Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Increased mechanical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

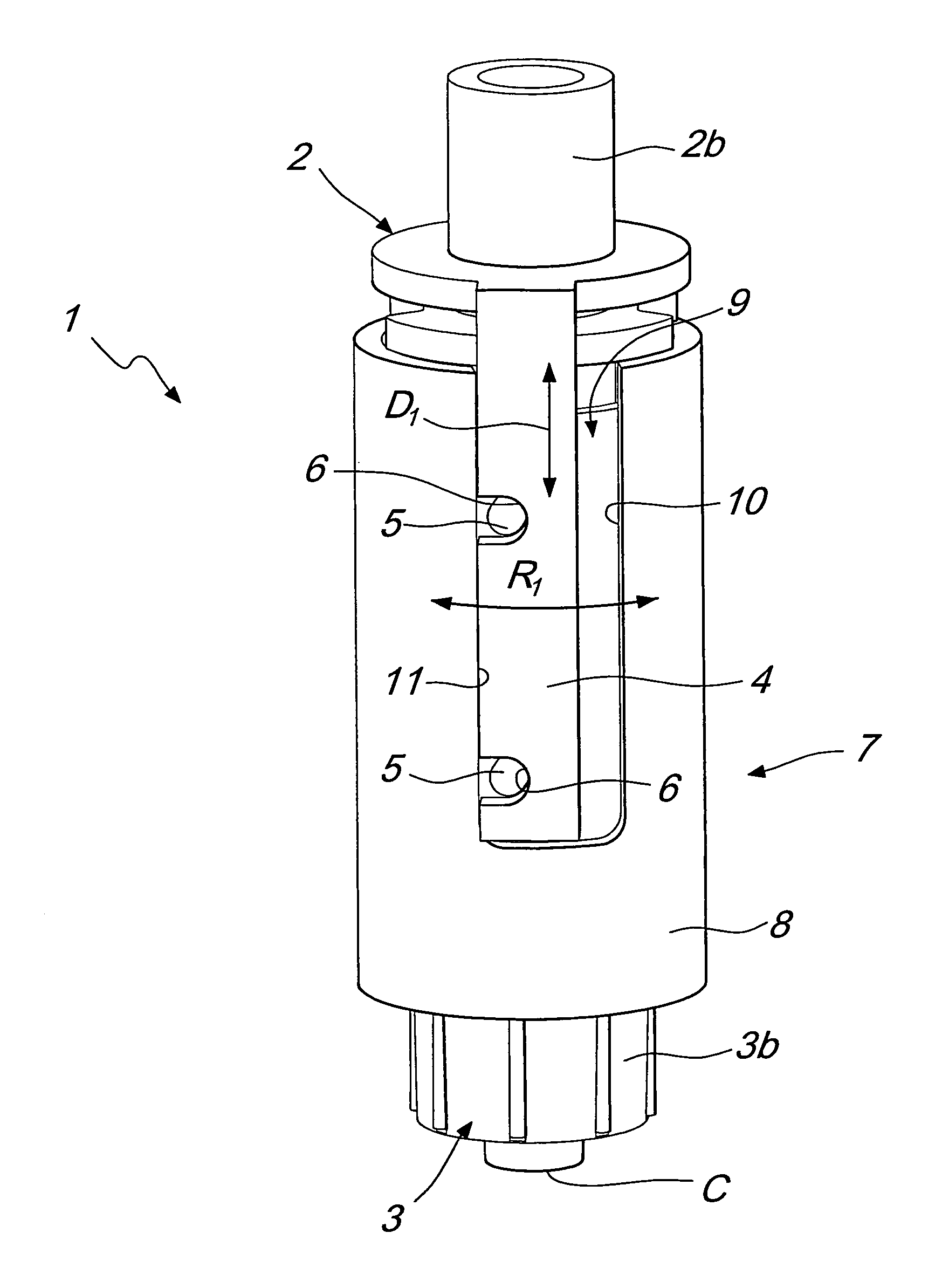

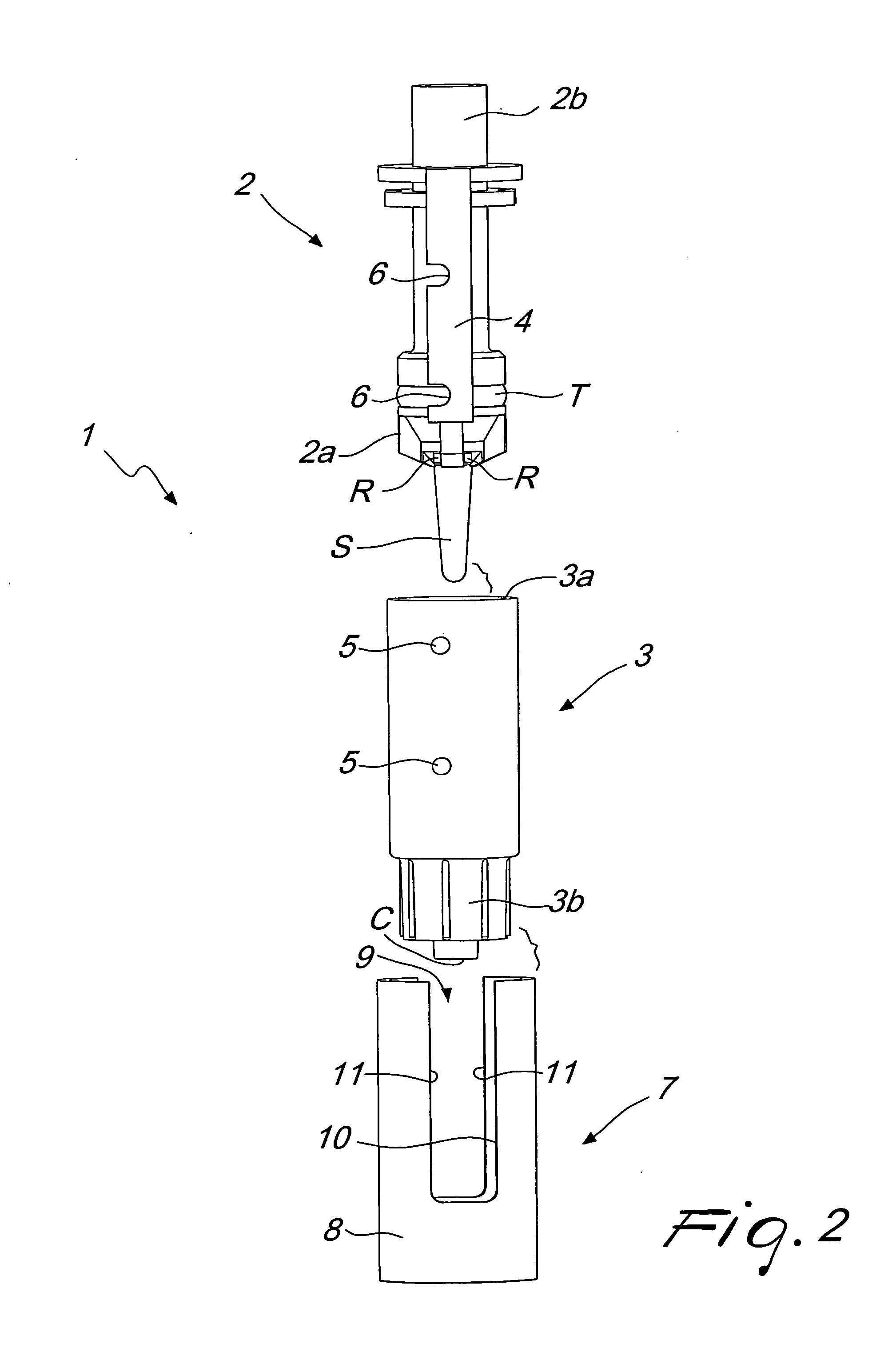

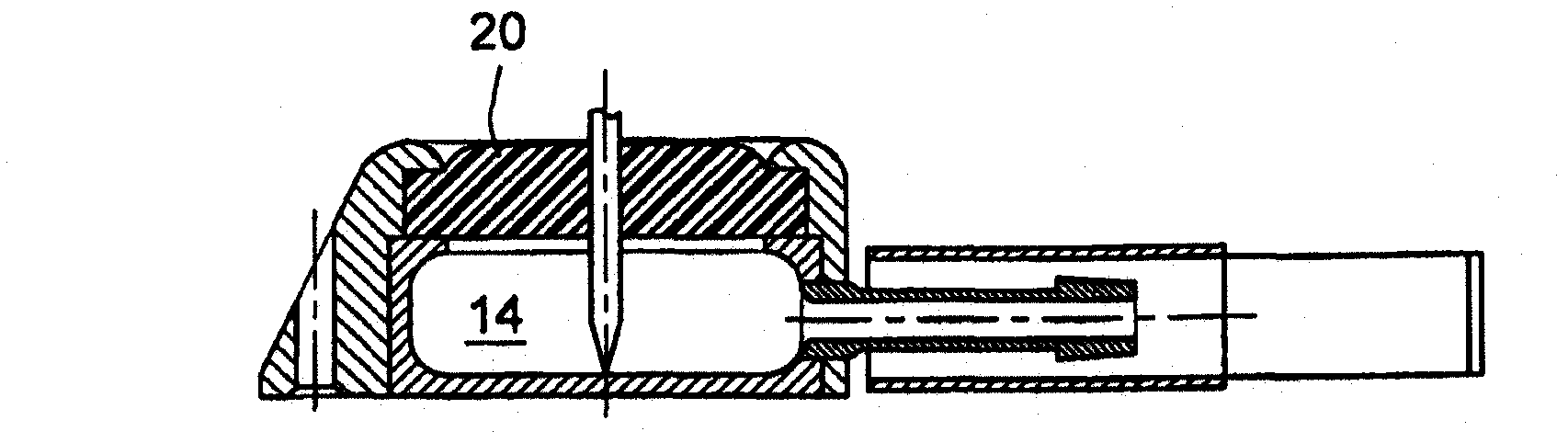

Closure device for lines for administering medical or pharmaceutical fluids from containers or the like

InactiveUS20100211019A1Improve efficiencyIncreased mechanical resistancePharmaceutical containersMedical packagingRelative motionMechanical engineering

Owner:ARIES

Time of flight mass spectrometer

ActiveUS20170098533A1Physically compactHigh resolutionTime-of-flight spectrometersElectron/ion optical arrangementsMass analyzerTime of flight

A time of flight (“TOF”) mass spectrometer including: an ion source configured to produce ions having a plurality of m / z values; a detector for detecting ions produced by the ion source; a tilt correction device located along a portion of a reference ion flight path extending from the ion source to a planar surface of the detector; wherein the tilt correction device includes tilt correction electrodes configured to generate at least one dipole electric field across the reference ion flight path, the at least one dipole electric field being configured to tilt an isochronous plane of ions produced by the ion source so as to correct a previous angular misalignment between the isochronous plane and the planar surface of the detector.

