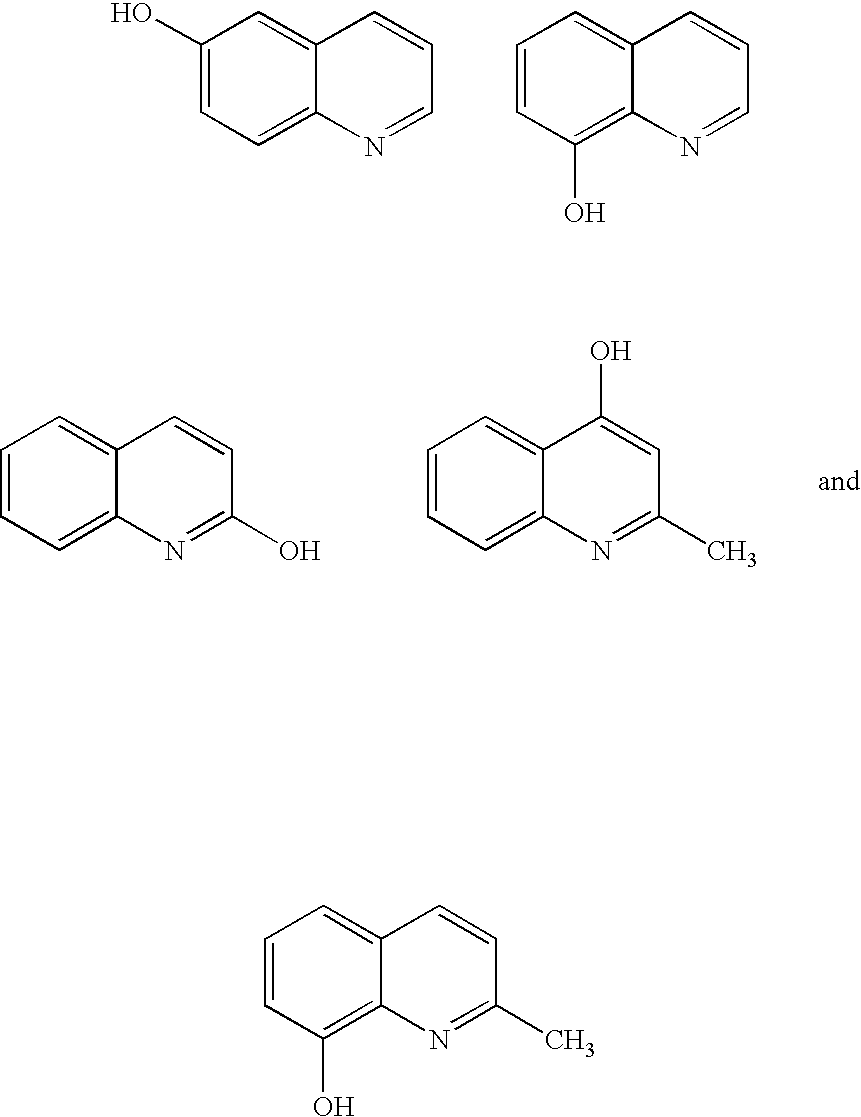

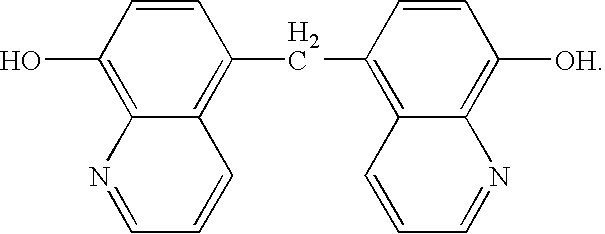

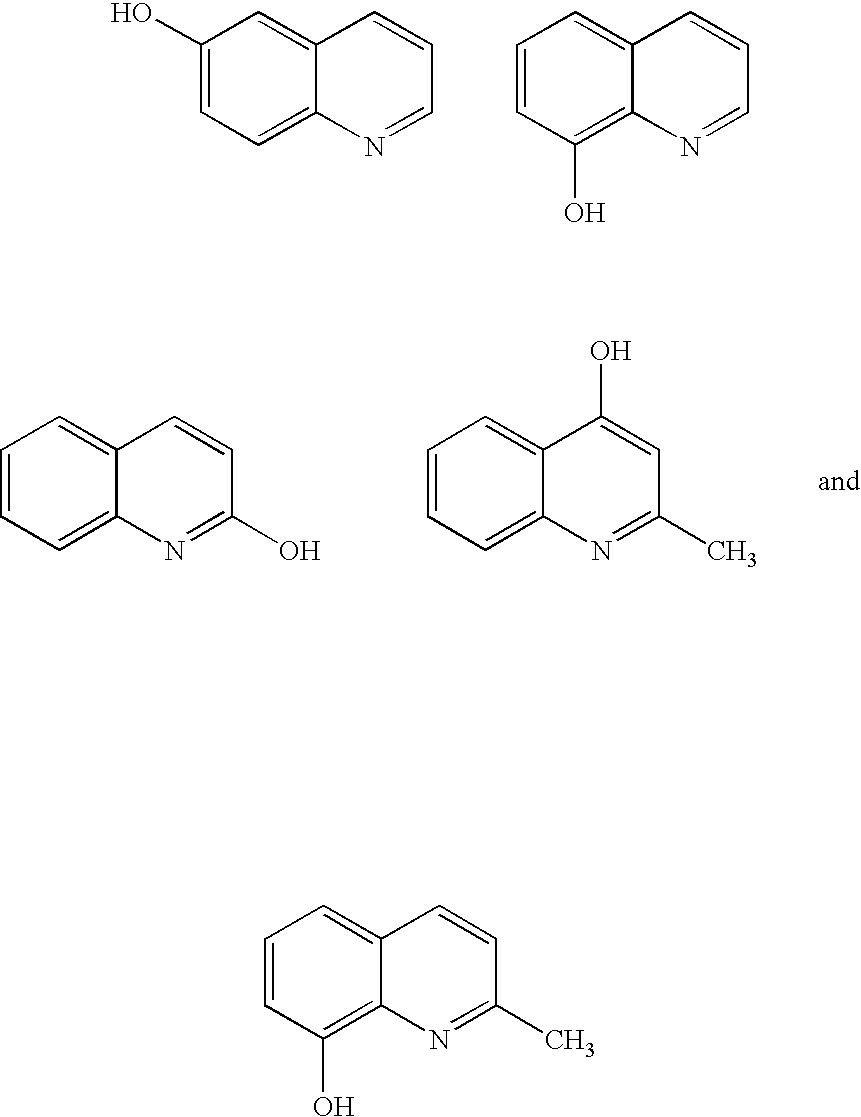

Quinolinols as fluxing and accelerating agents for underfill compositions

InactiveUS20070049722A1Increased TgImprove curingOrganic chemistrySemiconductor/solid-state device detailsAccelerantCorrosion

Underfill compositions comprise a quinolinol or a quinolinol derivative as a fluxing agent, as an accelerating agent, or as both. The compositions are sufficiently acidic to perform well as fluxes, but not so acidic as to cause premature gelation or corrosion. The compositions also demonstrate higher Tg values than similar compositions that do not contain quinolinol or a quinolinol derivative.

Owner:HENKEL KGAA

Low dissipation factor resin composition and product made thereby

A low dissipation factor resin composition comprises: (A) 100 to 150 parts by weight of a vinyl-containing compound or a polymer thereof; (B) 0 to 75 parts by weight of styrene-butadiene-divinylbenzene terpolymer, styrene-butadiene-maleic anhydride terpolymer, vinyl functional polybutadiene urethane oligomer or a combination thereof; (C) 30 to 150 parts by weight of flame retardant; and (D) 0.1 to 10 parts by weight of peroxide. The resin composition and a product made thereby are applicable to a copper-clad laminate and a printed circuit board, characterized by having low dissipation factor at high frequency and satisfactory thermal resistance and thermal expansion.

Owner:ELITE ELECTRONICS MATERIAL KUNSHAN

Thermosetting composition

InactiveUS20110135944A1Improve balanceIncrease temperatureSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceSulfonium

A thermosetting composition comprising(a) (a) at least one phosphorous-free dihydrobenzoxazine component;(b) at least a sulfonium salt and(c) optionally a compound comprising at least an epoxy group is disclosed.Cured products made from these compositions have valuable chemical, physical and mechanical properties.