Owner:SHIMADZU CORP

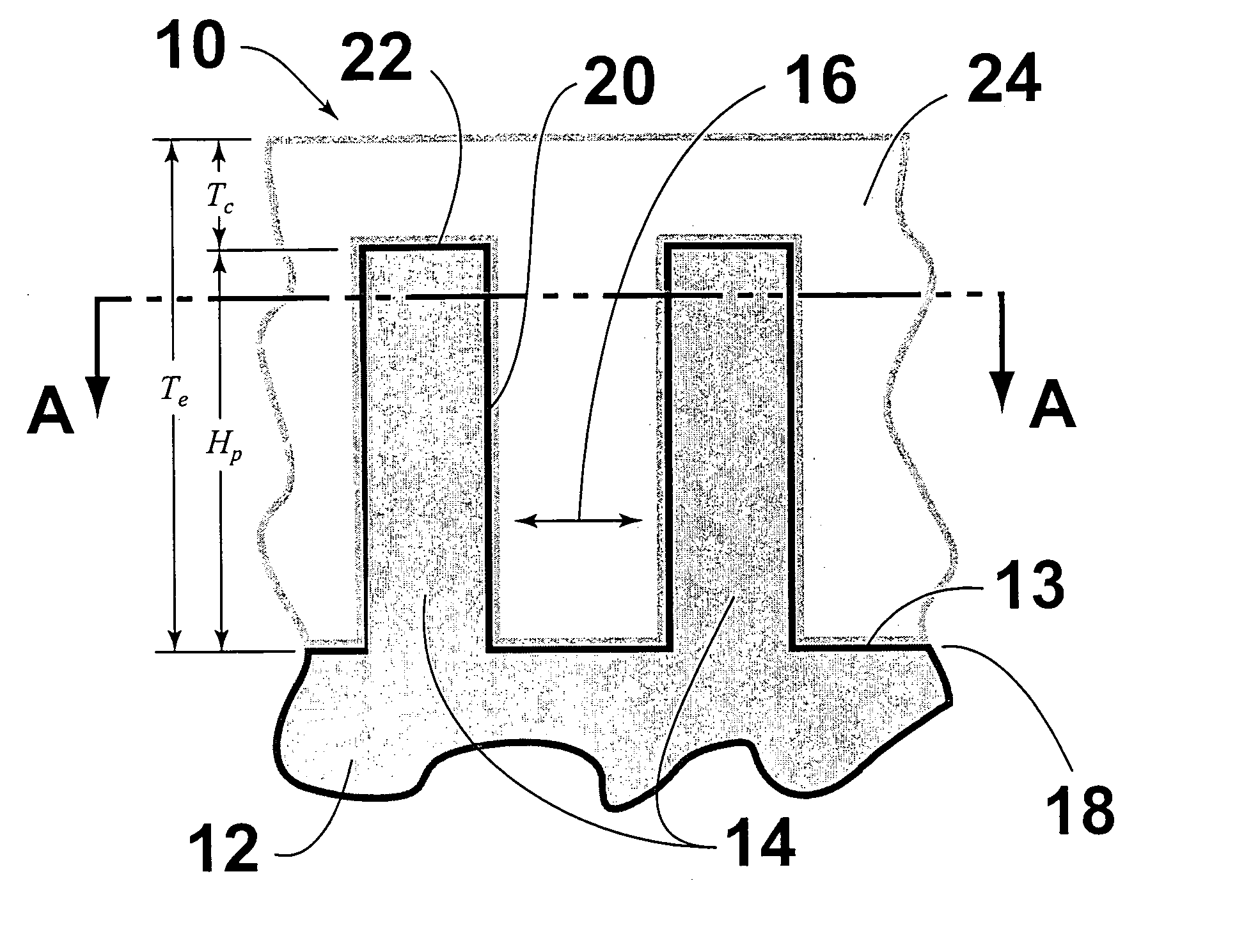

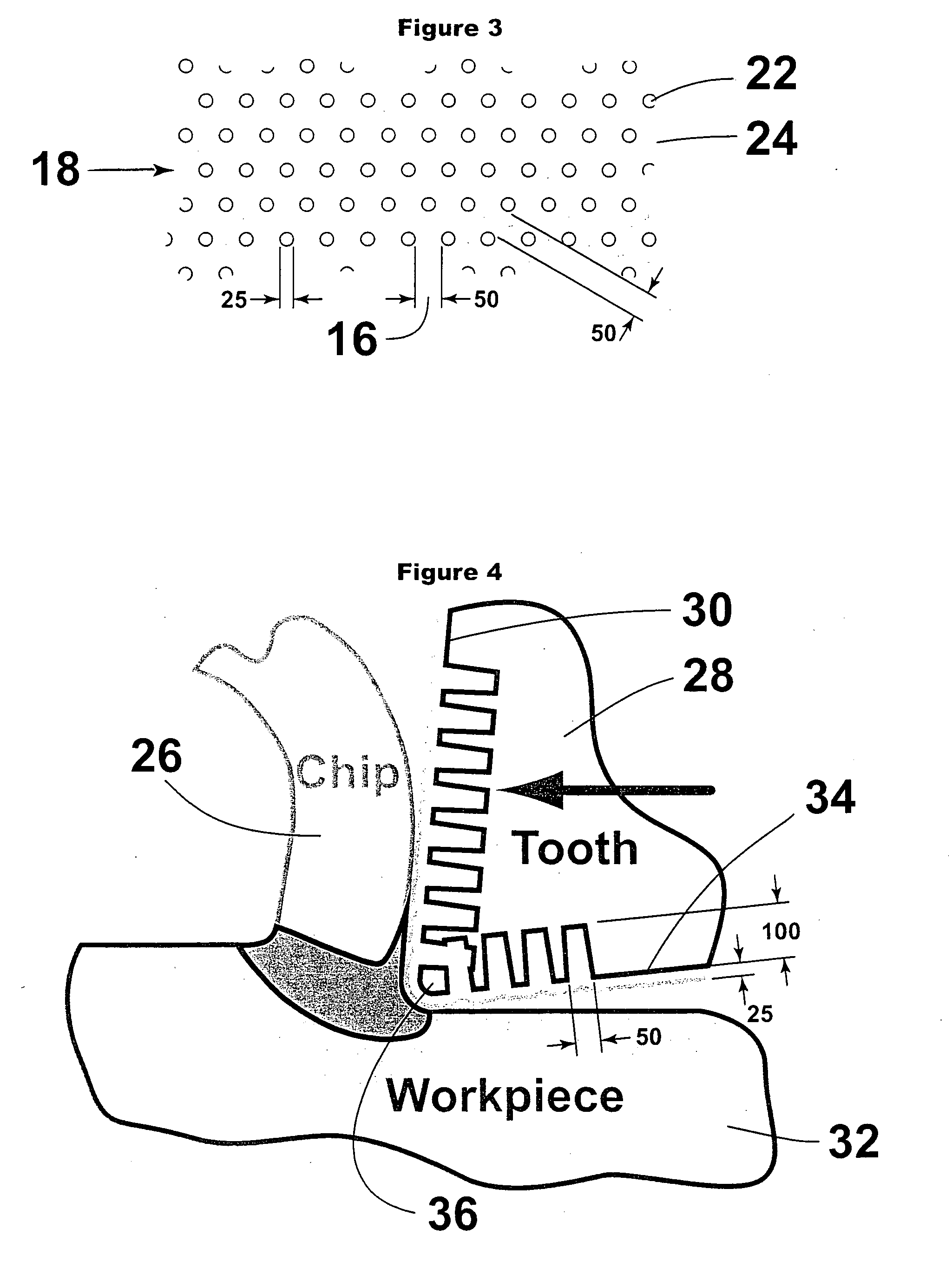

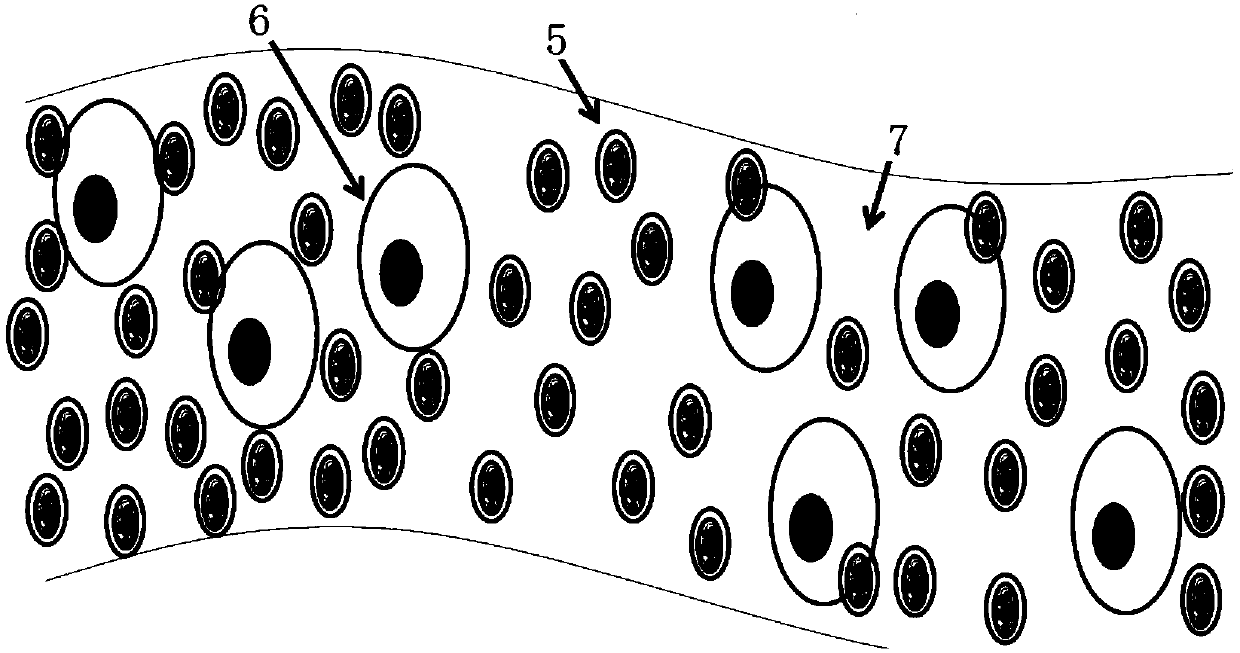

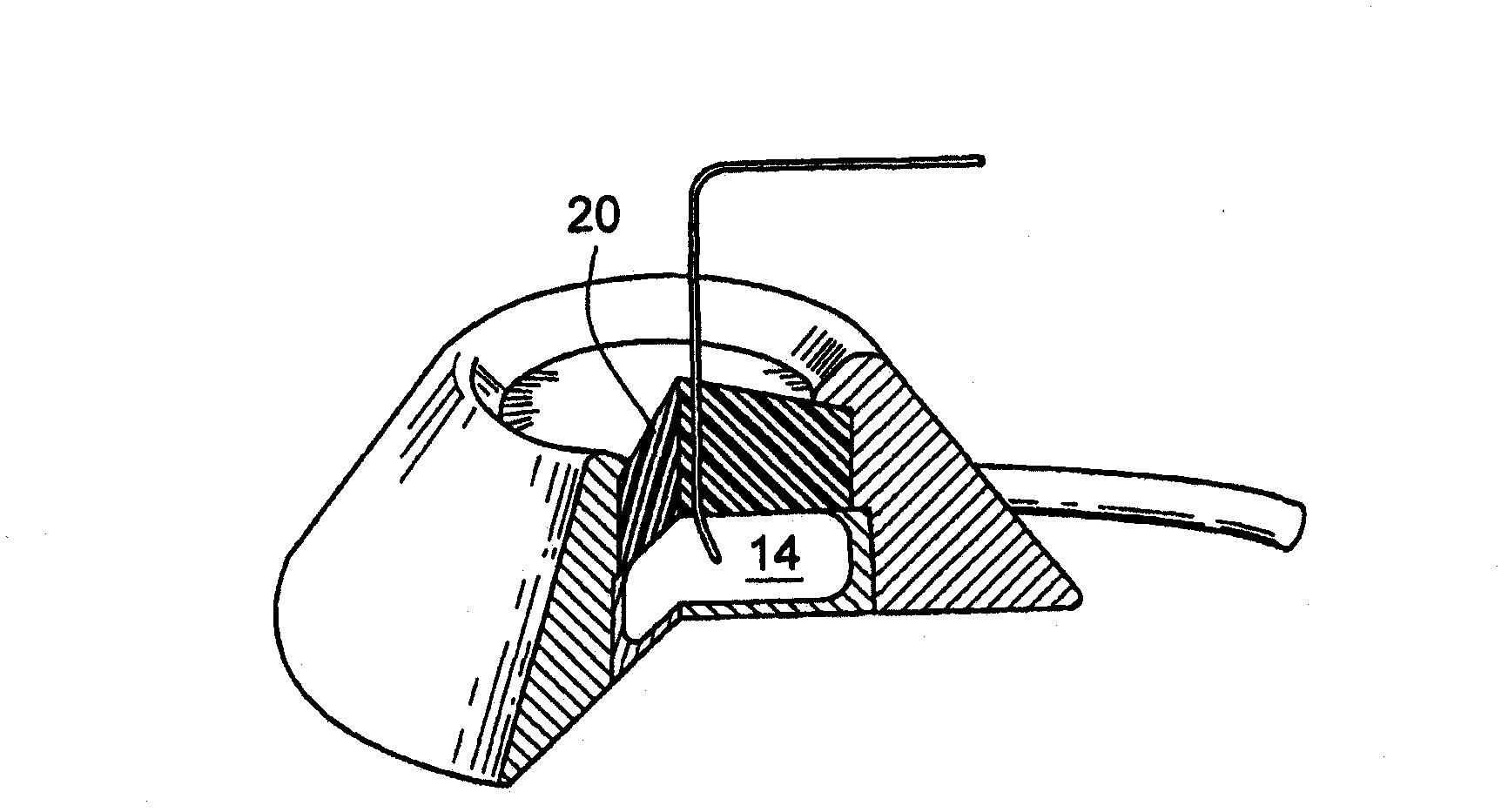

System for improving the wearability of a surface and related method

InactiveUS20070087211A1Improved resistance to chemical wearIncreased mechanical resistanceMolten spray coatingPretreated surfacesWear resistanceMaterials science

A wear surface system and method for preparing same. The wear surface system 10 has a substrate 12 with a surface 13 in which is defined three-dimensional, micro-metered prismatic anchoring sites 14. The sites include hairs that are separated by at least some spaces 16. To the textured surface 18 is applied a coating 24. The coating has substantially conforming three-dimensional features that mate with at least some of the anchoring sites. Upon solidification, the coating becomes hardened and is relatively immune from delamination due to internal and externally applied stresses during exposure to normal wear conditions. One method for improving the wearability of a surface comprises the steps of (1) providing a substrate; (2) texturizing its surface so that it is at least partially imbued with a three-dimensional, micro-metered, prismatic set of anchoring sites; and (3) coating at least a part of the textured surface with a mating coating that becomes hardened upon solidification.

Owner:EIP HLDG

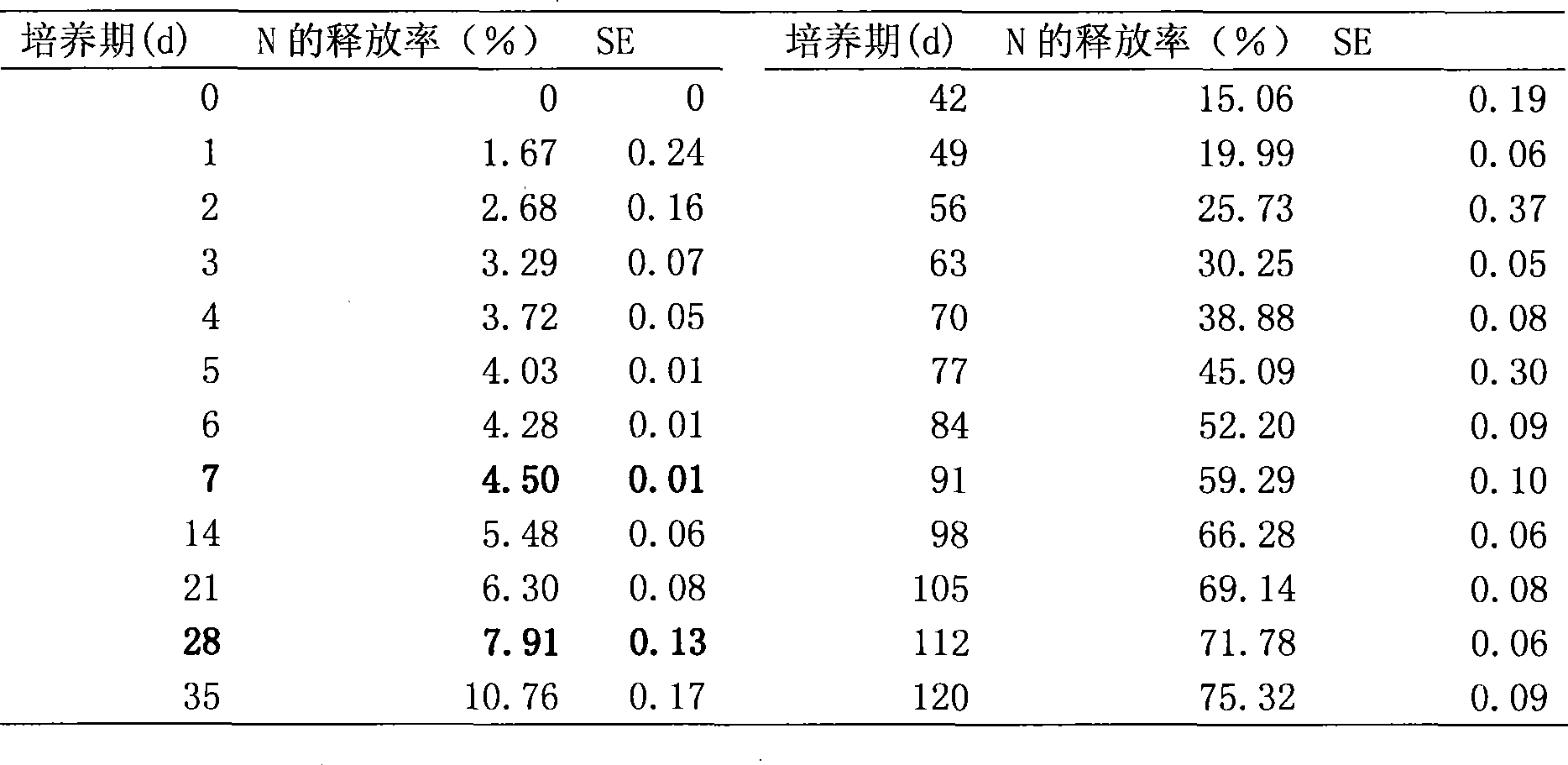

Industrial preparation method of water-soluble resin coating material and application thereof

ActiveCN101544707AIncreased mechanical resistanceImprove water resistanceFertiliser formsFertilizer mixturesControlled releaseResin coating

The invention discloses a preparation method of a water-soluble resin coating material and an application thereof. The preparation method comprises the steps as follows: water and emulsifier are prepared into an emulsifier solution; part of the emulsifier solution and a mixed monomer are prepared into an emulsive monomer; and the rest of the emulsifier solution and the emulsive monomer react under the evocation of an evocating agent to obtain the coating material. The invention realizes a high-temperature coating process of water polymer and adopts industrial-scale equipment and process condition so as to be conveniently used for the manufacture of the controlled-release coating material of an enterprise without pilot test and technique magnification. The Tg temperature of the coating material is 15-100 DEG C, and agglomeration can not occur when the fluidization coating temperature reaches 100 DDG C.

Owner:SOUTH CHINA AGRI UNIV

Volatile amines free polyurethane aqueous dispersions

InactiveUS20100098867A1Good chemical resistanceIncreased mechanical resistancePretreated surfacesPolyurea/polyurethane coatingsAqueous dispersionCoating

Owner:LAMBERTI SPA

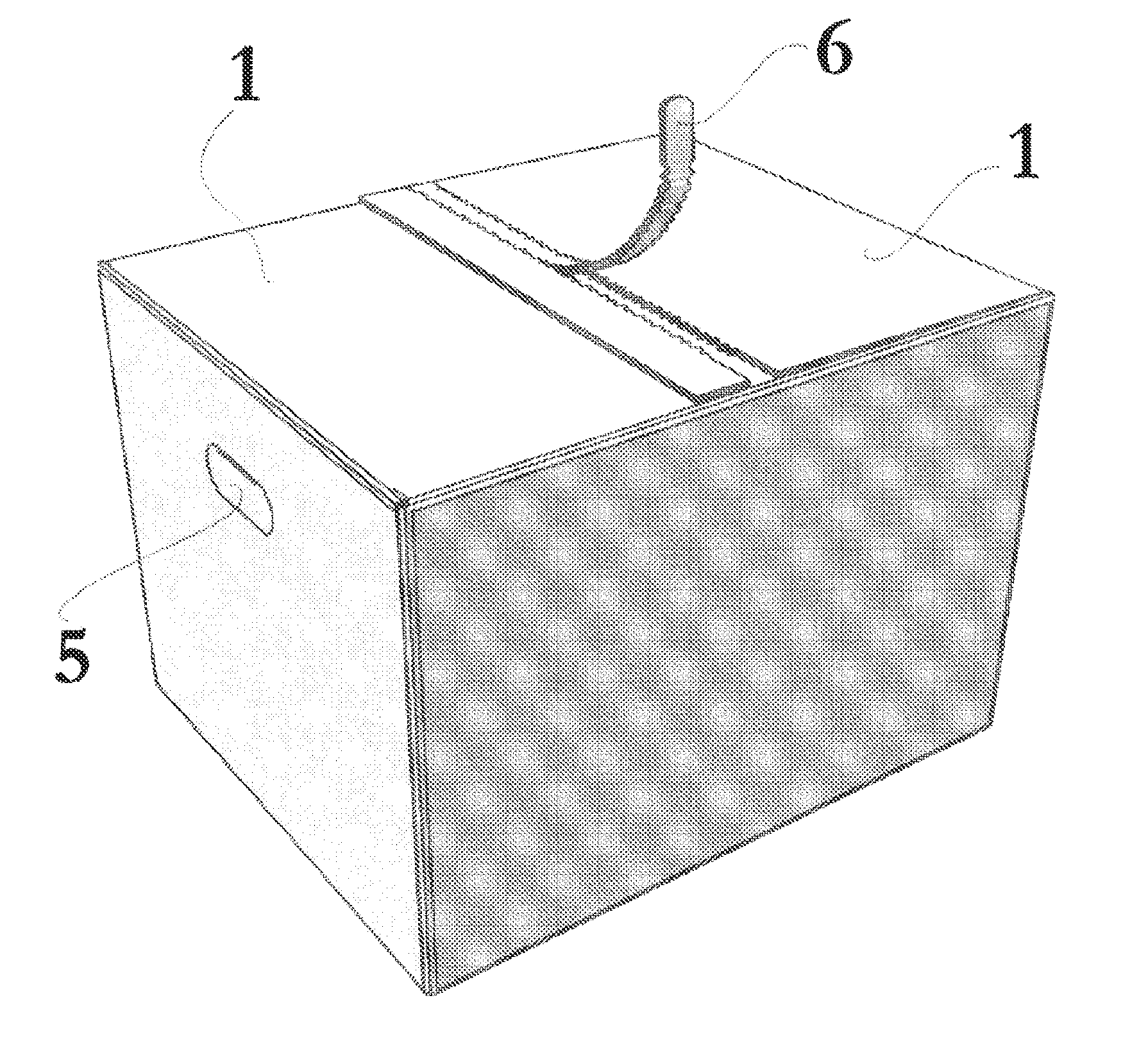

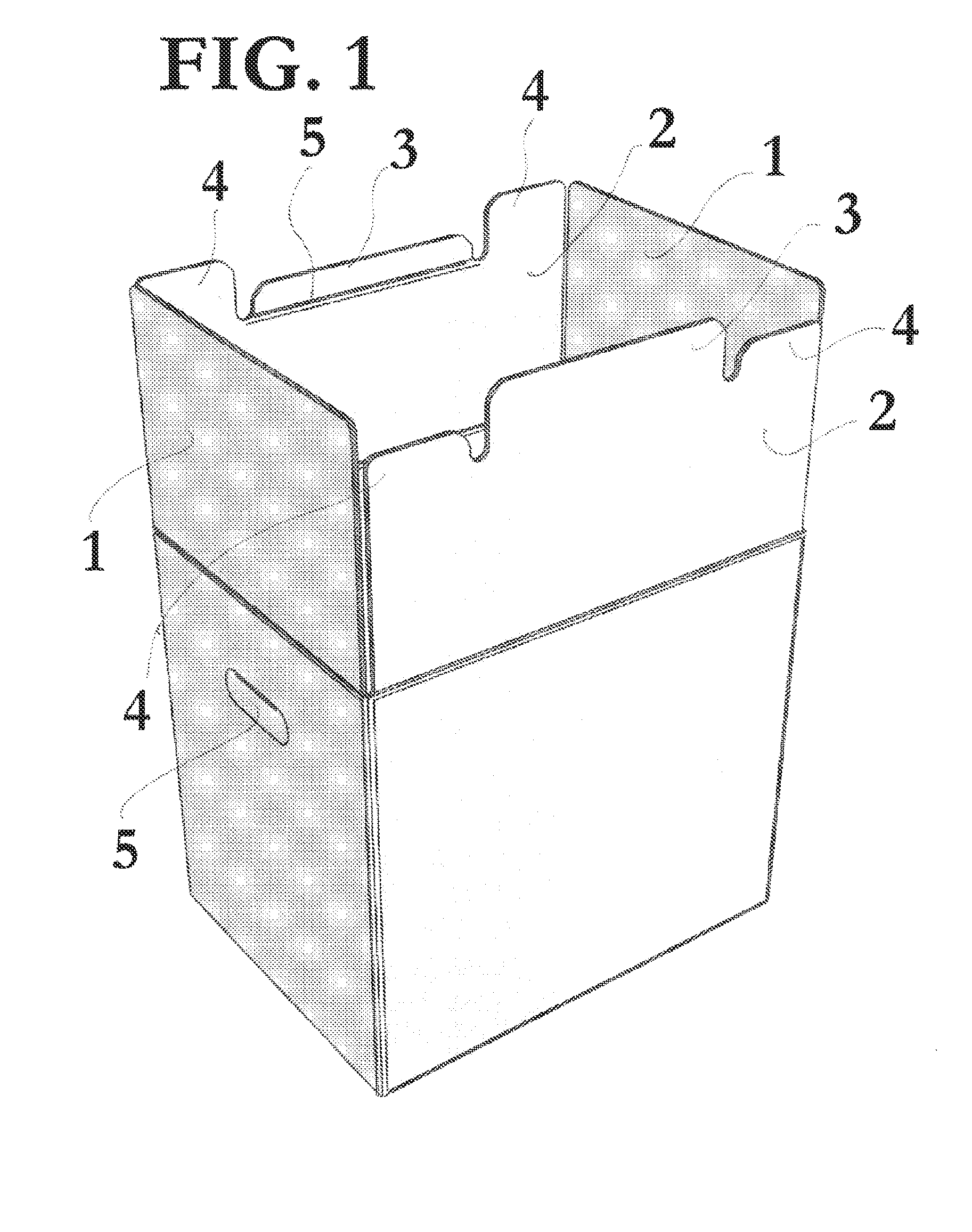

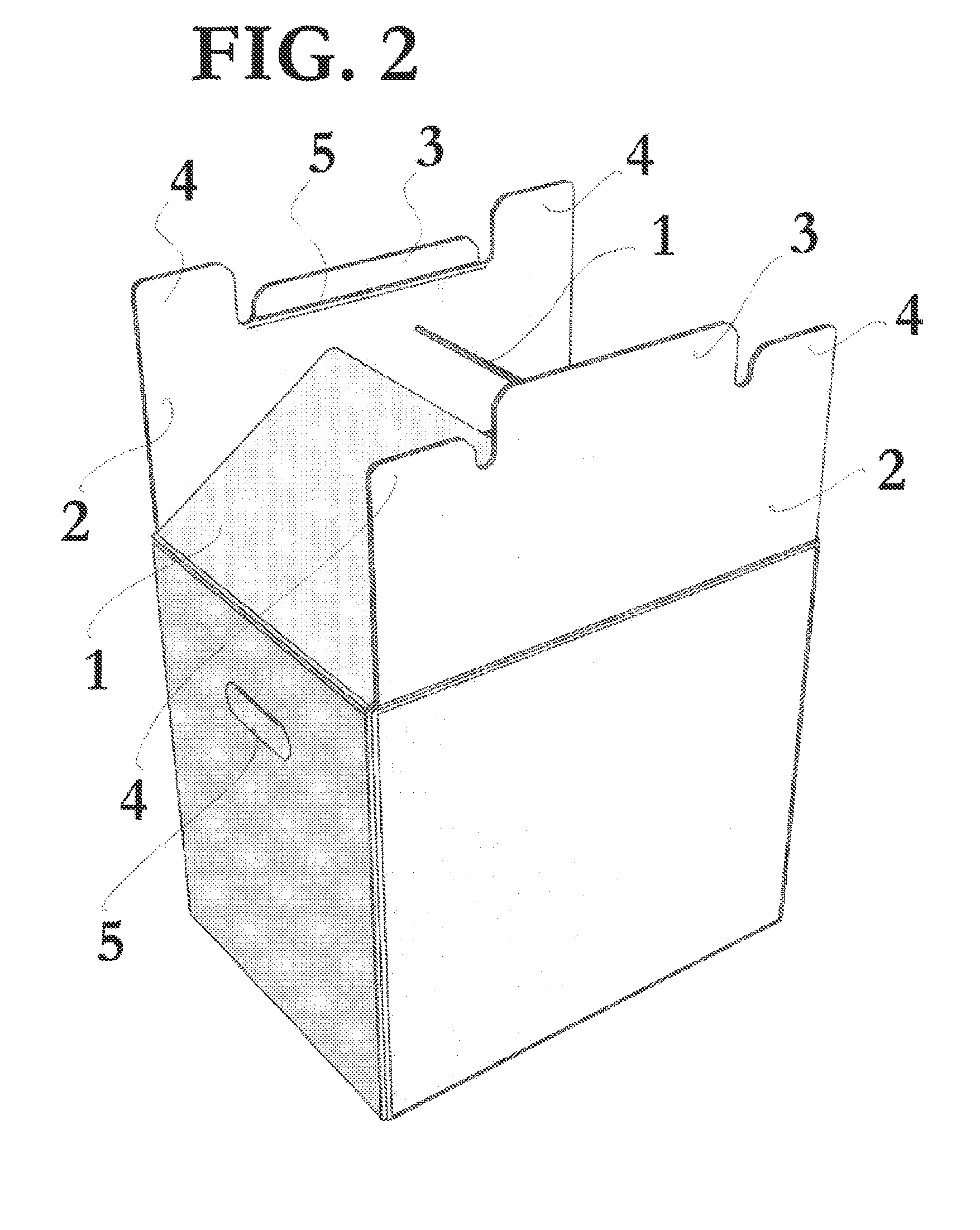

Storage and Shipping Box

ActiveUS20140197230A1Versatile boxGood mechanical resistanceLidsNon-removalbe lids/coversEngineeringStructural engineering

Owner:EMBALAJES CAPSA

Method for preparing para-aramid dissolving pulp and products

InactiveCN101457405AEasy to shapeFully microfibrillatedOther chemical processesFilament-forming treatmentSingle fiberDissolving pulp

A preparation method of a para-aramid pulp comprises the following steps: (1) para-aramid filaments are cut into 3-13mm short fibers by a mechanical cutter, and then the short fibers are dispersed into water to prepare 0.1%-5% suspension; (2) the suspension is disintegrated and cut off by a disc refiner, and fibrillated for 10-30min to prepare a sufficient micro-fibrillated pulp with the single fiber length of 0.8-3mm and the specific surface area of 5-10m<2> / g; (3) the pulp is dehydrated and dried by a paper machine to make paper; and (4) the paper is cut into pieces by a shredder, then loosened by a fiber opener to prepare the para-aramid pulp, and finally the obtained pulp is compressed and packaged. In the para-aramid pulp prepared by the method, average length of the pulp fiber is 0.8-3mm, and the specific surface area thereof is 5-10m<2> / g. The preparation method has the advantages of simple and stable process. The adopted devices are mostly paper making equipment without new equipment investment, therefore, the cost is well controlled.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

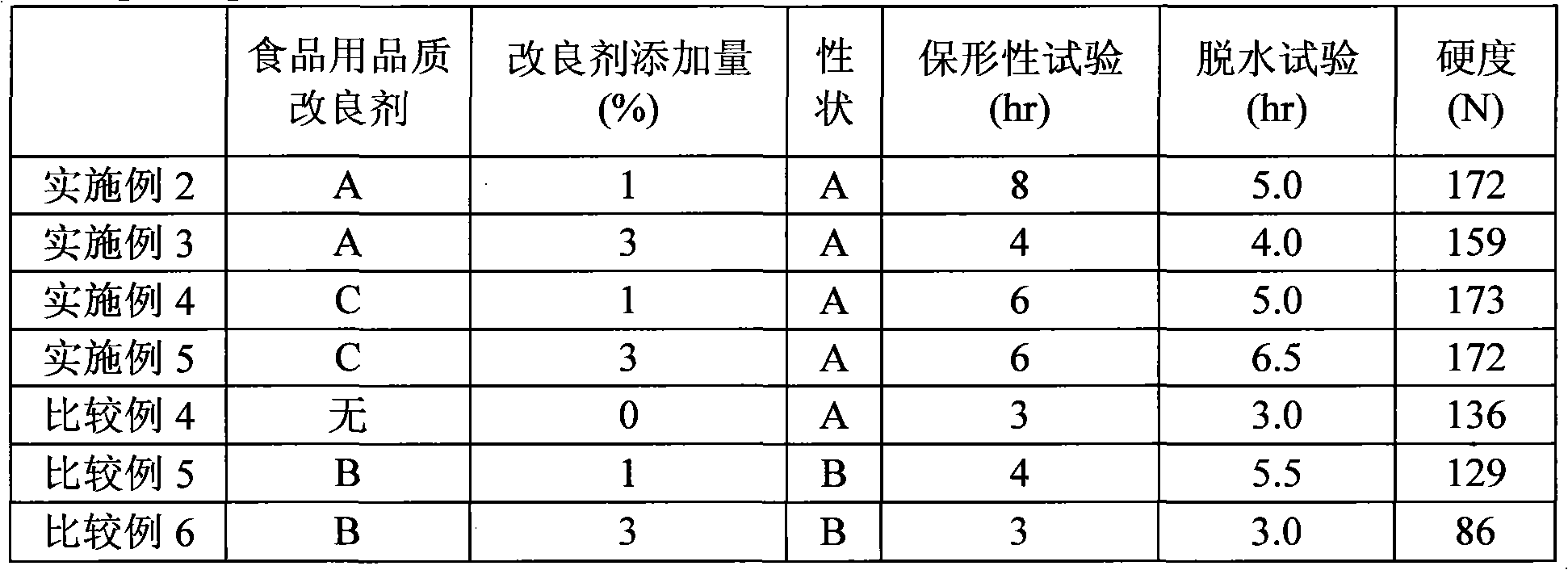

Food product conditioning agent and food product

Disclosed is a food product conditioning agent for which the manufacturing method is simple, that has excellent storage stability, and that, when added to various food products, maintains for a long period of time the texture and flavor that exist immediately after processing and cooking. The food product conditioning agent contains an emulsifier and a gel-forming substance, and said emulsifier forms a lamellar structure. In particular, with a preferred embodiment, the lamellar structure of the emulsifier is formed with an organic acid monoglyceride, and the gel-forming substance is glucomannan.

Owner:MITSUBISHI CHEM CORP

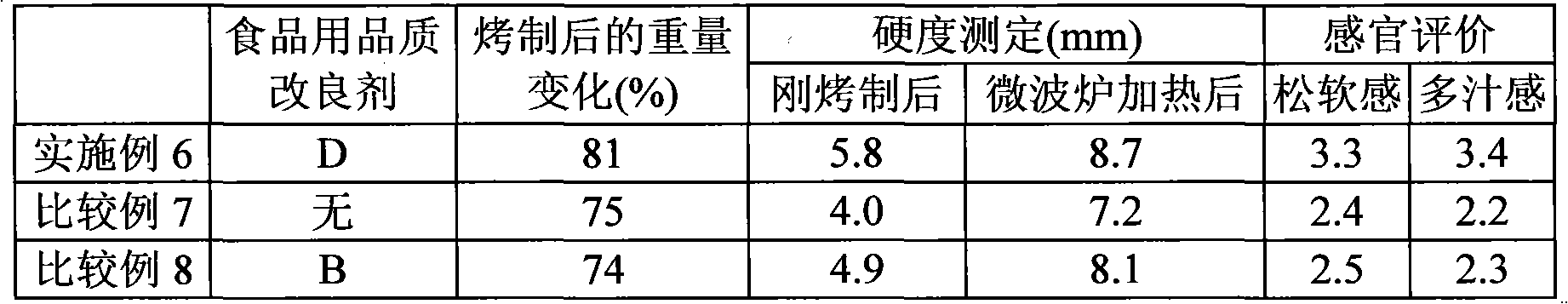

Automobile pipeline and method for producing automobile pipeline

InactiveCN101328992AEfficient preparationImprove corrosion resistanceHot-dipping/immersion processesCorrosion preventionMetalAluminium oxide

Owner:TI AUTOMOTIVE HEIDELBERG

Austenitic twip stainless steel, its production and use

ActiveUS20150329947A1Increase resistanceIncreasing energy of stacking faultHigh resistanceChemical composition

The object of the invention is an austenitic stainless steel with high plasticity induced by twinning with innovative chemical composition, and the use thereof in the automobile industry and in all applications wherein both a high resistance to corrosion and a high formability is requested, together with mechanical features of high-resistant steels. The invention also concerns a process for the production of this austenitic stainless steel with high twinning-induced plasticity.

Owner:CENT SVILUPPO MATERIALI SPA

Modified fiber board production process

The invention relates to a modified fiber board production process. The modified fiber board production process includes steps of chipping, digesting, hot grinding, preparation of modified fibers, drying, preparation of blank materials, cold pressing, hot pressing, saw cutting, sanding, thickness determination and the like. In the step of preparation of modified fibers, calcium powder is added into fibers and used for replacing part of wood fibers, the calcium powder is mixed with glue prior to being mixed with the fibers during filling so as to enable clearances of the fibers to be filled by mixture of the calcium powder and the glue, and accordingly physical and chemical performances of fiber boards are improved, and improvement of board density, reduction of wood consumption and improvement of elasticity modulus indexes and static bending strength of the boards are achieved while reduction of fiber board production cost and effective saving of wood resources are realized. Wood consumption is reduced by about 20% as compared with that of common fiber boards, and the modified fiber boards produced according to the process have the advantages of high strength, high nail holding ability, excellent bending resistance and high stability and flame retardance.

Owner:湖北益嘉林业发展有限公司

Handle for a pan or a similar kitchen vessel

ActiveUS20080245805A1Reduce weightIncreased mechanical resistanceWing handlesCooking vesselsSilicone resinMechanical engineering

A handle for a pan or a similar kitchen vessel comprises a handle supporting core integral with the pan body and combined by two reinforcement half-bodies made of a heat resistant material, the pan handle including reinforcement half bodies being coated by a silicone resin coating sheath.

Owner:BALLARINI PAOLO E FILI SPA

Long-acting sustained-release cell scaffold, and preparation method and application thereof

ActiveCN109602952ALong release periodIncreased mechanical resistanceTissue regenerationMicrocapsulesMicrosphereCytokine

The invention discloses a long-acting sustained-release cell scaffold, and a preparation method and application thereof. The long-acting sustained-release cell scaffold comprises a drug-cytokine protein, a silk fibroin and a complex protein. The drug-cytokine protein is coated by the silk fibroin to form cytokine sustained-release microspheres; the complex protein coats the outer layers of the cytokine sustained-release microspheres; the silk fibroin is a self-assembled silk fibroin by calcium salt regulation; the complex protein comprises gelatin capable of escaping body immune attack and degradable by cells. According to the preparation method, first the cytokine sustained release microspheres are formed through silk fibroin coating, and then the cytokine sustained release microspheres are coated with the complex protein degradable by cells, so that 3-5 month long-term sustained release of the drugs can be realized; a hydrogel hybrid formed by the complex protein is more mechanicallytolerant than simple collagen and chondroitin sulfate; and the scaffold has good homology, and a long drug sustained release period, so that the cartilage tissue has better mechanical tolerance and metabolic activity during conversion of the scaffold into a cartilage matrix.

Owner:上海北陆医药科技有限公司

Choke trim assembly

ActiveUS20120181470A1Increased mechanical resistanceImprove fitCheck valvesFlushingEngineeringBiomedical engineering

A choke trim assembly for use as a shuttle seat in a choke valve including a flange sleeve is disclosed, the choke trim assembly comprising a trim, a trim carrier, and a clamp ring, wherein the trim carrier and the clamp ring each have a tubular member, an outer diameter of the tubular member of the clamp ring being configured to enable a slip fit of the choke trim assembly into an inner diameter of the flange sleeve, the trim being centered in the clamp ring, and an outer diameter of the tubular member of the trim carrier and the inner diameter of the clamp ring being configured to enable a slip fit of the trim carrier into the clamp ring.