Owner:HUNTSMAN INT LLC

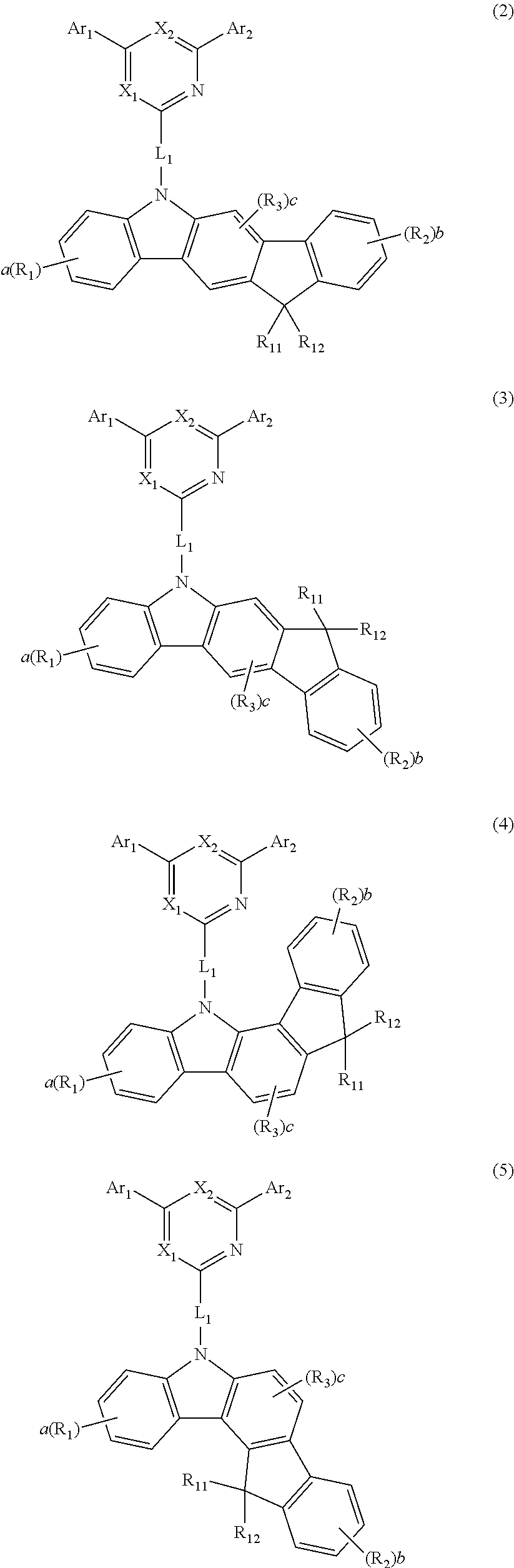

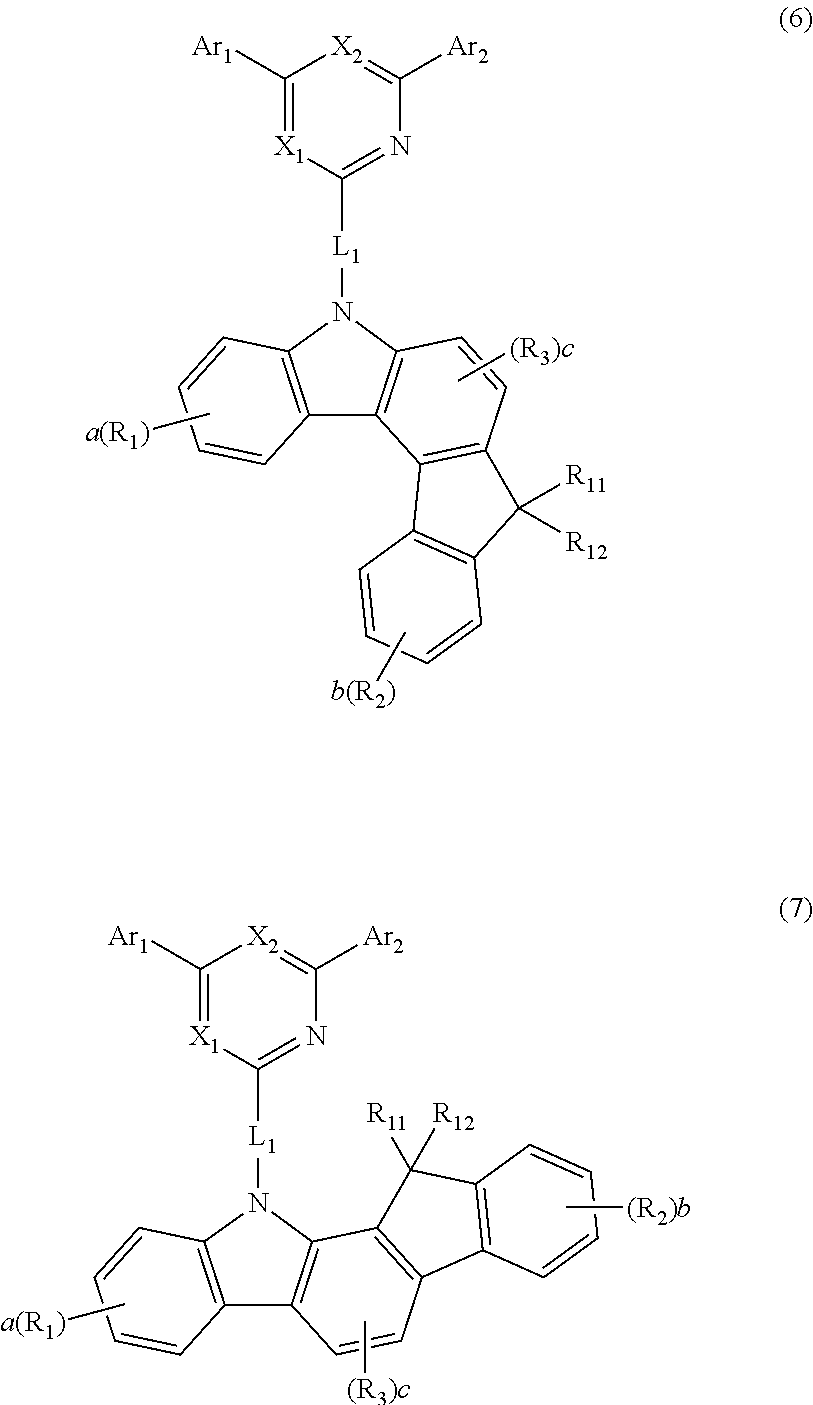

An organic electroluminescent compound and an organic electroluminescent device comprising the same

InactiveUS20170200904A1Improve life characteristicsImprove thermal stabilityOrganic chemistryElectroluminescent light sourcesOrganic electroluminescenceOrganic chemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Lowly heat-expandable laminate

InactiveUS20040096680A1Tg of an unsaturated polyester resin can be loweredLow densitySynthetic resin layered productsVehicle componentsThermal dilatationPolymer science

A low thermal expansion laminated plate which has excellent heat resistance, water resistance and toughness and whose average linear expansion coefficient within the temperature ranging from 40 to 150° C. is not higher than 20x10<-6> / ° C. can be obtained by laminating and curing fiber-reinforced layers impregnated with a resin composition consisting of a radically polymerizable resin, radically polymerizable monomer and inorganic filler combined with a specific amount of a thermoplastic resin.

Owner:MATSUSHITA ELECTRIC WORKS LTD +1

High Tg monolithic poly(vinyl acetal) sheet

ActiveUS10086590B2Increased TgAcceptable flowabilitySynthetic resin layered productsOptical articlesPolymer sciencePolyvinyl alcohol