Owner:MI

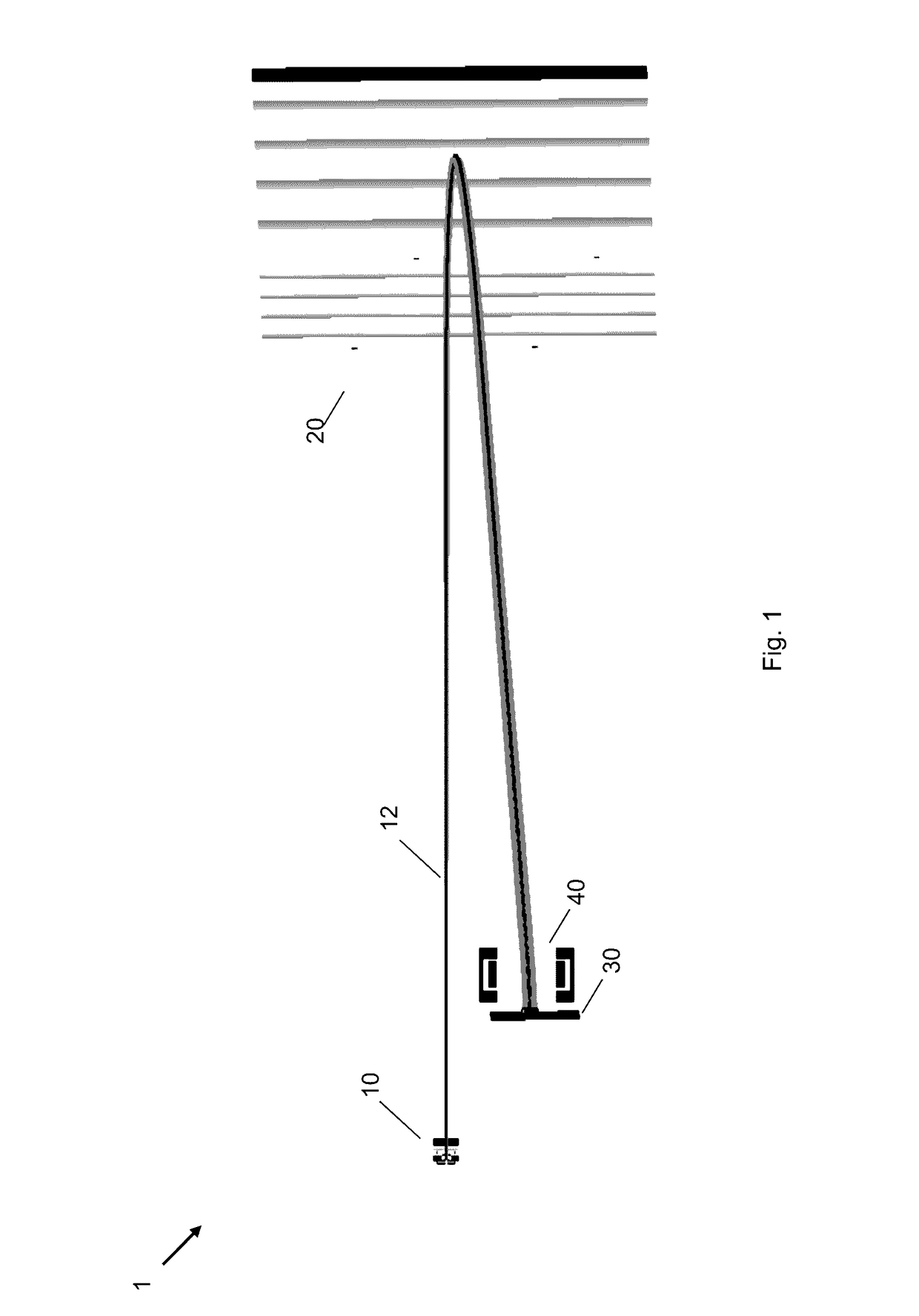

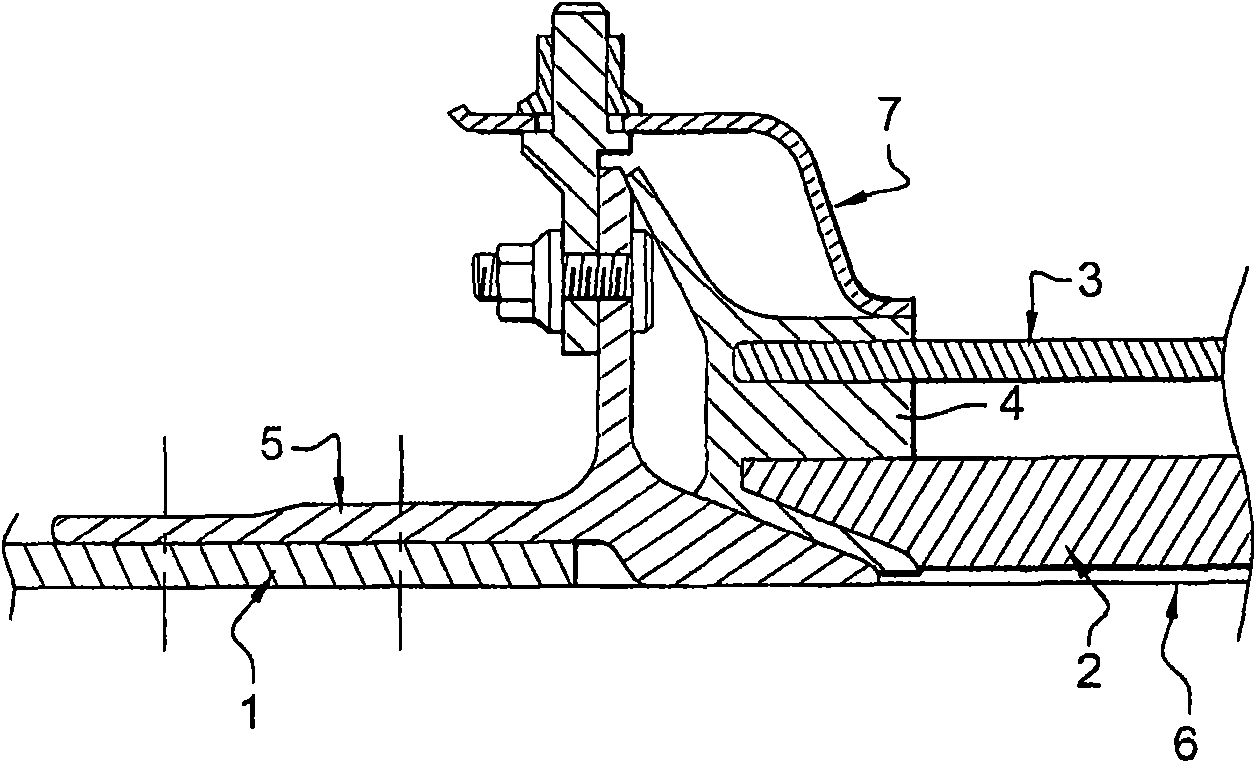

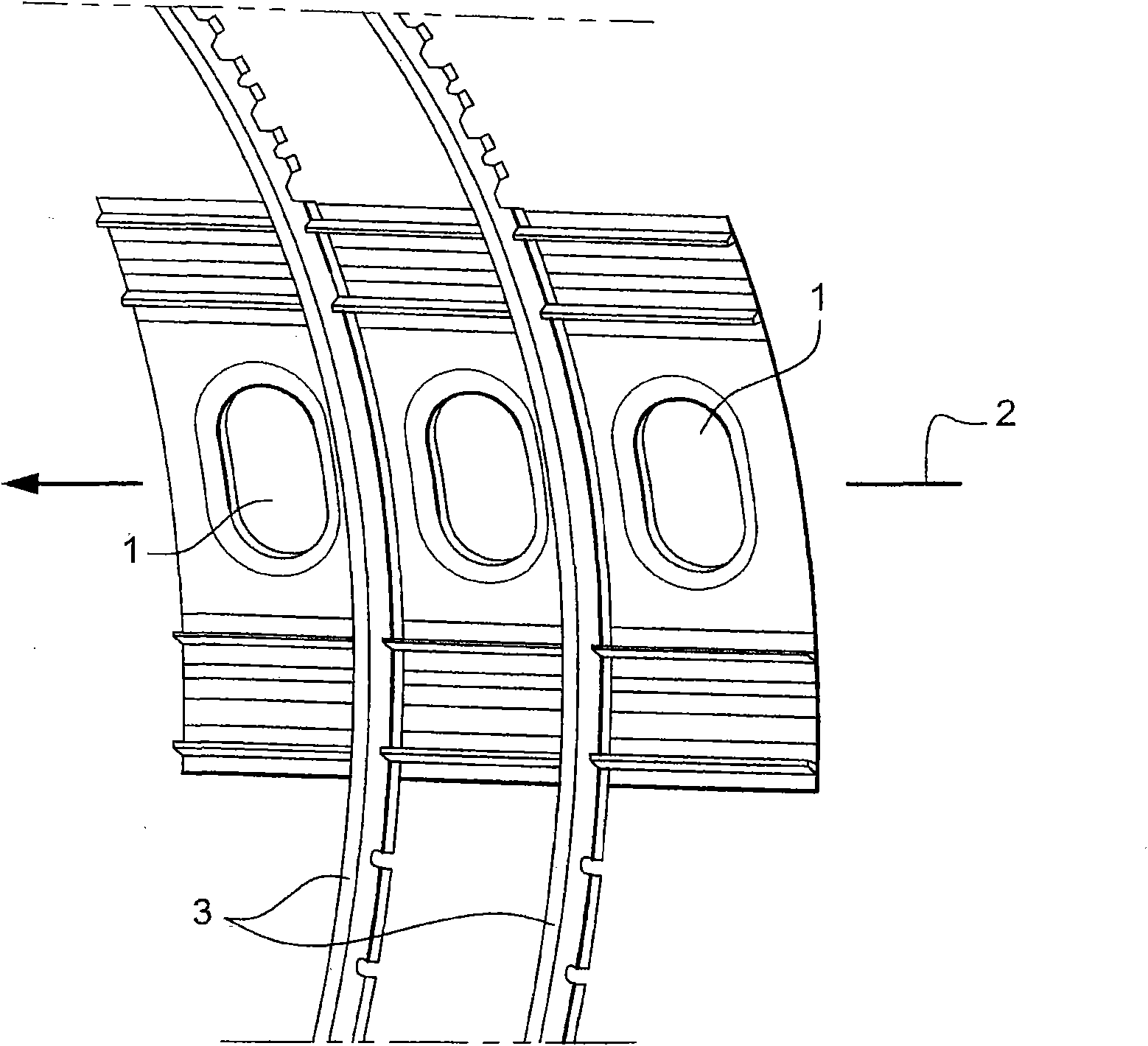

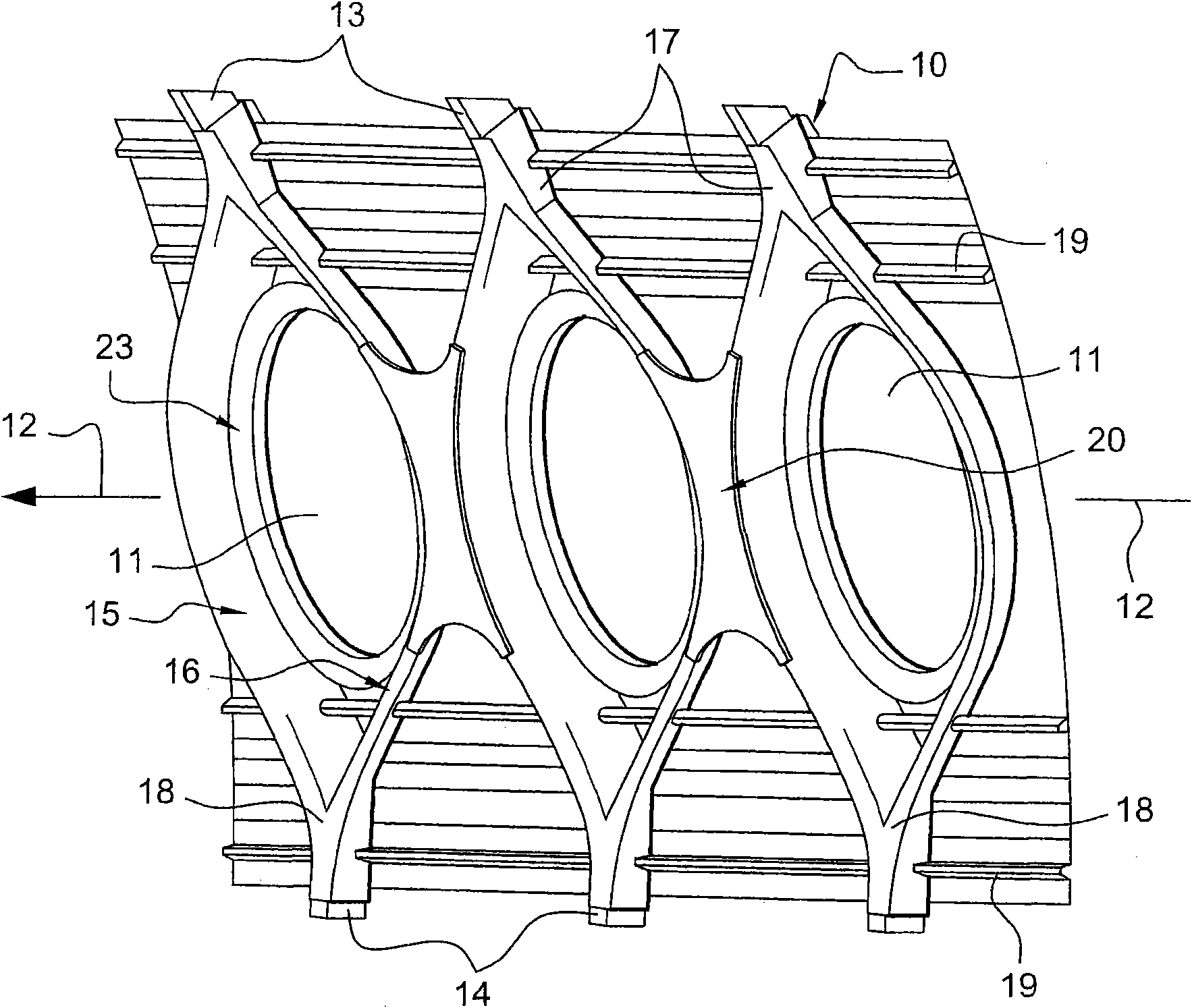

Aircraft cabin window assembly method

InactiveCN101605694AIncreased mechanical resistanceQuick releaseWindowsAircraft accessoriesMarine engineeringFlight vehicle

The invention relates to a method for assembling a cabin window to a bay in a side wall (12) of an aircraft fuselage, said cabin window comprising an outer transparent element (10) and at least one inner transparent element (11). According to the invention, a non-through hole is made in a portion of the side wall (12) along the edge of the bay. Subsequently, the outer transparent element (10) is positioned in the bay from the exterior of the fuselage, said element including a first part (13) which has a diameter greater than that of the bay and which is shaped to co-operate with the above-mentioned portion such as to block the outer transparent element (10) in the bay both laterally and longitudinally. The outer transparent element (10) also includes a second part (16) having a groove (17) that projects into the fuselage.; The outer transparent element (10) and the at least one inner transparent element (11) are welded to the fuselage using a strap (22) which presses a seal (21) against at least the fuselage and the inner wall of the groove (17).

Owner:AIRBUS OPERATIONS (SAS)

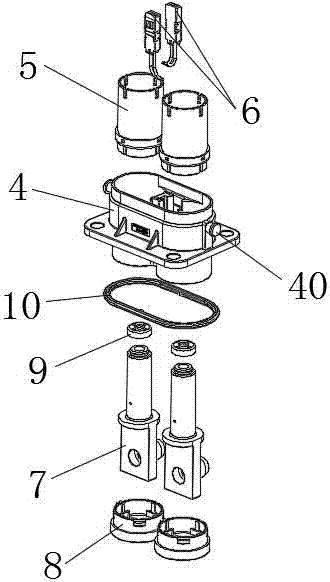

Metal high current connector

PendingCN107332023AImprove overload capacityReduce volumeVehicle connectorsCouplings bases/casesEngineeringMechanical engineering

The invention relates to the technical field of automobile fittings, and in particular relates to a metal high current connector. The metal high current connector comprises a socket assembly, a plug assembly and a locking device. A PIN pin is inserted in the through hole of the socket body of the socket assembly. A high voltage interlocking female terminal is snapped into an embedded groove in the socket body. A crown spring contact assembly is inserted into the through hole of the plug body of the plug assembly. A high voltage interlocking male terminal is snapped into an embedded groove in the plug assembly. A threaded post on the tail end of the crown spring contact assembly passes through a through hole in a wire nose, and then is in screwed connection with a locknut. The metal high current connector uses an all-metal casing, and matches a variety of shielding rings at a variety of parts to further improve the shielding effect. The mechanical resistance of the metal casing is strong, and the metal casing is not damaged during use. The one-piece casing and waterproof ring are used to improve the water resistance. The connector has the advantages of small size and large overload capacity, and is in line with the German Volkswagen LV215 standards and the United States USCAR37 standards.

Owner:AMPHENOL AUTOMOTIVE CONNECTION SYST CHANGZHOU CO LTD

Water-permeable concrete and preparation method thereof

The invention discloses water-permeable concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 10-15 parts of acrylate water-based laminating adhesive, 1500-1600 parts of crushed stone, 100-200 parts of super absorbent resin microspheres, 300-400 parts of cement, 5-7 parts of polyol, 5-10 parts of triisopropanolamine, 10-15 parts of nano calcium carbonate, 1-5 parts of nano silicon particles, 2-4 parts of sodium lignin sulfonate, 4-6 parts of an emulsifier and 130-160 parts of water. The acrylate water-based laminating adhesive isprepared from an ethylene-acrylic emulsion, an acrylate emulsion and a cross-linking agent; the cross-linking agent comprises polyetherimide. The water-permeable concrete can improve the water permeability and the bearing capacity, is not prone to breakage and has high freezing and thawing resistance and durability.

Owner:XIJING UNIV

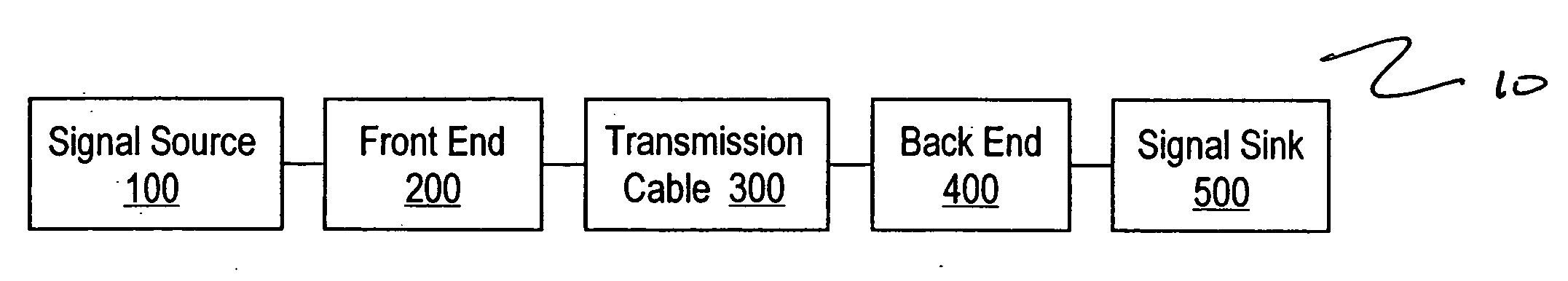

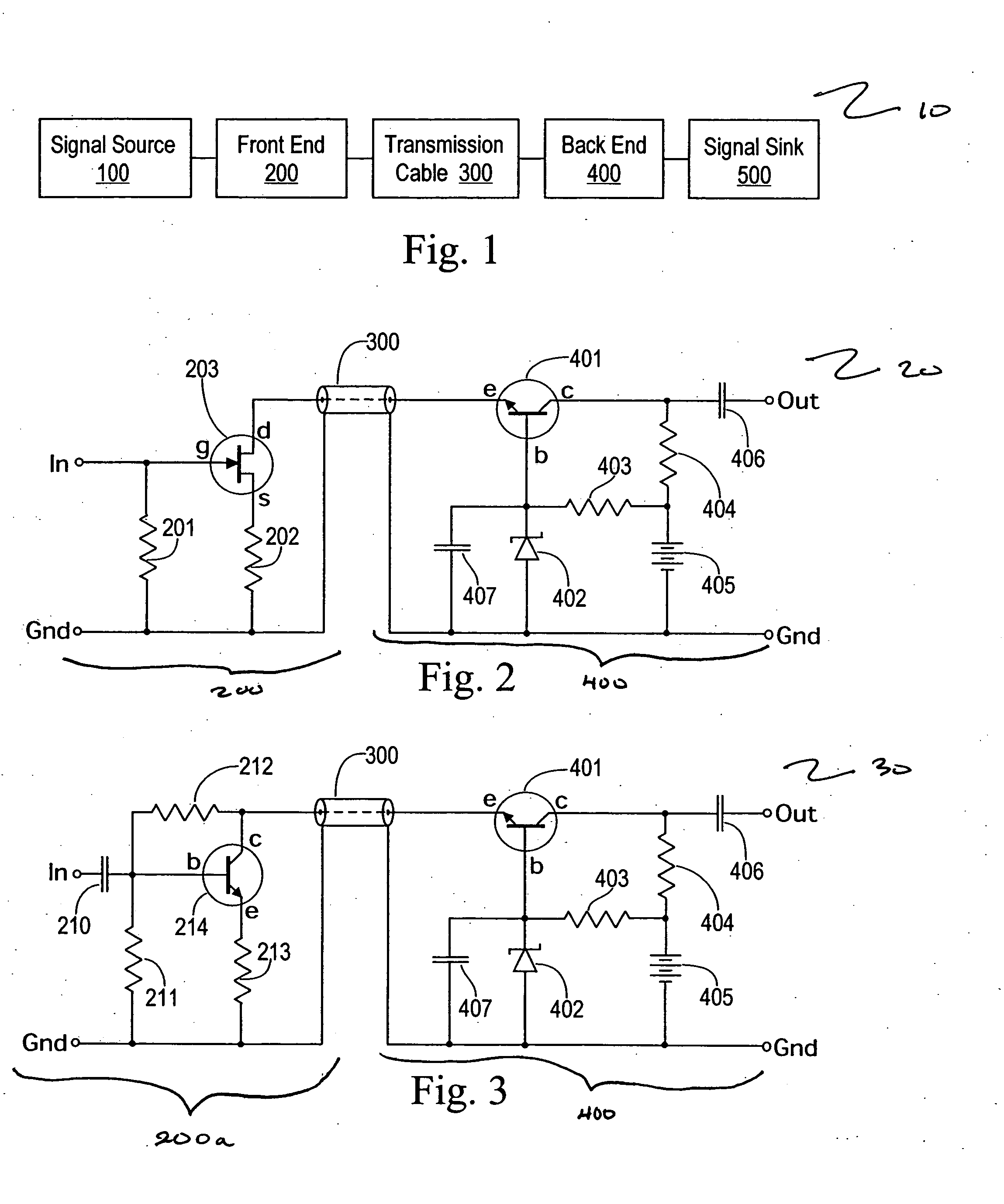

Split cascode line amplifier for current-mode signal transmission

InactiveUS20050146389A1Low costIncrease physical strengthReliability increasing modificationsMultiple-port networksElectrical conductorEngineering

Current-mode transmission is implemented in a cascode amplifier by splitting a cascode circuit into a front end and a back end to ensure wideband current-mode transmission of an audio signal. A transmission cable is located between the high impedance output of the first end and the low impedance input of the back end. The front end includes a first amplifying device, and the back end includes a second amplifying device. The front end is phantom powered by the back end using the same electrical conductors that carry the current-mode signal over the transmission cable.

Owner:GWINN JOSEPH

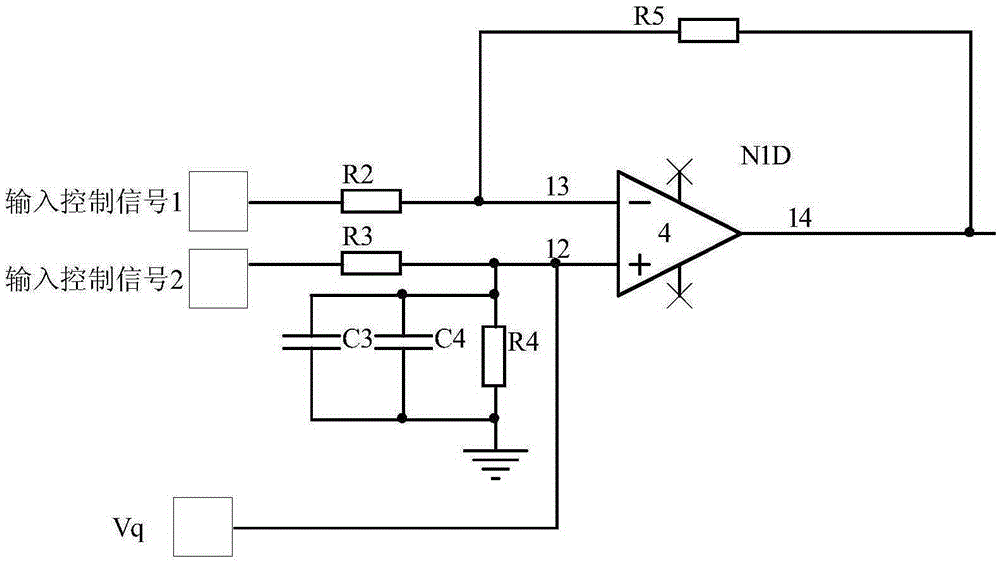

Frequency limiting control hybrid integrated circuit

ActiveCN105245210AThe output drive signal is stableHigh precision of differential amplificationSingle output arrangementsComparators circuitsTriangular wave

The invention relates to a frequency limiting control hybrid integrated circuit which comprises differential operational, compensation amplification, hysteresis comparator, totem-pole drive output and reference voltage circuits. The differential operational circuit carries out proportional amplification output on an external input control signal. The output signal of the differential operational circuit and second reference voltage are compensated and amplified by the compensation amplification circuit, and are used as the same-phase end input signal of the hysteresis comparator circuit. First reference voltage is used as the reverse-phase end input signal of the hysteresis comparator circuit. The hysteresis comparator circuit outputs PWM waveform with the duty cycle from 0 to100%. The PWM waveform is used as a drive output end through the totem-pole drive output circuit. The external control signal is a triangular wave signal sampled from a system, is amplified and compared to form a PWM signal, and is output by a totem pole. A reliable drive signal is provided for a post-stage power circuit of the system. The power supply voltage of the system is detected.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

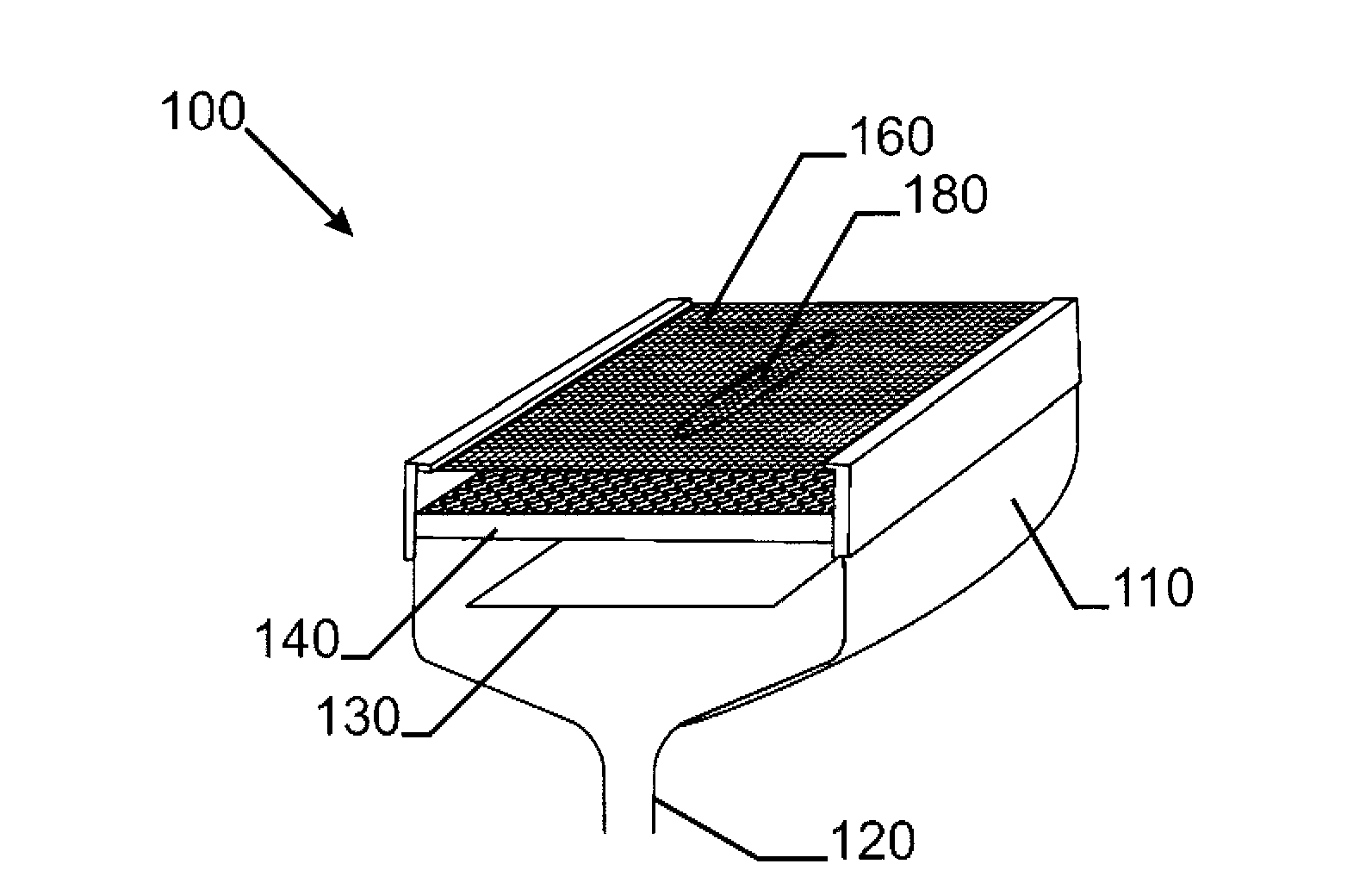

Gas fired radiation emitter with embossed screen

The present invention relates to a gas fired infrared radiation emitter comprising a burner plate (140) acting as combustion surface and a radiant screen (160) positioned at the combustion side of the perforated tiles. The radiant screen is embossed (180) proving locally different distances between th burner plate and the radiant screen. The result is a higher performance of the gas fired infrared radiation emitter.

Owner:SOLARONICS

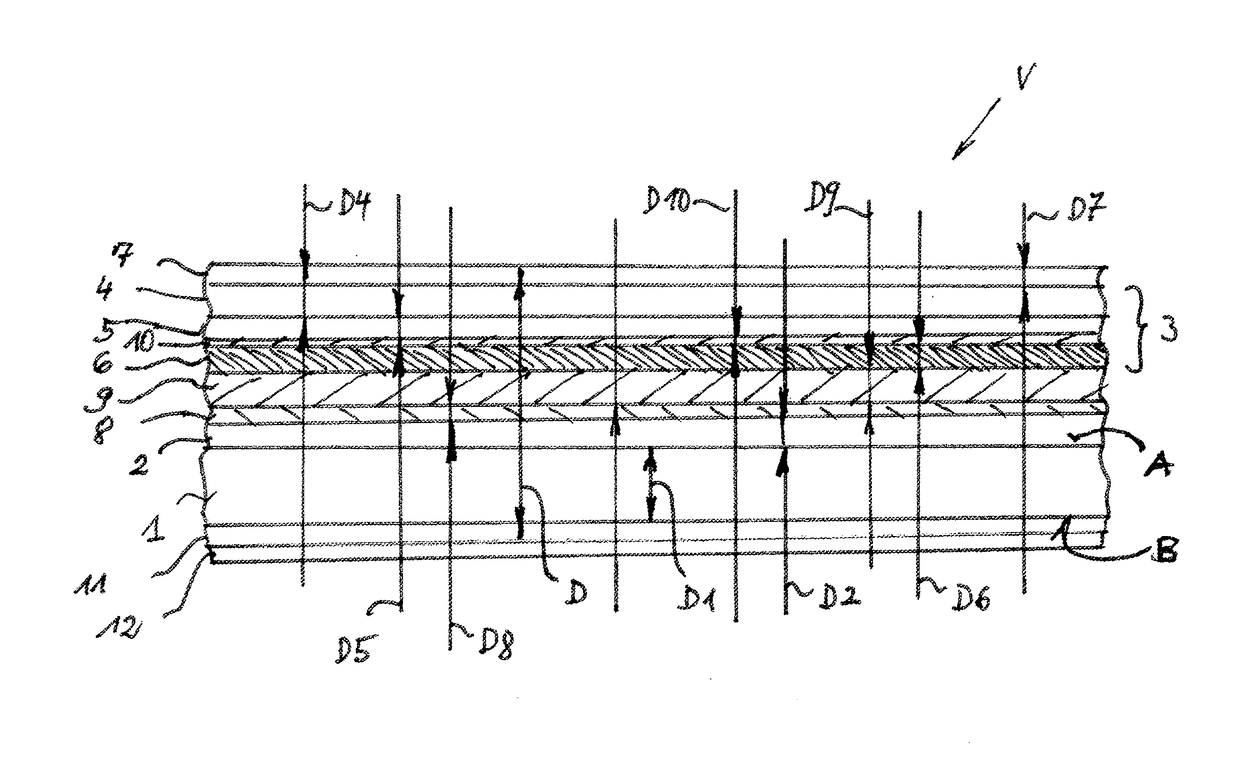

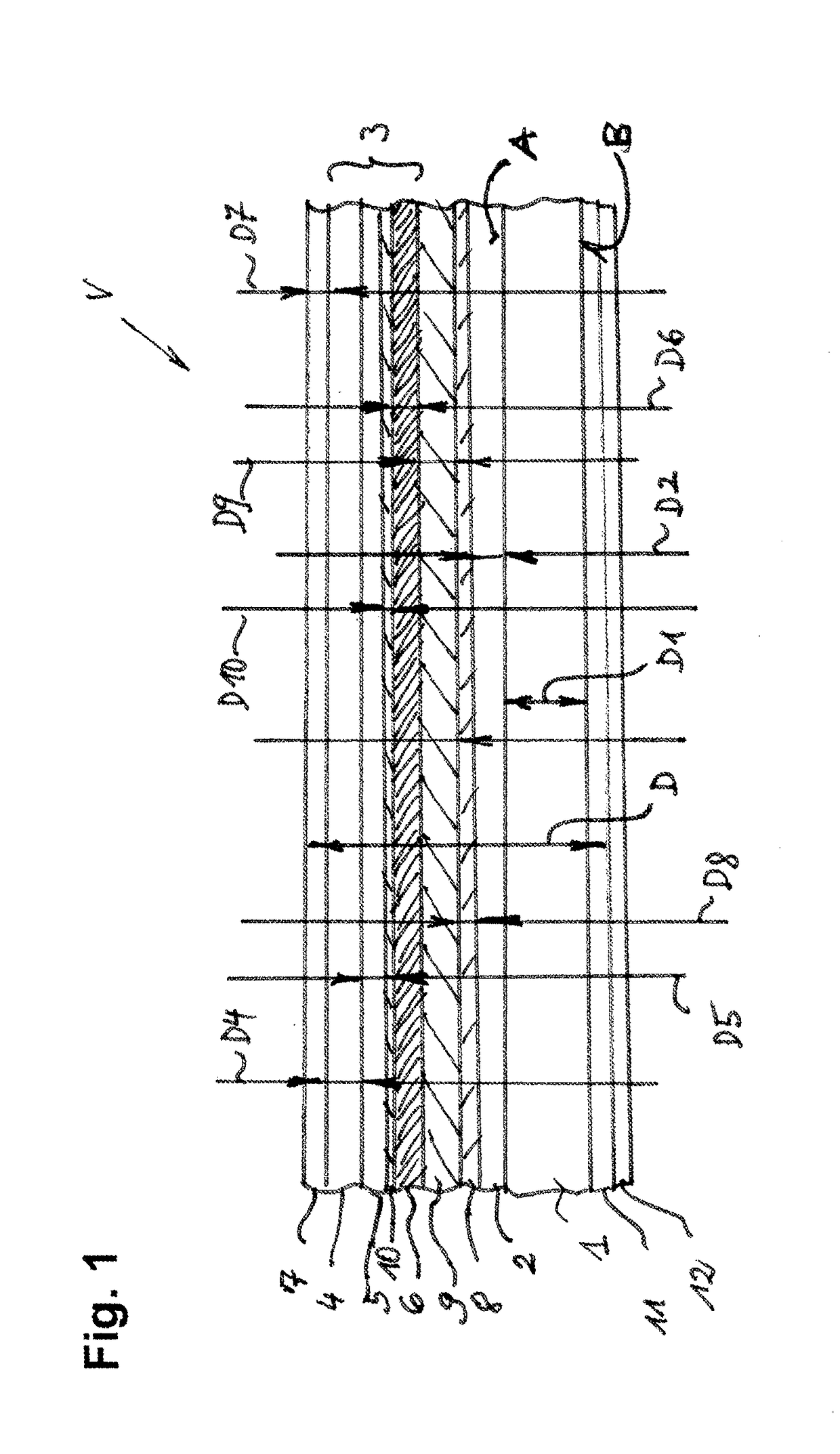

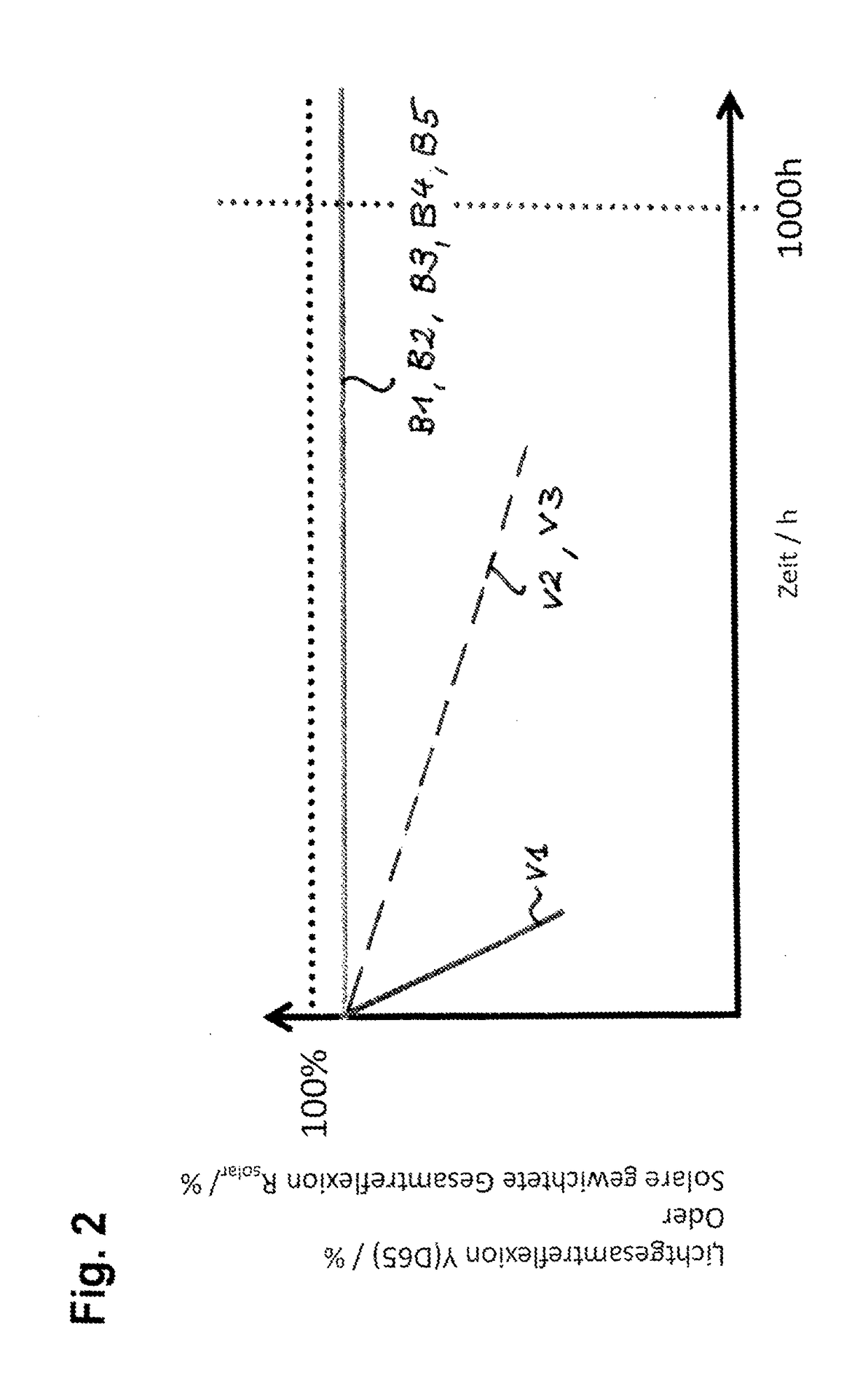

Reflective composite material comprising an aluminum substrate and a silver reflective layer