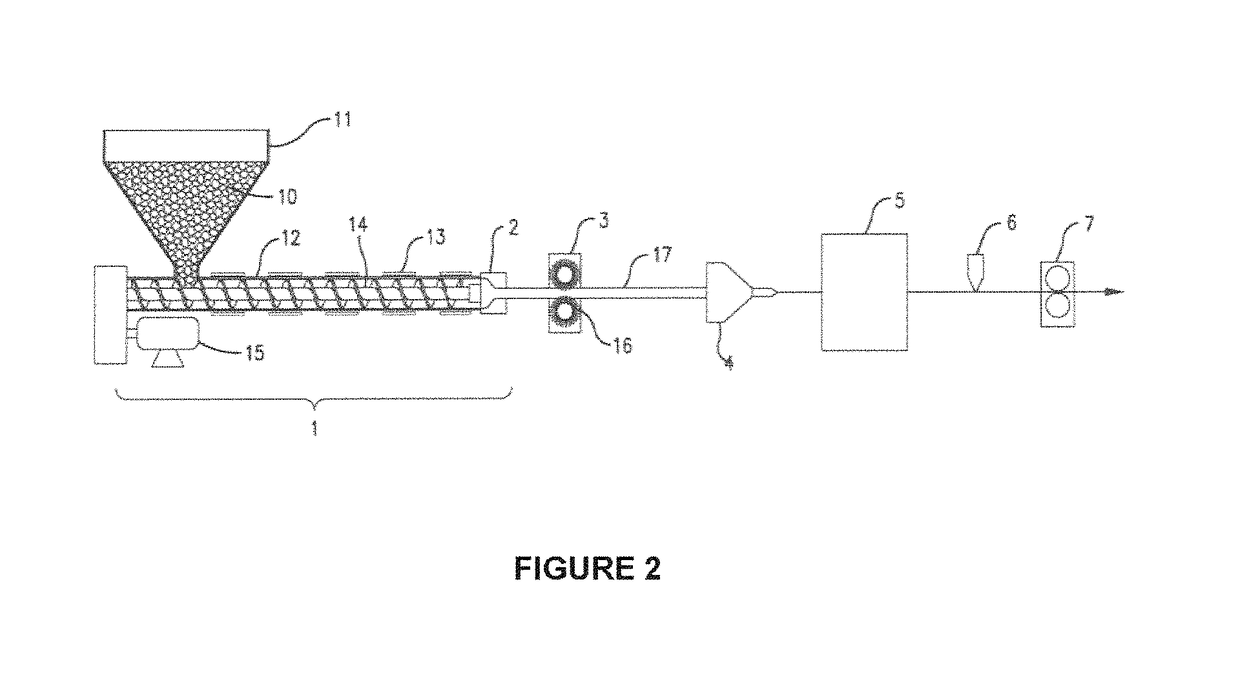

A polyvinyl acetal poly(vinyl acetal), such as polyvinyl butyral, resin formulation, a method of extruding poly(vinyl acetal) resins, and related materials and products that provide for monolithic poly(vinyl acetal) sheets and glass panes having high Tg of at least 50° C. and high modulus at acceptable rates as indicated by their high melt flow index. This is made possible by a reduction in the amount of plasticizer while using a low molecular weight resin not to exceed 160,000 to obtain a thermoplastic resin having a high melt flow index and high Tg. The articles made with these monolithic interlayer sheets can be used in applications that require good modulus at outdoor temperatures.

Owner:SOLUTIA INC

Prepreg for fiber reinforced plastic and production process thereof

A prepreg of FRP (fiber reinforced plastic) having with (i) a matrix resin composition containing a bifunctional isocyanate and / or a trifunctional isocyanate, a polyol and a bifunctional chain extender having two active hydrogen groups at a molar ratio, as a functional group, of isocyanate:polyol:chain extender=5.0 to 1.0:1.0:4.0 to 0, or containing a bifunctional isocyanate and / or a trifunctional isocyanate and a polyol at a molar ratio, as a functional group, of liquid isocyanate:polyol=0.9 to 1.1:1.0; and (ii) a fibrous material. A production process of the prepreg. According to the present invention, the prepreg has a sufficient pot life and permits convenient production of an FRP molding.

Owner:MITSUBISHI HEAVY IND LTD

Quinolinols as fluxing and accelerating agents for underfill compositions

InactiveUS7378523B2Increased TgImprove curingOrganic chemistrySemiconductor/solid-state device detailsAccelerantCorrosion

Underfill compositions comprise a quinolinol or a quinolinol derivative as a fluxing agent, as an accelerating agent, or as both. The compositions are sufficiently acidic to perform well as fluxes, but not so acidic as to cause premature gelation or corrosion. The compositions also demonstrate higher Tg values than similar compositions that do not contain quinolinol or a quinolinol derivative

Owner:HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com