InactiveUS20180246261A1Improve adhesionAvoid layeringMirrorsVacuum evaporation coatingDiffusionInter layer

The invention relates to a reflective composite material (V) with a substrate (1) consisting of aluminum, with an intermediate layer (2) of anodic oxidized substrate material located on one side (A) of the substrate (1), and with an optically active multi-layer system (3) applied above the intermediate layer (2), wherein the multi-layer system consists of at least three layers, and wherein the upper layers (4, 5) are dielectric and / or oxidic layers, and the bottom layer (6) is a metallic layer consisting of silver which forms a reflective layer (6). To increase the ageing resistance the invention proposes that a diffusion-inhibiting barrier layer (8) is disposed above the intermediate layer (2) and below the reflective layer (6), wherein the reflective layer (6) is bonded to the barrier layer (8) by an adhesion-promoting layer (9).

Owner:ALANOD GMBH

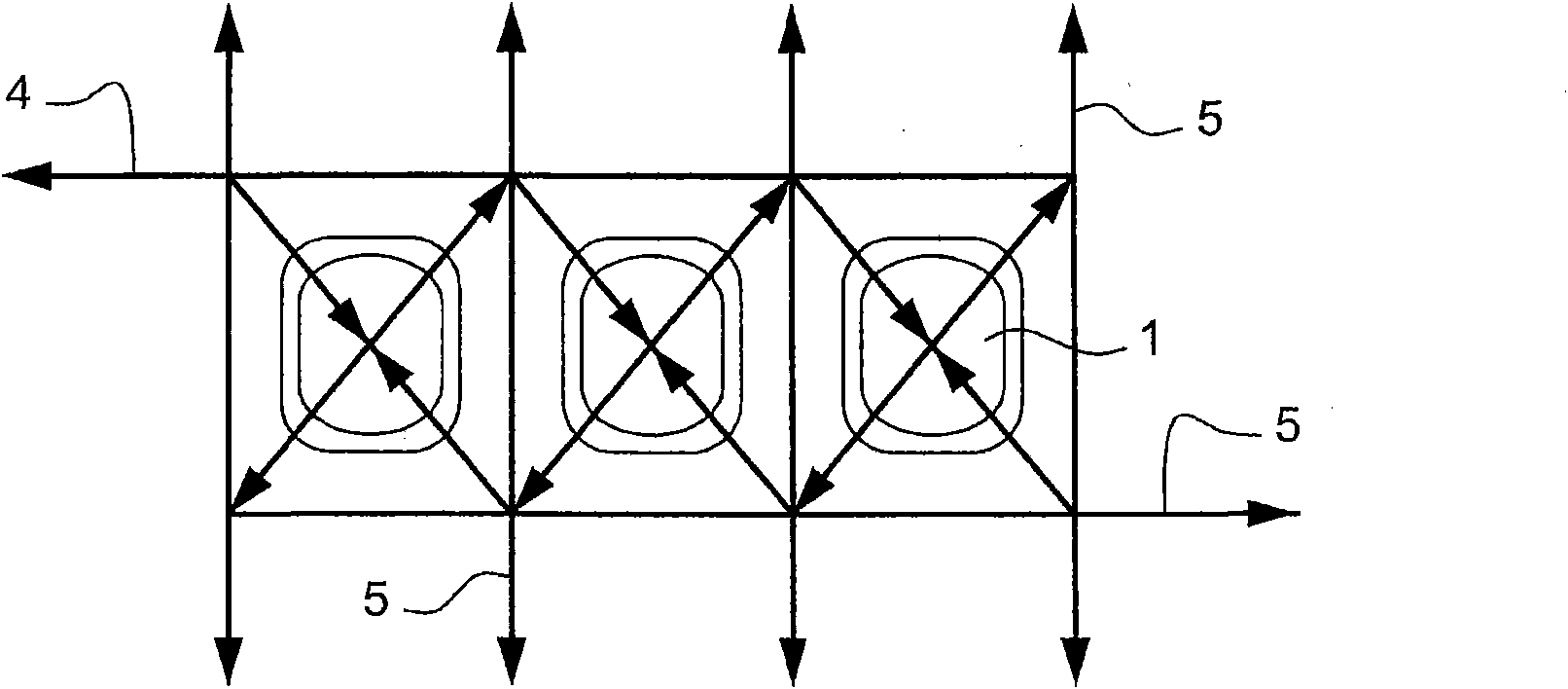

Section of aircraft fuselage and aircraft including one such section

InactiveCN101578220ASimple designEasy to operateFuselage framesAircraft accessoriesNacelleFlight vehicle

The invention relates to a section of fuselage for an aircraft, comprising frames and bays for receiving cabin windows (11). According to the invention, at least some of the frames include at least one frame segment that surrounds at least one bay, said frame segment comprising two branches (15, 16) that are disposed to the side of the bay. The ends of the branches are attached to each of the ends (17, 18) of the frame segment such as to form a Y.

Owner:AIRBUS OPERATIONS (SAS)

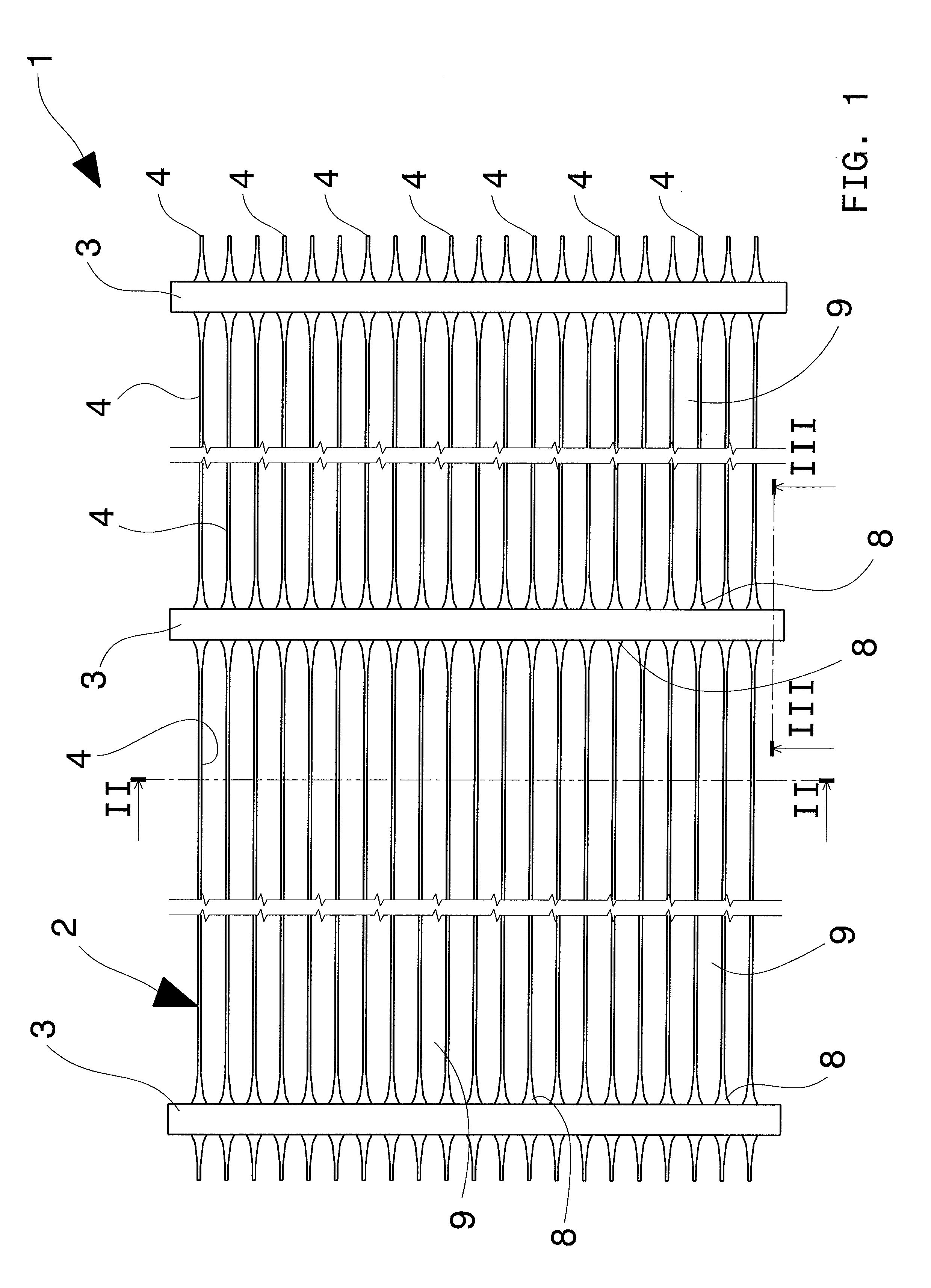

Reinforcing net structure for geotechnical applications, use of the reinforcing net structure, and a method for production of the reinforcing net structure

InactiveUS20120099933A1High mechanical resistanceIncrease flexibilityExcavationsSoil preservationTerrainEngineering

A product for reinforcing terrain includes a net structure made of a plastic material having a plurality of bars and a plurality of elongate elements that are transversal with respect to the bars. The elongate elements are arranged between adjacent pairs of bars and exhibit a substantially wire-like structure, with a transversal section having a smaller area than a transversal section of the bars. Also described are a use of the product and a method for manufacture thereof.

Owner:TENAX SPA

Corrosion-resistant sewage drainage tube material and preparation method thereof

InactiveCN108395645AStable physical and chemical propertiesImprove corrosion resistanceRed mudPolyvinyl chloride

The invention discloses a corrosion-resistant sewage drainage tube material and a preparation method thereof, and relates to the field of pipeline materials. The corrosion-resistant sewage drainage tube material is prepared from the following raw materials in parts by weight: 60-70 parts of polyvinyl chloride, 20-30 parts of acrylonitrile-butadiene-styrene copolymer, 20-30 parts of polyacrylate, 4-10 parts of dioctyl phthalate, 3-8 parts of dioctyl sebacate, 15-20 parts of heavy calcium carbonate, 8-16 parts of barium sulfate, 6-13 parts of red mud, 8-15 parts of modified glass fibers, 5-10 parts of glass micro beads, 3-8 parts of polyglutarylimide, 4-7 parts of nano titanium dioxide, 2-5 parts of magnesium stearate, 2-5 parts of calcium stearate and 2.5-5 parts of titanate coupling agent.The corrosion-resistant sewage drainage tube material is stable in physical and chemical property, has excellent corrosion resistance, wear resistance, temperature resistance and mechanical impact resistance, is resistant to corrosion of chemical substances in sewage, and is long in service life.

Owner:山东励仙电力工程有限公司

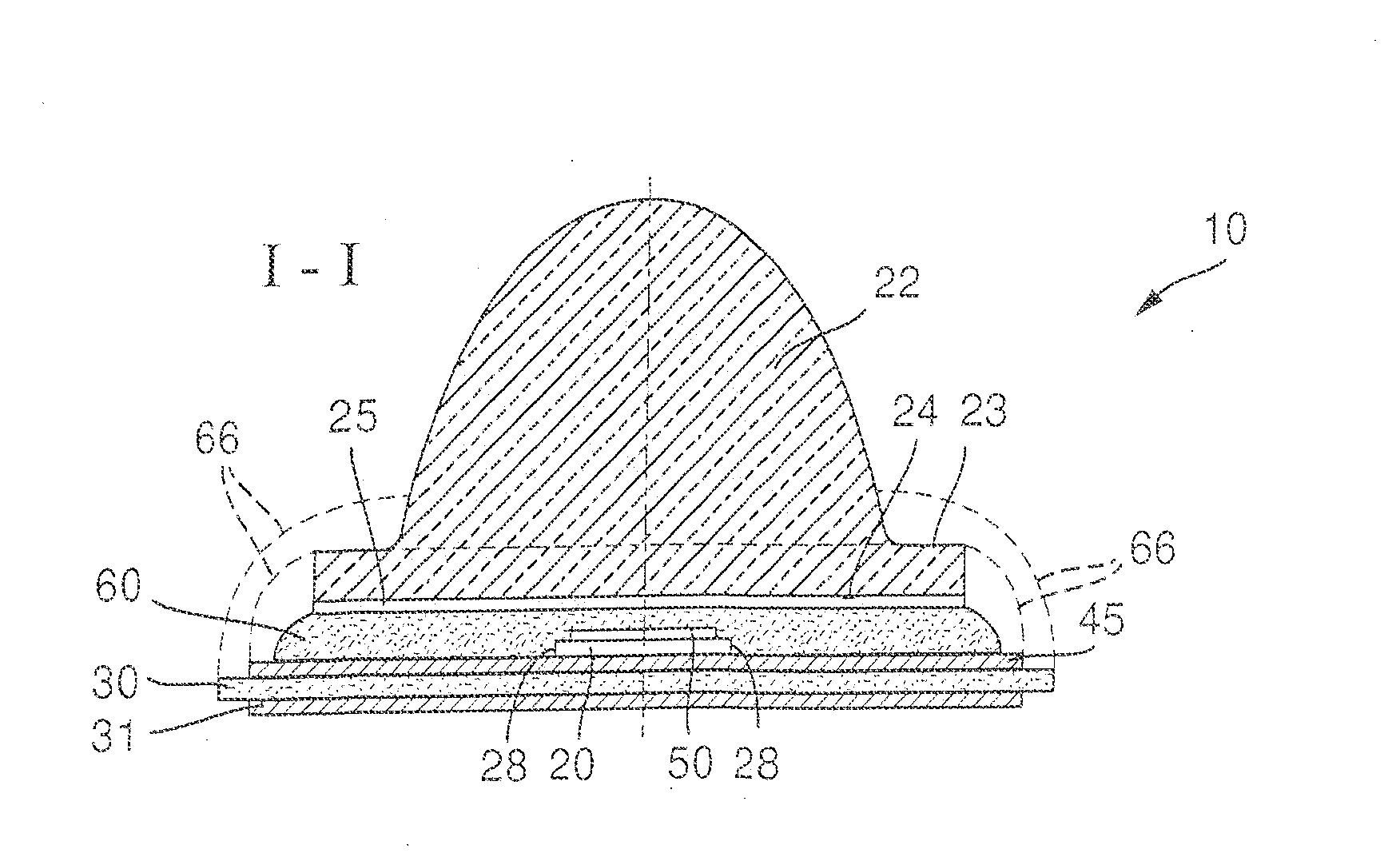

Solar cell unit

ActiveUS20150144189A1Strong frictional connectionGood UV transparencyDiodeEnergy conversion devicesElectrical connectionEngineering

A solar cell unit having a semiconductor body formed as a solar cell, whereby the semiconductor body has a front side with a first electrical connection and a back side with a second electrical connection and a side surface formed between the front side and the back side, and having a substrate with a top side and a bottom side, whereby the substrate on the top side has a first conductive trace region, configured as part of the substrate, and the first electrical connection is electrically connected to the first conductive trace region, and the substrate on the top side has a second conductive trace region, configured as part of the substrate, and the second electrical connection is electrically connected to the second conductive trace region, and having a secondary optical element, which has a bottom side and guides light to the front side of the semiconductor body.

Owner:AZUR SPACE SOLAR POWER

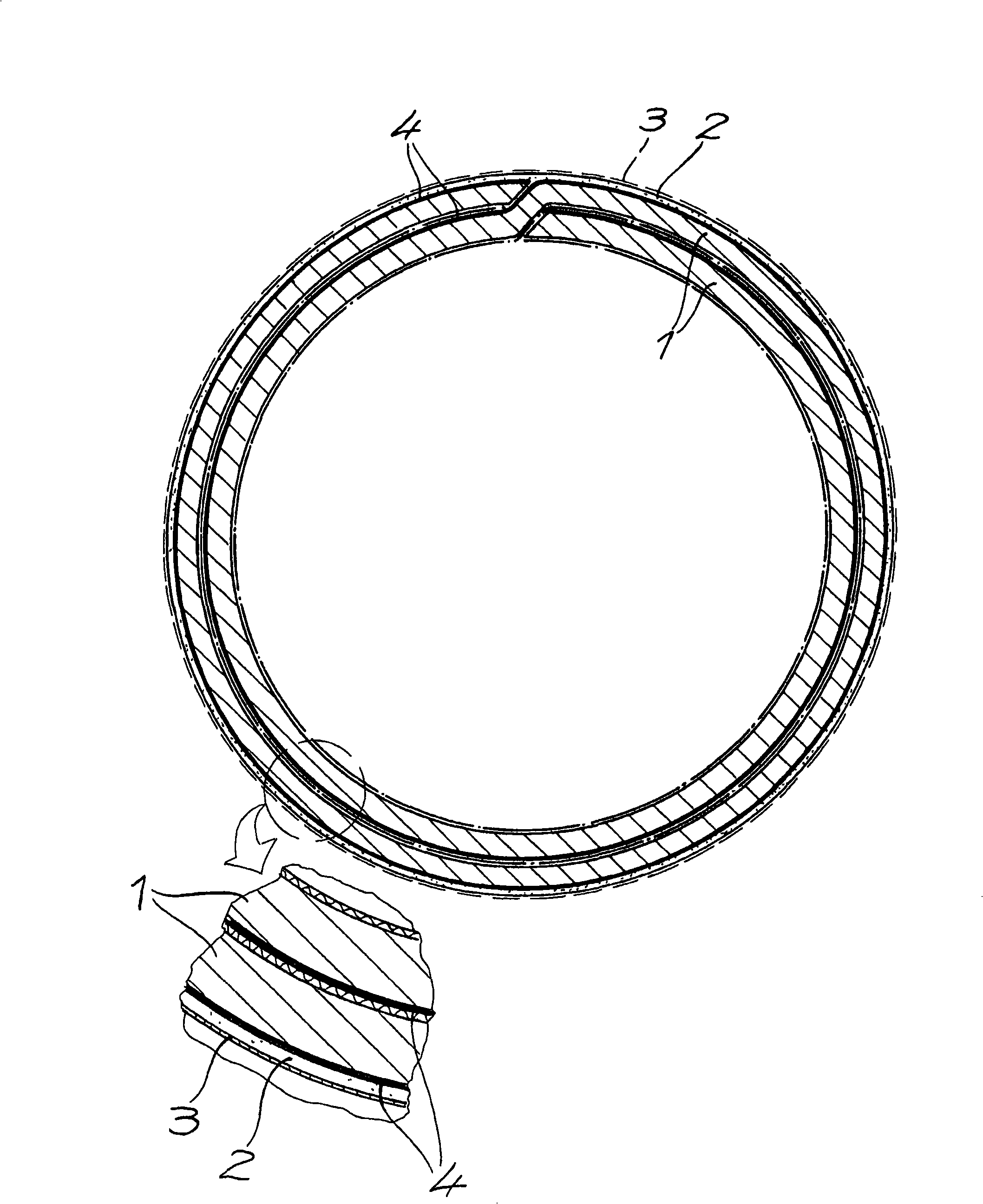

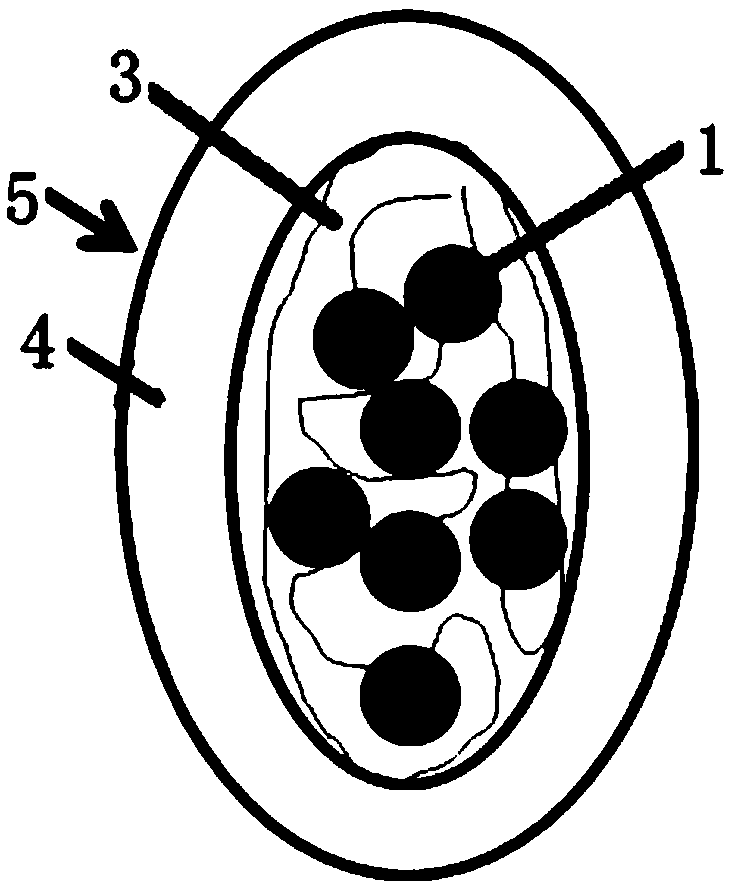

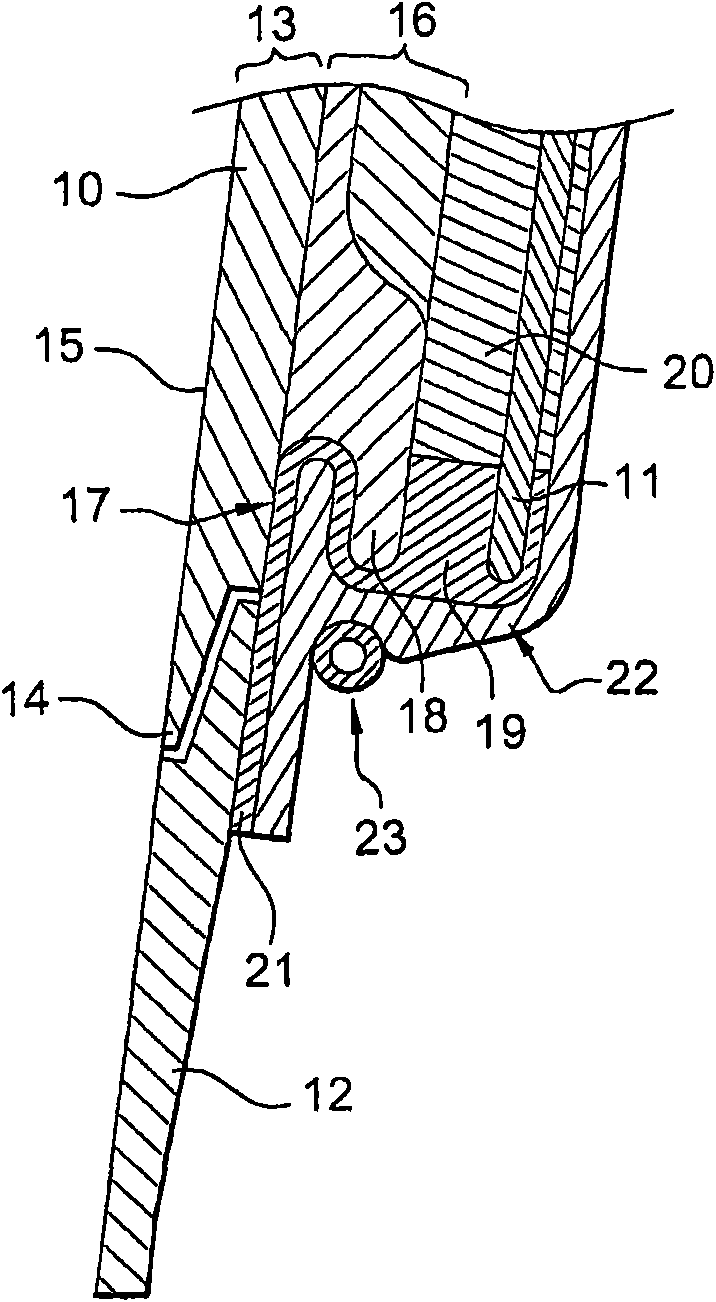

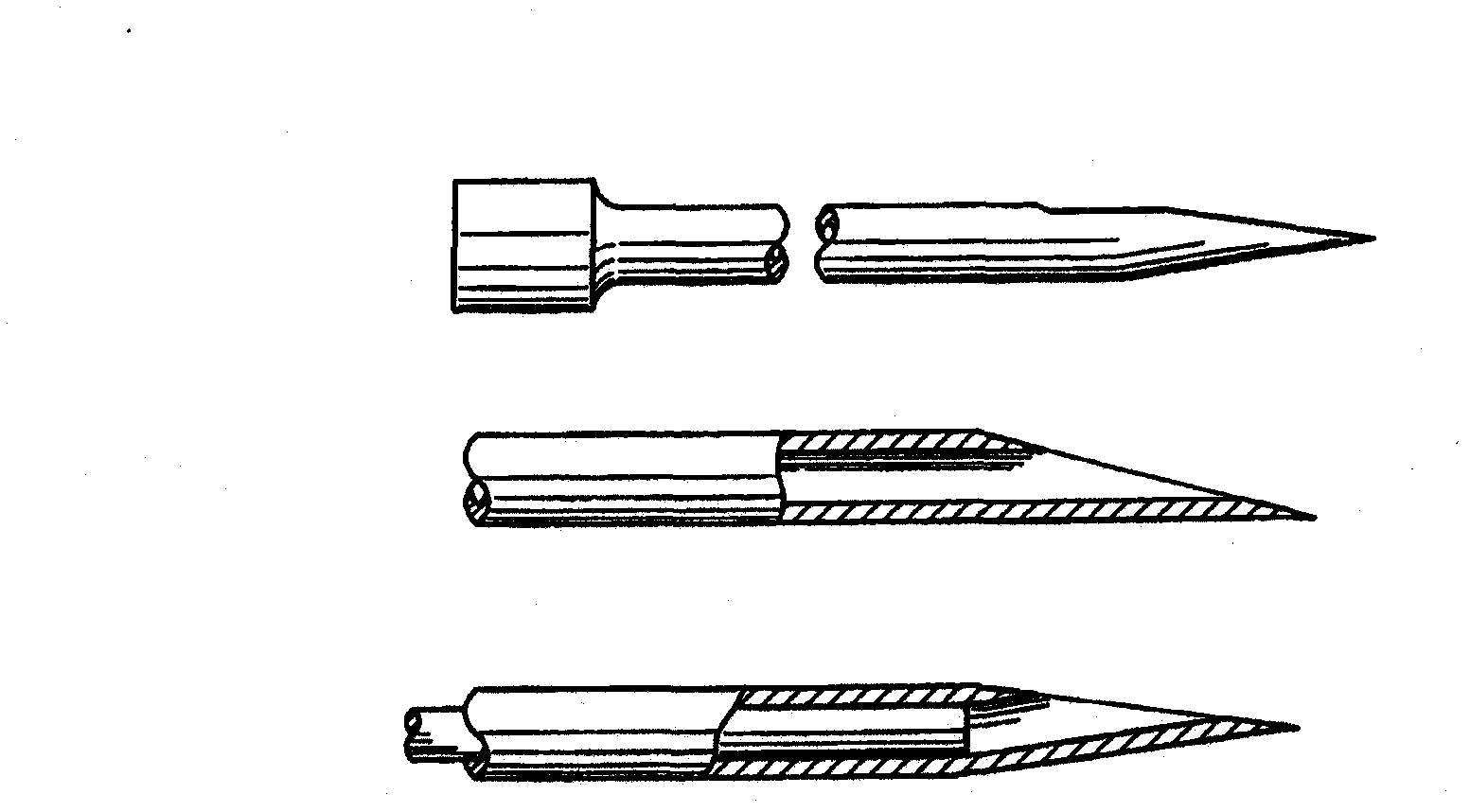

Needle for subcutaneous port

InactiveCN102159261AReduce distractionsIncreased mechanical resistanceMedical devicesInfusion needlesHypodermoclysisMechanical resistance

This disclosure relates to a new type of needed for a subcutaneous port or for any use where blood is recycled, and more precisely to a needle with reduced friction openings for easing blood and its elements along a passageway made of a through bore in the body of a needle. The needle includes an oval shape opening for increased mechanical resistance of the needle while allowing a greater passage curvature of the blood cells at the greatest zone of passage. In other embodiments, a plurality of staggered openings is used to reduce the flow through any single opening where damage occurs, the openings can be made in a curved area, or a plurality of smaller openings or a grid made of openings can be used to further reduce the interference of the needle tip and the needle openings on blood.

Owner:GRANTADLER

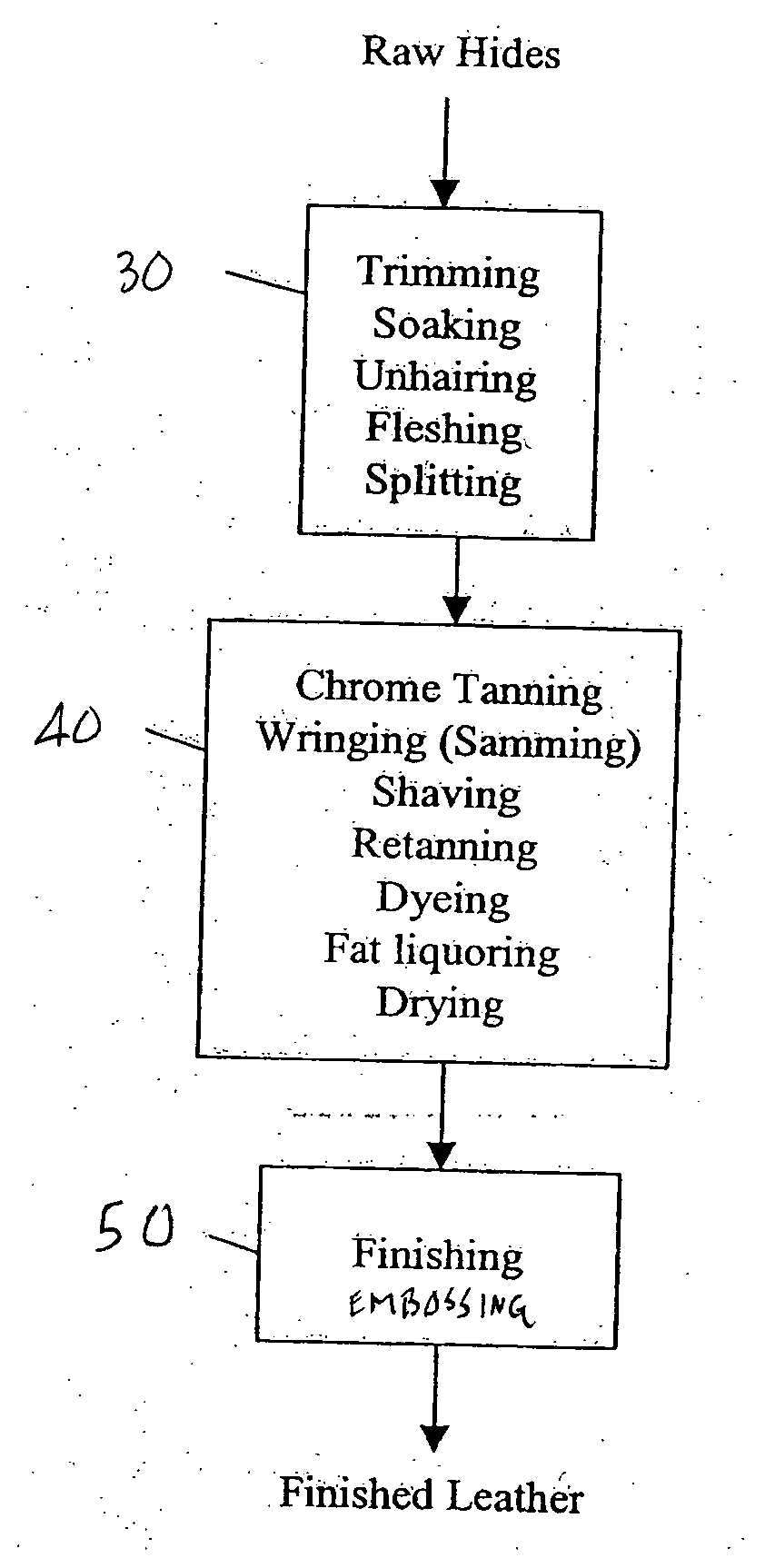

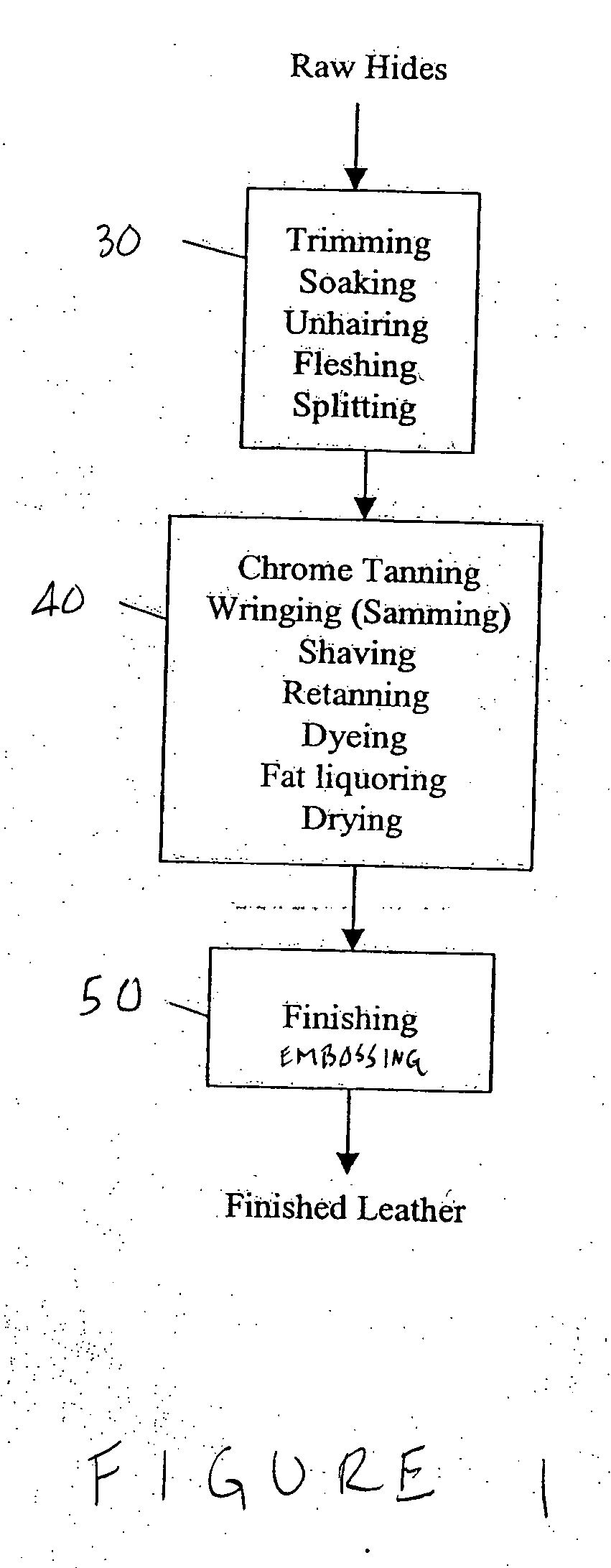

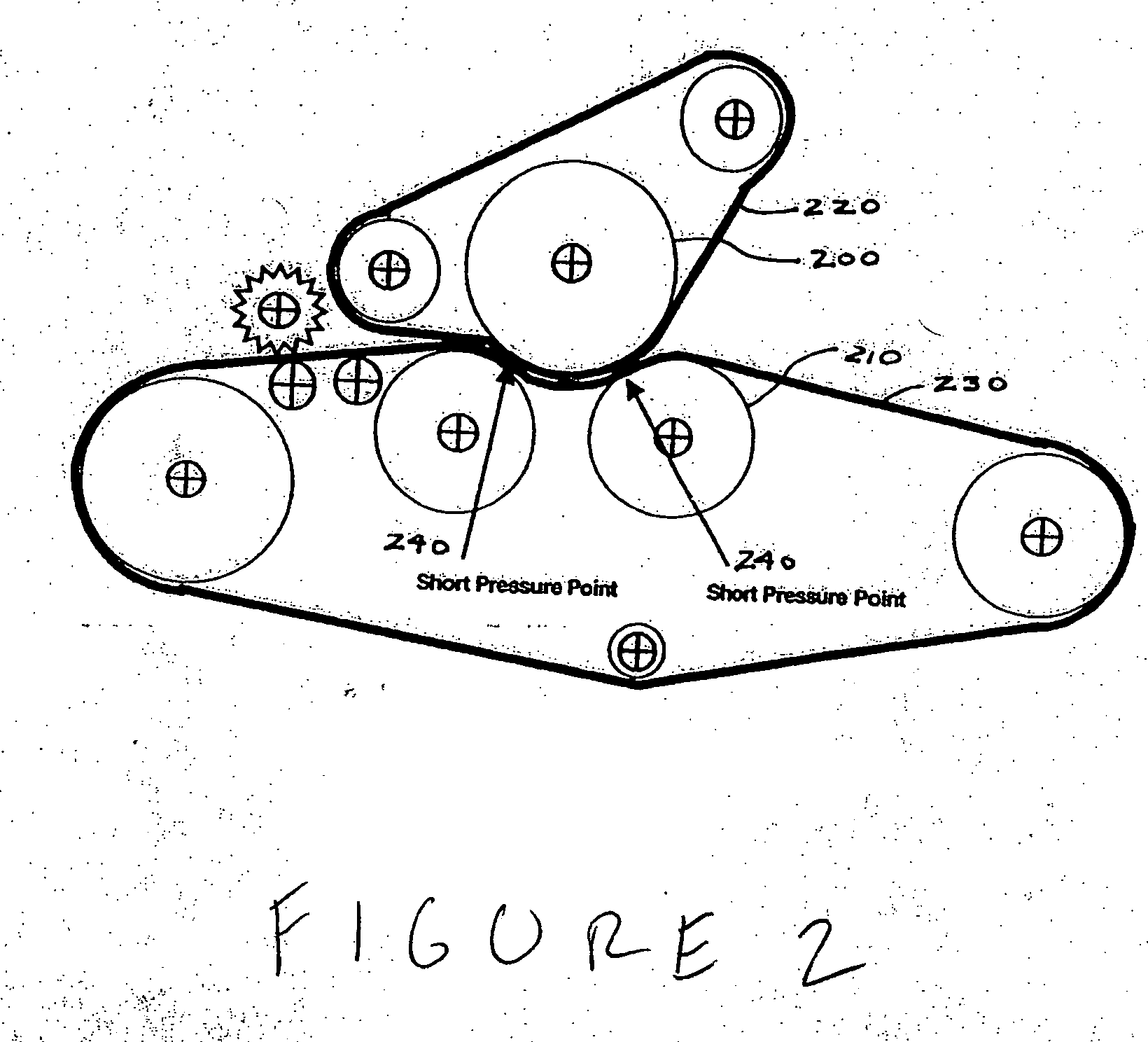

Apparatus and felt for embossing leather and artificial leather type textiles using high tension

InactiveUS20050193780A1High thermalHigh chemicalLeather surface mechanical treatmentLeather edge finishingLeather industryEngineering

An embossing apparatus, similar to those used in the paper industry, for use in the leather industry to emboss leather and leather type textiles. The apparatus includes a rotating felt under tension. In a preferred embodiment, the felt wraps around a heated embossing cylinder under tension and there is no nip. In this case, the leather textile is conveyed while sandwiched between the felt and the cylinder and is thereby embossed.

Owner:ALBANY INT CORP

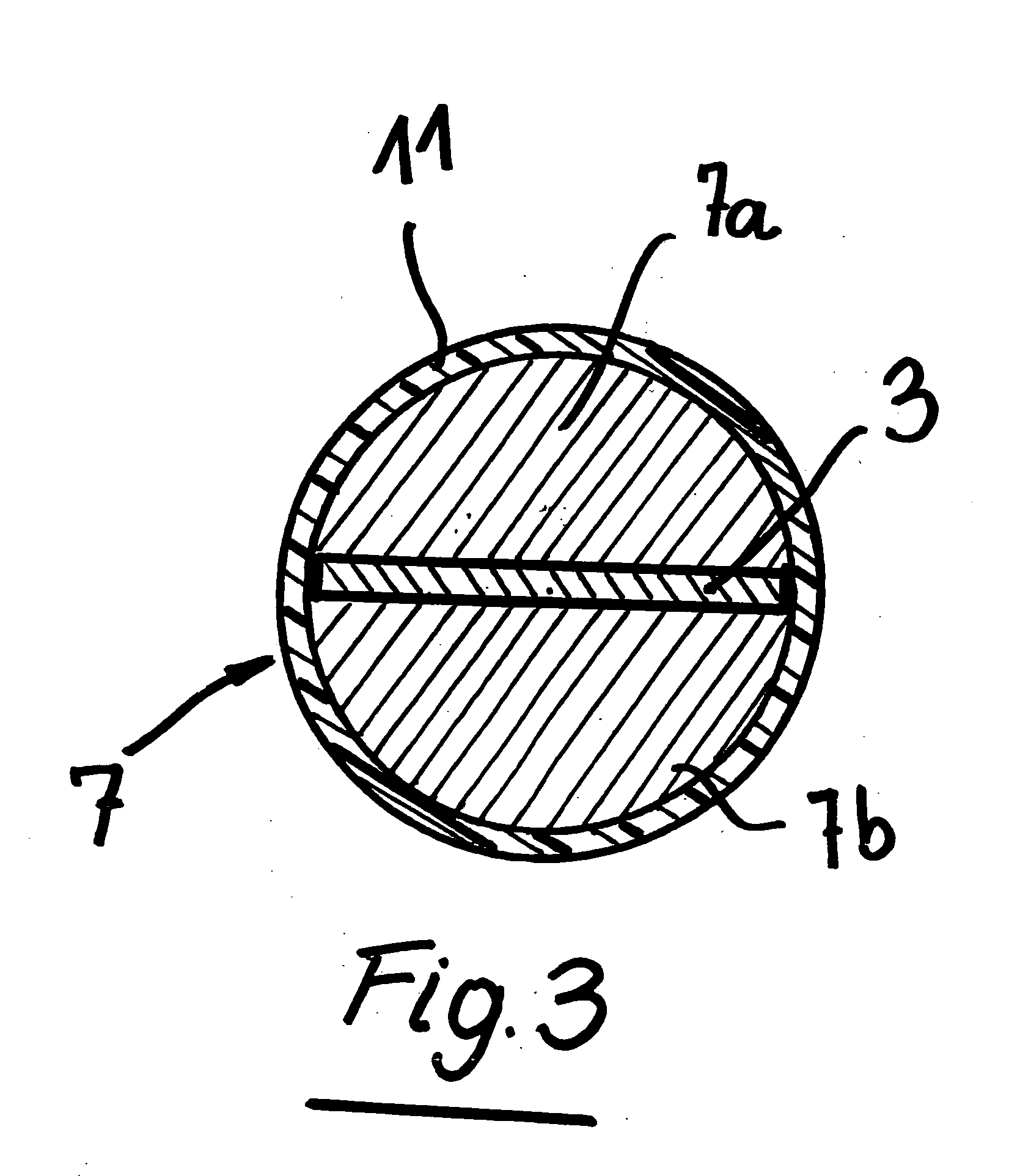

Process for the preparation of hollow cellulose vessels by culturing cellulose- producing microorganisms on the surface of a hollow carrier and providing a gas having an oxygen level of at least 35%

InactiveCN101595225AIncreased mechanical resistanceIncrease burst pressureChemical recyclingFermentationHollow fibreLymphatic vessel

Owner:ARTERION AB

Hazardous substance-removing material

InactiveUS20110021861A1Increase catch rateEfficient use ofAntibacterial agentsAntimycoticsFiberPolyolefin

The present invention provides a hazardous substance-removing material comprised of a support on which is supported an antibody, the support comprising a layer comprised of polyolefin fiber and a layer comprised of at least one other fiber, and the antibody being supported on the other fiber, which affords a high capture rate and permits long-term use, in which the antibody is efficiently utilized.

Owner:FUJIFILM CORP

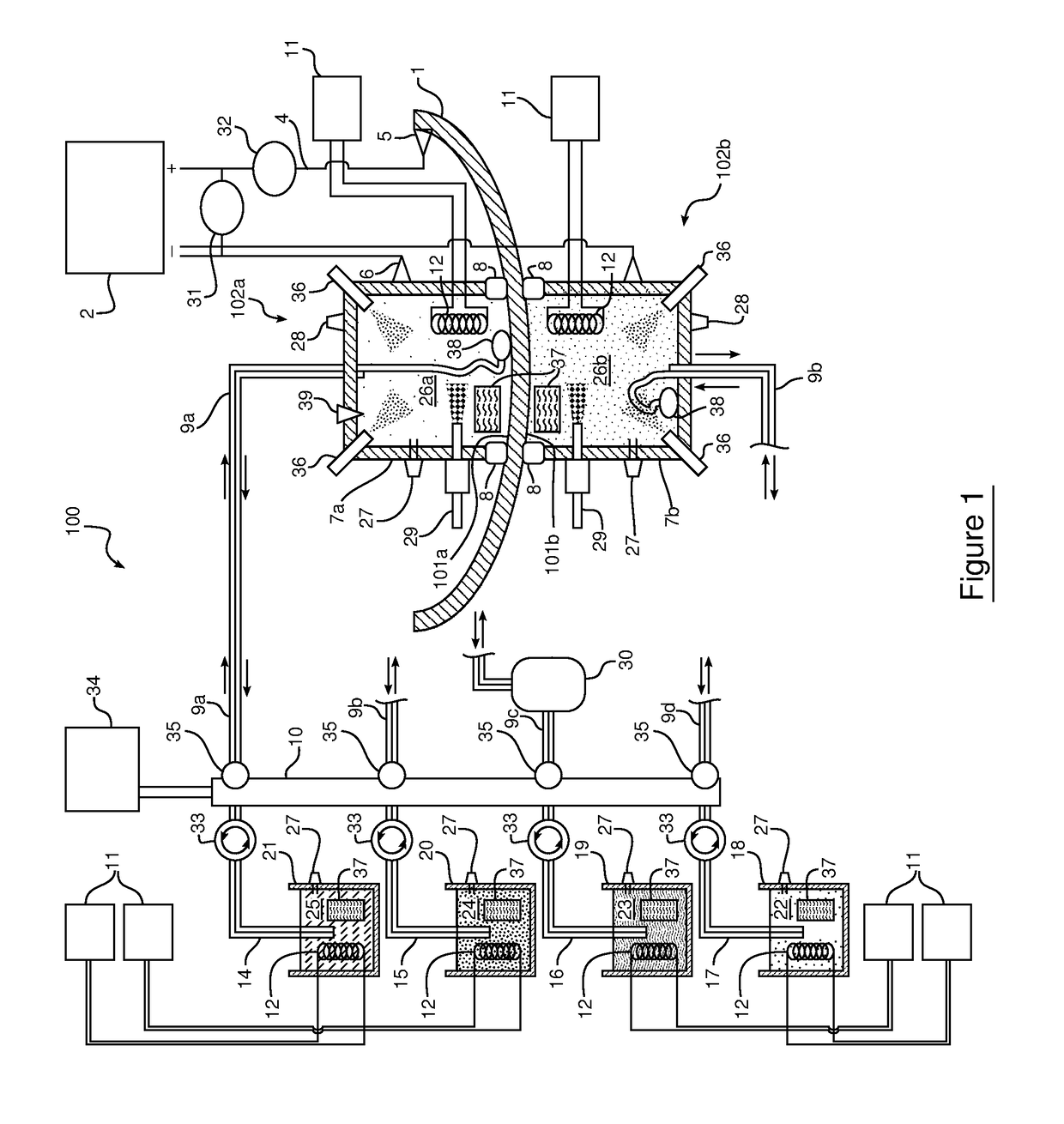

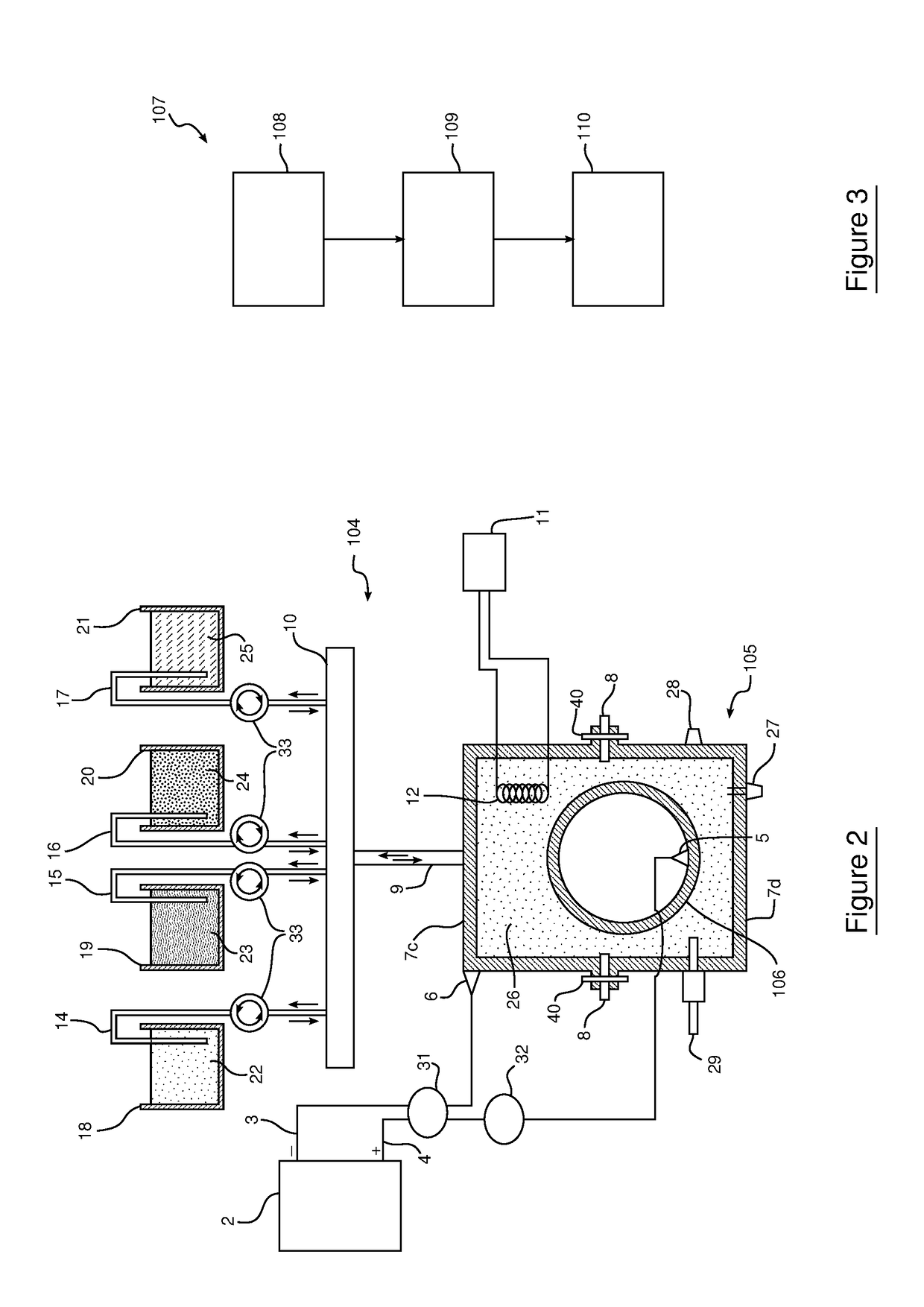

System and method for local surface treatment

InactiveUS20180195191A1Limit effect of corrosionControlling the riskCellsLiquid surface applicatorsEngineeringControl circuit

The invention relates to a system for the local surface treatment of an aeronautical part (1) to be treated.Said system is characterised in that it comprises a plurality of containers (18, 19, 20, 21) each comprising a treatment product (22, 23, 24, 25), at least one bath enclosure (102a, 102b) suitable for delimiting a fluid-tight space (26a, 26b) between this bath enclosure (102a, 102b) and a portion (101a, 101b) of the part to be treated, and a controlled circuit (10) for supplying said fluid-tight space (26a, 26b) with treatment product (22, 23, 24, 25) the containers (18, 19, 20, 21) connecting at least this container (18, 19, 20, 21) to said fluid-tight space (26a, 26b) and comprising valves for managing the supply to the fluid-tight space by one or more containers from the plurality of containers.

Owner:STELIA AEROSPACE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com